掩膜版(mask)制造技术

- 格式:doc

- 大小:3.14 MB

- 文档页数:40

光掩膜(mask)资料整理本文将收集涉及光掩膜从材料到检测的一些资料,进行整理和粗略的概括。

在半导体制造的整个流程中,其中一部分就是从版图到wafer制造中间的一个过程,即光掩膜或称光罩(mask)制造。

这一部分是流程衔接的关键部分,是流程中造价最高的一部分,也是限制最小线宽的瓶颈之一。

光掩膜除了应用于芯片制造外,还广泛的应用与像LCD,PCB等方面。

常见的光掩膜的种类有四种,铬版(chrome)、干版,凸版、液体凸版。

主要分两个组成部分,基板和不透光材料。

基板通常是高纯度,低反射率,低热膨胀系数的石英玻璃。

铬版的不透光层是通过溅射的方法镀在玻璃下方厚约0.1um的铬层。

铬的硬度比玻璃略小,虽不易受损但有可能被玻璃所伤害。

应用于芯片制造的光掩膜为高敏感度的铬版。

干版涂附的乳胶,硬度小且易吸附灰尘,不过干版还有包膜和超微颗粒干版,其中后者可以应用于芯片制造。

(顺便提一下,通常讲的菲林即film,底片或胶片的意思,感光为微小晶体颗粒)。

在刻画时,采用步进机刻画(stepper),其中有电子束和激光之分,激光束直接在涂有铬层的4-9“玻璃板上刻画,边缘起点5mm,与电子束相比,其弧形更逼真,线宽与间距更小。

光掩膜有掩膜原版(reticle mask,也有称为中间掩膜,reticle作为单位译为光栅),用步进机重复将比例缩小到master maks上,应用到实际曝光中的为工作掩膜(working mask),工作掩膜由master mask复制过来。

以下是具体的制造流程和检测流程:1,数据转换??将如GDSII版图格式分层,运算,格式转换为设备所知的数据形式。

(这一部分会产一些具体的描述)2,图形产生??通过电子束或激光进行图形曝光。

3,光阻显影??曝光多余图形,以便进行蚀刻。

4,铬层刻蚀??对铬层进行刻蚀,保留图形。

5,去除光阻??去除多余光刻胶。

6,尺寸测量??测量关键尺寸和检测图形定位。

7,初始清洗??清洗并检测作为准备。

详解掩膜mask什么是掩膜(mask)数字图像处理中的掩膜的概念是借鉴于PCB制版的过程,在半导体制造中,许多芯⽚⼯艺步骤采⽤光刻技术,⽤于这些步骤的图形“底⽚”称为掩膜(也称作“掩模”),其作⽤是:在硅⽚上选定的区域中对⼀个不透明的图形模板遮盖,继⽽下⾯的腐蚀或扩散将只影响选定的区域以外的区域。

图像掩膜与其类似,⽤选定的图像、图形或物体,对处理的图像(全部或局部)进⾏遮挡,来控制图像处理的区域或处理过程。

光学图像处理中,掩模可以是胶⽚、滤光⽚等。

数字图像处理中,掩模为⼆维矩阵数组,有时也⽤多值图像。

数字图像处理中,图像掩模主要⽤于:①提取感兴趣区,⽤预先制作的感兴趣区掩模与待处理图像相乘,得到感兴趣区图像,感兴趣区内图像值保持不变,⽽区外图像值都为0。

②屏蔽作⽤,⽤掩模对图像上某些区域作屏蔽,使其不参加处理或不参加处理参数的计算,或仅对屏蔽区作处理或统计。

③结构特征提取,⽤相似性变量或图像匹配⽅法检测和提取图像中与掩模相似的结构特征。

④特殊形状图像的制作。

掩膜是⼀种图像滤镜的模板,实⽤掩膜经常处理的是遥感图像。

当提取道路或者河流,或者房屋时,通过⼀个n*n的矩阵来对图像进⾏像素过滤,然后将我们需要的地物或者标志突出显⽰出来。

这个矩阵就是⼀种掩膜。

⽤选定的图像、图形或物体,对待处理的图像(全部或局部)进⾏遮挡,来控制图像处理的区域或处理过程。

⽤于覆盖的特定图像或物体称为掩模或模板。

光学图像处理中,掩模可以⾜胶⽚、滤光⽚等。

数字图像处理中,掩模为⼆维矩阵数组,有时也⽤多值图像。

数字图像处理中,图像掩模主要⽤于:①提取感兴趣区,⽤预先制作的感兴趣区掩模与待处理图像相乘,得到感兴趣区图像,感兴趣区内图像值保持不变,⽽区外图像值都为0。

②屏蔽作⽤,⽤掩模对图像上某些区域作屏蔽,使其不参加处理或不参加处理参数的计算,或仅对屏蔽区作处理或统计。

③结构特征提取,⽤相似性变量或图像匹配⽅法检测和提取图像中与掩模相似的结构特征。

掩膜版制造工艺_迎接45和32nm节点新挑战掩膜版制造工艺:迎接45和32nm节点新挑战whpzzseu123 发表于: 2007-7-06 10:18 来源: 半导体技术天地掩膜版制造工艺:迎接45和32nm节点新挑战随着集成电路制造工艺的飞速发展,45和32nm技术节点已成为近两年人们谈论的热点,作为集成电路制造工艺中最关键的光刻工艺首当其冲成为热点中的焦点。

浸入式光刻(Immersion)、两次曝光技术(Double Patterning)、超紫外光刻(EUV)反复被人们提及,而作为光刻工艺三要素之一的掩膜版却往往容易被人们忽略。

从概念上讲曝光系统的工作原理与相机类似,通过一系列光学系统将掩膜版上的图形按照4:1的比例投影在晶圆上的光刻胶涂层上。

从理论上讲,如果晶圆上的最小线宽(Critical Dimension)要达到45或32nm,掩膜版上的图形最小线宽(CD)只要达到180或128nm即可,与其他制作工艺相比,掩膜版的制造工艺相对要“容易”了很多。

