阿法拉伐换热器的操作手册中文版

- 格式:pdf

- 大小:2.06 MB

- 文档页数:18

Lit. Code200000419-4-ZH-CN操作手册中文由...出版阿法拉伐 Lund AB箱74参观:Rudeboksvägen 1226 55 Lund, 瑞典+46 46 36 65 00+46 46 30 50 90******************The original instructions are in English© Alfa Laval Corporate AB 2021-04本文件及其内容受阿法拉伐集团公司拥有的著作权及其他知识产权权利的保护。

未经阿法拉伐集团公司的事先明确书面许可,任何人不得以任何形式或通过任何方式,或出于任何目的,复制、重新制作或传输本文件的任何内容。

本文件所提供的信息和服务仅为用户提供便利和服务,对该信息和服务的准确性和适用性不做出于任何目的的陈述或保证。

保留所有权利。

EnglishDownload local language versions of this instruction manual from /gphe-manuals or use the QR codeбългарскиИзтеглете версиите на това ръководство заупотреба на местния език от / gphe-manuals или използвайте QR кода.ČeskýStáhněte si místní jazykovou verzi tohoto návodu k obsluze z /gphe-manuals nebo použijte QR kód.DanskHent lokale sprogversioner af denne brugervejledning på /gphe-manuals eller brug QR-koden.DeutschSie können die landessprachlichen Versionen dieses Handbuch von der Website /gphe-manuals oder über den QR-Code herunterladen.ελληνικάΠραγματοποιήστε λήψη εκδόσεων του παρόντοςεγχειριδίου οδηγιών σε τοπική γλώσσα από το/gphe-manuals ή χρησιμοποιήστετον κωδικό QR.EspañolDescárguese la versión de este Manual de instrucciones en su idioma local desde/gphe-manualso utilice el código QR.EestiSelle kasutusjuhendi kohaliku keele versiooni saate alla laadida lingilt /gphe-manuals või kasutades QR-koodi.SuomalainenLaitaa tämän käyttöohjeen suomenkielinen versio osoitteesta /gphe-manuals tai QR-koodilla.FrançaisTéléchargez des versions de ce manuel d’instructions en différentes langues sur /gphe-manuals ou utilisez le code QR.HrvatskiPreuzmite lokalne verzije jezika ovog korisničkog priručnika na poveznici /gphe-manuals ili upotrijebite QR kod.MagyarAz Ön nyelvére lefordított használati útmutatótletöltheti a /gphe-manuals weboldalról, vagy használja a QR-kódot.ItalianoScarica la versione in lingua locale del manuale di istruzioni da /gphe-manuals oppure utilizza il codice QR.日本の/gphe-manuals からご自分の言語の取扱説明書をダウンロードするか、QRコードをお使いください。

