奥太焊机120917Pulse MIG R系列说明书

- 格式:pdf

- 大小:14.70 MB

- 文档页数:48

点焊逆变电源使用说明书目录1. 使用注意事项 (2)1.1 安全注意事项 (3)1.2 使用前注意事项 (5)2. 概述 (5)2.1 机器的原理 (5)2.2 机器的特点 (5)2.3 技术参数 (6)3. 连接说明 (6)3.1 电源控制箱连接说明 (6)3.2 变压器箱连接说明 (7)4. 操作说明 (8)4.1 操作面板组成及其说明 (8)4.2 LCD显示屏 (8)4.2.1 显示屏及显示切换 (8)4.2.2 显示屏上的状态设定按钮 (10)4.2.3 焊接参数及其显示 (11)4.2.4 功能参数及其显示 (11)4.2.5 显示屏上的其它内容 (12)4.3 参数设定范围 (12)4.4 参数设定方法 (12)4.4.1 参数组设定 (12)4.4.2 参数值设定 (13)4.5 焊接操作 (13)5. 特别应用 (13)5.1 使用不同焊接参数 (13)5.2 双机头应用........................................................................................错误!未定义书签。

5.3 自动化应用 (13)6. 安装调试 (14)7. 一般故障处理 (15)1. 使用注意事项(1)安全上的注意使用前请熟读此「安全上的注意」,正 确使用本装置。

■为了安全使用,防止对使用者及他人造 成危害和损伤,请务必仔细阅读这些与 安全有关的注意事项。

由于任何一个都和安全都有重要关系, 因此请务必仔细阅读。

■ 各安全警示分危险、警告、注意。

警示标志的含义如下:请不要随意触摸装置的内部由于装置内部有高电压存在,随意触摸装置的内部是非常危险的。

供电电源连接插座带有高压,请不要触摸插座的连接端子。

除了我公司技术服务人员以外请不要随意触摸。

请绝对不要自行拆装、修理、改造本装置 会有触电、起火的危险。

需要检、修理时,请与经销商或本公司联系。

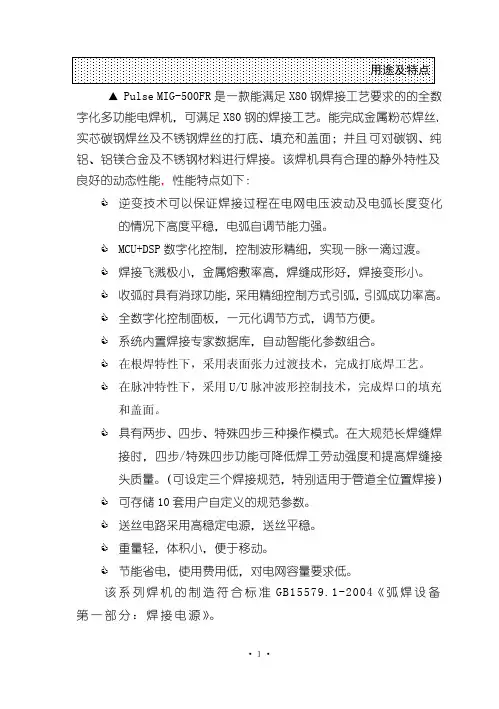

▲Pulse MIG-500FR是一款能满足X80钢焊接工艺要求的的全数字化多功能电焊机,可满足X80钢的焊接工艺。

能完成金属粉芯焊丝、实芯碳钢焊丝及不锈钢焊丝的打底、填充和盖面;并且可对碳钢、纯铝、铝镁合金及不锈钢材料进行焊接。

该焊机具有合理的静外特性及良好的动态性能,性能特点如下:�逆变技术可以保证焊接过程在电网电压波动及电弧长度变化的情况下高度平稳,电弧自调节能力强。

�MCU+DSP数字化控制,控制波形精细,实现一脉一滴过渡。

�焊接飞溅极小,金属熔敷率高,焊缝成形好,焊接变形小。

�收弧时具有消球功能,采用精细控制方式引弧,引弧成功率高。

�全数字化控制面板,一元化调节方式,调节方便。

�系统内置焊接专家数据库,自动智能化参数组合。

�在根焊特性下,采用表面张力过渡技术,完成打底焊工艺。

�在脉冲特性下,采用U/U脉冲波形控制技术,完成焊口的填充和盖面。

�具有两步、四步、特殊四步三种操作模式。

在大规范长焊缝焊接时,四步/特殊四步功能可降低焊工劳动强度和提高焊缝接头质量。

(可设定三个焊接规范,特别适用于管道全位置焊接)�可存储10套用户自定义的规范参数。

�送丝电路采用高稳定电源,送丝平稳。

�重量轻,体积小,便于移动。

�节能省电,使用费用低,对电网容量要求低。

该系列焊机的制造符合标准GB15579.1-2004《弧焊设备第一部分:焊接电源》。

安全注意事项�请务必遵守本说明书规定的注意事项,否则可能发生事故。

�输入电源的设计施工、安装场地的选择、高压气体的使用等,请按照相关标准和规定进行。

�无关人员请勿进入焊接作业场所内。

�请有专业资格的人员对焊机进行安装、检修、保养及使用。

�不得将本焊机用于焊接以外的用途(如充电、加热、管道解冻等等)。

�如果地面不平,要注意防止焊机倾倒。

造成电击或灼伤�请勿接触带电部位。

�请专业电气人员用规定截面的铜导线将焊机接地。

�请专业电气人员用规定截面的铜导线将焊机接入电源,绝缘护套不得破损。

奥太脉冲MIG焊接系统Pulse MIG-500III焊接系统是山东奥太MIG组依托山东大学的技术优势,结合高速列车中铝合金的焊接工艺研究和实践经验,消化吸收欧美等一流Pulse MIG焊接系统的先进技术,针对铝及其合金和不锈钢等有色金属及特种材料焊接而研制的焊接系统。

