哈工大大作业

- 格式:pdf

- 大小:856.65 KB

- 文档页数:16

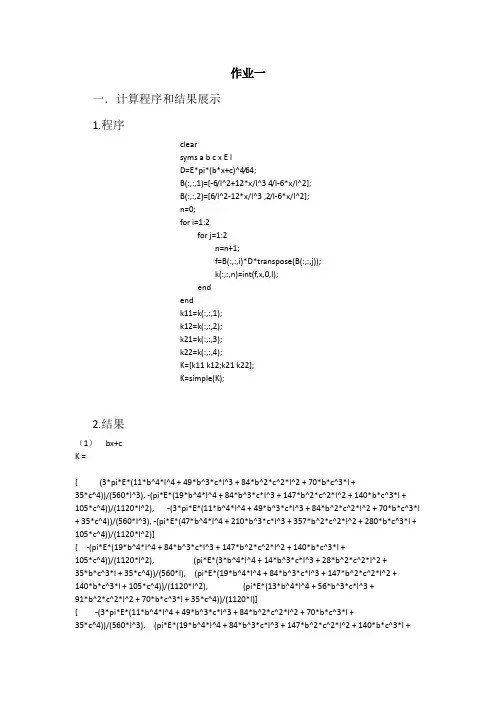

作业一一.计算程序和结果展示1.程序clearsyms a b c x E lD=E*pi*(b*x+c)^4/64;B(:,:,1)=[-6/l^2+12*x/l^3 4/l-6*x/l^2];B(:,:,2)=[6/l^2-12*x/l^3 ,2/l-6*x/l^2];n=0;for i=1:2for j=1:2n=n+1;f=B(:,:,i)*D*transpose(B(:,:,j));k(:,:,n)=int(f,x,0,l);endendk11=k(:,:,1);k12=k(:,:,2);k21=k(:,:,3);k22=k(:,:,4);K=[k11 k12;k21 k22];K=simple(K);2.结果(1)bx+cK =[ (3*pi*E*(11*b^4*l^4 + 49*b^3*c*l^3 + 84*b^2*c^2*l^2 + 70*b*c^3*l +35*c^4))/(560*l^3), -(pi*E*(19*b^4*l^4 + 84*b^3*c*l^3 + 147*b^2*c^2*l^2 + 140*b*c^3*l + 105*c^4))/(1120*l^2), -(3*pi*E*(11*b^4*l^4 + 49*b^3*c*l^3 + 84*b^2*c^2*l^2 + 70*b*c^3*l + 35*c^4))/(560*l^3), -(pi*E*(47*b^4*l^4 + 210*b^3*c*l^3 + 357*b^2*c^2*l^2 + 280*b*c^3*l + 105*c^4))/(1120*l^2)][ -(pi*E*(19*b^4*l^4 + 84*b^3*c*l^3 + 147*b^2*c^2*l^2 + 140*b*c^3*l +105*c^4))/(1120*l^2), (pi*E*(3*b^4*l^4 + 14*b^3*c*l^3 + 28*b^2*c^2*l^2 +35*b*c^3*l + 35*c^4))/(560*l), (pi*E*(19*b^4*l^4 + 84*b^3*c*l^3 + 147*b^2*c^2*l^2 +140*b*c^3*l + 105*c^4))/(1120*l^2), (pi*E*(13*b^4*l^4 + 56*b^3*c*l^3 +91*b^2*c^2*l^2 + 70*b*c^3*l + 35*c^4))/(1120*l)][ -(3*pi*E*(11*b^4*l^4 + 49*b^3*c*l^3 + 84*b^2*c^2*l^2 + 70*b*c^3*l +35*c^4))/(560*l^3), (pi*E*(19*b^4*l^4 + 84*b^3*c*l^3 + 147*b^2*c^2*l^2 + 140*b*c^3*l +105*c^4))/(1120*l^2), (3*pi*E*(11*b^4*l^4 + 49*b^3*c*l^3 + 84*b^2*c^2*l^2 +70*b*c^3*l + 35*c^4))/(560*l^3), (pi*E*(47*b^4*l^4 + 210*b^3*c*l^3 + 357*b^2*c^2*l^2 + 280*b*c^3*l + 105*c^4))/(1120*l^2)][ -(pi*E*(47*b^4*l^4 + 210*b^3*c*l^3 + 357*b^2*c^2*l^2 + 280*b*c^3*l +105*c^4))/(1120*l^2), (pi*E*(13*b^4*l^4 + 56*b^3*c*l^3 + 91*b^2*c^2*l^2 +70*b*c^3*l + 35*c^4))/(1120*l), (pi*E*(47*b^4*l^4 + 210*b^3*c*l^3 + 357*b^2*c^2*l^2 +280*b*c^3*l + 105*c^4))/(1120*l^2), (pi*E*(17*b^4*l^4 + 77*b^3*c*l^3 +133*b^2*c^2*l^2 + 105*b*c^3*l + 35*c^4))/(560*l)](2)ax^2+bx+c(将程序中D的直径换成“ax^2+bx+c”)K =[ (pi*E*(518*a^4*l^8+2233*a^3*b*l^7+2420*a^3*c*l^6+3630*a^2*b^2*l^6+7920*a^2*b*c*l^5 + 4356*a^2*c^2*l^4 +2640*a*b^3*l^5+8712*a*b^2*c*l^4+9702*a*b*c^2*l^3+3696*a*c^3*l^2 + 726*b^4*l^4 + 3234*b^3*c*l^3 + 5544*b^2*c^2*l^2 + 4620*b*c^3*l +2310*c^4))/(12320*l^3), -(pi*E*(938*a^4*l^8+4004*a^3*b*l^7+4290*a^3*c*l^6+6435*a^2*b^2*l^6+13860*a^2*b*c*l^ 5+7524*a^2*c^2*l^4+4620*a*b^3*l^5+15048*a*b^2*c*l^4+16632*a*b*c^2*l^3+6468*a*c^3*l ^2 +1254*b^4*l^4+5544*b^3*c*l^3+9702*b^2*c^2*l^2+9240*b*c^3*l+6930*c^4))/(73920*l^2), -(pi*E*(518*a^4*l^8 + 2233*a^3*b*l^7 + 2420*a^3*c*l^6 + 3630*a^2*b^2*l^6 +7920*a^2*b*c*l^5 + 4356*a^2*c^2*l^4 + 2640*a*b^3*l^5 + 8712*a*b^2*c*l^4 +9702*a*b*c^2*l^3 + 3696*a*c^3*l^2 + 726*b^4*l^4 + 3234*b^3*c*l^3 + 5544*b^2*c^2*l^2 + 4620*b*c^3*l + 2310*c^4))/(12320*l^3), -(pi*E*(2170*a^4*l^8 + 9394*a^3*b*l^7 +10230*a^3*c*l^6 + 15345*a^2*b^2*l^6 + 33660*a^2*b*c*l^5 + 18612*a^2*c^2*l^4 +11220*a*b^3*l^5 + 37224*a*b^2*c*l^4 + 41580*a*b*c^2*l^3 + 15708*a*c^3*l^2 +3102*b^4*l^4 + 13860*b^3*c*l^3 + 23562*b^2*c^2*l^2 + 18480*b*c^3*l +6930*c^4))/(73920*l^2)][ -(pi*E*(938*a^4*l^8 + 4004*a^3*b*l^7 + 4290*a^3*c*l^6 + 6435*a^2*b^2*l^6 + 13860*a^2*b*c*l^5 + 7524*a^2*c^2*l^4 + 4620*a*b^3*l^5 + 15048*a*b^2*c*l^4 +16632*a*b*c^2*l^3 + 6468*a*c^3*l^2 + 1254*b^4*l^4 + 5544*b^3*c*l^3 + 9702*b^2*c^2*l^2 + 9240*b*c^3*l + 6930*c^4))/(73920*l^2), (pi*E*(434*a^4*l^8 + 1848*a^3*b*l^7 + 1980*a^3*c*l^6 + 2970*a^2*b^2*l^6 + 6435*a^2*b*c*l^5 + 3564*a^2*c^2*l^4 +2145*a*b^3*l^5 + 7128*a*b^2*c*l^4 + 8316*a*b*c^2*l^3 + 3696*a*c^3*l^2 + 594*b^4*l^4 + 2772*b^3*c*l^3 + 5544*b^2*c^2*l^2 + 6930*b*c^3*l + 6930*c^4))/(110880*l),(pi*E*(938*a^4*l^8 + 4004*a^3*b*l^7 + 4290*a^3*c*l^6 + 6435*a^2*b^2*l^6 +13860*a^2*b*c*l^5 + 7524*a^2*c^2*l^4 + 4620*a*b^3*l^5 + 15048*a*b^2*c*l^4 +16632*a*b*c^2*l^3 + 6468*a*c^3*l^2 + 1254*b^4*l^4 + 5544*b^3*c*l^3 + 9702*b^2*c^2*l^2 + 9240*b*c^3*l + 6930*c^4))/(73920*l^2), (pi*E*(1946*a^4*l^8 + 8316*a^3*b*l^7 +8910*a^3*c*l^6 + 13365*a^2*b^2*l^6 + 28710*a^2*b*c*l^5 + 15444*a^2*c^2*l^4 +9570*a*b^3*l^5 + 30888*a*b^2*c*l^4 + 33264*a*b*c^2*l^3 + 12012*a*c^3*l^2 +2574*b^4*l^4 + 11088*b^3*c*l^3 + 18018*b^2*c^2*l^2 + 13860*b*c^3*l +6930*c^4))/(221760*l)][ -(pi*E*(518*a^4*l^8 + 2233*a^3*b*l^7 + 2420*a^3*c*l^6 +3630*a^2*b^2*l^6 + 7920*a^2*b*c*l^5 + 4356*a^2*c^2*l^4 + 2640*a*b^3*l^5 +8712*a*b^2*c*l^4 + 9702*a*b*c^2*l^3 + 3696*a*c^3*l^2 + 726*b^4*l^4 + 3234*b^3*c*l^3 +5544*b^2*c^2*l^2 + 4620*b*c^3*l + 2310*c^4))/(12320*l^3), (pi*E*(938*a^4*l^8 + 4004*a^3*b*l^7 + 4290*a^3*c*l^6 + 6435*a^2*b^2*l^6 + 13860*a^2*b*c*l^5 +7524*a^2*c^2*l^4 + 4620*a*b^3*l^5 + 15048*a*b^2*c*l^4 + 16632*a*b*c^2*l^3 +6468*a*c^3*l^2 + 1254*b^4*l^4 + 5544*b^3*c*l^3 + 9702*b^2*c^2*l^2 + 9240*b*c^3*l + 6930*c^4))/(73920*l^2), (pi*E*(518*a^4*l^8 + 2233*a^3*b*l^7 +2420*a^3*c*l^6 + 3630*a^2*b^2*l^6 + 7920*a^2*b*c*l^5 + 4356*a^2*c^2*l^4 +2640*a*b^3*l^5 + 8712*a*b^2*c*l^4 + 9702*a*b*c^2*l^3 + 3696*a*c^3*l^2 + 726*b^4*l^4 + 3234*b^3*c*l^3 + 5544*b^2*c^2*l^2 + 4620*b*c^3*l + 2310*c^4))/(12320*l^3),(pi*E*(2170*a^4*l^8 + 9394*a^3*b*l^7 + 10230*a^3*c*l^6 + 15345*a^2*b^2*l^6 +33660*a^2*b*c*l^5 + 18612*a^2*c^2*l^4 + 11220*a*b^3*l^5 + 37224*a*b^2*c*l^4 +41580*a*b*c^2*l^3 + 15708*a*c^3*l^2 + 3102*b^4*l^4 + 13860*b^3*c*l^3 +23562*b^2*c^2*l^2 + 18480*b*c^3*l + 6930*c^4))/(73920*l^2)][ -(pi*E*(2170*a^4*l^8 + 9394*a^3*b*l^7 + 10230*a^3*c*l^6 + 15345*a^2*b^2*l^6 +33660*a^2*b*c*l^5 + 18612*a^2*c^2*l^4 + 11220*a*b^3*l^5 + 37224*a*b^2*c*l^4 +41580*a*b*c^2*l^3 + 15708*a*c^3*l^2 + 3102*b^4*l^4 + 13860*b^3*c*l^3 +23562*b^2*c^2*l^2 + 18480*b*c^3*l + 6930*c^4))/(73920*l^2), (pi*E*(1946*a^4*l^8 +8316*a^3*b*l^7 + 8910*a^3*c*l^6 + 13365*a^2*b^2*l^6 + 28710*a^2*b*c*l^5 +15444*a^2*c^2*l^4 + 9570*a*b^3*l^5 + 30888*a*b^2*c*l^4 + 33264*a*b*c^2*l^3 +12012*a*c^3*l^2 + 2574*b^4*l^4 + 11088*b^3*c*l^3 + 18018*b^2*c^2*l^2 + 13860*b*c^3*l + 6930*c^4))/(221760*l), (pi*E*(2170*a^4*l^8 + 9394*a^3*b*l^7 + 10230*a^3*c*l^6 +15345*a^2*b^2*l^6 + 33660*a^2*b*c*l^5 + 18612*a^2*c^2*l^4 + 11220*a*b^3*l^5 +37224*a*b^2*c*l^4 + 41580*a*b*c^2*l^3 + 15708*a*c^3*l^2 + 3102*b^4*l^4 +13860*b^3*c*l^3 + 23562*b^2*c^2*l^2 + 18480*b*c^3*l + 6930*c^4))/(73920*l^2),(pi*E*(2282*a^4*l^8 + 9933*a^3*b*l^7 + 10890*a^3*c*l^6 + 16335*a^2*b^2*l^6 +36135*a^2*b*c*l^5 + 20196*a^2*c^2*l^4 + 12045*a*b^3*l^5 + 40392*a*b^2*c*l^4 +45738*a*b*c^2*l^3 + 17556*a*c^3*l^2 + 3366*b^4*l^4 + 15246*b^3*c*l^3 +26334*b^2*c^2*l^2 + 20790*b*c^3*l + 6930*c^4))/(110880*l)](3)b=0(等截面梁)K =[ (3*pi*E*c^4)/(16*l^3),-(3*pi*E*c^4)/(32*l^2),-(3*pi*E*c^4)/(16*l^3),-(3*pi*E*c^4)/(32*l^2)] [ -(3*pi*E*c^4)/(32*l^2), (pi*E*c^4)/(16*l), (3*pi*E*c^4)/(32*l^2), (pi*E*c^4)/(32*l)][ -(3*pi*E*c^4)/(16*l^3), (3*pi*E*c^4)/(32*l^2), (3*pi*E*c^4)/(16*l^3),(3*pi*E*c^4)/(32*l^2)] [ -(3*pi*E*c^4)/(32*l^2), (pi*E*c^4)/(32*l), (3*pi*E*c^4)/(32*l^2), (pi*E*c^4)/(16*l)]总结:将结果(3)与教材等截面梁刚度矩阵比较,发现表达式一样,侧面证明了程序的正确性。

