阿法拉伐 Alfa Laval

- 格式:ppt

- 大小:13.96 MB

- 文档页数:97

Total sevice commitment. hundreds of field engineers.Hello smartSimply better for heat transferInvesting in state-of-the-art R&D and expertise in materials development we test the resistance of our products until we are satisfied on pressure and thermal shocks in every aspect. That’s your guarantee of optimized performance, minimized costs and greatly reduced use of water and energy .Add ease of installation and long time between services and it’s obvious to see why our coolers are the first choice for the world’s major OEMs.The service you need, wherever you need itThrough a global network of producers, distributors and sales companies, we offer you expert help to design the optimal cooling system for your needs. And of course, we speak your language, whatever country you live in, and whatever technical challenge you face.And thanks to our highly efficient supply chain, we offer fast, reliable, on-time deliveries for all projects . Our worldwide parts and service network offers service for our Alfa Laval and other heat exchanger brands,ensuring nonstop performance and true peace of mind .energy savings.Looking for smart cooling solutions in your systems? Installing Alfa Laval’s heat exchangers save up to 60% space, weight and cooling water. With up to 5 times higher heat transfer capacity than other coolers such as shell-and-tubes, our products use much less of the world’s precious natural resources to cool hydraulic systems.Quality products.Compact, powerful and reliable oil coolers that optimize your operationsQuality service.70 years of experience in heat transfer technology available to you 24/7Quality partnership.World-class distributorsdedicated to supporting youHello quality Goodbye worry.coolers.Made from the highest quality materials, Alfa Laval oil coolers offer the best thermal transfer in thesmallest space, and are perfect for reliable oil cooling in all industrial hydraulic and lube oil applications.Their innovative design provides flexibility for all processes, increases operational performance and system reliability, lengthening service life. Add the combination of world-class service, technical support and a complete training program and it’s easy to see how Alfa Laval’s heat exchangers and oil coolers maintain safe fluid operating temperatures and protect your systems. Say hello to high performance. And goodbye to system failure.Alfa Laval offers a complete portfolio of compact oil coolers speciallydesigned to withstand the rigours of the toughest hydraulic systems .Alfa Laval’s compact and powerful oil coolers boostperformance, optimize operations and reduce maintenance in hydraulic and lube oil systems.Smaller footprint4Up to 60% less space than comparable shell-and-tube Less space thancomparable oil coolers Lower investment costsUses less energy5High heat transfer Close temperature approachesMore heat recovery, less energySelf cleaning6High turbulent flow High shear rateMaximized uptime and reduced maintenanceEasy to install1 Mounting blocks for high tightening torque and a good spanner gripFast, secure installation Cuts down man hours No risk of breaking connectionBuilt-in mechanical strengthMarket’s strongest system Sturdy constructionInterior connections never break23 Powerful, compact high-efficiency coolers Reliable under highpressure and temperatureRugged designGasketed plate heat exchangers, GPHEs, provide full flexibility to meet the demands of any oil cooling duty. In larger HPU systems they can be installed off-line in the cooling circuit. For applications with aggressive media, such as sea water, Alfa Laval can supply GPHEs with plates in corrosion-resistant materials. Another option could be double wall plates to avoid cross contamination.Fusion-bonded plate heat exchangers, Alfa Nova range, made of 100% stainless steel minimizes the risk of corrosion and makes this highly efficient heat exchanger suitable for oil applications using hazardous media where copper is not an option.Gasketed plate heat exchangersFusion-bonded plate heat exchangers, AlfaNova rangeBrazed plate heat exchangers, CB range, are high-efficiency oil coolers that contribute to long, maintenance-free life-times for hydraulic power pack cooling systems or lube oil systems. The CB range can be fitted with a wide range of different oil connections, such as NPT, SAE, hexagonal and internal threaded.Brazed plate heat exchangers, CB rangeAlfa Laval’s brazed plate heat exchanger series of dedicated oil coolers, DOC range, offer unparalleled efficiency for hydraulic oil cooling. The extra sturdy construction is easy to install, and the special connection block decreases stress on the standard connection by 80%. This connection block saves you installation time and avoids possible leakage.Dedicated oil coolers, DOC range。

