电感规格书模板

- 格式:pdf

- 大小:156.72 KB

- 文档页数:3

AMENDMENT RECORD TYPESDRH104 SYMBOL DATE PAGE CONTENTS DWN. BY CHK. BY APP. BY00 2010/09/09 NEW ISSUE L.WANG Y.L.LI Y.B.ZENGSPEC. No. 2/6U666-6063SPECIFICATION 1. DIMENSION(UNIT:mm)※ THE DIMENSIONS WITHOUT TOLERANCE ARE APPROX.2. RECOMMENDED DIMENSIONS (mm)3. CONNECTION (TOP VIEW)4.STAMPING (e.g.)TYPESDRH1044.7µH~39µHUNFIXED POSITION2.047µH~470µH5.ELECTRICAL CHARACTERISTIC* TESTING INSTRUMENTINDUCTANCE : HP 4284A OR EQUIV ALENT. D.C.R : TH2512B OR EQUIV ALENT. (Ta= 20℃)SATURA TION CURRENT: WK 3260B+3265B OR EQUIV ALENT.* TESTING CONDITIONS OF INDUCTANCE :(4.7-6.8µH )at 100 kHz /1V (10-470µH )at 1 kHz /1V . * SATURA TION CURRENT: INDICATES THE CURRENT WHEN THE INDUCTANCE DECREASES TO 75% OF INITIAL V ALUE. (Ta=20℃)No.UTOP P /N.CUS TOMERP /N.STAMPINDUCTANCE (µH)WI THI ND.C.R.(m Ω)Max.S ATURATION CURRENT(A)01 SDRH104-4R7NC 4R7 4.7±30% 35 3.2 02 SDRH104-6R8NC 6R8 6.8±30% 44 2.8 03 SDRH104-100MC 100 10±20% 50 2.4 04 SDRH104-120MC 120 12±20% 54 2.25 05 SDRH104-150MC 150 15±20% 61 2.0 06 SDRH104-180MC 180 18±20% 84 1.8 07 SDRH104-220MC 220 22±20% 94 1.65 08 SDRH104-270MC 270 27±20% 110 1.45 09 SDRH104-330MC 330 33±20% 150 1.35 10 SDRH104-390MC 390 39±20% 170 1.2 11 SDRH104-470MC 470 47±20% 210 1.1 12 SDRH104-560MC 560 56±20% 230 1.0 13 SDRH104-680MC 680 68±20% 260 0.93 14 SDRH104-820MC 820 82±20% 360 0.84 15 SDRH104-101MC 101 100±20% 410 0.76 16 SDRH104-121MC 121 120±20% 450 0.70 17 SDRH104-151MC 151 150±20% 640 0.63 18 SDRH104-181MC 181 180±20% 840 0.57 19 SDRH104-221MC 221 220±20% 960 0.52 20 SDRH104-271MC 271 270±20% 1070 0.47 21 SDRH104-331MC 331 330±20% 1370 0.43 22 SDRH104-391MC 391 390±20% 1550 0.39 23SDRH104-471MC471470±20%17400.36TYPESDRH104REMARKSPEC. No. 4/6U666-60636. GENERAL CHARACTERISTICS* STANDARD TESTING CONDITIONS:UNLESS OTHERWISE SPECIFIED, THE STANDARD RANGE OF ATMOSPHERIC CONDITIONS FOR MEASUREMENTS AND TESTS ARE AS FOLLOWS: AMBIENT TEMPERATURE: 15℃~35℃.RELATIVE HUMIDITY : 25% ~85%. AIR PRESSURE : 86kPa ~106kPa.IF THERE IS ANY DOUBT ABOUT THE RESULTS, MEASUREMENT SHALL BE MADE WITHIN THE FOLLOWING LIMITS: AMBIENT TEMPERATURE: 20℃±1℃. RELATIVE HUMIDITY: 63% ~67%.AIR PRESSURE : 86kPa ~106kPa.No. ITEMS CONDITIONS SPECIFICATION1 OPERA TION TEMPERA TURESTORAGE TEMPERA TURE -25 ~+ 85℃(INCLUDING COIL TEMPERA TURE RISE) -30 ~+ 85℃2 TEMPERA TURE COEFFICIENT -30 ~+85℃0 ~2000 ppm/℃3 FIXING STRENGTH SAMPLE IS PUSHED IN THREE DIRECTIONS OFX, Y AND Z WITH FORCE OF 5. 0N FOR 10±5SECONDS. AFTER SOLDERING BETWEENCOPPER PLA TE AND ELECTRODES.NO ELECTRODE DETACHMENT.4 RESISTANCE TO SOLDERINGHEA T TEST REFER TO THE SPEC “STD-001NP”. NO MECHANICAL BREAKAGE.DEVIA TION RELATIVE TO INITIALV ALUE:L: WITHIN ±5.0%5 SOLDERABILITY TEST IMMERSE THE ELECTRODE IN FLUX FOR 5SECONDS. THEN DIP THE ELECTRODE INTO ASOLDERING BA TH OF 245±5℃ FOR 2±0.5SECONDS. OVER 95% OF THE SURFACE BEING IMMERSED SHALL BE COVERED WITH NEW SOLDER UNIFORMLY.6 VIBRA TION TEST AMPLITUDE: 1.5mm P-PFREQUENCY:10~55~10Hz (1 MINUTE PER CYCLE)DURATION: 1 HOUR IN EACH OF X, Y, Z AXIS. DEVIA TION RELATIVE TO INITIAL V ALUE:L: WITHIN ±5.0%7 HUMIDITY TEST TEMPERA TURE: 40℃±2℃HUMIDITY: 90%~95%RHDURATION: 96±4 HOURS. DEVIA TION RELATIVE TO INITIAL V ALUE:L: WITHIN ±5.0%8 THERMAL SHOCK TEST 20 CYCLES OF +85℃FOR 30 MINUTES, -40℃FOR 30 MINUTES. CHARACTERISTICS AREMEASURED AFTER THE AMBIENT AIREXPOSURE OF 1 HOUR9 HIGH TEMPERA TURESTORAGE TEST TEMPERA TURE: 85℃±2℃DURATION: 96±4 HOURS10 LOW TEMPERA TURESTORAGE TEST TEMPERA TURE: -30℃±3℃DURATION: 96±4 HOURS.DEVIA TION RELATIVE TO INITIALV ALUE:L: WITHIN ±5.0%REMARK SPEC. No.5/6U666-60637. PACKINGPACKAGE TO BE ACCORDING TO PACKAGE SPECIFICATIONS (TICK THE RELEV ANT “ ” ) □KB-CTR049;* ENCLOSING CONDITION OF COILS.8. REMARK1.RoHS COMPLIANCE REMARKS* LEAD WILL BE PRESENT IN THE FERRITE CORE OF THE FRIT MATRIX IN THE COMPONENT.THIS USE, IS EXEMPT FROM RoHS LEGISLATION PER THE ANNEX (ITEM 7), WHICHREFERS TO “LEAD IN ELECTRONIC CERAMIC PART”.REMARK SPEC. No.6/6U666-6063。

