模具保护器

- 格式:pdf

- 大小:1.62 MB

- 文档页数:16

智觉模具保护器说明书1. 产品概述1.1 功能介绍智觉模具保护器是一种用于监测和控制模具温度的设备,可有效防止过热或过冷对模具造成损坏。

1.2 主要特点- 高精度传感器:采用先进的温度传感技术,能够准确地检测到不同区域的温度变化。

- 实时报警功能:当发现异常情况(如超高/低温)时,会立即发送警报通知操作人员进行处理。

- 远程监控与控制:支持通过方式应用程序远程实时查看、调整和记录数据。

2. 安装指南2.1 准备工作在安装之前,请确认以下事项:a) 确定所需数量及位置;b) 清理并平整安装表面;c) 确认电源供应是否符合规格要求。

3.使用方法步骤:a)将智觉模具保护器连接至电源,并开启设备。

等待系统自动初始化完成后,可以开始设置参数了;b)根据需要,在APP上选择相应选项来配置您想要达到目标值;c)设置完成后,系统将自动开始监测和控制模具温度。

4.故障排除以下是一些常见问题的解决方法:a) 设备无法启动:请检查电源是否连接正常,并确保供电稳定;b) 温度读数不准确:可能是传感器出现了故障,请联系售后服务进行维修或更换;c) 报警功能失效:请确认报警参数是否正确配置,并检查通知设备(如方式)与智觉模具保护器之间的连接状态。

5. 法律名词及注释- 模具: 在工业生产中用于成型、压铸等过程中所使用的装置。

- 监测: 对某个对象或者环境进行持续性地观察、记录以获得相关信息。

- 控制: 调节并使某物达到预期目标值。

在本文档指对模具温度进行调控操作。

6. 附件1. 安装手册.pdf2. 使用说明书.docx。

模具压模技术在没有做模具保护的情况下,模具被压、撞坏可能会出现下列问题:1、模具因结构较简单,压不坏。

2、模具被压,致使模具精密度下降,使注塑成形条件发生变化,给工艺参数的调试加大难度。

.3、模具被压,致使模具精密度下降,使成形产品的毛边加大、加多,加大了生产工人的工作强度与工作量,加速工人工作的疲劳,产品的产量、质量、效率往下降。

员工对工作的好感下降,员工流动可能会因此而有少许加大。

4、模具被压,致使模具精密度下降,使成形产品的毛边加大、加多。

原定的人员已经无法满足工作对劳动力的需要,需要增加人手,使劳动力密集的注塑行业,劳动力更加密集,增加人工支出,提高了产品生产制造成本。

5、模具被压、撞,致使模具受损害至无法生产的程度,耽误生产,需要时间与费用将模具进行维修。

6、模具型腔面被撞兼压伤,不管如何修补,也无法躲避留下一个补痕,在成形产品上留下一个印记,对于组合成品起来属于在直视面的塑料件的,- -个光滑的产品表面有一个修过的痕迹,这就是一个瑕疵,产品质量与档次将因此受影响。

7、模具被压、撞坏。

对坏模具进行烧焊、驳接、修修补补。

模具的质量与性能加速下降,坏模的发生率,上升,增加模具的运作维护的成本支出。

随着修多、补多以及精密度的逐步下降,模具使用的寿命最终会因在工作中没有得到好好地保护,而受到工作中意外撞压地的推残,最终寿命因此而缩短。

综上所述,这些都对质量、产量、成本、效率、造成不少影响的东西,我们是不是应该为避免其发生而作努力呢?!.在注塑成型过程中对模具保护是一个保证正常生产、产品质量等的重要技术手段。

注塑机模具保护方法主要有以下几种。

1)选择合适的材料或在模具表面喷涂特殊材料。

模具表面经常直接接触到高温胶料的冲击及磨损,长期处于冷热交变的环境下因此对于材料的选择尤为重要。

为了满足工况要求和保证塑料制品成型质量,塑料注塑模具的材料需要满足一定的力学性能和加工工艺性能的要求:①具有可加工性和易抛光性;②优良的耐蚀性和耐磨性;③良好的塑性、韧性匹配;④优良的高温性能;⑤优良的化学性能。