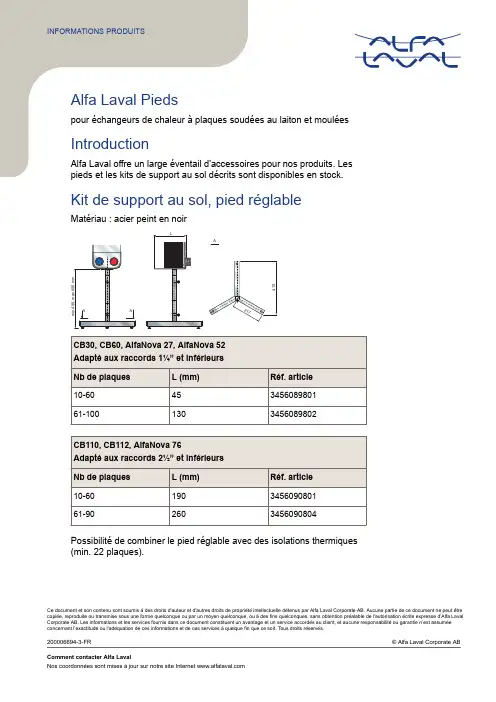

INFORMATIONS PRODUITSAlfa Laval Piedspour échangeurs de chaleur à plaques soudées au laiton et mouléesIntroductionAlfa Laval offre un large éventail d'accessoires pour nos produits. Lespieds et les kits de support au sol décrits sont disponibles en stock.Kit de support au sol, pied réglableMatériau : acier peint en noirPossibilité de combiner le pied réglable avec des isolations thermiques(min. 22 plaques).Ce document et son contenu sont soumis à des droits d'auteur et d'autres droits de propriété intellectuelle détenus par Alfa Laval Corporate AB. Aucune partie de ce document ne peut être copiée, reproduite ou transmise sous une forme quelconque ou par un moyen quelconque, ou à des fins quelconques, sans obtention préalable de l'autorisation écrite expresse d’Alfa Laval Corporate AB. Les informations et les services fournis dans ce document constituent un avantage et un service accordés au client, et aucune responsabilité ou garantie n’est assumée concernant l’exactitude ou l'adéquation de ces informations et de ces services à quelque fin que ce soit. Tous droits réservés.200006694-3-FR© Alfa Laval Corporate ABComment contacter Alfa LavalNos coordonnées sont mises à jour sur notre site Internet Kit de support au sol Matériau : acier galvaniséPieds rigidesDes goujons sont nécessaires sur l’échangeur de chaleur à plaques.Possibilité de combiner les pieds rigides avec des isolations thermiques contre la chaleur et le froid.。

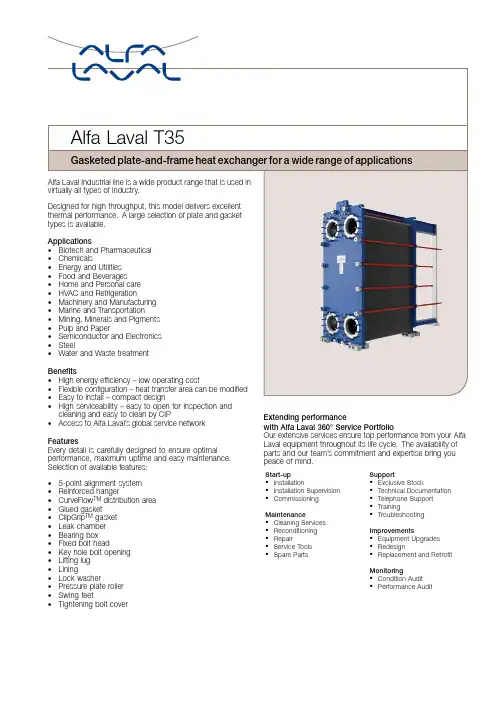

•High serviceability–easy to open for inspection andcleaning and easy to clean by CIP•Access to Alfa Laval’s global service network FeaturesEvery detail is carefully designed to ensure optimal performance,maximum uptime and easy maintenance. Selection of available features:•5-point alignment system•Reinforced hanger•CurveFlow TM distribution area•Glued gasket•ClipGrip TM gasket•Leak chamber•Bearing box•Fixed bolt head•Key hole bolt opening•Lifting lug•Lining•Lock washer•Pressure plate roller•Swing feet•Tightening bolt cover Extending performancewith Alfa Laval360°Service PortfolioOur extensive services ensure top performance from your Alfa Laval equipment throughout its life cycle.The availability of parts and our team’s commitment and expertise bring you peace of mind.Start-up Support •Installation•Exclusive