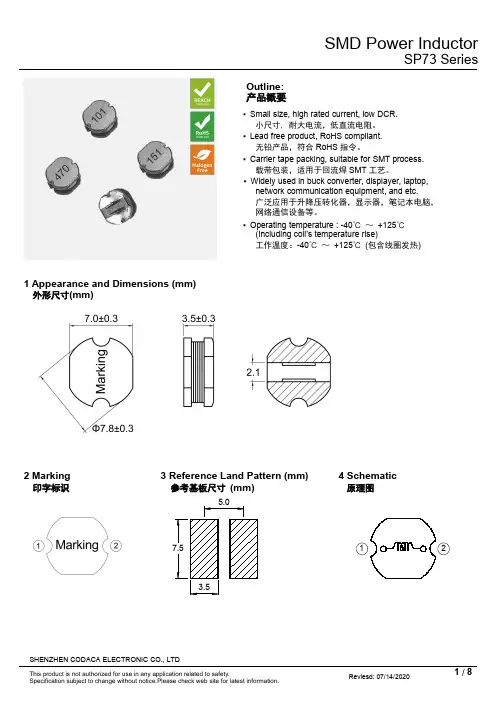

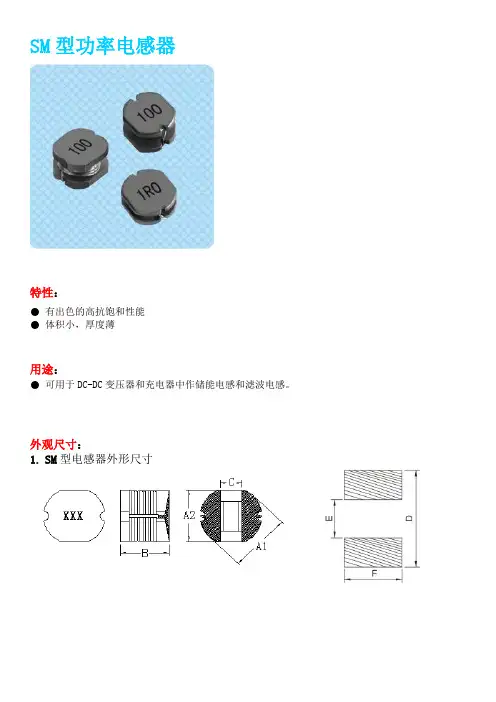

SM型功率电感器特性:●有出色的高抗饱和性能●体积小,厚度薄用途:●可用于DC-DC变压器和充电器中作储能电感和滤波电感。

外观尺寸:1.SM型电感器外形尺寸规格编码:SM 3521 – 1R0 M (f)○1○2○3○4○5①产品类型代号:②外形尺寸:直径×厚度如:3521:3.5×2.1③标称值:电感器电感量(L)用三位数字、字母表示:对L≥10μH,用三位数字表示,ABC=AB×10C,单位为微亨,如:100:10μH、121:120μH;对1.0nH≤L<10μH,用二位数字和表示小数点位置的字母R表示,单位为微亨:如2N7:2.7nH、R10:0.1μH。

○4公差值:用字母“N”表示电感器公差:J=±5%,K=±10%,M=±20%,N=±30%○5表示无铅产品规格特性:SM3511系列□:表示电感量偏差代号为K、M或者N。

K:±10%;M:±20%;N:±30% SM3516系列□:表示电感量偏差代号为K、M或者N。

K:±10%;M:±20%;N:±30%SM3521系列□:表示电感量偏差代号为K、M或者N。

K:±10%;M:±20%;N:±30%□:表示电感量偏差代号为K、M或者N。

K:±10%;M:±20%;N:±30%□:表示电感量偏差代号为K、M或者N。

K:±10%;M:±20%;N:±30% SM5845系列□:表示电感量偏差代号为K、M或者N。

K:±10%;M:±20%;N:±30% SM7835系列□:表示电感量偏差代号为K、M或者N。

K:±10%;M:±20%;N:±30% SM7850系列□:表示电感量偏差代号为K、M或者N。

电子有限公司电感规格书零件名称: EI型电感规格: 24X7文件编号: HKL-0074版本: 01适应产品:编制/日期:审核/日期:批准/日期:电子有限公司地址:电话:传真:第 1 页共 3 页电子有限公司电感性能要求零件名称EI型电感规格24X7一、原理图:1 12 32UEW 0.45mm 70Ts 20mm22UEW 0.45mm 50TS32UEW 0.45mm 61Ts4 425±1mm二、材料表:序材料规格供应商证书号码号1 矽钢片24*7*0.35mm2 漆包线 2UEW0.45mm3 PP胶芯 24*7mm4 铁桥 24*7mm5 ACT 5mm6 MT 11mm红色7 绝缘油 1:38 锡条普通锡条9 标签10 纸箱三、测试条件:温度在25℃1. TestFreq: @1KHz/1.0V2. L:①~④15.5mH ±10% ②~③1250uH±10%3. RDC:①~④1.2 ΩMAX编制:审核:批准:文件编号:版本:01第2页共3页电子有限公司电感参数实测零件名称EI型电感规格24X7参数①~④L(mH)1KHz/1.0V ②~③L(uH)1KHz/1.0V①~④RDC针脚长度20±2mm铁桥外形长度25±1mm铁桥两耳间距25±1mm样品1 16.89 1357.1 1.11 18.71 25.53 25.232 14.61 1155.5 0.90 18.85 25.30 25.183 15.42 1234.2 0.92 19.34 25.50 25.144 15.23 1213 0.90 19.42 25.75 25.485 14.93 1181.7 0.90 18.41 25.51 25.61参数样品1 2 3 4 5参数样品1 2 3 4 5编制:审核:批准:文件编号:版本:01第3页共3页。