塑封模具安全操作及保养规程一、前言塑封模具广泛应用于各种不同领域的产品制造,如电子产品、汽车配件、家具、玩具等。

然而,在使用塑封模具时,需注意其安全操作和保养,以确保生产效率、质量和安全。

本文旨在提供塑封模具的安全操作和保养规程及建议。

二、安全操作规程2.1 仅由经过培训的操作员使用塑封模具任何未经培训或未获得授权的工人不得操作塑封模具。

培训应包括塑封模具的基本结构和特性、适当的安全设备的使用、塑封模具的操作步骤以及对模具的保养维护等。

2.2 操作员必须遵循操作规程在操作塑封模具时,操作员必须遵循操作规程,特别是在更换模具、清理模具或关闭设备时。

如果出现故障或不寻常的情况,操作员应立即停止设备,并通知维护人员或主管。

2.3 保持清洁和整洁操作员应保持设备和周围区域的清洁和整洁,避免杂物或其他物品进入塑封模具。

这不仅可以防止不必要的损坏,还可以减少潜在的危险。

操作员必须正确使用适当的保护设备,如手套、安全镊子、眼睛保护器等。

这些保护设备可以减少潜在的危险,如电击、化学污染、热量等。

2.5 防止有害出气在运行塑封模具时,必须避免有害出气,如氧化物、二氧化碳和其他有害物质。

为了避免这些有害气体出现,可以通过良好的通风和使用呼吸保护设备来降低气体含量。

2.6 避免高温和高压操作员必须避免高温和高压,这是因为塑封模具需要高温和高压来生产产品。

这些高温和高压可以引起爆炸或火灾。

为了避免这种情况,操作员应保持适当的距离,并使用适当的保护设备。

2.7 停机前必须关闭塑封模具在停止设备之前,操作员必须关闭塑封模具。

这可以避免因存留塑料或化学物质而引起的不必要的事故。

三、保养维护规程3.1 定期检查和清洁塑封模具的使用寿命直接影响产品的生产效率和质量。

之所以能够维持模具的长寿命,是要求定期检查和清洁模具的各个部分,以确保运行的流畅性和效率。

在使用塑封模具时,必须使用适当的润滑剂来确保塑封模具的正常运行。

润滑剂可延长模具寿命,减少摩擦和磨损,从而提高产品的质量和周转时间。

冲压机床的安全防护范本冲压机床是一种常用的金属加工设备,具有高速运转、大功率、高能耗等特点。

由于其工作过程中存在一定的危险性,必须采取一系列的安全防护措施来确保工作人员的安全。

下面是一个关于冲压机床安全防护范本的示例,供参考。

一、冲压机床的安全环境1. 应当确保冲压机床的工作区域环境整洁、有序,无杂物和障碍物。

2. 应当设置警告标识,明确标示禁止入内、禁止触摸等指示,提醒工作人员注意安全。

3. 应当配备足够的照明设备,确保工作区域光线充足,避免操作时出现视线模糊或盲区,增加操作人员的安全感。

二、人员安全要求1. 操作冲压机床的人员应当具备相应的技术能力和经验,接受过相关培训,并持有有效的操作证书。

2. 操作人员必须穿戴符合要求的工作服和安全防护用品,如防护帽、防护鞋、防护眼镜、防护手套等。

3. 提醒操作人员禁止穿戴松散的衣物和饰品,以免被卷入机器的运动部件而引发事故。

三、机器设备安全要求1. 冲压机床应当经过专业人员的定期检测和维护,保持机器的正常工作状态,避免因设备故障而引发事故。

2. 应当安装安全门和防护罩,以防止工作人员接触到运动部件,减少伤害风险。

3. 应当配置电气保护装置,如短路保护、漏电保护、过载保护等,避免电气事故的发生。

4. 应当设置急停按钮,以便工作人员在紧急情况下迅速切断电源,停止机器的运转。

5. 应当配置自动装置,控制机器在正常工作状态下自动停机,并及时进行检修和维护,保持设备的安全性能。

四、安全操作规程1. 禁止未经许可的人员靠近冲压机床工作区域,严禁闲杂人员、非操作人员操作冲压机床。

2. 禁止在机器工作时进行任何调整、修理和加油等操作,必须在机器停机后才能进行维修等工作。

3. 工作人员在操作冲压机床前,应当对机器进行全面检查,确保设备处于正常工作状态。

4. 操作人员应当稳定地站在机器旁边,确保身体平衡,避免在工作过程中发生滑倒或摔倒等事故。

5. 操作人员应当正确使用机器上的操作按钮和控制装置,严禁私自更改系统参数或调整机器工作模式。

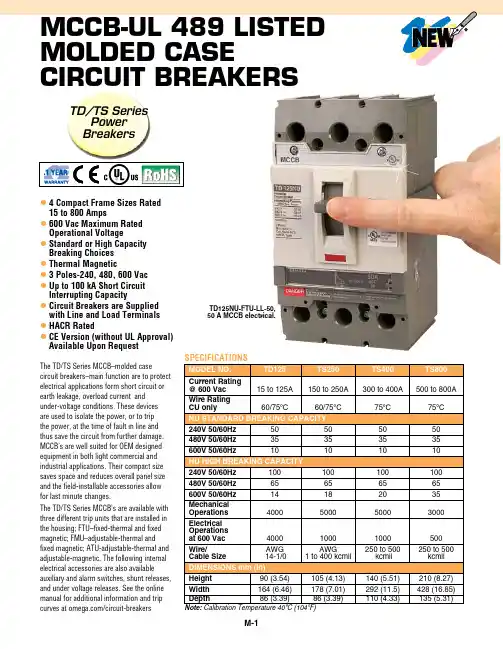