电源为数字化控制的多功能逆变电源。

可适用于脉冲MIG/MAG焊接、普通MIG/MAG焊接、提升引弧的TIG焊接、手弧焊焊接和碳弧气刨。

焊接系统具备的八项国内领先技术:熔滴一脉一滴过渡、弧长稳定、双脉冲、特殊设计的焊铝程序、全数字光栅反馈送丝系统、全数字外设、内置的专家数据库、100套用户自定义规范参数。

一脉一滴脉冲工艺参数与熔滴形成One Pulse One Drop过程(高速摄影截图)One Pulse One Drop即熔滴一脉一滴过渡技术主要是对脉冲工艺参数作出精确控制的一种技术,在焊接过程中,通过对熔滴过渡过程的检测,控制脉冲过程中各个阶段的电流波形,从而控制多余的电弧热量,提高电弧推力,结果在电弧中心产生高质量的熔深。

就实验结果而言, One Pulse One Drop技术对晶粒细化有明显的提高作用。

●焊接几乎无飞溅,保证高质量焊接●可以取代TIG焊, 用于不锈钢等有色金属焊接性能极佳●熔合性能好,有效防止未熔合现象●热影响区较小.●基本不需要清渣.●电源适应性强, 焊工容易掌握.弧长稳定●熔化速度和送丝速度平衡,使弧长稳定在一定值上。

●通过调节脉冲频率就能够改变单位时间内熔滴过渡的滴数,也就是焊丝熔化速度。

在下坡过程中电弧长度保持一致电流波形和熔滴过渡时刻对应焊接多种金属双脉冲双脉冲焊即低频调制脉冲焊是脉冲焊的一种延伸工艺,其工艺是在高频的基础上,再对高频电流波形进行低频调制, 使单位脉冲的强度在强和弱之间低频周期性切换,得到周期性变化的强弱脉冲群焊接电压 焊接电流焊接电压焊接电流H08Mn2Si 焊丝铝镁ER5356 铝硅ER4043不锈钢308L Ф1.2角焊试件铝硅合金Ф1.2-豪华游艇应用 碳钢Ф1.2-三峡涡壳应用● 可以获得均匀美观的波纹状焊缝,细化了焊缝晶粒。

奥太脉冲MIG焊接系统Pulse MIG-500III焊接系统是山东奥太MIG组依托山东大学的技术优势,结合高速列车中铝合金的焊接工艺研究和实践经验,消化吸收欧美等一流Pulse MIG焊接系统的先进技术,针对铝及其合金和不锈钢等有色金属及特种材料焊接而研制的焊接系统。

电源为数字化控制的多功能逆变电源。

可适用于脉冲MIG/MAG焊接、普通MIG/MAG焊接、提升引弧的TIG焊接、手弧焊焊接和碳弧气刨。

焊接系统具备的八项国内领先技术:熔滴一脉一滴过渡、弧长稳定、双脉冲、特殊设计的焊铝程序、全数字光栅反馈送丝系统、全数字外设、内置的专家数据库、100套用户自定义规范参数。

一脉一滴脉冲工艺参数与熔滴形成One Pulse One Drop过程(高速摄影截图)One Pulse One Drop即熔滴一脉一滴过渡技术主要是对脉冲工艺参数作出精确控制的一种技术,在焊接过程中,通过对熔滴过渡过程的检测,控制脉冲过程中各个阶段的电流波形,从而控制多余的电弧热量,提高电弧推力,结果在电弧中心产生高质量的熔深。

就实验结果而言, One Pulse One Drop技术对晶粒细化有明显的提高作用。

●焊接几乎无飞溅,保证高质量焊接●可以取代TIG焊, 用于不锈钢等有色金属焊接性能极佳●熔合性能好,有效防止未熔合现象●热影响区较小.●基本不需要清渣.●电源适应性强, 焊工容易掌握.弧长稳定●熔化速度和送丝速度平衡,使弧长稳定在一定值上。

●通过调节脉冲频率就能够改变单位时间内熔滴过渡的滴数,也就是焊丝熔化速度。

在下坡过程中电弧长度保持一致电流波形和熔滴过渡时刻对应焊接多种金属双脉冲双脉冲焊即低频调制脉冲焊是脉冲焊的一种延伸工艺,其工艺是在高频的基础上,再对高频电流波形进行低频调制, 使单位脉冲的强度在强和弱之间低频周期性切换,得到周期性变化的强弱脉冲群焊接电压 焊接电流焊接电压焊接电流H08Mn2Si 焊丝铝镁ER5356 铝硅ER4043不锈钢308L Ф1.2角焊试件铝硅合金Ф1.2-豪华游艇应用 碳钢Ф1.2-三峡涡壳应用● 可以获得均匀美观的波纹状焊缝,细化了焊缝晶粒。

Pulse-MIG 系列逆变脉冲气体保护焊机使用说明书操作前请认真阅读本说明书,并妥善保管,以便今后查阅成都易镕宜锢科技有限公司严禁复制目录一、产品简介......................................................................................................................1二、型号编制说明..............................................................................................................2三、技术参数......................................................................................................................2四、功能介绍......................................................................................................................2五、控制和接口介绍..........................................................................................................9六、送丝机........................................................................................................................10七、设备的连接与使用 (13)九、自动保护的代码 (17)十、焊接时常见的异常现象,原因及排除方法如下表所示。

