OQAS-客观视觉质量分析系统

- 格式:ppt

- 大小:1.24 MB

- 文档页数:43

pesq参数

PESQ(Perceptual Evaluation of Speech Quality)是一种用于评估语音质量的客观度量标准。

它是一种感知评估方法,基于人类听觉系统的特性来评估语音信号的质量。

PESQ的参数包括以下几项:

1.输入信号:这是用于评估的原始语音信号。

2.输出信号:这是经过处理或传输后的语音信号。

3.噪音水平:这是在输入信号中存在的噪音水平。

4.压缩率:这是对语音信号进行压缩的程度。

5.延迟:这是处理或传输过程中的延迟时间。

6.评估者:这是对语音质量进行评估的人。

7.测试环境:这是进行评估时的环境条件,如噪音水平、麦克风类

型等。

8.参考信号:这是用于比较的参考语音信号,通常是在理想条件下

录制的。

PESQ的评估结果是一个分数,范围从-0.5到4.5,其中-0.5表示非常差的语音质量,4.5表示非常好的语音质量。

PESQ评估结果受到多种因素的影响,包括输入信号的质量、输出信号的质量、噪音水平、压缩率、延迟等。

环境亮度及瞳孔直径对人眼神经对比敏感度的影响赵冠华;曹瑞丹;张磊;严伟明;陈涛;王斌;丁一峰;王美艳;张作明【摘要】目的:研究环境亮度及瞳孔直径对神经对比敏感度函数( NCSF)的影响,并与对比敏感度函数( CSF)相比较。

方法:招募健康男性志愿者10名10眼作为受试者,以右眼为测试眼,利用视觉监视系统设置不同环境亮度并附加眩光,测量自然、3.0 mm和5.0 mm瞳孔时的CSF;利用视觉质量分析仪测量3.0mm和5.0mm瞳孔时的调制传递函数( MTF),根据CSF与MTF的比值求得NCSF。

结果:NCSF 和CSF随环境亮度降低曲线整体下移,波峰向低频区移动,CSF更偏向低频区。

CSF 变化受NCSF和MTF共同作用,瞳孔开大,MTF下降,在明视觉环境和中间视觉环境中,NCSF和CSF上升,主要上升区为中低频区;当亮度较高或存在眩光源时,NCSF和CSF在中低频区上升不明显,在高频区有下降的趋势;在暗视觉环境中,小范围的瞳孔波动对NCSF和CSF没有显著影响。

结论:NCSF能够反映视觉神经系统的功能,与MTF共同决定CSF。

CSF曲线形状与NCSF相近,波峰更偏向低频区。

环境亮度降低会使NCSF下降, CSF随之下降;瞳孔<br> 开大会使NCSF在中低频区上升,CSF随之上升,而环境较亮或存在眩光源时,NCSF和CSF在高频区都有下降的趋势。

%• AIM: To analysis and compare the influence of surround luminance and pupil diameter on neural contrast sensitivity function( NCSF ) and contrast sensi tivity function ( CSF) .•METHODS: Ten healthy male volunteers ( 10 eyes ) were recruited in this study, and the right eye was tested in this experiment. Different surround luminance levels and glare were set by Vision Monitor System to measure CSF curves of normal pupil, 3. 0mm pupil and 5. 0mm pupil. Modulation transfer function ( MTF ) curves of 3. 0mm pupil and 5. 0mm pupil were measured by OpticalQuality Analysis System. NCSF was the ratio of CSF and MTF.• RESULTS: NCSF and CSF curves went downward <br> considerably and the curve waves shifted towards low spatial frequency as the surround luminance decreases. Compared with NCSF, the curve waves of CSF shifted towards lower spatial frequency. The change of CSF was affected by NCSF and MTF. When pupil diameter increases, MTF curve went downward. While the NCSF and CSF curves mounted up at low spatial frequency in the mesopic and photopic visual environment and showed downward trend at high spatial frequency in excessive bright environment or with glare. In the scotopic visual environment, the slight pupil diameter change cannot considerably affect CSF and NCSF curves.•CONCLUSION:CSF is influenced by MTF and NCSF which reflects the function of the retina-brain neural system. The curve shape of CSF is similar to NCSF, but the curve wave is at lower spatial frequency. NCSF and CSF curves go downward as the surround luminance decreases. As the pupil diameter increases, NCSF and CSF curves mount up at low spatial frequency but show downward trend at high spatial frequency in excessive bright environment or with glare.【期刊名称】《国际眼科杂志》【年(卷),期】2016(016)012【总页数】6页(P2279-2284)【关键词】对比敏感度;神经对比敏感度;亮度;瞳孔【作者】赵冠华;曹瑞丹;张磊;严伟明;陈涛;王斌;丁一峰;王美艳;张作明【作者单位】710032 中国陕西省西安市,第四军医大学航空航天医学系;710032 中国陕西省西安市,第四军医大学航空航天医学系;710032 中国陕西省西安市,第四军医大学航空航天医学系;710032 中国陕西省西安市,第四军医大学航空航天医学系;710032 中国陕西省西安市,第四军医大学航空航天医学系;710032 中国陕西省西安市,第四军医大学航空航天医学系;710032 中国陕西省西安市,第四军医大学学员一旅五营十七连;710032 中国陕西省西安市,第四军医大学航空航天医学系;710032 中国陕西省西安市,第四军医大学航空航天医学系【正文语种】中文Foundation items:The Military Logistics of Major Scientific Research Projects (No.AKJ11J002); the Military Logistics of Scientific Research Projects (No.BKJ14C008)1Department of Clinical Aerospace Medicine, the Fourth Military Medical University, Xi’an 710032, Shaanxi Province, China;2Cadet Brigade, th e Fourth Military Medical University, Xi’an 710032, Shaanxi Province, China •METHODS: Ten healthy male volunteers (10 eyes) were recruited in this study, and the right eye was tested in this experiment. Different surround luminance levels and glare were set by Vision Monitor System to measure CSF curves of normal pupil, 3.0mm pupil and 5.0mm pupil. Modulation transfer function (MTF) curves of 3.0mm pupil and 5.0mm pupil were measured by Optical Quality Analysis System. NCSF was the ratio of CSF and MTF.•RE SULTS:NCSF and CSF curves went downward considerably and the curve waves shifted towards low spatial frequency as the surroundluminance decreases. Compared with NCSF, the curve waves of CSF shifted towards lower spatial frequency. The change of CSF was affected by NCSF and MTF. When pupil diameter increases, MTF curve went downward. While the NCSF and CSF curves mounted up at low spatial frequency in the mesopic and photopic visual environment and showed downward trend at high spatial frequency in excessive bright environment or with glare. In the scotopic visual environment, the slight pupil diameter change cannot considerably affect CSF and NCSF curves.•CONCLUSION:CSF is influenced by MTF and NCSF which reflects the function of the retina-brain neural system. The curve shape of CSF is similar to NCSF, but the curve wave is at lower spatial frequency. NCSF and CSF curves go downward as the surround luminance decreases. As the pupil diameter increases, NCSF and CSF curves mount up at low spatial frequency but show downward trend at high spatial frequency in excessive bright environment or with glare.方法:招募健康男性志愿者10名10眼作为受试者,以右眼为测试眼,利用视觉监视系统设置不同环境亮度并附加眩光,测量自然、3.0mm和5.0mm瞳孔时的CSF;利用视觉质量分析仪测量3.0mm和5.0mm瞳孔时的调制传递函数(MTF),根据CSF与MTF的比值求得NCSF。