DATOS TÉCNICOS Lubricante:..................Lubricación mediante fluidode enjuague/limpieza Radio de humectación:..........Máx.4,5mRadio de limpieza de impacto:.....Máx.2,4mVapor o gas(aire):..............No se admite-contáctesecon ALPresiónPresión de funcionamiento:.......1-3baresPresión recomendada:...........2baresPatrón derociado 360°270°en aumentoDiseño estándarToftejorg SaniMagnum SB se puede entregar con Certificados3.1 para las piezas metálicas y certificados en conformidad con normativa 3-A*para la pieza de plástico.*Implica que el material cumple con FDA21CFR.También hay disponibles planos de instalación,y de tamaños y opciones.Si necesita recomendaciones,póngase en contacto con Alfa Laval.CertificadosCertificación de material2.2y EHEDG y3-AComo complemento:Certificado de material3.1yATEX.DATOS FÍSICOSMaterialesPiezas metálicas:..............316LPiezas no metálicas:............PEEK450GAcabado de la superficie:.........Ra0,8µmTemperaturaTemperatura de funcionamiento máx.:.95°CTemperatura ambiente máx.:.......150°CPeso:......................0,0.4kgConexionesPresilla:.....................1½”BPE US,1½”ISO2037Soldadura:..................2”BPE US*MordazaPresilla para encendido/apagado sencillo(ø4,0mm)Para montarla máquina,se necesita pinza en las dos versiones(soldada y depresilla).Tamaño de depósito recomendado:.23-68m3CaudalRadio de limpieza Presión de entrada Presión de entradaCaudal510152001020304050607080CaudalLongitud de eyección(radio)12354Longitud de eyección (radio)Presión de entradaPresión de entradaA =360°-B =270°A =baño -B =limpieza de impactoPara modelos con presilla,el caudal aumenta aproximadamente en 1,5m 3/h.Tenga en cuenta que:La presión de entrada se ha tomado inmediatamente antes de la entrada a la máquina.Para alcanzar el rendimiento indicado en las curvas,es preciso tener en cuenta las caídas de presión en las líneas de suministro entre la bomba y la má temperatura del agua durante la prueba fue aprox.de 20°C.PresillaSoldaduraDimensiones (mm)Tipo A B E G ID ODtMordaza Presilla118.354.725.4ø4.1ø38.4ø4.0Soldadura**138.954.7ø38.11.2**La versión de soldadura solo cumple los requisitos de la Norma sanitaria 3-A 78-01si se instala siguiendo el manual del usuario.ESE02216ES1507La información incluida en el presente documento es correcta en el momentode su publicación,no obstante puede estar sujeta a modificaciones sinprevio aviso.ALFA LAVAL es una marca registrada de Alfa Laval CorporateAB(Suecia).©Alfa LavalCómo ponerse en contacto con Alfa Laval Cómo ponerse en contacto con Alfa Laval nosotros en cada país,se actualiza constan-temente en nuestra página web.Visite para acceder a esta. información.。

陶郁华 阿法拉伐罐用设备部苏州惠氏营养课程 苏州惠氏营养课程2010年3月12日 年 月 日• • • • • • • 20min 20min 40min+15min 休息 60min 50min 20min 20min阿法拉伐的清洗技术 CAS选型及典型应用 清洗设备的维护 阿法拉伐的搅拌技术 搅拌器选型及装配 随时回答相关的问题 阿法拉伐新产品介绍阿法拉伐公司阿法拉伐在全球范围内提供 专业产品及工程解决方案。

专业产品及工程解决方案。

们向客户提供的服务, 我们向客户提供的服务,包 括对其产品,如石油、 括对其产品,如石油、水、 化学品、饮料、食品、 化学品、饮料、食品、淀粉 和药品进行加热、冷却、分 和药品进行加热、冷却、 离及输送。

离及输送。

阿法拉伐创始人“高速离心专家 高速离心专家” 高速离心专家• • •200 个项目及发明 92项专利,包括牛奶分 项专利, 项专利 离机 (1878) 和蒸汽涡轮 机 (1883) 建立了37家公司 建立了 家公司Gustaf de Laval (1845-1913)阿法拉伐核心技术• • •换热设备 离心设备 流体设备流体设备产品范围• • • • •Pumps 泵 Valves 阀门 Tank Equipment 罐用设备 Installation Material 安装材料 Sanitary PHE 卫生级板换阿法拉伐罐用设备罐用设备 目标: 目标:全球首家提供全套罐 用设备的供应商,包括: 用设备的供应商,包括:• • • •清洗设备 搅拌器 人孔盖 视镜及附件罐用设备的产品总概Everything you need for your tank罐用设备的产品总概Everything you need for your tank清洗设备罐用设备的产品总概Everything you need for your tank清洗设备搅拌器罐用设备的产品总概Everything you need for your tank人孔盖清洗设备搅拌器阿法拉伐 罐用清洗设备有关清洗的一些基本概念 阿法拉伐的清洗技术 CAS选型及典型应用为什么需要清洗?• • • • • • •防止交叉污染 去除残留产品 抑制微生物滋生 为工作人员进入做准备 防止爆炸气体聚集 符合法律法规规范 保护设备不被腐蚀清洗的重要性• •清洗在整个生产过程中占有了越来越多的时间。