但掩膜版如同投影用的电影胶片的底片一样,它的技术水平直接影响着光刻技术的发展,特别是随着最小线宽的逐渐缩小,投影到光刻胶涂层上的图形对比度和图形失真等问题将越演越烈,掩膜版制造将如何从设备、工艺、版图设计等多方面着手以应对45和32nm工艺节点的新挑战?掩膜版制造设备的最新进展谈到掩膜版,首先要谈到掩膜版制造设备——图形发生器(Pattern Generator)。

目前,掩膜版制造设备供应商主要有三家:Micronic、Jeol和NuFlare,制作工艺分为激光和电子束两种图形描绘方式,但两种方式各有利弊。

采用激光来描绘图形的优势是速度快、效率高,但精度不如电子束扫描方式;而采用电子束描绘图形,虽然精度高,但描绘速度慢、生产效率低。

由于两种方式的互补性,掩膜版制造商会分别购买两种设备,当制备线宽要求很高的电路图形时使用电子束扫描,对于线宽要求不是很高的电路图形则使用激光扫描,两种设备的交替使用既满足了精度要求,也大大提高了速度,同时也大大降低了制造商的投资成本。

掩模制造工艺掩模制造工艺,这可是个挺神秘又超有趣的事儿呢。

就好比咱们小时候玩的手工贴纸。

掩模就像是那特别定制的贴纸,不过这贴纸可不得了,是为了在半导体制造、平板显示等高端领域里大显身手的。

做掩模啊,就像是精心打造一把独特的钥匙,这把钥匙要能精准地开启微观世界里那些奇妙结构的大门。

先说说做掩模的材料。

这材料得是那种超级精细、高度稳定的。

就像咱们盖房子,地基得打得牢,这材料就是掩模的地基。

有的材料像石英玻璃,那是又纯净又透明,在上面搞创作就像在一张洁白无瑕的画布上画画一样,只不过这画画得用高科技手段。

而且这材料的热膨胀系数得特别小,为啥呢?要是热胀冷缩太厉害,那做出来的掩模就像一个调皮的小孩子,到处变形,就没法精准地工作啦。

再讲讲图案绘制。

这可不像咱们随便涂鸦那么简单。

那是要用电子束曝光或者激光直写这些超级厉害的技术。

想象一下,电子束就像一个超级小的笔,这个笔的笔尖啊,小到咱们肉眼根本看不到,它在掩模材料上一笔一笔地刻画着那些复杂的电路图案或者微小的结构。

这就像是一个超级细心的工匠,在一粒米上雕刻出一座精致的小房子一样神奇。

激光直写呢,就像是用一束超强的光剑,按照预定的路线在掩模上留下痕迹,这些痕迹组成的图案就是整个工艺的核心密码。

清洗环节也很关键。

掩模制造过程中,要是有一点点小灰尘或者杂质留在上面,那就像是米饭里混进了小石子,会把整个好事儿给搅黄了。

所以清洗的时候得像给宝贝洗澡一样小心翼翼。

用特殊的化学溶液,就像给掩模做一个舒服的温泉浴,把那些脏东西都给泡走。

而且清洗的设备也得很高级,得能全方位无死角地把掩模洗得干干净净。

检测这一步就像是考试打分一样。

要看看做出来的掩模到底合不合格。

用各种高端的检测设备,像显微镜这些,但是这显微镜可不是咱们普通的显微镜,那可是能把掩模上的微观世界放大到能看清每一个小细节的神器。

如果发现有哪里不对劲,就像发现一幅画里的人物少了一只眼睛一样,得赶紧返工。

掩模制造工艺就像是一场精心编排的舞蹈。

掩模板的制作过程在IC加⼯过程中,需要使⽤中间掩模版和光掩模版。

我们定义中间掩模版是为整个基⽚曝光⽽必须分步和重复的包含图像的⼯具。

通常图像的尺⼨被放⼤到基⽚上图像的2倍到20倍,但在⼀些情况下也⽤相等的图像。

光掩模版被定义为在⼀次曝光中能把图形转移到整个硅⽚中(或另⼀张光掩模版上)的⼯具。

中间掩模版有两种应⽤:1)把图形复印到⼯作掩模版上。

2)在分步重复对准仪中把图像直接转移到硅⽚上。

在1X硅⽚步进光刻机中,掩模版上的图形与投影到硅⽚上图形⼀样⼤;在缩⼩步进光刻机中,掩模版上的图形是放⼤的真实器件图像。

在VLSI中,电⼦束曝光10X或5X的掩模版,或直接⽤电⼦束产⽣1X 的⼯作掩模版玻璃的质量和准备:⽤以制作掩模版的玻璃必须内部和两表⾯都物缺陷。

必须于光刻胶的曝光波长下有⾼的光学透射率。

被⽤来制作掩模版的玻璃有好⼏种,包括:a)钠钙玻璃b)硼硅玻璃c)⽯英玻璃。

绿⾊的钠钙玻璃和低钠⽩钠钙玻璃(贵50%)容易被拉制成⼤⾯积的薄张,⽽且表现出很好的质量,它们热膨胀系数⾼(93×10- 7cm/cm°c),使得它门⼤⼤不适合在投影中应⽤。

