SMC资料下载

- 格式:doc

- 大小:685.46 KB

- 文档页数:5

SMC气动基础知识培训课件.一、教学内容本节课我们将学习《SMC气动基础知识》教材的第一章节,详细内容涉及气动元件的基本原理、气动系统的构成、气动执行元件的工作原理及其在自动化设备中的应用等。

二、教学目标1. 理解并掌握气动元件的基本原理及其在气动系统中的作用。

2. 学会分析气动系统的构成,了解各部分的功能和相互关系。

3. 掌握气动执行元件的工作原理,能够进行简单的气动设备故障排查。

三、教学难点与重点1. 教学难点:气动执行元件的工作原理及气动系统的设计。

2. 教学重点:气动元件的基本原理、气动系统的构成及各部分功能。

四、教具与学具准备1. 教具:SMC气动元件实物、气动系统演示装置、PPT课件。

2. 学具:笔记本、教材、计算器。

五、教学过程1. 导入:通过展示气动设备在工业生产中的应用,引发学生对气动知识的兴趣。

2. 新课内容:详细讲解气动元件的基本原理、气动系统的构成、气动执行元件的工作原理。

a. 气动元件基本原理:利用PPT展示气动元件的图片,讲解其工作原理。

b. 气动系统构成:分析气动系统各部分的功能和相互关系。

c. 气动执行元件:结合实物,讲解气动执行元件的工作原理。

3. 实践情景引入:展示气动设备故障排查实例,让学生了解气动知识在实际中的应用。

4. 例题讲解:针对气动系统的设计,进行例题讲解,巩固所学知识。

5. 随堂练习:布置相关练习题,让学生及时巩固所学内容。

六、板书设计1. 气动元件基本原理2. 气动系统构成气源部分控制部分执行部分3. 气动执行元件工作原理4. 气动设备故障排查实例七、作业设计1. 作业题目:a. 列举气动元件的基本原理。

b. 简述气动系统的构成及其各部分功能。

c. 解释气动执行元件的工作原理。

2. 答案:a. 气动元件基本原理:利用压缩空气作为动力源,实现机械部件的运动或控制。

b. 气动系统构成:气源部分(空气压缩机、气罐等)、控制部分(气动控制阀、电磁阀等)、执行部分(气缸、气马达等)。

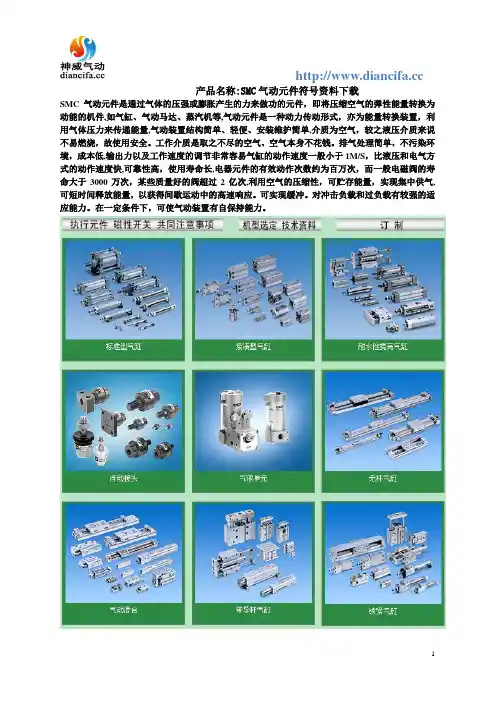

产品名称:SMC气动元件符号资料下载

SMC气动元件是通过气体的压强或膨胀产生的力来做功的元件,即将压缩空气的弹性能量转换为动能的机件,如气缸、气动马达、蒸汽机等,气动元件是一种动力传动形式,亦为能量转换装置,利用气体压力来传递能量,气动装置结构简单、轻便、安装维护简单,介质为空气,较之液压介质来说不易燃烧,故使用安全。

工作介质是取之不尽的空气、空气本身不花钱。

排气处理简单,不污染环境,成本低,输出力以及工作速度的调节非常容易气缸的动作速度一般小于1M/S,比液压和电气方式的动作速度快,可靠性高,使用寿命长,电器元件的有效动作次数约为百万次,而一般电磁阀的寿命大于3000万次,某些质量好的阀超过2亿次,利用空气的压缩性,可贮存能量,实现集中供气,可短时间释放能量,以获得间歇运动中的高速响应。