数学实验大作业——抽象群与应用“RSA加密系统”合作人:郭元镇尹庆宇杨瑞飞综述1)RSA 加密算法的历史RSA公钥加密算法是1977年由Ron Rivest、Adi Shamirh和LenAdleman在(美国麻省理工学院)开发的。

RSA取名来自开发他们三者的名字。

RSA是目前最有影响力的公钥加密算法,它能够抵抗到目前为止已知的所有密码攻击,已被ISO推荐为公钥数据加密标准。

RSA算法基于一个十分简单的数论事实:将两个大素数相乘十分容易,但那时想要对其乘积进行因式分解却极其困难,因此可以将乘积公开作为加密密钥。

这种算法1978年就出现了,它是第一个既能用于数据加密也能用于数字签名的算法。

它易于理解和操作,也很流行。

早在1973年,英国国家通信总局的数学家Clifford Cocks就发现了类似的算法。

但是他的发现被列为绝密,直到1998年才公诸于世。

RSA是被研究得最广泛的公钥算法,从提出到现在已近二十年,经历了各种攻击的考验,逐渐为人们接受,普遍认为是目前最优秀的公钥方案之一。

RSA的安全性依赖于大数的因子分解,但并没有从理论上证明破译RSA的难度与大数分解难度等价。

即RSA的重大缺陷是无法从理论上把握它的保密性能如何,而且密码学界多数人士倾向于因子分解不是NPC问题。

2)RSA 加密算法的原理RSA算法是一种非对称密码算法,所谓非对称,就是指该算法需要一对密钥,使用其中一个加密,则需要用另一个才能解密。

RSA的算法涉及三个参数,n、e1、e2。

其中,n是两个大质数p、q的积,n的二进制表示时所占用的位数,就是所谓的密钥长度。

e1和e2是一对相关的值,e1可以任意取,但要求e1与(p-1)*(q-1)互质;再选择e2,要求(e2*e1)mod((p-1)*(q-1))=1。

(n及e1),(n及e2)就是密钥对。

RSA加解密的算法完全相同,设A为明文,B为密文,则:A=B^e1 mod n;B=A^e2 mod n;e1和e2可以互换使用,即:A=B^e2 mod n;B=A^e1 mod n;3)RSA 加密算法的缺点1.产生密钥很麻烦,受到素数产生技术的限制,因而难以做到一次一密。

哈工大机械设计大作业4齿轮传动5.1.4(总11页)--本页仅作为文档封面,使用时请直接删除即可----内页可以根据需求调整合适字体及大小--H a r b i n I n s t i t u t e o f T e c h n o l o g y机械设计大作业说明书大作业名称:机械设计大作业设计题目:齿轮传动设计班级: 1设计者:学号: 112指导教师:张锋设计时间:哈尔滨工业大学设计任务书题目:设计带式传输机中的齿轮传动设计原始数据:带式传输机的传动方案如图所示,机器工作平稳、单向回转、成批生产,其它数据见表。

带式传输机中齿轮传动的已知数据方案电动机工作功率P d /kW电动机满载转速n m/(r/min)工作机的转速nw/(r/min)第一级传动比i1轴承座中心高H/mm最短工作年限工作环境年2班室内清洁目录1. 选择齿轮材料、热处理方式、精度等级........... 错误!未定义书签。

2.初步计算传动主要尺寸.......................... 错误!未定义书签。

(1)小齿轮传递的扭矩......................... 错误!未定义书签。

(2)确定载荷系数K ........................... 错误!未定义书签。

(3)确定齿宽系数dφ........................... 错误!未定义书签。

(4)初步确定齿轮齿数......................... 错误!未定义书签。

(5)确定齿形系数Y、应力修正系数S Y........... 错误!未定义书签。

F(6)确定重合度系数Y......................... 错误!未定义书签。

ε(7)确定许用弯曲应力......................... 错误!未定义书签。

(8)初算模数................................. 错误!未定义书签。

Harbin Institute of Technology机械制造装备设计大作业题目:无丝杠车床主传动系统设计学院:机电工程学院班级:姓名:学号:©工业大学工业大学机械制造装备设计大作业题目:无丝杠车床主传动系统设计目录一、运动设计 (3)1 确定极限转速 (3)2 确定公比 (3)3 求出主轴转速级数 (3)4 确定结构式 (3)5 绘制转速图 (4)6 绘制传动系统图 (5)7 确定变速组齿轮传动副的齿数 (6)8 校核主轴转速误差 (6)二、动力设计 (7)1 传动轴的直径确定 (7)2 齿轮模数的初步计算 (7)参考文献 (9)设计任务设计题目:无丝杠车床主传动系统设计已知条件:最大加工直径ф400mm,最低转速40r/min,公比φ=1.41,级数Z=11,切削功率N=5.5KW。