Stock •Installation Supervision•Technical Documentation •Commissioning•Telephone Support•Training Maintenance•Troubleshooting•Cleaning Services•Reconditioning Improvements •Repair•Equipment Upgrades •Service Tools•Redesign•Spare Parts•Replacement and RetrofitMonitoring•Condition Audit•Performance AuditDimensional drawingMeasurements mm (inches)The number of tightening bolts may vary depending on pressure rating.Technical data PlatesName Type Free channel,mm (inches)T35-PSingle plate3.4(0.13)MaterialsHeat transfer plates304/304L,316/316L,904L,254C-276,C-2000G-30Ti,TiPdField gaskets NBR,EPDM,FKMFlange connectionsCarbon steelMetal lined:stainless steel Alloy 316,titaniumFrame and pressure plateCarbon steel,epoxy paintedOther materials may be available on request.All option combinations may not be configurable.Operational dataFrame,PV-code Max.design pressure (barg/psig)Max.design temperature (°C/°F)FL,pvcALS6.0/87100/212FM,pvcALS 10.3/150120/248FM,PED 10.3/150180/356FG,pvcALS 16.0/232180/356FG,ASME 10.3/150250/482FG,PED16.0/232180/356FD,pvcALS 25.0/363180/356FD,ASME 20.7/300250/482FD,PED25.0/362180/356FS,ASME 27.6/400250/482FS,PED30.0/435180/356Extended pressure and temperature rating may be available on request.Flange connectionsFL,pvcALSEN 1092-1DN350/DN300PN10ASME B16.5Class 150NPS 14/NPS 12JIS B222010K 300A/350AFM,pvcALSEN 1092-1DN350/DN300PN10ASME B16.5Class 150NPS 14/NPS 12JIS B222010K 350A/300AFM,PED EN 1092-1DN350/DN300PN10ASME B16.5Class 150NPS 14/NPS 12FG,pvcALSEN 1092-1DN350/DN300PN16ASME B16.5Class 150NPS 14/NPS 12JIS B222016K 350A/300AFG,ASME ASME B16.5Class150NPS 14/NPS 12FG,PED EN 1092-1DN350/DN300PN16ASME B16.5Class 150NPS 14/NPS 12FD,pvcALS EN 1092-1DN350/DN300PN25ASME B16.5Class 300NPS 14/NPS 12JIS B222020K 350A/300AFD,ASME ASME B16.5Class 300NPS 14/NPS 12FD,PED EN 1092-1DN350/DN300PN25ASME B16.5Class 300NPS 14/NPS 12FS,ASMEASME B16.5Class 400NPS 14/NPS 12Standard EN1092-1corresponds to GOST 12815-80and GB/T 9115.CHE00079EN 2016-04Alfa Laval reserves the right to change specifications without prior notification.How to contact Alfa LavalContact details for all countries are continually updated on our website.Please visit to access the information direct.A l f a L a v a l i s a t r a d e m a r k r e g i s t e r e d a n d o w n e d b y A l f a L a v a l C o r p o r a t e AB .。