TD/TS SeriesPowerBreakersl4 Compact Frame Sizes Rated 15 to 800 Ampsl600 Vac Maximum Rated Operational Voltagel S tandard or High Capacity Breaking Choicesl Thermal Magneticl 3 Poles-240, 480, 600 Vacl U p to 100 kA Short Circuit Interrupting Capacityl C ircuit Breakers are Supplied with Line and Load Terminalsl HACR Ratedl C E Version (without UL Approval) Available Upon RequestThe TD/TS Series MCCB–molded case circuit breakers–main function are to protect electrical applications form short circuit or earth leakage, overload current and under-voltage conditions. These devices are used to isolate the power, or to tripthe power, at the time of fault in line and thus save the circuit from further damage. MCCB’s are well suited for OEM designed equipment in both light commercial and industrial applications. Their compact size saves space and reduces overall panel size and the field-installable accessories allow for last minute changes.The TD/TS Series MCCB’s are available with three different trip units that are installed in the housing; FTU–fixed-thermal and fixed magnetic; FMU–adjustable-thermal and fixed magnetic; ATU-adjustable-thermal and adjustable-magnetic. The following internal electrical accessories are also available auxiliary and alarm switches, shunt releases, and under voltage releases. See the online manual for additional information and trip curves at /circuit-breakersTD125NU-FTU-LL-50,50 a MCCB electrical.Comes complete with line and load terminal lugs and operator’s manual.Note: For adjustable-thermal/fixed-magnetic (FMU), or adjustable-thermal/Adjustable-magnetic (ATU), visit /auto for selection.Ordering Examples: TD125NU-FTU-LL-50, MCCB with standard interrupting capacity, 35 kA at 480V, rated for 50 Amp, fixed-thermal/ fixed-magnetic trip unit with line and load lugs.TD125HU-FTU-LL-100, MCCB with high capacity, 65k A at 480V, rated for 100 A, TDTS-S-AX, auxiliary switch , TDTS-S-AL alarm switch , TDTS-S-SHT-24, 24 Vdc shunt trip unit , TDTS-F-FH1-36, flange mount handle for disconnect enclosure with 36" cable.TDTS-S-EHU1-12.TDTS-S-FH-36.ACCESSORIESBoth models shown smaller than actual size.TDTS-S-UVT-24,。