设计任务:1.运动设计:确定系统的转速系列;分析比较拟定传动结构方案;确定传动副的传动比和齿轮的齿数;画出传动系统图;计算主轴的实际转速与标准转速的相对误差。

2.动力设计:确定各传动件的计算转速;初定传动轴直径、齿轮模数;选择机床主轴结构尺寸。

一、运动设计1. 确定极限转速已知最低转速为40r/min,公比φ=1.41,参考文献[1]表4-2标准转速系列的本系统转速系列如下:40 57 80 113 160 226 320 453 640 9051280 r/min,则转速的调整围maxmin 128032 40n nRn===。

2. 确定公比根据设计数据,公比φ=1.41。

3. 求出主轴转速级数Z根据设计数据,转速级数Z=11。

4.确定结构式(1)确定传动组和传动副数由于总级数为11,先按12设计再减掉一组。

共有以下几种方案:12=4×3 12=3×4 12=3×2×2 12=2×3×2 12=2×2×3 根据传动副前多后少原则,以减少传动副结构尺寸选择第三组方案,即: 12=3×2×2(2)确定结构式按前疏后密原则设计结构式中的级比指数,得到:12=31×23×26减掉一组转速为:12=31×23×25对于该结构式中的第二扩大组x 2=5、p 2=2,而因此r 2=φ5×(2-1)=1.415=5.57<8。

Harbin Institute of Technology大作业设计说明书课程名称:机械设计设计题目:轴系部件设计设计时间:2017.12哈尔滨工业大学设计任务原始数据如下:有冲击,室内工作,机器成批生产一.选择轴的材料、热处理方式因传递功率不大,并对质量及结构尺寸无特殊要求,故选用45号钢,调制处理。

二.按扭转强度估算轴径由大作业四P=3.84KW ,n =480r/min ,对于转轴,扭转强度初算轴径,查参考文献[1]表10.2得C =106~118,考虑轴端弯矩比转矩小,故取 C =106,则mm n P c d 2.2148084.310633min =⨯== 其中P ——轴的传递功率 n ——轴的转速C ——由许用扭转剪应力确定的系数由于考虑到轴的最小直径处要安装大带轮或小齿轮有键槽存在,故将其扩大为1.05倍,得mm d 26.222.2105.11=⨯≥,按标准GB2822-81的R10圆整后取d=25mm 。

三.设计轴的结构3.1确定机体和轴的结构形式箱体内无传动件,不需经常拆卸,箱体采用整体式。

由轴的功能可知,该轴应具有带轮、齿轮的安装段,两个轴承的安装段以及两个轴承对外的密封段,共7段尺寸。

由于没有轴向力的存在,且载荷、转速较低,故选用深沟球轴承。

由于传递功率小,转速不高,发热小,故轴承采用两端固定式。

由于轴转速较低,且两轴承间无传动件,所以采用脂润滑、毛毡圈密封。

确定轴的草图如图1所示:图1 确定轴的草图3.1.阶梯轴各部分直径的确定1) 轴段1和7轴段1和轴段7分别安放大带轮和小齿轮,所以其长度由带轮和齿轮轮毂长度确定,而直径由初算的最小直径得到。

所以,mm d d 2571==。

2) 轴段2和6轴段2和轴段6的确定应考虑齿轮、带轮的轴向固定和密封圈的尺寸。

由参考文献[3]图10.9计算得到轴肩高度mm h d d d )30~5.28(21162=⨯+==由参考文献[3]表14.4取毡圈油封直径mm d 29=,取轴径mm d d 3062==。

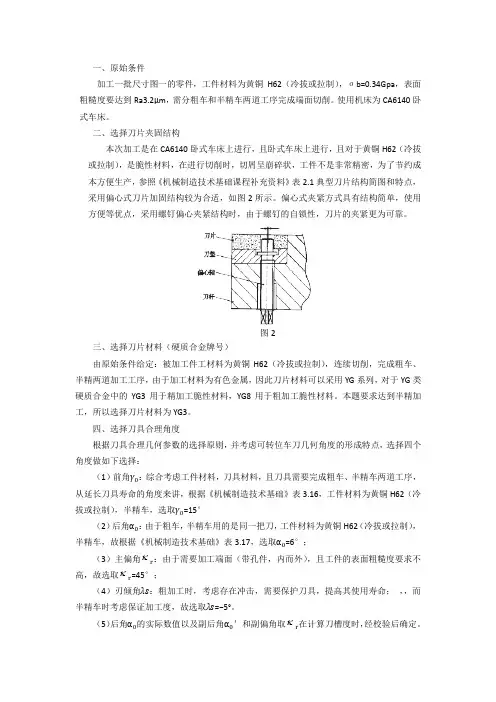

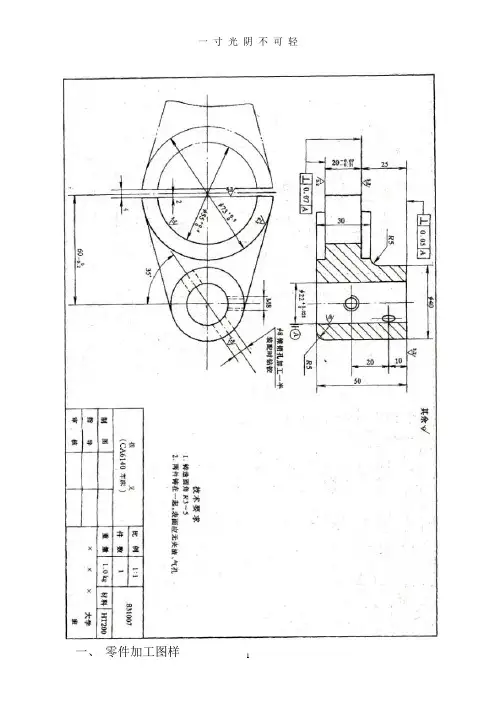

在CA6140机床中,拨叉在变速箱中起到控制齿轮组的移动,改变啮合齿轮对,从而改变传动比实现变速功能。

零件材料采用200HT 灰铸铁,生产工艺简单、可铸性高,但材料脆性大不易磨削。

需要加工的部分及加工要求如下:1、0.0210Φ22+孔,还有与其相连的8M 螺纹孔和Φ8锥销孔;2、小孔的上端面,大孔的上下两端面;3、大头的半圆孔0.40Φ55+;4、 Φ40上端面,表面粗5、 糙度为 3.2Ra ,该面和Φ20孔中心线垂直度误差为0.05mm ;5、0.50Φ73+半圆形上下端面与Φ22孔中心线垂直度误差为0.07mm 。

