高射程喷雾机说明书

- 格式:doc

- 大小:1021.50 KB

- 文档页数:8

消防设备喷雾机操作规程一、前言消防设备喷雾机是一种重要的消防设备,用于进行消防喷淋工作。

为了保障消防安全,提高喷雾机的操作效果,特制定本操作规程。

二、装备检查与准备1. 检查喷雾机设备的完好性,包括喷雾机本体、喷嘴、水源接口和电源等部分,确保没有损坏或松动。

2. 确定喷雾机的水源接口,并连接好水源。

同时,检查水源的稳定性和充足性,保证喷雾机的正常运行。

3. 检查电源接口的连接情况,确认喷雾机的电源正常供电。

4. 佩戴好个人防护装备,包括头盔、防护服、防护手套等。

三、操作步骤1. 打开水源:根据实际情况打开水源接口,确保稳定供水。

2. 操作喷雾机:按下开关,启动喷雾机。

根据需要可调节出水压力,确保喷雾机的工作在最佳状态。

3. 移动喷雾机:手握喷雾机把手,根据需要迅速移动到喷雾区域。

注意行走时要稳定,避免摔倒或滑倒。

4. 喷雾操作:对准喷雾目标,保持适当的喷雾距离,持续进行喷雾操作。

注意不要将喷嘴对准人员或电器等易受损物品。

5. 警戒周围环境:喷雾作业期间要时刻关注周围环境变化,确保人员安全。

如遇急事或突发情况,立即停止喷雾操作,采取相应的应急措施。

四、注意事项1. 操作喷雾机前必须熟悉设备的使用说明书,确保正确操作。

2. 喷雾机在使用过程中如有异常,应立即停用,排除故障后再使用。

3. 不得私自改动喷雾机的任何部件,必要时应由专业技术人员进行维修。

4. 喷雾机使用完毕后,及时关闭水源接口、切断电源,并进行设备的清洁和检查。

五、应急措施1. 在喷雾作业中如发生火灾等紧急情况,要立即停止喷雾操作,迅速撤离现场,并及时报警。

2. 如喷雾机发生故障或意外情况,应立即停机,并进行紧急处理。

3. 在执行消防喷雾任务时,要与其他人员保持有效的沟通,遵循指挥员的指示和命令。

六、总结本操作规程旨在确保消防设备喷雾机的正确操作,提高消防工作的效率和安全性。

在实际操作中,要严格按照规程要求进行操作,并做好相关安全措施,以保障人员的安全和消防工作的顺利进行。

喷雾机的使用流程解步骤1. 准备工作在使用喷雾机之前,需要进行以下准备工作:•确认喷雾机的完好性,检查是否有损坏或缺损的部件。

•确保喷雾机内部的液体储存容器已装满所需的药剂或液体。

•确保喷雾机的电源已连接,并且电源开关处于关闭状态。

•穿戴适当的个人防护装备,如手套、护目镜和口罩。

2. 设定喷雾机参数在开始使用喷雾机之前,需要进行以下参数设定:•调整喷雾机的喷雾量。

根据实际需求,选择合适的喷雾量大小。

•调整喷雾机的喷雾角度。

根据实际使用场景,选择合适的喷雾角度。

•调整喷雾机的喷雾距离。

根据实际需求,选择喷雾机的喷雾距离。

3. 启动喷雾机启动喷雾机的步骤如下:1.将喷雾机的电源开关打开。

2.确认喷雾机已连接到电源,并且电源供应正常。

3.按下喷雾机的启动按钮或开关,开始喷雾作业。

4. 进行喷雾作业在启动喷雾机之后,可以开始进行喷雾作业。

以下是进行喷雾作业的步骤:1.将喷雾机的喷雾喷嘴对准需要喷雾的目标区域。

2.按住喷雾机的扳机或按钮,开始喷雾操作。

3.均匀地移动喷雾机,确保喷雾液体均匀地覆盖目标区域。

4.根据需要,调整喷雾机的喷雾量、喷雾角度或喷雾距离。

5. 完成喷雾作业当喷雾作业完成之后,需要进行以下步骤:1.停止喷雾机的喷雾操作,松开扳机或按钮。

2.关闭喷雾机的电源开关,将电源供应切断。

3.清洁喷雾机的喷雾喷嘴和液体储存容器,以防止堵塞或残留液体对下次使用的影响。

4.存放喷雾机的储存容器和喷嘴,确保它们安全并易于找到。

6. 注意事项在使用喷雾机时,需要注意以下事项:•确保操作者按照说明书中的要求正确操作喷雾机。

•避免将喷雾机直接对准人体或动物,以免造成伤害或不适。

•避免将喷雾机的喷雾液体喷洒到食品、水源或草地等易受污染的区域。

•使用喷雾机时,确保周围环境通风良好,以避免喷雾液体引起呼吸道疾病或其他健康问题。

•每次使用喷雾机之前,要清洁喷嘴和液体储存容器,以防止不同药剂之间的交叉污染。

以上是使用喷雾机的使用流程解步骤,通过正确的准备工作、设定参数、启动喷雾机、进行喷雾作业和完成喷雾作业等步骤,可以确保喷雾机的正常使用和喷雾效果。

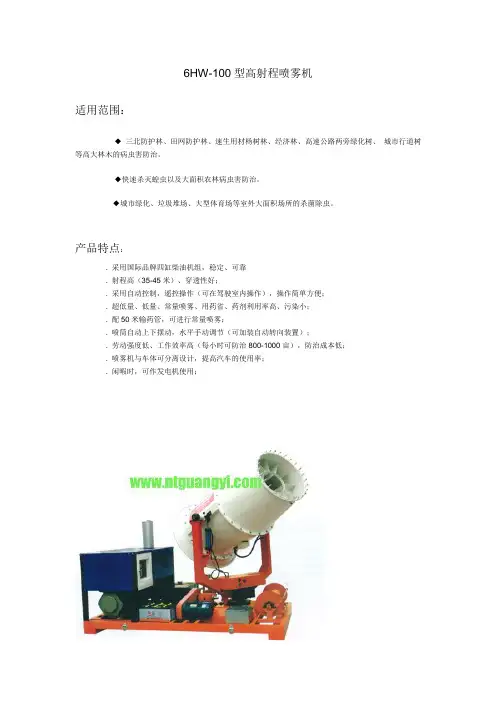

6HW-100型高射程喷雾机

适用范围:

◆三北防护林、田网防护林、速生用材杨树林、经济林、高速公路两旁绿化树、城市行道树等高大林木的病虫害防治。

◆快速杀灭蝗虫以及大面积农林病虫害防治。

◆城市绿化、垃圾堆场、大型体育场等室外大面积场所的杀菌除虫。

产品特点:

. 采用国际品牌四缸柴油机组,稳定、可靠

. 射程高(35-45米)、穿透性好;

. 采用自动控制,遥控操作(可在驾驶室内操作),操作简单方便;

. 超低量、低量、常量喷雾、用药省、药剂利用率高、污染小;

. 配50米输药管,可进行常量喷雾;

. 喷筒自动上下摆动,水平手动调节(可加装自动转向装置);

. 劳动强度低、工作效率高(每小时可防治800-1000亩),防治成本低;

. 喷雾机与车体可分离设计,提高汽车的使用率;