在应⽤中要求低的热膨胀系数的材料,就选择硼硅玻璃和⽯英玻璃(热膨胀系数分别是37和5×10- 7cm/cm°c)。

在⼀些情况下,周围温度的变化导致硅⽚上图形的定位错误,此时就要求选择硼硅玻璃和⽯英玻璃。

⽯英圆⽚是超低膨胀系数的玻璃,它的热膨胀系数⾮常⼩。

⽯英玻璃同样在深UV和近深UV区域内有很⾼的穿透系数。

⽯英相当贵,现在倾向于发展⾼质量的合成⽯英材料。

天然⽯英通过⽕焰熔融法加⼯,⽤氧氢⽓溶化岩⽯晶体。

合成⽯英是⽤超纯SiCl4,它提供宽的光投射铝区域,低的杂质含量和少的物理缺陷。

它的应⽤随着低膨胀率和深UV的要求变得逐渐⼴泛。

圆⽚被抛光、清洗,在形成掩模图像之前被检查。

抛光是个多重步骤,在图⽚两个表⾯连续不断地分级研磨。

图⽚在检测和掩模之前被清洗、冲洗、⼲燥。

光掩膜版生产工艺技术

光掩膜版生产工艺技术是一种常用的印刷工艺,它可以用于制作各种类型的印刷品,如海报、宣传单、名片等。

这种工艺技术的主要特点是使用光掩膜版来制作印刷版,这种版可以在印刷过程中起到非常重要的作用。

光掩膜版生产工艺技术的制作过程主要包括以下几个步骤:

1. 设计制版:首先需要根据印刷品的要求,设计出相应的版面。

这个过程需要考虑到印刷品的尺寸、颜色、字体等因素。

2. 制作光掩膜版:在设计好版面之后,需要将版面转移到光掩膜版上。

这个过程需要使用一种特殊的设备,将版面的图案透过光掩膜版上的透明部分转移到版面上。

3. 制作印刷版:在制作好光掩膜版之后,需要将其转移到印刷版上。

这个过程需要使用一种特殊的设备,将光掩膜版上的图案透过印刷版上的透明部分转移到印刷版上。

4. 印刷:在制作好印刷版之后,就可以进行印刷了。

这个过程需要使用一种特殊的设备,将印刷版上的图案透过印刷机上的印刷媒介转移到印刷品上。

光掩膜版生产工艺技术的优点是可以制作出非常精细的印刷品,同时也可以制作出大量的印刷品。

这种工艺技术的缺点是制作成本较

高,需要使用一些特殊的设备和材料。

光掩膜版生产工艺技术是一种非常重要的印刷工艺技术,它可以制作出高质量的印刷品,同时也可以满足大量印刷的需求。

在今后的印刷行业中,这种工艺技术将会继续得到广泛的应用和发展。

光掩膜(mask)资料:在半导体制造的整个流程中,其中一部分就是从版图到wafer制造中间的一个过程,即光掩膜或称光罩(mask)制造。

这一部分是流程衔接的关键部分,是流程中造价最高的一部分,也是限制最小线宽的瓶颈之一。

光掩膜除了应用于芯片制造外,还广泛的应用与像LCD,PCB等方面。

常见的光掩膜的种类有四种,铬版(chrome)、干版,凸版、液体凸版。

主要分两个组成部分,基板和不透光材料。

基板通常是高纯度,低反射率,低热膨胀系数的石英玻璃。

铬版的不透光层是通过溅射的方法镀在玻璃下方厚约0.1um的铬层。

铬的硬度比玻璃略小,虽不易受损但有可能被玻璃所伤害。

应用于芯片制造的光掩膜为高敏感度的铬版。

干版涂附的乳胶,硬度小且易吸附灰尘,不过干版还有包膜和超微颗粒干版,其中后者可以应用于芯片制造。

(顺便提一下,通常讲的菲林即film,底片或胶片的意思,感光为微小晶体颗粒)。

在刻画时,采用步进机刻画(stepper),其中有电子束和激光之分,激光束直接在涂有铬层的4-9“ 玻璃板上刻画,边缘起点5mm,与电子束相比,其弧形更逼真,线宽与间距更小。

光掩膜有掩膜原版(reticle mask,也有称为中间掩膜,reticle作为单位译为光栅),用步进机重复将比例缩小到master maks上,应用到实际曝光中的为工作掩膜(working mask),工作掩膜由master mask复制过来。

以下是具体的制造流程和检测流程:1,数据转换将如GDSII版图格式分层,运算,格式转换为设备所知的数据形式。

(这一部分会产一些具体的描述)2,图形产生通过电子束或激光进行图形曝光。

3,光阻显影曝光多余图形,以便进行蚀刻。

4,铬层刻蚀对铬层进行刻蚀,保留图形。

5,去除光阻去除多余光刻胶。

6,尺寸测量测量关键尺寸和检测图形定位。

7,初始清洗清洗并检测作为准备。

8,缺陷检测检测针孔或残余未蚀刻尽的图形9,缺陷补偿对缺陷进行修补。

掩膜版薄膜工艺

掩膜版薄膜工艺,也称为掩膜法薄膜工艺,是一种在薄膜制备过程中使用掩膜版进行模板化形状制作的方法。

以下是它的基本步骤:

