光幕说明书

- 格式:doc

- 大小:120.50 KB

- 文档页数:3

IDEC-DATASENSOR Safety Light CurtainsType 2 SG2 Series (Basic & Extended Models)Hand ProtectionPresence ProtectionIntegrated light curtain for Hand Protection or • Presence ControlOperating distance up to 19m• Controlled heights from 150 to 1800mm • Compact 32 x 37mm profile• Sturdy profile and rotating brackets• Test/Restart, Auto/Manual Restart, EDM, Anti-interference • User interface with display • Alignment function• The SG2 Type 2 series offers two models, the SG2 basic and the SG2 extended. Available functions include Test/Restart, EDM and Anti-interference. With very fast response times, the SG2 series can be installed right next to a hazardous area improving productivity. The ro-tating mounting brackets make installation and the alignment of the emitting and receiving units easy, even at long distances and in applica-tions that use mirrors.Type 4 SG4 SeriesFinger ProtectionHand ProtectionIntegrated light curtain for Finger Protection or • Hand ProtectionOperating distance up to 6m for Finger Protection series • & 19m for Hand Protection seriesControlled heights from 150 to 1800mm • Compact 32 x 37mm profile• Sturdy profile and rotating brackets • Test/Restart, Auto/Manual Restart, EDM • User interface with display • Alignment function• With mounting brackets that rotate, no connection necessary between emitter and receiver, and configuration that can be accomplished with-out external control units or supplementary cables, the SG4 Type 4 light curtains are one of the best available on the market today. In addition, the light curtains can be aligned using the 7 segment display on eitherthe emitter or receiver.Safety Light CurtainsSG2 SeriesSituation Solution Situation Solution Robotic ManufacturingSituation : Protect operator from being hit or crushed by a robotic arm’s movement.Solution Operating Point Protection on a Drilling Machine: An operator positions a part before machining and removes Paper Cutting MachinesThese machines typically cut paper to a specific size for : Protect operator from either being pinned between the top The SG safety light curtain family provides solutions for automation where access to hazardous areas must be controlled. In particular, safety curtains can be used to stop machine movement in the following industries.Automated manufacturing• Packaging, material handling & storage machines • Textile, woodworking and ceramic• Automatic and semi-automatic assembling lines • Automatic warehouse & inventory systems• Applications800-262-IDEC4W max (without load)*If a longer cable is needed, please verify that the capacitive load specifications are followed.Presence Control series.Hand30mmPresence50mm90mmFinger14mmHand30mmenter the Controlled Height code. See table on the right.Part NumbersControl series.AccessoriesM12 Unshielded Axial Connector Cable, UL 2464Used ForL L Ø169M2 nº3 x 2L L Ø16M2 nº3 x 2M2 nº3 x 29Ø1636.932.3M2 nº3 x 2Ø1636.932.3M2 nº3 x 250.514L LL L Ø16ø16OSSD1 OSSD2+24 V DC NOTEST/RESET12340 V+24 V DC Not Used Not Used0 V 1243 Manual RESTART - RESET/RESTART function+24 V DCRESET/RESTART0 VOSSD1 EDMEDMACTIVATION OSSD2 +24 V DC+24 V DCSEL. MAN / AUTO RESTART NONC external contact +24 V DCsee tablebelow 0 V TEST+24 V DCNODimension TableModel L 1 L 2 150* 233.3 153.3 300 383.2 303.2Indicators & SettingsSG4 and SG2 light curtains are equipped with an Alignment system that shows alignment status on a visual display, making configuration quick and easy. Alignment level and any change in environment conditions (presence of dust, light disturbance, etc.) are monitored during normal operating mode. The display also gives diagnostic messages to ensure accurate and correct functioning.Emitter (Tx)Receiver (Rx)Emitter (Tx)Receiver (Rx)800-262-IDECMounting Brackets Dimensions (mm)Rotating Mounting Bracket 1 (ST-K4ROT)Angled Mounting Bracket 2 (ST-KSTD)39.63031. Supplied with the SG2 extended models only.ø6.6ø6.63R2.7R2.718.517.525.637.834.530.76618.518.517.82. Supplied with SG2 standard models and all SG4 models.Anti-vibration Support Brackets (ST-K4AV/ST-K6AV)Mounting Bracket with Light Curtain (mm)BA12.95CL *L 1/SafetySafety Controllers - FS1A SafetyOneConsolidate safety relays to just one safety controller usingthe IDEC SafetyOne FS1A series safety controller.No programming required•Easy to setup: Select Logic, Wire Devices, Power Up•Replaces up to 6 safety relay modules•Select logic from 8 pre-programmed circuits•Connect one module with various types of safety inputs•Monitor status of safety I/Os and error codes•/safetyCustom Application AccessoriesIP67/IP69K EnclosureProtective GuardLens ShieldSafety Relay Module (CS-ME) & EDM Control Box (SE-SR2)IDEC Corporation • 1175 Elko Drive • Sunnyvale, CA 94089 • 800-262-IDEC (4332) • Fax: 408-745-5258 • /usa©2009 IDEC Corporation. All Rights Reserved. Catalog No. SG9Y-DS100-0 10/09 7.5KMore Information/SafetyTechnical support:****************800-262-IDEC。

