有关热处理的翻译

- 格式:docx

- 大小:1.58 MB

- 文档页数:20

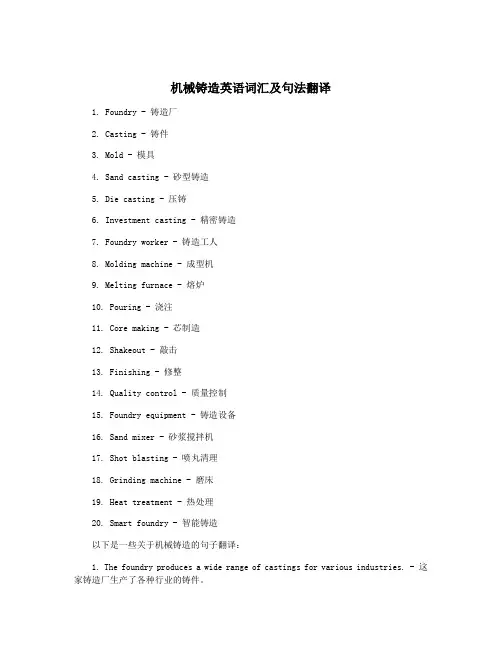

机械铸造英语词汇及句法翻译1. Foundry - 铸造厂2. Casting - 铸件3. Mold - 模具4. Sand casting - 砂型铸造5. Die casting - 压铸6. Investment casting - 精密铸造7. Foundry worker - 铸造工人8. Molding machine - 成型机9. Melting furnace - 熔炉10. Pouring - 浇注11. Core making - 芯制造12. Shakeout - 敲击13. Finishing - 修整14. Quality control - 质量控制15. Foundry equipment - 铸造设备16. Sand mixer - 砂浆搅拌机17. Shot blasting - 喷丸清理18. Grinding machine - 磨床19. Heat treatment - 热处理20. Smart foundry - 智能铸造以下是一些关于机械铸造的句子翻译:1. The foundry produces a wide range of castings for various industries. - 这家铸造厂生产了各种行业的铸件。

2. Sand casting is a common method used in foundries to produce metal castings. - 砂型铸造是铸造厂常用的一种方法,用于生产金属铸件。

3. The company has invested in state-of-the-art die casting machines to improve efficiency. - 公司已经投资购买了最先进的压铸机器,以提高效率。

4. Quality control is a crucial part of the foundry process to ensure the integrity of the castings. - 质量控制是铸造过程中至关重要的一部分,以确保铸件的完整性。