—MOLDED C A SE CIRCUIT-BRE AKERS SACE Tmax XTBreak new groundS ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)—A molded case circuit-breaker range that ensures extreme performance and protection features up to 1600A. Designed to maximize ease of use, integration and connectivity. Built to deliver safety, reliability and quality.—Table of contents004 – 005SACE Tmax XT006 – 007Added values008 – 009Key features012 – 013Choosing the right product 014 – 015 Accessories018 – 021Products in detail024 – 025E lectronic trip units—SACE Tmax XTThe right choice: a complete circuit-breaker range for any solutionSACE Tmax XT2SACE Tmax XT5SACE Tmax XT7SACE Tmax XT44S ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)5SACE Tmax XT3SACE Tmax XT1 SACE Tmax XT66S ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCBS)There is a lot more to the range of SACE Tmax XT than what meets the eye, and the benefits for your business are notice-able. To start with, the whole selection and ordering process has been overhauled to make it far easier to get your hands on the parts you need, speeding things up by about 30%. Installation has been simplified to increase user-friendliness, frames have been streamlined to save space, and improved connectivity - such as Bluetooth and Ekip mobile - will save you considerable time. Another additional benefit is the reliable cloud connectivity and overall increase in information available, meaning diagnostics and maintenance are vastly improved, resulting in less downtime. Finally, thanks to the smart power controller concept, overall energy consumption can be reduced by up to 20%.—Added value each step of the way There is more than just a circuit-breaker in the SACE Tmax XT rangeA new generation of molded case circuit-breakers delivering great added value.7Continuous operationOptimuminterfaceSafety and protectionSpeed up your projects OptimizedlogisticsSpace savingSpeed up your projects Easy toinstallContinuous operation EnergyefficiencyCommissioningThe SACE Tmax XT range offers the potential to save serious time. Thanks to simplified installation of frames, integrating the circuit-breakers into a communication network, trip unit settings per-formed via LCD and Bluetooth and Ekip Mobile con-nectivity , you stand to save up to 40% time overall.Diagnostics and maintenanceWith up to 30% more data available on the cloud and ABB unique power controller concept, it is far easier to diagnose problems and carry out necessary maintenance. This helps to prevent faults, restore energy more quickly and avoid any unnecessary charging of utilities.Energy savingThe SACE Tmax XT range comes with the exclu-sive ABB-patented Ekip Power Controller which monitors installation loads and can limit the amount of power consumed at any time. The result is an overall reduction in power consump-tion of up to 20% and lower energy bills. Further-more, you have 1% energy measurement accuracy according to IEC 61557-12.Selection, ordering and handling 30% faster thanks to part numbersreduction (-10%), online configurator (-40% time) and smart packaging (-30% space).A D D ED VA LU ES8S ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)—01 Choose and custom-ize exactly the rightproducts for your needs, based on how you will use them. 10,000 solutions in one click —02 Effective energy management: 20% less power consump-tion with Power Controller enabled —03 Top reliability:Products designed and tested to exceed stan-dard requirements. More than 30 certificationsCloud-connectedTailor-madetechnologyCloud-connectedBeing connected is a key feature of today’s tech-nology and the SACE Tmax XT range of circuit- breakers offers more than just standalone pro-tection. Being considered key elements of an electrical distribution system, Tmax XT circuit- breakers give you the ability to monitor andmanage a wealth of information, easily, wherever you are. So even when on the road, anytime of the day or night, the power of full-access flexi-bility is in your hands.—Being able to monitor everything while being off-site provides a genuine feeling of you being in control at all times.Tailor-made solutionsJust because your project is complex, this does not mean your circuit-breaker setup has to be. All frames from XT1 to XT7 provide a common pro d uct experience that is backed up by a com-prehensive range of accessories with intuitive interfaces and ergonomic design. With maximum Outstanding technologyFlexibility is nothing without performance and the SACE Tmax XT range is able to deal with the most extreme breaking capacities, regardless of operating voltage, application, and environmen-tal conditions. Combined with the most precise electronic trip units in the smallest of frames, this ensures continuity of service and equipment pro-tection at all times.Top-level qualityAlmost a century of research and experience results in highly-reliable, top-level products that are ready to face all future challenges. Products like the SACE Tmax XT range set standards for edge technologies. Safety, product quality and reliability under pressure are fundamental to all ABB prod-ucts and the SACE Tmax XT range is no different.