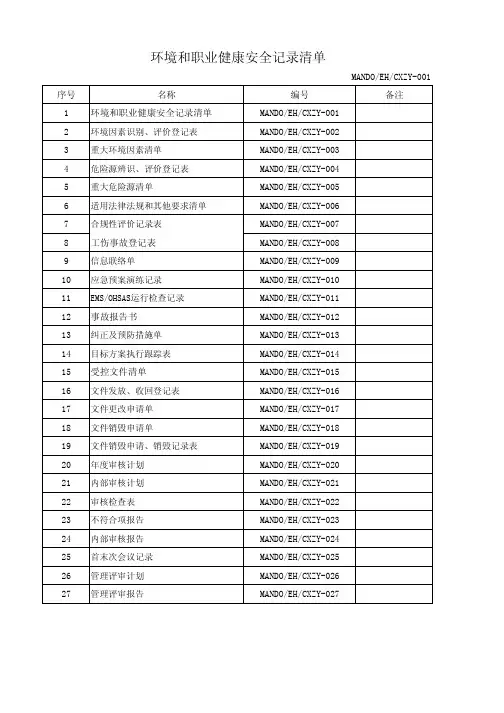

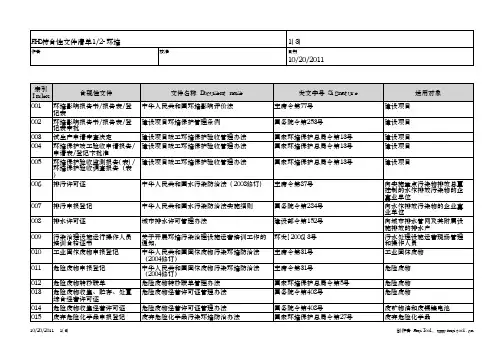

NIKE EHS 审核文件清单

- 格式:pdf

- 大小:134.57 KB

- 文档页数:6

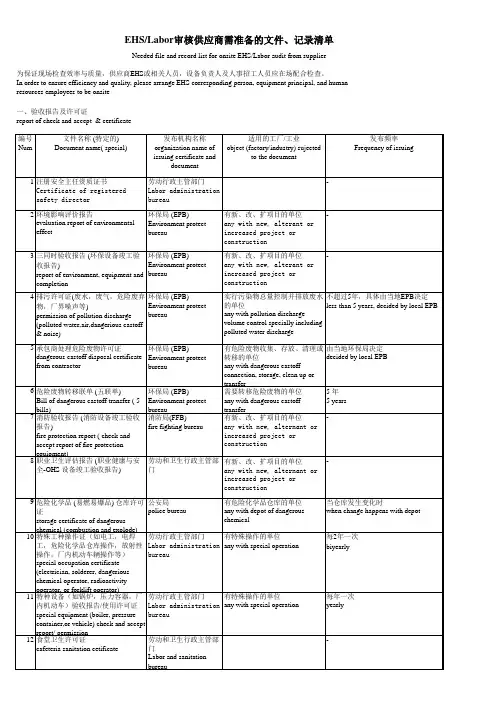

EHS/Labor审核供应商需准备的文件、记录清单

Needed file and record list for onsite EHS/Labor audit from supplier

为保证现场检查效率与质量,供应商EHS或相关人员,设备负责人及人事招工人员应在场配合检查。

In order to ensure efficiency and quality, please arrange EHS corresponding person, equipment principal, and human resources employees to be onsite

一、验收报告及许可证

report of check and accept & certificate

12345678

1234567

消防演习记录或文件或图片

经劳动局审批的综合计时工作制度 (如有)

经劳动局审批的计件工资定额标准或单价标准 (如有)