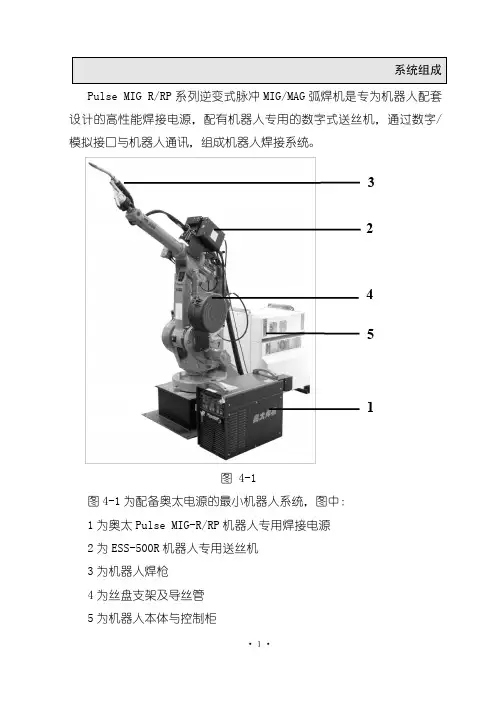

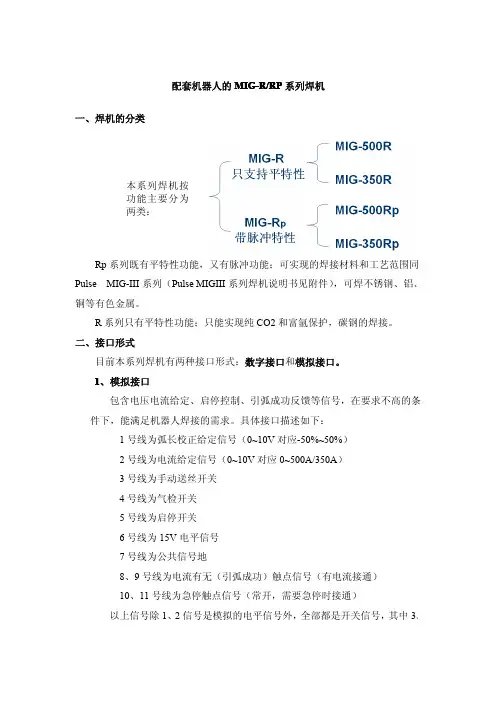

1.焊接测试流程图1.1 焊接测试流程2.焊机设置2.1 焊接设置奥太焊机焊接电源控制面板如图2.1所示,给焊接电源上电后(三相电+焊接电源侧面断路器)即可进行焊接设置。

焊接时需要根据焊接情况选择焊丝直径、焊丝材料与保护气体、操作方式、焊接方式等,操作方法为直接按控制面板底部按钮如图2.2所示,设置值可参考表1。

通过面板按钮F1和F2可以确定面板上显示的项目,一般调整至A(焊接电流)和V(焊接电压)即可。

图2.1焊接电源控制面板图2.2焊接调节按钮表12.2 报警代码和隐含参数焊机出错时,会在控制面板上显示错误代码,这些错误代码的具体解释可以在焊接电源上方粘贴的说明上找到,如图2.3所示。

图2.3焊接电源参数表焊接的高级参数设置可以在隐含参数表中进行设置,建议采用默认值即可,如果需要,可以通过以下方法进行修改:1.进入隐含参数方法:在待机状态下先按住焊机面板上的“存储”,然后再按“焊丝直径”。

2.退出隐含参数方法:轻按“存储”退出。

3.若焊接性能异常,可能内部参数混乱,请按下面板右侧旋钮约3s可以恢复出厂设置。

对两个重要参数进行说明:P09:近控有无。

为OFF时是HMI程序调节电流和电压值,为ON时控制面板调节电流。

默认为OFF P19:分别模式。

为OFF时为一元化模式,即只要给电流值即可,焊接相关电压值由焊机自动给出(此时需要将示教器电压值给0。

或者按照工艺需求,在0左右波动)。

为ON,则为分别模式,需要同时给出焊接电流电压参数,这种方式需要同时给出焊接电流电压,因此适合对焊接工艺了解的用户使用,一般采用默认值OFF即可。

2.3 控制盒丝检/气检以上各部完成后,可以通过控制盒上的丝检按钮(图2.4)来初步判断连接是否正确,按下以后如果送丝机构能正常送丝则正常,否则需要检查接线是否合适。