二、零件加工工艺设计(一)确定毛坯的制造形式零件材料为HT200。

考虑到零件在机床运行时过程中所受冲击不大,零件结构又比较简单,生产类型为大批生产,故选择铸件毛坯。

选用铸件尺寸公差等级CT9级。

(二)工艺初步安排零件的加工批量以大批量为主,用通用机床加工,工序适当集中,减少工件装夹次数以缩短生产周期、保证其位置精度。

(三)选择基准基准的选择是工艺规程设计中的重要工作之一。

基准选择得正确合理,可以使加工质量得到保证,生产效率得以提高。

(1)粗基准的选择:以零件的底面为主要的定位粗基准,以两个小头孔外圆表面为辅助粗基准。

这样就能限制工件的五个自由度,再加上垂直的一个机械加紧,就可达到完全定位。

(2)精基准的选择:考虑到要保证零件的加工精度和装夹准确方便,依据“基准重合”原则和“基准统一”原则,以粗加工后的底面为主要定位基准,以两个小孔头内圆柱表面为辅助的定位精基准。

(四)制定工艺路线1.工艺方案分析此零件加工工艺大致可分为两个:方案一是先加工完与Φ22mm的孔有垂直度要求的面再加工孔。

而方案二恰恰相反,先加工Φ22mm的孔,再以孔的中心线来定位加工完与之有垂直度要求的三个面。

方案一装夹次数较少,但在加工Φ22mm的时候最多只能保证一个面与定位面之间的垂直度要求。

其他的两个面很难保证。

第一作业调研报告 (1)1.1调研内容 (1)1.2工作量与要求 (1)1.3正文 (1)The development and application of NC machine tool servo system (2)第二作业:典型曲线数字积分法插补方法 (13)2.1目的 (13)2.2要求 (13)2.3 DDA法双曲线插补的积分表达式 (13)2.4终点判别 (15)2.5插补举例 (15)第三作业:加工中心零件加工编程 (17)3.1目的和要求 (17)3.2数控机床设备 (17)3.3加工工艺制订 (19)3.4要完成的程序编写任务 (22)《数控技术》课程(2015)大作业院(系)专业姓名学号班号任课教师完成日期哈尔滨工业大学机电工程学院2015年5月数控大作业第一作业调研报告1.1调研内容请以课堂所学习的知识为基础,自主选择课程中所涉及的任一知识点进行调研。