SG-BWS-T4-MTSERIESSafety control unit with double mutingQUICK GUIDESAFETY INFORMATIONThe following points must be observed for a correct and safe use of thesafety light curtains of the SG-BWS-T4-MT series:The stopping system of the machine must be electrically controlled. This control system must be able to stop the dangerous movement of the machine within the total machine stopping time T as per par. 3.4 of the complete manual inside the CD and during all working cycle phases.The safety system should be installed and connected by a qualified technician in compliance with the instructions specified in this manual and industry rules.The photocells must be securely installed in a particular position so that access to the dangerous zone is not possible without the interruption of the beams (see 3.3 “General information on sensors positioning” of the complete manual inside the CD). The personnel operating in the dangerous area must be well trained and must have adequate knowledge of all the operating procedures of the safety control unit.The START and TEST buttons must be located outside the protected area because the operator must check the protected area during all Test and Reset operations.Please carefully read the instructions for the correct functioning before powering the SG-BWS-T4-MT.Precautions to be observed for the choice and installation of the deviceMake sure that the protection level assured by the SG-BWS-T4-MT device (Type 4) is compatible with the real danger level of the machine to becontrolled, according to EN 954-1 and EN 13849-1.∙ The outputs (SAFCN) of the ESPE must be used as machine stopping devices and not as commanddevices. The machine must have its own START command. ∙ The dimension of the smallest object to be detected must be larger than the resolution level of theinstalled safety sensors.∙ The ESPE must be installed in a room complying with the technical characteristics indicated in section9 “Technical data” of the complete manual inside the CD. ∙ Do not install the sensors close to strong and/or flashing light sources or close to similar devices. ∙ Strong electromagnetic disturbance might negatively affect device operation. Should this be the casecontact Datalogic Automation Technical Service. ∙ The operating distance of the safety sensors can be reduced in presence of smog, fog or airbornedust. ∙ A sudden change in environment temperature, with very low minimum peaks, can generate a smallcondensation layer on the sensors lenses and so jeopardise functioning.∙ Pay special care when positioning the safety photocells so to offer effective protection. The safetysensors should be installed in such a way that the dangerous area can only be entered after detecting the sensitive area. Photocells position is fixed by normative and must respect measures in Tab. 4 of the complete manual inside the CD.The failure to respect the safety distance reducesor cancels ESPE the protection function.For more detailed information about calculation of safety distance,please refer to the complete manual contained in the CD supplied.CONNECTIONSSIGNAL CONTACT CONNECTION FUNCTIONVDC 1 24 Vdc ext. Power START 2 NO contact toward 24VDC Reset Function TEST/RESET 3 NC contact toward 24VDCTest/Reset functionEDM 4 - NC contact of external relay toward 24VDC (with EDM enabled)- NOT CONNECTED (with EDM disabled)EDM Input0 V 2 0 Vdc ext. Power MUTEN A 6 NO contact toward 24VDC Muting enable MUTEN B 7 NO contact toward 24VDC Muting enable DEFLAMP 8 Warning device positive terminal Lamp failure warningMUTA1 9 PNP output of muting sensor A1 Muting input OVRA1 10 Override A1 NO contact toward 24VDC Override input MUTB1 11 PNP output of muting sensor B1 Muting input OVRB1 12 Override B1 NO contact toward 24VDC Override input MUTA2 13 PNP output of muting sensor A2 Muting input OVRA2 14 Override A2 NO contact toward 24VDC Override input MUTB2 15 PNP output of muting sensor B2 Muting input OVRB2 16 Override B2 NO contact toward 24VDC Override input LAMPA- 17 Negative terminal of muting lamp A Muting lamp output LAMPA+ 18 Positive terminal of muting lamp A Muting lamp output SAFNC11 19Relays output NO 230V 1Safety contact SAFNC21 20 Safety contact LAMPB- 21 Negative terminal of muting lamp B Muting lamp output LAMPB+ 22 Positive terminal of muting lamp B Muting lamp output SAFNC12 23Relays output NO 230V 2Safety contact SAFNC22 24 Safety contact RX1 25 PNP output of receiver photocell 1 (black) Photocell Input RX2 26 PNP output of receiver photocell 2 (black) Photocell Input RX3 27 PNP output of receiver photocell 3 (black) Photocell Input RX4 28 PNP output of receiver photocell 4 (black) Photocell Input TX1 29 TEST of emitter photocell 1 (black) Photocell Output TX2 30 TEST of emitter photocell 2 (black) Photocell Output TX3 31 TEST of emitter photocell 3 (black) Photocell Output TX4 32 TEST of emitter photocell 4 (black) Photocell Output 24VRX12 33 24VDC photocell receivers 