现场接通气路的话可以按控制盒的气检按钮进行气检。

图2.4控制盒丝检3.焊接测试3.1 焊接工程工程由系统工程部提供,对于SA1400和奥太焊机,工程在文件夹下已经给出。

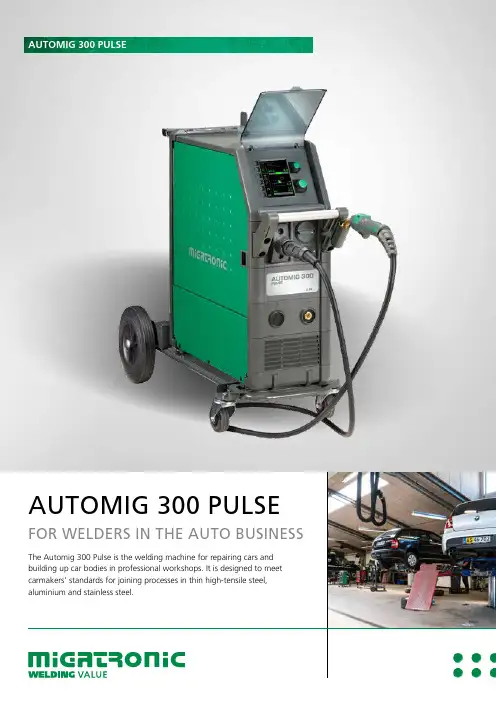

GALAXY SERIEAUTOMIG 300 PULSEDESIGNED FOR WELDING AND MIG BRAZING IN THE AUTO BUSINESS The Automig 300 Pulse is a compact, fully digital welding machine with 36 pre-set programs. The programs meet therequirements for welding and brazing for example high-tensile steel and aluminium, which are used by the auto business. Perfect for joining sheet metals and building up car bodies.EASY SWITCH-OVER WITH DUO OR TRIOThe Automig 300 Pulse is available in three versions: SINGLE, DUO and TRIO. The DUO version has room for two 15 kg wire coils and the TRIO version for three 5 kg wire coils, providing easy switch-over between operations without change of hose, wire, wire drive rolls and gas. The machine will automatically establish which torch/wire feed unit is active.MIG BRAZINGIn addition to sheet metal welding, the Automig 300 Pulse features MIG brazing with and without pulse of galvanisedsteel plates. This function ensures maintenance of the materials in terms of corrosion and strength and reduces post-treatment of distortion of plates and profiles to a minimum. The result is cost-effective and efficient welding. DOUBLE PULSE FOR WELDING AND BRAZINGAutomig 300 Pulse features double pulse – a function required by several carmakers. Double pulse ensures precise control of the arc and minimises weld spatter.BOOST FOR ALL MAINS MAINS VOLTAGESThe Automig 300 Pulse is available with built-in Boost Converter (electronic autotransformer) for welding on all mono-phase and three-phase mains voltages from 208V to 440V (50/60 Hz).MIG-A TWIST ®The ergonomic MIG-A Twist ® torch has a turnable swan neck for easy access to hard-do-reach locations.MIG-A Twist ® is available in different lengths and with different swan necks. It is configurable with different control units for adjustment of welding current at the torch handle. The control unit is easy to exchange as required – without the use of tools.ADVANCED, NOT COMPLICATED -SIMPLE AND VISUAL DISPLAYAUTOMIG 300 PULSE2SELECT PROGRAMEnter type of wire and gas; the program selector will find the rightprogram. SELECT PROCESSChoose between welding or brazing, with or without pulse. ACTIVATE FUNCTIONChoose between tack welding,step (weld/pause time in sequences) or double pulse.ARC ADJUSTA function for precision adjust-ment between soft and hard arc. MEMORY FUNCTIONSave up to five favourite settingsby the push of a button.FINE-ADJUSTMENT Set the arc length.SUPPLEMENTARY INFORMATIONSee description of the chosen job/program. MAIN PARAMETERS Set amperage, wire feed speed and plate thickness. CURRENT DISPLAYShort arc, globular transfer arc and spray arc.Soft-key control panel with colour display and intuitive icon-based menu.MIG-A Twist ® torch – illustratedwith a control unit, which isoptionally available.APPROVED BY THE BESTWHAT MORE COULD YOU POSSIBLY WANT?IGC ® - FOR OPTIMAL SHIELDING OF WELD POOLIGC ® (Intelligent Gas Control) en-sures optimal shielding of the weld pool and maintains the strength in the joint in the best way possible. The result is large-scale gas savingsand a minimum of weld spatter. IGC ® is a synergic gas regulation monitoring the consumption automatically.IGC ® is availableas optional equipment.FOUR-ROLL WIRE FEED SYSTEMFOR STABLE WIRE FEEDING The Automig 300 Pulse isequipped with four-roll wire feed system in the wire feed unit and Tacho control of wire motor for ultra precise wire feeding. LIGHT IN THE WIRE CONSOLE The Automig 300 Pulse isequipped with LED light in the wire console for easy change of wire and wire rolls in low light environment.Automig 300 Pulse is available in SINGLE, DUO and TRIO versions. offers free software update via SD card.3I G C®I n t e l l ig e n t G as C o n t r o l I n s i d eAUTOMIG 300 PULSEAUTOMIG 300 PULSE - LOTS OF OPTIONALLY AVAILABLE EQUIPMENTOPTIONALLY AVAILABLE EQUIPMENT•Wide range of torches/swan necks•Control unit for torch handle•Torch holder•Elevated torch holder for 3 torches•Adapter for 5 kg wire spools•Tool trayControl unit for adjustment of weld-ing current at the torch handle (itemnumber 80100402)Elevated torch holder for threetorches (item number 70617031)Torch holder. Fitted as standardequipment as illustrated. Optionallyavailable for fitting in the left handside of the welding machine(item number 78861557)• IGC® Intelligent Gas Control•Calibration certificate•MigaLOG software for data collection•CEE plugDevice for easy coil-upof long cables.Miga Log™ for storage and displayof welding data on an SD card;applicable for documentation ofcompliance with repair procedures.。