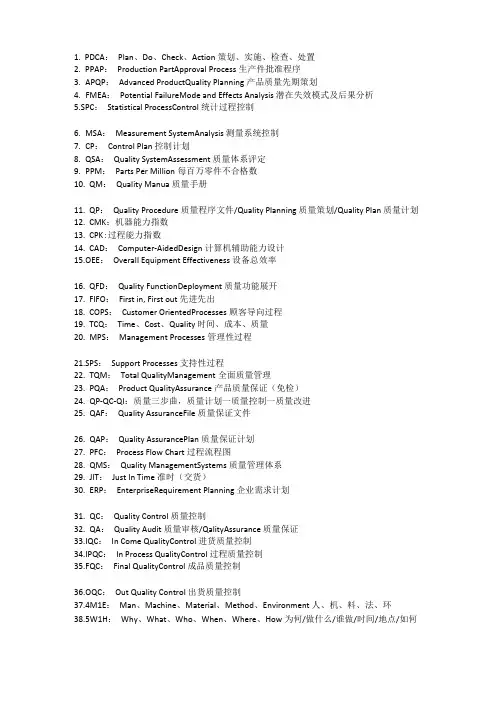

1.PDCA:Plan、Do、Check、Action 策划、实施、检查、处置2.PPAP:Production PartApproval Process生产件批准程序3.APQP:Advanced ProductQuality Planning产品质量先期策划4.FMEA:Potential FailureMode and Effects Analysis 潜在失效模式及后果分析5.SPC:Statistical ProcessControl 统计过程控制6.MSA:Measurement SystemAnalysis 测量系统控制7.CP:Control Plan 控制计划8.QSA:Quality SystemAssessment 质量体系评定9.PPM:Parts Per Million每百万零件不合格数10.QM:Quality Manua 质量手册11.QP:Quality Procedure 质量程序文件/Quality Planning 质量策划/Quality Plan 质量计划12.CMK:机器能力指数13.CPK:过程能力指数14.CAD:Computer-AidedDesign计算机辅助能力设计15.OEE:Overall Equipment Effectiveness 设备总效率16.QFD:Quality FunctionDeployment 质量功能展开17.FIFO:First in, First out 先进先出18.COPS:Customer OrientedProcesses顾客导向过程19.TCQ:Time、Cost、Quality 时间、成本、质量20.MPS:Management Processes管理性过程21.SPS:Support Processes 支持性过程22.TQM:Total QualityManagement全面质量管理23.PQA:Product QualityAssurance产品质量保证(免检)24.QP-QC-QI:质量三步曲,质量计划一质量控制一质量改进25.QAF:Quality AssuranceFile 质量保证文件26.QAP:Quality AssurancePlan 质量保证计划27.PFC:Process Flow Chart 过程流程图28.QMS:Quality ManagementSystems质量管理体系29.JIT:Just In Time 准时(交货)30.ERP:EnterpriseRequirement Planning 企业需求计划31.QC:Quality Control 质量控制32.QA:Quality Audit 质量审核/QalityAssurance 质量保证33.IQC:In Come QualityControl 进货质量控制34.IPQC:In Process QualityControl 过程质量控制35.FQC:Final QualityControl 成品质量控制36.OQC:Out Quality Control 出货质量控制37.4M1E:Man、Machine、Material、Method、Environment 人、机、料、法、环38.5W1H:Why、What、Who、When、Where、How为何/做什么/谁做/时间/地点/如何做39.6S:Seiri、Seiton、Seiso、Seiketsu、Shitsuke、Safety 整理、整顿、清扫、清洁、素养、安全40.TRI值:Total Record Injury(三种)可记录工伤值41.SMART:精明原则,SpecificMeasurable Achievable Result Oriented Timed (具体的描述、可以测量的、可以通过努力实现的、有结果导向性的、有时间性的)----------企业常用英文缩写----------I.5S:5S 管理2.ABC :作业制成本制度(Activity-BasedCosting)3.ABB :实施作业制预算制度(Activity-BasedBudgeting)4.ABM :作业制成本管理(Activity-BaseManagement)5.APS:先进规画与排程系统(AdvancedPlanning and Scheduling)6.ASP:应用程序服务供货商(ApplicationService Provider)7.ATP:可承诺量(Available ToPromise)8.AVL:认可的供货商清单(ApprovedVendor List)9.BOM :物料清单(Bill OfMaterial)10.BPR :企业流程再造(BusinessProcess Reengineering)II.BSC :平衡记分卡(BalancedScoreCard)12.BTF:计划生产(Build ToForecast)13.BTO:订单生产(Build To Order)14.CPM :要径法(Critical PathMethod)15.CPM:每一百万个使用者会有几次抱怨(Complaintper Million)16.CRM:客户关系管理(CustomerRelationship Management)17.CRP :产能需求规划(CapacityRequirements Planning)18.CTO:客制化生产(ConfigurationTo Order)19.DBR:限制驱导式排程法(Drum-Buffer-Rope)20.DMT:成熟度验证(DesignMaturing Testing)21.DVT :设计验证(DesignVerification Testing)22.DRP :运销资源计划(DistributionResource Planning)23.DSS:决策支持系统(DecisionSupport System)24.EC:设计变更/工程变更(EngineerChange)25.EC:电子商务(ElectronicCommerce)26.ECRN:原件规格更改通知(EngineerChange Request Notice)27.EDI:电子数据交换(ElectronicData Interchange)28.EIS :主管决策系统(ExecutiveInformation System)29.EMC:电磁相容(ElectricMagnetic Capability)30.EOQ:基本经济订购量(EconomicOrder Quantity)31.ERP:企业资源规划(EnterpriseResource Planning)32.FAE:应用工程师(FieldApplication Engineer)33.FCST :预估(Forecast)34.FMS:弹性制造系统(FlexibleManufacture System)35.FQC:成品质量管理(Finish orFinal Quality Control)36.IPQC:制程质量管理(In-ProcessQuality Control)37.IQC :进料质量管理(IncomingQuality Control)38.ISO:国际标准组织(InternationalOrganization for Standardization)39.ISAR :首批样品认可(InitialSample Approval Request)40.JIT :实时管理(Just In Time)41.KM :知识管理(KnowledgeManagement)42.L4L:逐批订购法(Lot-for-Lot)43.LTC:最小总成本法(Least TotalCost)44.LUC:最小单位成本(Least UnitCost)45.MES :制造执行系统(ManufacturingExecution System)46.MO :制令(Manufacture Order)47.MPS :主生产排程(MasterProduction Schedule)48.MRO :请修(购)单(MaintenanceRepair Operation)49.MRP :物料需求规划(MaterialRequirement Planning)50.MRPII:制造资源计划(ManufacturingResource Planning)51.NFCF:更改预估量的通知Notice forChanging Forecast52.OEM:委托代工(OriginalEquipment Manufacture)53.ODM :委托设计与制造(OriginalDesign & Manufacture)54.OLAP:在线分析处理(On-LineAnalytical Processing)55.OLTP:在线交易处理(On-LineTransaction Processing)56.OPT :最佳生产技术(OptimizedProduction Technology)57.OQC :出货质量管理(Out-goingQuality Control)58.PDCA:PDCA 管理循环(Plan-Do-Check-Action)59.PDM :产品数据管理系统(ProductData Management)60.PERT :计划评核术(ProgramEvaluation and Review Technique)61.PO:订单(Purchase Order)62.POH :预估在手量(Product onHand)63.PR :采购申请(PurchaseRequest)64.QA :品质保证(QualityAssurance)65.QC :质量管理(Quality Control)66.QCC:品管圈(Quality Controlcircle)67.QE:品质工程(QualityEngineering)68.RCCP :粗略产能规划(Rough CutCapacity Planning)69.RMA :退货验收(ReturnedMaterial Approval)70.ROP :再订购点(Re-Order Point)71.SCM :供应链管理(Supply ChainManagement) 72.SFC :现场控制(Shop FloorControl)73.SIS :策略信息系统(StrategicInformation System)74.SO:订单(Sales Order)75.SOR:特殊订单需求(Special OrderRequest)76.SPC :统计制程管制(StatisticProcess Control)77.TOC:限制理论(Theory ofConstraints)78.TPM :全面生产管理(TotalProduction Management)79.TQC:全面质量管理(Total QualityContro)80.TQM:全面品质管理(Total QualityManagement)81.WIP:在制品(Work In Process)----------部门名称的专有名词----------QS:Quality system 品质系统CS:Coutomer Sevice 客户服务QC:Quality control 品质管理IQC:Incoming quality control 进料检验LQC:Line Quality Control 生产线品质控制IPQC:In process quality control 制程检验FQC:Final quality control 最终检验OQC:Outgoing quality control 出货检验QA:Quality assurance 品质保证SQA:Source(supplier) Quality Assurance 供应商品质保证(VQA) CQA:Customer Quality Assurance客户质量保证PQA rocess Quality Assurance 制程品质保证Q巳Quality engineer 品质工程CE:component engineering 零件工程EE:equipment engineering 设备工程ME:manufacturing engineering 制造工程TE:testing engineering 测试工程PPE roduct Engineer 产品工程IE:Industrial engineer 工业工程ADM: Administration Department 行政部RMA:客户退回维修CSDI:检修PC:producing control 生管MC:mater control 物管GAD: General Affairs Dept 总务部A/D: Accountant /Finance Dept 会计LAB: Laboratory 实验室DO E:实验设计HR:人资PMC:企划RD:研发W/H:仓库SI:客验PD: Product Department 生产部PA:采购(PUR: Purchaing Dept)SMT:Surface mount technology 表面粘着技术MFG:Manufacturing 制造MIS:Management information system 资迅管理系统DCC:document control center 文件管制中心----------场内作业中的专有名词----------QT:Quality target 品质目标QP:Quality policy 目标方针QI:Quality improvement 品质改善CRITICAL DEFECT严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(MI)MAX:Maximum 最大值MIN:Minimum 最小值DIA iameter 直径DIM imension 尺寸LCL:Lower control limit 管制下限UCL:Upper control limit 管制上限EMI :电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO:Engineering change order 工程改动要求(客户)ECR:工程变更需求单CPI:Continuous Process Improvement 连续工序改善Compatibility:兼容性Marking :标记DWG rawing 图面Standardization :标准化Consensus:一致Code :代码ZD:Zero defect 零缺点Tolerance :公差Subject matter:主要事项Auditor:审核员BOM:Bill of material 物料清单Rework :重工ID:identification 识别,鉴别,证明PILOT RUN:(试投产)FAI :首件检查FPIR:First Piece Inspection Report 首件检查报告FAA:首件确认SPC:统计制程管制CP: capability index (准确度)CPK: capability index of process(制程能力)PMP:制程管理计划(生产管制计划)MPI:制程分析DAS efects Analysis System 缺陷分析系统PPB:十亿分之一Flux:助焊剂P/N:料号L/N:Lot Number 批号Version:版本Quantity :数量Valid date:有效日期MIL-STD:Military-Standard 军用标准ICT: In Circuit Test 线路测试)ATE:Automatic Test Equipment 自动测试设备MO: Manafacture Order 生产单T/U: Touch Up锡面修补)I/N:手插件P/T初测F/T: Function Test功能测试-终测)AS组立P/K :包装TQM:Total quality control 全面品质管理MDA:manufacturing defect analysis 制程不良分析(ICT)RUN-IN:老化实验HI-pot :高压测试FMI:Frequency Modulation Inspect高频测试DPPM: Defect Part Per Million(不良率的一种表达方式:百万分之一)1000PPM即为0.1%Corrective Action: (CAR 改善对策)ACC:允收REJ:拒收S/S:Sample size抽样检验样本大小SI-SIV:Special I-Special IV 特殊抽样水平等级CON:Concession / Waive特采ISO:国际标准化组织ISA:Industry Standard Architecture 工业标准体制结构OBA:开箱稽核FIFO:先进先出PDCA:管理循环Plan do check action计划,执行,检查,总结WIP:在制品(半成品)S/O: Sales Order (业务订单) P/O: Purchase Order 采购订单) P/R: Purchase Request (i W 购单) AQL:acceptable quality level 允收品质水准LQL;Limiting quality level 最低品质水准QVL:qualified vendor list 合格供应商名册AVL :认可的供货商清单(Approved Vendor List)QCD: Quality cost delivery (品质,交期,成本)MPM:Manufacturing project management 制造专案管理KPI:Key performance indicate 重要绩效指标MVT:Manufacturing Verification Test制造验证试产Q/R/S: Quality/Reliability/Service 质量/可靠度/服务STL:ship to line (料到上线)NTF:No trouble found 误判CIP:capacity improvement plan (产能改善计划)MRB:material review board (物料审核小组)MRB:Material reject bill 退货单JIT:just in time (即时管理)5S:seiri seiton seiso seiketsu shitsuke(整理,整顿,清扫,清洁,修养)SOP:standard operation process (标准作业程序)SIP:Specification inspection process 制程检验规格TOP: Test Operation Process 侧试作业流程) WI: working instruction (作业指导书)SMD:surface mounting device (表面粘着原件)FAR:failure aualysis report 故障分析报告CAR:Corrective action report 改善报告BPR:企业流程再造(Business Process Reengineering) ISAR :首批样品认可(Initial Sample Approval Request)- JIT:实时管理(Just In Time)QCC :品管圈(Quality Control Circle) Engineering Department (工程部)TQEM: Total Quality Environment Management(全面品质环境管理)PD: Production Department (制造)LOG: Logistics (后勤支持)Shipping:(进出口)AOQ:Average Output Quality平均出货质量AOQL:Average Output Quality Level平均出货质量水平FMEA:failure model effectiveness analysis失效模式分析CRB: Change Review Board (工程变更会议)CSA:Customer Simulate Analysis客户模拟分析SQMS:Supplier Quality Management System供应商品质管理系统QIT: Quality Improvement Team 品质改善小组QIP:Quality Improvement Plan 品质改善计划CIP:Continual Improvement Plan 持续改善计划M.Q.F.S: Material Quality Feedback Sheet 来料品质回馈单)SCAR: Supplier Corrective Action Report (供货商改善对策报告)8D Sheet: 8 Disciplines sheet ( 8D 单)PDCA:PDCA (Plan-Do-Check-Action) (管理循环)MPQ: Material Packing Quantity (物料最小包装量)DSCN: Delivery Schedule Change Notice (交期变更通知)QAPS: Quality Assurance Process Sheet (品质工程表)DRP :运销资源计划(Distribution Resource Planning) DSS:决策支持系统(Decision Support System)EC :电子商务(Electronic Commerce)EDI :电子资料交换(Electronic Data Interchange)EIS :主管决策系统(Excutive Information System)ERP :企业资源规划(Enterprise Resource Planning) FMS :弹性制造系统(Flexible Manufacture System)KM :知识管理(Knowledge Management)4L :逐批订购法(Lot-for-Lot)LTC :最小总成本法(Least Total Cost)LUC :最小单位成本(Least Unit Cost)MES :制造执行系统(Manufacturing Execution System) MPS :主生产排程(Master Production Schedule)MRP :物料需求规划(Material Requirement Planning) MRPII :制造资源计划(Manufacturing Resource Planning) OEM :委托代工(Original Equipment Manufacture)ODM :委托设计与制造(Original Design & Manufacture) OLAP:线上分析处理(On-Line Analytical Processing) OLTP:线上交易处理(On-Line Transaction Processing) OPT :最佳生产技术(Optimized Production Technology) PDCA:PDCA 管理循环(Plan-Do-Check-Action)PDM:产品数据管理系统(Product Data Management)) RCCP:粗略产能规划(Rough Cut Capacity Planning) SCM :供应链管理(Supply Chain Management)SFC :现场控制(Shop Floor Control)TOC:限制理论(Theory of Constraints)TQC :全面品质管制(Total Quality Control)FYI/R:for your information/reference 仅供参考ASAP:尽快S/T:Standard time 标准时间TPM:total production maintenance:全面生产保养ESD Wrist strap:静电环IT:information technology 信息技术,资讯科学CEO:Chief Executive Officer执行总裁COO:Chief Operaring Officer首席业务总裁SWOT:Strength,Weakness,Opportunity,Threat优势,弱点,机会,威胁Competence :专业能力Communication :有效沟通Cooperation:统御融合Vibration Testing :振动测试IDP:Individual Development Plan 个人发展计划MRP:Material Requirement Planning物料需求计划MAT'S:Material 材料LRR:Lot Rejeet Rate 批退率ATIN:Attention 知会3C:Computer ,Communication , Consumer electronic消费性电子5W1H:When , Where , Who , What , Why , Ho5M: Man , Machine , Material , Method , Measurement人,机器,材料,方法,测量4MIE: Man,Material,Machine,Method,Environment人力,物力,财务,技术,时间(资源)7M1I: Manpower , Machine , Material , Method, Market , Management , Money , Information 人力,机器,材料,方法,市场,管理,资金,资讯Accuracy准确度Action彳亍动Activity 活动Analysis Covariance 协方差分析Analysis of Variance 方差分析Approved 承认Attribute计数值Average平均数Balance sheet资产负债对照表Binomial二项分配Brainstorming Techniques 脑力风暴法Cause and Effect Matrix 因果图(鱼骨图)CL:Center Line 中心线Check Sheets 检查表Complaint 投诉Conformity合格(符合)Control 控制Control chart控制(管制)图Correction 纠正Correlation Methods 相关分析法CPI: continuouse Process Improvement 连续工序改善Cross Tabulation Tables 交叉表CS: Customer Sevice 客(户)服(务)中心DSA: Defects Analysis System 缺陷分析系统Data 数据Description:品名DCC: Document Control Center 文控中心Decision决策、判定Defects per unit单位缺点数Description 描述Device装置Do执行DOE: Design of Experiments 实验设计Element 元素Engineering recbnology 工程技Environmental 环境Equipment 设备Estimated accumulative frequency 计算估计累计数E Equipment Variation 设备变异External Failure外部失效,外部缺陷FA: Failure Analysis 失效分析Fact control事实管理Fatigue 疲劳FMEA: Failure Mode and Effect Analysis 失效模式与效果分析FP First-Pass Yield (第一次通过)合格率FQA: Final Quality Assurance 最终品质保证FQC: Final Quality control 最终品质控制Gauge system测量系统Grade等级Histogram直方图Improvement 改善Initial review 先期审查Inspection 检验Internal Failure内部失效、内部缺陷IPQC: In Process Quality Control 制程品质控制IQC: Incomming Quality Control 来料品质控制IS International Organization for Standardization 国际标准化组织LCL: Lower Control limit 管制下限LQC: Line Quality Control 生产线品质控制LSL: Lower Size Limit 规格下限Machine 机械Manage管理Materials 物料Measurement 测量Median中位数MSA: Measurement System Analysis 测量系统分析Occurrence 发生率Operation Instruction 作业指导书Organization 组织Parto柏拉图PPM arts per Million (百万分之)不良率Plan计划Policy方针Population 群体PQA: Process Quality Assurance 制程品质保证Practice 实务(践)Prevention 预防Probability 机率Probability density function 机率密度函数Procedure 流程Process 过程Process capability analysis 制程能力分析(图)Process control and Process capability 制程管制与制程能力Product 产品Production 生产Projects 项目QA: Quality Assurance 品质保证QC: Quality Control 品质控制Q巳Quality Engineering 品质工程QFD: Quality Function Desgin 品质机能展开(法)Quality 质量Quality manual 品质手册Quality policy品质政策(质量方针)Random experiment 随机试验Random numbers 随机数R:Range全距(极差)Reject拒收Repair返修Repeatusility 再现性Reproducibility 再生性Requirement 要求Responsibilities 职责Review评审Reword返工Rolled yield 直通率RPN: Risk Priority Number 风险系数Sample抽样,样本Sample space样本空间Sampling with replacement 放回抽样Sampling without replacement 不放回抽样Scatter diagram散布图分析Scrap报废Simple random sampling 简单随机取样Size规格SL: Size Line规格中心线Stratified random sampling 分层随机抽样SOP: Standard Operation Procedure 标准作业书SPC: Statistical Process Control 统计制程管制Specification 规范SQA: Source(Supplier) Quality Assurance 供货商品质保证Stage sampling分段随机抽样Standard Deviation 标准差Sum of squares 平方和Taguchi-method 田口(试验)方法Theory原理TQC: Total Quality Control 全面品质控制TQM: Total Quality Management 全面品质管理Traceablity 追溯Training 培训UCL: Upper Control Limit 管制(控制)上限USL: Upper Size Limit 规格上限Validation 确认Variable计量值Verification 验证Version 版本VOC: Voice of Customer 客户需求VOE: Voice of Engineer 工程需求Inventory stock report:厘存清单报告Sales order report :出货报告。