柏恩换热器备件网提供柏恩、阿法拉伐、基伊埃、安培威、传特等各大品牌产品及配件,更有维护清洗、以旧换新等特色服务,详情请登录官网进行查询!一.品牌介绍二.板式换热器特点三.板式换热器工作原理四.阿法拉伐板式换热器材质五.阿法拉伐换热器系列1.阿法拉伐可拆式板式换热器1)可拆式板式换热器结构2)可拆式板式换热器工作原理及性能3)阿法拉伐可拆式板式换热器系列2.半焊板式换热器1)半焊板式换热器的优点2)激光半焊板式换热器在化工领域的应用范围3.钎焊式换热器1)钎焊式换热器2)主要应用行业3)阿法拉伐钎焊式换热器系列及相关参数柏恩换热器备件网提供柏恩、阿法拉伐、基伊埃、安培威、传特等各大品牌产品及配件,更有维护清洗、以旧换新等特色服务,详情请登录官网进行查询!4.全焊式板式换热器1)全焊式板式换热器特点5.熔焊式换热器1)熔焊式换热器(AlfaNova)2)主要应用行业六.应用行业一.品牌介绍120多年的历史,深厚的文化底蕴和良好的企业文化,使公司一直保持良好的发展势头。

持续不断的创新是公司保持世界领先地位的基础。

公司每年都投入大量的资金用于新产品的研发工作,成绩斐然,使公司在众多领域一直是行业的领航者,也使Alfa Laval商标成为全球高质量、高技术、高效率和高信誉的象征。

阿法拉伐的产品以换热器、离心分离机和流体设备为主。

其中,离心分离设备约占1/3。

阿法拉伐公司于上世纪50年代发明卧式沉降离心机。

1988年,世界上著名的沉降式离心机(Decanter)制造商夏普尔斯/Sharples加入我公司之后,阿法拉伐更在沉降式离心机的生产和运用方面称雄于世。

2000年,美国著名的Dorr Oliver碟片离心机公司的加入,使阿法拉伐公司的实力空前壮大。

在2007年,卧式沉降离心机的产量近1000台,在同行业中处于绝对的领先地位。

二.板式换热器特点柏恩换热器备件网提供柏恩、阿法拉伐、基伊埃、安培威、传特等各大品牌产品及配件,更有维护清洗、以旧换新等特色服务,详情请登录官网进行查询!1.粘接垫片:阿法拉伐使用两种组合硫化环氧胶粘接垫片使垫片永久牢固地粘接在垫片槽内,当打开换热器时,垫片不会脱落。

阿法拉伐板式换热器

阿法拉伐板式换热器(Alfa Laval plate heat exchanger)是一种高效的换热设备,采用板式热交换技术实现热量的

传递。

该换热器由一系列平行排列的金属板组成,板之间

通过密封垫片将流体隔开,并形成多个热交换区域。

热交换过程中,热源流体和冷却流体通过板式换热器的不

同侧面流动,通过金属板的导热性,实现热能的传递。

由

于金属板之间的间隙很小,从而实现高效的换热。

阿法拉伐板式换热器具有以下优点:

1. 高效换热:金属板之间的小间隙和大表面积可以实现高

效换热,提高热能利用率。

2. 尺寸小巧:相比传统管壳式换热器,板式换热器的结构

更为紧凑,占用空间更小。

3. 温度控制精度高:板式换热器能够提供精确的温度控制,满足不同工艺要求。

4. 易于维护:板式换热器的结构简单,易于拆卸和清洗,

维护和保养较为方便。

5. 耐腐蚀性强:阿法拉伐板式换热器采用耐腐蚀材料制造,能够适应各种工况环境。

阿法拉伐是一家专业从事换热设备制造的国际企业,在板

式换热器领域具有较高的技术水平和市场影响力。

阿法拉

伐板式换热器广泛应用于石油化工、食品饮料、制药等行业,为工业生产提供高效能、节能环保的换热解决方案。

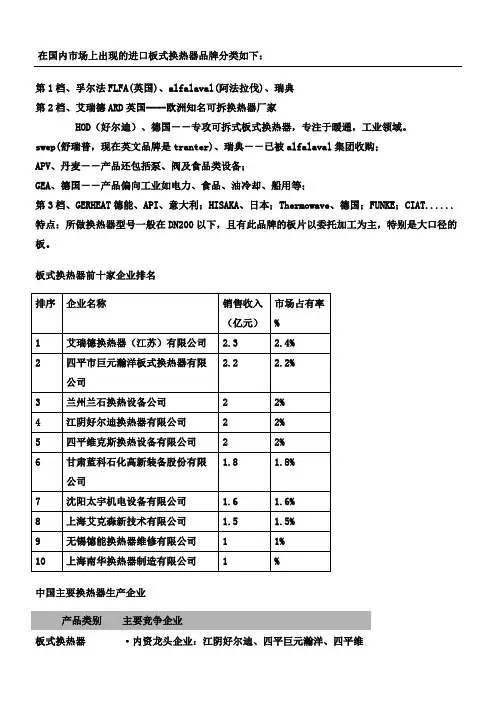

第1档、孚尔法FLFA(英国)、alfalaval(阿法拉伐)、瑞典

第2档、艾瑞德ARD英国----欧洲知名可拆换热器厂家

HOD(好尔迪)、德国--专攻可拆式板式换热器,专注于暖通,工业领域。

swep(舒瑞普,现在英文品牌是tranter)、瑞典--已被alfalaval集团收购;

APV、丹麦--产品还包括泵、阀及食品类设备;