forceArcHIGH-SPEED!Maximum efficiency for all requirements with reproducible welding results and low-spatter welding thanks to the fully digital inverter welding technology!EWM-forceArc – the high-pressure arc – up to 30% faster welding with thick panels!Self-explanatory, intuitive operating concepts for everyone – your choice of various control concepts – optimised for the target group and the application!Optimum preset JOBs (welding tasks) and synergic operation – so that you can concentrate fully on your welding task !Maximum mobility: Easily movable thanks to large wheels, fits through standard doors, easy loading and unloading thanks to the even wheel gauge, can be lifted by crane and moved on a fork lift!Multifunctional and ergonomic grip system: Effort-less mobility, practical holder for tube packages, impact protection!Intelligent casing design with optimised air guidance for longer duty cycle and ventilation control for less contamination in the machine!PROGRESS, EXPERT: Ideal for robot, industrial bus and mechanised applications and documentation via optional interfaces!Powerful cooling system for the torch, with centrifugalpump, cooler with large surface area and an extra-large tank (12 litres)!PHOENIX 521 PULS EXPERT forceArc HIGHSPEED:Efficient MAG welding with significantly higher fusion performance and welding speed as well as excellent weld seam quality thanks to low-spatter welding with deep and wide fusion penetration!Unalloyed, low-alloy and high-alloy steels, aluminium alloys, copper and its alloys, special alloys!Solid and fluxed-core wire electrodes (0.8-2.4 mm), coated electrodes: Rutile, basic!Production and repair work: Chemical and food industries, machine and plant construction, vehicle, automobile, railway vehicle and ship construction, container, closed container and equipment construction, steel and metal construction work, offshore, etc.Ergonomic, robust and perfect –MMA weldingTIG welding LiftarcMIG/MAG pulse welding of the highest qualityMIG/MAG pulse weldingEWM forceArc weldingMIG/MAGstandard weldingHIGHLIGHTSAREA OF APPLICATIONSHigh performance MAG welding HIGH-SPEED®(only PHOENIX 521 and DRIVE 4 in HIGHSPEED version)PHOENIX 301;351;421;521PHOENIX 301;351;421PHOENIX 301IP23S EN 50199IEC/EN 60974MIG/MAGon the welding machine – only the most important welding parameters immediately accessible on the wire feed.115 optimum pre-programmed JOBs (welding tasks) for selection on the wire feed/ welding machine – everything immediately accessible on the wire feed,16 welding programsMaximum ease-of-use – 256 optimum pre-programmed JOBs (welding tasks), including 128 for customised programming with immediate access – all welding parameters immediately accessible both from the welding machine and from the wire feed, 16 welding programs TECHNICAL DATAB A S I CP R O G R E S SE X P E R T *A L T E R N A T I V E L Y* Version decompact onlyWelding machine, gas / water cooledDCPHOENIX BASICGeneralŸ ŸSuperpulseŸS Ÿ115 JOBsDisplaysŸMIG/MAG standard, pulse and forceArc welding, TIG (Liftarc) and MMA welding Non-latched, latched, special non-latched, special latched, MIG spot ŸAutomatic cut-outynergic one-dial operationŸPreselection of welding task using material type, seam type, electrode diameter via a job list Ÿ 3 special JOBs, can be programmed for customised applications Ÿ16 programs per JOB ŸHold functionŸCurrentless gas test and wire inchingŸ2 displays for welding parameters before, during and after welding: Welding current and voltage, wire speed, panel thickness, program number, job number, etc.ŸLEDs: Faults, welding parametersFunctionsMIGŸTIGŸMMAŸArcforcingWire speed ŸArc length correction ŸChoke effect/dynamics ŸWire burn-back ŸWire creepŸGas pre-flow and post-flow timesŸSlope times, main, reduced main and end programŸIgnition, main, reduced main and end programs per jobŸSuperpulse: Pulse and pause programŸWelding currentŸGas pre-flow and post-flow times ŸUp and down slope timesIgnition, welding, secondary and end currentsŸWelding current ŸHotstart time ŸHotstart current ProgrammableŸVarious torch and function modesTorchOptionsSoftwareŸMIG standard ŸTIG comboRemote controlŸManual remote control: CurrentŸDinse central connector ŸPhoenix DRIVE: Wheel set ŸStar handle for wire feed ŸReinforced pump ŸDirt filterŸHolders for accessoriesŸPC 300 welding parameter softwareŸWelding data documentation for Q-DOC 9000 softwareŸWELDQAS welding data monitoring and documentation systemWelding parameters (infinite adjustable)Accessories/OptionsSelection on welding machineSet on welding machineWire feedWelding machine Welding parameter (infinite adjustable)Set on wire feedMIGŸWire speedŸArc length correctionDCPHOENIX PROGRESSGeneralŸ ŸSuperpulseŸ115 JOBsDisplayŸMIG/MAG standard, pulse and forceArc welding, TIG (Liftarc) and MMA welding Non-latched, latched, special non-latched, special latched, MIG spot ŸAutomatic cut-outŸSynergic one-dial operationŸPreselection of welding task using material type, seam type, electrode diameter via job listŸ 3 special JOBs, can be programmed for customised applications Ÿ16 programs per JOB ŸHold functionŸCurrentless gas test and wire inchingŸConnection capability for intermediate driveŸ2 displays for welding parameters before, during and after welding: Welding current and voltage, wire speed, panel thickness, program number, job number, etc.ŸLEDs: Faults, welding parametersFunktionsMIGTIGMMAŸ ŸArcforcingŸWire speedŸArc length correction ŸChoke effect/dynamics ŸWire burn-back ŸWire creepŸGas pre-flow and post-flow timesŸSlope times, main, reduced main and end programŸIgnition, main, reduced main and end programs per jobŸSuperpulse: Pulse and pause programŸWelding currentŸGas pre-flow and post-flow times ŸUp and down slope timesŸIgnition, welding, secondary and end currentsŸWelding current ŸHotstart time Hotstart current ProgrammableŸVarious torch and function modesTorchŸUp/ DownŸPush/Pull Remote controlOptionsInterfacesŸSoftwareŸProgram/job selectionŸRETOX: Up/down with display ŸTIG comboŸManual remote control: Current ŸProgram remote controlŸKey switchŸDinse central connector ŸPhoenix DRIVE: Wheel set ŸStar handle for wire feed ŸReinforced pump ŸDirt filterŸHolders for accessoriesŸAnalogue interface for mechanised welding Digital interfaces: PC, robot, industrial bus, wire feed, documentation ŸPC 300 welding parameter softwareŸWelding data documentation for Q-DOC 9000 softwareŸWELDQAS welding data monitoring and documentation systemWelding parameters (infinite adjustable)Accessories/OptionsSelect on wire feedSet on wire feedWire feedChecklist of Machine FunctionsGeneralŸŸŸŸŸŸŸSuperpulse Select on wire feedMIG/MAG pulse/standardNon-latched/latched, special latched Synergic one-dial operation Automatic cut-out Select on welding machineMIG/MAG and forceArc welding, TIG(Liftarc) and MMA weldingPreselection of welding task using materialtype, seam type, electrode diameter on the welding machineŸ256 JOBs: 128 preset and 128 freelyprogrammable for customised applications Ÿ 3 special JOBsŸ16 programs per JOB ŸHold functionŸCurrentless gas test and wire inchingŸConnection capability for intermediate driveDisplaysŸM310, M370: 2 displays for welding parameters before, during and afterwelding: Welding current and voltage, wire speed, panel thickness, program number, job number, operating hours, motor current, etc.ŸM310: LEDs: Faults, current typeFunctionsMIGŸTIG / MMAWire speed ŸArc length correction ŸChoke effect/dynamicsŸWelding current TorchŸUp/ DownŸPush/Pull OptionsInterfacesSoftwareŸSoftware Q-DOC 9000ŸProgram/job selectionŸRETOX: Up/down with display ŸTIG comboRemote controlŸManual remote control: Current ŸProgram remote controlŸKey switchŸDinse central connector ŸPhoenix DRIVE: Wheel set ŸStar handle for wire feed ŸReinforced pump ŸDirt filterŸHolders for accessoriesŸAnalogue interface for mechanised welding ŸDigital interfaces: PC, robot, industrial bus, wire feed, documentation ŸPC 300 welding parameter software Welding data documentation ŸWELDQAS welding data monitoring and documentation systemWelding parameters ()infinite adjustable Accessories/OptionsSet on wire feedWire feedWelding machine MIGTIGMMAŸ ŸArcforcingŸWire burn-back ŸWire creepŸGas pre-flow and post-flow timesŸSlope times, main, reduced main and end programŸIgnition, main, reduced main and end programs per jobŸSuperpulse: Pulse and break timesŸGas pre-flow and post-flow times ŸUp and down slope timesŸIgnition, welding, secondary and end currentsŸHotstart time Hotstart current ProgrammableŸVarious torch and function modes ŸExpert mode for creating customisedcharacteristicsSet on welding machine。