周边离焦框架眼镜对近视防控作用的研究进展[摘要]近视是现代临床较为常见的疾病,不仅影响患者的日常学习、工作和生活,而且随着近视程度的增加还可能引起视神经和视网膜病变,严重者甚至致盲。

近年来随着国家对预防近视的广泛宣传以及家长对儿童近视预防工作的重视,使得近视儿童防控工作成为社会和医疗机构共同关注的热点。

虽然利用手术方式来治疗近视在当前获得了一定的应用,但近视手术均有严格的适应症,且长期效果仍有待进一步的观察,对于大多数患者而言,通过佩戴眼镜来治疗近视仍然是首选。

随着近视眼镜的不断发展和进步,利用周边离焦框架眼镜对近视进行防控获得了广泛的关注,其有效性在临床上已取得一定认可,为患者制定个性化的治疗方案提供了新的思路。

为进一步探讨周边离焦眼镜对近视防控的作用,特开展此次综述。

[关键词]周边离焦框架眼镜;近视;防控作用;研究进展近视是眼科最为常见且高发的疾病,不仅会导致患者视力的下降,而且还可能会出现视疲劳、眼球突出变形、眼位外斜等临床症状,严重者还会因并发视网膜脱落等疾病导致失明,对患者的生活、工作、学习以及容貌等均造成不良影响[1]。

目前临床对于近视的治疗主要有佩戴框架眼镜、角膜接触镜以及屈光手术治疗[2]。

大多数近视患者仍然倾向通过佩戴眼镜来获得无创、无风险且能够有效防控近视的效果。

周边离焦框架眼镜作为新一代防控近视产品,自问世以来即备受患者和医师的青睐[3]。

为进一步评价周边离焦框架眼镜对近视防控的作用效果,本文特开展此次综述。

1近视的发生机制和原因研究表明,随着年龄的不断增加,人类眼睛的总屈光度总体水平呈现缓慢的下降趋势,而眼球的不断发育使得眼球水平径呈现增加趋势,因此当在近距离用眼时,通过睫状肌收缩使得晶状体变凸进行调焦,若长时间近距离用眼,会引起睫状肌的持续收缩痉挛,导致睫状肌收缩性降低,失去调节失衡能力,最终使得眼睛便从正视转变为近视[4]。

目前临床对于引起近视的原因尚无完全统一的标准,国内外相关研究结果显示:遗传因素以及不正确的用眼习惯可能引起眼轴或角膜曲率的变化,从而导致近视的发生,这也使得临床上对于防控近视的应对措施也多种多样[5]。