. 闲暇时,可作发电机使用;。

MF 9300Self-propelled SprayerDelivering precision, capacity and comfort, this is straight-forward machinery to cover more hectares per day while minimizing operating costs.To meet the demand in the market for a robust, entry level machine, Massey Ferguson introduces the MF 9300 self propelled sprayer. Designed for small and medium sized applications, operators will appreciate its simplicity, strength and value.The MF 9300 Plus is synonymous with technology, durability and performance. Manufactured in Canoas, Brazil for over six years, this machine has proven tremendous success.At Massey Ferguson, we understand the need for simplicity. Each featureof the MF 9300 Plus self-propelled sprayer has been designed, tried andtested to meet your needs.The joy of simplicityThe MF 9300 Plus is equipped with the distinguished AGCO POWER 6.6 liter Tier 3 engine .With unmatched fuel economy when coupled to the machine’s hydrostatic drive system, the power and torque characteristics of this machine surpass that of its competitors .The engine is programmed to create maximum torque where the drive system requires, providing healthy torque at low revs with 210 HP and 790 Nm of torque at 1,800 rpm.The excellent build quality and latest engine technology guarantees optimumfuel efficiency, maximum power, reliability and longevity.The heart of a BeastPrecision engine performanceThe MF 9300 Plus utilizes Bosch Rexroth components in its effective cross drive transmission.Undulating country, hills and boggy paddocks are a breeze, With huge amounts of torque and no loss of traction, the sprayer gives you the control in even the toughest conditions.Two large capacity 90cc variable displacement pumps drive opposing wheel motors on the front and rear of the machine. The hydrostatic drive system has a poly link between the flywheel and the first pump, providing a fail-safe in the event of a pump failure.The key to an efficient day’s work is choosing reliable machinery that will help you get more done in less time over a range of tasks.Cross Drive TransmissionA feature unique to the MF 9300 Plus is the addition of The DA (double acting) valve to the hydrostatic drive system.Most hydrostatic machines require 26 bars of pressure from the pumps beforethe wheel motors will accept oil, this in turn results in the engine running at over 2,000 rpm and in some cases, up to 2,500 rpm.The DA valve allows the wheel motors to accept oil at seven bars which occursat a low 1,250 rpm. The MF 9300 Plus differs when the system hits 26 barpressure at 1,800 rpm, allowing full torque from the engine and transmission providing fuel economy normally unseen in a hydro sprayer.Hydrostatic Drive SystemC-Flex ChassisThe fully bolted C-flex chassis gives the MF 9300 the ability to traverse channels, banks and contours most would not attempt.The frame is not welded at any point, so when the suspension runs out of travel, the chassis itself will flex, allowing all wheels to stay in contact with the ground, ensuring the safety and agility of the MF 9300 even in the most adverse conditionsManufactured from high rupture resistant material, the large C rails of the chassis add to the machine’s robustness, giving the operator piece of mind no matter how demanding the terrain is.Stay GroundedA sprayer covers demanding conditions, and a tough chassis is the assurance the operator needs to guarantee safety on any given day.SuspensionEach airbag is controlled by its own dedicated mechanical valve making sure the ride is adjusted to every change in condition.The suspension is fed by a large 20 liter reservoir with a mechanically driven compressor at the engine with two conveniently located outlets for cleaning the nozzles and cabin.The active airbag suspension is simple, reliable and delivers a smooth ride in the fieldand on the road in transport.Many of these parts are commonly used heavy duty truck components such as sway bars and shackles, which require no maintenance at all.Not only does the suspension system offer acomfortable ride, but it also offers a longer service life as shock loads are soaked up bythe suspension, not the chassis and boom.Independent active pneumatic suspensionStabilizer barBoomsThe boom is a design used by AGCO for many years with added strength to handle arduous South American conditions. Consequently, the boom is strong, reliable and floats exceedingly well even in high speed spraying applications.The Plumbing SystemMassey Ferguson is world-renowned for the easy use of its machines and the filling station of the MF 9300 is no different; it’s simple to understand and operate.Features include:• 2” and 3” cam lock fill point • 568 l/min reload pump • Unload point• 26.5 litre hypro chem hopper• Adjustable agitation rate• Fresh water pump on/off• Tank rinse• Hand wash• Air connection for nozzle cleaning The 3000 liter tank has dual hydraulic agitators and a singleoscillating tank rinse nozzle fed by a 240 litre fresh waterreservoir. The tank sits in a cradle which allows the chassisto flex if required beneath the tank.Features include:• 40 litre standalone hand wash tank• Adjustable agitation rate• high and low level tank sensors The main sprayer pump is a 549 l/min Hypro “Force Field” run dry pump controlled by a PWM valve. Enforcing its efficiency, the MF 9300 keeps the pump running at precisely the right rate to maintain the correct output of the product even during speed changes.Allowing the operator to quickly fill the tank from dams and tanks when necessary, the 568 l/min reload pump is also a standard fitting on the MF 9300.Main Commodity TankFilling Station Commodity PumpsThe best working environmentDesigned for safety, clarity and comfort; the MF 9300 gives you the kind of work environment you need to get through a tough day’s work.The cabin of the MF 9300 is simple, uncluttered and functional to maximize operator comfort and safety.Controls are ergonomically arranged, within easy reach and the cabin provides a generous amount of space to increase daily productivity and reduce fatigue, especially when spending long hours behind the wheel.The adjustable air ride seat combined with the air-conditioning system and low levels of noise and vibrations ensures a comfortable and pleasant work station at any time of the year.Effortless comfortIn addition to providing the operator with an excellent view of the front, sides and rear, the positioning of the cab allows great vision of the tyres and boom.Better visibilityTechnologyThe MF 9300 has been fitted with the latest technology, assisting with accuracy and data recording.The MF 9300 arrives from the factory fitted with autonomous auto steer. However, the options don’t end there; this can be upgraded to sub-meter at any time. If at any point, higher precision is required, it can be upgraded to RTK.To monitor productivity, all jobs and spray data can be recorded on the C3000 terminal and easily stored onto a USB for record keeping and data analysis.The MF 9300 is fitted with telemetry, offering the ability to track and monitor machines from your office which provides an insight into the machine’s operational efficiency and anypotential breakdowns before they may occur.Specifications© AGCO South Africa. 2021 | 17347 | English®is a worldwide brand of AGCO.Facebook: /MasseyFergusonSA Twitter: /MF_EAMEInstagram: /MasseyFergusonGlobal YouTube: /MasseyFergusonGlobal Blog: AGCO South Africa Marketing16 Pomona Road, Kempton Park, Gauteng, 1619。