—Break new ground Key features of an outstanding product9—01—03—02—E A S E OF US E A N D I NS TA LL ATI O NMaximum flexibility for every application – SACE Tmax XT sets the new standard for electrical installations.Easy selection, one-size-fits-all accessories and intuitive design pave the way for smart manufacturing of panels and fast upgrades. Even for the most critical projects.12S ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCBS)Heavy duty Basic functionalityThermal-magnetic, Ekip DipEkip Touch/Hi-Touch —• Standard performance• Icu 70kA at 415/480V AC —• Extreme breaking capacity • 200kA at 415V AC• 100kA at 690V AC—Thermal-magnetic• TMF - TMD - TMA - TMG - MF - MAElectronic• Ekip Dip LIG - LS/I - LSI - LSIG -G Dip LS/I - M Dip I - M Dip LIU -M Dip LRIUNo communication/No display —Ekip Touch • LSI - LSIG - G Touch LSIG - M Touch LRIU - + Energy M Ekip Hi-Touch • LSI - LSIG - G Hi-Touch LSIG Full connectivity - Advanced logic - Power managementUniversally compatibleThe world of circuit-breakers is a complex one,yet choosing the right device for your individualneeds has never been simpler thanks to SACETmax XT range. Maybe you are looking for a basicprotection device for a standard distributionplant. Or perhaps you need something morecomplex, such as a device that integrates —Choosing the right circuit-breaker has never been so easyYou consider what you need. We’ll show you what is possible.protection, automation, measuring and commu-nication into a cloud-based supervision system. Whatever you are looking for, with a wealth of customization possibilities and a range of possible solutions depending on the breaking part and trip unit you choose, the power of circuit breakingis firmly in your hands.Possible combinations within the rangeBasic functionalityWhether you are a hotel owner or planning a production line,where you need to consider the overall power voltage over aperiod of time, the whole SACE Tmax XT range offers all thecircuit breaking power you need to keep your business run-ning long into the future.Thermal-magnetic, Ekip Dip – manual operationThis either consists of the standard thermal-magnetic tripunit intended for basic protection or the Ekip Dip trip unit,the first level of electronic trip unit that can provide in-creased accuracy, a wider regulation range, delayedshort-circuit protection and individual trip information.Heavy duty When it comes to heavy duty usage – whether it’s ships, chemical parks, mining, or heavy duty machinery – the SACE Tmax XT2, XT4, XT5 and XT7 frames are designed to work well beyond the normal constraints when you will be pushing the limits of your installation to the maximum.Ekip Touch/Hi-Touch – cloud functionality Once you are working with the XT2, XT4 XT5 or XT7 frames, all activity can be remotely monitored via the cloud thanks to the Ekip Touch/Hi-Touch trip units which send all data to the ABB Ability TM EDCS and can be monitored through smart-phone or tablet whenever and wherever you like.CH O OSI N G TH E R I G HT PR O D U C T13Tmax XT1Tmax XT2Tmax XT3Tmax XT4Tmax XT5Tmax XT6Tmax XT7Basic functionality (Icu@415V<70 kA)Heavy duty (Icu@415V>70 kA)Thermal-magnetic trip units Ekip Dip (standard electronic)Ekip Touch/Hi-Touch (smart electronic)14S ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)—Udipsusam esciis pariamet, que et faci quia conet, sit magnatia dolora esciis pariamet, que et faci solupiste dollorpostem pliqui cum image—AccessoriesExpand the capabilities of the SACE Tmax XT rangeIntegrating circuit-breakers into any installation requires different levels of optimization. Whether physical, electrical, operational or safety-focused, accessories take SACE Tmax XT to the next level.AccessoriesA large range of connections has been conceived to match the most common distribution systems. Auxiliary contacts can provide precise information regarding breaker status and plant conditions, maximizing operator awareness and the overall accuracy of a supervision system. In addition, dif-ferent types of coils and motor operator versions, designed to operate with the most common voltage sources and reduced power consumption, enable the possibility to control all installations remotely. Residual current devices up to 630A, sig-naling modules, installation components (e.g. phase barriers, terminal covers), key-locks and padlocks are just a few examples of the care taken to safeguard appliances and operators alike. Metering15Various accessories are also available:1. Breaking unit2. Trip units3. Front4. Polish plate5. Terminal covers6. Auxiliary contacts7. Key lock8. Service releases9. Communication module10. C onversion kit for plug-in/withdrawable versions11. G uide of fixed part in thewithdrawable version 12. Fixed part - FP 13. Front for lever operating mechanism - FLD 14. Stored energy motor operator - MOE 15. Direct rotary handle - RHD 16. Transmitted rotary handle - RHE 17. Conversion kit RHE > RHS 18. Cable rack 19. Phase separators 20. R ear orientated terminals - R 21. F ront extended spread terminals - ES 22. Front terminals for copper-aluminium - FC CuAl 23. Front extended terminals - EF 24. Residual current release2419162122231761012911723138520151418415ACCE SSO R IE SS ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)—PER FO R M A NCE A N D PROTEC TI O NContinuity of service and equipmentprotection – SACE Tmax XT sets the new standard when extreme breaking capacity is needed. Sharing the same logic, interfaces andfeatures regardless of operating voltageand environmental conditions. Embeddingthe most advanced protection into thesmallest of frames.S ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)SACE Tmax XT1The founderSmall, reliable, versatile. Your reliable partner for