BVT是Build Verification Test,基本验证测试,对完成的代码进行编译和连接,DVT是Design Verification Test的简称,设计验证测试,是硬件生产中不可缺少的一个检PVT全称为Process Verification Test,意为小批量过程验证测试,硬件测试的一种,主EVT-Engineer Verification Test,工程样品验证测试CPU: central processing unit(中央处理器)IC: Integrated circuit(集成电路)Memory IC: Memory Integrated circuit(记忆集成电路)RAM: Random Access Memory(随机存取存储器)DRAM: Dynamic Random Access Memory(动态随机存取存储器)SRAM: Staic Random Access Memory(静态随机存储器)ROM: Read-only Memory(只读存储器)EPROM:Electrical Programmable Read-only Memory(电可抹只读存诸器)EEPROM: Electrical Erasbale Programmable Read-only Memory(电可抹可编程只读存储CMOS: Complementary Metal-Oxide-Semiconductor(互补金属氧化物半导体)BIOS: Basic Input Output System(基本输入输出系统)Transistor:电晶体LED:发光二极体Resistor:电阻Variator:可变电阻Capacitor:电容Capacitor array:排容Diode:二极体Transistor:三极体Transformer:变压器(ADP)Oscillator:频率振荡器(0sc)Crystal:石英振荡器XTAL/OSC:振荡产生器(X)Relay:延时器Sensor:感应器Bead core:磁珠Filter:滤波器Flat Cable:排线Inductor:电感Buzzer:蜂鸣器Socket:插座Slot:插槽Fuse:熔断器Current:电流表Solder iron:电烙铁Magnifying glass:放大镜Caliper:游标卡尺Driver:螺丝起子Oven:烤箱TFT:液晶显示器Oscilloscope:示波器Connector:连接器PCB:printed circuit board(印刷电路板)PCBA: printed circuit board assembly(电路板成品)PP:并行接口HDD:硬盘FDD:软盘PSU:power supply unit(电源供应器)SPEC:规格Attach:附件Case: 机箱,盖子Cover:上盖Base:下盖Bazel:面板(panel)Bracket:支架,铁片Lable:贴纸Guide:手册Manual:手册,指南Card:网卡Switch:交换机Hub:集线器Router:路由器Sample:样品Gap:间隙Sponge:海绵Pallet:栈板Foam:保利龙Fiber:光纤Disk:磁盘片PROG:程序Barcode:条码System:系统System Barcode:系统条码M/B:mother board:主板CD-ROM:光驱FAN:风扇Cable:线材Audio:音效K/B:Keyboard(键盘)Mouse:鼠标Riser card:转接卡Card reader:读卡器Screw:螺丝Thermal pad:散热垫Heat sink:散热片Rubber:橡胶垫Rubber foot:脚垫Bag:袋子Washer:垫圈Sleeve:袖套Config:机构Label hi-pot:高压标签Firmware label:烧录标签Metal cover:金属盖子Plastic cover:塑胶盖子Tape for packing:包装带Bar code:条码Tray:托盘Collecto:集线夹Holder:固定器,L铁Connecter:连接器IDE:集成电路设备,智能磁盘设备SCSI:小型计算机系统接口Gasket:导电泡棉AGP:加速图形接口PCI:周边组件扩展接口LAN:局域网USB:通用串形总线架构Slim:小型化COM:串型通讯端口LPT:打印口,并行口Power cord:电源线I/O:输入,输出Speaker:扬声器EPE:泡棉Carton:纸箱Button:按键,按钮Foot stand:脚架部门名称的专有名词QS:Quality system品质系统CS:Coutomer Sevice 客户服务QC:Quality control品质管理IQC:Incoming quality control 进料检验LQC:Line Quality Control 生产线品质控制IPQC:In process quality control 制程检验FQC:Final quality control 最终检验OQC:Outgoing quality control 出货检验QA:Quality assurance 品质保证 SQA:Source(supplier) Quality Assurance 供应商品质保证(VQA) CQA:Customer Quality Assurance客户质量保证PQA rocess Quality Assurance 制程品质保证QE:Quality engineer 品质工程CE:component engineering零件工程EE:equipment engineering设备工程ME:manufacturing engineering制造工程TE:testing engineering测试工程PPE roduct Engineer 产品工程IE:Industrial engineer 工业工程ADM: Administration Department行政部RMA:客户退回维修CSDI:检修PC:producing control生管MC:mater control物管GAD: General Affairs Dept总务部A/D: Accountant /Finance Dept会计LAB: Laboratory实验室DOE:实验设计HR:人资PMC:企划RD:研发W/H:仓库SI:客验PD: Product Department生产部PA:采购(PUR: Purchaing Dept)SMT:Surface mount technology 表面粘着技术MFG:Manufacturing 制造MIS:Management information system 资迅管理系统DCC:document control center 文件管制中心厂内作业中的专有名词QT:Quality target品质目标QP:Quality policy目标方针QI:Quality improvement品质改善CRITICAL DEFECT:严重缺点(CR)MAJOR DEFECT:主要缺点(MA)MINOR DEFECT:次要缺点(MI)MAX:Maximum最大值MIN:Minimum最小值DIA iameter直径DIM imension尺寸LCL:Lower control limit管制下限UCL:Upper control limit管制上限EMI:电磁干扰ESD:静电防护EPA:静电保护区域ECN:工程变更ECO:Engineering change order工程改动要求(客户)ECR:工程变更需求单CPI:Continuous Process Improvement 连续工序改善Compatibility:兼容性Marking:标记DWG rawing图面Standardization:标准化Consensus:一致Code:代码ZD:Zero defect零缺点Tolerance:公差Subject matter:主要事项Auditor:审核员BOM:Bill of material物料清单Rework:重工ID:identification识别,鉴别,证明PILOT RUN: (试投产)FAI:首件检查FPIR:First Piece Inspection Report首件检查报告FAA:首件确认SPC:统计制程管制CP: capability index(准确度)CPK: capability index of process(制程能力) PMP:制程管理计划(生产管制计划)MPI:制程分析DAS efects Analysis System 缺陷分析系统PPB:十亿分之一Flux:助焊剂P/N:料号L/N:Lot Number批号Version:版本Quantity:数量Valid date:有效日期MIL-STD:Military-Standard军用标准ICT: In Circuit Test (线路测试)ATE:Automatic Test Equipment自动测试设备MO: Manafacture Order生产单T/U: Touch Up (锡面修补)I/N:手插件P/T:初测F/T: Function Test (功能测试-终测)AS 组立P/K:包装TQM:Total quality control全面品质管理MDA:manufacturing defect analysis制程不良分析(ICT) RUN-IN:老化实验HI-pot:高压测试FMI:Frequency Modulation Inspect高频测试DPPM: Defect Part Per Million(不良率的一种表达方式:百万分之一) 1000PPM即为0.1% Corrective Action: (CAR改善对策)ACC:允收REJ:拒收S/S:Sample size抽样检验样本大小SI-SIV:Special I-Special IV特殊抽样水平等级CON:Concession / Waive特采ISO:国际标准化组织ISA:Industry Standard Architecture工业标准体制结构OBA:开箱稽核FIFO:先进先出PDCA:管理循环Plan do check action计划,执行,检查,总结WIP:在制品(半成品)S/O: Sales Order (业务订单)P/O: Purchase Order (采购订单)P/R: Purchase Request (请购单)AQL:acceptable quality level允收品质水准LQL;Limiting quality level最低品质水准QVL:qualified vendor list合格供应商名册AVL :认可的供货商清单(Approved Vendor List) QCD: Quality cost delivery(品质,交期,成本)MPM:Manufacturing project management制造专案管理KPI:Key performance indicate重要绩效指标MVT:Manufacturing Verification Test制造验证试产Q/R/S:Quality/Reliability/Service质量/可靠度/服务STL:ship to line(料到上线)NTF:No trouble found误判CIP:capacity improvement plan(产能改善计划)MRB:material review board(物料审核小组)MRB:Material reject bill退货单JIT:just in time(即时管理)5S:seiri seiton seiso seiketsu shitsuke(整理,整顿,清扫,清洁,修养)SOP:standard operation process(标准作业程序)SIP:Specification inspection process制程检验规格TOP: Test Operation Process (测试作业流程)WI: working instruction(作业指导书)SMD:surface mounting device(表面粘着原件)FAR:failure aualysis report故障分析报告CAR:Corrective action report改善报告BPR: 企业流程再造 (Business Process Reengineering)ISAR :首批样品认可(Initial Sample Approval Request)-JIT:实时管理 (Just In Time)QCC :品管圈 (Quality Control Circle)Engineering Department (工程部)TQEM: Total Quality Environment Management(全面品质环境管理)PD: Production Department (制造)LOG: Logistics (后勤支持)Shipping: (进出口)AOQ:Average Output Quality平均出货质量AOQL:Average Output Quality Level平均出货质量水平FMEA:failure model effectiveness analysis失效模式分析CRB: Change Review Board (工程变更会议)CSA:Customer Simulate Analysis客户模拟分析SQMS:Supplier Quality Management System供应商品质管理系统QIT: Quality Improvement Team 品质改善小组QIP:Quality Improvement Plan品质改善计划CIP:Continual Improvement Plan持续改善计划M.Q.F.S: Material Quality Feedback Sheet (来料品质回馈单) SCAR: Supplier Corrective Action Report (供货商改善对策报告) 8D Sheet: 8 Disciplines sheet ( 8D单)PDCA:PDCA (Plan-Do-Check-Action) (管理循环)MPQ: Material Packing Quantity (物料最小包装量)DSCN: Delivery Schedule Change Notice (交期变更通知) QAPS: Quality Assurance Process Sheet (品质工程表)DRP :运销资源计划 (Distribution Resource Planning)DSS:决策支持系统 (Decision Support System)EC :电子商务 (Electronic Commerce)EDI :电子资料交换 (Electronic Data Interchange)EIS :主管决策系统 (Excutive Information System)ERP :企业资源规划 (Enterprise Resource Planning)FMS :弹性制造系统 (Flexible Manufacture System)KM :知识管理 (Knowledge Management)4L :逐批订购法 (Lot-for-Lot)LTC :最小总成本法 (Least Total Cost)LUC :最小单位成本 (Least Unit Cost)MES :制造执行系统 (Manufacturing Execution System)MPS :主生产排程 (Master Production Schedule)MRP :物料需求规划 (Material Requirement Planning)MRPⅡ:制造资源计划 (Manufacturing Resource Planning)OEM :委托代工 (Original Equipment Manufacture)ODM :委托设计与制造 (Original Design & Manufacture) OLAP:线上分析处理 (On-Line Analytical Processing)OLTP:线上交易处理 (On-Line Transaction Processing)OPT :最佳生产技术 (Optimized Production Technology) PDCA:PDCA管理循环 (Plan-Do-Check-Action)PDM:产品数据管理系统 (Product Data Management))RCCP:粗略产能规划 (Rough Cut Capacity Planning)SCM :供应链管理 (Supply Chain Management)SFC :现场控制 (Shop Floor Control)TOC:限制理论 (Theory of Constraints)TQC :全面品质管制 (Total Quality Control)FYI/R:for your information/reference仅供参考ASAP:尽快S/T:Standard time标准时间TPM:total production maintenance:全面生产保养ESD Wrist strap:静电环IT:information technology信息技术,资讯科学CEO:Chief Executive Officer执行总裁COO:Chief Operaring Officer首席业务总裁SWOT:Strength,Weakness,Opportunity,Threat优势﹐弱点﹐机会﹐威胁Competence:专业能力Communication:有效沟通Cooperation:统御融合Vibration Testing:振动测试IDP:Individual Development Plan个人发展计划MRP:Material Requirement Planning物料需求计划MAT'S:Material材料LRR:Lot Rejeet Rate批退率ATIN:Attention知会3C:Computer ,Communication , Consumer electronic消费性电子5W1H:When , Where , Who , What , Why , Ho5M: Man , Machine , Material , Method , Measurement人,机器,材料,方法,测量4MIE: Man,Material,Machine,Method,Environment人力,物力,财务,技术,时间(资源)7M1I: Manpower , Machine , Material , Method, Market , Management , Money , In 人力, 机器, 材料, 方法, 市场, 管理, 资金, 资讯1 Accuracy 准确度2 Action 行动3 Activity 活动4 Analysis Covariance 协方差分析5 Analysis