三、其它相关记录

若5年内有被政府部门罚款或收到违规通知,提供相关记录若工作场所噪声可能超标,提供噪声监测记录

若工作场所某一种或几种粉尘或其它有害化学品浓度可能超标,提供相关监测记录若5年内发生重伤或死亡事故,提供事故报告记录及整改措施落实情况的证据员工录用程序/规定

员工录用时的个人简历,身份证复印件加班工作制度/规定当地最低工资标准记录

员工工资发放表(包括基本工资,津贴,奖金,加班工资等)若工作场所有放射源,提供放射监测报告二、工资,用工制度与记录

消防设备(包括应急报警系统,灭火器等)定期检查记录

员工雇用合同。

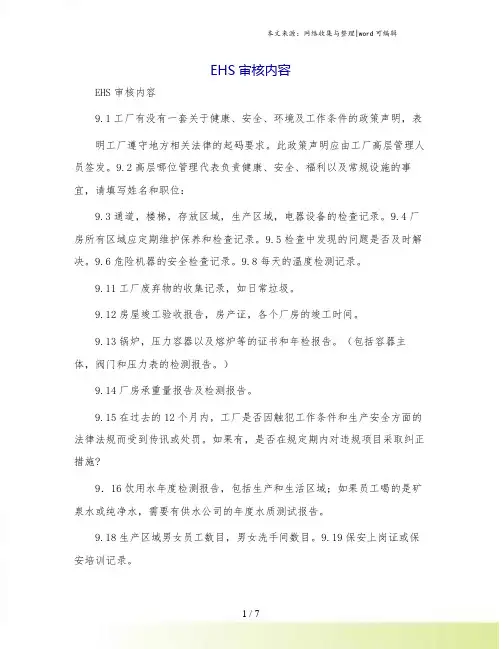

EHS审核内容EHS审核内容9.1工厂有没有一套关于健康、安全、环境及工作条件的政策声明,表明工厂遵守地方相关法律的起码要求。

此政策声明应由工厂高层管理人员签发。

9.2高层哪位管理代表负责健康、安全、福利以及常规设施的事宜,请填写姓名和职位:9.3通道,楼梯,存放区域,生产区域,电器设备的检查记录。

9.4厂房所有区域应定期维护保养和检查记录。

9.5检查中发现的问题是否及时解决。

9.6危险机器的安全检查记录。

9.8每天的温度检测记录。

9.11工厂废弃物的收集记录,如日常垃圾。

9.12房屋竣工验收报告,房产证,各个厂房的竣工时间。

9.13锅炉,压力容器以及熔炉等的证书和年检报告。

(包括容器主体,阀门和压力表的检测报告。

)9.14厂房承重量报告及检测报告。

9.15在过去的12个月内,工厂是否因触犯工作条件和生产安全方面的法律法规而受到传讯或处罚。

如果有,是否在规定期内对违规项目采取纠正措施?9.16饮用水年度检测报告,包括生产和生活区域;如果员工喝的是矿泉水或纯净水,需要有供水公司的年度水质测试报告。

9.18生产区域男女员工数目,男女洗手间数目。

9.19保安上岗证或保安培训记录。

9.20吸烟规定。

整个厂区为禁烟区域还是指定区域为禁烟区域?如果是指定区域,请列明包含哪些区域。

10.1有关火灾等危险的应急预案。

10.2关于防火规范,消防程序和应急预案的培训记录。

10.3工厂是否指定了一名作业现场统筹协调员负责管理消防程序和应急准备计划?如果有,请填写此人的姓名和职位。

10.4火警铃和消防器材的检测记录。

10.5应急灯的检测记录。

10.6安全出口,安全出口标示,逃生通道的检测记录。

10.11逃生演习记录。

10.20电工数目?全部电工的电工证。

10.23生产楼和宿舍楼的防雷证书和检查记录。

10.27热工作业许可证,热工作业的程序文件,全体热工作业人员的证书,观火员的培训记录。

10.28气瓶的检查记录。

10.30喷涂车间的通风管道,传输管道,过滤装置的清理记录。

9.1 工厂有没有一套关于健康、安全、环境及工作条件的政策声明,表明工厂遵守地方相关法律的起码要求。

此政策声明应由工厂高层管理人员签发。

9.2 高层哪位管理代表负责健康、安全、福利以及常规设施的事宜,请填写姓名和职位:9.3 通道,楼梯,存放区域,生产区域,电器设备的检查记录。

9.4 厂房所有区域应定期维护保养和检查记录。

9.5 检查中发现的问题是否及时解决。

9.6 危险机器的安全检查记录。

9.8 每天的温度检测记录。

9.11 工厂废弃物的收集记录,如日常垃圾。

9.12 房屋竣工验收报告,房产证,各个厂房的竣工时间。

9.13 锅炉,压力容器以及熔炉等的证书和年检报告。

(包括容器主体,阀门和压力表的检测报告。

)9.14 厂房承重量报告及检测报告。

9.15 在过去的12个月内,工厂是否因触犯工作条件和生产安全方面的法律法规而受到传讯或处罚。

如果有,是否在规定期内对违规项目采取纠正措施?9.16 饮用水年度检测报告,包括生产和生活区域;如果员工喝的是矿泉水或纯净水,需要有供水公司的年度水质测试报告。

9.18 生产区域男女员工数目,男女洗手间数目。

9.19 保安上岗证或保安培训记录。

9.20 吸烟规定。

整个厂区为禁烟区域还是指定区域为禁烟区域?如果是指定区域,请列明包含哪些区域。

10.1 有关火灾等危险的应急预案。

10.2 关于防火规范,消防程序和应急预案的培训记录。

10.3 工厂是否指定了一名作业现场统筹协调员负责管理消防程序和应急准备计划?如果有,请填写此人的姓名和职位。

10.4 火警铃和消防器材的检测记录。

10.5 应急灯的检测记录。

10.6 安全出口,安全出口标示,逃生通道的检测记录。

10.11 逃生演习记录。

10.20 电工数目?全部电工的电工证。

10.23 生产楼和宿舍楼的防雷证书和检查记录。

10.27热工作业许可证, 热工作业的程序文件,全体热工作业人员的证书,观火员的培训记录。

10.28 气瓶的检查记录。

环境安全健康手册E S H 环境安全健康手册2002年版本手册所包含的内容仅供参考并仅为Nike合约商和雇主提供环境、安全和健康方面的帮助。

本手册的内容并非等同于与之相关的操作或情形的法定符合性。

不应当认为本手册已经权威性地列出了所有的规章,也不应当认为它就是环境、安全及健康方面的所有问题的绝对的解决方案。

耐克公司对于本手册所包含的实施、管理或者程序方面的内容不承担任何责任。

美国俄勒冈州97005 – 6453比法顿,温鲍尔曼地拉夫耐克有限公司版权 2002耐克有限公司版权所有用酱油墨水和循环再生纸张印刷目录环境安全健康管理 ···················································································· 1-1A .管理体系 ·························································································· 1-1B .环境安全与健康委员会 ·································································· 1-12C .工伤/疾病系统管理 ········································································· 1-15未遂事件/事故调查 ··································································· 1-16危害报告 ···················································································· 1-17危害评估 ···················································································· 1-17危害纠正 ···················································································· 1-18 环境保护 ····································································································· 2-1A .废气排放 ·························································································· 2-1B .有害废物 ·························································································· 2-9C .多氯联苯(PCBs ) ········································································· 2-14D .废水 ·································································································· 2-16E .固体废物 ··························································································· 2-20F .地下储罐 ··························································································· 2-22G .地面储罐 ·························································································· 2-26H .泄漏处理 ·························································································· 2-29化学品管理 ································································································ 3-1A .