GEA、德国--产品偏向工业如电力、食品、油冷却、船用等;

第3档、GERHEAT德能、API、意大利;HISAKA、日本;Thermowave、德国;FUNKE;CIAT...... 特点:所做换热器型号一般在DN200以下,且有此品牌的板片以委托加工为主,特别是大口径的板。

板式换热器前十家企业排名

中国主要换热器生产企业

主要外资换热器企业在华布局。

高节能效率,低维护成本SpiralPro永远不会结垢SpiralCond:真空冷凝的理想解决方案SpiralPro用于液-液工况SpiralCond用于真空冷凝和蒸发SpiralPro用作蒸汽加热器SpiralCond“多合一”配置提升螺旋板式换热器的可持续性阿法拉伐全焊接螺旋板式换热器系列为高要求的液-液和两相工况提供了强大而可靠的选择,具有极低的维护要求。

全球已有超过80000台螺旋板式换热器装置交付使用,在化工、废水、采矿等应用领域久经验证,可应对其他类型的换热器难以解决的挑战,是值得信赖的可靠解决方案。

阿法拉伐螺旋板换的传热效率是同类管壳式换热器的2-3倍。

因此可回收更多的废热,从而为节约能源创造巨大潜力。

阿法拉伐螺旋板将更低的燃料成本和更少的排放相结合,可以为提升工艺流程的可持续性以及盈利能力提供更明智的解决方案。

同时,紧凑的设计能降低安装和材料成本,简化的服务减少了年度维护预算。

阿法拉伐螺旋板式换热器能缩短投资回收期、降低总投资成本。

对于涉及结垢流体、污泥、乳剂、泥浆、纤维或颗粒负载液体的工艺过程,阿法拉伐SpiralPro换热器的可靠性无与伦比。

SelfClean™的设计可防止脏流体结垢和堵塞,而这些脏流体会导致任何其他类型的换热器出现问题。

最大的正常运行时间和易于清洁性,极大地降低了运营费用,同时提高了生产能力。

SpiralPro换热器可以作为液液换热器或作为蒸汽加热器。

SpiralCond换热器是两相换热的高效解决方案,紧凑的立式安装,比同等效果的管壳式换热器占地面积小得多。

每一个SpiralCond换热器都完全根据所需的热负荷进行定制,并调整通道间距以提供最低的压降。

因此,Spiral-Cond换热器非常适合具有挑战性的真空冷凝和蒸发工况。

SpiralCond换热器能够安装在现有的工艺塔上或者作为“多合一”塔顶冷凝器,同时适配多种冷媒。

解决棘手问题的优势SpiralProSpiralCond适用于液液或者蒸汽加热工况适用于真空冷凝或蒸发工况能够被安装在现有的工艺塔上或者作为“多合一”塔顶冷凝器同时适配多种冷媒温度:-100°C 到400°C 温度:-100°C 到400°C 设计压力:全真空至 100 barg 设计压力:全真空至 100 barg 压差:高达50 barg 压差:高达50 barg 传热面积(最大):900 m 2传热面积(最大):2500 m 2 (“多合一“冷凝器)• 提升热回收效率可显著降低能源消耗,同时减少化石燃料消耗和二氧化碳排放。

阿法拉伐中文说明书1(共94页) -本页仅作为预览文档封面,使用时请删除本页-目录1安全说明…………………………………………………………..... 2卧螺离心机的操作原理……………………………………….....主电机………..…………………………………………….………………......后驱动系统……………..………………………………………………… ...变频后驱动(VFD)..…….……………………………………………… ..... 3操作和日常维护…………………………………………………在第一次开车前……………..………………………………………………噪声和振动…………...……...………………………………………….…开车和停车程序…………………..…………………………………………检查转鼓……..…………………………………………………………….开车前…………..………………………………………………………….检查要点………….……………….……………………………………..具有机械密封的离心机…………………..……………………………..启动离心机………………………………………..……………………….离心机停车……………………………………………..………………….监控操作……………………………………………………………………..过载………………………………………………………………………...过载的原因………………………………………………………………清理过载的转鼓…………………………………………………………振动………………………………………………………………………... ..振动开关(可选设备)…………………………………………………监测螺旋磨损……………………………………………………………...定期清洗过程………………………………………………………………..优化操作……………………………………………………………………..主电机………………………………………………………………………..变频驱(VFD)……………………………………………………………...调整转鼓速度传感器(图)………………………………………..润滑…………………………………………………………………………..主轴承……………………………...………………………………………螺旋轴承(图中的加油嘴3和4)………………………………...齿轮箱(图)………………………………………………………...维护表……………………………...…………………………………………润滑时间和维护方法……………………………………………………...表润滑表………………………………………………………….…表维护周期…………………………………………………………润滑剂型号………………………………………………………………...表润滑剂、润滑工具表……………………………………………4拆卸和组装………………………………………………………旋转组件……………………………………………………………………...拆卸转鼓(图和)…………………………………………….安装转鼓(图和)…………………………………………….拆卸大端轴颈(图)………………………………………………...安装大端轴颈(图)………………………………………………...拆卸小端轴颈(图)………………………………………………...安装小端轴颈(图)……………………………………………….拆卸齿轮箱(图和)………………………………………….安装齿轮箱(图和)…………………………………………装配新的排污口衬套…………………….………………………………主轴承…………….…………………………………………………………..拆卸大端主轴承(图)…………………………………….…………..组装大端主轴承(图)………………………………………………...拆卸小端主轴承(图)………………………………………………...安装小端主轴承(图)………………………………………………...螺旋轴承……………………………………………………….…….……….拆卸螺旋大端轴承(图)…………………………………….………..组装螺旋轴承大端轴承(图)………………………………………拆卸螺旋轴承小端轴承(图)……………………………………...安装螺旋轴承小端轴承(图)……………………………………...螺旋…………………………………………………………………………...从转鼓中拆卸螺旋(图)……………………………………………将螺旋装入转鼓(图)………………………………………………...主电机………………………………………………………………………..拆卸主电机(图)……………………………………………….…..组装主电机(图,和)………………………………….…..调紧V形皮带,皮带张力表………………………………………………变频后驱动装置(VFD)…………………….……………………………..拆卸变频驱动器(图)………….………………………………….组装变频驱动器(图)……………………………………………..5补充文档…………………………………………………………1安全说明请务必严格按照以下要求进行操作,否则会给您造成人员以及财产的损失。