动力喷雾机的使用说明

A.操作说明。

1.检查每个扣件,确定喷雾机与马达都稳固的装在架子上。

2.两个皮带轮应装于一直线上,皮带应松紧适中。

3.管子的每个接头都要锁紧以防止拽漏。

4.启动马达以前应关掉出水开关,转松调压螺丝,再将调压把手拉倒顶端。

5.启动马达带动喷雾机,保持适当转速,并将调压把手压至低端。

调整调压螺

丝保持压力于21KG至35KG之间。

6.打开出水开关,开始喷雾。

7.喷雾完毕,将调压把手拉至顶端,并以清水操作喷雾机以清除内部残留之化

学品。

B.泵的润滑。

1.喷雾机在使用最初10小时与50小时量应更换机油,以后每隔70小时应更

换一次。

2.旋开拽油螺丝,排除肮脏机油。

3.拽油螺丝锁紧后,打开加油盖并注入30至40号清洁机油。

4.油面应保持在油镜三分之二的位置。

5.黄油杯经常要加满黄油,每使用2小时应将黄油杯旋转2至3圈。

C.故障排除。

a.无法供水及压力不稳。

1.检查吸水塑料管是否拽油或阻塞。

2.打开出水开关排除多余空气。

3.取下进水室及排水室,检查活门是否阻塞或损坏。

b.压力不足。

1.检查压力是否调整适当。

2.检查皮带是否太松。

3.检查喷雾管与接头是否拽漏或损坏。

c.气缸拽油。

1.取下防尘盖,旋紧调整圈。

2.如仍无效,则换掉气缸内V型迫紧。

产品简介为了解决老式喷雾器的一些不足和将一些喷雾器的优点尽量进行整合,本厂生产的拥有自主知识产权的新型无能耗可升级高压自锁自动喷雾器,是您的首选。

该喷雾器有益效果是:(1)每次压进喷雾器内的药液能一次喷完,中途不要加压,而且药液喷完后自锁装置会自动锁气提醒使用者关闭喷药开关,从而能使液气罐内保留一定的预置气压供下次循环使用。

(2)用户嫌容水量小时可进行容量升级扩展,无须将原来喷雾器搁置重买。

(3)喷雾器自身带有安全阀和气压表既能直观知道液气罐内压力又能在液气罐内压力超过规定值时自动释放多余压力,保证喷雾器不被超压损坏。

(4)该喷雾器粗喷雾射程达7到9米,细喷雾比普通喷雾器效率提高2到4倍。

(5)喷管组件的安装位置可左右对调,适应使用者用手习惯。

(6)无燃料消耗、废气排放、药液泄漏、不产生噪音、振动和高温,整个喷雾器采用开放式设计,即使有故障很容易找到故障点,维修方便。

下面分别从使用和技术层面上作些说明:一.使用须知(1)新购喷雾器拆箱后,先观察外观是否完好无损,如有损坏请当场调换,检查随机的修理包是否丢失。

(产品批次不同所配备的喷头可能型状有所区别)察看压力表是否指示桶内压力为0.16—0.18mpa,气压表表盘上的宽蓝线部分(0.16至0.18之间)为空桶时,喷雾器内应具备的预置基础气体压强,如果压力为0或低于0.16mpa,可先关上开关再将进水管的入水口伸到水里,抬压加压手柄几次吸入少量水,压水器皮圈长时间不用如果拉不动或阻力比较大不要硬拉,硬拉会损坏皮圈,此时应该拧下加压泵上盖帽向活塞上面不锈钢管内灌点水润滑一下活塞就拉得动了,条件许可加一点(约0.5毫升)食用油效果会更好些。

然后把进水管的入水口从水里拿出来,让进水口暴露在空气中只进空气不进水,此时快速抬压压水器手柄,就可向桶内(液气罐)打气。

当表针指到0.16mpa 便可投入使用,整个过程(从0打到0.16mpa)只要3分钟左右。

顺便说一下,喷雾器内的基础气压能长期保存和不能长期保存具有一定的偶然性,大家要有一个平和的心态去对待,不要认为喷雾器内没有基础气压就是坏了,正确的观点应该是:有气直接用;没气先打气;气少补一点。