1.设计模板:根据需要制作的薄膜形状,设计制作相应的掩

膜版。

掩膜版通常由透明或半透明的材料制成,如聚酯薄

膜或玻璃,上面印有所需的图案或形状。

2.准备基材:选择适当的基材进行准备。

常用的基材包括聚

合物薄膜(如聚酯薄膜、聚酰胺薄膜等)、玻璃、金属等。

3.准备薄膜涂料:根据需要制备的薄膜材料,准备相应的薄

膜涂料。

薄膜涂料可以是液态或溶液状,并根据需求可以

添加颜料或其他添加剂。

4.涂覆掩膜版:将准备好的薄膜涂料均匀涂覆在掩膜版上,

可以使用刮刀、喷涂或滚涂等方法。

确保涂料均匀、厚度

合适。

5.掩膜印刷:将涂覆有薄膜涂料的掩膜版与基材接触,轻轻

压在基材上,使薄膜涂料与基材接触并附着。

一般采用平

板印刷的方式进行掩膜印刷,也可以使用其他印刷方法。

6.固化和剥离:经过一定的固化时间,使薄膜涂料在基材上

完全固化。

然后,将掩膜版从基材上剥离,使形成的薄膜

保留在基材上。

7.后处理:根据需要,可以对薄膜进行后处理,如烘干、硬

化、清洗等,以进一步改善薄膜品质和性能。

掩膜版薄膜工艺适用于许多应用,如柔性显示器、光学薄膜、微电子器件等领域。

它允许制备出具有特定形状和性能的薄膜,具有一定的灵活性和可塑性。

掩模制作技术目录掩模制作掩模材料制备掩模制作掩模材料制备展开掩模制作技术是半导体工艺技术中制作光刻工艺用的光复印掩蔽模版的技术,亦称制版技术。

编辑本段掩模制作半导体集成电路制作过程通常需要经过多次光刻工艺,在半导体晶体表面的介质层上开凿各种掺杂窗口、电极接触孔或在导电层上刻蚀金属互连图形。

光刻工艺需要一整套(几块多至十几块)相互间能精确套准的、具有特定几何图形的光复印掩蔽模版,简称光掩模版。

光掩模版是光刻工艺中复印光致抗蚀掩蔽层的“印相底片”。

随着大规模集成电路工艺技术的迅速发展,对光掩模版的质量,包括各种掩模精度、缺陷密度和掩模版的耐用性能等都提出了极高的要求。

以64千位MOS存储器光掩模版为例,每个芯片单元有效面积 0.22~0.28厘米2内含约15万个元件、器件;最细的线宽约2~3微米;套刻精度约±0.5~±1微米;掩模版的分步重复精度、定位精度等都必须控制在±0.1~±0.25微米范围以内。

此外,光掩模版的随机缺陷密度对芯片成品率的影响,将满足博塞-爱因斯坦分布,即芯片成品率随着单元有效面积的增大或随机缺陷密度的增大而按负指数关系急剧下降。

据推算,若要达到95%以上的成品率,掩模版的缺陷密度必须控制在每平方厘米0.175 个以下。

如果缺陷密度增大到每平方厘米1.25个,则成品率因缺陷的直接影响会下降到65%以下。

因此,光掩模版质量的优劣直接影响光刻工艺的质量,从而影响半导体器件或集成电路的电学性能、可靠性和芯片成品率。

光掩模制作技术大体上可分为传统的刻图缩微制版技术系统、计算机辅助设计、光学图形发生器自动制版技术系统和以电子束扫描成像为代表的各种短波长射线成像曝光技术系统。

①刻图缩微制版技术最初是从印刷工业中的印刷制版技术移植到微电子工艺技术中来的。

制作一套光掩模版需要经过复杂的过程。

首先需要根据半导体器件或集成电路电学参数的要求、工艺条件和精度的要求确定适当的放大倍率来绘制掩模原图。

光掩膜版生产工艺技术光掩膜版生产工艺技术一、前言光掩膜版,是一种由晶体石英片(微孔材料)表面再经过规整成表面微噪波的器件,其原理是:利用有规律的微孔材料受外力激励,对场在其表面的光线产生一种反射或折射的效应。

由于“微噪波成像”的原理,光的反射效果可以利用 UV 光照射,使“微噪波成像”的准确性达到最大,而反射效果则可以根据具体应用与所需的频率来确定其具体而灵活的结构形式,如波长,反射率,电磁波的折射率。

其功能是基于圆形或椭圆形的微孔材料表面,在其中可以塑造出各种光线在表面上的不同反射特性,对于不同的光源,可以捕获和反射,可以抑制反射,可以实现抗阻力等作用。

二、光掩膜版生产方法1、光掩膜版的制作方法(1)制备光膜晶体石英片:将原料加入搅拌机中,搅拌至所需相,然后倒入热油槽中加热,逐步加热,循环搅拌,继续加热,然后将其加入模具中成型,即可出现光膜晶体石英片。

(2)表面处理:将光膜晶体石英片放入特殊的表面处理容器中,采用特殊的液体进行表面处理。

通常表面处理液体是有机溶剂,其功能是去除污染物,使光膜晶体石英片表面光滑。

(3)光掩膜结构处理:将光膜晶体石英片的表面放入特殊的结构处理仪器内,使用特殊的物料清洗及结构化处理。

2、光掩膜版的制作流程(1)将原料加入搅拌机中,搅拌至所需相,然后倒入热油槽中加热,逐步加热,循环搅拌,继续加热,然后将其加入模具中进行成型;(2)将光膜晶体石英片放入特殊的表面处理容器中,采用特殊的液体进行表面处理,去除污染物,使其表面光滑;(3)将光膜晶体石英片的表面放入特殊的结构处理仪器内,使用特殊的物料清洗及结构化处理;(4)将光膜晶体石英片放入光学调试仪中,逐步调整光的反射率、折射率及电磁波的折射率,使其在反射、折射和抑制反射各方面达到最佳效果;(5)将已调整好的光膜晶体石英片放入封装装置中,进行封装,完成光掩膜版的制作。

三、结论光掩膜版是一种具有高性能、高精度、高特性的光学器件,在我国已大量应用于各种光学仪器及光电产品中。

如何高效制造掩膜?一起来了解掩膜制造工

艺!