SPECIFICATIONINDEXCOVER PAGE▓SHAPE & DIMENSION…………………….………...........1-8▓ ELECTRICAL CHARACTERISTICS AND EXTERNALTEST REPORT…….……………………………………….2-8▓ELECTRICAL CHARACTERISTICS……………………..3-8▓ELECTRICAL CHARACTERISTICS……………………..4-8▓ ELECTRICAL CHARACTERI STICS……………………..5-8▓PACKING FOR SPECIFICATION…………………………6-8▓GENERAL CHARACTERISTICS………………………….7-8▓THE CONDITION OF REFLOW…………………………..8-8 APPROVED BY CHECKED BY DRAWING BYJesse 6/21Tony6/21Chin6/21SPECIFICATIONCustomers Part Number Item Name DatePower Inductor 21-Jun-11 Gan Tong Part NO. Sample NO. PageGPSR0530-2R2M S1******* 1-8External Dimensions Unit (mm)2R2Coating:uncoloredConnection Recommended Land PatternElectrical SpecificationMeasurementItemUnitToleranceSpecificationTestFrequencyTest InstrumentLuH (±20%)2.2uH ±20% 100KHz/1V LCR Meter Agilent/4284A or Chroma/11300DCR mΩ40mΩ(Max)Chroma /16502I rms Amps4A 100KHz/1V LCR Meter Agilent/4284A+42841Aor Chroma /11300+3302+1320+1320S I sat Amps7A 100KHz/1V‧I rms: Current that causes a 40℃ temperature rise from 25℃ ambient.‧I sat: DC current at which the inductance drops 35% from it’s value without current.‧All test Data is referenced to 25℃ ambient.‧Operating Temperature Range: -25℃ to +125℃A 5.2±0.5B 4.7±0.3C 3.0MaxD ≤0.15E 2.0±0.5F 1.0±0.5G 7.0 REFH 3.0 REFI 2.5 REFTEST REPORTCustomers Part NumberItem Name DatePower Inductor 21-Jun-11Gan Tong Part NO. Sample NO. Revision No.Page GPSR0530-2R2MS1*******A2-8 Electrical CharacteristicItem L0A DCR I rmsI sat Specification 2.2uH 40m Ω 4Amps 7Amps Tolerance±20% Max △T ≦40℃L ≧65%1 2.08 26.26 10.3℃80.8%2 1.95 26.873 2.03 26.54 4 2.01 26.495 1.98 26.386 2.01 26.767 2.15 26.118 2.13 26.349 2.10 26.44 10 2.05 26.58 X2.05 26.48 σ0.070.21External DimensionsItem A B C D E F Specification 5.24.7 3.0 2.0 1.0 Tolerance±0.5 ±0.3 Max ≤0.15 ±0.5 ±0.5 1 5.34 4.78 2.89 0.07 2.03 1.08 2 5.27 4.76 2.88 0.09 2.01 1.10 3 5.30 4.77 2.82 0.08 2.00 1.09 4 5.29 4.75 2.90 0.09 2.04 1.03 5 5.26 4.75 2.88 0.10 2.01 1.05 6 5.23 4.73 2.87 0.06 1.99 1.04 7 5.21 4.76 2.90 0.05 2.05 1.06 8 5.28 4.72 2.86 0.07 2.06 1.12 9 5.24 4.75 2.84 0.05 2.04 1.05 10 5.26 4.73 2.89 0.06 2.00 1.08 X5.274.752.870.072.021.07σ0.04 0.02 0.02 0.02 0.02 0.03Inductance measured at 100KHz/1Vrms.Electrical specifications at 25℃. Humidity 60±10%ELECTRICAL CHARACTERISTICSCustomers Part Number Item Name DatePower Inductor 21-Jun-11Gan Tong Part NO. Sample NO. PageGPSR0530-2R2M S1******* 3-8Inductance VS DC currentIDC L %L0A0A 2.13 100.0%1A 2.12 99.5%2A 2.08 97.7%3A 2.02 94.8%4A 1.95 91.5%5A 1.88 88.3%6A 