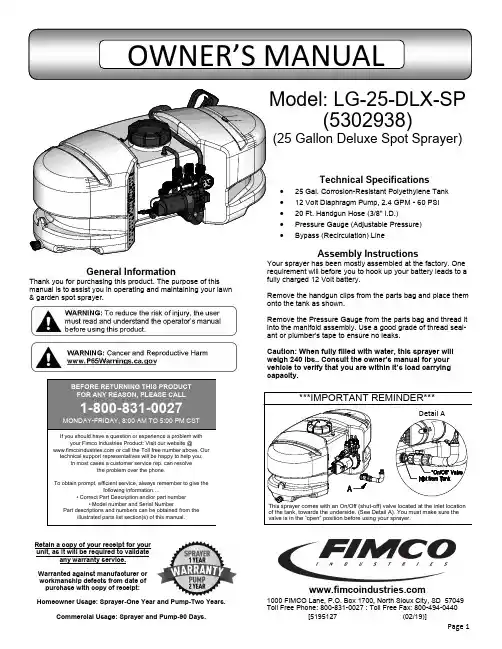

1000 FIMCO Lane, P.O. Box 1700, North Sioux City, SD 57049 Toll Free Phone: 800-831-0027 : Toll Free Fax: 800-494-0440[5195127 (02/19)]BEFORE RETURNING THIS PRODUCT FOR ANY REASON, PLEASE CALLRetain a copy of your receipt for your unit, as it will be required to validateany warranty service.Warranted against manufacturer or workmanship defects from date of purchase with copy of receipt:Homeowner Usage: Sprayer -One Year and Pump -Two Years.Commercial Usage: Sprayer and Pump -90 Days.Connect the lead wire to a fully charged 12 volt battery. You may use either a stand-alone battery or the battery on your towing vehicle. Connect to the positive (red) terminal first, then connect to the negative (black) terminal. Then connect the end of the lead wire to the end of the pump. When discon-necting, disconnect the end of the pump wire from the lead wire, then disconnect the negative (black) connection and finally the positive (red) connec-tion. The lead wire has an On/Off switch to activate the pump. “-” is on and “O” is off.Fill the tank part way with water and then add the desired amount of chemical to be sprayed. Finish filling tank to proper level. Turn the pump on and by depressing the “-” side of the rocker switch. The pump is equipped with a pressure switch that is pre-set at the factory to shut the pump off when all discharges are closed.The pump will turn back on when one of the following actions occurs:♦ Handgun lever is squeezed to spray the handgun.♦ Bypass valve is opened to re-circulate solution back into the tank.When spraying with the handgun, pressure may be reduced by slowly opening the bypass valve until desired pressure is achieved. Opening the valve decreases pressure, closing the valve increases pressure.Maintenance During/After SprayingPeriodically check the strainer and clean the screen on your intake line.Proper care and maintenance will prolong the life of your sprayer.After use, drain the tank and store or dispose of chemical properly. Fill the sprayer half way with clean water. Start the pump and allow the water to pump through the entire plumbing system and nozzle. Drain and then refill half full, add the recommended amount of a good quality tank cleaner, such as FIMCO Tank Neutralizer and Cleaner. (If no tank cleaner is available, you may substitute dish soap for this step, about 1-2 oz. per gallon). Turn pump on and circulate through system for 15 minutes and then spray out through handgun nozzle. Refill sprayer half way with clean water and repeat. Follow the chemical manufacturer’s disposal instructions of all wash or rinsing water.If handgun nozzle needs cleaning, remove from the sprayer and soak in warm soapy water. Clean with a soft bristled brush or toothpick if necessary. Never use a metal object. Even the slightest damage can change the flow rate and spray distribution. Water rinse and dry the tip before storing. WARNING: Some chemicals will damage the pump valves if allowed to soak untreated for a length of time! ALWAYS f lush the pump as instructed after each use. DO NOT allow chemicals to sit in the pump for extended times of idleness. Follow the chemical manufacturer’s instructions on disposal of all waste water from the sprayer.Winter StoragePrepare the sprayer for end-of-season storage by running RV antifreeze through the system. This will keep internal parts lubricated, protect against corrosion and keep the unit from freezing. Note: RV antifreeze is non-toxic and biodegradable and generally safer for the environment than automotive antifreeze.Before storing your sprayer for winter or long term storage, thoroughly clean and drain it as much as possible. Then pour enough pink RV antifreeze into the tank so that when the pump is turned on you can pump the antifreeze throughout the entire plumbing system, including the bypass, if equipped. Make sure to operate the handgun until you see pink fluid spraying from the nozzle. Leave any remaining antifreeze in the tank. Before your next usage, rinse the antifreeze from the sprayer with clean water.It is nearly impossible to drain all of the water from the sprayer and any trapped water can freeze in cold weather and damage parts of the sprayer. Pumping the antifreeze through the system will displace the water and help prevent this damage.Removing from storage: drain the antifreeze. Fill the tank with fresh water and run through the system. Dispose of antifreeze and flush water properly.DO∙ Clean and rinse your pump after each use with Fimco Tank Neutralizer∙ Winterize your pump or sprayer by rinsing, draining and running RV Antifreeze through it before storing for the winter.∙ Use clean water for your spray mixture∙ Store inside a building when not in use.DON’T∙ Use to pump bleach.∙ Use to pump petroleum products such as diesel fuel,gasoline or kerosene∙ Leave your pump sit with spray mixture in it for extended periods∙ Use dirty or unfiltered water for sprayingTroubleshooting the Pump: Motor does not run:∙ Check for loose wiring connection(s).∙ Make sure the 'ON/OFF' switch in the lead wire assembly is in the 'ON' position. "I" is the 'ON' position and 'O' isthe 'OFF' position.∙ Check for defective pressure switch. Make sure you are connected to a good 12 volt power source. Make sureany on/off switches are in the 'on' position. Remove the cap to the pressure switch. Pull both red wires off of their terminals, and touch the two ends together. If your pump runs when you do this, your pressure switch will need to be replaced.∙ Check the fuse.∙ Check for low voltage at the power supply.∙Pump does not prime:∙ Check for air leaks in supply line.∙ Check for debris in the check valve assembly.∙ Check for defective check valve.∙ Check for clogged strainer/filter.∙ Check for cracks in the pump housing.∙ Check for empty product supply.Low Pressure/Low Flow:∙ Check for leaks in the discharge line.∙ Check for restriction in the discharge line.∙ Check for debris in nozzle orifice.∙ Check for clogged strainer.∙ Check for proper voltage—try another 12-volt battery.Pulsating flow (surging):∙ Low flow may cause pump to surge.∙ Spray wand is adjusted for a small or fine spray pattern.∙ Slightly open bypass (if applicable) to overcome.∙ If needed, pressure switch may need to be adjusted—adjust a quarter turn at a time clockwise until surgingstops.∙ Check for defective pressure switch.∙ Check for leaks in the discharge line.∙ Check for restriction in the discharge line.∙ Check for debris in nozzle orifice.∙ Discharge hose may be too long.∙ Check for clogged strainer.Motor continues to run after discharge is shut off:∙ Check for empty product supply.∙ Check for open bypass valve. (if equipped)∙ Check for low voltage.∙ Check for leak in discharge line.∙ Check for defective pressure switch.∙ System has leaks.Fuse blows:∙ Excessive voltage.∙ Improper adjustment of pressure switch.∙ Damaged or defective wiring harness.∙ Half-moon & counterweight are sticking.∙ Defective pressure switch.Available Replacement PartsChecking the Pressure Switch:lead wire was “ON” and made sure you were connected to a fully charged battery and everything is fine, but themotor won’t run, then it’s time to check to see if the pressure switch is bad.∙ Remove the cover off the 1” square box (pressure switch) on the head of the pump, the cover is held on by one phillips-head screw. This will expose the two red wires.∙ With the pump connected to a good 12 volt power source and everything on.∙ Slip the two red wires off the terminals and touch them together.If the motor runs, it means the pressure switch is bad and needs to be replaced.bottom of the tank surface. (see Detail Views). Reach in and rotate it, as needed, if not already in this position.A shut-of solution to access your system’s screen for cleaning.Checking/Cleaning the sprayer’s filter/screen:♦ Start your pump and before it shuts off, reach down and shut the valve to the ‘Closed’ position (lever is perpendicular to the flow of fluid), then shut off your pump.♦ Unscrew the knurled nut from the shut-off valve, leaving the valve connected to the tank.♦ Swing (swivel) the intake assembly towards you. Look in the nut you JUST unscrewed. There is a screen/washer there.♦ Remove the screen and clean as necessary. Replace when done and reassemble the entire assembly.♦ Make sure the valve is turned to the ‘Open’ position before restarting your pump.‘Cut’ View of a ‘Typical’ Tank(looking inside) Intake/Siphon Tube/Screen Detail of a Typical L&G/ATV Sprayer (not including the ‘EC’Units)Notes:WarrantyLIMITED WARRANTY FOR NEW FIMCO, IND. EQUIPMENTWHO MAY USE THIS LIMITED WARRANTY. This limited warranty (the “Limited Warranty”) is provided by Fimco, Ind. to the original purchaser (“you”) of the Equipment (as defined below) from Fimco, Ind. or one of Fimco, Ind.’s authorized dealers. This Limited Warranty does not apply to any subsequent owner or other transferee of the Equipment. THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.WHAT THIS LIMITED WARRANTY COVERS AND FOR HOW LONG. Fimco, Ind. warrants that any new Equipment will be free from defects in material and workmanship for a period of one (1) year for sprayer and two (2) years for High-Flo High Performance pump (homeowner), 90 days for sprayer and pump (commercial user), after delivery of the Equipment to you (the “Warranty Period”). The Warranty Period is not extended if Fimco, Ind. repairs or replaces the Equipment.WHAT IS NOT COVERED BY THIS LIMITED WARRANTY. This Limited Warranty does not apply to: (1) used Equipment; (2) any Equipment that has been altered, changed, repaired or treated since its delivery to you, other than by Fimco, Ind. or its authorized dealers; (3) damage or deprecia-tion due to normal wear and tear; (4) defects or damage due to failure to follow Fimco, Ind.’s operator’s manual, specifications or other written instructions, or improper storage, operation, maintenance, application or installation of parts; (5) defects or damage due to misuse, accident or neglect, “acts of God” or other events beyond Fimco, Ind.’s reasonable control; (6) accessories, attachments, tools or parts that were not manu-factured by Fimco, Ind., whether or not sold or operated with the Equipment; or (7) rubber parts, such as tires, hoses and grommets.HOW TO OBTAIN WARRANTY SERVICE. To obtain warranty service under this Limited Warranty, you must (1) provide written notice to Fimco, Ind. of the defect during the Warranty Period and within thirty (30) days after the defect becomes apparent or the repair becomes necessary, at the following address: Fimco, Ind., 1000 Fimco Lane, North Sioux City, SD 57049; and (2) make the Equipment available to Fimco, Ind. or an authorized dealer within a reasonable period of time. For more information about this Limited Warranty, please call: 800-831-0027.WHAT REMEDIES ARE AVAILABLE UNDER THIS LIMITED WARRANTY. If the conditions set forth above are fulfilled and the Equipment or any part thereof is found to be defective, Fimco, Ind. shall, at its own cost, and at its option, either repair or replace the defective Equipment or part. Fimco, Ind. will pay for shipping and handling fees to return the repaired or replacement Equipment or part to you.LIMITATION OF IMPLIED WARRANTIES AND OTHER REMEDIES. THE REMEDIES DESCRIBED ABOVE ARE YOUR SOLE AND EXCLUSIVE REMEDIES, AND FIMCO, IND.’S SOLE LIABILITY, FOR ANY BREACH OF THIS LIMITED WARRANTY. TO THE EXTENT APPLICABLE, ANY IMPLIED WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, SHALL BE LIM-ITED IN DURATION TO THE WARRANTY PERIOD, AND THE REMEDIES AVAILABLE FOR BREACH THEREOF SHALL BE LIMITED TO THE REMEDIES AVAILABLE UNDER THIS EXPRESS LIMITED WARRANTY. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL FIMCO, IND.’S LIABILITY UNDER THIS LIMITED WARRANTY EX-CEED THE ACTUAL AMOUNT PAID BY YOU FOR THE DEFECTIVE EQUIPMENT, NOR SHALL FIMCO, IND. BE LIABLE, UNDER ANY CIRCUMSTANCES, FOR ANY CONSEQUENTIAL, INCIDENTAL, SPECIAL OR PUNITIVE DAMAGES OR LOSSES, WHETHER DIRECT OR INDIRECT. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.。