化学品危害信息交流 ······································································ 3-1B .化学品标签 ······················································································ 3-1C .限制性生产材料(RMS ) ······························································ 3-9D .化学品储存、搬运、配送、分发 ·················································· 3-11设施及维护 ································································································ 4-1A .一般工作环境 ·················································································· 4-1整理工作 ···················································································· 4-1墙与地面 ···················································································· 4-2楼梯及梯道 ················································································ 4-3出口 ···························································································· 4-7照明 ···························································································· 4-9 1. 2. 3. 4.ii ESH 手册 nikeB .通风 ·································································································· 4-14排气通风 ···················································································· 4-14排烟罩 ························································································ 4-18C .意外事故预防标识和标签 ······························································ 4-21D .机械加工车间安全 ·········································································· 4-23总则 ···························································································· 4-23台式和立式磨床 ········································································ 4-24废气软管、工具和压缩机 ························································ 4-26风防护 ························································································ 4-28便携式及电动手工工具 ···························································· 4-28工具及设备维护 ········································································ 4-32梯子安全 ···················································································· 4-45压缩气瓶 ···················································································· 4-48E .合约商及下一级合约商安全守则 ··················································· 4-52F .密闭空间保护 ··················································································· 4-53G .焊接、切割及铜焊 ·········································································· 4-55工业健康 ····································································································· 5-1A .高温预防 ·························································································· 5-1B .低温预防 ·························································································· 5-4C .职业性噪声暴露 ·············································································· 5-7D .人机工效学/人机工程 ····································································· 5-15E .非-电离辐射(紫外线(UV )和射频(RF )辐射) ··················· 5-23F .血媒传染病 ······················································································· 5-32G .石棉 ·································································································· 5-35H .职业暴露限值 ·················································································· 5-39应急准备及响应 ························································································ 6-1A .应急行动 ·························································································· 6-1B .消防 ·································································································· 6-4消防计划 ···················································································· 6-4消防措施 ···················································································· 6-7消防队 ························································································ 6-7灭火器 ························································································ 6-10 5. 6.。