可以调研知识点的发展脉络,也可以重点介绍该知识点的发展现状、争议与未来发展趋势。

请提交交独一无二的报告1.2工作量与要求1. 报告需用英文撰写,可计算机打印,也可手写,但最后封面需手工签名。

2. 格式请参照本科生毕业论文要求(见教务处网站),总字数不少于2000字。

3.在调研报告的最后,请列出参考的主要文献(英文学术刊物上正式发表的文献不少于5篇)或网址,并在正文中标注引用。

4. 如果出现雷同,两位同学均无成绩。

1.3正文The development and application of NC machine tool servo system Since the invention of NC machine tool in 1950s, servo system has been the indispensable component of the NC machine tool. With the rapid development of new materials, electronic power and controlling system, the servo system has evolved from the step-by-step system to DC system and then to AC system. As the blossom of AC servo technology, AC servo system will replace the DC system wholly and take up the dominant position in the family of servo system.With the electronic power conversion unit as actuator and controlle r as core , Servo system which contains the servo driver and servo motor constitutes the main part of the electric-driving and autom atic control system . When working, firstly the servo system will receive the signal from NC devices, and then drive the motion of machine tool as well as ensure the accuracy and speediness of mov ement under the guidance of pulse command . Usually, precision a nd speed of the NC machine tool and other technical indicators mainly depend on the servo system itself1.The improvement and assortment of NC servo systemAt present, engineers tend to assess the quality by reference to seve ral important indicators, such as precision, speed and so on. Theref ore, a NC servo system must meet these requirements.High precisionUnlike the traditional manufacturing which can be manually handle d to regulate and compensate errors, the NC servo system has a hi gh demand on positioning accuracy and repeated positioning accura cyQuick repose characteristicQuick response is one of important indicators of servo system’s dynamic quality which requires the servo system following the command signal with minimum error as well as quick repose and high stability. Once receiving the instruction of manipulator, the working machine can restore the original state of equilibrium quickly after a short regulation or a disturbance from outer space.Wide speed rangeDue to the difference in work piece materials, cutting tool and process requirements, servo system must have wide speed range, so as to ensure that the CNC machine in any circumstances can get the optimal cutting condition. Thus the machine tool can satisfy the requirement of high speed machining as well as the requirement of low speed feed.The speed range is generally larger than 1 to 10000. when the machine isworking in a low cutting speed which ask for a larger stable torque output, NC servo system must maintain a good reliability.Good reliabilitythe usage of machine tool is frequent, usually with 24 hours' continuous work, so the servo system must have good working reliability. Servo system of NC machine tool can be divided into open loop control system and closed loop control system according to the presence of feedback test components. Drive control Unit transforms feeding instructions to perform signal needed by actuator, and then actuator convert this signal into mechanical displacement.In Open loop control system, there is no feedback detecting components and comparing control links. On the contrary, these are essential part of a closed-loop control system.The composition of servo systemServo system can be classified into the feed drive system and the spindle drive system on the basis of function and usage. Besides,the NC servo system can also be sorted into open loop control system and the closed loop control system in light of the presence of feedback detecting element.In addition, according to the difference of actuators, servo system can be divided into stepping servo system, dc servo system and ac servo system.Stepping servo systemBefore the 1960 s,the stepping servo system is based on step motor driven hydraulic servo motor or characterized by power steppingmotor as direct drive,and servo system uses open-loop control. Stepping servo system works with the pulse signal, and its speed and turning Angle depends on the frequency or the number ofInstruction pulses.Because there is no testing and feedback loop, the precision of the stepper motor step depends on the step angle, the accuracy of the gear transmission clearance and so on, its accuracy is low. stepping motor is easy to appear vibration phenomenon when working in the low frequency,and its output torque decreases with increment of speed. Because the stepping servo system is the open loop control, step motor in the start of machine with the over-high frequency or large load shows"lost" or "blocked" phenomenon and prone to appear phenomenon of high speed overshoot in the braking of the machine tool. At the same time, step motor speed accelerating from 0 to working speed requires longer time and slower speed response. But because of its simple structure, easy adjustment, and good working reliability and the low prices, the stepping system is a good choice in many many occasionsof low occasions.Dc servo systemAfter 60 and 70 s, most of numerical control system adopts dc servo system. Dc servo motor has a good wide range speed performance, large output torque, and strong overload capacity. servo system also has evolved from open loop control into closed-loop control, thus in the industry as well as its related fields gains the more extensive or aboard application. However, with the rapid development of modern industry, the corresponding equivalents such as precision CNC machine tools, industrial robots make higher and higher requirements to the electrical servo system, especially the precision, reliability and other performance.The traditional dc motor uses a mechanical commutator, faced up with many problems in the application process, such as brush and commutator wear easily, maintenance work is heavy and the cost of it is high. Commutator reversing would produce sparks, the maximum speed of the motor and the application environment is limited;Dc motor has a more complex structure, higher cost,and prone to interfere other devices'work.Ac servo systemThe existence of these problems, limiting the dc servo system in highprecision, high performance requires the application of servo drive occasion.Because hard-overcoming weakness of dc motor, people have been seeking the development of ac servo motor to replace the dc motor whose advantage is limited by mechanical commutor and brush to satisfy the needs of various application fields, especially in the field of high precision and high-performance servo drive .But because the ac motor has strong coupling, nonlinear characteristics, so control is very complete and the high-performance application has been limited. Since the 1980 s, with the boom of the new technology such as electronic electricity, the modern control theory, and the breakthrough in the field of vector control algorithm, the original problems of AC motor which has bothered so many engineers has been solved, and ac servo development faster and faster.The characteristics of the ac servo systemIn addition to good stability, good rapidity,and high precision,servo motor system has a series of other advantages.with out the limitation of commutator circumferential speed and armature reactance potential numerical element, the speed limit ofAC motor can be design higher than DC motor in the same given motor. with a wide range of speed regulation, the most ac servo motor speed ratio can reach 1:50000,and high-performance servo motor speed ratiocan even amount to ver 100000. Meet the numerical control machine tool drive, wide speed range and small static rate request.good torque speed characteristicAC motor as the constant torque output, i.e. within its rated speed output rated torque, in for a constant power output above the rated speed.And torque overload capacity, can overcome the inertia moment of inertia load moment at start-up.Meet the machine tool servo system, large output torque, good dynamic accordingly, high positioning accuracy demands.The research status of domestic ac servoAc servo system consists of the ac servo system based on asynchronous motor and the ac servo system on the base of synchronous motor.At present machine mainly adopts a permanent magnet synchronous ac servo system.In the field of ac servo research, the Japan, the United States and Europe are in the forefront.In the mid 1980s, Japan yaskawa company has successfully developed the world's first ac servo drive.Then F ANUC, Mitsubishi, Panasonic and other companies have launched their own ac servo system. Most of these products from aboard companies are based on the asynchronous motor. However,domestic institutes has set up late in ac servo system with asynchronous motor,and so far there are still no products available. Many domestic researchers put much importance on the research of permanent magnet synchronous motorservo system. Huazhong university of science and technology, Beijing machine tool research institute, xi 'an micro motor research institute, shenyang institute of automation of Chinese academy of sciences, lanzhou electric factory etc have started out in the research of AC servo system and are expected to launch their own products. DA98 all-digital ac servo drive unit from guangzhou NC manufacturing company has already knock at the door of high-precision servo driver industry in our country, broken the monopoly of foreign countries , and initiated a new era belonging to our national brands.Ac servo signal and numerical control system interface have three different modes, which can also divided into three stages.Domestically, Guangzhou CNC DA98 which belongs to the first generation and is also a epoch-making servo drive, at the same time, it is first all-digital domestic ac servo drive unit, pulse command it accept direction. The second generation is EDB series delegated by Aston, it can not only accept pulse command signal, but also receive the signal from the speed control and torque control analog input.The third generation is networked ac servo worked servo system is the organic combination of industrial field-bus technology and full digital ac servo,which enables users to adjust the parameters according to load conditions and saves some unstable factors such as drift produced byanalog circuits. Based on field bus network control technology,the servo system the microprocessor and field bus interface in all type ac motor servo drive, form independent of intelligent digital servo control unit, it directly connected to the industrial field bus, it formed a new type of network control system based on field-bus.Reduced the number of hardware and the attachment, the structure of intelligent units on independent, to the outside world and realize data sharing between each other, but also can use other field control equipment, easy to extend.So far, the network communication server product in domestic has not yet mature.Robotics institute of Beijing university of aeronautics and astronautics development design a network based on DSP + FPGA + ASIPM ac servo control system, the principle prototype has been got preliminary validation of the three-dimensional carving machine. currently, the most server drive adopt high-speed DSP processors,which promote the movement of all kinds of advanced control algorithms in the use of new type of drive. Mostly, suppliers of servo system employ the structure of DSP + CPLD (FPGA) on the hardware. Because the DSP and CPLD (FPGA) can repeat programming,they are easy to realize modular re-configurable of the ac servo system.As long as the software for corresponding different system configurations, including the control algorithm can control and asynchronous motor, permanent magnet synchronous servo motor, brush-less dc motor, and through thereconfiguration of FPGA can also drive dc motor and three phase induction of stepping motor.It's for NC machine tool upgrade and innovation has left a lot of space.The development tendency of ac servoWith the constant improvement of productive forces, the ac servo system will be sophisticated in the direction of the integration, intelligent and network .integrationBy using a single and multi-function control unit, the servo system can achieve position control and speed control function through the setting of software and constitute a half closed loop feedback unit configuration or full closed loop control system of high accuracy through the external interface composition.intelligentServer intelligent control mode, such as internal programming can achieve a certain trajectory in advance and control the surrounding IO port as well as the adjustment of master-slave's following with electronic CAM, etc.networkServer implementation is distributed by network.The server's modulation could be reconstructed with low cost .conclusionThe modern NC machine tool is developing rapidly in the direction of high speed and high precision.As the essential component of the NC machine tool,servo system has gradually equated to ac servo system which has several incomparable advantages compared with other servo systems. With the progress of the ac servo technology, it will gradually replace dc servo system overall.[参考文献][1]Tryling, David P.Simple servo uses.ProQuest Journal,2009.[2]J. Cao ;Z.W. Li ;Z.X. Meng.Development Of A Nc Servo System Based On Fuzzy Adaptive Control.Key engineering materials,2009.[3]Fusaomi&Nagata.Development of CAM system based on industrial robotic servo controller without using robot languag.Robotics andComputer Integrated Manufacturing,2013.[4]Mulan Wang Kaiyun Xu Chuan He Lei Zhou.Research on Servo System for CNC Machine Tool Driven by Permanent Magnet Synchronous Torque Motor.Materials Engineering and Automatic Control,2012[5]Xu, Kaiyun Li, Ning Lin, Jian He, Chuan.Development of linear servo control system for CNC machine tool based on DSP.International Conference on Mechatronic Science, Electric Engineering and Computer,2011第二作业:典型曲线数字积分法插补方法2.1目的数字积分插补方法是实现数控插补功能的重要方法之一。