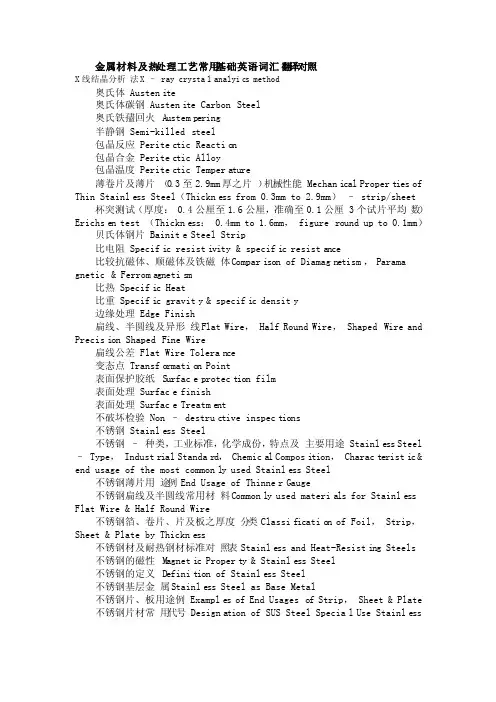

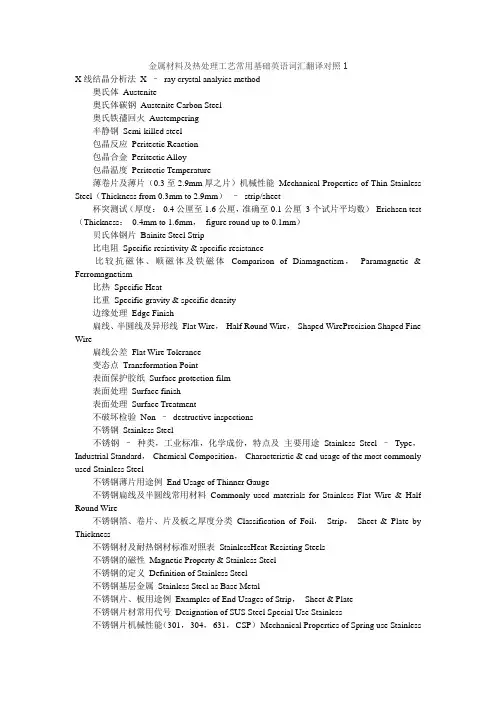

金属材料及热处理工艺常用基础英语词汇翻译对照X线结晶分析法X – ray crystal analyic s method奥氏体 Austeni te奥氏体碳钢 Austeni te CarbonSteel奥氏铁孻回火A ustemp ering半静钢 Semi-killedsteel包晶反应 Peritec tic Reactio n包晶合金 Peritec tic Alloy包晶温度 Peritec tic Tempera ture薄卷片及薄片(0.3至2.9mm厚之片)机械性能 Mechani cal Propert ies of Thin Stainle ss Steel(Thickne ss from 0.3mm to 2.9mm)– strip/sheet 杯突测试(厚度: 0.4公厘至1.6公厘,准确至0.1公厘 3个试片平均数)Erichse n test (Thickne ss: 0.4mm to 1.6mm, figureround up to 0.1mm)贝氏体钢片 Bainite Steel Strip比电阻 Specifi c resisti vity & specifi c resista nce比较抗磁体、顺磁体及铁磁体Compari son of Diamagn etism, Paramagnetic& Ferroma gnetis m比热 Specifi c Heat比重 Specifi c gravity & specifi c density边缘处理 Edge Finish扁线、半圆线及异形线Flat Wire, Half Round Wire, ShapedWire and Precisi on ShapedFine Wire扁线公差 Flat Wire Toleran ce变态点 Transfo rmatio n Point表面保护胶纸S urface protect ion film表面处理 Surface finish表面处理 Surface Treatme nt不破坏检验 Non – destruc tive inspect ions不锈钢 Stainle ss Steel不锈钢–种类,工业标准,化学成份,特点及主要用途 Stainle ss Steel – Type, Industr ial Standar d, Chemica l Composi tion, Charact eristi c & end usage of the most commonl y used Stainle ss Steel不锈钢薄片用途例 End Usage of Thinner Gauge不锈钢扁线及半圆线常用材料Commonl y used materia ls for Stainle ss Flat Wire & Half Round Wire不锈钢箔、卷片、片及板之厚度分类 Classif icatio n of Foil, Strip,Sheet & Plate by Thickne ss不锈钢材及耐热钢材标准对照表 Stainle ss and Heat-Resisti ng Steels不锈钢的磁性M agneti c Propert y & Stainle ss Steel不锈钢的定义D efinit ion of Stainle ss Steel不锈钢基层金属Stainle ss Steel as Base Metal不锈钢片、板用途例 Example s of End Usagesof Strip, Sheet & Plate 不锈钢片材常用代号 Designa tion of SUS Steel Special Use Stainle ss不锈钢片机械性能(301, 304, 631, CSP) Mechani cal Propert ies of Springuse Stainle ss Steel不锈钢应力退火卷片常用规格名词图解 General Specifi cation of Tensio n Anneale d Stainle ss Steel Strips不锈钢之分类,耐腐蚀性及耐热性 Classif icatio n, Corrosi on Resistant & Heat Resista nce of Stainle ss Steel材料的加工性能Drawing abillit y插入型固熔体I nterst ital solid solutio n常用尺寸 Commonl y Used Size常用的弹簧不锈钢线-编号,特性,表面处理及化学成份 Stainle ssSpri ng Wire – Nationa l Standar d number, Charate ristic, Surface finish& Chemica l composi tion常用的镀锌钢片(电解片)的基层金属、用途、日工标准、美材标准及一般厚度 Base metal, applica tion, JIS & ASTM standar d, and Normalthickn e s s of galvani zed steel sheet长度公差 LengthToleran ce超耐热钢 Special Heat Resista nce Steel超声波探伤法U ltraso nic inspect ion冲击测试 ImpactTest冲剪 Drawing & stampin g初释纯铁体 Pro-entecto id ferrite处理及表面状况Finish& Surface纯铁体 Ferrite磁场 Magneti c Field磁畴 Magneti c domain磁粉探伤法 Magneti c particl e inspect ion磁化率 Magneti c Suscept ibilit y (Xm)磁矩 magneti c moment磁力 Magneti c磁力 Magneti c Force磁偶极子 Dipole磁性 Magneti sum磁性变态 Magneti c Transfo rmatio n磁性变态点 Magneti c Transfo rmatio n磁性感应 Magneti c Inducti on粗珠光体 Coarsepearlit e淬火 Quenchi ng淬火及回火状态Hardene d & Tempere d Strip/ Precisi on – Quenche d Steel Strip淬火剂 Quenchi ng Media单相金属 SinglePhase Metal单相轧压镀锡薄铁片(白铁皮/马口铁) Single-Reduced Tinplat e弹簧不锈钢线,线径及拉力列表Stainle ss SpringSteel, Wire diameter and Tensile strengt h of SpringWire弹簧用碳钢片C arbonS teel Strip For SpringUse弹簧用碳钢片材之边缘处理E dge Finishe d弹性限度、阳氏弹性系数及屈服点 elastic limit, Yeung's moduleof elastic ity to yield point倒后擦发条 Pull Back Power Spring导热度 Heat conduct ivity低碳钢或铁基层金属 Iron & Low Carbonas Base Metal低碳马氏体不锈钢 Low CarbonMartens ite Stainle ss Steel低温脆性 Cold brittle ness低温退火 Low Tempera ture Anneali ng第二潜变期 Seconda ry Creep第三潜变期 Tertiar y Creep第壹潜变期 Primary Creep点焊 Spot welding电镀金属钢片P late Metal Strip电镀金属捆片的优点 Advanta ge of Using Plate Metal Strip电镀锌(电解)钢片 Electro-galvani zed Steel Sheet电镀锌钢片的焊接 Welding of Electro-galvani zed steel sheet电镀锌钢片或电解钢片 Electro-galvani zed Steel Sheet/Electro lyticZinc CoatedSteel Sheet电解/电镀锌大大增强钢片的防锈能力 Galvani c Actionimprovi ng Weathe r& Corrosi on Resista nce of the Base Steel Sheet电解冷轧钢片厚度公差 Thickne ss Toleran ce of Electro lyticCold-rolledsheet电炉 Electri c furnace电器及家电外壳用镀层冷辘[低碳] 钢片 Coated(Low Carbon) Steel Sheetsfor Casing,Electri cals & Home Applian ces电器用的硅 [硅] 钢片之分类 Classif icatio n of Silicon Steel Sheet for Electri cal Use电器用钢片的绝缘涂层 Perform ance of Surface Insulat ion of Electrical Steel Sheets电器用钢片用家需自行应力退火原因 Anneali ng of the Electri cal Steel Sheet电器用硅 [硅] 钢片 Electri cal Steel Sheet电阻焊 Resista nce Welding定型发条 Constan t TorqueSpring定型发条的形状及翻动过程S hape and SpringBack of Constan t TorqueSpring定型发条及上炼发条的驱动力SpringForce of Constan t TorqueSpringand Wing-up Spring定型发条驱动力公式及代号T he Formula and Symbolof Constan t Torque S pring镀层质量标记M arking s & Designa tionsof Differe ntialCoating s镀铬 ChromePlated镀黄铜 Brass Plated镀铝(硅)钢片–美材试标准(ASTM A-463-77)35.7 JIS G3314镀热浸铝片的机械性能 Mechani cal Propert ies of JIS G 3314 Hot-Dip Aluminum-coatedSheetsand Coils镀铝(硅)钢片–日工标准(JIS G3314) Hot-aluminu m-coatedsheets a nd coils to JIS G 3314镀铝(硅)钢片及其它种类钢片的抗腐蚀性能比较 Compars ion of various resista nce of alumini zed steel & other kinds of steel镀铝(硅)钢片生产流程A luminu m Steel Sheet, Product ion Flow Chart 镀铝硅钢片 Alumini zed Silicon Alloy Steel Sheet镀铝硅合金钢片的特色 Feature of Alumini zed Silicon Alloy Steel Sheet 镀镍 NickelPlated镀锡薄钢片(白铁皮/马日铁)制造过程 Product ion Process of ElectrolyticTinplat e镀锡薄铁片(白铁皮/马口铁)(日工标准 JIS G3303)镀锡薄铁片的构造 Constru ctionof Electro lyticTinplat e锻造 Fogging断面缩率 Reducti on of area发条的分类及材料 Power SpringStrip Classif icatio n and Materia ls 发条片 Power SpringStrip反铁磁体 Antifer romagn etism方线公差 SquareWire Toleran ce防止生锈 Rust Protect ion放射线探伤法R adiogr aphicinspect ion非晶粒取向电力用钢片的电力、磁力、机械性能及夹层系数 Laminat ion Factors of Electri cal, Magneti c & Mechani cal Non-Grain Oriente d Electr i c al沸腾钢(未净钢) Rimmedsteel分类 Classif icatio n负磁力效应 Negativ e effect钢板 Steel Plate钢板订货需知O rderin g of Steel Plate钢板生产流程P roduct ion Flow Chart钢板用途分类及各国钢板的工业标准包括日工标准及美材试标准 Type of steel Plate & Related JIS, ASTM and Other Major Industr ial Standar ds 钢材的熔铸、锻造、挤压及延轧 The Casting, Fogging, Extrusi on,Rolling & Steel钢的脆性 Brittle ness of Steel钢的种类 Type of Steel钢铁的名称 Name of steel钢铁的制造 Manufac turing of Steel钢铁的主要成份The major element of steel钢铁生产流程S teel Product ion Flow Chart钢铁用“碳”之含量来分类C lassif icatio n of Steel accordi ng to Carboncontent s高锰钢铸–日工标准 High mangane se steel to JIS standar d高碳钢化学成份及用途 High CarbonTool Steel, Chemica l Composi tion and Usage高碳钢片 High CarbonSteel Strip高碳钢片用途E nd Usage of High CarbonSteel Strip高碳钢线枝 High CarbonSteel Wire Rod (to JIS G3506)高温回火 High Tempera ture Temperi ng格子常数 Lattice constan t铬钢–日工标准 JIS G4104 Chromesteel to JIS G4104铬镍不锈钢及抗热钢弹簧线材–美国材验学会A STM A313 – 1987 Chromium – NickelStainle ss and Heat-resisti ng Steel SpringWire – ASTMA313 – 1987铬系耐热钢 ChromeHeat Resista nce Steel铬钼钢钢材–日工标准 G4105 62 ChromeMolybde num steel to JIS G4105 各种不锈钢线在不同处理拉力比较表 Tensile Strengt h of various kinds of Stainle ss Steel Wire under Differe nt Finish工业标准及规格–铁及非铁金属I ndustr ial Standar d – Ferrous & Non – ferrous Metal公差 Size Toleran ce共晶 Eutecti c共释变态 Eutecto id Transfo rmatio n固熔体 Solid solutio n光辉退火 BrightAnneali ng光线(低碳钢线),火线(退火低碳钢线),铅水线(镀锌低碳钢线)及制造钉用低碳钢线之代号、公差及备注 Ordinar y Low CarbonSteel Wire, Anneal e d Low CarbonSteel Wire, Galvani zed low CarbonSteel Wire & Low Carbon S teel Wire for nail manufac turing- classif icatio n, Symbolof Grade,Toleran ce and Remarks.硅含量对电器用的低碳钢片的最大好处 The Advanta ge of Using Silicon low CarbonSteel滚焊 Seam welding过共晶体 Hyper-ectecti c Alloy过共释钢 Hype-eutecto id含硫易车钢 Sulphur ic Free Cutting Steel含铅易车钢 LeadedFree Cutting Steel含铁体不锈钢F errite Stainle ss Steel焊接 Welding焊接合金 Solderi ng and Brazing Alloy焊接能力 Weldabi lity 镀铝钢片的焊接状态(比较冷辘钢片)Tips on welding of Alumini zed sheet in compara sion with cold rolledsteel strip 合金平衡状态T hermal Equilib rium厚度及阔度公差Toleran ce on Thickne ss & Width滑动面 Slip Plan化学成份 Chemica l Composi tion化学结合 Chemica l bond化学性能 Chemica l Propert ies化学元素 Chemica l element黄铜基层金属B rass as Base Metal回复柔软 Crystal Recover y回火脆性 Temperbrittle ness回火有低温回火及高温回火L ow & High Tempera ture Temperi ng回火状态 Anneale d Strip基层金属 Base Metal of PlatedMetal Strip机械性能 Mechani cal Properi tes机械性能 Mechani cal propert ies畸变 Distort ion级别、电镀方法、镀层质量及常用称号 Grade, Plating type, Designation of Coating Mass & CommonCoating Mass级别,代号,扭曲特性及可用之线材直径C lasses, symbols, twistin g charact eristi c and applied Wire Diamete rs级别,代号及化学成份Classif icatio n, Symbolof Grade and Chemica l Composi tion挤压 Extrusi on加工方法 Manufac turing Method加工性能 Machina bility简介 General交换能量 Positiv e energyexchang e矫顽磁力 Coerciv e Force金属变态 Transfo rmatio n金属材料的试验方法 The Methodof Metal inspect ion金属材料的性能及试验 Propert ies & testing of metal金属的特性 Feature s of Metal金属的相融、相融温度、晶体反应及合金在共晶合金、固熔孻共晶合金及偏晶反应的比较 Equilib rium Compari sion金属间化物 Interme tallic compoun d金属结晶格子M etal space lattice金属捆片电镀层PlatedLayer of PlatedMetal Strip金属塑性 Plastic Deforma tion金属特性 Special metalli c feature s金属与合金 Metal and Alloy金相及相律 Metal Phase and Phase Rule晶粒取向(Grain-Oriente d)及非晶粒取向(N on-Oriente d)晶粒取向,定取向芯钢片及高硼定取向芯钢片之磁力性能及夹层系数(日工标准及美材标准) Magneti c Propert ies and Laminat ion FactorofSI-ORIENT-CORE& SI-ORIENT-CORE-HI B Electri cal Steel Strip (JIS and AISI Standar d)晶粒取向电器用硅 [硅] 钢;片–高硼低硫(LS)定取向钢片之磁力及电力性能 Magneti c and Electri cal Propert ies of SI-ORIENT-CORE-HI-B-LS 晶粒取向电器用硅 [硅] 钢片–高硼(HI-B)定取向芯钢片及定取向芯钢片之机械性能及夹层系数 Mechani cal Propert ies and Laminat ion Factors of SI-ORIENT-CORE-HI-B and SI-ORIENT-CORE Grain OrientElectri cal Steel Sheets晶粒取向电器用硅 [硅] 钢片–高硼低硫(LS)定取向钢片之机械性能及夹层系数 Mechani cal Propert ies and Laminat ion Factors of SI-ORIENT-CORE-HI-B-LS晶粒取向电器用硅(硅)钢片–高硼(HI-B)定取向芯钢片,定取向芯钢片及高硼低硫(LS)定取向芯钢片之标准尺寸及包装 Standar d Forms and Size of SI-ORIENT-CORE-HI-B,SI-CORE, & SI-ORIENT-CORE-HI-B-LS Grain- 晶粒取向电器用硅(硅)钢片-高硼(HI-B)定取向芯钢片,定取向芯钢片及高硼低硫(LS)定取向芯钢片之厚度及阔度公差 Physica l Toleran ce ofSI-ORIENT-CORE-HI-B, SI-ORIENT-CORE, & SI-CORE-HI-B-LS Grain 晶粒取向电器用硅钢片 Grain-Oriente d Electri cal Steel晶粒取向电器用硅钢片主要工业标准 Interna tional Standar d –Grain-Oriente d Electri cal Steel Silicon Steel Sheet for Electri cal Use 晶体结构 Crystal Pattern晶体结构,定向格子及单位晶格 Crystal structu re, Space lattice & Unit cell净磁矩 Net magneti c moment绝缘表面 Surface Insulat ion均热炉 Soaking pit抗磁体 Diamagn etism抗腐蚀及耐用C orrosi on & resista nce durabil ity抗化学品能力C hemica l Resista nce抗敏感及环境保护 Allergi c, re-cycling & environ mental protect ion 抗热超级合金H eat Resista nce Super Alloy扩散退火 Diffusi on Anneali ng拉尺发条 Measure Tape拉伸测试(顺纹测试) Elongat ion test冷冲及冷锻用碳钢线枝 CarbonSteel Wire Rods for Cold Heading& Cold Forging(to JIS G3507)冷拉钢板重量表Cold Drawn Steel Bar WeightTable冷拉钢枝材 Cold Drawn CarbonSteel Shaftin g Bar冷拉高碳钢线H ard Drawn High CarbonSteel Wire冷轧钢片 Cold-RolledSteel Sheet/Strip冷轧高碳钢–日本工业标准C old-Rolled(Special Steel) CarbonSteel Strip to JIS G3311冷轧或热轧钢片阔度公差 Width Toleran ce of Cold or Hot-rolledsheet 冷轧状态 Cold RolledStrip冷辘(低碳)钢片的分类用、途、工业标准、品质、加热状态及硬度表End usages, industr ial standar d, quality, conditi on and hardnes s of cold rolledsteel strip冷辘低碳钢片(双单光片)(日工标准 JIS G3141) 73 - 95 Cold Rolled (Low carbon) Steel Strip (to JIS G 3141)冷辘钢捆片及张片的电镀和印刷方法 Cold rolledsteel coil & sheet electro-plating & paintin g method冷辘钢捆片及张片制作流程图表 Product ion flow chart cold rolledsteel coil sheet冷辘钢片(拉力: 30-32公斤/平方米)在没有表面处理状态下的焊接状况Spot welding conditi ons for bared (free from paint, oxidesetc) Cold rolledmild steel sheets(T/S:30-32 Kgf/ μ m2)冷辘钢片储存与处理提示 General adviceon handlin g& storage of cold rolledsteel coil & sheet冷辘钢片的“理论重量”计算方程式 Cold RolledSteel Sheet – Theore t i cal mass冷辘钢片订货需知 Orderin g of cold rolledsteel strip/sheet理论质量 Theoret ical Mass连续铸造法 Continu ous casting process两面不均等锡层Both Side Differe nt Thickne ss CoatedMass两面均等锡层B oth Side Equally CoatedMass裂纹之容许深度及脱碳层 Permiss ible depth of flaw and decarbu rizedlayer临界温度 Critica l tempert ure马氏体不锈钢M artens ite Stainle ss Steel马氏铁体淬火M arquen ching埋弧焊 Submerg ed-arc Welding每公斤发条的长度简易公式T he Lengthof 1 Kg of SpringSteel Strip 美材试标准的冷辘低碳钢片C old RolledSteel Strip America n Standar d – America n Society for testing and materia ls (ASTM)美国工业标准–不锈钢及防热钢材的化学成份(先数字后字母排列)AISI – Chemica l Composi tion of Stainle ss Steel & Heat-Resista nt Steel (in order of number& alphabe t)米勒指数 Mill's Index魔术手环 Magic Tape魔术手环尺寸图D rawin g of Magic Tap耐热不锈钢 Heat-Resista nce Stainle ss Steel耐热不锈钢比重表 Specifi c Gravity of Heat – resista nce steel platesand sheetsstainle ss steel镍铬–日工标准 G4102 63 ChromeNickelsteel to JIS G4102镍铬耐热钢 Ni - Cr Heat Resista nce Steel镍铬系不锈钢N ickelChromeStainle ss Steel镍铬系耐热不锈钢特性、化学成份、及操作温度 Heat-Resista nce Stainless Steel镍铬钼钢–日工标准 G4103 64 Nickel, Chrome& Molybde num Steel to JIS G4103疲劳测试 Fatigue Test片及板材 Chapter Four-Strip, Steel & Plate平坦度(阔度大于500公厘,标准回火) Flatnes s (width>500mm, temper :standar d)破坏的检验 Destruc tive Inspect ion其它焊接材料请参阅日工标准目录 Other Solderi ng Materia l其它日工标准冷轧钢片(用途及编号) JIS standar d & applica tion of other cold RolledSpecial Steel气焊 Gas Welding潜变测试 Creep Test潜变强度 CreepsStrengt h强度 Strengt h琴线(日本标准 G3522) Piano Wires ( to G3522)球化退火 Spheroi dizing Anneali ng曲面(假曲率) Camber屈服强度(降伏强度)(Yield strangt h)全静钢 Killedsteel热力应先从工件边缘透入 Heat from the Laminat ed StacksEdges热膨胀系数 Coeffic ient of thermal expansi on热轧钢片 Hot-RolledSheet/Strip热轧钢片厚度公差 Thickne ss Toleran ce of Hot-rolledsheet日本工业标准–不锈钢的化学成份(先数字后字母排列) JIS – Chemica l Composi tion of Stainle ss Steel (in order of number& alphabe t)日工标准(JIS G3141)冷辘钢片化学成份 Chemica l composi tion – cold rolledsteel sheet to JIS G3141日工标准(JIS G3141)冷辘钢片重量列表 Mass of Cold-RolledSteel Sheet to JIS G3141日工标准JIS G3141冷辘低碳钢片(双单光片)的编号浅释 Decodin g of cold rolled(Low carbon)steel strip JIS G3141日工标准下的特殊钢材 Specail Steel accordi ng to JIS Standar d熔铸 Casting软磁 Soft Magneti c软磁材料 Soft Magneti c Materia l软焊 Solderi ng Alloy软焊合金–日本标准 JIS H 4341 Solderi ng Alloy to JIS H 4341上链发条 Wind-up Spring上漆能力 Paint Adhesio n伸长度 Elongat ion渗碳体 Cementi tle渗透探伤法 Penetra te inspect ion生产流程 Product ion Flow Chart生锈速度表 Speed of rusting时间淬火 Time Quenchi ng时间效应(老化)及拉伸应变 Aging & Stretch er Strains释出硬化不锈钢Precipi tation Hardeni ng Stainle ss Steel双相辗压镀锡薄钢片(马口铁/白铁皮) Dual-Reducti on Tinplat e顺磁体 Paramag netic碳钢回火 Temperi ng碳污染 Prevent CarbonContami nation特点 Charact eristi c特殊钢 Special Steel特殊钢以用途来分类 Classif icatio n of Special Steel accordi ng to End Usage特殊钢以原素分类 Classif icatio n of Special Steel accordi ng to Elemen t提防过份氧化N o Excessi ve Oxidati on铁磁体 Ferroma gnetis m铁铬系不锈钢片ChromeStainle ss Steel铁及非铁金属F errous & Non Ferrous Metal铁锰铝不锈钢F e / Mn / Al / Stainle ss Steel铁线(低碳钢线)日工标准 JIS G 3532 Low CarbonSteel Wires ( Iron Wire ) to JIS G 3532铁相 Steel Phases同素变态 Allotro pic Transfo rmatio n铜基层金属 Copperas Base Metal透磁度 Magneti c Permeab ility退火 Anneali ng退火时注意事项Anneali ng Precaut ionary外价电子 Outer valence electro ns弯度 Camber完全退火 Full Anneali ng物理性能 Physica l Propert ies物料科学 Materia l Science物料科学定义M ateria l Science Definit ion锡层质量 Mass of Tin Coating(JIS G3303-1987)锡基、铅基及锌基轴承合金比较表C ompari son of Tin base, Lead base and Zinc base alloy for Bearing purpose细线材、枝材、棒材 Chapter Five Wire, Rod & Bar显微观察法 Microsc opic inspect ion线材/枝材材质分类及制成品 Classif icatio n and End Product s ofWire/Rod线径、公差及机械性能(日本工业标准G 3521) Mechani cal Propert ies (JIS G 3521)相反旋转 Opposit e span相律 Phase Rule锌包层之重量,铜硫酸盐试验之酸洗次数及测试用卷筒直径Weightof Zinc-Coating, Numberof Dipping s in CupricSulphat e Test and Diamete rs of Mandrel Used for Coiling Test锌镀层质量 Zinc Coating Mass锌镀层质量(两个不同锌镀层厚度) Mass Calcula tion of coating(For differe ntialcoating)/MM锌镀层质量(两个相同锌镀层厚度) Mass Calcula tion of coating(For equal coating)/MM亚共晶体 Hypoeut etic Alloy亚铁磁体 Ferrima gnetis m亚铁释体 Hyppo-Eutecto id延轧 Rolling颜色 Colour易车(快削)不锈钢 Free Cutting Stainle ss Steel易车(快削)不锈钢拉力表T ensile Strengt h of Free Cutting Wires 易车(快削)不锈钢种类 Type of steel易车不锈钢及易车钢之不同尺寸及硬度比较Hardnes s of Differe nt Types & Size of Free Cutting Steel易车碳钢 Free Cutting CarbonSteels(to JIS G4804 )易溶合金 Fusible Alloy应力退火温度S tress–relievi ng Anneali ng Tempera ture应用材料 Materia l Used硬磁 Hard Magneti c硬磁材料 Hard Magneti c Materia l硬度 Hardnes s硬度及拉力 Hardnes s & Tensile strengt h test硬焊 Brazing Alloy硬化 Work Hardeni ng硬化性能 Hardena bility用含碳量分类–即低碳钢、中碳钢及高碳钢Classif icatio n Accordi ng to CarbonContain s用途 End Usages用组织结构分类Classif icatio n Accordi ng to Grain Structu re幼珠光体 Fine pearlit e元素的原子序数Atom of Element s原子的组成、大小、体积和单位图表The size, mass, chargeof an atom, and is particl es (Pronton,Nentron and Electro n)原子的组织图A tom Constit utes原子及固体物质Atom and solid materia l原子键结 Atom Bonding圆钢枝,方钢枝及六角钢枝之形状及尺寸之公差 Toleran ce on Shape and Dimensi ons for Round Steel Bar, SquareSteel Bar, Hexagon al Steel Bar 圆径及偏圆度之公差 Toleran ce of Wire Diamete rs & Ovality圆面(“卜竹”)发条 ConvexSpringStrip再结晶 Recryst alliza tion正磁化率 Positiv e magneti c suscept ibilit y枝/棒无芯磨公差表(μ)(μ = 1/100 mm) Rod/Bar Centrel ess Grind Toleran ce枝材之美工标准,日工标准,用途及化学成份AISI, JIS End Usage and Chemica l Composi tion of Cold Drawn CarbonSteel Shaftin g Bar 直径,公差及拉力强度Diamete r, Toleran ce and Tensile Strengt h直径公差,偏圆度及脱碳层的平均深度D iamete r Toleran ce, Ovality and Average Decarbu rizedLayer Depth置换型固熔体S ubstit utiona l type solid solutio n滞后回线 NarrowHysters is中途退火 Process Anneali ng中珠光体 Mediumpearlit e周期表 Periodi c Table轴承合金 Bearing Alloy轴承合金–日工标准 JIS H 5401 Bearing Alloy to JIS H 5401珠光体 Pearlit e珠光体及共释钢Pearlit e &Eutecto id主要金属元素之物理性质 Physica l propert ies of major Metal Element s 转变元素 Transit ion element自发上磁 Spontan eous magneti zation自由度 Degreeof freedom最大能量积 Maximum EnergyProduct(to JIS G3521, ISO-84580-1&2)化学成份分析表Chemica l Analysi s of Wire Rod305, 316, 321及347之拉力表 Tensile Strengt h Require mentsfor Types 305, 316, 321 and 347A1S1-302 贰级线材之拉力表 Tensile Strengt h of A1S1-302 WireGrain Oriente d & Non-Oriente d 电器用硅 [硅] 钢片的最终用途及规格End Usage and Designa tionsof Electri cal Steel StripOriente d Electri cal Steel SheetsSK-5 & AISI-301 每公尺长的重量/公斤(阔2.0-10公厘) Weightper one meter long (kg)(Width 2.0-10mm)SK-5 & AISI-301 每公斤长的重量/公斤(阔100-200公厘) Weightper one meter long (kg)(Width 100-200mm)SK-5 & AISI-301 每公斤之长度(阔100-200公厘) Lengthper one kg (Width 100-200mm)SK-5 & AISI-301 每公斤之长度(阔2.0-10公厘) Lengthper one kg (Width 2.0-10mm)。