全自动焊机使用说明书DMCS全自动多轴控制系统(复杂5轴5联动/复杂4轴4联动焊接专用)用户手册V1.6感谢您选择本公司的产品!本手册对DMCS全自动焊接控制系统的使用做了详细的介绍,包括系统特性、部件操作、编程及加工说明等。

在使用本控制系统及相关的设备之前,请您详细阅读本手册。

这将有助于您更好地使用它。

由于软件的不断更新,您所收到的产品在某些方面可能与本手册的陈述有所出入。

在此谨表歉意。

目录1. 概述 (1)1.1.控制卡规格 (1)1.2. 教导手柄规格 (1)1.3. 屏幕显示说明 (2)1.3.1. 标题栏 (2)1.3.2. 按钮 (2)1.4. 组合快捷键一览表 (3)2示教基础知识 (4)2.1. 功能层次图 (4)2.2. 功能简介 (4)2.2.1. 示教编程功能 (4)2.2.2. 起点校正功能 (5)2.2.3. 阵列功能 (5)2.2.4. 修改加工参数功能 (5)2.2.5. 文件复制功能 (5)2.2.6. 删除文件 (5)2.2.7. 修改文件名功能 (5)3操作说明 (6)3.1. 系统初始化界面 (6)3.2 主界面 (6)3.2.1. 界面显示信息 (7)3.2.2. 启动、暂停、停止加工 (7)3.2.3. 进入示教编辑 (7)3.2.4. 修改当前文件加工参数 (7)3.2.5. 进入系统测试 (7)3.2.7. 修改硬件参数 (7)3.2.8. 密码说明 (7)3.3. 加工参数界面 (8)3.3.1. 界面显示信息 (8)3.3.2. 参数设置方法 (9)3.3.3. 加工参数含义 (9)3.4. 硬件参数界面 (9)3.4.1. 各硬件参数含义 (13)3.4.2 (15)3.5. 系统测试界面 (15)3.5.1. 工作台测试 (15)3.5.2. I/O 测试 (16)3.6. 示教编辑界面 (16)3.6.1. 屏幕信息显示 (17)3.6.2. 新建文件 (17)3.6.3. 下载文件 (19)3.6.4. 修改文件 (19)3.6.5. 加工参数 (19)3.6.6. 焊枪校正 (20)3.6.7. 设置阵列 (20)3.6.8. 复制文件 (22)3.6.9. 删除文件 (22)3.6.10. 改文件名 (22)3.6.11. 选择文件 (23)3.7. 用户功能配置界面 (23)3.8. 用户授权界面 (23)3.8.1. 屏幕信息显示为 (23)3.9. 产品权限(密码修改) (24)3.9.1. 屏幕信息显示为 (24)3.9.3. 设备厂商密码 (25)3.9.4. 用户密码 (25)3.10. 设备初始化向导 (25)3.10.1. 输入密码后,屏幕信息显示为 (25)3.11. 设备初始化向导 (26)3.11.1. 屏幕信息显示为 (26)3.11.2. 锁定编辑界面的目的 (26)3.12. 默认加工参数界面 (26)3.12.1. 屏幕信息显示为 (26)3.12.2. 要想使新建的文件 (27)3.13. 系统版本界面 (27)3.13.1. 屏幕信息显示为如下,方便查阅系统版本 (27)3.14. 系统高级配置 (27)3.14.1. 支持起弧检测 (28)3.14.2. 支持断弧检测 (28)3.14.3. 支持暂停专用IO (28)3.14.4. 支持循环加工 (28)3.14.5. 支持多圈复位 (29)3.14.6. 急停有复位 (29)3.14.7. 驱动报警IO (29)3.15. 输入IO与启动文件表 (29)3.16. 系统高级修改 (29)3.16.1. 开机画面修改 (30)3.16.2. 系统语言 (30)3.16.3. 导入系统参数到U盘或恢复参数到系统 (30)3.16.4. U盘升级系统软件 (30)4. 编程 (31)4.1. 程序编辑界面 (31)4.2. 编程基础 (31)4.3. 输入坐标 (33)4.4. 起点开焊延时、终点关焊延时、上抬高度 (33)4.5. 单点 (33)4.6. 空移动点 (33)4.7. 直线 (34)4.8. 圆弧 (35)4.9. 工艺点 (36)4.10. 延时 (36)4.11. IO口 (37)4.12. IO输入等待 (37)4.13. 指令阵列 (38)4.14. 出丝和退丝 (39)4.15. 批量修改 (39)4.16. 单步和保存 (40)5系统安装 (41)5.1. 系统尺寸图 (41)5.2. 硬件资源配置 (42)5.3. 示教串口硬件连接 (42)5.4. 输入IO定义 (42)5.5. 限位IO定义 (43)5.6. 输出IO定义 (44)5.7. 电机输出控制 (44)5.7.1. 差分电路接法 (44)5.7.2. 单端电路接法 (45)5.8. IO输出 (45)1. 概述DMCS 系列连续轨迹运动控制器是针对需要高速高精度连续轨迹运动场合自主开发的一类经济型运动控制器。