1 and 2 (brown) Power supply output 0VRX12 34 0VDC photocell receivers 1 and 2 (blue) Power supply output 24VRX34 35 24VDC photocell receivers 3 and 4 (brown) Power supply output 0VRX34 36 0VDC photocell receivers 3 and 4 (blue) Power supply output 24VTX12 37 24VDC photocell emitters 1 and 2 (brown) Power supply output 0VTX12 38 0VDC photocell emitters 1 and 2 (blue) Power supply output 24VTX34 39 24VDC photocell emitters 3 and 4 (brown)Power supply outputSIGNAL CONTACT CONNECTION FUNCTION 0VTX34 40 0VDC photocell emitters 3 and 4 (blue) Power supply output OSSD11 41 OSSD 1 output of light curtain 1 (grey) Safety light curtain input OSSD21 42 OSSD 1 output of light curtain 2 (grey) Safety light curtain input24LRX12 43 24VDC light curtain receivers 1 and 2(brown)Power supply output0LRX12 44 0VDC light curtain receivers 1 and 2 (brown) Power supply output OSSD12 45 OSSD 2 output of light curtain 1 (pink) Safety light curtain input OSSD22 46 OSSD 2 output of light curtain 2 (pink) Safety light curtain input 24LTX12 47 24VDC light curtain emitters 1 and 2 (brown) Power supply output 0LTX12 48 0VDC light curtain emitters 1 and 2 (brown) Power supply outputNO: Normally Open – NC: Normally ClosedMinimum connection (1 photocell, no EDM, automatic RESTART)The control unit terminals layout and the minimum connection to check system operation are shown below.The photocells set power (blue and brown wires) reaches terminals 33-34, 37-38 as specified in the table in the complete manual inside the CD.For the other configuration (for example concerning muting and override) please refer to section 4 in the complete manual inside the CD.SIGNAL CONTACT CONNECTION FUNCTIONext. PowerVdcVDC 1 24TEST/RESET 3 24 Vdc ext. Test function0 V 2 0 Vdc ext. PowerRX1 25 PNP output of receiver photocell 1 (black) Photocell InputTX1 29 TEST of emitter photocell 1 (black) Photocell OutputRX2 26 TX2 (30) Photocell InputRX3 27 TX3 (31) Photocell InputRX4 28 TX4 (32) Photocell InputOSSD11 41 OSSD21 (42) Safety light curtain input OSSD21 42 24LRX12 (43) Safety light curtain input OSSD12 45 OSSD22 (46) Safety light curtain input OSSD22 46 24LTX12 (47) Safety light curtain input24VRX12 33 24VDC power supply RX (brown) Power supply output 0VRX12 34 0VDC power supply RX (blue) Power supply output24VTX12 37 24VDC power supply TX (brown) Power supply output0VTX12 38 0VDC power supply TX (blue) Power supply outputSG-BWS-T4-MT as MPCE (Machine Primary Control Equipment)SG-BWST-T4-MT can be directly used as a Machine Primary Control Equipment (MPCE) since it’s equipped with internal monitored relays which can switch a maximum load of 3,6A at 250V. The proper connections are shown in the next figure.SG-BWS-T4-MT as external safety relays controllerWhen utilizing SG-BWS-T4 for external safety relays control proper connections are shown in the following figure.K1K2SAFCN11 (19)SAFCN21 (20)SAFCN12 (23)SAFCN22 (24)B W S -T 4-M TMain Supply VoltageT o machine powerALIGNMENT SAFETY DEVICESOnce all components are in place and connected, emitters and receivers shall be mutually aligned.In alignment mode, the OSSD safety outputs are open. The alignment mode and relevantprocedure are described here below:∙Cut off control unit power supply.∙Power on the control unit while holding pressed Test button (Test contact open)∙The 7-segment display shows the first device to be aligned (Photocells 1-4, light curtains 5-6)∙∙The control unit will run the initial test routines and display a countdown, the display will then turn off and the control unit will switch to NORMAL OPERATION status ( NORMAL).Now carry out the following inspections:∙The ESPE stays in SAFE mode during photocells and light curtains beam interruption using the suitable “Test Piece”, along the entire protected area.∙Enabling the TEST function, the OSSD outputs should open ( SAFE and the controlled machine stops).∙The response time upon machine STOP (including response time of the ESPE and of the machine) is within the limits defined for the calculation of the safety distance (see section 3 “Installation” of the complete manual inside the CD).∙The safety distance between the dangerous areas and the safety sensors is in accordance with the instructions included in section 3 “Installation” of the complete manual inside the CD.∙Access of a person between sensors and machine dangerous parts is not possible nor is it possible for him/her to stay there.