热处理论坛? 热处理工艺 ? 〖表面热处理〗 ? 金属材料及热处理工艺常用基础英语词汇翻译对照1返回列表发帖热处理新手keweijiani [原创] 金属材料及热处理工艺常用基础英语词汇翻译对照1X 线结晶分析法 X – ray crystal analyics method奥氏体 Austenite奥氏体碳钢 Austenite Carbon Steel奥氏铁孻回火 Austempering半静钢 Semi-killed steel包晶反应 Peritectic Reaction包晶合金 Peritectic Alloy包晶温度 Peritectic Temperature薄卷片及薄片(0.3至2.9mm 厚之片)机械性能 Mechanical Properties of Thin Stainless Steel (Thickness from 0.3mm to2.9mm ) – strip/sheet杯突测试(厚度: 0.4公厘至1.6公厘,准确至0.1公厘 3个试片平均数) Erichsen test (Thickness : 0.4mm to 1.6mm ,figure round up to 0.1mm )贝氏体钢片 Bainite Steel Strip比电阻 Specific resistivity & specific resistance比较抗磁体、顺磁体及铁磁体 Comparison of Diamagnetism , Paramagnetic & Ferromagnetism比热 Specific Heat比重 Specific gravity & specific density边缘处理 Edge Finish扁线、半圆线及异形线 Flat Wire , Half Round Wire , Shaped WirePrecision Shaped Fine Wire扁线公差 Flat Wire Tolerance变态点 Transformation Point表面保护胶纸 Surface protection film表面处理 Surface finish表面处理 Surface Treatment不破坏检验 Non – destructive inspections打印字体大小:1楼跳转到 ?倒序看帖 发表于 16 分钟前 | 只看该作者注册 登录论坛空间百科导航不锈钢基层金属 Stainless Steel as Base Metal不锈钢片、板用途例 Examples of End Usages of Strip, Sheet & Plate不锈钢片材常用代号 Designation of SUS Steel Special Use Stainless不锈钢片机械性能(301, 304, 631, CSP) Mechanical Properties of Spring use Stainless Steel不锈钢应力退火卷片常用规格名词图解 General Specification of Tension Annealed Stainless Steel Strips不锈钢之分类,耐腐蚀性及耐热性 Classification, Corrosion Resistant & Heat Resistance of Stainless Steel材料的加工性能 Drawing abillity插入型固熔体 Interstital solid solution常用尺寸 Commonly Used Size常用的弹簧不锈钢线-编号,特性,表面处理及化学成份 StainlessSpring Wire – National Standard number, Charateristic,Surface finish & Chemical composition常用的镀锌钢片(电解片)的基层金属、用途、日工标准、美材标准及一般厚度 Base metal, application, JIS & ASTM standard,Normal thickness of galvanized steel sheet长度公差 Length Tolerance超耐热钢 Special Heat Resistance Steel超声波探伤法 Ultrasonic inspection冲击测试 Impact Test冲剪 Drawing & stamping初释纯铁体 Pro-entectoid ferrite处理及表面状况 Finish & Surface纯铁体 Ferrite磁场 Magnetic Field磁畴 Magnetic domain磁粉探伤法 Magnetic particle inspection磁化率 Magnetic Susceptibility (Xm)磁矩 magnetic moment磁力 Magnetic磁力 Magnetic Force磁偶极子 Dipole磁性 Magnetisum磁性变态 Magnetic Transformation磁性变态点 Magnetic Transformation磁性感应 Magnetic Induction粗珠光体 Coarse pearlite淬火 Quenching淬火及回火状态 Hardened & Tempered Strip/ Precision – Quenched Steel Strip淬火剂 Quenching Media单相金属 Single Phase Metal单相轧压镀锡薄铁片(白铁皮/马口铁) Single-Reduced Tinplate弹簧不锈钢线,线径及拉力列表 Stainless Spring Steel, Wire diameterTensile strength of Spring Wire弹簧用碳钢片 CarbonSteel Strip For Spring Use弹簧用碳钢片材之边缘处理 Edge Finished弹性限度、阳氏弹性系数及屈服点 elastic limit, Yeung''s module of elasticity to yield point倒后擦发条 Pull Back Power Spring导热度 Heat conductivity低碳钢或铁基层金属 Iron & Low Carbon as Base Metal低碳马氏体不锈钢 Low Carbon Martensite Stainless Steel低温脆性 Cold brittleness低温退火 Low Temperature Annealing第二潜变期 Secondary Creep第三潜变期 Tertiary Creep第壹潜变期 Primary Creep点焊 Spot welding电镀金属钢片 Plate Metal Strip电镀金属捆片的优点 Advantage of Using Plate Metal Strip电镀锌(电解)钢片 Electro-galvanized Steel Sheet电镀锌钢片的焊接 Welding of Electro-galvanized steel sheet电镀锌钢片或电解钢片 Electro-galvanized Steel Sheet/Electrolytic Zinc Coated Steel Sheet电解/电镀锌大大增强钢片的防锈能力 Galvanic Action improving Weather & Corrosion Resistance of the Base Steel Sheet电解冷轧钢片厚度公差 Thickness Tolerance of Electrolytic Cold-rolled sheet电炉 Electric furnace电器及家电外壳用镀层冷辘 [低碳] 钢片 Coated (Low Carbon) Steel Sheets for Casing,Electricals & Home Appliances电器用的硅 [硅] 钢片之分类 Classification of Silicon Steel Sheet for Electrical Use电器用钢片的绝缘涂层 Performance of Surface Insulation of Electrical Steel Sheets电器用钢片用家需自行应力退火原因 Annealing of the Electrical Steel Sheet电器用硅 [硅] 钢片 Electrical Steel Sheet电阻焊 Resistance Welding定型发条 Constant Torque Spring定型发条的形状及翻动过程 ShapeSpring Back of Constant Torque Spring定型发条及上炼发条的驱动力 Spring Force of Constant Torque SpringWing-up Spring定型发条驱动力公式及代号 The FormulaSymbol of Constant Torque Spring镀层质量标记 Markings & Designations of Differential Coatings镀铬 Chrome Plated镀黄铜 Brass Plated镀铝(硅)钢片 – 美材试标准(ASTM A-463-77)35.7 JIS G3314镀热浸铝片的机械性能 Mechanical Properties of JIS G 3314 Hot-Dip Aluminum-coated SheetsCoils镀铝(硅)钢片 – 日工标准(JIS G3314) Hot-aluminum-coated sheetscoils to JIS G 3314镀铝(硅)钢片及其它种类钢片的抗腐蚀性能比较 Comparsion of various resistance of aluminized steel & other kinds of steel 镀铝(硅)钢片生产流程 Aluminum Steel Sheet, Production Flow Chart镀铝硅钢片 Aluminized Silicon Alloy Steel Sheet镀铝硅合金钢片的特色 Feature of Aluminized Silicon Alloy Steel Sheet镀镍 Nickel Plated镀锡薄钢片(白铁皮/马日铁)制造过程 Production Process of Electrolytic Tinplate镀锡薄铁片(白铁皮/马口铁)(日工标准 JIS G3303)镀锡薄铁片的构造 Construction of Electrolytic Tinplate锻造 Fogging断面缩率 Reduction of area发条的分类及材料 Power Spring Strip ClassificationMaterials发条片 Power Spring Strip反铁磁体 Antiferromagnetism方线公差 Square Wire Tolerance防止生锈 Rust Protection放射线探伤法 Radiographic inspection非晶粒取向电力用钢片的电力、磁力、机械性能及夹层系数 Lamination Factors of Electrical, Magnetic & Mechanical Non-Grain Oriented Electrical沸腾钢(未净钢) Rimmed steel分类 Classification负磁力效应 Negative effect钢板 Steel Plate钢板订货需知 Ordering of Steel Plate钢板生产流程 Production Flow Chart钢板用途分类及各国钢板的工业标准包括日工标准及美材试标准 Type of steel Plate & Related JIS, ASTMOther Major Industrial Standards钢材的熔铸、锻造、挤压及延轧 The Casting, Fogging, Extrusion, Rolling & Steel钢的脆性 Brittleness of Steel钢的种类 Type of Steel钢铁的名称 Name of steel钢铁的制造 Manufacturing of Steel钢铁的主要成份 The major element of steel钢铁生产流程 Steel Production Flow Chart钢铁用“碳”之含量来分类 Classification of Steel according to Carbon contents高锰钢铸 – 日工标准 High manganese steel to JIS standard高碳钢化学成份及用途 High Carbon Tool Steel, Chemical CompositionUsage高碳钢片 High Carbon Steel Strip高碳钢片用途 End Usage of High Carbon Steel Strip高碳钢线枝 High Carbon Steel Wire Rod (to JIS G3506)高温回火 High Temperature Tempering格子常数 Lattice constant铬钢 – 日工标准 JIS G4104 Chrome steel to JIS G4104铬镍不锈钢及抗热钢弹簧线材–美国材验学会 ASTM A313 – 1987 Chromium – Nickel StainlessHeat-resisting Steel Spring Wire – ASTM A313 – 1987铬系耐热钢 Chrome Heat Resistance Steel铬钼钢钢材 – 日工标准 G4105 62 Chrome Molybdenum steel to JIS G4105各种不锈钢线在不同处理拉力比较表 Tensile Strength of various kinds of Stainless Steel Wire under Different Finish工业标准及规格 – 铁及非铁金属 Industrial Standard – Ferrous & Non – ferrous Metal公差 Size Tolerance共晶 Eutectic共释变态 Eutectoid Transformation固熔体 Solid solution光辉退火 Bright Annealing光线(低碳钢线),火线(退火低碳钢线),铅水线(镀锌低碳钢线)及制造钉用低碳钢线之代号、公差及备注 Ordinary Low Carbon Steel Wire, Annealed Low Carbon Steel Wire, Galvanized low Carbon Steel Wire & Low Carbon Steel Wire for nail manufacturing - classification, Symbol of Grade, ToleranceRemarks.硅含量对电器用的低碳钢片的最大好处 The Advantage of Using Silicon low Carbon Steel滚焊 Seam welding过共晶体 Hyper-ectectic Alloy过共释钢 Hype-eutectoid含硫易车钢 Sulphuric Free Cutting Steel含铅易车钢 Leaded Free Cutting Steel含铁体不锈钢 Ferrite Stainless Steel焊接 Welding焊接合金 SolderingBrazing Alloy焊接能力 Weldability 镀铝钢片的焊接状态(比较冷辘钢片) Tips on welding of Aluminized sheet in comparasion with cold rolled steel strip合金平衡状态 Thermal Equilibrium厚度及阔度公差 Tolerance on Thickness & Width滑动面 Slip Plan化学成份 Chemical Composition化学结合 Chemical bond化学性能 Chemical Properties化学元素 Chemical element黄铜基层金属 Brass as Base Metal回复柔软 Crystal Recovery回火脆性 Temper brittleness回火有低温回火及高温回火 Low & High Temperature Tempering回火状态 Annealed Strip基层金属 Base Metal of Plated Metal Strip机械性能 Mechanical Properites机械性能 Mechanical properties畸变 Distortion级别、电镀方法、镀层质量及常用称号 Grade, Plating type, Designation of Coating Mass & Common Coating Mass级别,代号,扭曲特性及可用之线材直径 Classes, symbols, twisting characteristicapplied Wire Diameters级别,代号及化学成份 Classification, Symbol of GradeChemical Composition挤压 Extrusion加工方法 Manufacturing Method加工性能 Machinability简介 General交换能量 Positive energy exchange矫顽磁力 Coercive Force金属变态 Transformation金属材料的试验方法 The Method of Metal inspection金属材料的性能及试验 Properties & testing of metal金属的特性 Features of Metal金属的相融、相融温度、晶体反应及合金在共晶合金、固熔孻共晶合金及偏晶反应的比较 Equilibrium Comparision金属间化物 Intermetallic compound金属结晶格子 Metal space lattice金属捆片电镀层 Plated Layer of Plated Metal Strip金属塑性 Plastic Deformation金属特性 Special metallic features金属与合金 MetalAlloy金相及相律 Metal PhasePhase Rule晶粒取向(Grain-Oriented)及非晶粒取向(Non-Oriented)晶粒取向,定取向芯钢片及高硼定取向芯钢片之磁力性能及夹层系数(日工标准及美材标准) Magnetic PropertiesLamination Factor of SI-ORIENT-CORE& SI-ORIENT-CORE-HI B Electrical Steel Strip (JISAISI Standard)晶粒取向电器用硅 [硅] 钢;片 – 高硼低硫(LS)定取向钢片之磁力及电力性能 MagneticElectrical Properties of SI-ORIENT-CORE-HI-B-LS晶粒取向电器用硅 [硅] 钢片 – 高硼(HI-B)定取向芯钢片及定取向芯钢片之机械性能及夹层系数 Mechanical PropertiesLamination Factors of SI-ORIENT-CORE-HI-BSI-ORIENT-CORE Grain Orient Electrical Steel Sheets晶粒取向电器用硅 [硅] 钢片 – 高硼低硫(LS)定取向钢片之机械性能及夹层系数 Mechanical PropertiesLamination Factors of SI-ORIENT-CORE-HI-B-LS晶粒取向电器用硅(硅)钢片 – 高硼(HI-B)定取向芯钢片,定取向芯钢片及高硼低硫(LS)定取向芯钢片之标准尺寸及包装Standard FormsSize of SI-ORIENT-CORE-HI-B,SI-CORE, & SI-ORIENT-CORE-HI-B-LS Grain-晶粒取向电器用硅(硅)钢片-高硼(HI-B)定取向芯钢片,定取向芯钢片及高硼低硫(LS)定取向芯钢片之厚度及阔度公差Physical Tolerance of SI-ORIENT-CORE-HI-B, SI-ORIENT-CORE, & SI-CORE-HI-B-LS Grain晶粒取向电器用硅钢片 Grain-Oriented Electrical Steel晶粒取向电器用硅钢片主要工业标准 International Standard – Grain-Oriented Electrical Steel Silicon Steel Sheet for Electrical Use晶体结构 Crystal Pattern晶体结构,定向格子及单位晶格 Crystal structure, Space lattice & Unit cell净磁矩 Net magnetic moment绝缘表面 Surface Insulation均热炉 Soaking pit抗磁体 Diamagnetism抗腐蚀及耐用 Corrosion & resistance durability抗化学品能力 Chemical Resistance抗敏感及环境保护 Allergic, re-cycling & environmental protection抗热超级合金 Heat Resistance Super Alloy扩散退火 Diffusion Annealing拉尺发条 Measure Tape拉伸测试(顺纹测试) Elongation test冷冲及冷锻用碳钢线枝 Carbon Steel Wire Rods for Cold Heading & Cold Forging (to JIS G3507)冷拉钢板重量表 Cold Drawn Steel Bar Weight Table冷拉钢枝材 Cold Drawn Carbon Steel Shafting Bar冷拉高碳钢线 Hard Drawn High Carbon Steel Wire冷轧钢片 Cold-Rolled Steel Sheet/Strip冷轧高碳钢–日本工业标准 Cold-Rolled (Special Steel) Carbon Steel Strip to JIS G3311冷轧或热轧钢片阔度公差 Width Tolerance of Cold or Hot-rolled sheet冷轧状态 Cold Rolled Strip冷辘(低碳)钢片的分类用、途、工业标准、品质、加热状态及硬度表 End usages, industrial standard, quality,conditionhardness of cold rolled steel strip收藏分享球化退火 Spheroidizing Annealing曲面(假曲率) Camber屈服强度(降伏强度)(Yield strangth)全静钢 Killed steel热力应先从工件边缘透入 Heat from the Laminated Stacks Edges热膨胀系数 Coefficient of thermal expansion热轧钢片 Hot-Rolled Sheet/Strip热轧钢片厚度公差 Thickness Tolerance of Hot-rolled sheet日本工业标准–不锈钢的化学成份(先数字后字母排列) JIS – Chemical Composition of Stainless Steel (in order of number & alphabet)日工标准(JIS G3141)冷辘钢片化学成份 Chemical composition – cold rolled steel sheet to JIS G3141日工标准(JIS G3141)冷辘钢片重量列表 Mass of Cold-Rolled Steel Sheet to JIS G3141日工标准JIS G3141冷辘低碳钢片(双单光片)的编号浅释 Decoding of cold rolled(Low carbon)steel strip JIS G3141日工标准下的特殊钢材 Specail Steel according to JIS Standard熔铸 Casting软磁 Soft Magnetic软磁材料 Soft Magnetic Material软焊 Soldering Alloy软焊合金 – 日本标准 JIS H 4341 Soldering Alloy to JIS H 4341上链发条 Wind-up Spring上漆能力 Paint Adhesion伸长度 Elongation渗碳体 Cementitle渗透探伤法 Penetrate inspection生产流程 Production Flow Chart生锈速度表 Speed of rusting时间淬火 Time Quenching时间效应(老化)及拉伸应变 Aging & Stretcher Strains释出硬化不锈钢 Precipitation Hardening Stainless Steel双相辗压镀锡薄钢片(马口铁/白铁皮) Dual-Reduction Tinplate顺磁体 Paramagnetic碳钢回火 Tempering碳污染 Prevent Carbon Contamination特点 Characteristic特殊钢 Special Steel特殊钢以用途来分类 Classification of Special Steel according to End Usage特殊钢以原素分类 Classification of Special Steel according to Element提防过份氧化 No Excessive Oxidation铁磁体 Ferromagnetism铁铬系不锈钢片 Chrome Stainless Steel铁及非铁金属 Ferrous & Non Ferrous Metal铁锰铝不锈钢 Fe / Mn / Al / Stainless Steel铁线(低碳钢线)日工标准 JIS G 3532 Low Carbon Steel Wires ( Iron Wire ) to JIS G 3532铁相 Steel Phases同素变态 Allotropic Transformation铜基层金属 Copper as Base Metal透磁度 Magnetic Permeability退火 Annealing退火时注意事项 Annealing Precautionary外价电子 Outer valence electrons弯度 Camber完全退火 Full Annealing物理性能 Physical Properties物料科学 Material Science物料科学定义 Material Science Definition锡层质量 Mass of Tin Coating (JIS G3303-1987)锡基、铅基及锌基轴承合金比较表 Comparison of Tin base, Lead baseZinc base alloy for Bearing purpose细线材、枝材、棒材 Chapter Five Wire, Rod & Bar显微观察法 Microscopic inspection线材/枝材材质分类及制成品 ClassificationEnd Products of Wire/Rod线径、公差及机械性能(日本工业标准 G 3521) Mechanical Properties (JIS G 3521)相反旋转 Opposite span相律 Phase Rule锌包层之重量,铜硫酸盐试验之酸洗次数及测试用卷筒直径 Weight of Zinc-Coating, Number of Dippings in Cupric Sulphate TestDiameters of Mandrel Used for Coiling Test锌镀层质量 Zinc Coating Mass锌镀层质量(两个不同锌镀层厚度) Mass Calculation of coating (For differential coating)/MM锌镀层质量(两个相同锌镀层厚度) Mass Calculation of coating (For equal coating)/MM亚共晶体 Hypoeutetic Alloy亚铁磁体 Ferrimagnetism亚铁释体 Hyppo-Eutectoid延轧 Rolling颜色 Colour易车(快削)不锈钢 Free Cutting Stainless Steel易车(快削)不锈钢拉力表 Tensile Strength of Free Cutting Wires易车(快削)不锈钢种类 Type of steel易车不锈钢及易车钢之不同尺寸及硬度比较 Hardness of Different Types & Size of Free Cutting Steel易车碳钢 Free Cutting Carbon Steels (to JIS G4804 )易溶合金 Fusible Alloy应力退火温度 Stress –relieving Annealing Temperature应用材料 Material Used硬磁 Hard Magnetic硬磁材料 Hard Magnetic Material硬度 Hardness硬度及拉力 Hardness & Tensile strength test硬焊 Brazing Alloy硬化 Work Hardening硬化性能 Hardenability用含碳量分类 – 即低碳钢、中碳钢及高碳钢 Classification According to Carbon Contains用途 End Usages用组织结构分类 Classification According to Grain Structure幼珠光体 Fine pearlite元素的原子序数 Atom of Elements原子的组成、大小、体积和单位图表 The size, mass, charge of an atom,is particles (Pronton,NentronElectron)原子的组织图 Atom Constitutes原子及固体物质 Atomsolid material原子键结 Atom Bonding圆钢枝,方钢枝及六角钢枝之形状及尺寸之公差 Tolerance on ShapeDimensions for Round Steel Bar, Square Steel Bar,Hexagonal Steel Bar圆径及偏圆度之公差 Tolerance of Wire Diameters & Ovality圆面(“卜竹”)发条 Convex Spring Strip再结晶 Recrystallization正磁化率 Positive magnetic susceptibility枝/棒无芯磨公差表(μ)(μ = 1/100 mm) Rod/Bar Centreless Grind Tolerance枝材之美工标准,日工标准,用途及化学成份 AISI, JIS End UsageChemical Composition of Cold Drawn Carbon Steel Shafting Bar直径,公差及拉力强度 Diameter, ToleranceTensile Strength直径公差,偏圆度及脱碳层的平均深度 Diameter Tolerance, OvalityAverage Decarburized Layer Depth置换型固熔体 Substitutional type solid solution滞后回线 Narrow Hystersis。