全数字化逆变式气体保护焊机控制软件用户说明书全数字化逆变式气体保护焊机控制软件是基于美国TI 公司高性能数字信号处理器TMS320LF2407A 开发的数字化逆变焊机的控制软件,实现了逆变式气保焊机的全数字化控制。

在国内和国际同行业都具有领先的设计思想。

该控制软件具有丰富的功能,可靠的性能。

以下为该软件的主要功能使用说明:一、该控制软件设置了气体保护焊机的控制功能和辅助的药皮手工焊功能,可根据用户在操作界面的选择,输出不同的焊接输出特性。

(1) 药皮手工焊(2) 气保焊(C02、MIG 、TIG )每种功能都具有很多可调参数,用户既可以采用系统默认的参数非常方便地设置焊机,也可以根据不同的焊接要求精细地调整焊机,使之达到最佳的焊接效果。

在选择焊机方式时,软件系统设计了逻辑加密锁,根据用户的定制要求,可以在控制软件中解锁某些焊接方式的使用权限。

从而为生产带来方便,只要下载更新不同版本的软件,就可以完成生成不同功能的焊机,而无需在硬件电路中作更多的改动或焊接设备库存。

该控制软件有效的节约了焊接设备的库存、提高生产率。

二、该软件具有良好的用户操作界面,用户可以通过操作界面方便的了解焊机的各项功能和使用说明。

很快可以学会焊机的操作方法。

也可以方便的设定焊接参数,存储和调用焊机的专家库数据,清晰的显示焊接电压和电流数据方便焊接参数的观察和设定。

该控制软件使用LCD 液晶显示器作为用户和焊机的接口界面,红色LED 数码管显示器作为焊机的工作电流和工作电压的显示界面。

面板布局如下图1示:按键符号定义表:,“”增加键,用“+”表示 ,“”减少键,用“-”表示 ,“”退出键,用“ESC ”表示 ,“”确认键,用“OK ”表示,“”上移键,用“↑”表示 ,“”下移键,用“↓”表示 7,“ ” 菜单光标图1 表1采用了包括汉字在内的六种语言文字可选的菜单进行操作,方便、快捷、直观。

通过面板组合按键的操作,用户可以完成控制软件提供的丰富的功能,其主要操作如下:打开焊机后部的自动空气开关,焊机得电,系统上电复位,初始化DSP 处理器,初始化LCD 液晶显示器,初始化系统设定变量、寄存器及相关标志位,并读取内部存储器数据,更新LCD 及LED 显示数据。