of Variance 方差分析6 Approved 承认7 Attribute 计数值8 Average 平均数9 Balance sheet 资产负债对照表10 Binomial 二项分配11 Brainstorming Techniques 脑力风暴法12 Cause and Effect Matrix 因果图(鱼骨图)13 CL:Center Line 中心线14 Check Sheets 检查表15 Complaint 投诉16 Conformity 合格(符合)17 Control 控制18 Control chart 控制(管制)图19 Correction 纠正20 Correlation Methods 相关分析法21 CPI: continuouse Process Improvement 连续工序改善22 Cross Tabulation Tables 交叉表23 CS: Customer Sevice 客(户)服(务)中心24 DSA: Defects Analysis System 缺陷分析系统25 Data 数据 Description:品名26 DCC: Document Control Center 文控中心27 Decision 决策、判定28 Defects per unit 单位缺点数29 Description 描述30 Device 装置31 Do 执行32 DOE: Design of Experiments 实验设计33 Element 元素34 Engineering recbnology 工程技35 Environmental 环境36 Equipment 设备37 Estimated accumulative frequency 计算估计累计数38 E Equipment Variation 设备变异39 External Failure 外部失效,外部缺陷40 FA: Failure Analysis 失效分析41 Fact control 事实管理42 Fatigue 疲劳43 FMEA: Failure Mode and Effect Analysis失效模式与效果分析44 FP First-Pass Yield (第一次通过)合格率45 FQA: Final Quality Assurance 最终品质保证46 FQC: Final Quality control 最终品质控制47 Gauge system 测量系统48 Grade 等级49 Histogram 直方图50 Improvement 改善51 Initial review 先期审查52 Inspection 检验53 Internal Failure 内部失效、内部缺陷54 IPQC: In Process Quality Control 制程品质控制55 IQC: Incomming Quality Control 来料品质控制56 IS International Organization for Standardization 国际标准化组织57 LCL: Lower Control limit 管制下限58 LQC: Line Quality Control 生产线品质控制59 LSL: Lower Size Limit 规格下限60 Machine 机械61 Manage 管理62 Materials 物料63 Measurement 测量64 Median 中位数65 MSA: Measurement System Analysis 测量系统分析66 Occurrence 发生率67 Operation Instruction 作业指导书68 Organization 组织69 Parto 柏拉图70 PPM arts per Million (百万分之)不良率71 Plan 计划72 Policy 方针73 Population 群体74 PQA: Process Quality Assurance 制程品质保证75 Practice 实务(践)76 Prevention 预防77 Probability 机率78 Probability density function 机率密度函数79 Procedure 流程80 Process 过程81 Process capability analysis 制程能力分析(图)82 Process control and Process capability制程管制与制程能力83 Product 产品84 Production 生产85 Projects 项目86 QA: Quality Assurance 品质保证87 QC: Quality Control 品质控制88 QE: Quality Engineering 品质工程89 QFD: Quality Function Desgin 品质机能展开(法)90 Quality 质量91 Quality manual 品质手册92 Quality policy 品质政策(质量方针)93 Random experiment 随机试验94 Random numbers 随机数95 R:Range 全距(极差)96 Reject 拒收97 Repair 返修98 Repeatusility 再现性99 Reproducibility 再生性100 Requirement 要求101 Responsibilities 职责102 Review 评审103 Reword 返工104 Rolled yield 直通率105 RPN: Risk Priority Number 风险系数106 Sample 抽样,样本107 Sample space 样本空间108 Sampling with replacement 放回抽样109 Sampling without replacement 不放回抽样110 Scatter diagram 散布图分析111 Scrap 报废112 Simple random sampling 简单随机取样113 Size 规格114 SL: Size Line 规格中心线115 Stratified random sampling 分层随机抽样116 SOP: Standard Operation Procedure 标准作业书117 SPC: Statistical Process Control 统计制程管制118 Specification 规范119 SQA: Source(Supplier) Quality Assurance 供货商品质保证120 Stage sampling 分段随机抽样121 Standard Deviation 标准差122 Sum of squares 平方和123 Taguchi-method 田口(试验)方法124 Theory 原理125 TQC: Total Quality Control 全面品质控制126 TQM: Total Quality Management 全面品质管理127 Traceablity 追溯128 Training 培训129 UCL: Upper Control Limit 管制(控制)上限130 USL: Upper Size Limit 规格上限131 Validation 确认132 Variable 计量值133 Verification 验证134 Version 版本135 VOC: Voice of Customer 客户需求136 VOE: Voice of Engineer 工程需求137 Inventory stock report:庫存清单报告138 Sales order report:出货报告质量人员名称类QC quality control 品质管理人员FQC final quality control 终点质量管理人员IPQC in process quality control 制程中的质量管理人员OQC output quality control 最终出货质量管理人员IQC incoming quality control 进料质量管理人员TQC total quality control 全面质量管理POC passage quality control 段检人员QA quality assurance 质量保证人员OQA output quality assurance 出货质量保证人员QE quality engineering 质量工程人员质量保证类FAI first article inspection 新品首件检查FAA first article assurance 首件确认CP capability index 能力指数CPK capability process index 模具制程能力参数SSQA standardized supplier quality audit 合格供货商质量评估FMEA failure model effectiveness analysis 失效模式分析FQC运作类AQL Acceptable Quality Level 运作类允收质量水平S/S Sample size 抽样检验样本大小ACC Accept 允收REE Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Minor 轻微的Q/R/S Quality/Reliability/Service 质量/可靠度/服务P/N Part Number 料号L/N Lot Number 批号AOD Accept On Deviation 特采UAI Use As It 特采FPIR First Piece Inspection Report 首件检查报告PPM Percent Per Million 百万分之一制程统计品管专类SPC Statistical Process Control 统计制程管制SQC Statistical Quality Control 统计质量管理GRR Gauge Reproductiveness & Repeatability 量具之再制性及重测性判断量可靠与DIM Dimension 尺寸DIA Diameter 直径N Number 样品数其它质量术语类QIT Quality Improvement Team 质量改善小组ZD Zero Defect 零缺点QI Quality Improvement 质量改善QP Quality Policy 目标方针TQM Total Quality Management 全面质量管理RMA Return Material Audit 退料认可7QCTools 7 Quality Control Tools 品管七大手法通用之件类ECN Engineering Change Notice 工程变更通知(供货商) ECO Engineering Change Order 工程改动要求(客户)PCN Process Change Notice 工序改动通知PMP Product Management Plan 生产管制计划SIP Standard Inspection Procedure 制程检验标准程序SOP Standard Operation Procedure 制造作业规范IS Inspection Specification 成品检验规范BOM Bill Of Material 物料清单PS Package Specification 包装规范SPEC Specification 规格DWG Drawing 图面系统文件类ES Engineering Standard 工程标准CGOO China General PCE龙华厂文件IWS International Workman Standard 工艺标准ISO International Standard Organization 国际标准化组织GS General Specification 一般规格部类PMC Production & Material Control 生产和物料控制PCC Product control center 生产管制中心PPC Production Plan Control 生产计划控制MC Material Control 物料控制DC Document Center 资料中心QE Quality Engineering 质量工程(部)QA Quality Assurance 质量保证(处)QC Quality Control 质量管理(课)PD Product Department 生产部LAB Laboratory 实验室IE Industrial Engineering 工业工程R&D Research & Design 设计开发部生产类PCs Pieces 个(根,块等)PRS Pairs 双(对等)CTN Carton 卡通箱PAL Pallet/skid 栈板PO Purchasing Order 采购订单MO Manufacture Order 生产单D/C Date Code 生产日期码ID/C Identification Code (供货商)识别码SWR Special Work Request 特殊工作需求L/N Lot Number 批号P/N Part Number 料号OEM Original Equipment Manufacture 原设备制造PC Personal Computer 个人计算机CPU Central Processing Unit 中央处理器A.S.A.P As Soon As Possible 尽可能快的E-MAIL Electrical-Mail 电子邮件N/A Not Applicable 不适用QTY Quantity 数量I/O input/output 输入/输出NG Not Good 不行,不合格C=0 Critical=0 极严重不允许APP Approve 核准,认可,承认CHK Check 确认ASS'Y Assembly 装配,组装T/P True Position 真位度5WIH When, Where, Who, What, Why, How to6M Man, Machine, Material, Method, Measurement, Message4MTH Man, Material, Money, Method, Time, How 人力,物力,财务,技术,时间(资源SQA Strategy Quality Assurance 策略质量保证DQA Design Quality Assurance 设计质量保证MQA Manufacture Quality Assurance 制造质量保证SSQA Sales and service Quality Assurance 销售及服务质量保证LRR Lot Reject Rate 批退率SPS Switching power supply 电源箱DT Desk Top 卧式(机箱)MT Mini-Tower 立式(机箱)DVD Digital Video DiskVCD Video Compact DiskLCD Liquid Crystal DisplayCAD Computer Aided DesignCAM Computer Aided ManufacturingCAE Computer Aided EngineeringPCB Printed Circuit Board 印刷电路板CAR Correction Action Report 改善报告NG Not Good 不良WDR Weekly Delivery Requirement 周出货要求PPM Percent Per Million 百万分之一TPM Total Production Maintenance 全面生产保养MRP Material Requirement Planning 物料需计划OS Operation System 操作系统TBA To Be Assured 待定,定缺D/C Drawing ChangeP/P Plans & ProcedureEMI Electrical-Music Industry 电子音乐工业Electrical Magnetic Interference 电子干扰RFI Read Frequency Input 读频输入MMC Maximum Material ConditionMMS Maximum Material SizeLMC Least Material ConditionLMS Least Material SizeLED lighting-emitting diode 发光二极管QBR Quarter Business RecordCIP Continuous improvement processFGI Forecasted Goal InventoryCNC Computerized numeral controllerB2C Business to customerB2B Business to businessAVL Approved vendor listPOP Procedure of packagingEOL End of lifeVDCS Vender defect correcting sheet PDCS Process defect correcting sheet GRN Goods receiving noteA/R Accounting receivableA/P Accounting payable专业词汇通用类president董事长operator作业员position职务general manager总经理special assistant 特助deputy manager |'depjuti| =vice manager副理deputy supervisor =vice supervisor副课长group leader组长line leader线长supervisor 课长responsible department负责单位Human Resources Department人力资源部Head count 人头数production department生产部门planning department企划部QC Section品管课stamping factory冲压厂painting factory烤漆厂molding factory成型厂administration/general affairs dept./总务部production unit生产单位meeting minutes会议记录distribution department分发单位subject主题conclusion结论decision items决议事项pre-fixed finishing date预定完成日Color management 颜色管理Visual