1、整体热处理 bulk heat treatment2、表面热处理 surface heat treatment3、化学热处理 thermo-chemical treatment4、预备热处理 conditioning heat treatment5、局部热处理 local heat treatment6、可控气氛热处理 heat treatment in-controlled atmosphere7、真空热处理 vacuum heat treatment008、离子热处理 ion heat treatment9、高能束热处理high energy density heat treatment10、形变热处理 thermomechanical treatment11、复合热处理 complex heat treatment12、流态床热处理 heat treatment in fluidized beds13、吸热式气氛 endothermic atmosphere14、放热式气氛 exothermic atmosphere15、放热-吸热式气氛 exo-endothermic atmosphere16、滴注式气氛 drip feed atmosphere17、氮基气氛nitrogen-base atmosphere18、合成气氛artificial atmosphere019、直生式气氛 direct prepared atmosphere20、淬火冷却介质 quenching media21、淬火冷却烈度 quenching severity22、淬透性 hardenability23、淬硬性 hardening capacity24、端淬试验Jominy test25、奥氏体化austenitizing26、等温转变isothermal transformation27、连续冷却转变 continuous cooling transformation28、退火 annealing29、完全退火full annealing30、不完全退火 incomplete annealing31、去应力退火 stress relieving annealing32、球化退火spheroidizing033、正火 normalizing34、等温正火isothermal normalizing35、淬火 quenching harding36、等温淬火austempering37、分级淬火martempering38、亚温淬火intercritical hardening39、冷处理 subzero treatment40、深冷处理cryogenic treatment41、马氏体临界冷却速度 critical colding rate42、有效淬硬深度 effective hardening depth043、回火tempering44、低温回火 low temperature tempering045、高温回火high temperature tempering46、自回火 self tempering47、回火脆性temper brittlement48、淬冷畸变quenching distortion49、氢脆 hydrogen embrittlement50、残留应力residual stresses51、热应力 thermal stresses52、相变应力transformation stresses53、固溶处理solution treatment54、时效 ageing055、沉淀硬化precipitation hardening56、氧化 oxidation57、脱碳 decarburizing58、内氧化 internal oxidation59、渗碳 carburizing60、固体渗碳pack carburizing61、气体渗碳gas caiburizing62、液体渗碳liquid carburizing63、真空渗碳vacuum carburizing64、离子渗碳plasma carburizing065、复碳 carbon restoration66、碳势 carbon potential67、露点 dew point68、强渗期 carburizing period69、扩散期 diffusion period70、载气 carrier gas71、富化气 enrich gas72、渗氮 nitriding73、液体渗氮liquid nitriding74、气体渗氮gas nitriding75、离子渗氮ion nitriding076、退氮 denitriding77、渗氮化合物层 compound layer78、氨分解率ammonia dissociation rate79、渗金属 metal cementation80、多元共渗multicomponent cementation81、碳氮共渗carbonitriding082、氮碳共渗nitrocarburizing83、流氮共渗sulpho-nitriding84、氧氮共渗oxynitriding85、化学气象沉淀 chemical vapor deposition86、物理气相沉淀 physical vapor deposition87、相phase88、组织 structure89、晶粒 grain90、晶界 grain boundary91、晶粒度grain size92、晶粒度等级 grain size number93、共晶组织 eutectic-structure094、共析组织 eutectoid structure95、层片状组织 lamellar-structure96、弥散相dispersed phase97、亚组织substructure98、位错 dislocation099、结构 texture机械专业名词金属切削 metal cutting机床 machine tool金属工艺学 technology of metals 刀具 cutter摩擦 friction联结 link传动 drive/transmission轴 shaft弹性 elasticity频率特性 frequency characteristic 误差 error响应 response定位 allocation机床夹具 jig动力学 dynamic运动学 kinematic静力学 static分析力学 analyse mechanics拉伸 pulling压缩 hitting剪切 shear扭转 twist弯曲应力 bending stress强度 intensity三相交流电 three-phase AC磁路 magnetic circles变压器 transformer异步电动机 asynchronous motor几何形状 geometrical精度 precision正弦形的 sinusoid交流电路 AC circuit机械加工余量 machining allowance 变形力 deforming force变形 deformation应力 stress硬度 rigidity热处理 heat treatment退火 anneal正火 normalizing脱碳 decarburization渗碳 carburization电路 circuit半导体元件 semiconductor element 反馈 feedback发生器 generator直流电源 DC electrical source门电路 gate circuit逻辑代数 logic algebra外圆磨削 external grinding内圆磨削 internal grinding平面磨削 plane grinding变速箱 gearbox离合器 clutch绞孔 fraising绞刀 reamer螺纹加工 thread processing螺钉 screw铣削 mill铣刀 milling cutter功率 power工件 workpiece齿轮加工 gear mechining齿轮 gear主运动 main movement主运动方向 direction of main movement进给方向 direction of feed进给运动 feed movement合成进给运动 resultant movement of feed合成切削运动 resultant movement of cutting合成切削运动方向 direction of resultant movement of cutting 切削深度 cutting depth前刀面 rake face刀尖 nose of tool前角 rake angle后角 clearance angle龙门刨削 planing主轴 spindle主轴箱 headstock卡盘 chuck加工中心 machining center车刀 lathe tool车床 lathe钻削镗削 bore车削 turning磨床 grinder基准 benchmark钳工 locksmith锻 forge压模 stamping焊 weld拉床 broaching machine拉孔 broaching装配 assembling铸造 found流体动力学 fluid dynamics流体力学 fluid mechanics加工 machining液压 hydraulic pressure切线 tangent机电一体化 mechanotronics mechanical-electrical integration 气压 air pressure pneumatic pressure稳定性 stability介质 medium液压驱动泵 fluid clutch 液压泵 hydraulic pump阀门 valve失效 invalidation强度 intensity载荷 load应力 stress安全系数 safty factor可靠性 reliability螺纹 thread螺旋 helix键 spline销 pin滚动轴承 rolling bearing 滑动轴承 sliding bearing 弹簧 spring制动器 arrester brake十字结联轴节 crosshead 联轴歧 coupling链 chain皮带 strap精加工 finish machining粗加工 rough machining变速箱体 gearbox casing腐蚀 rust氧化 oxidation磨损 wear耐用度 durability随机信号 random signal离散信号 discrete signal超声传感器 ultrasonic sensor 集成电路 integrate circuit 挡板 orifice plate残余应力 residual stress套筒 sleeve扭力 torsion冷加工 cold machining电动机 electromotor汽缸 cylinder过盈配合 interference fit热加工 hotwork摄像头 CCD camera倒角 rounding chamfer优化设计 optimal design工业造型设计 industrial moulding design有限元 finite element滚齿 hobbing插齿 gear shaping伺服电机 actuating motor铣床 milling machine钻床 drill machine镗床 boring machine步进电机 stepper motor丝杠 screw rod导轨 lead rail组件 subassembly可编程序逻辑控制器 Programmable Logic Controller PLC 电火花加工 electric spark machining电火花线切割加工 electrical discharge wire - cutting 相图 phase diagram热处理 heat treatment固态相变 solid state phase changes有色金属 nonferrous metal合成纤维 synthetic fibre电化学腐蚀 electrochemical corrosion 车架 automotive chassis悬架 suspension转向器 redirector变速器 speed changer板料冲压 sheet metal parts孔加工 spot facing machining车间 workshop工程技术人员 engineer气动夹紧 pneuma lock数学模型 mathematical model画法几何 descriptive geometry机械制图 Mechanical drawing投影 projection视图 view剖视图 profile chart标准件 standard component零件图 part drawing装配图 assembly drawing尺寸标注 size marking技术要求 technical requirements刚度 rigidity内力 internal force位移 displacement截面 section疲劳极限 fatigue limit断裂 fracture塑性变形 plastic distortion脆性材料 brittleness material刚度准则 rigidity criterion垫圈 washer垫片 spacer直齿圆柱齿轮 straight toothed spur gear 斜齿圆柱齿轮 helical-spur gear直齿锥齿轮 straight bevel gear运动简图 kinematic sketch齿轮齿条 pinion and rack蜗杆蜗轮 worm and worm gear虚约束 passive constraint曲柄 crank摇杆 racker凸轮 cams共轭曲线 conjugate curve范成法 generation method定义域 definitional domain值域 range导数\微分 differential coefficient求导 derivation定积分 definite integral不定积菲 indefinite integral曲率 curvature偏微分 partial differential毛坯 rough游标卡尺 slide caliper千分尺 micrometer calipers攻丝 tap二阶行列式 second order determinant 逆矩阵 inverse matrix线性方程组 linear equations概率 probability随机变量 random variable排列组合 permutation and combination 气体状态方程 equation of state of gas 动能 kinetic energy势能 potential energy机械能守恒 conservation of mechanical energy 动量 momentum桁架 truss轴线 axes余子式 cofactor逻辑电路 logic circuit触发器 flip-flop脉冲波形 pulse shape数模 digital analogy液压传动机构 fluid drive mechanism机械零件 mechanical parts淬火冷却 quench淬火 hardening回火 tempering调质 hardening and tempering磨粒 abrasive grain结合剂 bonding agent砂轮 grinding wheel。