1.80 84.5%7A 1.72 80.8%8A 1.65 77.5%CONDITTON:100KHz/1.0VrmsELECTRICAL CHARACTERISTICSCustomers Part Number Item Name DatePower Inductor 21-Jun-11 Gan Tong Part NO. Sample NO. Page GPSR0530-2R2M S1******* 4-8DC current VS TemperatureTime L(μН)T(℃)△T(℃)0H 1.77 33.60.5H 1.76 38.1 4.51H 1.76 43.9 10.32H 1.76 43.9 10.33H 1.76 43.9 10.34H 1.76 43.9 10.35H 1.76 43.9 10.3CONDITTON: Load 4A43.9℃33.6℃ELECTRICAL CHARACTERISTICSCustomers Part Number Item Name DatePower Inductor 21-Jun-11 Gan Tong Part NO. Sample NO. Page GPSR0530-2R2M S1******* 5-8Inductance VS FrequencyFREQ. L(μН)1KHZ 2.1510KHZ 2.14100KHZ 2.13500KHZ 2.09800KHZ 2.081000KHZ 2.08PACKING FOR SPECIFICATIONCustomers Part Number Item Name DatePower Inductor 21-Jun-11 Gan Tong Part NO. Sample NO. PageGPSR0530-2R2MS1*******6-8Packaging Information:TYPE A(mm) B(mm) C(mm) D(mm)13´´*12mm 12.0±0.5 100±2 13.5±0.5 330TYPE A B C W PGPSR0530 2000 12 330 12 8GENGRAL CHARACTERISTICSGan Tong Part NO. GPSR0530-2R2M PAGE : 7-8.STORAGE TEMPERATURE:25℃~30℃ HUMIDITY 45~85% RH-30℃~+125℃(CONTAIN HEATING COIL)2.OPERATING TEMPERATURERANGE :3.EXTERNAL APPEARANCE : NO EXTERNAL DEFECTS CAN BE FOUND IN THE VISUAL INSPECTION.4. TERMINAL STRENGTH : NO TERMINAL DETACHMENT SHOULD BE FOUND WHEN THE DEVICE IS PUSHED IN TWO DIRECTIONS OF X AND Y WITHTHE FORCE OF 10.0N FOR 10±2 SECONDS AFTER SOLDERING BETWEEN COPPER PLATE AND THE TERMINALS.(REFERTO FIGURE AT RIGHT)5.HEAT ENDURANCE TEST :REFER TO Recommended Soldering Temperature Graph.(AT PAGE 2).6.INSULATING RESISTANCE : THE INSULATION RESISTANCE SHOULD BE OVER 100MΩ WHEN D.C.100V IS APPLIED TO THE WINDING –CORE.MEANWHILE NO STRUCTURE AND ELECTRIC DEFECTS SHOULD BE FOUND FOR 1 MINUTE.7. TEMPERATURE FEATURE:INDUCTANCE COEFFICIENT IS (0~2000)x10-6(-25~+85℃)8. HUMIDITY TEST :INDUCTANCE DEVIATION IS WITHIN ±5.0% AND NO STRUCTURE AND ELECTRIC DEFECTS CAN BE FOUND AFTER 96 HOURSTEST UNDER THE CONDITIONOF RELATIVE HUMIDITY OF 90~95% AND TEMPERATURE OF 40±2℃. AND 1 HOUR STORAGEUNDER ROOM AMBIENT CONDITIONS AFTER THE DEVICE IS WIPED WITH DRY CLOTH.9. VIBRATION TEST :INDUCTANCE DEVIATION IS WITHIN ±5.0% AFTER 1 HOUR SWEEPING VIBRATION IN EACH THREE DIRECTIONS.NAMELY, FREQUENCY IS 10~55~10Hz ANDTHE AMPLITUDE OF 1MINUTE CYCLE IS 1.5mm PP.10.SHOCK TEST : INDUCTANCE DEVIATION IS WITHIN ±5.0% AFTER THE TEST WITH GOM-BLOCK SHOCK TESTING MACHINE,ONCE IN EACHOF THE THREE PERPENDICULAR AXIS DIRECTIONS. THE SHOCK ACCELERATION IS 981m/s2.THE CONDITION OF REFLOWGan Tong Part NO. : GPSR0530-2R2M PAGE : 8-8Wave SolderingHand soldering。