掩膜在电子制造行业中扮演着重要的角色,它可以在制造过程中防止光照和化学物质的污染,从而保护电路板上的金属线路不受损坏。

那么,接下来我们就来了解掩膜的制造工艺。

第一步:确定掩膜的尺寸和形状。

在制造掩膜之前,必须先确定它的尺寸和形状,这是制造掩膜的第一步。

通常,我们会使用计算机软件来帮助我们设计掩膜,需要注意的是,设计出来的掩膜必须符合实际制造的要求。

第二步:准备基板材料。

制造掩膜的下一步是准备基板材料,基板通常采用的是聚酰亚胺(PI),聚四氟乙烯(PTFE)等高温材料,能够耐受高温和有机溶剂的腐蚀。

第三步:涂覆光刻胶。

将光刻胶涂覆在基板上,使其均匀分布。

然后,将基板放在紫外灯下,使用模板使光刻胶暴露在光源下。

紫外线照射使光刻胶与基板产生反应,形成固体图案,即为掩膜。

第四步:去除未固化的光刻胶。

去除未固化的光刻胶,这通常使用化学溶剂,如盐酸或高温去离子水,这可以去除未固化的光刻胶,并将图案固定在基板上。

第五步:铜化。

将铜化液体倒入容器中,放入固定的掩膜。

在铜化液体中进行电镀或浸泡,形成需求的金属芯片。

通过以上几个步骤,我们就可以完成掩膜的制造了。

这一工艺需要仔细操作,确保掩膜质量稳定,以保证成品的质量可靠性。

纳米刻蚀工艺中的掩膜版设计与制作流程一、概述纳米刻蚀工艺是制造纳米级结构的重要步骤,而掩膜版的设计与制作则是该工艺的关键环节。

掩膜版作为光刻机的光学模板,将光线精确地投射到待蚀刻的区域,从而实现精确的纳米级加工。

二、设计阶段1. 确定设计目标:根据具体的应用需求,确定所需的纳米结构形状、尺寸和位置。

2. 绘制设计图:根据确定的设计目标,使用CAD软件绘制出精确的掩膜版设计图。

设计图应包括所需的纳米结构形状、尺寸、间距和位置等信息。

3. 审核与修改:对设计图进行审核,如发现有误或需要修改的地方,及时进行调整和修改。

三、制作阶段1. 准备材料:选用适合制作掩膜版的材料,如聚酰亚胺、聚对苯二甲酸乙二醇酯(PET)等。

这些材料具有优异的绝缘性、耐热性和耐化学品性。

2. 制版前处理:清洗材料表面,去除污染物和杂质,保证材料的洁净度。

3. 涂胶:将材料表面的涂胶层涂覆均匀,保证光刻胶的附着力。

4. 曝光:使用激光曝光机将设计图转移到光刻胶上。

这一步骤需要精确控制曝光时间和功率,以保证光刻胶的曝光质量。

5. 显影与去胶:显影是将光刻胶中的透明部分去除,形成与设计图相同的图形。

去胶则是将光刻胶从材料上分离下来。

这一步骤需要严格控制显影时间和温度,以保证掩膜版的完整性。

6. 后处理:对掩膜版进行后处理,如清洗、整形、检验等,保证其质量。

总结:掩膜版的设计与制作是纳米刻蚀工艺中至关重要的一环。

通过对材料的选择和处理,以及对光刻胶的涂覆、曝光、显影和去胶等步骤的精确控制,可以制作出高质量的掩膜版,为纳米刻蚀工艺提供可靠的支撑。

实际操作中还需根据具体情况进行不断的尝试和改进,以实现更高的精度和更优的性能。

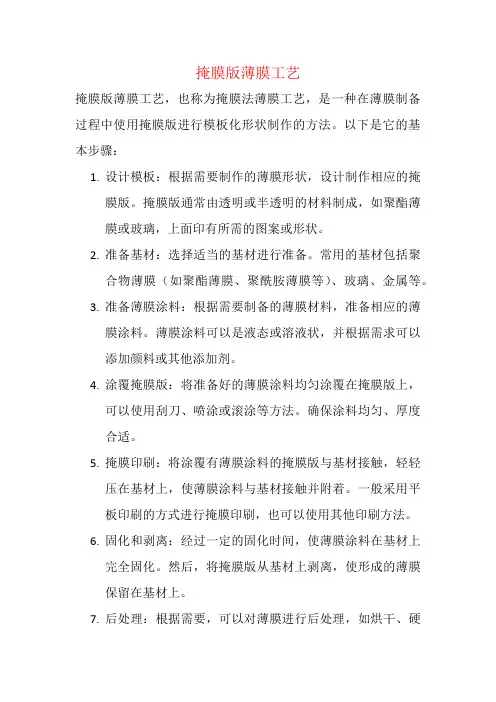

Photomask MakingRoger Robbins 3/6/2007The University of Texas at DallasErik Jonsson School of EngineeringTitle: Photomask Making Page 1 of 24Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasPhotomask MakingRoger Robbins 3/6/2007Table of ContentsPhotomask Making (2)Table of Contents (2)Photomask Making (3)Purpose (3)Introduction (3)Mask “Color” (3)Process Description (4)Step 1: Plasma Cleaning (4)Step 2: HMDS Application (5)Step 3: Resist Application (6)Step 4: Pre-Bake (8)Step 5: Lithographic Patterning (8)Step 6: Post Bake (10)Step 7: Develop (10)Step 8: Plasma De-scum (11)Step 9: Cr Etch (12)Step 10: Resist Removal and Mask Clean (12)Step 11: Final Inspection (14)Conclusion (14)Appendix A (15)Appendix B (18)Title: Photomask Making Page 2 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasPhotomask MakingRoger Robbins 3/6/2007PurposeThis paper describes a starting process for making photomasks with the tools in the UTD Cleanroom. Special needs may dictate variations in this process flow.IntroductionPhotomasks are generally Chrome coated glass lithographic templates designed to optically transfer patterns to wafers or other substrates in order to fabricate planar type devices of all types. Basically the pattern information is created in a drawing package and stored in a database, reformatted and transferred to a lithography tool –laser writer or e-beam writer in our case – then printed in a layer of photoresist coated onto the photomask plate. The imaged pattern is next developed to form a template over the opaque Chrome and then the Chrome is etched away where the resist is clear. After the etch process is complete, the remaining photoresist is removed, the plate cleaned, and then stored for later use in an optical printer.This paper will describe in detail all the fundamental process steps required to fabricate a photomask in the UTD Cleanroom Labs.Figure 1. Example of standard photomasks: “Clear field” on left, “dark field” on rightMask “Color”First, there are some key details to discuss that determine what “color”photomask you will need to make, (Figure 1). Normally, we use “positive” photoresist to make masks. This means that wherever light exposes the photoresist, the developer will wash away the photoresist. This exposed area, then, will expose the Chrome and allow it to be washed away in the acid etch solution, leaving holes in the Chrome throughTitle: Photomask Making Page 3 of 24Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at Dallaswhich light will pass to expose the substrate during the pattern transfer process – (Dark Field mask color).Following that logic, if the substrate also has positive photoresist, the mask will allow exposure to the substrate in the same pattern as the clear regions on the mask. The development of the substrate resist will produce exposed areas in the same location as the clear areas on the mask. This will allow an etch process to transfer the clear area pattern to an underlying film by etching away the underlying film in the clear area.This may seem simple to the casual observer, but there is a complication when you consider the common “lift-off” process which will change the “color” of the pattern on the substrate. In the lift-off process, the patterned substrate is first developed and then a film is deposited on top of the patterned resist. The next step strips the resist under the deposited film. This will leave a pattern of deposited film in the areas where the positive photoresist was exposed and leave bare the areas under the unexposed resist that were washed away, taking the deposited film away with the wash.Then to further complicate a complicated logic, there is negative photoresist which stays put when exposed and washes away in unexposed areas. This negative process does the opposite thing to the above positive resist. The resists can be used either on the mask or the substrate in any order. Thus you must keep exact logical understanding and control of your process in order to make what you want.Process DescriptionThe following process description will assume that we start with a bare, blank photomask and describe all the steps to fabricate a complete mask. There may be sections that are optional or unnecessary due to the particular situation you have, such as a pre-coated mask that does not need to be coated with photoresist.Step 1: Plasma CleaningBoth new and recycled bare photomasks may have a thin invisible layer of organic contamination on the Cr surface. This organic layer will sometimes cause adhesion problems between the Cr and the photoresist later in the process. It also may interfere with the Cr etch process after photomask imaging. However it is easy to remove the contamination with a short, but aggressive Oxygen plasma treatment before starting the photomask process. The current process designed and tested for this purpose is shown in