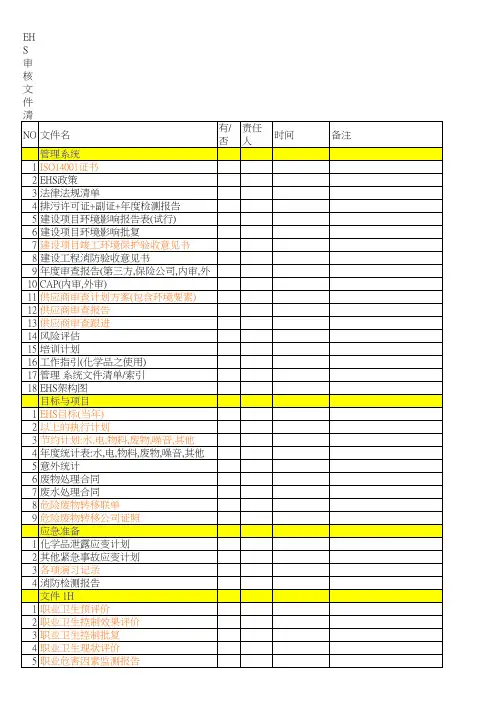

ISO14001&OHSAS18001 内审清单所有部门(审核日期/时间:)1)风险评估OP-(OHS)MD-001a.定期评估(半年一次),以往评估记录的保存(文件查看)b.风险评估-地下作业/饭堂摔倒/滑倒/人体工程学方面的工作岗位,如搬运工(文件查看)c.重大危险源的控制措施及控制效果(文件查看/现场查看)2)6S管理(所有区域)及检查记录(文件查看/现场查看)3)办公室/洗手间管理(现场查看)a. 安全/卫生b. 照明/通风情况4) 环境因素的识别OP-(EN)MD-001a. 定期评估(半年一次),以往评估记录的保存,是否涵盖所有区域,所有活动(文件查看)b. 新材料/新地点/新设备使用的环境因素评估(如果有的话)(文件查看)c. 重大环境因素的控制措施及成效(文件查看/现场查看)5)年度EHS目标指标/管理方案,执行情况,定期评审(文件查看)6)EHS 法律法规获取途径,收集情况及合规性评价,修改记录的追踪(文件查看/询问)7)ROHS培训情况,执行情况,ROHS客户投诉跟进(文件查看)8)所有区域的健康安全情况/节能情况(水/电等方面)(现场审核)工程部(审核日期/时间:)1)噪声控制a.内部噪声月度检测(文件查看)2)机器保护罩的安装/月度检查记录(文件查看/现场审核)3)模房技术员的操作安全,PPE配备,含油抹布的回收情况,模具搬运的安全(现场观察)4)机器标识是否正确(现场审核)物流部(审核日期/时间:)1)叉车管理a. 叉车维修计划/检查记录(文件查看)b. 叉车使用许可证(文件查看)c. 叉车驾驶员培训及证书(文件查看)d. 叉车驾驶过程的安全情况(现场观察)2) 危险废物管理a. 危险废物转移清单(文件查看)b. 承包商合同/资质确认(文件查看)c. 危险废物仓库管理情况(现场查看)d. 危险废物跨省转移许可证(文件查看)3) 化学品仓库管理& MSDS表格a. 化学品管理人员资格证(文件查看)b. 化学品管理人员的操作是否规范(现场审核/询问)c. 化学品柜的防泄漏装置(现场审核)d. 化学品的标识是否清晰可见(现场审核)4)消防通道是否畅通无阻(现场观察)5)搬运工是否在上岗前接受到相关培训?查看培训记录,现场观察其搬运情况是否符合健康安全标准。