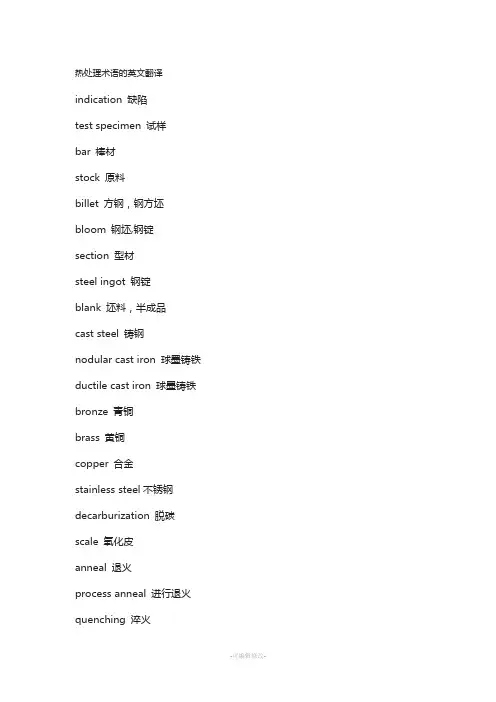

热处理术语的英文翻译indication 缺陷test specimen 试样bar 棒材stock 原料billet 方钢,钢方坯bloom 钢坯,钢锭section 型材steel ingot 钢锭blank 坯料,半成品cast steel 铸钢nodular cast iron 球墨铸铁ductile cast iron 球墨铸铁bronze 青铜brass 黄铜copper 合金stainless steel不锈钢decarburization 脱碳scale 氧化皮anneal 退火process anneal 进行退火quenching 淬火normalizing 正火Charpy impact text 夏比冲击试验fatigue 疲劳tensile testing 拉伸试验solution 固溶处理aging 时效处理Vickers hardness维氏硬度Rockwell hardness 洛氏硬度Brinell hardness 布氏硬度hardness tester硬度计descale 除污,除氧化皮等ferrite 铁素体austenite 奥氏体martensite马氏体cementite 渗碳体iron carbide 渗碳体solid solution 固溶体sorbite 索氏体bainite 贝氏体pearlite 珠光体nodular fine pearlite/ troostite屈氏体black oxide coating 发黑grain 晶粒chromium 铬cadmium 镉tungsten 钨molybdenum 钼manganese 锰vanadium 钒molybdenum 钼silicon 硅sulfer/sulphur 硫phosphor/ phosphorus 磷nitrided 氮化的case hardening 表面硬化,表面淬硬air cooling 空冷furnace cooling 炉冷oil cooling 油冷electrocladding /plating 电镀brittleness 脆性strength 强度rigidity 刚性,刚度creep 蠕变deflection 挠度elongation 延伸率yield strength 屈服强度elastoplasticity 弹塑性metallographic structure 金相组织metallographic test 金相试验carbon content 含碳量induction hardening 感应淬火impedance matching 感应淬火hardening and tempering 调质crack 裂纹shrinkage 缩孔,疏松forging 锻(件)casting 铸(件)rolling 轧(件)drawing 拉(件)shot blasting 喷丸(处理)grit blasting 喷钢砂(处理)sand blasting 喷砂(处理)carburizing 渗碳nitriding 渗氮ageing/aging 时效grain size 晶粒度pore 气孔sonim 夹砂cinder inclusion 夹渣lattice晶格abrasion/abrasive/rub/wear/wearing resistance (property) 耐磨性spectrum analysis光谱分析heat/thermal treatment 热处理inclusion 夹杂物segregation 偏析picking 酸洗,酸浸residual stress 残余应力remaining stress 残余应力relaxation of residual stress 消除残余应力stress relief 应力释放THANKS !!!致力为企业和个人提供合同协议,策划案计划书,学习课件等等打造全网一站式需求欢迎您的下载,资料仅供参考。

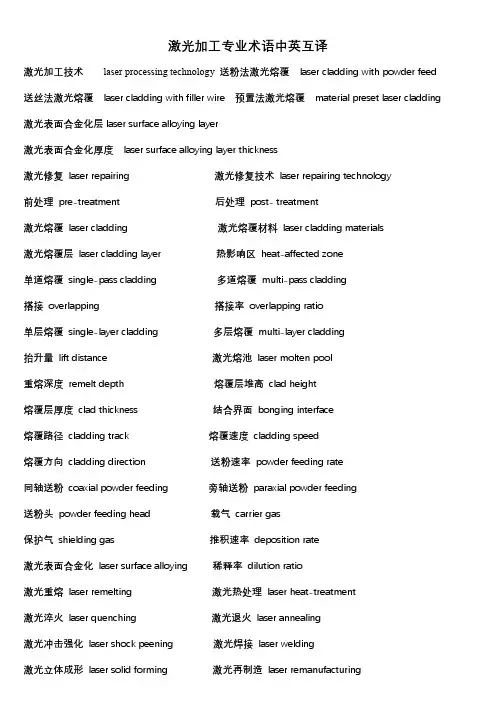

激光加工专业术语中英互译激光加工技术laser processing technology 送粉法激光熔覆laser cladding with powder feed 送丝法激光熔覆laser cladding with filler wire 预置法激光熔覆material preset laser cladding 激光表面合金化层laser surface alloying layer激光表面合金化厚度laser surface alloying layer thickness激光修复laser repairing 激光修复技术laser repairing technology前处理pre-treatment 后处理post- treatment激光熔覆laser cladding 激光熔覆材料laser cladding materials激光熔覆层laser cladding layer 热影响区heat-affected zone单道熔覆single-pass cladding 多道熔覆multi-pass cladding搭接overlapping 搭接率overlapping ratio单层熔覆single-layer cladding 多层熔覆multi-layer cladding抬升量lift distance 激光熔池laser molten pool重熔深度remelt depth 熔覆层堆高clad height熔覆层厚度clad thickness 结合界面bonging interface熔覆路径cladding track 熔覆速度cladding speed熔覆方向cladding direction 送粉速率powder feeding rate同轴送粉coaxial powder feeding 旁轴送粉paraxial powder feeding送粉头powder feeding head 载气carrier gas保护气shielding gas 推积速率deposition rate激光表面合金化laser surface alloying 稀释率dilution ratio激光重熔laser remelting 激光热处理laser heat-treatment激光淬火laser quenching 激光退火laser annealing激光冲击强化laser shock peening 激光焊接laser welding激光立体成形laser solid forming 激光再制造laser remanufacturing。

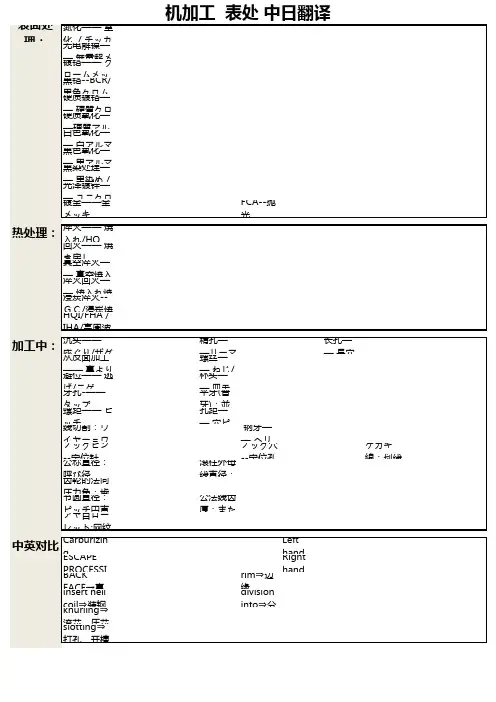

机加工 表处 中日翻译表面处理:氮化—— 窒化 / チッカ / タフトライド /HNT /HNT-G(软氮化)无电解镍—— 無電解メッキ / 無電解ニッケルメッキ / Pni /カニゼン /MFNiIII / ElpFe/Ni-P镀铬—— クロームメッキ黑铬--BCR/黒色クロムメッキ硬质镀铬—— 硬質クロームメッキ / ハードクロム /HCR /MICr /EP-FE /ICR /白上 / Hard chrome硬质氧化——硬質アルマイト白色氧化—— 白アルマイト /AM / AA10 / AM-N4 / SA10 / anodized黑色氧化—— 黒アルマイト / BAM / anodized(black)黑染处理—— 黒染め / パーカ / SOB / blacken / BL / SO 光泽镀锌—— ユニクロ/ MFZnII-C镀金——金メッキFCA--抛光热处理:淬火—— 焼入れ/HQ回火—— 焼き戻し真空淬火—— 真空焼入れ、バーナー焼入れ/VH/HE淬火回火—— 焼入れ焼き戻し/QT/HQ-HT浸炭淬火--GC/浸炭焼入れ/HC.HQHQI/FHA / IHA/高周波淬火 火炎焼き入れ /HEP/フレームハード:火炎淬火加工中:沉头—— 座ぐり/ザグリ精孔——リーマ 长孔—— 長穴从反面加工—— 裏より螺丝—— ねじ/ネジ/螺子避位—— 逃げ/ニゲ杯头—— 皿モミ 牙孔-—— タップ 平牙(普牙):並目 普目螺距—— ピッチ 孔距—— 穴ピッチ线切割:ワイヤー=ワイヤーカット 钢牙—— ヘリサート 黄铜:真鍮 BSBMノックピン --定位针 ノック穴--定位孔ケガキ線:划线公称直径:呼び径滚柱外母线直径:オーバーピン経齿轮的法向压力角:歯直角压力角 模数:モジュール 节圆直径:ピッチ円直径公法线齿厚:またぎ歯厚アヤ目ローレット:网纹滚花中英对比Carburizing prevention→浸炭防止Left hand thread⇒左螺丝ESCAPE PROCESSING→研磨逃がし/研磨避位Right hand thread⇒右螺丝BACK FACE→裏から/从反面加工rim⇒边缘 Hole⇒孔insert heli coil⇒装钢牙division into⇒分为knurling⇒滚花,压花纹 mesh-pattern ⇒网格花样slotting⇒打孔,开槽 through⇒通。