Table 1. It uses the March Asher1 tool, (Figure 2), but fortunately it can be used in any other month of the year as well. ☺Table IMarch Asher Cleaning*Step Parameter Value1 Vacuum Pressure 230 mTorr2 Gas O23 Gas Flow 31 sccm4 Time 600 sec1 Roger Robbins, “March Asher Operation,”/~rar011300/public_html/MarchAsher/MarchAsherOperation.pdf,(7/31/2006)Title: Photomask Making Page 4 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at Dallas*Set the photomask Cr side up on the poweredelectrode plate for RIE conditions.Figure 2. March Plasma Asher tool: RF power supply at left, Control section in center,and access door to RF plasma chamber on right.Step 2: HMDS ApplicationIn order to enhance the adhesion of the photoresist to the Cr, we bake the mask in a special oven that applies a molecular monolayer of Hexamethyldisilizane (HMDS), to the surface2. This molecule chemically bonds to the Cr and then bonds to the photoresist so that the photoresist will not allow developers or etch solutions to lift the edges of resist patterns away from the mask. This step is pretty much mandatory for coating a mask prior to exposure.This is a simple process. Basically you open the oven door, insert your mask (riding on a quartz boat), close the door and push the start button. During the oven process, the mask is brought to temperature (120 C), and pressure is automatically cycled between 10 mTorr and 1200 mTorr several times to drive off moisture from the surface of the substrate. The oven fills with HMDS vapor for 5 minutes. This is the application step in which HMDS chemically attaches one end of its molecule to the substrate. The atmosphere in the oven is then cleared of vapor by introducing N2 into the oven and pumping it out again over several cycles. After about 27 minutes, the oven buzzes rather loudly indicating it is done. Reset the buzzer, open the oven door and remove your mask using the forked lifting tool – the mask is hotter than boiling water (120 C). Let it cool. Cooling is important because the temperature uniformity of the mask determines the film thickness uniformity during the spin coating of the resist. To quickly achieve temperature uniformity, set the mask on a cool metal surface like thespecial ½ in thick Cr plated Stainless steel table normally used to level SU8 photoresist. It will take about 3 – 5 minutes to cool to room temperature.2 Daggett, Joe, Villareal, Sam, and Robbins, Roger, “UT Dallas IC Fabrication Laboratory HMDS Process Setup,”/research/cleanroom/documents/HMDS_Process.pdf,(2/21/2003).Title: Photomask Making Page 5 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasFigure 3. HMDS Oven showing logbook, mask, quartz holder with extractable handle and open door. The start button is the black button in the upper center of the control box. The red button is the reset and buzzer silencer.Step 3: Resist ApplicationAfter the blank photomask is prepared, the next step is to apply the photoresist. This is done on the CEE spinner3 manually, (Figure 4). We use two photoresists for photomasks in our lab: S1813, and AZ1518. (See Appendix A and B for resist spec sheets). Normally, the AZ1518 is pre-applied by the photomask vendor, and we don’t have to worry about applying that resist. But if we are coating a blank one, we normally use the S1813 or a new, faster resist AZ TFP650.3 Robbins, Roger “CEE Spin Coater/Hotplate Operation,”/research/cleanroom/documents/CEEcoater.pdf, (10/7/2004).Title: Photomask MakingPage 6 of 24Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasFigure 4. Manual application of S1813 photoresist to a blankphotomask in the CEE spinner.You must be trained on this tool before using. The design of the CEE spinner requires that you learn how to program the spin cycle. This is described in detail in reference #3, but verbal instruction with demonstration is required. The parameters of a nominal coating program are listed in Table 2. These parameters are regularly changed by users, so you must first check the installed values and put in your own values before coating.Table 2CEE Spinner Parameters for Mask Photoresist CoatingStep Parameter Value1 Dispense 02 Spin Speed #1 500 rpm3 Acceleration 500 rpm/sec4 Spin Time Duration #1 2 sec5 Spin Speed #2 4000 rpm6 Acceleration 4000 rpm/sec7 Spin Time Duration #2 60 secThe resist is dispensed from a plastic pipette by sucking up just the right amount of liquid photoresist and dispensing it onto the center of the wafer and then closing thelid and starting the CEE spin cycle. For a 5 inch square photomask, the amount of photoresist is about 2 ml. The first spin cycle quickly spreads the resist without throwing it off the mask, and the second spin cycle stretches the resist film into a highly uniform thin film at the desired thickness based on a spin-speed curve from the manufacturer. For a photomask, you would typically want about 6,000 –10,000Ǻof thickness.Title: Photomask Making Page 7 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasStep 4: Pre-BakeAfter the resist is coated it still contains a considerable amount of solvent that needs to be driven out via a moderately high temperature bake. This is usually done on the integral CEE spinner hotplate shown in Figure 5. This step is called “pre-bake”because it happens before exposure.Figure 5. CEE spinner hotplate with mask baking under exhaust lid.The CEE spinner has a special programmable hotplate with an integral hinged lidwith fume exhaust capabilities. This lid captures the solvent vapors emanating from thehot photoresist, and ports them away from your nose so you w on’t come down withcentral nervous system problems. Table 3 lists the baking parameters for S1813.Temperature and time are important here and vary with the photoresist type.Table 3Bake Parameters for S1813 PhotoresistStep Parameter Value1 Temperature 115 C2 Bake Time 90 secStep 5: Lithographic PatterningLithography is a complex process and will not be described here in detail. In the UTD clean room there is one method for making photomasks – the HeidelbergTitle: Photomask Making Page 8 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasInstruments “D WL-66” laser mask writer. The principle steps involved in making a