PI RANGEMMA in a V-jointAdvanced TIG - very easyPI RANGEMORE AUTOMATION AND SUPER DESIGNFOR BOTH MANUALAND AUTOMATIC/ROBOT WELDING Migatronic’s Pi range covers the entire spectrum from portableon-location versions to dedicated special and heavy duty machineswith up to 500 A for automatic/robot welding.ADVANCED FUNCTIONS AT HANDMigatronic’s Pi machines combine proven inverter technology with new control and communication options. These features optimise welding performance and make the most advanced functions child’s play to use. NEW PULSE SOUND WITH SYNERGY PLUS™In addition to traditional pulse and quick pulse for TIG DC, Pi offers the Migatronic invention Synergy PLUS™;A special pulse function where the machine automatically and dynamically sets all primary pulse parameters when welding in synergy mode.The traditional sound of pulse welding has therefore been replaced by clean metallic tones thanks to Synergy PLUS™.WELDING WITH UP TO 200 A USING JUST A 16 A FUSEBoth the mono-phase Pi 200 TIG machines feature PFC – Power Factor Correction: an electronic circuit which makes it possible to weld using up to 200 A using just a 16 A fuse.UP TO 4 X 64 PROGRAMSETTINGSAll Pi 350-500 TIG versions contain 64program settings per welding process:TIG DC, TIG AC, MMA DC and MMA AC,so that the welder can quickly and safelycall up customised settings for repetitivewelding jobs. Pi 200-250 contain 10program settings per welding process.TIG LIFTIG® IS STANDARD ON ALLMACHINESAll Pi TIG and MMA machines aresupplied as standard with TIG LIFTIG®function (ignition without HF) for TIGwelding in electrically sensitiveenvironments.TRIGGER MODES IN THESUB-MENUThe user-friendly control panels of thePi machines feature many short-cutsthat make welding much easier. Inthe sub-menu there are variouspossibilities for individual setting ofthe welding progress.TIG-A-TACK™ - ULTIMATE TACK-WELDINGTIG-A-Tack™ (standard) is a feature thatmakes quick and extremely small andprecise tacks. This reduces the risk ofdistortion and damage to the material.FAN REDUCED NOISE ANDENERGY CONSUMPTIONMigatronic Pi was developed withrespect for both environment and workenvironment. The infinitely variable fanoperates precisely and adaptsautomatically to the actual load/coolingrequirement of the machine. Theresults are reduced noise level, energyconsumption and dust intake andlonger life of the machine.GOUGING FOR THICK WALL MATERIALPi 500 features gouging function forgouging root passes or locating lackof fusion.PI RANGE4 - 5AWARD-WINNING USER-FRIENDLY DESIGN WITH FUNCTIONAL DETAILSAC WELDING: ONE BUTTON – FOUR PARAMETERSThe art of simplification: On the Pi AC/DC versions, the welder can adjust four primary AC parameters using just one button:1 Time balance- overall control of cleaning effect 2 AC frequency- arc control and control of weld pool 3 Electrode preheating- perfect ignition and reduced electrode wear - ready for new gas types4 Current balance- maintains a DC-like tungsten tip - ensures arc focusD.O.C ® - QUICKER AC WELDINGAll Pi AC machines are equipped with D.O.C.® function (Dynamic Oxide Control): aMigatronic patent that ensures a controlled, narrow cleaning zone. The result is an increase in welding speed of up to 30% and a corresponding reduction in the consumption of both energy and tungsten electrodes.SYNCHRONISED AC WELDINGPi 350/500 can be used for synchronised AC welding by means of a synchronising kit; an efficient welding method using two arcs in the weld pool. The method is used for butt welding of large aluminium structures in wall thicknesses from approx. 3 mm and gives metallurgically pure joints.Ignition pulse Open circuit voltage Arc voltageD.O.C ® adds the positive half-period time to the negative half-periodIncreased energy in the negative half-period+–Max. 0,1 msTechnique is for the sake of man, not the other way round. That is why the design of the control panel was an ambitious development project in itself with focus onwelding value…! The result is a logical and icon-based control panel. The software in the control panel meets future demands. The machines are easily adjustable accordingto new user-defined applications.Pi AC/DC with D.O.C ®TIG AC/DC control panel with all relevantparameters for professional welding results in allmaterials4-AC balance parameters TIG-A-T ackfunction (standard)4 x 64 program settings*D.O.C.®-functionTraditional pulse with time adjustmentQuick pulse with frequency adjust-mentSynergi PLUS ™.All important parameters in one button4 x 64 program settings*LIFTIG ® - simpleTIG ignition of the arc Hot start - safe ignitionArcPower ™ - prevents the electrode from sticking to theweld poolPi DC HP with Synergi Plus™TIG HP control panel in all its simplicity with Synergy Plus™ as standardFOUR DIFFERENT CONTROL PANELSWITH OPTIMIZED OPERATIONAL COMFORTPi DC HTIG H special version for high frequency ignition without pulse. This option is only available in combination with Pi 350/500Pi MMAMMA control panel with the option of TIG process with LIFTIG ® ignitionPi MMA CELLThe same facilities as for Pi MMA plus special program for vertical downwards welding positionusing cellulose electrodes* PI 200-250: 4 x 10 program settingsPI RANGE6 - 7QUICK CHANGE-OVER BETWEEN JOBSMIGATRONIC PI – IT’S QUITE SIMPLEPress one button and change over between up to 64 different fixed settings in the welding process chosen.Activate Synergy PLUS ™ and Pi automatically sets all primary pulse parameters (synergy mode).TIG-A-T ack™: a quick and extremely precise function with ultra-small tacks.IGC ® Intelligent Gas Control (option)reduces the gas consumption by up to 50%. Gas consumption read-out on the display.The patented D.O.C ® system isalways active and ensures a controlled narrow cleaning zone along the TIG weld. Welding speed is increased by up to 30%.PI 350 MMA CELLPi 350 MMA CELL is designed specifically for tube/pipeline welding and vertical downwards welding position using cellulose electrodes. This means considerably increased welding speed, increased melting performance and higher efficiency. Pi 350 MMA CELL can be used with an asynchronous generator.The Pi 350 is availablewith five differentcontrol panels. DC HP , DC H, AC/DC, MMA, and MMA CELLINTELLIGENT GAS CONTROL IGC ®SYNERGIC GAS FLOW WITH LARGE-SCALE REDUCTION OF GAS CONSUMPTIONPI RANGETHE PI CAN BE CUSTOMISED TOANY WELDING SITUATION- INCLUDING AUTOMATED DEVICES AND ROBOTS AUTOMATED TIG WELDINGThe two largest TIG inverters, thePi 350 and 500, are obvious powersources for automatic devices/robotsand prepared for communication witha robot or automatic device in a setupwith the CWF Multi.INTERFACES FOR ALL TYPESOF ROBOTSThe RCI (Robot Communication Interface) integrates the large Pi machines with most types of robots and controllers. RCI is also used for”Retrofit” - upgrade to state-of-the-art technology of old types of robots. All RCI’s are supplied to order by Migatronic in the required configuration.THE OPERATING COMFORT FOLLOWSTHE OPERATORAll Pi machines for automated weldingprocesses can be equipped with anextra identical control panel at the ro-bot cell where the robot operator getsthe same functions and facilities forsetting the welding parameters.Pi 350 and 500 are suitable power sourcesfor automated welding processes.Extra identical control panel RWF - Robot Wire Feeder.Robotinterfacewire feed speed from 0.2 to 5.0 m/min.We reserve the right to make changes.PI RANGE10 - 11We reserve the right to make changes.PI DATAPI RANGE。