金属材料及热处理工艺常用基础英语词汇翻译对照1X线结晶分析法X –ray crystal analyics method奥氏体Austenite奥氏体碳钢Austenite Carbon Steel奥氏铁孻回火Austempering半静钢Semi-killed steel包晶反应Peritectic Reaction包晶合金Peritectic Alloy包晶温度Peritectic Temperature薄卷片及薄片(0.3至2.9mm厚之片)机械性能Mechanical Properties of Thin Stainless Steel(Thickness from 0.3mm to 2.9mm)–strip/sheet杯突测试(厚度:0.4公厘至1.6公厘,准确至0.1公厘3个试片平均数)Erichsen test (Thickness:0.4mm to 1.6mm,figure round up to 0.1mm)贝氏体钢片Bainite Steel Strip比电阻Specific resistivity & specific resistance比较抗磁体、顺磁体及铁磁体Comparison of Diamagnetism,Paramagnetic & Ferromagnetism比热Specific Heat比重Specific gravity & specific density边缘处理Edge Finish扁线、半圆线及异形线Flat Wire,Half Round Wire,Shaped WirePrecision Shaped Fine Wire扁线公差Flat Wire Tolerance变态点Transformation Point表面保护胶纸Surface protection film表面处理Surface finish表面处理Surface Treatment不破坏检验Non –destructive inspections不锈钢Stainless Steel不锈钢–种类,工业标准,化学成份,特点及主要用途Stainless Steel –Type,Industrial Standard,Chemical Composition,Characteristic & end usage of the most commonly used Stainless Steel不锈钢薄片用途例End Usage of Thinner Gauge不锈钢扁线及半圆线常用材料Commonly used materials for Stainless Flat Wire & Half Round Wire不锈钢箔、卷片、片及板之厚度分类Classification of Foil,Strip,Sheet & Plate by Thickness不锈钢材及耐热钢材标准对照表StainlessHeat-Resisting Steels不锈钢的磁性Magnetic Property & Stainless Steel不锈钢的定义Definition of Stainless Steel不锈钢基层金属Stainless Steel as Base Metal不锈钢片、板用途例Examples of End Usages of Strip,Sheet & Plate不锈钢片材常用代号Designation of SUS Steel Special Use Stainless不锈钢片机械性能(301,304,631,CSP)Mechanical Properties of Spring use StainlessSteel不锈钢应力退火卷片常用规格名词图解General Specification of Tension Annealed Stainless Steel Strips不锈钢之分类,耐腐蚀性及耐热性Classification,Corrosion Resistant & Heat Resistance of Stainless Steel材料的加工性能Drawing abillity插入型固熔体Interstital solid solution常用尺寸Commonly Used Size常用的弹簧不锈钢线-编号,特性,表面处理及化学成份StainlessSpring Wire –National Standard number,Charateristic,Surface finish & Chemical composition 常用的镀锌钢片(电解片)的基层金属、用途、日工标准、美材标准及一般厚度Base metal,application,JIS & ASTM standard,Normal thickness of galvanized steel sheet 长度公差Length Tolerance超耐热钢Special Heat Resistance Steel超声波探伤法Ultrasonic inspection冲击测试Impact Test冲剪Drawing & stamping初释纯铁体Pro-entectoid ferrite处理及表面状况Finish & Surface纯铁体Ferrite磁场Magnetic Field磁畴Magnetic domain磁粉探伤法Magnetic particle inspection磁化率Magnetic Susceptibility (Xm)磁矩magnetic moment磁力Magnetic磁力Magnetic Force磁偶极子Dipole磁性Magnetisum磁性变态Magnetic Transformation磁性变态点Magnetic Transformation磁性感应Magnetic Induction粗珠光体Coarse pearlite淬火Quenching淬火及回火状态Hardened & Tempered Strip/ Precision – Quenched Steel Strip淬火剂Quenching Media单相金属Single Phase Metal单相轧压镀锡薄铁片(白铁皮/马口铁)Single-Reduced Tinplate弹簧不锈钢线,线径及拉力列表Stainless Spring Steel,Wire diameterTensile strength of Spring Wire弹簧用碳钢片CarbonSteel Strip For Spring Use弹簧用碳钢片材之边缘处理Edge Finished弹性限度、阳氏弹性系数及屈服点elastic limit,Yeung''s module of elasticity to yield point倒后擦发条Pull Back Power Spring导热度Heat conductivity低碳钢或铁基层金属Iron & Low Carbon as Base Metal低碳马氏体不锈钢Low Carbon Martensite Stainless Steel低温脆性Cold brittleness低温退火Low Temperature Annealing第二潜变期Secondary Creep第三潜变期Tertiary Creep第壹潜变期Primary Creep点焊Spot welding电镀金属钢片Plate Metal Strip电镀金属捆片的优点Advantage of Using Plate Metal Strip电镀锌(电解)钢片Electro-galvanized Steel Sheet电镀锌钢片的焊接Welding of Electro-galvanized steel sheet电镀锌钢片或电解钢片Electro-galvanized Steel Sheet/Electrolytic Zinc Coated Steel Sheet电解/电镀锌大大增强钢片的防锈能力Galvanic Action improving Weather & Corrosion Resistance of the Base Steel Sheet电解冷轧钢片厚度公差Thickness Tolerance of Electrolytic Cold-rolled sheet电炉Electric furnace电器及家电外壳用镀层冷辘[低碳] 钢片Coated (Low Carbon)Steel Sheets for Casing,Electricals & Home Appliances电器用的硅[硅] 钢片之分类Classification of Silicon Steel Sheet for Electrical Use电器用钢片的绝缘涂层Performance of Surface Insulation of Electrical Steel Sheets电器用钢片用家需自行应力退火原因Annealing of the Electrical Steel Sheet电器用硅[硅] 钢片Electrical Steel Sheet电阻焊Resistance Welding定型发条Constant Torque Spring定型发条的形状及翻动过程ShapeSpring Back of Constant Torque Spring定型发条及上炼发条的驱动力Spring Force of Constant Torque SpringWing-up Spring 定型发条驱动力公式及代号The FormulaSymbol of Constant Torque Spring镀层质量标记Markings & Designations of Differential Coatings镀铬Chrome Plated镀黄铜Brass Plated镀铝(硅)钢片–美材试标准(ASTM A-463-77)35.7 JIS G3314镀热浸铝片的机械性能Mechanical Properties of JIS G 3314 Hot-Dip Aluminum-coated SheetsCoils 镀铝(硅)钢片–日工标准(JIS G3314)Hot-aluminum-coated sheetscoils to JIS G 3314 镀铝(硅)钢片及其它种类钢片的抗腐蚀性能比较Comparsion of various resistance of aluminized steel & other kinds of steel镀铝(硅)钢片生产流程Aluminum Steel Sheet,Production Flow Chart镀铝硅钢片Aluminized Silicon Alloy Steel Sheet镀铝硅合金钢片的特色Feature of Aluminized Silicon Alloy Steel Sheet镀镍Nickel Plated镀锡薄钢片(白铁皮/马日铁)制造过程Production Process of Electrolytic Tinplate镀锡薄铁片(白铁皮/马口铁)(日工标准JIS G3303)镀锡薄铁片的构造Construction of Electrolytic Tinplate锻造Fogging断面缩率Reduction of area发条的分类及材料Power Spring Strip ClassificationMaterials发条片Power Spring Strip反铁磁体Antiferromagnetism方线公差Square Wire Tolerance防止生锈Rust Protection放射线探伤法Radiographic inspection非晶粒取向电力用钢片的电力、磁力、机械性能及夹层系数Lamination Factors of Electrical,Magnetic & Mechanical Non-Grain Oriented Electrical沸腾钢(未净钢)Rimmed steel分类Classification负磁力效应Negative effect钢板Steel Plate钢板订货需知Ordering of Steel Plate钢板生产流程Production Flow Chart钢板用途分类及各国钢板的工业标准包括日工标准及美材试标准Type of steel Plate & Related JIS,ASTMOther Major Industrial Standards钢材的熔铸、锻造、挤压及延轧The Casting,Fogging,Extrusion,Rolling & Steel 钢的脆性Brittleness of Steel钢的种类Type of Steel钢铁的名称Name of steel钢铁的制造Manufacturing of Steel钢铁的主要成份The major element of steel钢铁生产流程Steel Production Flow Chart钢铁用“碳”之含量来分类Classification of Steel according to Carbon contents高锰钢铸–日工标准High manganese steel to JIS standard高碳钢化学成份及用途High Carbon Tool Steel,Chemical CompositionUsage高碳钢片High Carbon Steel Strip高碳钢片用途End Usage of High Carbon Steel Strip高碳钢线枝High Carbon Steel Wire Rod (to JIS G3506)高温回火High Temperature Tempering格子常数Lattice constant铬钢–日工标准JIS G4104 Chrome steel to JIS G4104铬镍不锈钢及抗热钢弹簧线材–美国材验学会ASTM A313 –1987 Chromium –Nickel StainlessHeat-resisting Steel Spring Wire – ASTM A313 – 1987铬系耐热钢Chrome Heat Resistance Steel铬钼钢钢材–日工标准G4105 62 Chrome Molybdenum steel to JIS G4105各种不锈钢线在不同处理拉力比较表Tensile Strength of various kinds of Stainless Steel Wire under Different Finish工业标准及规格–铁及非铁金属Industrial Standard –Ferrous & Non –ferrous Metal公差Size Tolerance共晶Eutectic共释变态Eutectoid Transformation固熔体Solid solution光辉退火Bright Annealing光线(低碳钢线),火线(退火低碳钢线),铅水线(镀锌低碳钢线)及制造钉用低碳钢线之代号、公差及备注Ordinary Low Carbon Steel Wire,Annealed Low Carbon Steel Wire,Galvanized low Carbon Steel Wire & Low Carbon Steel Wire for nail manufacturing - classification,Symbol of Grade,ToleranceRemarks.硅含量对电器用的低碳钢片的最大好处The Advantage of Using Silicon low Carbon Steel滚焊Seam welding过共晶体Hyper-ectectic Alloy过共释钢Hype-eutectoid含硫易车钢Sulphuric Free Cutting Steel含铅易车钢Leaded Free Cutting Steel含铁体不锈钢Ferrite Stainless Steel焊接Welding焊接合金SolderingBrazing Alloy焊接能力Weldability 镀铝钢片的焊接状态(比较冷辘钢片)Tips on welding of Aluminized sheet in comparasion with cold rolled steel strip合金平衡状态Thermal Equilibrium厚度及阔度公差Tolerance on Thickness & Width滑动面Slip Plan化学成份Chemical Composition化学结合Chemical bond化学性能Chemical Properties化学元素Chemical element黄铜基层金属Brass as Base Metal回复柔软Crystal Recovery回火脆性Temper brittleness回火有低温回火及高温回火Low & High Temperature Tempering回火状态Annealed Strip基层金属Base Metal of Plated Metal Strip机械性能Mechanical Properites机械性能Mechanical properties畸变Distortion级别、电镀方法、镀层质量及常用称号Grade,Plating type,Designation of Coating Mass & Common Coating Mass级别,代号,扭曲特性及可用之线材直径Classes,symbols,twisting characteristicapplied Wire Diameters级别,代号及化学成份Classification,Symbol of GradeChemical Composition挤压Extrusion加工方法Manufacturing Method加工性能Machinability简介General交换能量Positive energy exchange矫顽磁力Coercive Force金属变态Transformation金属材料的试验方法The Method of Metal inspection金属材料的性能及试验Properties & testing of metal金属的特性Features of Metal金属的相融、相融温度、晶体反应及合金在共晶合金、固熔孻共晶合金及偏晶反应的比较Equilibrium Comparision金属间化物Intermetallic compound金属结晶格子Metal space lattice金属捆片电镀层Plated Layer of Plated Metal Strip金属塑性Plastic Deformation金属特性Special metallic features金属与合金MetalAlloy金相及相律Metal PhasePhase Rule晶粒取向(Grain-Oriented)及非晶粒取向(Non-Oriented)晶粒取向,定取向芯钢片及高硼定取向芯钢片之磁力性能及夹层系数(日工标准及美材标准)Magnetic PropertiesLamination Factor of SI-ORIENT-CORE& SI-ORIENT-CORE-HI B Electrical Steel Strip (JISAISI Standard)晶粒取向电器用硅[硅] 钢;片–高硼低硫(LS)定取向钢片之磁力及电力性能MagneticElectrical Properties of SI-ORIENT-CORE-HI-B-LS晶粒取向电器用硅[硅] 钢片–高硼(HI-B)定取向芯钢片及定取向芯钢片之机械性能及夹层系数Mechanical PropertiesLamination Factors of SI-ORIENT-CORE-HI-BSI-ORIENT-CORE Grain Orient Electrical Steel Sheets 晶粒取向电器用硅[硅] 钢片–高硼低硫(LS)定取向钢片之机械性能及夹层系数Mechanical PropertiesLamination Factors of SI-ORIENT-CORE-HI-B-LS晶粒取向电器用硅(硅)钢片–高硼(HI-B)定取向芯钢片,定取向芯钢片及高硼低硫(LS)定取向芯钢片之标准尺寸及包装Standard FormsSize of SI-ORIENT-CORE-HI-B,SI-CORE,& SI-ORIENT-CORE-HI-B-LS Grain-晶粒取向电器用硅(硅)钢片-高硼(HI-B)定取向芯钢片,定取向芯钢片及高硼低硫(LS)定取向芯钢片之厚度及阔度公差Physical Tolerance of SI-ORIENT-CORE-HI-B,SI-ORIENT-CORE,& SI-CORE-HI-B-LS Grain晶粒取向电器用硅钢片Grain-Oriented Electrical Steel晶粒取向电器用硅钢片主要工业标准International Standard –Grain-Oriented Electrical Steel Silicon Steel Sheet for Electrical Use晶体结构Crystal Pattern晶体结构,定向格子及单位晶格Crystal structure,Space lattice & Unit cell净磁矩Net magnetic moment绝缘表面Surface Insulation均热炉Soaking pit抗磁体Diamagnetism抗腐蚀及耐用Corrosion & resistance durability抗化学品能力Chemical Resistance抗敏感及环境保护Allergic,re-cycling & environmental protection抗热超级合金Heat Resistance Super Alloy扩散退火Diffusion Annealing拉尺发条Measure Tape拉伸测试(顺纹测试)Elongation test冷冲及冷锻用碳钢线枝Carbon Steel Wire Rods for Cold Heading & Cold Forging (to JIS G3507)冷拉钢板重量表Cold Drawn Steel Bar Weight Table冷拉钢枝材Cold Drawn Carbon Steel Shafting Bar冷拉高碳钢线Hard Drawn High Carbon Steel Wire冷轧钢片Cold-Rolled Steel Sheet/Strip冷轧高碳钢–日本工业标准Cold-Rolled (Special Steel)Carbon Steel Strip to JIS G3311 冷轧或热轧钢片阔度公差Width Tolerance of Cold or Hot-rolled sheet冷轧状态Cold Rolled Strip冷辘(低碳)钢片的分类用、途、工业标准、品质、加热状态及硬度表End usages,industrial standard,quality,conditionhardness of cold rolled steel strip冷辘低碳钢片(双单光片)(日工标准JIS G3141)73 - 95 Cold Rolled (Low carbon)Steel Strip (to JIS G 3141)冷辘钢捆片及张片的电镀和印刷方法Cold rolled steel coil & sheet electro-plating & painting method冷辘钢捆片及张片制作流程图表Production flow chart cold rolled steel coil sheet冷辘钢片(拉力:30-32公斤/平方米)在没有表面处理状态下的焊接状况Spot welding conditions for bared (free from paint,oxides etc)Cold rolled mild steel sheets(T/S:30-32 Kgf/ μm2)冷辘钢片储存与处理提示General advice on handling & storage of cold rolled steel coil & sheet冷辘钢片的“理论重量”计算方程式Cold Rolled Steel Sheet – Theoretical mass冷辘钢片订货需知Ordering of cold rolled steel strip/sheet理论质量Theoretical Mass连续铸造法Continuous casting process两面不均等锡层Both Side Different Thickness Coated Mass两面均等锡层Both Side Equally Coated Mass裂纹之容许深度及脱碳层Permissible depth of flawdecarburized layer临界温度Critical temperture马氏体不锈钢Martensite Stainless Steel马氏铁体淬火Marquenching埋弧焊Submerged-arc Welding每公斤发条的长度简易公式The Length of 1 Kg of Spring Steel Strip美材试标准的冷辘低碳钢片Cold Rolled Steel Strip American Standard –American Society for testingmaterials (ASTM)美国工业标准–不锈钢及防热钢材的化学成份(先数字后字母排列)AISI –Chemical Composition of Stainless Steel & Heat-Resistant Steel(in order of number & alphabet)金属材料及热处理工艺常用基础英语词汇翻译对照2米勒指数Mill''s Index魔术手环Magic Tape魔术手环尺寸图Drawing of Magic Tap耐热不锈钢Heat-Resistance Stainless Steel耐热不锈钢比重表Specific Gravity of Heat –resistance steel platessheets stainless steel 镍铬–日工标准G4102 63 Chrome Nickel steel to JIS G4102镍铬耐热钢Ni - Cr Heat Resistance Steel镍铬系不锈钢Nickel Chrome Stainless Steel镍铬系耐热不锈钢特性、化学成份、及操作温度Heat-Resistance Stainless Steel镍铬钼钢–日工标准G4103 64 Nickel,Chrome & Molybdenum Steel to JIS G4103疲劳测试Fatigue Test片及板材Chapter Four-Strip,Steel & Plate平坦度(阔度大于500公厘,标准回火)Flatness (width>500mm,temper:standard)破坏的检验Destructive Inspection其它焊接材料请参阅日工标准目录Other Soldering Material其它日工标准冷轧钢片(用途及编号)JIS standard & application of other cold RolledSpecial Steel气焊Gas Welding潜变测试Creep Test潜变强度Creeps Strength强度Strength琴线(日本标准G3522)Piano Wires (to G3522)球化退火Spheroidizing Annealing曲面(假曲率)Camber屈服强度(降伏强度)(Yield strangth)全静钢Killed steel热力应先从工件边缘透入Heat from the Laminated Stacks Edges热膨胀系数Coefficient of thermal expansion热轧钢片Hot-Rolled Sheet/Strip热轧钢片厚度公差Thickness Tolerance of Hot-rolled sheet日本工业标准–不锈钢的化学成份(先数字后字母排列)JIS –Chemical Composition of Stainless Steel (in order of number & alphabet)日工标准(JIS G3141)冷辘钢片化学成份Chemical composition – cold rolled steel sheet toJIS G3141日工标准(JIS G3141)冷辘钢片重量列表Mass of Cold-Rolled Steel Sheet to JIS G3141 日工标准JIS G3141冷辘低碳钢片(双单光片)的编号浅释Decoding of cold rolled(Lowcarbon)steel strip JIS G3141日工标准下的特殊钢材Specail Steel according to JIS Standard熔铸Casting软磁Soft Magnetic软磁材料Soft Magnetic Material软焊Soldering Alloy软焊合金–日本标准JIS H 4341 Soldering Alloy to JIS H 4341上链发条Wind-up Spring上漆能力Paint Adhesion伸长度Elongation渗碳体Cementitle渗透探伤法Penetrate inspection生产流程Production Flow Chart生锈速度表Speed of rusting时间淬火Time Quenching时间效应(老化)及拉伸应变Aging & Stretcher Strains释出硬化不锈钢Precipitation Hardening Stainless Steel双相辗压镀锡薄钢片(马口铁/白铁皮)Dual-Reduction Tinplate顺磁体Paramagnetic碳钢回火Tempering碳污染Prevent Carbon Contamination特点Characteristic特殊钢Special Steel特殊钢以用途来分类Classification of Special Steel according to End Usage 特殊钢以原素分类Classification of Special Steel according to Element提防过份氧化No Excessive Oxidation铁磁体Ferromagnetism铁铬系不锈钢片Chrome Stainless Steel铁及非铁金属Ferrous & Non Ferrous Metal铁锰铝不锈钢Fe / Mn / Al / Stainless Steel铁线(低碳钢线)日工标准JIS G 3532 Low Carbon Steel Wires (Iron Wire )to JIS G3532铁相Steel Phases同素变态Allotropic Transformation铜基层金属Copper as Base Metal透磁度Magnetic Permeability退火Annealing退火时注意事项Annealing Precautionary外价电子Outer valence electrons弯度Camber完全退火Full Annealing物理性能Physical Properties物料科学Material Science物料科学定义Material Science Definition锡层质量Mass of Tin Coating (JIS G3303-1987)锡基、铅基及锌基轴承合金比较表Comparison of Tin base,Lead baseZinc base alloy forBearing purpose细线材、枝材、棒材Chapter Five Wire,Rod & Bar显微观察法Microscopic inspection线材/枝材材质分类及制成品ClassificationEnd Products of Wire/Rod线径、公差及机械性能(日本工业标准G 3521)Mechanical Properties (JIS G 3521)相反旋转Opposite span相律Phase Rule锌包层之重量,铜硫酸盐试验之酸洗次数及测试用卷筒直径Weight of Zinc-Coating,Number of Dippings in Cupric Sulphate TestDiameters of Mandrel Used for Coiling Test锌镀层质量Zinc Coating Mass锌镀层质量(两个不同锌镀层厚度)Mass Calculation of coating (For differential coating)/MM锌镀层质量(两个相同锌镀层厚度)Mass Calculation of coating (For equal coating)/MM亚共晶体Hypoeutetic Alloy亚铁磁体Ferrimagnetism亚铁释体Hyppo-Eutectoid延轧Rolling颜色Colour易车(快削)不锈钢Free Cutting Stainless Steel易车(快削)不锈钢拉力表Tensile Strength of Free Cutting Wires易车(快削)不锈钢种类Type of steel易车不锈钢及易车钢之不同尺寸及硬度比较Hardness of Different Types & Size of FreeCutting Steel易车碳钢Free Cutting Carbon Steels (to JIS G4804 )易溶合金Fusible Alloy应力退火温度Stress –relieving Annealing Temperature应用材料Material Used硬磁Hard Magnetic硬磁材料Hard Magnetic Material硬度Hardness硬度及拉力Hardness & Tensile strength test硬焊Brazing Alloy硬化Work Hardening硬化性能Hardenability用含碳量分类–即低碳钢、中碳钢及高碳钢Classification According to CarbonContains用途End Usages用组织结构分类Classification According to Grain Structure幼珠光体Fine pearlite元素的原子序数Atom of Elements原子的组成、大小、体积和单位图表The size,mass,charge of an atom,is particles(Pronton,NentronElectron)原子的组织图Atom Constitutes原子及固体物质Atomsolid material原子键结Atom Bonding圆钢枝,方钢枝及六角钢枝之形状及尺寸之公差Tolerance on ShapeDimensions for Round Steel Bar,Square Steel Bar,Hexagonal Steel Bar圆径及偏圆度之公差Tolerance of Wire Diameters & Ovality圆面(“卜竹”)发条Convex Spring Strip再结晶Recrystallization正磁化率Positive magnetic susceptibility枝/棒无芯磨公差表(μ)(μ= 1/100 mm)Rod/Bar Centreless Grind Tolerance 枝材之美工标准,日工标准,用途及化学成份AISI,JIS End UsageChemical Composition of Cold Drawn Carbon Steel Shafting Bar直径,公差及拉力强度Diameter,ToleranceTensile Strength 直径公差,偏圆度及脱碳层的平均深度Diameter Tolerance,OvalityAverageDecarburized Layer Depth置换型固熔体Substitutional type solid solution滞后回线Narrow Hystersis中途退火Process Annealing中珠光体Medium pearlite周期表Periodic Table轴承合金Bearing Alloy轴承合金–日工标准JIS H 5401 Bearing Alloy to JIS H 5401珠光体Pearlite珠光体及共释钢Pearlite &Eutectoid主要金属元素之物理性质Physical properties of major Metal Elements转变元素Transition element自发上磁Spontaneous magnetization自由度Degree of freedom最大能量积Maximum Energy Product(to JIS G3521,ISO-84580-1&2)化学成份分析表Chemical Analysis of Wire Rod 305,316,321及347之拉力表Tensile Strength Requirements for Types 305,316,321347A1S1-302 贰级线材之拉力表Tensile Strength of A1S1-302 Wire Grain Oriented & Non-Oriented 电器用硅[硅] 钢片的最终用途及规格EndUsageDesignations of Electrical Steel StripOriented Electrical Steel SheetsSK-5 & AISI-301 每公尺长的重量/公斤(阔2.0-10公厘)Weight per one meter long (kg)(Width 2.0-10mm)SK-5 & AISI-301 每公斤长的重量/公斤(阔100-200公厘)Weight per one meter long(kg)(Width 100-200mm)SK-5 & AISI-301 每公斤之长度(阔100-200公厘)Length per one kg (Width100-200mm)SK-5 & AISI-301 每公斤之长度(阔2.0-10公厘)Length per one kg (Width 2.0-10mm。