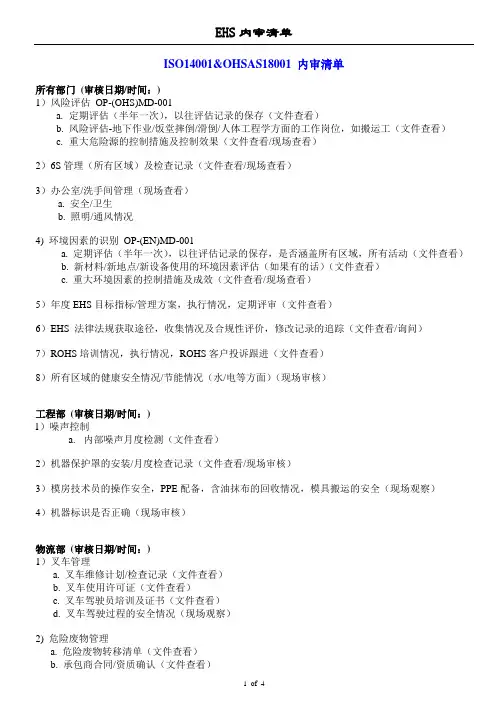

EMS 环境方针(中、英文版)总部/总公司的环境政策(如有)厂区平面布置图;工艺流程简图;重要环境因素分布图(如具备时);重要环境因素清单适用法律法规和其他要求清单目标指标和管理方案一览表组织的营业执照及其法人姓名行政组织结构图;或环境管理体系组织结构图,如与上述不同环境管理体系文件一览表由具有法定资格的环境监测机构近一年内出具的各项污染物监测结果;由所在地地(市)级以上环境保护主管部门出具的一年内未因环境违法受处罚的证明;有关许可证的信息,例如排污许可证、排水许可证、地下水取用许可证、排污申报登记证等;危险废物转移、处理处置承包方的许可证和协定/合同;由具有法定资格的环境影响评价机构实施环境影响评价的结论”三同时”验收证明等;OHSAS 安卫方针(中、英文版)总部/总公司的安卫政策(如有)厂区平面布置图;工艺流程简图;重大危险源分布图(如具备时);重大危险源和风险级别清单适用法律法规和其他要求清单目标指标和管理方案一览表组织的营业执照及其法人姓名行政组织结构图;或安卫管理体系组织结构图,如与上述不同安卫管理体系文件一览表由具有法定资格的安卫监测机构近一年内出具的各项作业场所有毒有害因素的监测结果;由所在地地(市)级以上安全生产监督管理部门出具的一年内未因职业安全卫生违法受处罚的证明;有关许可证的信息,例如危险品安全生产许可证、特种设施设备使用证、防雷接地许可证、食品卫生许可证(如有食堂)等;消防设施承包商的许可证和其协定/合同;由具有法定资格的安卫评价机构实施的安卫评价的结论安卫和消防“三同时”验收证明等;。

EICC Document list / EICC文檔清單Please provide the below documents for review:請在審核當天提供以下資料以供審核:C-EnvironmentC1.1: EIA (Environment impact assessment) report, Approval for EIA + Acceptance report of the environment protecting + Waste discharge permit (if applicable), Radiation safety permit of X-Ray equipment, other legal required environment permits, procedure to timely renew these documents to ensure they keep valid.環境影響評價報告,環境影響評價批復,環保竣工驗收報告,排汙許可證, X-Ray (或其他幅射儀器)機器輻射安全許可證, 檔定期審查的程式去確保這些許可證不會過期。

C1.2: legal environment reports of recent 3 years which required to submitted to local environment authorities最近3年的年度排汙申報登記C2.1:Sample reports of the pollution prevention and resource reduction (energy, water, materials), EHS targets of the most recent year and current year, the progress report of the targets in current year.工廠節能減排的案例及報告(能源, 水資源, 原材料), 工廠上年度及本年度環境目標,完成情況報告C3.1 Hazardous waste dispose contract, certificate of the unit to transfer the hazardous waste, certificate of the unit to dispose the hazardous waste, hazardous waste transfer manifest (recent 3 years); Documented procedures for reception, storage, dispensing, use, return and disposal危險廢棄物處理合同,道路運輸許可證,危廢處理供應商的危險廢棄物經營許可證,危險廢棄物轉移聯單(最近3年), 廢物接收,儲存,分配,使用,回收和處置的書面程式C3.2: Chemical training records of workers (training material and attendance sheet)員工化學品培訓記錄(培訓教材及簽到表)C3.3: Onsite assessment report for the hazardous waste dispose supplier最近2年內對危險廢棄物處理供應商的現場審查報告C4.1: Valid contract signed with waste contractors, transfer manifest, license of the contractor to dispose the solid waste固體廢物承包商的資質文件,處理合同及轉移記錄C4.2:Monitoring reports for wastewater discharge (recent 3 years), Maintenance records of the wastewater treatment facilities, wastewater operator certificate or training record.廢水檢測報告(最近3年), 廢水處理設施運營資質證書 / 廢水處理人員操作工證, 廢水處理設施維護記錄C5.1:Monitoring reports for air emission (recent 3 years), Maintenance records of the waste gas treatment facilities, waste gas treatment system operator training records廢氣檢測報告(最近3年), 廢氣處理設施維護記錄,廢氣處理人員的培訓記錄C5.2: Monitoring reports for boundary noise (recent 3 years)廠界噪音檢測報告(最近3年)C6.1: Internal Hazardous substance control limit, Hazardous substance in the product management procedure, ROHS testing procedure to the incoming material and related records工廠有害物質內部控制限值,產品有害物質控制管理程式, 來料有害物質檢測程式及檢測記錄。