Lowering operational cost and optimizes the productivity of your plant with the right heat exchanger19th November 20201.Save cost of ownership and boost heat recovery by Spiral HeatExchanger2.Minimise CAPEX cost while maintaining efficiency usingCompabloc Heat Exchanger3.Robust solution in cyclic process conditions with DuroshellHeat ExchangerEngineering from University of Malaya.He is responsiblein refinery and oleochemical industries in Malaysia andSingaporeUniversity of Kocaeli.His work in Alfa Laval is focused onglobal sales for ethanol,sugar,starch,biodiesel andvegetable oil industriesSave cost of ownership and boost heat recovery in Spiral Heat ExchangerChoy Weng KeanSales Manager –Edible Oil Thermal & Separation−Challenges faced nowadays by refiners•Low heat recovery, high fuel cost making business unprofitable•Reduced heat efficiency and production flow rate due to fouling issue•Leaking in heat exchanger causing down time−RBDPO-BPO heat recovery profileTypical heat recovery in deodorization ~75%140°C260°C100°C 220°CType of heat exchangers in BPO-RBDPO heat recoveryImproved heat recovery up to 85%120°C260°C100°C240°C−2-stage heat recovery with lower capital costLow temp. Duty RBDPO: 260°C from deodorization columnBPO: ~160/170°CBPO: ~235~240°C to final oil heaterRBDPO: 120 °CHigh Temp. dutyFrom bleacher : BPO: ~100°COr other type i.e. fallingfilm/coil/S&T−•Higher saving on natural gas/diesel fuel in High Pressure Boiler•Lower overall capital cost with gasketed type at lower temperature duty •Easy to retrofit into your existing heat recovery system•Redundancy of operation/reduce downtime 150-200 kEURyearly−Self cleaning effectHorizontal mode can infuse self-cleaning effect to minimizefouling and reduce cleaning frequency−Open-open channel for better cleaning•Open-open channel -see through design •Better cleanability for BPO channel •RBDPO channel is closed-closed channelWater jet inWater jet out−Important for high temperature/pressure dutyTransition plate between the bodyand tubular center•Higher thermal & pressure fatigueresistance•Less leaking -no intermixing of hotand cold side−Way of welding is important for welded type heat exchanger CMT welding for channel closure•Fast welding and smaller heat affected area •More robust and less cracking issue •Important for open-open channelChannel closure−Specially designed for palm oil economizerLimit projection in case of leakageLimit leakage and protect gasket from deforming+30% hook bolts for better strengthReinforced cover to limit fluid bypassMinimise CAPEX cost while maintaining efficiency using CompablocEser AydinGlobal technology process expert•Down time caused by improper selectionof heat exchanger−Compabloc Welded Heat Exchanger•High efficiency•Temperature cross•High wall shear stress•Low fouling built up•Fully repairable•Compact•Fully cleanable•From -46°C to 343°C as standard and up to 400°C on request•From full vacuum to 40/42 barg1.Liquid to Liquid2.Reboiler3. 1-pass condenser4. 2-pass condenser−How to reduce installation cost?Minimized size•5-10 times less installation & service space•Saving in capital and installation costReduced weight•2-5 times less flooded weight•Saving in space and maintenance costSmaller hold up volume•Faster reaction during operation•Shorter column needed•Free service space is not required above reboiler•Less installation cost•Less transportation cost•Lower ΔT needed which can decrease the design & operationpressure of the columns•Less investment cost for columns −How to reduce total investment costReboiler and condenser in distillation columnGlycerin purificationMethanol recoveryHow to reduce downtime with the correct selection of Heat Exchanger?•End-to-end laser weld of the plates guarantees accessibility and protects against corrosion •Minimal risk of corrosion•Butt weld geometry with very strong joint, no place for cracks to start forming•Laser welded joint with higher welding speed, smaller heat-affected zone and minimal residual stress.•Essential for thin plates.Laser Welding technology for robustnessWatch C-Weld video hereColumn linerHeat transfer coreTabUnobstructed cornersWatch Compabloc cleaning video here−Fully CleanableNo stagnant zones•100% mechanicallycleanable plates•Good-as-new performanceafter cleaning.Inefficienthydro jetIneffectivecleaning•Stagnant zones •Poor cleanability •Fouling flushedacross the plates•CP50 reboiler for glycerine purification column•Rectification column reboiler •Methanol recovery column reboilers in Europe•Methanol recovery and glycerinepurification column reboilers in SouthEast AsiaRobust solution for cyclic process conditions with Duroshell Heat ExchangerEser AydinGlobal technology process expert•High total cost of ownership of shell andtubeSpecifically designed for demanding duties such as high pressure and high temperature applications •Robustness due to unique design•High resistance to thermal and mechanical fatigue •Superior thermal performance•Compact solution which you can save capital cost •Design pressure: 100bar/FV•Design temperature: -160°C/450°C−Duroshellheat exchangers−How Duroshell worksWatch Duroshell video hereCompact design with flow pathDistribution tube 1 Distribution tube 2Distribution tube openings Heat transfer plate−Key features of DuroShellUnique Cut Wings plate shape•High thermal flexibility (easy multi-pass)•Excellent compacity •Less weightPower Pack distribution tubes through all plate packs•Guide fluid for maximizing use of HTA •Smaller footprint required •Strengthen plate pack •Increase fatigue resistanceWatch Cut Wings plate video hereWatch Power Pack distribution tubes video here−Key features of DuroShellUnique Roller Coaster plate pattern•Humps up & down with homogeneous resistance acting as stiffenersin all directions•Same resistance in homogeneous expansion•Increased fatigue resistance•Optimized flow distribution•No peak stresses in port areasWatch video here•Heat recovery 1-phase & 2-phase •Liquid heating / cooling •Evaporation / Condensation•Partial condensation•Gas coolingRobust solution for cyclic process conditions with Duroshell•Unique design•High efficiency•Robustness for cyclic duties•Less installation cost and compact footprint1.Save cost of ownership and boost heat recovery -Spiral Heat Exchanger2.Minimize CAPEX cost while maintaining the efficiency -Compabloc3.Robust solution in cyclic process condition -Duroshell。