management 目视管理production capacity生产力first count初盘first check初盘复棹second count 复盘second check复盘复核quantity of physical inventory second count 复盘点数量physical inventory盘点数量physical count quantity账面数量difference quantity差异量spare parts physical inventory list备品盘点清单cause analysis原因分析waste materials废料description品名specification 规格model机种work order工令revision版次remark备注registration登记registration card登记卡to control管制application form for purchase请购单consume, consumption消耗to notify通知to fill in填写to collect, to gather收集statistics统计cosmetic inspection standard 外观检验规范 computer case 计算机外壳(组件)personal computer enclosure 计算机机箱产品front plate前板rear plate后板chassis |'∫æsi| 基座bezel panel面板Hood 上盖base pan 基座bezel 面板riser card 扩充卡flat cable 排线TOP driver cage 上磁架bottom driver cage 下磁架resin film 树脂膜raw materials原料materials物料steel plate钢板roll/coil material卷料spare parts =buffer备品plastic parts塑料件sheet metal parts/stamping parts 冲件material check list物料检查表finished product成品semi-finished product半成品good product/accepted goods/ accepted parts/good parts良品defective product/non-good parts不良品disposed goods处理品warehouse/hub仓库packing material包材basket蝴蝶竺plastic basket胶筐flow chart流程窗体production tempo生产进度现状lots of production生产批量manufacture procedure制程to revise, modify修订to switch over to, switch—to, switching over切换engineering bottleneck, project difficulty工程瓶颈glove(s)手套glove(s) with exposed fingers割手套Band-Aid创可贴Industrial alcohol工业酒精broom扫把mop拖把vacuum cleaner吸尘器rag 抹布garbage container灰箕garbage can垃圾箱garbage bag垃圾袋liaison联络单rags抹布lamp holder灯架to mop the floor拖地to clean a table擦桌子air pipe 气管delivery deadline交货期die worker模工production, to produce生产equipment设备resistance电阻beacon警示灯coolant冷却液crusher破碎机club car高尔夫球车plate电镀power button电源按键reset button重置键forklift叉车Workshop traveler 天车trailer =long vehicle拖板车Hydraulic trolley手压车hydraulic hand jack油压板车casing = containerization装箱velocity速度patent专利coordinate坐标supply and demand供求career card履历卡barricade隔板carton box纸箱to pull and stretch拉深work cell/work shop工作间sub-line支线bottleneck 瓶颈模具工程类plain die简易模pierce die冲孔模forming die成型模progressive die连续模stage die工程模compound die复合模shearing die剪边模riveting die铆合模feature die公母模male die公模female die母模cavity型控 母模core模心 公模die change 换模to fix a die装模to repair a die修模punch set上模座punch pad上垫板punch holder上夹板stripper pad脱料背板up stripper上脱料板upper plate上模板lower plate下模板die pad下垫板die holder下夹板bottom block下垫脚bottom plate下托板(底板)upper supporting blank上承板upper padding plate blank上垫板top plate上托板(顶板)top block上垫脚stripping plate内外打(脱料板)outer stripper外脱料板inner stripper内脱料板lower stripper下脱料板punch冲头insert入块(嵌入件)deburring punch压毛边冲子groove punch压线冲子stamped punch字模冲子round punch圆冲子special shape punch异形冲子bending block折刀roller滚轴baffle plate挡块located block定位块supporting block for location定位支承块air cushion plate气垫板air-cushion eject-rod气垫顶杆trimming punch切边冲子stiffening rib punch = stinger 加强筋冲子ribbon punch压筋冲子reel-stretch punch卷圆压平冲子guide plate定位板sliding block滑块sliding dowel block滑块固定块die locker锁模器pressure plate =plate pinch压板thickness gauge厚薄规cutting die, blanking die冲裁模folded block折弯块sliding block滑块location pin定位销lifting pin顶料销die plate, front board模板padding block垫块stepping bar垫条panel board镶块to load a die装上模具to unload a die 御模具active plate活动板lower sliding plate下滑块板upper holder block上压块upper mid plate上中间板spring box弹簧箱spring-box eject-rod弹簧箱顶杆spring-box eject-plate弹簧箱顶板bushing block衬套cover plate盖板guide pad导料块pilot导正筒trim剪外边pierce剪内边pocket for the punch head挂钩槽slug hole废料孔radius半径shim/wedge/heel/pad/spacer/gasket楔子torch-flame cut火焰切割set screw止付螺丝form block折刀round pierce punch =die button圆冲子shape punch =die insert异形子stock located block定位块metal plate钣金miller铣床grinder磨床tolerance公差score =groove压线sliding block滑块lathe车active plate活动板baffle plate挡块cover plate盖板groove punch压线冲子air-cushion eject-rod气垫顶杆spring-box eject-plate弹簧箱顶板capability能力parameter参数factor系数driller钻床set up die架模height of die setting up架模高度analog-mode device类模器inner guiding post内导柱inner hexagon screw内六角螺钉dowel pin固定销coil spring弹簧lifter pin顶料销eq-height sleeves =spool等高套筒pin销lifter guide pin浮升导料销guide pin导正销wire spring圆线弹簧outer guiding post外导柱stop screw止付螺丝located pin定位销outer bush外导套press specification冲床规格die height闭模高度flow mark流痕welding mark溶合痕post screw insert螺纹套筒埋值self tapping screw自攻螺丝stripper plate脱料板piston活塞handle mold手持式模具flash mold溢流式模具positive mold挤压式模具split mold分割式模具die lifter举模器top stop上死点bottom stop下死点one stroke一行程to continue, cont.连动to grip(material)吸料location lump, locating piece, location block定位块reset复位to file burr 锉毛刺embedded lump |in'bed| |l mp|镶块stamping-missing漏冲to tight a bolt拧紧螺栓to loosen a bolt拧松螺栓punched hole冲孔to cut edge =side cut =side scrap 切边to bending折弯to pull, to stretch拉伸engraving, to engrave刻印stamping 油印to stake铆合designing, to design设计design modification 设计修改成gauge(or jig)治具pedal踩踏板stopper阻挡器flow board流水板torque扭矩spline =the multiple keys花键quenching淬火tempering回火annealing退火carbonization碳化alloy合金tungsten high speed steel钨高速的moly high speed steel钼高速的forming成型(抽凸,冲凸)draw hole抽孔bending折弯emboss凸点dome凸圆semi-shearing半剪stamp mark冲记号deburr or coin压毛边punch riveting冲压铆合side stretch侧冲压平reel stretch卷圆压平groove压线stamp letter冲字(料号)tick-mark nearside正面压印tick-mark farside反面压印冲压类punch, press冲punching machine 冲床hydraulic machine油压机jack升降机decoiler整平机manufacture management制造管理stamping, press冲压feeder送料机rack, shelf, stack料架taker取料机to reverse material 翻料to load material上料to unload material卸料to return material/stock to退料scraped |'skræpid|报废scrape ..v.刮;削robot机械手production line流水线packaging tool打包机packaging打包成型类well type蓄料井insulated runner绝缘浇道方式hot runner热浇道runner plat浇道模块valve gate阀门浇口band heater环带状的电热器spindle阀针spear head刨尖头slag well冷料井cold slag冷料渣air vent排气道welding line熔合痕eject pin顶出针knock pin顶出销return pin回位销反顶针sleeve套筒stripper plate脱料板insert core放置入子runner stripper plate浇道脱料板guide pin导销eject rod (bar)(成型机)顶业捧subzero深冷处理three plate三极式模具runner system浇道系统stress crack应力电裂orientation定向sprue gate射料浇口,直浇口nozzle射嘴sprue lock pin料头钩销(拉料杆)slag well冷料井side gate侧浇口edge gate侧缘浇口tab gate搭接浇口film gate薄膜浇口flash gate闸门浇口slit gate缝隙浇口fan gate扇形浇口dish gate因盘形浇口diaphragm gate隔膜浇口ring gate环形浇口submarine gate潜入式浇口tunnel gate隧道式浇口pin gate针点浇口runner less无浇道sprue less 无射料管方式long nozzle延长喷嘴方式spur浇口;溶waste废料board广告牌sliding rack滑料架to impose lines压线to compress, compressing压缩character die字模to feed, feeding送料material change, stock change材料变更feature change 特性变更prepare for, make preparations for 准备rotating speed, revolution转速abnormal handling异常处理组装类Assembly line组装线Layout布置图Conveyer流水线运输带Rivet machine拉钉机Rivet gun拉钉枪Screw driver起子Electric screw driver电动起子Hydraulic machine 液压机Pneumatic screw driver气动起子automation自动化to stake, staking, riveting铆合add lubricant oil加润滑油argon welding氩焊cylinder油缸robot机械手conveying belt输送带transmission rack输送架to draw holes抽孔bolt螺栓nut 螺母screw 螺丝identification tag标示单screwdriver plug起子插座automatic screwdriver电动启子to move, to carry, to handle搬运be put in storage入库packing包装staker = riveting machine铆合机fit together组装在一起fasten锁紧(螺丝)fixture 夹具(治具)pallet/skid栈板barcode条形码barcode scanner条形码扫描仪fuse together熔合fuse machine/heat stake热熔机processing, to process加工delivery, to deliver 交货to return delivery to. to send delivery back to return of goods退货easily damaged parts易损件standard parts标准件to lubricate润滑spring 弹簧spare tools location/buffer手工备品仓spare molds location模具备品仓tox machine自铆机烤漆类phosphate皮膜化成viscosity涂料粘度alkalidipping脱脂main manifold主集流脉organic solvent有机溶剂demagnetization去磁;消磁high-speed transmission高速传递heat dissipation热传rack上料volatile挥发性degrease脱脂rinse水洗alkaline etch龄咬desmot剥黑膜D.I. rinse纯水次Chromate铬酸处理Anodize阳性处理seal封孔scraped products报放品disposed products处理品dismantle the die折模auxiliary function辅助功能heater band 加热片thermocouple热电偶derusting machine除锈机degate打浇口dryer烘干机induction感应induction light感应光response =reaction =interaction感应ram连杆edge finder巡边器concave凸convex凹cold slug冷块blush 导色gouge沟槽;凿槽satin texture段面咬花witness line证示线grit沙砾granule =pellet =grain细粒sand blasting喷沙grit maker抽粒机cushion缓冲fillet镶;嵌边roller pin formality滚针形式cam driver铡楔shank摸柄crank shaft曲柄轴品质类qualified products, up-to-grade products良品defective products, not up-to-grade products不良品defective product box不良品箱poor processing 制程不良poor incoming part来件不良exposed metal/bare metal金属裸露。