SunlordEXPERT IN PASSIVE PARTSPower Inductor SPH Series香港伟创国际有限公司2012.8Sunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSContentsInner Structure Process Flow Chart Electrical Characteristics Failure Mode Land Pattern Compatibility Sunlord Product RoadmapSunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSInner StructureSunlord SPH252012H Copper wire Copper wire TDK VLS252012TMagnetic ResinFerrite CoreMagnetic ResinFerrite CoreCYNTEC PSE25201BTOKO DFE252012CCopper wireCopper wireMagnetic ResinFerrite Core Iron powder ElectrodeThe structure of Cyntec’s/TDK’s and Sunlord’s power inductor are similar. The structure of Toko’s DFE252012C is different from others.Sunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSProcess Flow ChartSunlord SPH Process:PlatingWire woundSolderingResin CoatingCYNTEC PSE25201B Process:Almost the samePlatingWire WoundsolderingResin CoatingTDK VLS252012T Process:PlatingWire WoundWeldingResin CoatingHot pressure welding makes ferrite and electrode connectedSunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSProcess Flow ChartTOKO DFE Process:Wire woundmoldingThe film of copper wire processingConductive glueCuringThe process of Toko’s DFE252012C is absolutely different from others.Sunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSComparisons of manufacturing processesItem Uncontrolla ble risk Sunlord SPH252012H All parameters are quantitative, and under control. TDK VLS252012T Using welding Method, exists visual defect (fissure) and open circuit risk. Cyntec PSE 25201B All parameters are quantitative, and under control. Toko DFE252012 Pressure (Molding process) is not easy to control, exists the risk to damage copper wire and result in short. Low(80%)First pass yieldHigh(99.7%) (Japanese accuracy devices) High(100%) It’s easy to produce smallsize products, such as the 2016 &2012.Low(80%) (core visual defect in molding and welding) High(100%) GoodGood(95%) (Taiwan devices)Automatic Processing ExtensibilityHigh(100%) It’s easy to produce small-size products, such as the 2016 &2012.Low(50%) Can NotSunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSElectric CharacteristicFor Example (spec.):Indctance (μH) DCR(Ω) Max. 0.090 0.155 Typ. 0.080 0.129 Isat(A) Max. 1.75 1.8 Typ. 1.85 2.0 Irms(A) Max. 1.95 Typ. 2.15 1.30CompanyP/NCyntec TDKPSE25201B-2R2MS-39 VLS252012T-2R2M1R3 DFE252012 Series 1239AS-H-2R2 SPH252012H2R2MT2.2±20% 2.2±20%Toko2.2±30%0.1080.0902.202.702.002.30Sunlord2.2±20%0.0960.0801.801.951.802.00Sunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSElectric CharacteristicFor Example (test value.):Company P/N Indctance (μH) 2.2±20% 2.2±30% 2.2±20% DCR(Ω) Max. / / / Typ. 0.084 0.090 0.085 Isat(A) Max. 1.85 1.80 1.80 Typ. 2.15 2.70 2.05 Irms(A) Max. 1.84 1.71 1.82 Typ. 2.09 1.96 2.05Cyntec Toko SunlordPSE25201B-2R2MS-39 DFE252012 Series 1239AS-H-2R2 SPH252012H2R2MTTemperature Rise Curve60 Temperature Rise (℃)Satraution Curve 10% TOKO DFE252012C-2R2 Cyntec PSE252001B-2R2MS Sunlord SPH252012H-2R2TOKO DFE252012C-2R2 Cyntec PSE25201B-2R2Drop ratio40Sunlord SPH252012H-2R20%-10%20-20%0 0.0 0.5 1.5 D.C. Current (A) 1.0 2.0 2.5-30% 0.0 0.5 1.0 1.5 D.C. Current (A) 2.0 2.5Sunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSFor Example (test value):L-F Curve 6 5 Inductance (μH) 4 3 2 1 0 1 10 Frequency (MHz )Electric CharacteristicQ-F CurveTOKO DFE252012C-2R2 Cyntec PSE25201B-2R2 Sunlord SPH252012H-2R240TOKO