高节能效率,低维护成本SpiralPro永远不会结垢SpiralCond:真空冷凝的理想解决方案SpiralPro用于液-液工况SpiralCond用于真空冷凝和蒸发SpiralPro用作蒸汽加热器SpiralCond“多合一”配置提升螺旋板式换热器的可持续性阿法拉伐全焊接螺旋板式换热器系列为高要求的液-液和两相工况提供了强大而可靠的选择,具有极低的维护要求。

全球已有超过80000台螺旋板式换热器装置交付使用,在化工、废水、采矿等应用领域久经验证,可应对其他类型的换热器难以解决的挑战,是值得信赖的可靠解决方案。

阿法拉伐螺旋板换的传热效率是同类管壳式换热器的2-3倍。

因此可回收更多的废热,从而为节约能源创造巨大潜力。

阿法拉伐螺旋板将更低的燃料成本和更少的排放相结合,可以为提升工艺流程的可持续性以及盈利能力提供更明智的解决方案。

同时,紧凑的设计能降低安装和材料成本,简化的服务减少了年度维护预算。

阿法拉伐螺旋板式换热器能缩短投资回收期、降低总投资成本。

对于涉及结垢流体、污泥、乳剂、泥浆、纤维或颗粒负载液体的工艺过程,阿法拉伐SpiralPro换热器的可靠性无与伦比。

SelfClean™的设计可防止脏流体结垢和堵塞,而这些脏流体会导致任何其他类型的换热器出现问题。

最大的正常运行时间和易于清洁性,极大地降低了运营费用,同时提高了生产能力。

SpiralPro换热器可以作为液液换热器或作为蒸汽加热器。

SpiralCond换热器是两相换热的高效解决方案,紧凑的立式安装,比同等效果的管壳式换热器占地面积小得多。

每一个SpiralCond换热器都完全根据所需的热负荷进行定制,并调整通道间距以提供最低的压降。

因此,Spiral-Cond换热器非常适合具有挑战性的真空冷凝和蒸发工况。

SpiralCond换热器能够安装在现有的工艺塔上或者作为“多合一”塔顶冷凝器,同时适配多种冷媒。

解决棘手问题的优势SpiralProSpiralCond适用于液液或者蒸汽加热工况适用于真空冷凝或蒸发工况能够被安装在现有的工艺塔上或者作为“多合一”塔顶冷凝器同时适配多种冷媒温度:-100°C 到400°C 温度:-100°C 到400°C 设计压力:全真空至 100 barg 设计压力:全真空至 100 barg 压差:高达50 barg 压差:高达50 barg 传热面积(最大):900 m 2传热面积(最大):2500 m 2 (“多合一“冷凝器)• 提升热回收效率可显著降低能源消耗,同时减少化石燃料消耗和二氧化碳排放。

阿法拉伐中文说明书1(共94页) -本页仅作为预览文档封面,使用时请删除本页-目录1安全说明…………………………………………………………..... 2卧螺离心机的操作原理……………………………………….....主电机………..…………………………………………….………………......后驱动系统……………..………………………………………………… ...变频后驱动(VFD)..…….……………………………………………… ..... 3操作和日常维护…………………………………………………在第一次开车前……………..………………………………………………噪声和振动…………...……...………………………………………….…开车和停车程序…………………..…………………………………………检查转鼓……..…………………………………………………………….开车前…………..………………………………………………………….检查要点………….……………….……………………………………..具有机械密封的离心机…………………..……………………………..启动离心机………………………………………..……………………….离心机停车……………………………………………..………………….监控操作……………………………………………………………………..过载………………………………………………………………………...过载的原因………………………………………………………………清理过载的转鼓…………………………………………………………振动………………………………………………………………………... ..振动开关(可选设备)…………………………………………………监测螺旋磨损……………………………………………………………...定期清洗过程………………………………………………………………..优化操作……………………………………………………………………..主电机………………………………………………………………………..变频驱(VFD)……………………………………………………………...调整转鼓速度传感器(图)………………………………………..润滑…………………………………………………………………………..主轴承……………………………...………………………………………螺旋轴承(图中的加油嘴3和4)………………………………...齿轮箱(图)………………………………………………………...维护表……………………………...…………………………………………润滑时间和维护方法……………………………………………………...表润滑表………………………………………………………….…表维护周期…………………………………………………………润滑剂型号………………………………………………………………...表润滑剂、润滑工具表……………………………………………4拆卸和组装………………………………………………………旋转组件……………………………………………………………………...拆卸转鼓(图和)…………………………………………….安装转鼓(图和)…………………………………………….拆卸大端轴颈(图)………………………………………………...安装大端轴颈(图)………………………………………………...拆卸小端轴颈(图)………………………………………………...安装小端轴颈(图)……………………………………………….拆卸齿轮箱(图和)………………………………………….安装齿轮箱(图和)…………………………………………装配新的排污口衬套…………………….………………………………主轴承…………….…………………………………………………………..拆卸大端主轴承(图)…………………………………….…………..组装大端主轴承(图)………………………………………………...拆卸小端主轴承(图)………………………………………………...安装小端主轴承(图)………………………………………………...螺旋轴承……………………………………………………….…….……….拆卸螺旋大端轴承(图)…………………………………….………..组装螺旋轴承大端轴承(图)………………………………………拆卸螺旋轴承小端轴承(图)……………………………………...安装螺旋轴承小端轴承(图)……………………………………...螺旋…………………………………………………………………………...从转鼓中拆卸螺旋(图)……………………………………………将螺旋装入转鼓(图)………………………………………………...主电机………………………………………………………………………..拆卸主电机(图)……………………………………………….…..组装主电机(图,和)………………………………….…..调紧V形皮带,皮带张力表………………………………………………变频后驱动装置(VFD)…………………….……………………………..拆卸变频驱动器(图)………….………………………………….组装变频驱动器(图)……………………………………………..5补充文档…………………………………………………………1安全说明请务必严格按照以下要求进行操作,否则会给您造成人员以及财产的损失。