A rounded approach to tank cleaning At Alfa Laval we take a panoramic view of tank cleaning. That’s to say rather than simply seeing it as a maintenance issue, experience has taught us tank cleaning holds far-reaching benefits for the entire production cycle. This know-how is clearly reflected in the cleaning machines and services we supply.Let’s face it, for most companies tank cleaning is a necessary evil, a constant hindrance to maximum throughput. However, at Alfa Laval we take a slightly different view.We believe tank cleaning has an important role to play in the drive for efficiency. You see we don’t look at tank cleaning in isolation, but rather as an integral link in the production line. By optimizing every stage of the cleaning process, it’s possible to have a significant impact on overall plant output.Our ability to dramatically streamline tank cleaning – and plant efficiency – hinges on two vital proprietary resources: cutting-edge cleaning heads and an unparalleled knowledge base. To be more explicit, an intimate knowledge of process engineering lets us assess customer needs and weigh up system variations quickly. Then our exhaustive range of cleaning heads and implementation expertise allows us to select and configure a suitable cleaning system in a cost-effective, timely manner.360º coverageIntegral to our broader view of tank cleaning are the cleaning machines themselves. Including our respected Toftejorg brand, we supply a complete range of rotary spray and jet cleaning heads as well as fixed spray heads.We also supply verification systems that let you electronically certify each stage of a CIP cycle has been carried out as expected. Rotary spray and jet heads are designedto make sure every square inch of a tank’sinternal surfaces are covered by detergentduring a cleaning cycle. The physicalimpact of cleaning media combined withthe rotary motion is highly effective inremoving residual material.As a result the heads have the obviouseffect of improving tank cleanliness.But their effectiveness also has a widerimpact on time and costs. Rotary cleaningheads significantly cut the amount oftime, chemicals, water and energy usedduring cleaning. This means the volumeof waste generated is reduced too. Allthis adds up to increased efficiency atlower cost, and the effect on throughputis often striking.In other words, when you invest in anautomated cleaning system from Alfa Laval,the impact is not only felt in your tanks,it resonates throughout your business.Toftejorg rotary jet headsclean tanks by castingjets of cleaning mediaagainst tank walls. Theflow of detergent throughthe head’s turbine andgears causes the nozzlesto perform rotationsaround the vertical andhorizontal axes, generat-ing a criss-cross spraypattern inside the tank.Benefits of rotary cleaning heads•Improved tank hygiene•Increased plant efficiency andreduced cleaning time•Considerable savings in water,energy and chemical consumption•Enhanced employee safety•Significant reduction in waste•Verification of cleaning processAlfa Laval Tank Equipment 3This background translates into meaning-ful benefits for our customers in that our cleaning heads display a profound under-standing of industry and regulatory needs, with many designed to cope with specific applications.Industry knowledge is also an invaluable guide in product development. We con-stantly refine and update our cleaning head range in response to customer feedback, changes in production techniques and new regulations.Here are some key benefits our Toftejorg cleaning heads hold for specific industries. Beyond the sectors covered here, our products also cater to many other process cleaning applications.Beverage applicationsOur T oftejorg range represents the cleaning benchmark for breweries, and the rotary cleaning machines streamline every stage of the process: from yeast propagation and fermentation to bright beer. A 30% saving in cleaning time and chemical con-sumption is quite normal when switching from conventional cleaning techniques to rotary jet heads.Our proprietary knowledge of the industry means we can optimize CIP performance for all types of brewery vessels extremely quickly. And for added peace of mind, a Rotacheck verification system lets you confirm that each stage of a CIP cycle is carried out as expected. All these benefits also hold true for the bev-erage industry at large, and rotary heads are ideal for streamlining cleaning opera-tions in the wine and soft drink sectors.Food applicationsOur cleaning machines for the food industry are designed to meet all manner of cleaning challenges common in food production, including the removal of burnt residue and biofilm, elimination of cross-contamination, and cleaning tanks and mixers with agitators or baffles. Our tech-nology complies with industry hygiene requirements, and many of the heads are self-cleaning and self-draining. In addition, products come in FDA-compliant materi-als, and adding a Rotacheck verification system lets you document that your tanks are being consistently cleaned to the required standards.Dairy applicationsConsistent