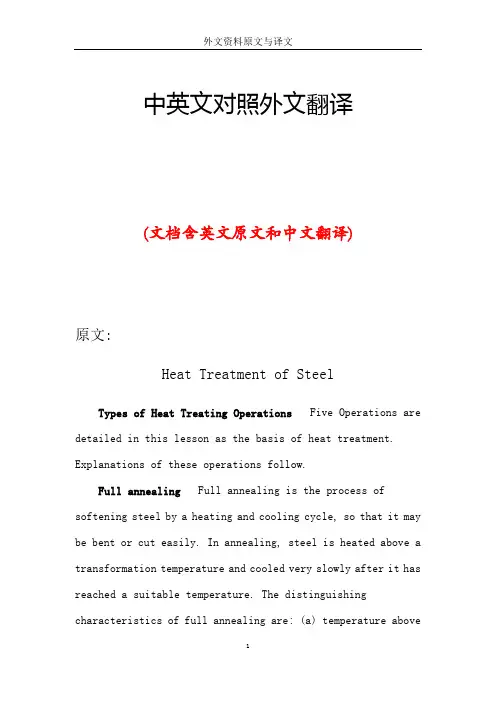

中英文对照外文翻译(文档含英文原文和中文翻译)原文:Heat Treatment of SteelTypes of Heat Treating Operations Five Operations are detailed in this lesson as the basis of heat treatment. Explanations of these operations follow.Full annealing Full annealing is the process of softening steel by a heating and cooling cycle, so that it may be bent or cut easily. In annealing, steel is heated above a transformation temperature and cooled very slowly after it has reached a suitable temperature. The distinguishing characteristics of full annealing are: (a) temperature abovethe critical temperature and (b) very slow cooling, usually in the furnace.Normalizing Normalizing is identical with annealing, except that the steel is air cooled; this is much faster than cooling in a furnace. Steel is normalized to refine grain size, make its structure more uniform, or to improve machinability.Hardening Hardening is carried out y quenching a steel, that is, cooling it rapidly from a temperature above the transformation temperature. Steel is quenched in water or brine for the most rapid cooling, in oil for some alloy steels, and in air for certain higher alloy steels. After steel is quenched, it is usually very hard and brittle; it may even crack if dropped. To make the steel more ductile, it must be tempered.Tempering Tempering consistes of reheating a quenched steel to a suitable temperature below the transformation temperature for an appropriate time and cooling back to room temperature. How this process makes steel tough will be discussed later.Stress relieving Stress relieving is the heating of steel to a temperature below the transformation temperature, as in tempering, but is done primarily to relieve internal stress and thus prevent distortion or cracking during machining.This is sometimes called process annealing.Reasons for Heat Treating Heat treatment of steel is usually intended to accomplish any one of the following objectives:●Remove stresses induced by cold working or toremove stresses set up by nonuniform cooling of hot metalobjects;●Refine the grain structure of hot worked steelswhich may have developed coarse grain size;●Secure the proper grain structure;●Decrease the hardness and increase the ductility;●Increase the hardness so as to increase resistanceto wear or to enable the steel to withstand more serviceconditions;●Increase the toughness; that is, to produce a steelhaving both a high tensile strength and good ductility,enabling it to withstand high impact;●Improve the machinability;●Improve the electrical properties;●Change or modify the magnetic properties of steel.Heat Treatment The hardest condition for any givens steel is obtained by quenching to a fully martensitic structure.Since hardness is directly related to strength, a steel composed of 100% martensite is at its strongest possible condition. However, strength is not the only property that must be considered in the application of steel parts. Ductility may be equally important.Tempering Ductility is the ability of a metal to change shape before it breaks. Fleshly quenched martensite is hard but not ductile; in fact, it is very brittle. Tempering is needed to impart ductility to the martensite, usually at a smell sacrifice in strength. In addition, tempering greatly increases the resistance of martensite to shock loading.The effect of tempering may be illustrated as follows. If the head of a hammer were quenched to a fully martensitic structure, it probably would crack after the first few blows. Tempering during manufacture of the hammer imparts shock resistance with only a slight decrease in hardness. Tempering is accomplished by heating a quenched pert to some point below the transformation temperature, and holding it at this temperature for an hour or more, depending on its size. Most steels are tempered between 205 and 5,950C. As higher temperatures are employed, toughness or shock resistance of the steel is increased, but the hardness and strength decrease.Annealing the two-stage heat treating process of quenching and tempering is designed to produce high strength steel capable of resisting shock and deformation without breaking. On the other hand, the annealing process is intend to make steel easier to deform of machine. In manufacturing steel products, machining and severe bending operations are often employed. Even tempered steel may not cut or bend very easily and annealing is often necessary.Process annealing Process annealing consists of heating steel to a temperature just below the lowest transformation temperature for a short time. This makes the steel easier to form. This heat treatment is commonly applied in the sheet and wire industries, and the temperatures generally used are from 550 to 650o C.Full annealing Process annealing, where steel is heated 50 to 100 o C above the third transformation temperature for hypoeutectoid steels, and above the lowest transformation temperature for hypereutectoid steels, and slow cooled, makes the steel much easier to cut, as well as bend. In full annealing, cooling must take place very slowly so that a coarse pearlite is formed. Show cooling is not essential for process annealing, since any cooling rate from temperatures below the lowesttransformation temperature will result in the same microstructure and hardness.During cold deformation, steel has a tendency to harden in deformed areas, making it more difficult to bend and liable to breakage. Alternate deforming and annealing operations are performed on most manufactured steel products.Normalizing The process of normalizing consists of heating to a temperature above the third transformation temperature and allowing the pert to cool in still air. The actual temperature required for this depends on the composition of the steel, but is usually around 870o C. Actually, the term normalize does not describe the purpose. The process might be more accurately described as a homogenizing or grain-refining treatment. Within any piece of steel, the composition is usually not uniform throughout. That is, one area may have more carbon than the area adjacent to it. These compositional differences affect the way in which the steel will respond t heat treatment. If it is heated to a high temperature, the carbon can readily diffuse throughout, and the result is a reasonably uniform composition from one area to next. The steel is then more homogeneous and will respond to the heat treatment in a more uniform way.Because of characteristics inherent in cast steel, the normalizing treatment is more frequently applied to ingots prior to working, and to steel castings and forgings prior to hardening.Stress Relieving When a metal is heated, expansion occurs which is more or less proportional to the temperature rise. Upon cooling metal, the reverse reaction takes place. That is, a contraction is observed. When a steel bar or plate is heated at one point more than at another, as in welding or during forging, internal stress are set up. During heating, expansion of the heated area cannot take place unhindered, and it tends to deform. On cooling, contraction is prevented from taking place by the unyielding cold metal surrounding the heated area. The forces attempting to contract the metal are not relieved, and when the metal is cold again, the forces remain as internal stresses. Stresses also result from volume changes, which accompany metal transformations and precipitation. Internal or residual stresses are bad because they may cause warping of steel parts when they are machined. To relieve these stresses, steel is heated to around 595o C, assuming that the entire pert is heated uniformly, then cooled slowly back to room temperature. This procedure is calledstress relief annealing, or merely stress relieving.译文:钢的热处理各种类型的热处理本单元详细介绍了五种热处理的基本方法。