•Easy to install–compact design•High serviceability–easy to open for inspection and cleaning and easy to clean by CIP•Access to Alfa Laval’s global service network FeaturesEvery detail is carefully designed to ensure optimal performance,maximum uptime and easy maintenance. Selection of available features:•Corner guided alignment system•Chocolate pattern distribution area•Clip-on gasket•Leak chamber•Fixed bolt head•Key hole bolt opening•Lifting lug•Lining•Lock washer•Tightening bolt cover Extending performancewith Alfa Laval360°Service PortfolioOur extensive services ensure top performance from your Alfa Laval equipment throughout its life cycle.The availability of parts and our team’s commitment and expertise bring you peace of mind.Start-up Support •Installation•Exclusive Stock •Installation Supervision•Technical Documentation •Commissioning•Telephone Support•Training Maintenance•Troubleshooting•Cleaning Services•Reconditioning Improvements •Repair•Equipment Upgrades •Service Tools•Redesign•Spare Parts•Replacement and RetrofitMonitoring•Condition Audit•Performance AuditDimensional drawingMeasurements mm (inches)Type HWh TS6-FG 704(27.7”)400(15.7”)188(7.4”)TS6-FD 704(27.7”)410(16.1”)188(7.4”)Technical data PlatesName Type Free channel,mm (inches)TS6-MSingle plate4.0(0.16)MaterialsHeat transfer plates 316/316L TiField gaskets NBR,EPDM,FKMFlange connections Carbon steelMetal lined:stainless steel,titanium Frame and pressure plateCarbon steel,epoxy paintedOther materials may be available on request.All option combinations may not be configurable.Operational dataFrame,PV-code Max.design pressure (barg/psig)Max.design temperature (°C/°F)FG,pvcALS 16.0/232180/356FG,ASME 14.3/207250/482FG,PED 16.0/232180/356FD,ASME20.7/300250/482FD,PED25.0/362180/356Extended pressure and temperature rating may be available on request.Flange connectionsFG,pvcALSEN 1092-1DN65PN16JIS B222010K 65A JIS B222016K 65AFG,ASME ASME B16.5Class150NPS 3FG,PEDEN 1092-1DN65PN16ASME B16.5Class 150NPS 3FD,pvcALSEN 1092-1DN65PN25JIS B222010K 65A JIS B222020K 65AFD,ASME ASME B16.5Class 300NPS 3FD,PEDEN 1092-1DN65PN25ASME B16.5Class 300NPS 3Standard EN1092-1corresponds to GOST 12815-80and GB/T 9115.CHE00087EN 2016-04Alfa Laval reserves the right to change specifications without prior notification.How to contact Alfa LavalContact details for all countries are continually updated on our website.Please visit to access the information direct.A l f a L a v a l i s a t r a d e m a r k r e g i s t e r e d a n d o w n e d b y A l f a L a v a l C o r p o r a t e AB .。