∙Access to the dangerous area of the machine from any unprotected area is not possible.During alignment or normal operation, make sure that the photocells connected to the same or other units do not interfere with each other. Should you find interference, change their position, for instance you could set some emitter sets on the side of the other receivers. In case of interference, the control unit will lock out and display the relevant error code.DIP-SWITCHES CONFIGURATIONAt control unit top part you will find two units made up of 8 Dip-Switches each: SG-BWS-T4-MT safety rating requires installation of two switches for setting up each function, so that the setup defined for the first unit shall be set even for the second unit.The table below is a list of possible settings selectable through the 8 Dip-Switches available.DIP PURPOSE OFF(Default) ON1 ENABLEEDM ENABLED DISABLED2 RESETMODE AUTOMATIC MANUAL3 MUTING TIME-OUT 10 MINUTES INFINITY4 MUTINGDIRECTION T L5 TRIGGEROVERRIDE LEVEL FRONT6 MUTINGSELECTIONVedi tabella seguente7 MUTINGSELECTION8 MUTINGSELECTIONDatalogic Automation supplies the control unit in the “Default” setup (all switches OFF).The Dip-Switches 6-7-8 allow user to couple the single devices to the 2 muting channels available on the SG-BWS-T4-MT.Activating a channel muting involves temporarily suspending the safety function of all devices associated to it. Extreme care is hence required when associating channel to devices: any dangerous settings shall be avoided.DIAGNOSTICS AND SIGNALLINGSG-BWS-T4-MT is equipped with a user interface featuring 3 LEDs and a 7-segment display.LED INDICATIONPOWER Device is powered correctlyNORMAL No danger: safety outputs closedSAFE Danger or fault: safety outputs openThe 7-segment display shows detailed information on control unit current status Normal operation signallingINDICATION STATUS DESCRIPTION TO DO POWERNORMALSAFE NORMALOPERATIONThe Override function is active on channel A, B or both. The muting indicator isflashing.POWERNORMALSAFE NORMALOPERATION One of the two muting lampsis disconnected or faulty(only one muting channel isactive).Change the faulty lamp.It is not necessary torestart.POWER⇨NORMALSAFEInterlockWaiting for the STARTcommand in manual resetmodePush reset controlPOWER/ NORMAL/ SAFE NORMALOPERATION/SAFE The decimal point indicates that the EDM function isactive (see 4.7)POWER NORMALSAFESAFE TEST push-button pressed(contact 3 open)Check TEST push-button connections (see4.9)Failure state signallingINDICATION STATUS DESCRIPTION WHATTODO POWERNORMALSAFEOff Power disconnected or innerfuse blown due to overload.Check power supply. Iferror persists, pleasecontact the TechnicalService.POWER NORMAL SAFEINTERNALDEVICEMONITORINGFAILURELOCKOUTInternal relays contactsmonitoring test has failed.Reset the control unit(see 4.6). If errorpersists, please contactthe Technical Service.POWER NORMAL SAFE INTERNALOSSDFAILURELOCKOUTInternal OSSD test routinehas failed.Reset the control unit(see 4.9). If errorpersists, please contactthe Technical Service.INDICATION STATUS DESCRIPTION TODO POWERNORMALSAFE EDM FAILURELOCKOUT EDM test has failedCheck EDMconnections (see 4.7)or disable EDMfunction (see 4.4) ifyou do not wish to useit.POWERNORMAL SAFEMICRO-PROCESSORFAILURELOCKOUTOne of microprocessor testshas failedDisconnect powersupply and reconnectit. If error persists,please contact theTechnical Service.POWERNORMALSAFE DIPSWITCHES FAILURE LOCKOUTThe Dip-Switches settingconsistency test has failedMake sure that thesettings of the two setsof switches is the same(see 4.4). Reset thecontrol unit (see4.9). If error persists,please contact theTechnical Service.POWERNORMAL SAFE RESTARTFAILURELOCKOUTStart signal time-out tripped.Make sure you hold theStart button depressedfor less than 5s.POWER NORMAL SAFESENSOR FAILURE LOCKOUT Test of indicated safetysensor has failed.- F 1-4: Make surethere is no interferenceacross differentphotocell sets.- F 5-6: Check lightcurtains OSSDconnections (see4.5).POWERNORMAL SAFELAMPFAILURELOCKOUTMuting lamp faulty ordisconnected.Change the faultylamp, then Reset thecontrol unit (see4.9)POWERNORMALSAFE OVERRIDEFAILUREThe Override commandactivation test has failed(push-buttons not pressed atthe same time)Press the Overridepush-buttons at thesame time.DECLARATION OF CONFORMITYWe DATALOGIC AUTOMATION declare under our sole responsibility that these products are conform to the 2006/42/EC and successive amendments.WARRANTYDATALOGIC AUTOMATION warrants its products to be free from defects.DATALOGIC AUTOMATION will repair or replace, free of charge, any product found to be defective during the warranty period of 36 months from the manufacturing date.This warranty does not cover damage or liability deriving from the improper application of Datalogic Automation products. DATALOGIC AUTOMATION srlVia Lavino 265 - 40050 Monte S.Pietro - Bologna – ItalyTel: +39 051 6765611 - Fax: +39 051 6759324 DATALOGIC AUTOMATION cares for the environment: 100% recycled paper.DATALOGIC AUTOMATION reserves the right to make modifications and improvements without prior notification.© 2009 – 2014 Datalogic Automation - ALL RIGHTS RESERVED - Protected to the fullest extent under U.S. and international laws. • Copying, or altering of this document is prohibited without express written consent from Datalogic Automation. Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries, including the U.S.A. and the E.U.830000502 rev.C。