mask are listed below.Create a device design.Lay out the mask geometries using a drawing package such as AutoCad.Convert the drawing data into a form familiar to the DWL-66 computer(.cif), using a special conversion software and special separate computer.Note: You should write a label on each mask you make to avoid using thewrong mask during your device fabrication.Send the converted data to the DWL-66 computer.Reserve time on the DWL-66 laser writerSign the LogbookLoad the resist coated photomask blank onto the laser writer stage.Set up the layout on the DWL-66 computer. Setup the job on theDWL-66 computer.Focus the DWL-66.Find the center of the photomask blank.Start the Job.Wait a long, long time before the mask is complete (many hours).Remove the mask from the DWL-66.Basically, the exposure step modifies the chemistry of the photoresist so that the exposed portion either dissolves in the developer and washes away - (Positive resist), or solidifies and remains on the mask while all the unexposed resist washes away in the developer - (Negative resist). The two photo resists listed in this document are positive resists which wash away after exposure.There are a lot of pitfalls involved with the stream of actions listed above – you must follow them exactly – deviations may cause computer confusion crashes. The lithography step will require extensive training and practice along with recurrent help –ask if you are uncertain. Use the available instruction sheets for detailed guidance so you won’t forget anything. Let us assume here that the lithography exposure goes well. Figure 6 shows the illustrious DWL-66 mask writer.Figure 6. DWL-66 Laser Mask WriterTitle: Photomask Making Page 9 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasStep 6: Post BakeSome resists require a short bake after exposure to “activate” the exposure. The two photomask resists, S1813 and AZ1518 do not, so we just skip right by this step in this document.Step 7: DevelopAfter exposure, the resist needs development to show the pattern. Each photoresist has its own developer and we have automatic programs set up in the CPK spin developer tools to develop your mask or wafer, (Figure 7). For optical resists, the developer chemical is basically a solution of Tetra Methyl Ammonium Hydroxide (TMAH). The rinse cycle utilizes de-ionized water.Figure 7. Photo of the CPK Spin Develop/Etch tool. The process fluids are forcedthrough the spray nozzles via pressurized source tanks (black tanks with green bolthandles in lower drawers). Note the “POLOS” controller panel at the top left of the overhead panel – this is where the tool is programmed and where process progress is displayed. Also note that if a light goes on above one of the switches at the top right, the fluid is low in that particular pressure canister. It will complete the current process evenif the light goes on during process.The steps involved in developing the mask in the CPK acid/base developer tool are as follows:Sign the LOGBOOKInsure that the machine is on – press the green start button on theoverhead panel if needed.When the display asks for help, follow the directions on screen and pressthe “other” button – (the blank pad between the “MODE” and “UP arrow”).If required, exchange the substrate holder for the appropriate sized maskholder. This involves turning off the “VACUUM” on the controller paneland lifting the chuck off the spindle, then replacing it with the appropriatemask holder. Note that the fit between holder and spindle is tight andrequires that the two posts on the spindle fit into the receiver holes on the Title: Photomask Making Page 10 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at Dallasbottom of the chuck assembly. Place the chuck over the spindle andslide it around until the two posts slip into the receiver holes and thechuck base seats against the o-ring in the spindle.Turn on the vacuum by pressing the “VAC” button on the overhead panelcontroller. Check to see that the chuck is properly seated and will notwobble excessively during the rotation.Place the mask securely inside the corner posts on the substrate holder.Close the lid.Select the proper program number from the list of programs posted justunder the controller on the overhead panel. Enter this program numberby pressing the “PROGRAM” button, entering the appropriate number, (2for S1813), then pressing the “ENTER” button.To start the develop program, press the I/O button at the lower left of theoverhead display.The develop program has a multitude of steps and comes to a completestop several times to “puddle-develop” in order to save developer fluid.Allow the program to complete and then press “VAC” to open the lid andremove your developed mask. NOTE: These lids are notorious fordripping fluid droplets on perfectly good masks – be very gentle in liftingthe lid.Close the lid and remove your mask.Step 8: Plasma De-scumAfter development, have a look at your pattern under a microscope. Look at it for a long time to check the pattern and quality of develop. Look for things like scalloped resist edges, lifted resist, pinholes, under or over development, particles, and other things that look like they could damage the image. If a severe fault is found, do not go on to the next step. Stop and recycle the mask. The resist can be stripped off and new resist applied at this point, saving cost and material.If the inspection goes well, you need to prepare for the Cr etch. The first thing to do here is to insure that all of the pattern will etch in the etch time allowed. This can be helped if you do a very light O2 “de-scum” etch in the March Asher. The “de-scum” etch parameters are listed in Table 4.Table 4March Etcher “Descum” ParametersParameter Value1 Gas O22 Flow of gas313 RF Power50 Watts4 Etch Time10 secThe effect of this light etch is to clean out the bottom of the developed features in the resist. This insures that there are no areas covered with a very thin film of resist leftby the developer. If all is clean, the etch process will be uniform and complete all at once.Title: Photomask Making Page 11 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasStep 9: Cr EtchAfter the short plasma “de-scum,” it is time