all standard applications.At a glance:• Up to 160A• For basic functionalities• Dimensions 76.2x70x130 (WxDxH mm)• Thermal-magnetic trip unit SACE Tmax XT2The aspirerCompact yet powerful. It fits everywhere and is able to deal with all complex tasks. At a glance:• Up to 160A• For heavy duty• Dimensions 90x82.5x130 (WxDxH mm)• Thermal-magnetic, Ekip Dip,Ekip Touch/Hi-Touch18—The SACE Tmax XT range at a glance The world of circuit breaking and circuit protection in your handsThe SACE Tmax XT range takes circuit protection to the nextlevel. Designed to perform at extremely high levels, simpleto install and able to provide increasingly better safety,there is a frame to meet each and every one of your require-ments. From a basic solution for standard applications -such as hotels - through to advanced, heavy-duty applica-tions with cloud connectivity for ships, chemical parks orairports, the new range has got it covered: securely, profes-sionally, reliably.19PR O D U C TS I N D E TA I LSACE Tmax XT4The entrepreneur A forward-thinking, multitasker. It finds solutions for all levels of complexity.At a glance:• Up to 250A • For heavy duty • Dimensions 105x82.5x160 (WxDxH mm)• Thermal-magnetic, Ekip Dip,Ekip Touch/Hi-TouchSACE Tmax XT3The workhorseSmall and experienced. For standardapplications that need few efforts.At a glance:• Up to 250 A• For basic functionalities• Dimensions 105x70x150 (WxDxH mm)•Thermal-magnetic trip unitS ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCBS)SACE Tmax XT5The gamechanger.Compact, extremely powerful and flexible. It shows the world what a circuit-breaker of the future can do, today. At a glance:• Up to 630A• For heavy duty• Dimensions 140x103x205 (WxDxH mm)• Thermal-magnetic, Ekip Dip, Ekip Touch/Hi-Touch SACE Tmax XT6The carpenterBuilt to last. It completes all assignments it has been entrusted with.At a glance:• Up to 1000A• For basic functionalities• Dimensions 210x103.5x268 (WxDxH mm)• Thermal-magnetic, Ekip Dip2021PR O D U C TS I N D E TA I LSACE Tmax XT7 M The motorized superhero The ultimate choice, with motor. It deals with the most heavy-duty demands smoothly.At a glance:• Up to 1600A • For heavy duty • Dimensions 210x178x268 (WxDxH mm)• Ekip Dip, Ekip Touch/Hi-TouchSACE Tmax XT7The superheroThe ultimate choice. It deals with the mostheavy-duty demands effortlessly.At a glance:• Up to 1600A• For heavy duty• Dimensions 210x166x268 (WxDxH mm)•Ekip Dip, Ekip Touch/Hi-TouchS ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)—DATA A N D CO N N EC TI V IT YPlant management of the future – SACE Tmax XT sets the new standard in modern plant and energy management. Access, monitor and control information remotely, anywhere, at any time. Improving efficiency and saving energy.24S ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)—01 All the tools neededto set up a compe-tent and effectiveenergy managementstrategy. 30% moreinformation abouta running system toempower ABB Ability TM P r o t e c t i o n a n di n f o r m a t i o n AccuracyThermal-magnetic trip units Thermal-magnetic trip units are intended for the protection of AC and DC networks. They are a solution for basic protection such as overloads and short-circuits.Ekip Dip trip unitsEkip Dip trip units represent the first level ofelectronic trip unit and are used to protect ACnetworks. Compared to thermal-magnetic tripunits, they can provide increased accuracy, a widerreg ulation range, delayed short-circuit protection,in di v idual trip information and test capa bility.Ekip Touch/Hi-Touch trip units Ekip Touch/Hi-Touch trip units offer state-of-the-art technology for AC-network protection. These trip units integrate a great number of protection and automation functionalities, performed with best-in-class accuracy. Measurement and supervi-sion data can be transmitted both on the local communication network (the most popular com-munication protocols are available) or directly over the Internet. Configuration of the trip unit is extremely user-friendly, mainly on the sizes where a color touchscreen display is available. Furthermore, as operational requirements evolve,for the first time ever customers can downloadnew functions from the ABB Ability Marketplace TM ,choosing among more than fifty different protec-tion, metering and automation functionalities.—Electronic trip units Ekip Dip and Ekip Touch/Hi-Touch The network under controlWhen it comes to accurate protection of the network, you cannot go wrong with Ekip Dip and Touch technology.Trip unit rangeThe protection units available for the SACE Tmax XTrange is organized in three layers, characterizedby increasing performance, interfaces, informa-tion sets and integration functions. Each layerincludes several trip unit versions, designed to match specific application needs such as distribu-tion, generator protection and motor protection.25CampaignS ACE TM A X X T M O L D ED C A SE CI R C U IT-B R E A K ER S (M CCB S)—QUA LIT Y A N D R ELI A B I LIT YAbsolute attention to detail, withstyle – from design to manufacturing, SACETmax XT sets the new standard for edgetechnologies. Almost a century of research and experience means top-level products that areready to face future challenges.© Copyright 2019 ABB. All rights reserved.Specifications subject to change without notice.9A K K 107046A 3308 - 05/2019—ABB SACEElectrification business Smart Power business line 5, Via PescariaI-24123 Bergamo - ItalyPhone: +39 035 395-111go.abb/xt。