家,看问题应当如何得到关注和解决。

气污染物、固体废物和噪声,适用于总量控制区域)户也被要求办理此证;其他很多城市暂停发放此证,原已发放的旧证无效。

业病竣工验收批文。

一般地,职业病危害申报登记也不能代替职业病竣工验收批文。

(l)职业病危害项目申报是否及时、如实(应对应许可文件工免受骚扰,现有的政策是否在工厂内向1、一份书面政策;该公司还必须有一个处理流程来处理投诉,有一个害,设施风险。

评估系统应该使用正式危害评价法,例如安全风险评估,岗位安全分析,岗位风险分析,或者失效模式和影响性分析,以审核?体系的代表等等)。

检查是否有审核报告。

了解所2、员工乘坐的车辆是否装有铁窗或限制性的措施安装(如囚车)3、员工的穿着有无任何明显的标志来说明员劳工如果否,请指出相关区域。

烟雾。

2、对照#1.3.7的工业卫生监测报告,确定是其化学品使用、产生灰尘、或研磨/焊接/镀做的车如果否,请描述桶和其它存储器管理不善2、观察存储场所是否有污染痕迹(例如土壤或于2台灭火器。

每台手提式灭火器的有效可及距离根据火灾险情最远为9至25米(b)检查在噪声区域内,雇主是否为员工提供听限用的化学品的废料的来源材料。

(e)[买方各业务集团填入自己的清单]; 或(f) 当买方的化学品,铅,汞和六价铬,并且供应商必须有相关的管理控制措施,以确保这些化学物质不被用来制造或合成到产品中,物质不被用来制造或合成到产品中,或其是否已获得通用电气公司已经以书面批准其使用。

2003年1月)(ROHS指令)所限制使用的任何其它有害物质; (b)砷、石棉、苯、多氯联苯(PCB)、或四氯化接地保护。

储存区应有明显标志或标记,如"限制入境" , "禁止吸烟"。

所有液体贮存区应该有二次围堰(如护堤,收集井或其他设施),足以围堵此(b)桶的存放:每行桶不超过2镉桶宽;过道应保证宽敞让应急设备进入( 2-3英尺或1米宽),有充足的空气流通,使没有强烈的气味,为可燃废弃物提供2、工资是否通过银行发放,检查供应商向银行划帐的时间,工资是否能够按时到达员工账户。

EHS审核清单EHS是英文单词Environmental, Health, Safety的首字母缩写。

EHS关注的问题是生产的环境保护和控制、员工的身体健康、员工的人身安全和企业的设备安全。

EHS管理的目标就是创造安全、整洁、有序的工作的工作环境,为生产管理提供支持和保证。

E-环境→即保证生产环境处于良好的状态,如室内的空气质量、照明、温度、地面的清洁、设备的布置,也就是保证生产现场秩序井然、布局合理,为员工提供良好舒适的工作环境;H-健康→即考虑员工在生产过程中健康问题,如操作接触有毒有害化学品、车间噪声、生产设备的振动等可能对员工的身体造成一定的健康影响。

如噪声的影响可能会导致神经系统的紊乱,从而产生焦躁不安、头痛、头晕等不良反应。

S-安全→关注整个生产过程可能导致员工受伤、设备损坏的因素,并通过预防控制的手段阻止危害因素诱发至事故的发生。

E、H、S并不是各自独立的部分,而是紧密联系在一起的三个环节,因此在管理中也逐步将其进行整合统一的管理。

EHS管理的核心是在预防,这也正符合了凡事预则立,不预则废的道理。

无论从EHS的工程层面还是管理层面,EHS的三个方面都是互相制约、互相支持的,比如我们的生产环境存在很大的问题(现场设备物品乱堆乱放、设备布局空间狭小、光线昏暗、空气污浊等),那么将直接影响员工的心理和生理健康,在不良的身体状况下(如烦躁不安、疲劳困顿)发生事故的概率就会增大,最终将导致伤害员工或损坏设备的事故发生。

因此,可以说如果不能创造良好的现场环境,员工的健康、生产的安全都将不能得到保证。

上面说到EHS管理的核心是在预防,那么还有一个方面需要考虑的,就是任何的预防控制管理都不可能杜绝事故的发生,当在事故发生的阶段,如何处理呢,这就需要我们考虑可能发生的事故,并针对这类事故的发生采取现场的控制管理,以减少事故的扩大化。