高地隙自走式喷杆喷雾机的使用手册高地隙自走式喷杆喷雾机的适用范围及相关优点高地隙自走式喷杆喷雾机属于大型、高端农业装备的一种。

长期以来,该设备的技术、产品长期把握在兴旺国家的少数企业手中,进口价格相当昂贵,由于缺乏自走式高地隙喷药机械,我国优势经济作物如棉花、大豆、玉米、油菜等的中后期病虫害防治问题始终没有得到很好的解决,导致了产量削减、品质降低等诸多损失。

“十一五”以来,以中国农机院为代表的国内企业渐渐突破了这项技术的研发瓶颈,结合我国实际研制开发的高地隙自走式喷杆喷雾机系列产品已可以替代进口,从而扭转了玉米、棉花、大豆等作物中后期病虫草害防治缺乏高效、先进、安全、适用型施药装备的落后局面,为促进我国重要农作物的生产,提高我国重要农产品的品质和产量做出了奉献。

这里介绍这种机具的性能、操作和维护方法。

同一般拖拉机配套使用的悬挂或牵引式喷雾机相比,自走式喷杆喷雾机具有机械化和自动化程度高、使用便利、通过性好、适用范围广、施药精准高效等优点,可有效提高农药利用率、削减农药使用量和对环境的污染,适用于我国大田种植的棉花、大豆、油菜、蔬菜以及玉米、甘蔗等不同作物在不同生长期进展杀虫剂、杀菌剂、除草剂及催熟脱叶剂、增产增糖剂、叶面肥料等的病虫草害防治,适用范围如下:1 .适宜平坦坡度不大的大地块,不适宜有大石块、坡度较陡的地块。

2.农药或液态肥料必需符合有关标准,并适用于所要作业的农作物。

3.除农药外,制止使用酸、碱及其他有较强腐蚀性的工作液。

4.喷药时使用的水要干净,如河水等自然水源,要经过沉淀过滤等处理后使用。

高地隙自走式喷杆喷雾机使用前的检查和预备1..使用前的检查(1)检查机具各处的紧固件有无松动现象。

如觉察松动,应准时紧固。

(2)检查发动机机油尺、油面是否在规定刻度之内。

假设油量不够应加足后使用,加油不行超出标尺刻度上限。

(3)检查机具燃油箱内的燃油是否充分,假设油量不够须加足。

(4)检查变速箱、副箱、分动箱、后桥、驱动箱齿轮油面,油量缺乏时要添加。

天津市排水管理处高压喷雾除臭系统操作及维修手册操作维护手册北京天传海特环境科技有限公司2009年01月一、系统介绍针对污水提升泵站主要的臭气产生源,高压造雾除臭系统在臭气扩散以前进行工作,将之捕获并分解和降落,防止臭气扩散,同时保持臭气浓度在规定的范围之内。

系统工艺过程为:首先自来水经过滤到达水箱与药液充分混合,然后再经过过滤器过滤,进入动力系统进行加压,加压以后液体进入管路由喷头喷射而出进行除臭降尘,系统的工作通过控制系统的指令进行。

系统配件及特性:全部管路采用高压不锈钢管材,耐腐蚀、耐酸碱、耐高压,新型连接式高压喷雾机,超细雾喷嘴,操作压力20—50kg,雾长2—4米,雾粒大小为1—15微米(0.04mm)。

本系统自动化程度高,采用了西门子PLC与触摸屏相结合的操作方式,操作直观,易于掌握;系统集成了硫化氢浓度传感器、温度传感器,在硫化氢浓度达到临界值时自动启动系统,在环境温度低于零摄氏度时保温子系统自动运行以保证整个系统的正常工作。

二、系统准备电检查配电室空开,给配电箱上电。

水打开加水阀门。

药剂检查除臭剂药箱液位。

三、启动系统系统加电时,触摸屏直接上电,如果需要重新启动触摸屏,请直接切断触摸屏的电源,然后重新上电。

触摸屏电源位于机箱内部。

有两种方式可以切断触摸屏的电源,一个是直接切断触摸屏的24V变压器的220V输入电源,拉下相应的空气开关即可;另一个方法是将触摸屏的24V电源从触摸屏上拔下。

以上两种方式皆可以切断触摸屏的电源。

设置系统处于自动运行状态时,系统将自动根据预设定的工作时间运行,设定方法如下:系统使用长时间格式,一个工作日的界定从凌晨0时起,到23点59分停止首先判断本工作日是星期几,然后根据本日的具体的运行参数进行工作,当时间到达开始时间,同时时间小于停止时间时,系统开始工作。