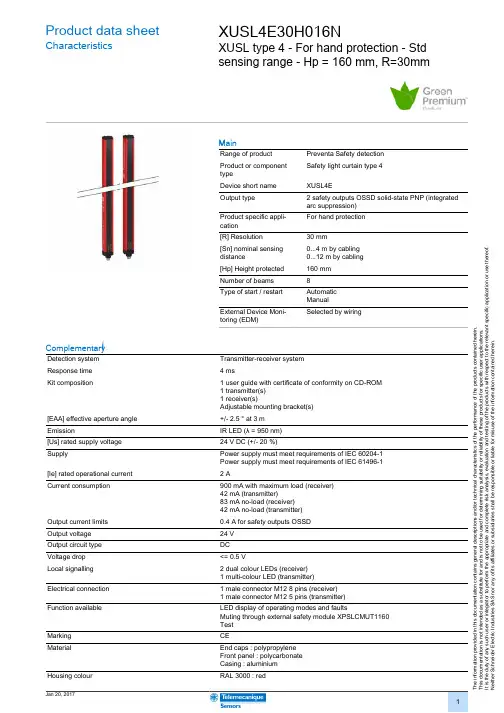

T h e i n f o r m a t i o n p r o v i d e d i n t h i s d o c u m e n t a t i o n c o n t a i n s g e n e r a l d e s c r i p t i o n s a n d /o r t e c h n i c a l c h a r a c t e r i s t i c s o f t h e p e r f o r m a n c e o f t h e p r o d u c t s c o n t a i n e d h e r e i n .T h i s d o c u m e n t a t i o n i s n o t i n t e n d e d a s a s u b s t i t u t e f o r a n d i s n o t t o b e u s e d f o r d e t e r m i n i n g s u i t a b i l i t y o r r e l i a b i l i t y o f t h e s e p r o d u c t s f o r s p e c i f i c u s e r a p p l i c a t i o n s .I t i s t h e d u t y o f a n y s u c h u s e r o r i n t e g r a t o r t o p e r f o r m t h e a p p r o p r i a t e a n d c o m p l e t e r i s k a n a l y s i s , e v a l u a t i o n a n d t e s t i n g o f t h e p r o d u c t s w i t h r e s p e c t t o t h e r e l e v a n t s p e c i f i c a p p l i c a t i o n o r u s e t h e r e o f .N e i t h e r S c h n e i d e r E l e c t r i c I n d u s t r i e s S A S n o r a n y o f i t s a f f i l i a t e s o r s u b s i d i a r i e s s h a l l b e r e s p o n s i b l e o r l i a b l e f o r m i s u s e o f t h e i n f o r m a t i o n c o n t a i n e d h e r e i n .Product data sheetCharacteristicsXUSL4E30H016NXUSL type 4 - For hand protection - Stdsensing range - Hp = 160 mm, R=30mmMainRange of product Preventa Safety detection Product or component typeSafety light curtain type 4Device short name XUSL4EOutput type2 safety outputs OSSD solid-state PNP (integrated arc suppression)Product specific appli-cation For hand protection [R] Resolution 30 mm[Sn] nominal sensing distance0...4 m by cabling 0...12 m by cabling [Hp] Height protected 160 mm Number of beams 8Type of start / restart Automatic ManualExternal Device Moni-toring (EDM)Selected by wiringComplementaryDetection system Transmitter-receiver system Response time 4 msKit composition1 user guide with certificate of conformity on CD-ROM 1 transmitter(s)1 receiver(s)Adjustable mounting bracket(s)[EAA] effective aperture angle +/- 2.5 ° at 3 m EmissionIR LED (λ = 950 nm)[Us] rated supply voltage 24 V DC (+/- 20 %)SupplyPower supply must meet requirements of IEC 60204-1Power supply must meet requirements of IEC 61496-1[Ie] rated operational current 2 ACurrent consumption900 mA with maximum load (receiver)42 mA (transmitter)83 mA no-load (receiver)42 mA no-load (transmitter)Output current limits 0.4 A for safety outputs OSSD Output voltage 24 V Output circuit type DC Voltage drop <= 0.5 VLocal signalling 2 dual colour LEDs (receiver)1 multi-colour LED (transmitter)Electrical connection 1 male connector M12 8 pins (receiver)1 male connector M12 5 pins (transmitter)Function availableLED display of operating modes and faultsMuting through external safety module XPSLCMUT1160Test Marking CEMaterialEnd caps : polypropylene Front panel : polycarbonate Casing : aluminium Housing colourRAL 3000 : redFixing mode By fixing bracketsProduct weight0.4 kgOffer type Standard distanceEnvironmentDirectives89/336/EEC - electromagnetic compatibility2002/96/EC - WEEE directive2002/95/EC - RoHS directive98/37/EEC - machinery89/655/EEC - work equipmentProduct certifications CECULusTÜVSafety level (correctly wired)PL = e conforming to EN/ISO 13849-1Category 4 conforming to EN/ISO 13849-1SILCL 3 conforming to IEC 62061SIL 3 conforming to IEC 61508Type 4 conforming to IEC 61496-1Optical characteristic Resistance to light disturbance conforming to EN/IEC 61496-2 Mission time20 yrSafety reliability data PFHd = 7.8E-9 1/h conforming to IEC 61508Ambient air temperature for operation-10...55 °C14...131 °FAmbient air temperature for storage-25...70 °C-13...158 °FRelative humidity<= 95 % without condensationIP degree of protection IP67IP65Shock resistance10 gn for 16 ms conforming to IEC 61496-1Vibration resistance0.35 +/- 0.05 mm (f = 10...55 Hz) conforming to IEC 61496-1Offer SustainabilitySustainable offer status Green Premium productRoHS (date code: YYWW)Compliant - since 1425 -Schneider Electric declaration of conformityREACh Reference not containing SVHC above the thresholdProduct environmental profile Available Download Product EnvironmentalProduct end of life instructions Available Download End Of Life ManualContractual warrantyPeriod18 monthsDimensions Drawings DimensionsBrackets DimensionsMounting and Clearance Mounting and Clearance(1)Insert(2)Bracket(3)Washer(4)Spring washer(5)NutConnections and SchemaWiring DiagramsTransmitter Connections(1)+24 Vdc(2)Configuration_0(3)0 Vdc(4)Configuration_1(5)FEReceiver Connections(1)OSSD1(2)+ 24 V(3)OSSD2(4)Configuration_A(5)K1_K2 Feeback/Restart(6)Configuration_B(7)0 Vdc(8)FEReceiver Configurations and Operating ModesAutomatic Start/RestartWithout External Device Monitoring (EDM) feedback loopWith External Device Monitoring (EDM) feedback loopManual Start/RestartWithout External Device Monitoring (EDM) feedback loop(1)RestartWith External Device Monitoring (EDM) feedback loop(1)RestartConnection SchematicsStandalone ApplicationXUSL4E light curtains are conforming to Type 4 (IEC 61496-1), SIL3 (IEC 61508) - SILCL3 (IEC 62061) and PLd- Cat.4 (EN ISO 13849-1:2008)Example of wiring diagram with manual start, external device monitoring and low range(1)Power supply(2)XUSL Receiver(3)XUSL transmitter(4)Low range(5)StartThe contactors K1/K2 must have :*Normally closed mirror contact, according to IEC 60947-4-1 for power contactors*Linked contacts (or force guided contacts), according to IEC 60947-5-1 or EN 50205 for auxiliary contactors or control relays。

SF系列安全光幕使用说明书◆ 安全光幕的使用关系人身安全,使用前请仔细阅读使用说明书◆ 说明书是指导用户正确安装、使用安全光幕的重要文件,请代理商、经销商、机床厂务必将使用说明书随安全光幕交付用户山东莱恩光电科技股份有限公司SHANDONG LAIEN OPTIC-ELECTRONIC TECHNOLOGY CO.,LTD.感谢您选用“LNTECH(莱恩)”牌安全光幕!本安全光幕主要用于汽车电子产业、包装业等自动化领域,防止工作人员误入危险区域造成的人身伤害,保护人身安全。

本安全光幕仅保护发光器与受光器(SF系列)之间的矩形光幕区域。

如果其安装位置不正确,或不按说明书与相关安全作业条例操作,或被保护设备执行机构故障,都可能使其无法起到保护作用。

因此,安装本光幕之前,请仔细阅读说明书,充分理解有关事项,尤其是说明书中标出的“警告”、“注意”等内容;在使用过程中,请正确理解安全光幕的工作性能,严格按照本说明书所提出的要求,制定相应的安全作业条例。