螺旋起重器设计一、 螺旋起重器〔千斤顶〕简介螺旋起重器是一种简单的起重装置,用手鞭策手柄即可升起重物。

它一般由底座、螺杆、螺母、托杯、手柄或扳手等零件所组成。

二、 螺旋起重器〔千斤顶〕布局与功能螺旋起重器布局示意图如右图所示。

零件1为托杯,当千斤顶承受重载时,由1直接托住重物。

螺母5与螺杆7组成螺旋副,同时,螺母5又与底座8固定联接,当动弹手柄4时,托杯便会随着螺杆而上下移动,从而将重物托起。

紧定螺钉6主要是为了提高了联接可靠性。

三、 设计标题问题设计起重量F = 50 000 N,最大起重高度H=150 mm 的螺旋起重器〔千斤顶〕。

四、 标题问题解答螺杆、螺母材料螺杆采用45钢调质,抗拉强度σb =600Mpa , σs =355Mpa 。

由于速度较低,螺母材料用铝青铜ZCuAll0Fe3。

2. 耐磨性计算按耐磨性性条件设计螺纹中径d 2,对于梯形螺纹,8.02≥d ][ψp F 螺杆选用45钢,螺母用铝青铜ZCuAll0Fe3,由参考文献[3]表 5.8 查得[]p =18~25MPa ,从表5.8注释中可以查得,人力驱动可提高约20%,则[]p =21.6 ~30MPa ,取[]p =25MPa 。

由参考文献[3]查得,对于整体式螺母系数ψ=1.2~1.5,取ψ=2。

则代入数据,得8.02≥d ][ ψp F ⨯=8.0√50 0002×25 =25.3 mm 式中:F ──螺杆所受轴向载荷, N ;2d ──螺纹中径,mm ;[ p ]─—螺旋副材料的许用压力,MPa 。

查参考文献[4]表 11.5 取公称直径d =32 mm,螺距P =3 mm,中径2d mm, 小径d 3〔d 1〕=28. 5 mm,内螺纹大径D 4 mm 。

3. 螺杆强度校核螺杆危险截面的强度条件为:σe =√(4F πd12)2+3(16T1πd13)2 ≤ [σe ]式中:F ──螺杆所受轴向载荷,F =50 000 N ;d 3〔d 1〕──螺纹小径,mm d 3〔d 1〕=28. 5 mm ;T 1──螺纹副摩擦力矩,T 1=F tan (φ+ρ’ )2d 2, ψ为螺纹升角,ψ=arctan npπ2d =arctan 1×3π×30.5=42°;[σe ]——螺杆材料的许用应力, MPa查参考文献[1]表 5.10 .得钢对青铜的当量摩擦因数 f ’~,取f ’= 0.09,螺纹副当量摩擦角ρ’ = arctan f ’ = = °。

数字信号处理上机实验报告学号:姓名:实验题目一1. 实验要求:序列卷积计算(1)编写序列基本运算函数,序列相加、相乘、翻转、求和;(2)使用自定义函数计算序列线性卷积,并与直接计算结果相比较。

两个序列分别为:() 1,05 0,others n nx n≤≤⎧=⎨⎩,()2,030,othersn nx n≤≤⎧=⎨⎩2. 实验过程和步骤:包含题目分析,实验程序和流程图(程序要有必要的注释)3. 实验结果和分析:包含程序运行结果图,结果分析和讨论(一)基本运算函数1.原序列2.序列相加序列相加程序function [y,n]=sigadd(x1,n1,x2,n2)%implements y(n)=x1(n)+x2(n)%---------------------------------------------% [y,n] = sigadd(x1,n1,x2,n2)% y = sum sequence over n, which includes n1 and n2% x1 = first sequence over n1% x2 = second sequence over n2 (n2 can be different from n1)%n=min(min(n1),min(n2)):max(max(n1),max(n2)); %duration of y(n) y1=zeros(1,length(n));y2=y1;y1(find((n>=min(n1))&(n<=max(n1))==1))=x1; %x1 with duration of y y2(find((n>=min(n2))&(n<=max(n2))==1))=x2; %x2 with duration of y y=y1+y2; %sequence addition3.序列相乘序列相乘程序function [y,n]=sigmult(x1,n1,x2,n2)%implements y(n)=x1(n)*x2(n)%---------------------------------------------% [y,n] = sigmult(x1,n1,x2,n2)% y = product sequence over n, which includes n1 and n2% x1 = first sequence over n1% x2 = second sequence over n2 (n2 can be different from n1)%n=min(min(n1),min(n2)):m(min(n1),min(n2)) %duration of y(n)y1=zeros(1,length(n));y2=y1;y1(find((n>=min(n1))&(n<=max(n1))==1))=x1; %x1 with duration of y y2(find((n>=min(n2))&(n<=max(n2))==1))=x2; %x2 with duration of y y=y1.*y2; %sequence multiplication4.序列翻转序列翻转程序function [y,n]=sigfold(x, n)%implements y(n)=x(-n)%--------------------------------------------- % [y,n] = sigfold(x,n)%y=fliplr(x);n=-fliplr(n);5.序列移位序列移位程序function [y,n]=sigshift(x,m,n0)%implements y(n)=x(n-n0)%--------------------------------------------- % [y,n] = sigshift(x,m,n0)%n=m+n0;y=x;主程序x1=[0:5];x2=[0,1,2,3];n1=0:5;n2=0:3;%N=n1+n2-1;figure(1)subplot(211)stem(x1)xlabel('x1')subplot(212)stem(x2)xlabel('x2')title('原序列')x= sigadd(x1,n1,x2,n2);figure(2)stem(x)xlabel('x1+x2')title('序列相加')figure(3)[x,n] = sigfold(x1,n1);stem(n,x)xlabel('x1(-n)')title('序列翻转')[x,n] = sigshift(x,n,2);figure(4)stem(n,x)xlabel('x1(-n+2)')title('序列移位')x= sigmult(x1,n1,x2,n2);figure(5)stem(x)title('序列相乘')xlabel('x1*x2')(二)自定义函数计算线性卷积1.题目分析使用上一题中的序列相乘、翻转和求和子函数计算线性卷积,并与这直接用conv 函数计算的线性卷积结果相比较。