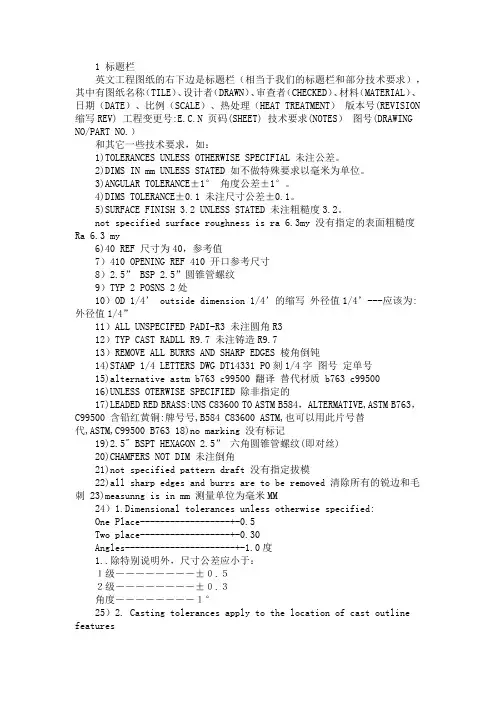

1 标题栏英文工程图纸的右下边是标题栏(相当于我们的标题栏和部分技术要求),其中有图纸名称(TILE)、设计者(DRAWN)、审查者(CHECKED)、材料(MATERIAL)、日期(DATE)、比例(SCALE)、热处理(HEAT TREATMENT)版本号(REVISION 缩写REV) 工程变更号:E.C.N 页码(SHEET) 技术要求(NOTES)图号(DRAWING NO/PART NO.)和其它一些技术要求,如:1)TOLERANCES UNLESS OTHERWISE SPECIFIAL 未注公差。

2)DIMS IN mm UNLESS STATED 如不做特殊要求以毫米为单位。

3)ANGULAR TOLERANCE±1° 角度公差±1°。

4)DIMS TOLERANCE±0.1 未注尺寸公差±0.1。

5)SURFACE FINISH 3.2 UNLESS STATED 未注粗糙度3.2。

not specified surface roughness is ra 6.3my 没有指定的表面粗糙度Ra 6.3 my6)40 REF 尺寸为40,参考值7)410 OPENING REF 410 开口参考尺寸8)2.5” BSP 2.5”圆锥管螺纹9)TYP 2 POSNS 2处10)OD 1/4’ outside dimension 1/4’的缩写外径值1/4’---应该为:外径值1/4”11)ALL UNSPECIFED PADI-R3 未注圆角R312)TYP CAST RADLL R9.7 未注铸造R9.713)REMOVE ALL BURRS AND SHARP EDGES 棱角倒钝14)STAMP 1/4 LETTERS DWG DT14331 PO刻1/4字图号定单号15)alternative astm b763 c99500 翻译替代材质 b763 c9950016)UNLESS OTERWISE SPECIFIED 除非指定的17)LEADED RED BRASS:UNS C83600 TO ASTM B584,ALTERMATIVE,ASTM B763,C99500 含铅红黄铜:牌号号,B584 C83600 ASTM,也可以用此片号替代,ASTM,C99500 B763 18)no marking 没有标记19)2.5" BSPT HEXAGON 2.5” 六角圆锥管螺纹(即对丝)20)CHAMFERS NOT DIM 未注倒角21)not specified pattern draft 没有指定拔模22)all sharp edges and burrs are to be removed 清除所有的锐边和毛刺 23)measunng is in mm 测量单位为毫米MM24)1.Dimensional tolerances unless otherwise specified:One Place------------------+-0.5Two place------------------+-0.30Angles----------------------+-1.0度1..除特别说明外,尺寸公差应小于:1级--------±0.52级--------±0.3角度--------1°25)2. Casting tolerances apply to the location of cast outline featureslocated with basic dimensions2.铸造公差适用于具有基准尺寸的铸件轮廓特征区域;26)3.Casting to be free from oil,grit,dirt and loose particles. 3.铸件(表面)须经除油、除尘、除锈和喷砂处理;27)4.Porosity holes to be max 2.3 diameter by 1.6 deep.4.砂眼孔最大不能超过直径2.3,深度1.6;28)5. casting quality to conform with general motors standards and specifications.5.铸件的质量应符合通用汽车(GM)的标准和技术说明书;29)6. Casting tolerances are not cumulative.6.铸件误差不累积; 30)7.casting tolerances unless otherwise specified:0.0 to 75.0 ------------------------------- +-0.7575.0 to 200.0 ---------------------------- +-1.15draft angles ------------------------------2度fillet radii --------------------------------3.0corner radii ------------------------------3.0all walls & ribs ------------------------- 4.57.无特殊说明时,铸造公差应小于:0.0~75.0------±0.7575.0~200.0----±1.15拔模角度---------2°内圆角半径--------3外圆角半径--------3所有壁板和筋厚------4.531)8.Material cast iron per GM274M grade 2058.材料:铸铁依照GM274M 等级 205;32)9.restricted and reportable substances for parts per GMW 30599.零件中的限制物质和必须明示的物质(环保要求)依照标准GMW 3059;33)10.Must comply with QP-I.6-009 for production and QP-I.6-004 for Prototypes.10.必须依照QP-6.I-009产品和QP-I.6-004原型生产34)Machining allowance to be adopted when turning a surface to be ground is equal to Max value for required dimension with 0.05 mm deviation 表达的是加工后基本尺寸的上下偏差,就是±0.0534)METARIAL : ALLOY 24, PERMOLD.1,材质:合金24,由模具成型。

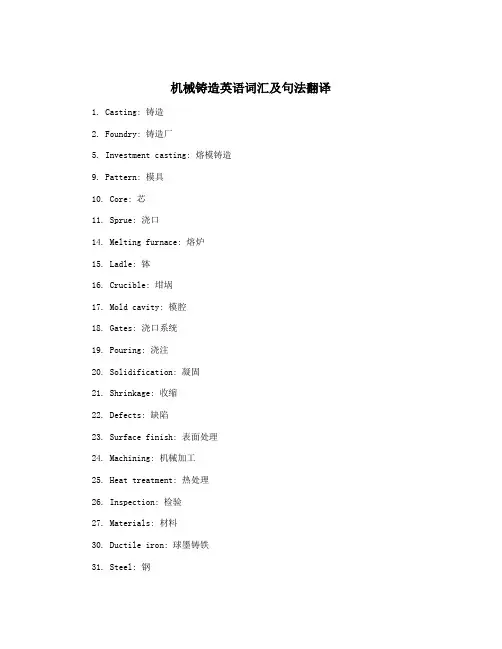

机械铸造英语词汇及句法翻译1. Casting: 铸造2. Foundry: 铸造厂5. Investment casting: 熔模铸造9. Pattern: 模具10. Core: 芯11. Sprue: 浇口14. Melting furnace: 熔炉15. Ladle: 钵16. Crucible: 坩埚17. Mold cavity: 模腔18. Gates: 浇口系统19. Pouring: 浇注20. Solidification: 凝固21. Shrinkage: 收缩22. Defects: 缺陷23. Surface finish: 表面处理24. Machining: 机械加工25. Heat treatment: 热处理26. Inspection: 检验27. Materials: 材料30. Ductile iron: 球墨铸铁31. Steel: 钢32. Aluminum alloys: 铝合金37. High-temperature alloys: 高温合金39. Foundry processes use a wide variety of materials to produce a range of products: 铸造工艺使用多种材料生产各种产品47. Inspection is an important part of the casting process to ensure that parts meet the required specifications and tolerances: 检验是铸造过程中的重要部分,以确保零件符合要求的规格和容差。

模具术语英文翻译近年来,随着全球经济的发展,模具制造业也迎来了新的机遇和发展。

模具术语的英文翻译在国际贸易和工程项目中扮演了重要的角色。

本文从工艺、制造、部件等方面介绍了模具术语的英文翻译,并对其应用进行了分析。

一、工艺模具的工艺对模具的质量至关重要。

以下是模具常见术语的英文翻译:1. 热处理:Heat treatment2. 光洁度:Smoothness3. 组装:Assembling4. 冲压:Stamping5. 雕出:Engraving6. 研削:Grinding7. 砂光:Sandblasting8. 抛光:Polishing9. 硅胶模具:Silicone mold10. 三维打印:3D printing二、制造模具的制造是一个复杂的过程,需要使用各种设备和材料。

以下是模具常见术语的英文翻译:1. 铸造:Casting2. 钳工:Tinsmith3. 拉伸:Stretching4.喷涂:Spray painting5. 垂线:Plumb line6. 马口铁:Cast iron7. 硬度:Hardness8. 涂层:Coating9. 机加工:Machining10. 加热炉:Furnace三、部件模具的不同部件有不同的名称和功能。

以下是模具常见部件的英文翻译:1. 模板:Template2. 开关模:Switch mold3. 压模:Press mold4. 发射针:Ejection pin5. 模芯:Core6. 插筋:Insertion bar7. 弹簧:Spring8. 模架:Mould base9. 储料斗:Material hopper10. 吸塑板:Vacuum forming plate四、应用模具应用广泛,包括塑料、金属、陶瓷等多个行业。

以下是模具应用的英文翻译:1. 塑料模具:Plastic mold2. 金属模具:Metal mold3. 自动化模具:Automation mold4. 陶瓷模具:Ceramic mold5. 压铸模具:Die casting mold6. 打印模具:Printing mould7. 拉伸模具:Stretch mold8. 管道模具:Pipe mold9. 粉末冶金模具:Powder metallurgy mold10. 加工模具:Processing mold结论模具术语的英文翻译是在全球经济发展和国际贸易交流中非常重要的一环。

英文机械图纸常用翻译词句(自己重新整理)62外商传真发来的图纸都是英文标注,平时阅看有一定的困难。

下面把我们积累的几点看英文图纸的经验与同行们交流。

近几年,我厂和英国、西班牙的几个公司有业务往来,外商传真发来的图纸都是英文标注,平时阅看有一定的困难。

下面把我们积累的几点看英文图纸的经验与同行们交流。

1 标题栏英文工程图纸的右下边是标题栏(相当于我们的标题栏和部分技术要求),其中有图纸名称(TILE)、设计者(DRAWN)、审查者(CHECKED)、材料(MATERIAL)、日期(DATE)、比例(SCALE)、热处理(HEAT TREATMENT)版本号(REVISION缩写REV) 工程变更号:E.C.N 页码(SHEET) 技术要求(NOTES)图号(DRAWING NO/PART NO.)和其它一些技术要求,如:1)TOLERANCES UNLESS OTHERWISE SPECIFIAL 未注公差。

2)DIMS IN mm UNLESS STATED 如不做特殊要求以毫米为单位。

3)ANGULAR TOLERANCE±1° 角度公差±1°。

4)DIMS TOLERANCE±0.1 未注尺寸公差±0.1。

5)SURFACE FINISH 3.2 UNLESS STATED 未注粗糙度3.2。

not specified surface roughness is ra 6.3my 没有指定的表面粗糙度Ra 6.3 my6)40 REF 尺寸为40,参考值7)410 OPENING REF 410 开口参考尺寸8)2.5” BSP 2.5”圆锥管螺纹9)TYP 2 POSNS 2处10)OD 1/4’ outside dimension 1/4’的缩写外径值1/4’---应该为:外径值1/4”11)ALL UNSPECIFED PADI-R3 未注圆角R312)TYP CAST RADLL R9.7 未注铸造R9.713)REMOVE ALL BURRS AND SHARP EDGES 棱角倒钝14)STAMP 1/4 LETTERS DWG DT14331 PO刻1/4字图号定单号15)alternative astm b763 c99500 翻译替代材质 b763c9950016)UNLESS OTERWISE SPECIFIED 除非指定的17)LEADED RED BRASS:UNS C83600 TO ASTM B584,ALTERMATIVE,ASTM B763,C99500 含铅红黄铜:牌号号,B584 C83600 ASTM,也可以用此片号替代,ASTM,C99500 B763 18)no marking 没有标记19)2.5" BSPT HEXAGON 2.5” 六角圆锥管螺纹(即对丝)20)CHAMFERS NOT DIM 未注倒角21)not specified pattern draft 没有指定拔模22)all sharp edges and burrs are to be removed 清除所有的锐边和毛刺23)measunng is in mm 测量单位为毫米MM24)1.Dimensional tolerances unless otherwise specified:One Place------------------+-0.5Two place------------------+-0.30Angles----------------------+-1.0度1..除特别说明外,尺寸公差应小于:1级--------±0.52级--------±0.3角度--------1°25)2. Casting tolerances apply to the location of cast outline featureslocated with basic dimensions2.铸造公差适用于具有基准尺寸的铸件轮廓特征区域;26)3.Casting to be free from oil,grit,dirt and loose particles.3.铸件(表面)须经除油、除尘、除锈和喷砂处理;27)4.Porosity holes to be max 2.3 diameter by 1.6 deep.4.砂眼孔最大不能超过直径2.3,深度1.6;28)5. casting quality to conform with general motors standards and specifications.5.铸件的质量应符合通用汽车(GM)的标准和技术说明书;29)6. Casting tolerances are not cumulative.6.铸件误差不累积; 30)7.casting tolerances unless otherwise specified:0.0 to 75.0 ------------------------------- +-0.7575.0 to 200.0 ---------------------------- +-1.15draft angles ------------------------------2度fillet radii --------------------------------3.0corner radii ------------------------------3.0all walls & ribs ------------------------- 4.57.无特殊说明时,铸造公差应小于:0.0~75.0------±0.7575.0~200.0----±1.15拔模角度---------2°内圆角半径--------3外圆角半径--------3所有壁板和筋厚------4.531)8.Material cast iron per GM274M grade 2058.材料:铸铁依照GM274M 等级 205;32)9.restricted and reportable substances for parts per GMW 30599.零件中的限制物质和必须明示的物质(环保要求)依照标准GMW 3059;33)10.Must comply with QP-I.6-009 for production and QP-I.6-004 for Prototypes.10.必须依照QP-6.I-009产品和QP-I.6-004原型生产34)Machining allowance to be adopted when turning a surface to be ground is equal to Max value for required dimension with 0.05 mm deviation表达的是加工后基本尺寸的上下偏差,就是±0.0534)METARIAL : ALLOY 24, PERMOLD.1,材质:合金24,由模具成型。