with EHEDG design require-ments, our rotary heads can significantly improve tank cleanliness in dairies, while minimizing time, water and chemical con-sumption. The scrubbing action that rotaryWith over a century’sexperience of workingwith industrial compo-nents and processes,few companies matchAlfa Laval’s depth ofknowledge and range oftank cleaning products.An insider’s understanding of industry4 Alfa Laval Tank EquipmentAlfa Laval Tank Equipment 5technology delivers is ideal for removing stubborn residues such as fermented products, eg, yogurt or fresh cheese.Rotary heads heat up tanks faster during a CIP cycle, thereby reducing total turn-around time. For powder applications or where internal components or geometry complicate installing permanent cleaning machines, our self-actuated retractable systems represent an extremely effective and reliable solution.Pharmaceutical applicationsAs well as delivering highly effective tank cleaning, our machines for the pharma-ceutical sector are self-cleaning and self-draining and some have integrated self-cleaning down-pipes (patent pending).Using automated CIP systems severely reduces employee exposure to hazardous materials, and including a Rotacheck verification system lets you certify elec-tronically that tanks are being consistently cleaned to validated standards.Our sanitary product line conforms with the strictest guidelines laid down byindustry regulators (e.g. FDA, cGMP , ICH Q7A, EHEDG). As such we can provideall required documentation and data onToftejorg SaniMidget •Full coverage•Effective cleaning at low flow rate •Sanitary designToftejorg SaniMidget Retractor •Retractable•Suited to tanks with internal components •Self cleaning andself drainingToftejorg SaniJet 20•Totally self cleaning •Follows EHEDG guidelines•FDA compliant •High-impactcleaningToftejorg TJ 20G•360°impact cleaning and coverage•Award-winninghygienic design Toftejorg TZ-74•360°impact cleaning and coverage•Effective cleaningat low flow ratemachines, application analyses, or both.Product documentation includes surface roughness data, material traceability, FDA material conformance, factory test reports,manuals and validation support.Personal care applicationsThe complete coverage, rotary action and impact afforded by rotary jet heads makes them particularly effective in cleaning vis-cous, foaming or thixotropic products of the type commonly produced in the per-sonal care industry. The efficient removal of such residue also grants significant savings in terms of time and water consumption.8000 Series Spray Balls •3A compliant •Custom optionsincluding laser drilling •A variety of surfacefinishes including EPA scientific route to implementation, a human path to customer service Purchasing a tank cleaning system from Alfa Laval is also an investment in peace of mind. That’s because our wealth of experience in selecting, configuring and maintaining tank cleaning machines leaves nothing to chance.We’re quite aware tank cleaning isn’t the foremost thought in your mind. On the contrary, it’s probably something you’d rather forget in your daily life. Our senti-ments exactly.By taking the care and attention up front to ensure all equipment is correctly implemented, and by delivering responsive post-sales support, customers can spend their energy on issues other than tank cleaning. T o help in this endeavor, we have several unique resources at our disposal.TRAX®simulationOn each rotary jet head within a tank cleaning system, all variables are carefully selected and adjusted for best results. Then our proprietary TRAX®simulation soft-ware is used to recreate how a machine would perform in a customer’s tank. The simulation gives information on wetting intensity, pattern mesh width and cleaning jet velocity. Using this information it’s not only possible to determine an appropriate jet head and its placement, but also the correct combination of flow, time and pressure to implement in a CIP program.Test facilityCustomers have access to Alfa Laval’s world-class tank cleaning test facilities. Here it’s possible to recreate a huge variety of specific tank cleaning operations under carefully controlled conditions. The facility has two full-scale production tanks, each connected to a CIP unit. The test facility allows customers to compare the cleaning performance of different machines and multiple CIP programs under varying conditions of temperature and detergent concentration.Among other things, the test facility aids in determining suitable machines, the placement and configuration of each machine, and CIP program steps.Global customer supportOur tank cleaning machines are guaran-teed to deliver high performance and complete coverage. The same is true for our sales companies and global distribu-tion network. That’s to say our offices around the world are always ready to provide you with the parts, advice and service you may need at any time.Known as “Nonstop Performance”, our service commitment gives customers total confi-dence they won’t be left high and dry should a tank cleaning system fail.6 Alfa Laval Tank Equipment。