计算机化系统的OQ和PQ有什么不同CSV执行过程的PQ内容,在OQ中都做过了,在PQ中又重复做了一遍。

完全不知道这个PQ的意义在哪里首先我们来看一下计算机化系统OQ和PQ的官方定义(WHO计算机化系统验证指南):0Q:运行或功能测试,提供软件和硬件功能在预期范围内的文件化证明。

基于风险的功能测试包含:1.合理程度的挑战性测试(如,界限、范围、限度及无意义的输入),确认系统可以正确的处理不正确的输入和使用。

2 .确认警报或基于条件的触发。

3 .标识无效信号或数据被修改。

PQ:包含UAT,以确认URS及设计确认中,或其他等同文件的预期或管理.1PQ应在生产环境下执行,或等同生产环境(硬件和软件条件)。

2 .如适用,基于系统预期用途在生产环境下的负载/压力/容量测试。

3 .应执行适当的端到端的回归测试,证明系统组件配置完成并部署到生产环境后,可以满足预期用途。

4 .应进行UAT测试、SOP使用及培训项目的妥善性,确认在计算机化系统内生产数据的能力,系统能够有效的审核数据和元数据的能力,如审计追踪。

通过定义,我很容易发现,OQ和PQ的区别如下:IQQ仅仅是各模块功能测试,其不追求流程的完整性。

并且其没有系统环境的要求。

2 .PQ包含软件配置的流程测试、硬件的性能测试、必要的OQ回归测试。

3 .PQ需要在生产环境下,如果不是生产环境,在PQ结束后,我们需要证明用于验证的环境与生产环境的等同性。

另外,还需要基于风险进行一定的OQ回归。

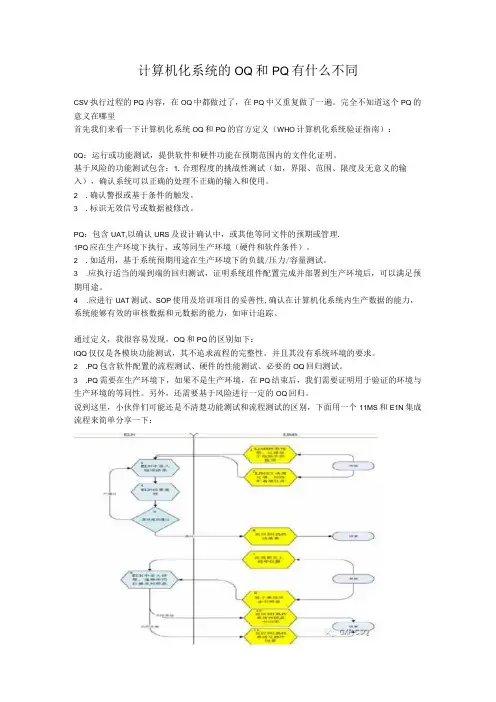

说到这里,小伙伴们可能还是不清楚功能测试和流程测试的区别,下面用一个11MS和E1N集成流程来简单分享一下:上图为一个E1N和1IMS集成的流程图,我们来分析一下OQ和UAT的不同:OQ需要测试每个功能块的功能,如IE1N录入功能,正确其系统可以录入有效数据,避免无效录入,录入后数字签名及审计追踪等。