DFE252012C-2R2 Cyntec PSE25201B-2R2 Sunlord SPH252012H-2R23020Q100 1000100 1 10 Frequency (MHz) 100 1000Z-F Curve 5 TOKO DFE252012C-2R2 Cyntec PSE25201B-2R2 Sunlord SPH252012H-2R24Z(KΩ)3210 1 10 Frequency (MHz) 100 1000Sunlord confidential0755-89667799 www.foxtron.com.cnSunlordEXPERT IN PASSIVE PARTSFor Example (test value):Electric CharacteristicAC R -F C u rv e 20 T O K O D F E 2 5 2 0 1 2 C -2 R 2 C y n te c P S E 2 5 2 0 1 B -2 R 2 S u n lo rd S P H 2 5 2 0 1 2 H -2 R 215 ACR(Ω)1050 1 2 3 4 5 6 7 8 9 10 F re q u e n c y (M H z )At frequency above 2.5MHz, DFE's Rac begins to increase sharply. This is not compliant with the requirements of high-frequency trend Sunlord confidential0755-89667799 www.foxtron.com.cnEXPERT IN PASSIVE PARTSTemperature coefficient :Electric CharacteristicL-T Curve1.82.02.2-50-30-101030507090Temperature (℃)I n d u c t a n c e(μH )TOKO DFE252012C-2R2Cyntec PSE25201B-2R2Sunlord SPH252012H-2R2I=0AEXPERT IN PASSIVE PARTSTemperature coefficient :Electric CharacteristicI=0.5AL-T Curve1.82.02.2-50-30-101030507090Temperature (℃)I n d u c t a n c e (μH )TOKO DFE252012C-2R2Cyntec PSE25201B-2R2Sunlord SPH252012H-2R2EXPERT IN PASSIVE PARTSTemperature coefficient :Electric CharacteristicI=1.0AL-T Curve1.82.02.2-50-30-101030507090Temperature (℃)I n d u c t a n c e (μH )TOKO DFE252012C-2R2Cyntec PSE25201B-2R2Sunlord SPH252012H-2R2EXPERT IN PASSIVE PARTSTemperature coefficient :Electric CharacteristicI=1.5AL-T Curve1.61.82.02.2-50-30-101030507090Temperature (℃)I n d u c t a n c e (μH )TOKO DFE252012C-2R2Cyntec PSE25201B-2R2Sunlord SPH252012H-2R2EXPERT IN PASSIVE PARTSTemperature coefficient :Electric CharacteristicI=2.0AL-T Curve1.21.41.61.82.0-50-30-101030507090Temperature (℃)I n d u c t a n c e (μH )TOKO DFE252012C-2R2Cyntec PSE25201B-2R2Sunlord SPH252012H-2R2EXPERT IN PASSIVE PARTSTemperature coefficient :Electric CharacteristicI=2.5AL-T Curve0.30.50.70.91.11.31.51.71.9-50-30-101030507090Temperature (℃)I n d u c t a n c e (μH )TOKO DFE252012C-2R2Cyntec PSE25201B-2R2Sunlord SPH252012H-2R2EXPERT IN PASSIVE PARTSWithstanding voltage test Test condition: 1000V/0.2sec Measuring device:TH2817B200060Test times -4.4%-98.1%L Rate of change +2.5%-41.8%DCR OKNG (Short)Result 0.0830.0522DCR(m OHM)2.170.0812.27Sunlord SPH252012H0.0420.08972.23Toko DFE252012C L(uH)DCR(m OHM)L(uH)After Test Before Test Item Failure(short) LocationFailure ModeEXPERT IN PASSIVE PARTSacb bacb bBACTest valueSpec. 2.10.81.01.2Max.2.0±0.22.5±0.2///1.222.212.68c b a T L WSunlord SPH252012HCYNTEC PSE25201BTDK VLS252012T (spec.)TOKO DFE252012CShape and DimensionsTest valueSpec. 2.10.850.801.2Max.2.0±0.22.5±0.2///1.152.202.52c b a T L WTest valueSpec.///1.2Max.2.0±0.22.5±0.2///1.192.202.68c b a T L W ¾Sunlord’s power inductor has the smallest shape in testing value.EXPERT IN PASSIVE PARTS Land Pattern Compatibility¾TDK’s and Sunlord’s power inductor are the same in land pattern.¾Cyntec’s power inductor has a little different from the two maker’s products in land pattern.¾The land pattern of Toko’s power inductor is incompatible with mainstream makers’.In case of emergency, it’s very hard to be replaced.EXPERT IN PASSIVE PARTSWire Wound Power Inductors RoadmapFor Wire Wound Power Inductors, focus on the height of 1.0mm and overSPH8030SSPH4018SSPH4012SSPH3015SSPH252012SSPH252010SSPH202012SSPH201610SSPH1608SSunlordEXPERT IN PASSIVE PARTSSunlord confidential0755-89667799 www.foxtron.com.cn。