系统工作时,将根据设置的工作和暂停间歇进行相应的状态改变。

更改自动运行参数时,应注意首先停止系统运行,然后停止自动运行,否则容易导致系统的设置紊乱。

动力喷雾机的使用说明使用说明:动力喷雾机感谢您购买我们的动力喷雾机!本使用说明将提供关于如何正确使用以及维护您的喷雾机的详细信息。

请在使用之前仔细阅读,并按照说明进行操作。

部件1.喷雾机主体:包括电动机、喷雾器、喷雾嘴等部件。

2.容量桶:用于储存需要喷洒的液体。

3.电源插头:用于将喷雾机连接到电源。

操作步骤1.准备工作a.将主机和容量桶连接在一起,并确保连接紧固。

b.确保电源插头与电源插座完全匹配,并插入插座。

c.将液体倒入容量桶中,但不要超过最大容量标记。

2.启动a.打开液体控制开关,确保液体能够流入喷雾器。

b.按下电源按钮启动喷雾机。

c.调节喷雾机的喷雾量和范围,根据需要选择合适的模式。

3.喷雾操作a.将喷雾嘴对准需要喷洒的区域。

b.手握手柄,轻按扳机控制喷雾输出。

c.移动手柄,确保喷洒覆盖到全面的区域。

d.如果需要更换喷雾嘴,请先关闭电源,并用扳手轻松卸下原有喷雾嘴,再安装新的喷雾嘴。

4.停机a.当喷雾操作结束时,松开扳机。

b.按下电源按钮关闭喷雾机。

c.关闭液体控制开关。

d.拔掉电源插头。

维护保养1.清洁a.在使用喷雾机之前和之后,务必清洁喷雾器及喷雾嘴。

b.使用清水或清洁剂将容量桶内残留的液体彻底清洗干净。

c.使用软刷清洁喷雾嘴,确保喷雾通道畅通无阻。

2.液体储存a.当不使用喷雾机时,清空容量桶内的液体。

b.将剩余液体密封保存以确保其质量。

3.维修和更换a.在任何维修或更换部件之前,务必关闭电源,并断开插头。

注意事项1.请确保在使用喷雾机时周围没有人员以及其他易燃物品。

2.在使用喷雾机期间,应戴好个人防护装备,如手套、防护镜等。

3.在使用喷雾机时,不要长时间连续使用,以防闷热导致电机过热。

4.不要将喷雾机置于高温、潮湿或阳光直射的环境中。

5.使用喷雾机时,请确保电源稳定,并防止电源线受到损坏。

6.液体控制开关应在喷洒开始和结束时进行操作。

7.请勿将流体倒入喷雾机内部以外的任何部分。

山东益晨电动喷雾器: 16L/8A 转速:3000(r/min)净重量:5(kg)适用对象:平地,山丘,草坪,果树,茶树,蔬菜,路旁树篱等外型尺寸:35*20*49(mm)动力类型:电动,其他适用场所:适用领域:林业,农业16L老款电动喷雾器侧面16L老款电动喷雾器底部上部视觉图产品详细介绍电瓶:12V8A免维护铅酸蓄电池水泵:隔膜泵充电器:1.2A智能充电器喷杆:不锈钢伸缩喷杆喷头:单眼喷头双喷头五眼喷头开关:直桶水开关电开关:双开关银触点开关桶身:全新聚炳烯料电池容量显示:电压力表显示喷雾幅宽:4-5米药箱容量:16L电瓶容量:12V电机转速:3000/分钟工作压力:0。

20-0。

40MPA工作时间:电量满可连续工作4-5小时整机净重:6.5KG外形尺寸:35*20*49CM 随机附件:充电器1只背带 1付单喷头 1个双喷头 1只五眼喷头 1只直通水开关 1只不锈钢喷杆 1根产品使用说明1、充电:购机后立即充电,将电瓶充满电。

因为电瓶出厂前只有部分电量,完全充满后方可使用。

一般充电时间为8—1 2个小时。

因为本充电器具有过充电保护功能充满后自动断电,不会因为忘记切断电源长时间(几天几夜)过充电而损伤电瓶。

2、充电时必需使用本机专用的充电器,与220V电压连接。

充电器红灯亮,表示正在充电。

充电器绿灯亮,表示充电基本完成,但此时电量较虚,需要再充1-2个小时才能真正充满。

3、每次使用完后(无论使用时间长短)回家立即充电,这样可以延长电瓶的寿命。

4、如果喷雾器长时间不用(农闲时),一般二三个月充一次电,保证电瓶不亏电,这样可以延长电瓶的寿命。

5、必须使用较干净水,添加药液时必须使用本机配有的专用过滤网。

维护与保养1、本产品电源电瓶为特制密封高能电瓶,用户不须加电解液,但在停用时应一个月进行一次维护(经常对电瓶进行充电,保养可延长电瓶使用寿命2、药液喷洒后,应用清水进行一次清洗,并按下电控开关清洗泵及喷杆部件3、清洗后将余水清除,放置干燥处存放,以保护桶底电机防止受潮。