所有的风险功能点全部测试到,并且不会重复。

UAT涉及多个功能块组成的流程,涉及1IMS仪器创建模块-E1N仪器录入模块-1IMS对照品模块并和1IMS 及E1N安全模块共同组合完成了对照品仪器选择录入的流程。

oqcq自动化线体架设阶段OQCQ(Optical Quality Control and Quality Assurance)是一种光学质量控制和质量保证系统,它通常用于光学元件或光学产品的制造过程中。

在自动化线体架设阶段,你可能需要考虑以下步骤:1. 确定系统需求:首先,你需要明确自动化线体的要求和目标。

这包括确定需要进行的质量控制和质量保证的任务、测试的类型和标准,以及所需的自动化设备和工具。

2. 设计线体布局:根据系统需求,设计线体的布局。

考虑到测试设备的安装位置、光学元件的输送和定位方式,以及线体中的工作站和工作流程。

确保线体布局合理,方便操作和维护。

3. 选择自动化设备:根据系统需求,选择适合的自动化设备和工具。

这可能包括自动化输送系统、机械臂、视觉检测系统、精密定位装置等。

确保选用的设备能够满足质量控制和质量保证的要求,并能够与其他设备和系统进行良好的集成。

4. 安装设备和系统:按照设计的线体布局,安装自动化设备和系统。

确保设备安装牢固、稳定,并进行必要的校准和调试。

5. 开发自动化控制程序:根据系统需求和设备特性,开发自动化控制程序。

这包括编写控制软件、编程机械臂的运动轨迹、配置视觉检测系统等。

确保控制程序能够实现准确的测试和检测,并能够与其他系统进行数据交互和通信。

6. 进行测试和验证:在线体架设完成后,进行测试和验证。

这包括对自动化线体进行功能测试、性能测试和质量验证。

确保线体能够正常运行,并满足质量控制和质量保证的要求。

7. 进行优化和改进:根据测试和验证的结果,对线体进行优化和改进。

这可能包括调整设备的参数和设置,改进控制程序的算法和逻辑,以及优化工作流程和效率。

8. 培训和运营:为操作员提供必要的培训,确保他们了解如何正确操作和维护自动化线体。

建立运营和维护的流程和标准,定期进行线体的维护和保养。

质量体系缩写中英文对照AAR:外观批准报告ADV:分析/开发/验证ADV-DV:ADV设计验证A/S/V P &R:分析/开发/验证计划和报告ADV-PV:ADV产品验证AIAG:汽车工业行动集团AP:先期采购APQP:产品质量先期筹划APO:(通用)亚太分部APQP Project Plan:APQP项目筹划ASQE:先期供应商质量工程师BOM:材料清单BOP:过程清单Brownfield Site:扩建场地CMM:三坐标测试仪M Complex System/Subassembly:M复杂系统/分总成CPK:过程能力指数CTS:零件技术规范Defect outflow detection:缺陷检测DFM/DFA:可制造性/可装配性设计DFMEA:设计失效模式分析DPV:每辆车缺陷数DRE:设计发放工程师Error Occurrence Prevevtion:防错EWO:工程更改指令FE1,2,3:功能评估GD&T:几何尺寸&尺寸GM:通用汽车公司GME:通用汽车欧洲分部GM9000:指QS9000GP:总体环节GPDS:全球产品描述系统GPS:全球采购系统GQTS:全球质量跟踪系统GR&R:量具旳反复性与再现性Greenfield Site:新建工厂GVDP:全球车辆开发工程IPTV:每千辆车缺陷数KCC:核心控制特性KCDS:核心特性批示系统Kiek-Off Meeting:启动会议KPC:核心产品特性LAO:(通用)拉丁美洲分部LCR:最低生产能力MCR:最大生产能力MOP:制造/采购MPC:物料生产控制MPCE:欧洲物料生产控制MRD:物料需求日期MSA:测量系统分析MVBns:非销售车制造验证MVBs:销售车制造验证NAO:(通用)北美分部NBH:停止新业务N.O.D:决策告知OEM:主机客户PAD:生产装配文献PC&L:生产控制&物流PDT:产品开发小组PFMEA:潜在失效模式分析PPAP:生产件批准程序PPM:1)项目采购经理2)每百万件旳产品缺陷数PPK:过程能力指数PQC:产品质量特性PR/R:问题报告及解决PSA:潜在供应商评审QSA:质量系统评审QTC:工装报价能力RASIC:负责、批准、支持、告知、讨论RFQ:报价规定RPN:风险顺序数RPN Reduction Plan:减少RPN值计划SDE:供应商开发工程师SFMEA:系统失效模式失效SMT:系统管理小组SOA:加速开始SOP:正式生产SOR:规定声明:SPC:记录过程控制SPO:(通用汽车)零件与服务分部SQ:供应商质量SQE:供应商质量工程师SQIP:供应商质量改善过程SSF:系统填充开始SSTS:分系统技术规范S.T.E.P:采购定点小组评估过程M Subcontractor:M分供方Team Feasibility Commitment:小组可行性承诺UG:UG工程绘图造型系统VDP:车辆开发过程VLE:车辆平台负责人WWP:全球采购序号缩写英文原文解释1 OTS overall tooling sample用批量生产旳工模器具制造出旳样件2 PVS Produktions – Versuchs - Serie 批量试生产3 TMA Trial Manufacturing Agreement 试制合同4 QSV Qualitaes-Sicherungs-Vereinbarung 质量保证合同5 BMG Bau-Muster-Genehmigung产品工程样件性能检查承认6 B- Freigabe 采购承认7 D- Freigabe 试制/0批量旳承认8 P- Freigabe 计划承认9 TL 技术资料汇编10 LH LastenHeft 规定汇总书11 Pflichtenheft 责任汇总书12 ME Markt-Einfuehrung 市场导入13 MIS Management Informations-System 管理信息系统14 Nullserie 零批量15 QPN Qualifizierungs-Programm Neuteile 新零件质量提高计划16 SOP Start-Of-Production 批量生产启动Standard Operating Procedure 原则操作程序17 QSR 质量体系规定18 APQP Adavanced part quality plan 高级产品质量计划19 PPAP product part approval procedure 生产件批准程序20 QSA 质量体系评审21 MSA measurement system analysis 测量系统分析22 FMEA 失效模式及成果分析23 SPC 记录过程控制QC(Quality Control)质量控制,就是质检,通俗说就是检查QA(Quality Assurance)QA中文全称:质量保证IPQC(In-Process Quality Control)品质管理项目制程检查IQC来料检查,就是原材料检查QC旳层次要比QA低,通俗来说就是检查员QA人员旳重要任务就是监督药物从原料进厂到成品出厂旳全过程旳质量;QC 就是对药物原料和成品旳所含重要成分进行检测,重要是给出原料和成品旳检测数据.在药厂QC比QA轻松一点,但QA不需要懂得仪器旳操作,只要懂得成品和原料旳指标,并用QC提供旳数据来判断原料和成品与否合格批准进厂或出厂.在液相中设立这个重要是为制药厂考虑旳,能减少诸多不必要旳反复工作.IQC 是来料控制,也就是进货检查OQC 是出货检查也就是出厂检查QC 是质量检查QA 指质量测试IPQC 制程控制PE 指制程工程师IE 指文献工程师-----------------------------------------------QC中文全称: 即英文QUALITY CONTROL旳简称,中文意义是品质控制,质量检查。

IQ,OQ,PQ验证分析仪器的3Q验证并不是一个新的课题,但由于长久以来,国内制药界普遍对于产品品质系统的轻忽,导致我们对于各项认证的内含,亦感到相当陌生与疑惑,本文将对分析仪器的各项验证作概略性的介绍,并提出关键性的策略,供药界先进参考。

概述严格说来,药品在制造生产的过程当中均需透过层层严密的确认,来证实药品的安全性及其品质确实有效、可靠,而欲达到这样的目的,就必须对各种生产有关的事 项,作一连串符合科学性的评鉴,包括各种仪器、分析方法、支援系统与制造过程的验证等,而我们将这些过程统称为确效(Validation)。

换句话说确 效是对产品的各项相关事项作出科学性的评价及书面记录的过程,因此仪器的验证只是确效作业中的一环,其目的是保证仪器在使用的过程当中,符合原设计的要求 并达到原拟的目的,亦即产生可信赖的量测结果。

欲达到上述的要求,我们就必须设计出一套审慎周密的验证(Qualification)计划及有效的测试(Test)方法;但首先我们要强调的是,验证与 测试并不相同,验证是着重于评鉴系统是否按预期的功能运行,它的重点在于核对文件是否完整正确,而测试则是指对系统中误差的鉴定,重点在于评估预测值与实 际结果的差异。

因此我们可以说验证包含测试;而一套完整的仪器验证计划书通常包含三个部分,亦即我们所熟悉的:安装验证IQ、操作验证OQ及性能验证 PQ。

仪器验证的内含:在使用者的层阶,合理的仪器验证应包含上述三个的进程,但实际上仪器在出厂前,还必须历经所谓的设计及开发验证DQ(Design and Development Qualification)才能真正算是通过合格的仪器测试,如表1所示:表1、4Q关系表设计 ----→安装----→调整----→开机----→使用----→Design and Development Qualification (DQ)设计及开发验证 InstallationQualification(IQ)安装验证OperationalQualification(OQ)操作验证PerformanceQualification(PQ)性能验证因此,我们很清楚的从上图中,区分出整个确效的三个阶段,DQ部分完全是仪器供应商的工作,而IQ/OQ则必须由供应商与使用者共同来参与,至于PQ则应由使用者来完成,而且执行的顺序不能颠倒。