本说明书内容解释权归山东莱恩光电科技股份有限公司,阅读或使用本说明书时,如有不明之处,请与本公司联系。

禁止事项:禁止擅自复印、转载本使用说明书的部分或全部内容。

关于本使用说明书的内容,将来可能因装置改良等原因而进行修改,恕不另行预告。

本使用说明书虽经精心制作以期万全,但如果您发现有不明之处或异常、错页或缺页等时,烦请您通知最近的本公司办事处。

1)2)3)1 重要资料1.1 概述 (1)1.2 使用说明书的组成 (1)1.3 适用范围 (1)1.4 欧洲指令验证 (1)1.5 欧洲标准验证 (2)1.6 中国标准验证 (2)1.7 术语 (3)1.8 安全须知 (4)2 基本介绍2.1 外形尺寸图 (5)2.2 规格型号 (6)2.3 检测精度与光轴间距的关系 (7)2.4 技术标牌 (8)3 产品描述3.1 技术参数 (9)3.2 特点 (10)3.3 工作示意图 (10)3.4 应用案例 (11)3.5 应用条件 (13)4 功能配置4.1 外部装置监视功能(EDM) (14)4.2 辅助输出功能 (15)4.3 辅助对光功能 (15)4.4 对光强弱指示功能 (16)5 SF系列安全光幕的安装5.1 安全距离的计算 (17)5.2 相邻安装时的注意事项 (19)5.3 有反射物时的正确安装位置 (20)5.4 安装说明 (21)5.5 安装工具 (25)6 SF系列安全光幕部件说明6.1 主体部件说明 (26)6.2 发光器指示灯说明 (27)6.3 受光器指示灯说明 (28)7 接线7.1 SF系列安全光幕I/O接线 (29)7.2SF系列安全光幕与SR4P2A1B24N/P接线 (32)7.3 SF系列安全光幕与SR4P3A1B24接线 (34)7.4 SF系列安全光幕与SR4P2A1B24N/P-M接线 (35)7.5 信号电缆 (37)7.6 接线注意事项 (38)8 SF系列安全光幕的调试8.1 安全光幕的调试 (39)8.2 试运行 (39)9 使用、检查、保养9.1 使用注意事项 (40)9.2 检查与保养 (40)10 简单故障检修10.1 安全光幕故障判别 (41)11 配货信息11.1 配货 (42)1.重要资料1.1 概述本说明书包含了关于SF系列产品的说明、操作、安装、电气连接、维护和故障判断等资料。

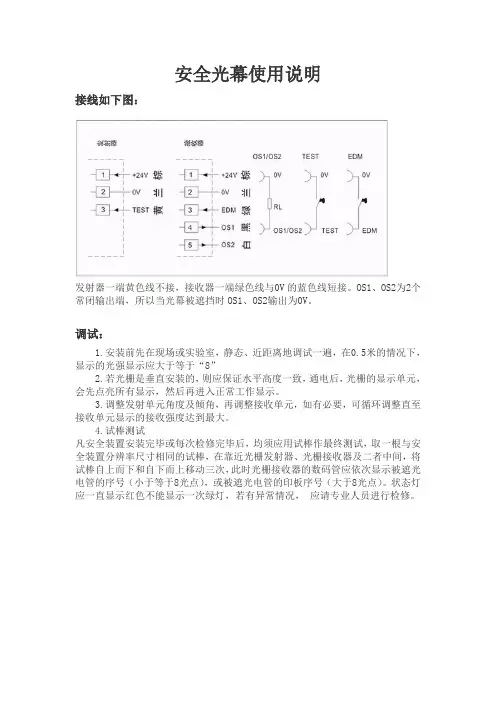

安全光幕使用说明

接线如下图:

发射器一端黄色线不接,接收器一端绿色线与0V的蓝色线短接。

OS1、OS2为2个常闭输出端,所以当光幕被遮挡时OS1、OS2输出为0V。

调试:

1.安装前先在现场或实验室,静态、近距离地调试一遍,在0.5米的情况下,显示的光强显示应大于等于“8”

2.若光栅是垂直安装的,则应保证水平高度一致,通电后,光栅的显示单元,会先点亮所有显示,然后再进入正常工作显示。

3.调整发射单元角度及倾角,再调整接收单元,如有必要,可循环调整直至接收单元显示的接收强度达到最大。

4.试棒测试

凡安全装置安装完毕或每次检修完毕后,均须应用试棒作最终测试,取一根与安全装置分辨率尺寸相同的试棒,在靠近光栅发射器、光栅接收器及二者中间,将试棒自上而下和自下而上移动三次,此时光栅接收器的数码管应依次显示被遮光电管的序号(小于等于8光点),或被遮光电管的印板序号(大于8光点)。

状态灯应一直显示红色不能显示一次绿灯,若有异常情况,应请专业人员进行检修。

故障处理:

如果发射单元或接收单元显示报警,可按下表处理:SSGS20安全光栅故障及处理(发射单元)

SSGS20安全光栅故障及处理 (接收单元)

安装支架简图:。

ḋ 㓪 SCHG-C-718BF3SJ-A P ㋏ (Ver.2) 㓪 SCHG-C-718B F3SJ-A P ㋏ (Ver.2)㓪 ˖SCHG-C-718B200607S01ㅔҟ䇶 䌁фF3SJ㋏ ˄ҹ ㅔ⿄ĀF3SJā˅DŽ䖭 ㅔ ҟ㒡F3SJⱘ⫼⊩DŽՓ⫼F3SJ 㽕⊼ ҹϟ ⚍ ˖g 䆕F3SJⱘ 㗙 ❳ 㺙ⱘ ⱘĀ䋷ӏҎāDŽg ЁՓ⫼ⱘ 䆡Ā䋷ӏҎā 䌘䋼ⱘǃ㒣䖛 ⱘǃ 䋳䋷 䆕ⱘ䆒䅵ǃ 㺙ǃ ǃ㓈 㕂ⱘ 䖛ⱘĀ āⱘҎ DŽg 䆒 ḍ ⱘ 㺙⦃ ǃ 㛑 㛑 ℷ⹂Փ⫼F3SJDŽg䋷ӏҎ 㺙 䖯㸠 ⱘ亢䰽䆘Ԅ 䗖 Ѣ ѻ DŽg 㺙 ѻ ˈ䅸ⳳ䯙䇏 ˈ⧚㾷 ⫼ 䗄DŽ㕂 ӏԩ䳔㽕ⱘ 䛑㛑⫼ 䯙ⱘ DŽiF3SJ-A 用户手册简介简介C 1.单独使用F3SJ-A 传感器将不能获得日本劳动卫生法的第44-2条的类型批准。