特色每一个细节都经过精心设计,以确保最佳性能、最大正常运行时间和易于维护性。

选择可用的功能:5点对准系统角引导的对准系统巧克力模式分布区胶粘密封垫Clip-on密封垫泄漏室固定的螺栓头关键孔螺栓开口吊耳衬套锁紧垫圈压板滚柱紧固螺栓盖延伸性能阿法拉伐360°服务组合我们有系列广泛的服务,确保从您的阿法拉伐设备在其整个生命周期中都有最高性能。

零件的高储备量和我们的团队的专业承诺和知识让您安心使用。

启动支持安装专有存货安装监管技术文件试运行电话支持培训维护故障排除清洗服务翻新改进维修设备升级维修工具重新设计备件更换和改造监控条件审计性能审计尺寸说明图单位mm (英寸)类型HW h TL10-FM 1885(74.2”)480(18.9”)255(10.0”)TL10-FG 1981(78.0”)480(18.9”)297(11.7”)TL10-FD 1981(78.0”)480(18.9”)297(11.7”)TL10-FS1981(78.0”)510(20.1”)297(11.7”)拉紧螺栓的数量会因额定压力的不同而有所不同。

技术数据板片名称类型自由通道,mm(inch)TL10-B 单板片 2.0(0.079)TL10-P单板片3.0(0.12)材料传热板片304/304L,316/316L,254C-276Ni,Ti,TiPd现场胶垫NBR,EPDM,FKM,FEPM法兰连接碳钢金属衬里:不锈钢、Alloy 254、Alloy C-276、镍、钛橡胶衬里:NBR、EPDM 框架和压板碳钢,喷涂环氧漆可以根据要求提供其他材质的部件。

所有选项组合可能不是可配置的。

工作数据框架,PV-代码最大设计压力(barg/psig)最大设计温度(°C/°F)FM,pvcALS 10.0/145180/356FG,pvcALS 16.0/232180/356FG,ASME 10.3/150250/482FG,PED 16.0/232180/356FD,PED 25.0/362180/356FS,ASME27.6/400250/482可以根据要求提供扩展的压力和温度额定值。

Tri-Clamp - The industry standard.Alfa Laval’s program of bends,tees and reducers are available indiameters from 1" to 6" in size.Bends, Tees & ReducersAlfa Laval constantly focuses on producing fittings with long durability, problem-free welding and assembly, and highestpossible strength. Key criteria in the manufacturing process include tight tolerances, a variety of finishes and uniform wall Alfa Laval is aware of the constantly increasing demands placed upon the quality of welding. In accordance with these demands, all our reducers meet the highest of standards. The reducers have cylindrical welding ends and are available The Right Partfor Your ApplicationAlfa Laval offers installation material in different standards so you can always find the right part, with the process quality you need, for your specific application.Sanitarywhere applicable• Sizes are available from stock are 1/2 inch to 6 inch Whatever your sanitary application,Alfa Laval is able to supply the right tube.Bio-Pharmaceutical FittingsAlfa Laval is proud to present their line of fittings designed for use in the pharmaceutical and bio-technologies industries. This line consists of parts with either Tri-Weld ends suitable for use with orbital welding equipment or self-aligning Tri-Clamp end connections. Alfa Laval offers a full line of bio-pharm fittings that are manufactured in compliance with the ASME This allows for the most accurate and consistent orbital weld result. All fittings are put through 100% visual inspection and ovality and squareness tolerances are inspected with calibrated equipment. Surface finish is inspected with a calibrated profilometer to ensure the Roughness average (Ra) maximum is not exceeded.The industry standard for quality.。

产品名称: lfa laval 阿法拉伐板换热器 -Alfa laval一、阿法拉伐板式热交换器的优点:1.分流区域:阿法拉伐先进的板片设计其另一个特点是分流区的设计,这也是法法拉伐众多专利之一。