目录1安全说明…………………………………………………………1.0—1 2卧螺离心机的操作原理………………………………………2。

0-1 2.1 主电机………。

.…………………………………………….……………… 2。

1—12.2后驱动系统……………。

.…………………………………………………2。

2—12.2.1变频后驱动(VFD)。

.……。

……………………………………………… .... 2。

2—23操作和日常维护…………………………………………………3.1-1 3.1在第一次开车前……………。

.………………………………………………3。

1-13.1。

1噪声和振动…………。

.…….。

………………………………………….…3.1—23.2开车和停车程序…………………。

…………………………………………3.2—13.2.1 检查转鼓…….。

…………………………………………………………….3.2—13.2.2开车前…………。

………………………………………………………….3.2—13.2.2.1检查要点………….……………….……………………………………。

.3.2-13.2。

2.2具有机械密封的离心机…………………..……………………………。

3。

2—13。

2.3启动离心机………………………………………。

……………………….3。

2—23.2.4离心机停车……………………………………………。

………………….3。

2—23。

3监控操作……………………………………………………………………。

3.3—13.3.1过载………………………………………………………………………。

..3.3—13.3。

1.1.. 过载的原因………………………………………………………………3。

3-13。

3.1。

2清理过载的转鼓…………………………………………………………3。

3—23。

3。

2振3.3。

2.1振动开关(可选设备)…………………………………………………3.3—33.3.3监测螺旋磨损……………………………………………………………。

文献代号200002797-4-ZH-CN说明手册中文出版方阿法拉伐技术有限公司箱74SE–226 55226 55 Lund, 瑞典电话总机:+46 46 36 65 00******************原始说明为英文版© Alfa Laval 2023-05本文件及其内容受阿法拉伐公司[Alfa Laval AB (publ)]或其任何关联公司(合称“阿法拉伐”)拥有的版权和其他知识产权的约束。

未经阿法拉伐明确事先书面许可,不得以任何形式、任何方式或出于任何目的复印、复制或传播文件的任何部分。

本文件中提供的信息和服务对用户有利并服务于用户,对于信息和服务的准确性或适用性,阿法拉伐不作任何陈述或保证。

版权所有。

EnglishUse the QR code, or visit /gphe-manuals, to download a local language version of the manual.ةيبرعلا،ليزنتلرادصإةغللاةيلحملاليلدلل/gphe-manuals مدختسازمرةباجتسالاةعيرسلاوأمقةرايزبбългарскиИзползвайте QR кода или посетете следния адрес/gphe-manuals, за да свалитеверсия на ръководството за употреба на Вашияезик.ČeskýPoužijte kód QR nebo navštivte / gphe-manualsa stáhněte si místní jazykovou verzi tohoto návodu.DanskBrug QR-koden, eller følg /gphe-manuals for at downloade en lokal sprogversion af manualen.DeutschVerwenden Sie den QR-Code oder besuchen Sie /gphe-manuals, um die lokale Sprachversion des Handbuchs herunterzuladen.ελληνικάΧρησιμοποιήστε τον κωδικό QR ή επισκεφτείτε τησελίδα /gphe-manuals, για νακατεβάσετε μια έκδοση του εγχειριδίου στην τοπικήσας γλώσσα.EspañolUtilice el código QR o visite /gphe-manuals para descargar una versión del manual en el idioma local.EestiKasutusjuhendi kohaliku keeleversiooni allalaadimiseks kasutage QR-koodi või külastage aadressi /gphe-manuals.SuomiKäytä QR-koodia tai avaa osoite / gphe-manuals, niin voit ladata käyttöohjeen paikallisella kielellä.FrançaisUtilisez le QR-code ou rendez-vous sur le site /gphe-manuals, pour télécharger une version du manuel dans la langue locale. HrvatskiUpotrijebite QR kod ili posjetite / gphe-manuals ako želite preuzeti verziju priručnika na lokalnom jeziku.MagyarHasználja a QR-kódot, vagy látogasson el a/gphe-manualswebhelyre akézikönyv helyi nyelvű változatának letöltéséhez. ItalianoUtilizzate il codice QR o visitate il sito/gphe-manuals per scaricare una versione del manuale nella lingua locale.日本語コード、または /gphe-manuals、現地語版のマニュアルをダウンロードすることができます。