喷雾机操作规程喷雾机操作规程喷雾机是一种常见的农业设备,广泛用于农作物的喷洒、施肥和防治病虫害。

为了确保喷雾机的安全使用和高效运行,以下是喷雾机操作的一些基本规程:1. 操作前准备(1) 检查喷雾机的外观是否完好,各部位是否松动或有异常磨损。

(2) 确保机器内放的机油和汽油是清洁完好的,并且数量充足。

(3) 检查液压系统是否正常,油位是否足够。

(4) 确保安全装置和防护装置是否完好。

(5) 打开水泵并检查喷雾枪和喷嘴是否正常工作。

2. 进入作业现场(1) 根据实际情况选择喷洒药剂的类型和浓度,并在操作前准备好所需的药剂。

(2) 确保喷雾机周围没有人员和动物,远离易燃易爆物品。

(3) 检查天气状况,选择适宜的天气进行喷雾作业,避免在风速较大或雨天进行作业。

(4) 根据作业面积调整喷雾机的喷射范围和速度,确保作业均匀。

3. 操作过程(1) 打开喷雾机的发动机,将喷雾机调整到适当的转速。

(2) 将喷雾机的泵增压到适当压力,并确保喷雾枪和喷嘴处于正常工作状态。

(3) 手持喷雾枪进行喷洒时,将喷雾枪持稳,并保持均匀的喷射速度。

(4) 注意避免喷雾药液直接溅到地面或水体上,防止对环境造成污染。

(5) 喷洒结束后,关闭喷雾机的发动机和泵,清理喷雾枪和喷嘴。

4. 安全操作(1) 操作喷雾机时应穿戴好防护设备,包括手套、口罩、帽子、防护服和护目镜等。

(2) 禁止在雾气密集的区域内长时间停留,以免对健康造成危害。

(3) 确保喷雾机上的安全装置和防护装置完好,并在操作过程中严格遵守相关安全规定。

(4) 在发现异常情况或故障时,应立即停止操作,检查并修理。

(5) 喷雾机操作完毕后,及时清理和维护机器,存放在干燥通风处。

以上是喷雾机操作规程的一些基本要点,操作人员应严格遵守以上规则,确保喷雾机的安全使用和高效运行。

同时,根据实际情况,还应结合操作手册和相关安全规定进行操作。

TST喷雾仪说明书1. 简介TST喷雾仪是一种高效、方便、安全的喷雾设备,广泛应用于家庭、办公室和公共场所等环境中。

本说明书将为您提供关于TST喷雾仪的详细介绍和使用指南。

2. 功能特点•高效喷雾:TST喷雾仪采用先进的超声波技术,能够将液体药剂快速转化为微小颗粒,并均匀地散布在空气中。

•安全可靠:TST喷雾仪具备多重保护功能,如过热保护和自动关机等,确保使用过程安全可靠。

•多功能操作:TST喷雾仪配备直观的操作面板,可调节药剂浓度、定时启动和停止等功能,满足不同需求。

•静音运行:采用噪音减少技术,TST喷雾仪在工作时噪音低至30分贝以下,不会干扰您的正常生活和工作。

3. 使用方法步骤1:准备工作•将TST喷雾仪放置在平稳的水平台上,并确保周围没有障碍物。

•打开TST喷雾仪的药剂仓,将合适的液体药剂倒入其中。

•关闭药剂仓盖,并确保密封良好。

步骤2:开机操作•将电源线插入TST喷雾仪的电源插孔,并将另一端插入电源插座。

•按下电源开关,TST喷雾仪即可开始工作。

步骤3:设置参数•通过操作面板上的按钮,您可以设置药剂浓度、定时启动和停止等参数。

根据需要进行调整。

步骤4:使用喷雾功能•当TST喷雾仪开始工作后,您可以看到微小颗粒从出风口散布出来。

请确保站在距离出风口一定距离的位置,以避免直接吸入药剂。

4. 注意事项•在使用TST喷雾仪之前,请先阅读本说明书并了解相关安全知识。

•请勿将TST喷雾仪放置在高温、潮湿或有明火的环境中。

•使用过程中,请勿触摸工作面板和出风口,以免烫伤。

•请勿将TST喷雾仪倒置或摔落,以免损坏设备。

•使用完毕后,请及时清洁TST喷雾仪,并将其存放在干燥通风的地方。

5. 常见问题解答Q: TST喷雾仪工作时会产生异味吗?A: TST喷雾仪使用的药剂经过专业调配,不会产生刺激性气味。

Q: TST喷雾仪的药剂可以更换吗?A: 是的,您可以根据需要更换不同种类的液体药剂。

Q: TST喷雾仪可以用于哪些场所?A: TST喷雾仪适用于家庭、办公室、医院、学校等各种公共场所。

高压喷雾打药机使用流程1.确保喷雾打药机处于关闭状态。

Make sure the high-pressure sprayer is in the off position.2.检查喷雾打药机的液体容量,确保有足够的药液。

Check the liquid capacity of the sprayer to ensure thereis enough pesticide.3.打开喷雾打药机的盖子,将药液倒入其中。

Open the lid of the sprayer and pour the pesticide inside.4.确保盖子密封好,以免药液泄漏。

Ensure the lid is tightly sealed to prevent any leakage.5.检查喷雾打药机的喷嘴,并清洁其表面。

Inspect the nozzles of the sprayer and clean their surfaces.6.调整喷雾打药机的压力,确保能够达到需要的喷雾效果。

Adjust the pressure of the sprayer to achieve the desired spraying effect.7.连接喷雾打药机的电源,并打开开关。

Connect the power source of the sprayer and turn on the switch.8.测试喷雾打药机的喷雾效果,调整喷嘴角度和喷射范围。

Test the spraying effect of the sprayer and adjust the nozzle angle and spraying range.9.穿上防护服和口罩,以免接触药液。

Wear protective clothing and a mask to avoid contact with the pesticide.10.将喷雾打药机举起,开始进行打药作业。

KXJT-2/127C型喷雾泵用隔爆兼本质安全型控制箱产品说明书平顶山市巨鹰科技有限公司电话:0375*******/4915955在使用本产品前,请先仔细阅读此手册并妥为保存以便日后查阅目录1 概述 (1)1.1 产品特点 (1)1.2 适用环境 (1)1.3 执行标准 (1)1.4 型号及含义 (1)2 结构、技术参数及控制保护原理 (4)2.1 主要技术参数 (4)2.2 结构 (4)2.3 控制及保护原理 (3)3 安装、调整 (3)3.1 (3)3.2 (3)3.3 (3)3.4 (3)3.5 (5)3.6电控电磁卸载阀的调整方法 (3)4 使用、操作和显示 (3)4.1 (4)4.2 (4)4.3 (4)4.4 (5)4.5 (5)5 安全警示 (5)5.1 (5)5.2 (5)5.3 (5)6 常见故障的分析及处理 (5)6.1 (5)6.2 (5)6.3 (6)6.4 (6)7. 保养、存输和运输 (6)附录 (7)1 概述1.1 产品特点KXJT-2/127C型喷雾泵用隔爆兼本质安全型控制箱(以下简称“控制箱”)是喷雾泵站的控制核心。

它采用了plc控制技术、大屏幕中文显示技术。

可实现喷雾泵站内控、外控控制,系统控制可靠,保护完善,显示直观,操作方便。

1.2 适用环境·海拔高度不超过2000m;·周围环境温度不高于+40℃,不低于-5℃;·在无破坏绝缘的气体或蒸汽的环境中;·在有瓦斯和爆炸性混合物的矿井中;·采取防滴水措施的地方;·污染等级:3级;·安装类别:Ⅲ类。

1.3 执行标准GB3836.1~4-2000 爆炸性气体环境用防爆电气设备Q/S-*-0**-2009KXJT-2/127C 型喷雾泵用隔爆兼本质安全型控制箱1.4 型号及含义KX J T - 2/127 C喷雾泵用额定电流/额定电压控制隔爆兼本安型控制箱2 结构、技术参数及控制保护原理2.1 主要技术参数输入电源:127V 50Hz防爆形式:矿用隔爆兼本安型“Exd[ib]I”2.2 结构整个控制箱由外部壳体和内部元件板组成。

KCS400-3000风送式喷雾机

产品使用说明书

邹城市北华机电设备有限公司

注意:使用前务必仔细阅读本说明书!

尊敬的顾客:

欢迎您使用本公司研发生产的KCS-400-3000 风送式喷雾机、蒸发塘式喷雾机、车载式喷雾机、高塔式喷雾机、牵引式环保除尘喷雾机产品。

产品实行质量三包、保修一年、终身服务。

一、产品特点:

●结构紧奏、布局合理、做工精细、配置完善、操作性能好;

●射程远、覆盖面积大、雾粒细小、与飘起的尘埃接触时,形成一种潮湿雾状体,

能快速将尘埃抑制降沉;

●工作效率高、喷雾速度快、对尘埃有较强的穿透力和雾珠附着力、能有效地节约

用水量和减少环境污染;

●遥控/电控兼容、起动快捷、使用安全、灵活方便、性价比高;

●工作效率高、适用范围广,电机控制水平旋转,液压系统控制俯仰角度,变换角

度速度快;

●耗水量相比其它抑尘喷洒设备可节约70%~80%(喷淋喷枪、洒水机车),且水雾覆

盖粉尘面积远远大于其它抑尘喷洒设备;

●动力使用市电三相380V电源。

二、适用范围:

适用于环保行业、煤化工蒸发塘污水处理、易起尘的煤炭及其它物料堆场、卸料口、车辆卸料时、码头、炼钢厂等的喷水除尘、抑尘、降温;公共场所或垃圾填埋场喷洒药物等。

三、主要配置:

系统机架、18.5kw轴流风机配特制喷筒、高压泵站配置4kw电动机、电控系统、无线遥控器、手动控制开关、PLC集中控制系统等。

电控箱版面上设有:电压、电流、频率表,相压检测钮、风机开、风机关、液泵开、液泵关、向上、向下、向左、向右按钮、时间继电器。

四、主要技术参数:

水泵工作压力:1.5~4.5Pa 风量: 990m³/h

风压:1080Pa 射程:60m

流量:20~150 L/min 雾粒度:50~200um

俯仰角:-10°~45°水平旋转:320°

五、设备的电源装接:

1、本产品使用的是外接市电电源,如电力不足的地方,也可自行配置柴油发电机组。

2、当使用三相380伏市电时,电控箱前头的电源必须要有控制开关,在电源开关上应

有良好的接地;将电源线接至设备的电控箱内。

3、在接入电源时,应先将电控箱上的电源开关断开、处于OFF位置;