我们可以把其称之为紧急事件的处置管理。

因此从EHS的管理阶段来分,可将EHS分为预防管理和事后处置管理。

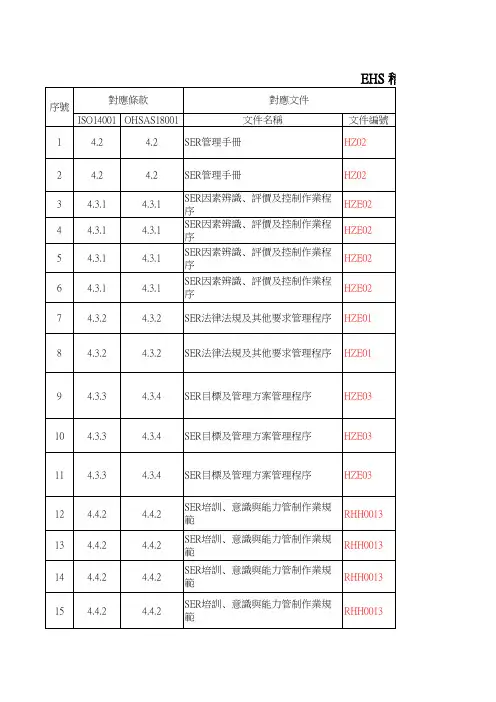

部门责任人:组长:ISO14001

OHSAS180011

5.2 4.22

7.2/7.3 4.4.23

6.1.2 4.3.14

8.2 4.4.75

6.2 4.3.36

5.3/7.1 4.4.17

5.3/7.1 4.4.18

5.3/7.1 4.4.199.1.2 4.5.1判定EHS管理体系内部审核查核表

审核部门:

审核准则ISO14001:2015标准;OHSAS18001:2007标准;体系文件;适用法律法规;

审核员:

项次

条款

本部门人员是否知道公司的管理方针?审查内容审核发现和不符合事项的描述本部门有没有目标管理方案?公司有没有进行消防演练?何时进行?本部门人员是否知道最近的逃生通道口?本部门有没有建立《环境因素识别表》及《危险源辨识与风险评估表》?是否考量完整?从事有职业病危害的岗位人员有没有安排职业病体检?频率是多久?岗位存在职业病危害的有没有对从业人员进行告知?公司有没有未成年工?有没有定期安排体检?是否确定了需要监视和测量的关键环境绩效?是否明确了监测方法?。

环境审核所需文件清单1.工厂位置图,包括周围居民区、工业设施、江河、溪流和保护区等。

2.该地区的环境规划,如功能区划分等3.包括以下内容的工厂布局规划或者工程图纸:z工厂布局图(过去和现在);z包括存储分配在内的化学品(包括溶剂、油类等)的储存位置;z废物存放点;z厂内废物堆放点和临时存放区域(包括现存的堆放区和弃置的堆放区);z现场排放系统(污水和雨水)及其排放点;z烟囱和通风口位置;z地下储罐位置。

4.工厂工艺流程图或方框图5.环境政策6.环境管理组织机构图7.工厂环境培训程序和记录8.环境管理程序,包括废水,废气,废物,能源,消防、化学品安全等程序。

9.表明有关环境事项的项目许可(包括项目扩建)的文件,包括:z环境影响评价(EIA)报告或者环境影响评价表;z项目审核或审批的文件;z“三同时”审核报告,“三同时”竣工验收报告。

z改建/扩建项目环境影响评价和验收报告10.由环境监测中心、卫生防疫站,官方机构或第三方颁发的各项监测报告和分析报告:z污水排放;z烟囱气体排放;z车间空气质量;z厂界噪声水平;z土壤和地下水监测。

z其他特殊作业场合检测报告11.由环保局批准并颁发的排污登记表和排污许可证的复印件,包括:z污染排放登记表;z由环保局颁发的排污登记表;z排污许可证。

12.工厂工程地质调查报告(工程勘查)13.厂内使用的化学清单,包括,但不局限于:溶剂、油类、气体等。

提供月或年使用量的明细清单。

14.垃圾和废物的详细清单和数量(公斤/年)15.能源包括电/液化气/煤/柴油/汽油/天然气/煤气/使用统计报告16.水的使用详情,包括:z来源;z水质分析数据;z采用的预处理技术;z年度使用量(工业用水和生活用水)。