第一章概要感谢惠购本公司的M350型罐体在线检测机。

M350罐体在线检测机是准确度高且信赖度高的金属罐内部在线检测系统。

应用高性能及高解析度的数字相机在生产线上检测罐体底部及罐体内壁落入的蚊子,苍蝇或其它异物,并通过将异常品剔除出去以保证生产线上罐体内的品质本设备还可以检测罐体内部喷涂不良。

保证罐内喷涂的品质。

本设备采用高强度LED照明,光源寿命长。

本设备操作简单,维护方便,亦能满足24小时工作的需求第二章系统组成1.系统组成1.分流系统:分流整理框架:用于把传送带上散乱的罐体分流整理为预定的队列,以便于下一步检测的执行2.触发传感器:对射式激光传感器:为视觉传感器拍照时的触发提供精确信号3.主控制箱:内部装有视觉传感器,控制器,照明光源,以及其它的辅助设施:用于拍照检测,并为不合格品的剔除提供触发信号.4.不合格品剔除系统:电磁控制阀,气嘴:用于不合格品的剔除2.关于各线缆网线电源线电源侧本体侧3.面板说明指示灯电源开关电源插口保险网线端口第三章安装1. 安装操作流程安装分流系统安装触发传感器安装剔除系统安装主控制箱连接线缆开启电源设定软件参数启动检测第四章设备参数及联机操作1.设备参数:控制箱外形尺寸:800*625*302; 电源:AC220V;解析度:640*480像素;传感器类型:CMOS;色彩模式:黑白;环境温度:0-50℃;周围湿度:20-80% (未结露);2.控制器说明:在控制器中有指示灯和按钮开关,它们的作用分别是:电源开关:控制目前检测机是否在开启状态。

指示灯准备:黄色亮时,告知检测机已经进入准备状态,时刻可以触发拍照。

检测:绿色亮时,说明经过检测,判断检测合格不良品剔除:红色亮时,说明经过检测,判断制品内部有异物,并进行剔除动作第五章 软件画面设定1.起始画面各项参数说明设置:用于获得模板画面,设定触发方式和完成自动曝光。

(详见软件设置面板)。

工具:用于设定模具保护器的各种监测条件,及数据连接(详见软件工具面板)。

HASCO标准HASCO标准是世界三大模具配件生产标准之一,以其互配性强,设计简洁,容易安装,可换性好,操作可靠,性能稳定,兼容各国家工业标准等优点屹立于世界各模具标准,与美国的DME标准、日本的MISUMI标准齐名是世界覆盖范围最广的模具配件生产标准。

HASCO标准镀彩锌的顶针HASCO标准的精神勇气-在一个长期历史过程中的传统公司,哈斯科一直成功地面临新的挑战。

I n this way, HASCO developed from a trade workshop to an internationally a ctive industrial company within its 80-year history.这样,哈斯科发达国家从贸易国际研讨会,积极工业公司在其80年历史。

Even today, at a time of globally o rientated markets, this company virtue is a mark of our trade.即使在今天,在面向全球市场的时间,这家公司是我们商标的美德。

Courageous, confident and highly motivated, we cope with the tasks that lie before us, together with ou r partners.勇敢,自信和充满活力,我们面对的任务摆在我们面前,我们与我们的合作伙伴。

只有勇敢的人才能灌输勇气。

性能-性能和质量,我们公司愿意无限带来了传统的价值观和对未来的展望持久的成功是我们的座右铭。

Excellent products for tool and mould construction an d customer-orientated, co-operative service are our trademarks.优质的产品为工具和模具的建设和用户至上,合作的服务是我们的商标。