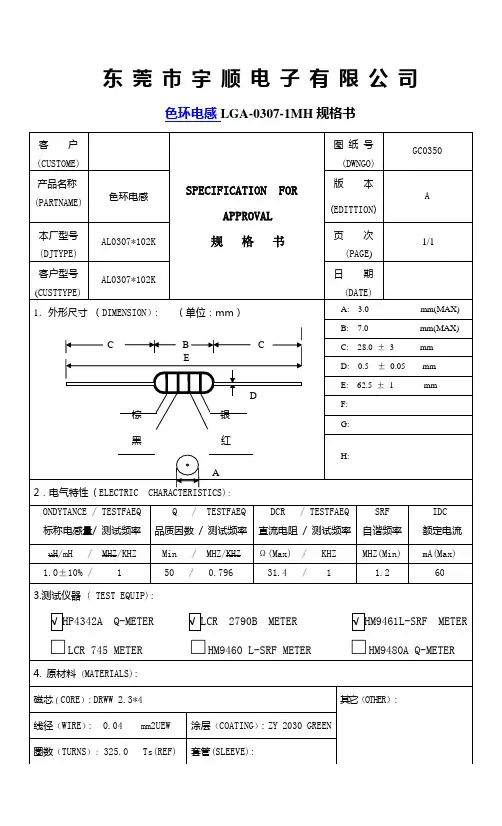

DCM4532[1812 inch]DCM3225[1210 inch]DCM2520[1008 inch]DCM2012[0805 inch]*DCM series•All specifications are subject to change without notice.•Conformity to RoHS Directive: This means that, in conformity with EU Directive 2002/95/EC, lead, cadmium, mercury, hexavalent chromium, and specific bromine-based flame retardants, PBB and PBDE, have not been used, except for exempted applications.Common Mode FiltersFor high-speed differential signal line/general signal line Type:* Dimensions Code [EIA](6) internal codeDCM4532DCM3225DCM2520DCM2012DCM Series DCM2012, 2520, 3225, 4532DCM 2012 -900-2P -T Common Mode FiltersFor High-speed Differential Signal Line / General Signal LineFEATURES•Although greatly miniaturized, this wire-wound chip-type filter maintains the characteristics needed for a common mode filter. Common mode impedance is 1000Ω [at 100MHz], so this filter is greatly effective in supporting noise.•Almost no affect upon even high speed signals since differential mode impedance is kept low.•This series includes both 2-line and 3-line types. They are used for various types of circuits and noise.APPLICATIONS•Used for radiation noise suppression for any electronic devices. •Used to counter common mode noise affecting signals within high-speed lines.•USB line for personal computers and peripheral equipment. •IEEE1394 line for personal computers, DVC, STB, etc.•LVDS, panel link line for liquid crystal display panels.TEMPERATURE RANGESPACKAGING STYLE AND QUANTITIESPRODUCT IDENTIFICATION (1) Series name(2) Dimensions L ×W 2012: 2.0×1.2mm(3) Impedance[at 100MHz]900: 90Ω(4) Number of line2P: 2-line 3P: 3-line(5) Packaging styleT: ø180mm reel taping TL: ø330mm reel taping RECOMMENDED SOLDERING CONDITIONS RECOMMENDED TEMPERATURE PROFILE FOR LEAD-FREE SOLDERREFLOW PROFILE FOR SOLDER HEAT RESISTANCEConformity to RoHS Directive Operating–25 to +85°C Storage(After mount)–25 to +85°CPackaging styleT ype Reel QuantityT apingø180mm 2000 pieces/reel ø330mm 10000 pieces/reel ø180mm 2000 pieces/reel ø330mm 10000 pieces/reel ø180mm 1000 pieces/reel ø330mm 5000 pieces/reel ø180mm 500 pieces/reel ø330mm2000 pieces/reel(1)(2)(3)(4)(5)(6)DCM2520-3P DCM4532-102-3PDCM2520-2P DCM3225-2PDCM2012-2PSHAPES AND DIMENSIONS/CIRCUIT DIAGRAMS/RECOMMENDED PC BOARD PATTERNS 2-LINE TYPE 3-LINE TYPEDCM4532-102-3P10000.6200.2DCM2520-801-3P 800 1.6200.15DCM3225-102-2P 10000.5200.2DCM3225-271-2P 2700.3200.3DCM3225-161-2P 1600.2200.35DCM3225-800-2P 800.15200.4DCM2520-102-2P 10000.9200.2DCM2520-601-2P 6000.45200.3DCM2520-451-2P 4500.4200.35DCM2520-301-2P 3000.35200.4DCM2012-361-2P 3600.5500.22DCM2012-201-2P 2000.25500.35DCM2012-121-2P 1200.22500.37DCM2012-900-2P 900.19500.4ELECTRICAL CHARACTERISTICSPart No.Impedance(Ω)typ.[100MHz]DC resistance(Ω)max.[per 1 line]Rated voltage Edc(V)max.Rated current Idc(A)max.2-LINE3-LINEDCM3225-271-2P DCM3225-102-2PDCM3225-800-2P DCM3225-161-2PDCM2520-601-2P DCM2520-102-2PDCM2520-301-2P DCM2520-451-2PDCM2012-201-2P DCM2012-361-2PDCM2012-900-2P DCM2012-121-2PMEASURING CIRCUITS 2-LINEDCM2520-801-3P DCM4532-102-3PIMPEDANCE vs. FREQUENCY CHARACTERISTICS 3-LINEMEASURING CIRCUITS 3-LINE。