17.由工厂、官方法律机构或第三方颁发的下列有关文件:z密封性测试(地下储罐监测报告);z合同商进行废物外运的相关记录,包括危险废物运输五联单;z危险货物的存储许可。

z任何有关安全环境和安全的信函/邮件/罚款通知/整改统治单等18.大宗物料存储详情:z大型储罐的存储量和存储内容z储罐使用年数和每月的吞吐量;z与大型储罐相应的警报、通风系统和其他相应的保护措施;z大型储罐装卸的书面程序。

19.PCBs(多氯联苯)/消耗臭氧层物质和石棉的调查和处理记录20.环境事故,例如:溅出、泄漏,大气事故性排放等的事故记录及补救措施21.如果有环境投诉事件发生,提供详情记录和处理结果(包括信息交流文件)22.环境表现评估报告(每月/季度/年等)23.以往所有有关环境的审核报告(包括内审或第二/三方审核)24.工厂风险评估报告25.所有化学品的MSDS(物料安全数据表)26.设备年度维修计划27.紧急反应计划(自然灾害/火灾/化学品泄漏/紧急医疗服务/炸弹威胁/生物危害等)28.工厂保险合同及保险公司年度审核报告29.安排与熟悉,但不局限于厂内以下情况的人员见面:z环境、卫生和安全的协调和管理人员;z人事主管/经理;z生产经理;z工程或维修经理。

FACILITY DOCUMENT REQUESTFOR ENVIRONMENTAL SITE ASSESSMENTFollowing comprises a checklist of relevant documentation to be provided by site management to the consultant.1.Location map indicating site in relation to surrounding residential andindustrial properties, streams, river, conservation areas, etc.2.area environmental planning, function division, etc3.Facility layout plans/ Engineering drawings which show locations of thefollowings:z Site layout (past and present)z Chemical (including solvents, oils, etc.) storage, with details of storage arrangements;z Waste/waste materials storage areas;z On-site waste disposal site, and temporary storage areas (current and abandoned);z Site drainage system (wastewater and storm water) and discharge outletz Stacks and Ventsz Underground storage tanks4.Process flow diagram5.Environmental policy6.Environmental management organization chart7.Facility environmental training program and record8.Environmental management programs, including wastewater, airemission, waste, energy, chemical safety, and etc9.Documents indicating project approval (including project expansion) onenvironmental issues, including:z EIA report or EIF;z Project Inspection or Approval Documents;z Three Synchronies Inspection Reports, Three SynchroniesInspection Approval;z Modification / expansion EIA and approval10.Monitoring report/Analytical report from Environmental MonitoringStations or other authorities or a third party on:z Wastewater discharge;z Air emission from stacks;z Facility boundary noise level;z Soil and groundwater testing.z other special work area testing11.Copies of discharge registrations and permits issued by and to the EPBincluding:z Pollution discharge registration formz EPB’s approval of pollution discharge registrationz Pollution discharge permit12.Geotechnical investigation report (GongChenKanCha)13.List of chemicals used at the facility including, but not limited to solvents,oils, gas, etc. Provide inventory of monthly/annual quantities used.14.List of waste/waste materials and quantity generated (kg/yr)15.energy consumption statistics, including electricity, LPG, coal, diesel,gasoline, natural gas, coal gas, etc16.Details of water usage:z Source of waterz Analytical data of water qualityz Any pre-treatment before usez Annual consumption (for industrial use and domestic use)17.Documentation produced by the facility, the regulatory authorities or by athird party on:z integrity testing (underground tanks monitoring report)z records of wastes removed by contractors, including hazardous waste manifest documents;z storage of dangerous goods18.Details of storage arrangements:z Volumes and contents of bulk storage tanksz Ages and monthly throughputs of storage tanksz Alarms, vent pumps and cathodic protection fitted to bulk tanksz Documented procedures for filling and unloading bulk storage tanks19.Surveys/disposal records of PCBs and asbestos.20.Records of environmental incidents and remedial steps taken such asspills, leaks, air emissions etc.21.Details and outcome of complaints if any (including correspondence).22.Environmental performance evaluation report(monthly/quarterly/annual)23.all formal Environmental audit reports (including internal audit orsecond/third party audit)24.Facility risk assessment report25.All chemical material safety data sheets (MSDSs)26.Emergency response plan (natural disaster/ fire/ chemical spill/ medicalservice/ bomb threat/ biological hazard/ etc)27.Facility insurance policy and insurance company annual audit report28.Interviews arrangement with facility personnel who are familiar with thefacility including, but may not limited to:z EHS coordinators/managersz HR supervisor / managerz Production managerz Engineering or Maintenance Manager.。