to do the Cr etch. This etch can be accomplished on the CPK developer/etcher that developed the mask in the first place. Just select the Cr etch program and set the mask firmly into the corner post nests. The actual operation is very similar to the CPK develop program in Step 7, and the steps are outlined below.Sign the LOGBOOKInsure that the machine is on – press the green start button on theoverhead panel if necessary.When the display asks for help, follow the directions on screen and pressthe “other” button – (the blank pad between the “MODE” and “UP arrow”).If required, exchange the substrate holder for the appropriate sized maskholder. This involves turning off the “VACUUM” on the controller paneland lifting the chuck off the spindle, then replacing it with the appropriatemask holder. Note that the fit between holder and spindle is tight andrequires that the two posts on the spindle fit into the receiver holes on thebottom of the chuck assembly. Place the chuck over the spindle andslide it around until the two posts slip into the receiver holes and thechuck base seats against the o-ring in the spindle.Turn on the vacuum by pressing the “VAC” button on the overhead panelcontroller. Check to see that the chuck is properly seated and will notwobble excessively during the rotation.Place the mask securely inside the corner posts on the substrate holder.Close the lid.Select the proper program number from the list of programs posted justunder the controller on the overhead panel. Enter this program numberby pressing the “PROGRAM” button, entering the appropriate number, (4for Cr Etch), and hitting the “ENTER” button.To start the etch program, press the I/O button at the lower left of theoverhead display.The etch program has a multitude of steps and comes to a complete stopseveral times to “Puddle” develop in order to save etch fluid.Allow the program to complete and then press “VAC” to open the lid andremove your etched mask. NOTE: These lids are notorious for drippingdroplets on perfectly good masks, so be very gentle in lifting the lid.Close the lid.Step 10: Resist Removal and Mask CleanAfter inspecting the etched pattern under a microscope, it is time to remove the photoresist from the mask. This is done to avoid polymer-to-polymer contact at the contact print step between the old resist on the mask and the new coat of resist on a wafer. Polymer contact generates high friction and the resist on the wafer could be torn by sliding the wafer around during alignment.This resist removal can usually be done in the solvent CPK spinner. This tool is very similar to the CPK Chrome etch spinner – identical control and user interface, so Title: Photomask Making Page 12 of 24Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at Dallasthe instructions are almost identical to the previous section – simply select the Acetone Strip program and run your mask. This process uses puddles of Acetone to dissolve the photoresist remaining on the photomask and then spins it off and finally rinses the mask with Isopropyl Alcohol.To assure that the photoresist film is chemically removed, you can also send the mask through the March Asher using the same procedure as described in Step 1: “Plasma Cleaning.”Mask CleaningAs a final cleanup to remove remnants from the CPK process, particularly from the back side, you can clean the mask in the UltraTech Mask Washer. Use program “0”for a simple high pressure DI water wash of both sides. This tool is pictured in Figure 8 with its control panel.Note that the big rotor has to be balanced before starting the wash. When you load your mask onto the spin wheel, another mask of the exact mass as yours has to be loaded opposite to yours or the resulting momentum vibration during the spin cycle will cause the tool to stop to protect itself and your mask from disaster. Make sure the balancing mask is the same mass as your mask – compare the thickness! The Door to the chamber opens by sliding downwards after you release the latch with the black button at the lower left of the control panel (below and left of the “Big Red emergency OFF” button).To select the program to run, press “Go To Program,” then “0,” and then “Enter”to access the water-only wash program “0.”This will load the “0” program and indicate it by placing a “0” in the “Prog” box in the upper right of the keypad area. To start the program, press the “Off/On Start” button in the upper left of the instruction keypad.Figure 8. UltraTech Mask Washer.Title: Photomask Making Page 13 of 24Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasStep 11: Final InspectionThe last step should be a thorough inspection of the etched pattern. It is better to find errors and poor quality at this stage than after a bad pattern that can potentially ruin a multi-level substrate.ConclusionThis document has briefly illustrated the Masking making lithography trail through the UTD Clean Room Labs. Once the mask is made, a new trail is followed to transfer the mask pattern to a substrate to build a device. That trail is multivariate and depends on the device being fabricated. Usually, instruction for that portion of the trail is obtained from your research group or directly from literature. Cleanroom staff can help with additional advice if necessary. Take care and be SAFE!Title: Photomask Making Page 14 of 24Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasAppendix AS1813 Photoresist Spec SheetRather than clutter up this document with an appendix of many pages, please find the data on the web. The spec sheet for S1813 photoresist can be found on the web at the following address: http://cmi.epfl.ch/materials/Data_S1800.pdf Well, I suppose I should include the spin speed curves and the dose characteristic since I had to include the data sheet for the other resist.Title: Photomask Making Page 15 of 24 Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at DallasAppendix BAZ1518 Photoresist Spec SheetIt seems that the manufacturer of AZ1518 does not post its data sheets on the internet. Consequently, I will clutter up this document with a copied version of their data sheet.Author: Roger Robbins 3/6/2007 Document Number: SP-07-001 The University of Texas at Dallas。