可实现缓冲。

对冲击负载和过负载有较强的适应能力。

在一定条件下,可使气动装置有自保持能力。

产品名称:SMC气缸3D资料下载

SMC气缸引导活塞在其中进行直线往复运动的圆筒形金属机件。

工质在发动机气缸中通过膨胀将热能转化为机械能;气体在压缩机气缸中接受活塞压缩而提高压力。

涡轮机、旋转活塞式发动机等的壳体通常也称“气缸”。

气缸的应用领域:印刷(张力控制)、半导体(点焊机、芯片研磨)、自动化控制、机器人等等,气压传动中将压缩气体的压力能转换为机械能的气动执行元件。

气缸有作往复直线运动的和作往复摆动的两类(见图)。

作往复直线运动的气缸又可分为单作用、双作用、膜片式和冲击气缸4种。

将压缩空气的压力能转换为机械能,驱动机构作直线往复运动、摆动和旋转运动,直线运动往复运动的气缸、摆动运动的摆动气缸、气爪等。

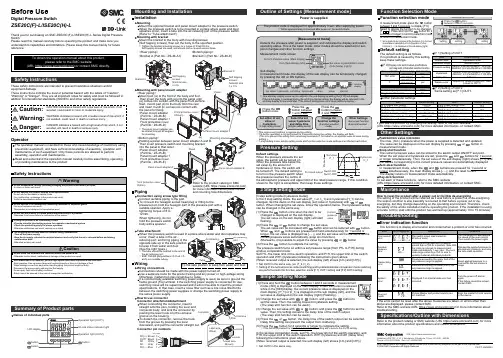

Other SettingsSummary of Product partsSimple Setting ModeTroubleshootingNote: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.© 2020 SMC Corporation All Rights ReservedAkihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPANPhone: +81 3-5207-8249 Fax: +81 3-5298-5362URL https://Specifications/Outline with DimensionsRefer to the product catalog or SMC website (URL https://) for moreinformation about the product specifications and outline dimensions.PS※※-OMX0003 DC(+)OUT1NCNCDC(-)BrownBlackWhiteGrayBlueDefault settingsWhen the pressure exceeds the setvalue, the switch will be turned on.When the pressure falls below theset value by the amount ofhysteresis or more, the switch willbe turned off. The default setting isto turn on the pressure switch whenthe pressure reaches the centre ofthe atmospheric pressure and upper limit of the rated pressure range. If this condition,shown to the right, is acceptable, then keep these settings.Error indication functionThis function is to display error location and content when a problem or error has occurred.above are displayed, please contact SMC.Refer to the SMC website (URL https://) for more information abouttroubleshooting.button between3 and 5 sec.∗:The outputs will continue to operate during setting.∗:If a button operation is not performed for 3 seconds during the setting, the display will flash.(This is to prevent the setting from remaining incomplete if, for instance, an operator were to leave duringsetting.)∗:3 step setting mode, simple setting mode and function selection mode settings are reflected each other.[3 step setting mode (hysteresis mode)]orcan be changed in the same way.button once when the item to beThe set value on the sub display (right) will startflashing.orbutton and can be reduced with button.buttons are pressed and held simultaneously for 1 second orlonger, the set value is displayed as [- - -], and the set value will be the same as thecurrent pressure value automatically (snap shot function).Afterwards, it is possible to adjust the value by pressing button.button to complete the setting.The pressure switch turns on within a set pressure range (from P1L to P1H) duringwindow comparator mode.Set P1L, the lower limit of the switch operation, and P1H, the upper limit of the switchoperation and WH1 (hysteresis) following the instructions given above.(When reversed output is selected, the sub display (left) shows [n1L] and [n1H].)∗:Set OUT2 in the same way. (ex. P_2, H_2)∗:Setting of the normal/reverse output switching and hysteresis/window comparator mode switchingare performed with the function selection mode [F 1] OUT1 setting and [F 2] OUT2 setting.value[F 0] Display units, switch output specificationsand diagnostic information selection functionPeak/bottom value indicationThe value can be displayed on the sub display by pressing button inmeasurement mode.Snap shot functionbuttons for 1 secondor longer simultaneously. Then, the set value of the sub display (right) shows [- - -], andthe values corresponding to the current pressure values are automatically displayed.Zero-clear functionIn measurement mode, when the buttons are pressed for 1 second orlonger simultaneously, the main display shows [- - -], and the reset to zero.The display returns to measurement mode automatically.Key-lock functionTo set each of these functions, refer to the SMC website(URL https://) for more detailed information, or contact SMC.button between 1 and 3 seconds in measurementmode. [SEt] is displayed on the main display. When the button is releasedwhile in the [SEt] display, the current pressure value is displayed on themain display, [P_1] or [n_1] is displayed on the sub display (left), and theset value is displayed on the sub display (right) (Flashing).or button to(The snap shot function can be used.)or button to set the(The snap shot function can be used.)or button, the delay time of the switch output can be selected.button for 2 seconds or longer to complete the setting.