必须将它用在一个系统中。

因此,在日本把F3SJ-A 当作这个法律的第42条所描述的“压力或剪切机器的安全系统”使用时,系统必须获得类型批准。

2.根据欧盟(EU )的机械指令索引附件IV ,B ,安全部件,第1条,F3SJ-A 是光电保护设备(ESPE )。

3.F3SJ-A 符合下列法规和标准(1)EU 法规机械指令 98/37/ECEMC 指令 89/336/EEC(2)欧洲标准EN61496-1(类型4 ESPE ),prEN61496-2(类型4 AOPD ),EN61508-1~-7(SIL3)(3)国际标准IEC61496-1(类型4 ESPE ),IEC61496-2(类型4 AOPD ),IEC61508-1~-7(SIL3)(4)JIS 标准JIS B 9704-1(类型4 ESPE ),JIS B 9704-2(类型4 AOPD )(5)北美标准UL61496-1(类型4 ESPE ), UL61496-2(类型4 AOPD ), UL508, UL1998, CAN/CSA 22.2 No.14, CAN/CSA 22.2 No.0.84.F3SJ-A 从EU 公认的认证机构TÜV-PS 取得了以下的认证:•EU 类型检验符合EU 机械指令,类型4 ESPE (EN61496-1),类型4 AOPD (prEN61496-2)•EMC 证书(测试的电源:OMRON S82K )..•TUV-PS 类型批准,类型4 ESPE (EN61496-1),类型4 AOPD (prEN61496-2),SIL1,2,3(EN61508-1~-7),应用:EN954-1 分类B ,1,2,3,45.F3SJ-A 计划将从第三方评估机构UL 取得符合美国和加拿大安全标准的UL 证书。

ESN3220光幕说明书一、引言感谢您选择购买ESN3220光幕产品,请在使用前仔细阅读本说明书,并按照说明书的指示正确使用该产品。

本说明书将为您提供ESN3220光幕的安装、使用和维护等全面的指导。

二、产品概述1.高亮度显示:ESN3220光幕配备了高亮度LED灯珠,可以在户外光照充足的情况下保持清晰明亮的显示效果。

2.超大显示面积:ESN3220光幕的显示面积达到了XX寸,能够满足户外大型广告宣传的需求。

3.高分辨率:ESN3220光幕具备高分辨率显示,能够呈现更加细腻的图像和文字。

4.高防护等级:ESN3220光幕采用了防水、防尘和防腐蚀的设计,能够适应各种恶劣的户外环境。

三、安装步骤1.安装位置选择:选择一个适合的位置来安装ESN3220光幕,确保光幕不会受到突然大风、暴雨等自然因素的影响。

2.固定安装支架:使用配套的固定支架将ESN3220光幕牢固地固定在安装位置上,确保其稳定性和安全性。

3.连接电源:将光幕与电源连接,确保提供足够的电力支持光幕的正常运行。

四、使用说明1.开机与关机:按下电源按钮开机,按住电源按钮数秒后松开可关闭光幕。

2.画面调整:通过遥控器或面板按键进行亮度、对比度、色彩等画面参数的调整。

3.播放多媒体文件:ESN3220光幕支持通过USB接口连接外部存储设备进行多媒体文件的播放,通过遥控器或面板按钮控制播放。

4.定时开关机:设置光幕的定时开关机时间,能够自动开关机,方便管理和节约能源。

五、注意事项1.使用环境温度:ESN3220光幕适用的环境温度范围为-20℃至+50℃,请勿在超出该范围的环境中使用。

2.防护措施:光幕使用过程中,请避免各种机械碰撞和化学腐蚀,以保护其外观和功能。

3.遥控器操作:使用遥控器时,请确保操作距离合理,避免遥控器的信号受到干扰。

六、保养与维护1.清洁光幕:定期使用柔软无纤维的布擦拭光幕,防止灰尘堆积影响显示效果。

注意:在购买ESN3220光幕之前,请仔细阅读本说明书,并根据说明操作光幕。

LES系列区域传感器(光幕)使用说明天津市杰泰克自动化技术有限公司LES 系列区域传感器(光幕)使用说明一、 产品型号定义说明:LES 产品系列号;① 选C 为带RS485串口通讯功能,不选为常规; ② 光轴间距:12、20、40、80mm ; ③ 光轴数;④ 故障报警输出(发射器)形式,NPN/PNP 型晶体管,常开(O)/常闭(C) ⑤ 检测输出(接收器)形式,NPN/PNP 型晶体管,常开(O)/常闭(C);;例:LES1248NCNO ,光轴间距12mm ,光轴数48,报警输出为NPN型常闭,检测输出为NPN 型常开;LESC1248NN ,带RS485串口通讯功能,光轴间距12mm ,光轴数48,报警输出为NPN 型,检测输出为NPN 型;二、产品组成及其性能参数2.1、产品组成LES 系列光幕由发射器、接收器及其配套4芯电缆(带RS485串口通讯功能的产品,接收器配套电缆为6芯)组成。

发射器和接收器内置相同数量的发光管和光电管,发射器内部的发光器件和接收器内部的受光器件同步触发,并确认光路是否导通。

当光路被阻断时,系统即有检测输出。

发射器和接收器按工作单元(8个光轴为一个单元)设置段指示灯,用于指示各个单元的工作状态,同时设置有电源指示灯,用于指示本产品的工作。

发射器和接收器分别有一路开关量输出,用于指示产品故障(故障输出,发射器端)和检测物体的存在(检测输出,接收器端)。

LES2.2、产品性能参数三、产品型号及其参数列表3.1、LES(C)12系列3.2、LES(C)20系列3.3、LES(C)40系列3.4、LES(C)80系列3.5、产品外观示意图()系列光幕机械尺寸示意图1()系列光幕机械尺寸示意图2()系列光幕机械尺寸示意图3四、指示灯说明LED指示灯(红色)用于指示产品的工作状态和故障状态,发射器和接收器配置有相同数量的指示灯,其布置图见图4.1。