4、选择电源时,应根据产品技术参数上所载明的总功率而确定使用线径,以确保有足

够的电过流量;

六、操作使用方法:

1、管路检查:开机前应检查各供液管道相应开关是否打开或关闭:

2、如果你选择药液箱装药原液,向外界抽取净水与药原液自动混合喷射,则应适当打

开药箱后的供药管路开关,并控制好药原液的流量。

打开向外界抽取净水的管路开关。

关闭高压泵和管路排水开关。

3、如果你仅选择药液箱装药液进行喷射,则可关闭向外界抽取净水的管路开关,打开

药箱后的供药管路开关,关闭高压泵和管路排水开关。

4、相压检查:当安装检查完毕无误后,将电控箱上的电源拨至ON位置,然后用相压

检测钮检查各相线电压是否平衡,如果不平衡,应检查线路和接线端是否断电、接触不良或其他故障原因,如无法排除,应与生产厂家或销售服务网点联系。

5、试运行:

1、在电控箱或遥控器上点动“风机开按钮”试运行,如发现风机反转,应在电源开关

上调节接线位置,待风机正常运行1—2分钟。

2、做好喷雾前的准备工作,对准喷雾目标。

3、在电控箱或遥控器上点动“液泵开按钮”检查各供液管道和喷嘴是否会漏液,各喷

嘴喷雾是否均匀,如不均匀可对喷嘴进行调整;检查液泵压力表指针是否达到技术数据的要求,否则,应适当调整高压泵调节手把。

6、喷雾作业:

1)俯仰角喷射:首先应将喷筒轴耳上的压紧手轮旋松,否则无法动作和损坏设备。

俯仰角设定为—10度到45度。

角度变化由液压马达控制液压撑臂作向下向上运动。

在电控箱或手持遥控器上点动“向下”或“向上”按钮,将喷筒调整至所需喷射角度。

2、注意:在没有放松压紧手轮时,点动“向下”或“向上”按钮,液压升降撑臂将无法动作,会损坏或烧溃设备,造成事故发生。

液压系统:液压系统安装在旋转支架上,用于控制喷筒的俯仰角度。

其主要由油缸、液压马达、电磁阀、高压油管、液压伸缩臂组成。

使用时必须经常检查液压站液压油是否足够,否则应加油。

液压站使用的液压油为46号抗磨液压油,耐低温—20度以上,如果在使用地温度低于—20度时必须更换适合当地温度的防冻液压油。

液压站加油量加至液压油箱的油位和油温显示孔能看到油为好。

经常检查油管、连接处是否会漏油,接口螺丝是否会松动,以便及时处理故障。

3水平旋转喷射:水平旋转喷射角度设定为320°,您可在电控箱或手持遥控器上点动“向左”或“向右”按钮,这时喷筒或向左或向右移动喷射,当喷筒转到设定的角度时,喷筒挡片会碰触一个行程开关,使喷筒停止转动,若需再到另一个角度时,必须等待2—3秒钟后在点动另一个方向按钮;喷射时液体通过高压泵产生雾状由喷嘴喷至喷筒口,在经风机风力切割破碎后形成液气流喷向物体;

4水平旋转控制系统:水平旋转系统安装在转盘底部,主要由微电机、减速传动箱、主动齿轮和传动齿轮、行程开关等构成。

当使用一段时间后,必须对齿轮上加润滑黄油,以保证其润滑良好。

5.雾量的调整:如发现雾量不够,可适当调节高压泵的调压手柄,使其压力上升在3.5Mpa 或参照高压泵使用说明书。

若风力不够可检查电压是否不足,检查供电电源线线径过流量是否足够、是否在有效保证范围内;

6、作业结束停机:

1)在电控箱上或手持遥控器上先按下“液泵停”按钮1至2分钟后,再按下“风机停”

按钮。

点动“向左”或“向右”按钮,将风机喷筒回复至最佳安全位置。

2)点动“向上”或“向下”按钮,将喷筒回复至水平位置后,将喷筒压紧手轮锁紧,防止在行驶时喷筒摆动损坏设备。

3)将电源开关拨至OFF位置,实现安全停机,防止触电事故,收好电源线。

七、手持遥控发射器使用说明和操作特性:

A:操作

1、经常检查手持遥控发射器的天线,保证良好的连接,否则遥控器不能正常工作。

2、开机时,请先开电源开关,由OFF—ON,然后松开紧急开关。

3、关机时,先按下紧急开关(或者将紧急开关由箭头指向ON的位置转换至箭头指向

STOP停止位)然后将电源开关由ON位置转向OFF位置。

4、开机时如有不响应操作指令时,请将手持遥控发射器和接收器若电源关闭10秒后在

开启,如再不响应,请与本厂联系。

B、工作指示灯说明:

指示灯位于手持遥控发射器的电源开关中间。

1、开机连机时程黄色,接收到反馈信号时程绿色,这时可正常操作。

2、正常操作时,绿色指示灯闪烁0.5秒,操作结束后绿色指示灯熄灭,其后每隔90秒

指示灯亮一次手持遥控发射器自动发射信号,维持接收机后主电源接触器正常收令,直至下一组指令才结束。

3、当指示灯呈红色闪烁,表示电池电力不足,手持遥控发射器会停止发送任何指令。

4、当按下急停按钮时,指示灯呈红色常亮。

不闪烁。

5、当开机时,指示灯一直呈黄色,表示手持发射器和接收器没有建立联系,请关掉手

持遥控发射器电源后再重开,若无效请关闭接收机电源后过10秒在通电,如不能正常工作请与本厂联系。

C、电池维护:

本手持遥控发射器采用三节5号1.5V碱性干电池;当手持遥控发射器指示灯变为红色时,表示低电压,请立即更换电池,否则遥控器不能正常操作。

D、注意事项:

1、经常检查手持遥控发射器的天线、确保正确连接不能松动,否则遥控器不能正常工作,发现电池不足应立即更换电池。

2、注意手持遥控发射器防止进水,如有进水请立即取下电池,待处理后在使用。

3、爱护手持遥控发射器,请不要随意乱摔乱扔。

4、在视线不佳时,禁止使用遥控器控制设备。

八、安全操作说明:

1、作业时,请严格按操作规程操作,严禁先按“液泵开”按钮,必须先启动风机,待风机运行正常后才启动液泵,以免造成由于先启动高压泵使液体倒流至轴流风机和喷筒内;风机转动后,勿靠近轴流风机进风口,任何人员不得在风筒出风口站立;

2、禁止使用特殊的工作液;

3、严禁泥砂、杂物进入药箱,以免堵塞管道、喷头或损坏高压泵;

4、若遇喷头堵塞或漏液,应关闭供液管路开关或停机清理排除;

5、经常检查高压泵内润滑油和黄油杯黄油是否足够,否则应加油;高压泵不得无水工作;

6、高压泵维修保养和更换零件可参照使用说明书;

7、根据实际使用情况,定期或不定期清理过滤器;

8、高压泵在无水的情况下不得开机

二:警告标志

警告喷射时喷筒口严禁朝向人

警告

调紧时注意防止

挤压手指

警告

喷筒喷射变换

角度时注意避让

警告

作业时应带口罩,穿防护衣。