∗:If the button is pressed for less than 2 seconds, the setting will moves to the OUT2 setting.In the window comparator mode, set P1L, the lower limit of the switch operation, andP1H, the upper limit of the switch operation, WH1 (hysteresis) and dt1 (delay time)following the instructions given above.(When reversed output is selected, the sub display (left) shows [n1L] and [n1H].)∗:Set OUT2 in the same way.Function selection modebuttonbetween 3 and 5 seconds, to display [F 0].Select to display the function to be changed[F button for 2seconds or longer in function selection modeto return to measurement mode.∗:Some products do not have all the functions. If no functionis available or selected due to configuration of otherfunctions, [- - -] is displayed on the sub display (right).Names of individual partsPressure Setting3 Step Setting Mode(URL https://) for more detailed information, or contact SMC.MaintenanceHow to reset the product after a power cut or forcible de-energizingThe setting of the product will be retained as it was before a power cut or de-energizing.The output condition is also basically recovered to that before a power cut or de-energizing, but may change depending on the operating environment. Therefore, checkthe safety of the whole installation before operating the product. If the installation is usingaccurate control, wait until the product has warmed up (approximately 10 to 15 minutes). Safety InstructionsBefore UseDigital Pressure SwitchZSE20C(F)-L/ISE20C(H)-LThank you for purchasing an SMC ZSE20C(F)-L/ISE20C(H)-L Series Digital PressureSwitch.Please read this manual carefully before operating the product and make sure youunderstand its capabilities and limitations. Please keep this manual handy for futurereference.Safety InstructionsThese safety instructions are intended to prevent hazardous situations and/orequipment damage.These instructions indicate the level of potential hazard with the labels of "Caution","Warning" or "Danger". They are all important notes for safety and must be followed inaddition to International standards (ISO/IEC) and other safety regulations.OperatorSwitch ONAt normal output Switch OFFSet valueP_1HysteresisH_1TimePressureDefault settingThe default setting is as follows.If no problem is caused by this setting,keep these settings.[F 1] Setting of OUT1[F 2] Setting of OUT2Same setting as [F 1] OUT1.InstallationMountingMount the optional bracket and panel mount adapter to the pressure switch.When the pressure switch is to be mounted in a place where water and dustsplashes occur, insert a tube into the air-relieving port of the pressure switch.(Refer to "Tube attachment")Mounting with bracketMount the bracket to the body with mounting screws(Self tapping screws), then set the body to the specified position.∗: Tighten the bracket mounting screws to a torque of 0.5±0.05 Nm.Self tapping screws are used, and should not be re-used several times.∗•Bracket A (Part No.: ZS-46-A1)•Bracket C (Part No.: ZS-46-E)<Rear piping><Bottom piping>WiringWiring connectionsConnections should be made with the power supply turned off.Use a separate route for the product wiring and any power or high voltage wiring.Otherwise, malfunction may result due to noise.If a commercially available switching power supply is used, be sure to ground theframe ground (FG) terminal. If the switching power supply is connected for use,switching noise will be superimposed and it will not be able to meet the productspecifications. In that case, insert a noise filter such as a line noise filter/ferritebetween the switching power supplies or change the switching power supply toHow to use connectorConnection using screw type fittingConnect suitable piping to the port.To connect the hexagon socket head plug or fitting to thepressure port, hold the hexagon part of the pressure port with asuitable spanner. Apply atightening torque of 8 to12 Nm.When tightening, do nothold the pressure switchbody with a spanner.Tube attachmentWhen this pressure switch is used in a place where water and dust splashes mayoccur, insert a tube in the air-opposite side up to the safe positionto keep it from water and dust.(See the right figure.)∗: The tube should be inserted to the end ofthe air-relieving port.∗: SMC TU0425 (polyurethane, O.D ø4, I.Dø2.5) is a suitable tubing.To the safe position to keep from water and dust。

产品名称:SMC气动产品说明书

气动是利用撞击作用或转动作用产生的空气压力使其运动或作功,气动就是以压缩空气为动力源,带动机械完成伸缩或旋转动作。

因为是利用空气具有压缩性的特点,吸入空气压缩储存,空气便像弹簧一样具有了弹力,然后用控制元件控制其方向,带动执行元件的旋转与伸缩。

从大气中吸入多少空气就会排出多少到大气中,不会产生任何化学反应,也不会消耗污染空气的任何成分,另外气体的粘性较液体要小,所以说流动速度快,也很环保。