H a r b i n I n s t i t u t e o f T e c h n o l o g y机械设计大作业说明书大作业名称:机械设计大作业设计题目:螺旋传动设计班级:设计者:学号:指导教师:宋宝玉设计时间:2014·10·03哈尔滨工业大学目录1设计题目-------------------------------------------------------------------------------------------------------3 2螺母、螺杆选材----------------------------------------------------------------------------------------------3 3耐磨性计算-----------------------------------------------------------------------------------------------------3 4螺杆强度校核-------------------------------------------------------------------------------------------------3 5螺纹牙强度校核----------------------------------------------------------------------------------------------4 6螺纹副自锁条件校核---------------------------------------------------------------------------------------5 7螺杆稳定性校核----------------------------------------------------------------------------------------------5 8螺母外径及凸缘设计---------------------------------------------------------------------------------------6 9手柄设计--------------------------------------------------------------------------------------------------------6 10底座设计-------------------------------------------------------------------------------------------------------7 11各部分尺寸及参数-----------------------------------------------------------------------------------712参考资料-------------------------------------------------------------------------------------------------------81、设计题目螺旋起重器(千斤顶)已知条件:3.1.2起重量Q F =40KN ,最大起重高度H=200mm 。

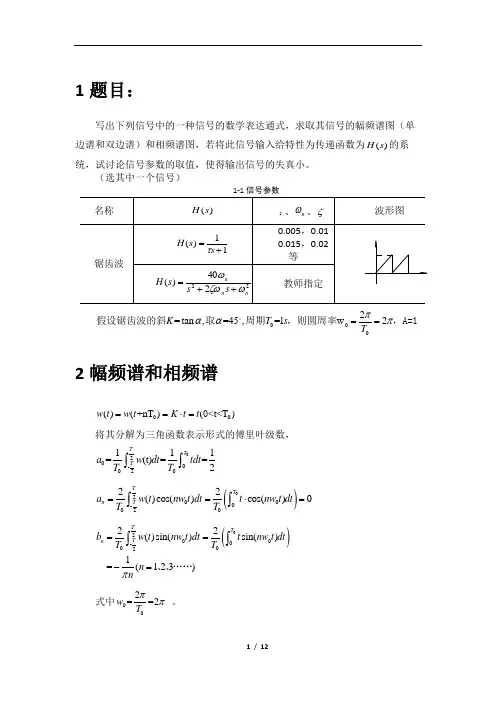

HarbinInstitute of Technology课程大作业说明书课程名称:院系:班级:设计者:学号:指导教师:设计时间:哈尔滨工业大学目录信号的分析与系统特性........................ (3)一、设计题目……………………………………………………………………3二、求解信号的幅频谱和相频谱............ (3)三、频率成分分布情况 (5)四、H(s)伯德图 (6)五、将此信号输入给特征为传递函数为H(s)的系统 (7)传感器综合运用 (10)一、题目要求 (10)二、方案设计……………………………………………………………………10三、传感器的选择………………………………………………………………11四、总体测量方案 (12)五、参考文献 (12)信号的分析与系统特性一、设计题目写出下列方波信号的数学表达通式,求取其信号的幅频谱图(单边谱和双边谱)和相频谱图,若将此信号输入给特性为传递函数为)(s H 的系统,试讨论信号参数的取值,使得输出信号的失真小。

名称)(s H、、波形图 方波11)(+=s s H τ=0。

1,0。

5,0.70722240)(nn n s s s H ωζωω++= =0。

5,0.707 =10,500作业要求(1)要求学生利用第1章所学知识,求解信号的幅频谱和相频谱,并画图表示出来。

(2)分析其频率成分分布情况。

教师可以设定信号周期及幅值,每个学生的取值不同,避免重复.(3)利用第2章所学内容,画出表中所给出的系统)(s H 的伯德图,教师设定时间常数或阻尼比和固有频率的取值.(4)对比2、3图分析将2所分析的信号作为输入)(t x ,输入给3所分析的系统)(s H ,求解其输出)(t y 的表达式,并且讨论信号的失真情况(幅值失真与相位失真)若想减小失真,应如何调整系统)(s H 的参数。

二、求解信号的幅频谱和相频谱002200-200211=(t)=+-=0TT T T T a w dt Adt Adt T T ⎛⎫ ⎪⎝⎭⎰⎰⎰tTT 0/A00220000-200222()cos()cos()-cos()0TT T T T n a w t nw t dt A nw t dt A nw t dt T T ⎛⎫==+= ⎪⎝⎭⎰⎰⎰00220000-20020000000022()sin()sin()-sin()4 2 cos()-cos()200 2TTT T T n b w t nw t dt A nw t dt A nw t dt T T A T T n A A nw t nw t nT T nw nw n π⎛⎫==+ ⎪⎝⎭⎛⎫⎧⎪ ⎪==⎨ ⎪ ⎪⎪⎩⎝⎭⎰⎰⎰为奇数为偶数式中000411(t)=(sin(w t)+sin(3w t)+sin(5w t)+)35Aw π…转换为复指数展开式的傅里叶级数:()()0000000000002-j 000-2000000011=(t)e=e +-e 1121 =(e -e ) =e -e | =e -e = 2T jnw tnw tjnw t n T jnw t jnw t jnw t jnw t jnw jnw c w dt A dt A dt T T A A AA dt j T T jnw T nw j n ττττττπ-----⎛⎫ ⎪⎝⎭⎰⎰⎰⎰当0,2,4,...n =±±时,0n C =; 当1,3,5,...n =±±±时,2n A C j n π=-则幅频函数为:2,1,3,5,...n AC jn n π=-=±±±42||,1,3,5,...n n AA C n n π===相频函数为:arctanarctan(),1,3,5, (2)nI n nR C n C πϕ==-∞=-=arctanarctan(),1,3,5, (2)nI n nR C n C πϕ==+∞==---双边幅频图:单边幅频图:相频图:三、频率成分分布情况由信号的傅里叶级数形式及其频谱图可以看出,矩形波是由一系列正弦波叠加而成,正弦波的频率由到3,5……,其幅值由4Aπ到43Aπ,45Aπ,……依次减小,各频率成分的相位都为0。