Eaton PDG54N0800P4YMEaton Power Defense molded case circuit breaker, Globally Rated, Frame 5, Four Pole (100% N), 800A, 85kA/480V, PXR25 ARMS LSI w/ Modbus RTU, CAM Link, ZSI and Relays, No Terminals (Metric Tapped Conductors)Eaton Power Defense molded case circuit breakerPDG54N0800P4YM 786679873106139.7 mm 406.4 mm 282.7 mm 21.32 kg Eaton Selling Policy 25-000, one (1) year from the date of installation of theProduct or eighteen (18) months from thedate of shipment of the Product,whichever occurs first.RoHS Compliant UL 489CSAIEC 60947-2CCC MarkedProduct NameCatalog Number UPCProduct Length/Depth Product Height Product Width Product Weight WarrantyCompliancesCertifications800 AComplete breaker 5Four-pole (100% N)PD5 GlobalClass APXR 25 LSI w/ARMS Modbus RTU and CAM Link600 Vac600 V100% neutral protectionNo Terminals85 kAIC at 480 Vac35 kAIC Icu/ 25 kAIC Ics/ 73.5 kAIC Icm @525V South Africa (IEC)65 kAIC Icu/ 40 kAIC Ics/ 143 kAIC Icm @480V Brazil (IEC) 20 kAIC Icu/ 10 kAIC Ics/ 42 kAIC Icm @690V (IEC)70 kAIC Icu/ 50 kAIC Ics/ 154 kAIC Icm @440V (IEC)50 kAIC @600/347V (UL)150 kAIC @240V (UL)150 kAIC Icu/ 100 kAIC Ics/ 330 kAIC Icm @240V (IEC)85 kAIC @480/277V (UL)70 kAIC Icu/ 50 kAIC Ics/ 154 kAIC Icm @380-415V (IEC)Eaton Power Defense PDG54N0800P4YM 3D drawingConsulting application guide - molded case circuit breakers Power Xpert Protection Manager x64Power Xpert Protection Manager x32StrandAble terminals product aidPower Defense molded case circuit breaker selection poster Power Defense brochurePower Defense technical selling bookletAmperage RatingCircuit breaker frame type FrameNumber of poles Circuit breaker type ClassTrip Type CommunicationVoltage ratingVoltage rating - maxProtectionTerminalsInterrupt rating Interrupt rating range 3D CAD drawing package Application notesBrochuresCatalogsPower Defense molded case circuit breakers - Frame 5 product aid Power Xpert Release trip units for Power Defense molded case circuit breakersMolded case circuit breakers catalogCertification reportsPDG6 CSA certificationPDG6 CCC certificatePDG5 CCC certificationPDG5 CSA CertificationPDG5 CB reportPDG5 UL authorizationEU Declaration of Conformity - Power Defense molded case circuit breakersInstallation instructionsPower Defense Frame 5 aux, alarm, shunt trip and uvr instructions(IL012201EN).pdfPower Defense Frame 2/3/4/5/6 voltage neutral sensor module wiring instructions – IL012316ENPower Defense Frame 4_5 flex shaft handle mech assembly instructions - IL012284ENPower Defense Frame 5 key interlock installation instructions -IL012294ENPower Defense Frame 5 walking beam installation instructions -IL012290ENPower Defense Frame 4_5_6 high performance flex shaft handle mech assembly instructions - IL012296ENPower Defense Frame 5 vertical padlockable handle lock hasp installation instructions - IL012283ENPower Defense Frame 5 breaker status module installation instructions – IL012307ENPower Defense Frame 5 interphase barrier kit 4 pole installation instructions - IL012293ENInstallation videosPower Defense Frame 5 Trip Unit Upgrade Relays Board, Animated Instructions.rhPower Defense Frame 5 Shunt Trip, Aux and Alarm Trip How-To Video Power Defense Frame 5 Aux, Alarm, ST and UVR Animated Instructions.rh1Power Defense Frame 5 UVR Trip How-To VideoPower Defense Frame 5 Trip Unit Replacement Animated Instructions Power Defense Frame 5 Trip Unit Upgrade Wire Harnesses, AnimatedEaton Corporation plc Eaton House30 Pembroke Road Dublin 4, Ireland © 2023 Eaton. All Rights Reserved. Eaton is a registered trademark.All other trademarks areproperty of their respectiveowners./socialmediaInstructions.rh Power Defense Frame 2 Variable Depth Rotary Handle Mechanism Installation How-To VideoPower Defense molded case circuit breakers Power Defense Frame 5 Trip Unit How-To VideoPower Defense Frame 3 Variable Depth Rotary Handle Mechanism Installation How-To Video Power Defense BreakersEaton Power Defense for superior arc flash safety Power Defense Frame 6 Trip Unit How-To Video Eaton Specification Sheet - PDG54N0800P4YM Power Defense time current curve Frame 5 - PD5Making a better machineImplementation of arc flash mitigating solutions at industrial manufacturing facilitiesIntelligent circuit protection yields space savings Intelligent power starts with accurate, actionable data Single and double break MCCB performance revisited Molded case and low-voltage power circuit breaker health Molded case and low-voltage breaker health Safer by design: arc energy reduction techniquesMultimediaSpecifications and datasheetsTime/current curvesWhite papers。