为便于配置接管,现代的板式换热器的进出口接管都采用单边。

要充分利用全部的换热面积,必须保证流体均匀分布在整个板片。

阿法拉伐独特的流区设计,即使对一个最宽的板面,也能保证均匀分布。

另一个显著特点是压力降较低,可以使更经济的压力降用于传热,从而获得最高的穿热系数。

其他制造商由于缺乏良好的导流区,因此需要采用对角流来分配流体到整个板面,对角板结构会令配管复杂,需要两种不同的板片和垫片,给维修带来极度不便。

2.粘接垫片:阿法拉伐使用两种组合硫化环氧胶粘接垫片使垫片永久牢固地粘接在垫片槽内,当打开换热器时,垫片不会脱落。

而其他制造商并未硫化粘胶,有些甚至不用两种组合胶,这样不能保证牢固粘接,打开换热器时垫片常常脱落,而不得不更换垫片。

3.免粘接垫片:Clip—on 垫片是阿法拉伐超级免粘系统,特点是以方便快捷地就地更换垫片。

Clip—on垫片通过两个叉与板片边缘相连,使垫片沿胶垫槽整齐定位。

阿法拉伐的免粘系统设计中,密封功能和销扣功能是分开的:在此如除去胶叉,不会影响密封。

4.先进框架技术:优越的夹紧螺栓系统,阿法拉伐为方便拆装换热器,设计了独特而优越的夹紧螺栓,它由以下系统组成: a.轴承盒使螺栓很好就位而且容易拧紧。

b.防滑垫圈防止螺栓在拧紧时转动。

5.五点金属定位系统:这系统是用于角孔直径在140mm以上的换热器上。

板片的定位是以五点金属与金属接触而确定,上承杆的三点,可以防止板片上下移动,加上下承杆的两点,板片也不会左右移动。

用五点定位,板片组可以在承杆上没有阻力的前后移动。

垫片密封准确,丝毫不差,垫片寿命也更耐久。

这是阿法拉伐独特的设计。

这套系统只需要一个人用简单的工具就可以轻易地装拆换热器,这是其他制造商无法比拟的。

ALFALAVAL阿法拉伐分油机排渣原理

ALFALAVAL分油机的排渣原理主要基于离心力和重力分离的原理。

当

混合物进入分油机后,机内的旋转部件会以高速旋转,产生巨大的离心力。

由于油水混合物中油的比重较轻,而固体废物的比重较重,离心力会使得

油水混合物中的油分子向外运动,而固体废物则向内沉积。

通过这种分离

过程,清洁的液体和固体废物被分离开来。

具体来说,当混合物进入分油机后,它首先通过进料管道进入分离器

的圆锥形壳体。

分离器的旋转部件旋转,使得混合物在圆锥形壳体内形成

一层薄的液体膜。

在旋转的同时,离心力会将固体废物推向离心分离机的

内部壁面,并积聚在离心分离机的壁面上。

随着旋转的继续进行,固体废物在离心分离机的壁面上形成一层厚实

的沉渣。

此时,清洁的液体则在沉渣的上方形成一个液面。

通过设备上的

液面控制器,可以控制清洁液体的排出速度,以便确保分离过程的稳定性

和效率。

当清洁液体经过液面控制器排出时,它会经过分离机中的出料管道,

最终被排出设备。

而固体废物则会保留在离心分离机的壁面上,形成一层

厚实的沉渣。

这些沉渣可以定期清理或通过自动排渣系统进行排出。

总之,ALFALAVAL分油机的排渣原理是基于离心力和重力分离原理的。

通过旋转部件产生的离心力,混合物中的油分子被推向外侧,而固体废物

则沉积在分离机的壁面上,从而实现了油水混合物的分离和排渣的目的。

目录1安全说明2卧螺离心机的操作原理2.1主电机2.2后驱动系统2.2.1变频后驱动装置(VFD)3操作和日常维护3.1在第一次开车前3.1.1噪声和振动3.2开车和停车程序3.2.1检查转鼓3.2.2开车前3.2.2.1检查要点3.2.2.2具有机械密封的离心机3.2.3启动离心机3.2.4离心机停车3.3监控操作3.3.1过载3.3.1.1过载的原因3.3.1.2清理过载的转鼓3.3.2振动3.3.2.1振动开关3.3.3监测螺旋磨损3.4定期清洗过程3.5优化操作3.6主电机3.7变频驱动装置(VFD)3.8润滑3.8.1主轴承3.8.2螺旋轴承(图3.8.2中的位号1和2)3.8.3齿轮箱(图3.8.3)3.9维护表(表3.9.1, 和)3.9.1润滑时间和维护方法3.9.2选用润滑剂型号4拆卸和组装4.1旋转部件4.1.1拆卸转鼓(图4.1.1和)4.1.2安装转鼓(图4.1.1和)4.1.3拆卸大端轴颈(图4.1.4)4.1.4安装大端轴颈(图4.1.4)4.1.5拆卸小端轴颈(图4.1.5)4.1.6安装小端轴颈(图4.1.5)4.1.7拆卸齿轮箱(图4.1.6和)4.1.8安装齿轮箱(图4.1.7和)4.1.9装配新的排污口抗磨衬套4.2主轴承(图4.2.1)4.2.1拆卸大端主轴承4.2.2组装大端主轴承(图4.2.1)4.2.3拆卸小端主轴承(图4.2.4)4.2.4安装小端主轴承(图4.2.4)4.3螺旋轴承(图4.3.1)4.3.1拆卸螺旋大端轴承4.3.2组装螺旋轴承大端轴承(图4.3.1)4.3.3拆卸螺旋轴承小端轴承(图4.3.4)4.3.4安装螺旋小端轴承(图4.3.4)4.4螺旋4.4.1从转鼓中拆卸螺旋(图4.4.1)4.4.2将螺旋装入转鼓(图4.4.1)4.5主电机4.5.1拆卸主电机(图4.5.1)4.5.2组装主电机(图4.5.1,和)4.5.3拉紧V形皮带,皮带张力表4.6变频后动装置(VFD)4.6.1拆卸变频器(图4.6.1)4.6.2组装变频器(图4.6.1)1安全说明请务必严格按照以下要求进行操作,否则会给您造成人员以及财产的损失。