图4.1 指示灯布置图表4.1 各指示灯功能定义注:若接收器电源指示灯常亮,发射器电源指示灯闪烁/常灭,则发射器和接收器之间通讯异常。

•Integrated light curtains for PRESENCE CONTROL PROTECTION •50 and 90 mm resolution and operating distance up to 15 m •31 x 32 mm compact profile•Versions with automatic or manual RESTARTThe SAFEasy TM light curtains of the SF2series, according to the IEC 61496-1 and IEC 61496-2 st andards, are very suit able for presence detection of operators exposed to risks.Different models are available with nine st andard heights ranging from 300 to 1500 mm, with 50 or 90 mm resolution and an operating distance reaching 15 m.The emitter and receiver unit s are optically synchronised and cont ain all the control circuits, test input and two safety outputs inside the housing.The connection with the machine stopping circuit s are guaranteed by unshielded M12 4-pole connectors for the emitter and M12 5-pole connectors for the receiver.The SAFEasy TM light curtains of the SF2series have also integrated the test function, automatically activated every 0.5 seconds, without stopping the machine's working cycle.A wide range of industrial applications, requiring operator safety , can be solved by the SAFEasy TM light curt ains, thanks to the extremely comp act dimensions (31x32 mm), easy installation and excellent performances.SF2-PRESENCE CONTROL SERIESSAFEasy ™TYPE 2 LIGHT CURTAINSS A F E T Y D E V I C E SPresence control is obt ained positioning horizontally the safety light curt ain. This inst allation allows to continuously control the presence of an obst acle inside a specific area. This is a p articularly useful solution when dangerous area, not visible from the machine control points, has to be protected.DIMENSIONSRECEIVER (RX)EMITTER (TX)CONNECTIONSOSSD1 PNPOSSD2 PNP0 V+24 Vdc+24 Vdc1= brown = +24 Vdc 2= white = OSSD13= blue = 0V 4= black = OSSD25=grey = TEST **= automatic RESTART (X version) TEST/RESET function= manual RESTART (Y version) TEST/RESTART/RESET functionCONTROLLEDHEIGHT L 1 L 2 (mm)300374294450521441600668588750815735900962882105011091029120012561176135014031323150015501470L 323153.314.9M 12 x 11L 2mm+24 VdcNOT USED NOT USED0 V 1= brown = +24 Vdc 2= white = NOT USED 3= blue = 0V4= black = NOT USEDPower supply (Vdd):24 Vdc ± 20% (SELV /PELV)Consumption:50 mA max. / 1 W (emitter)90 mA max. / 2.5 W (receiver without load)Light emission: infrared LED 880 nm Optic diameter:Ø 18 mmNumber of controlled beams: refer to table 1Optic interaxis: 37,5 mm (SF2-50); 74 mm (SF2-90) Resolution:50 / 90 mm Controlled height: refer to table 2Operating distance: 0.2 ... 15 mReceiver inputs:external switches for Test and Restart Receiver indicators: 2 yellow ALIGNMENT LEDs red BREAK LED green SAFE LEDEmitter indicators: yellow WORKING UNIT CHECK LED green POWER ON LED Output type:2 PNPshort-circuit protection:max.1.4 A at 55°Cmin. 1.2 A at 0 °COutput current (for all loads): 500 mA max. per output Output voltage ON min.:Vdd - 1 V Output voltage OFF max.:0.2 V Leakage current:0.65 mA Capacitive load (pure):100 nF max.Resistive load (pure):60 Ωmin.Response time:refer to table 3Receiver connection: M12 5-pole connector Emitter connection: M12 4-pole connector Safety category:type 2Electrical protection: class 1Mechanical protection: IP65 (EN 60529)IP67(connector part)Housing material:painted aluminium Cap end material:PBT Lens material:PMMACable length:50 m max * (at 100nF capacitive load and Vdd=24V)M12 conductors (according to EN 50044, EN 60947-5-2) poles Ø = 32x0.1mm, external Ø = 0.5mm Weight:1 Kg. max. / m of total height Operating temperature:0 ...+55 °C Storage temperature: -25 ... +70 °CReference standards:EN 954-1, IEC 61496-1, IEC 61496-2* = if a longer cable has to be used, please verify that the same specifications are respectedTECHNICAL DATATABLESModelSF2-50SF2-90SF2 height 30095SF2 height 450 137SF2 height 600179SF2 height 7502111SF2 height 900 2513SF2 height 1050 2915SF2 height 12003317SF2 height 1350 3719SF2 height 15004121Table 2: CONTROLLED HEIGHT (mm)ModelSF2SF2 height 300334SF2 height 450 481SF2 height 600628SF2 height 750775SF2 height 900 922SF2 height 1050 1069SF2 height 12001216SF2 height 1350 1363SF2 height 15001510Table 1:NUMBER OF CONTROLLED BEAMSTable 3: RESPONSE TIME (ms)ModelSF2SF2 height 30015SF2 height 450 16SF2 height 60017SF2 height 75018SF2 height 900 19SF2 height 1050 20SF2 height 120022SF2 height 1350 23SF2 height 1500 24II3DPlease refer also to Safey Device Accessories Distributed by:。

ounting brackets included with all unitsnstruction manual and testing rod included• Type 4 and Category 4 PLe Hand-safePart Number PriceYBB-30S4-0250-G012Sender$277.00YBB-30R4-0250-G012Receiver$305.00YBB-30K4-0250-G012Set$485.00YBB-30S4-0400-G012Sender$331.00YBB-30R4-0400-G012Receiver$372.00Company InformationTerminal BlocksPower Distribution BlocksWiring AccessoriesZIPLink Connection SystemMulti-wire ConnectorsSensor Cables and ConnectorsM12 Junction BlocksPanel Interface ConnectorsWiring DuctCable TiesWireBulkMulti-conductor CablesWire Management ProductsPower SuppliesDC ConvertersTransformers and FiltersCircuit ProtectionToolsTest EquipmentEnclosuresEnclosure Climate ControlSafety: Electrical ComponentsSafety: Protective WearTerms and ConditionsContrinex Safety Light Curtains – Hand-safeNote: AutomationDirect does not recommend using these light curtains with any device other than our Safety Relay Light Curtain Controllers.Contrinex Safety Light Curtains – Hand-safeon the specific part number's web page at Company Information Terminal Blocks Power Distribution Blocks Wiring Accessories ZIPLink Connection System Multi-wire Connectors Sensor Cables and Connectors M12 Junction Blocks Panel Interface Connectors Wiring Duct Cable Ties Wire BulkMulti-conductor Cables WireManagement Products Power Supplies DC Converters Transformers and Filters Circuit Protection Tools Test EquipmentEnclosures Enclosure Climate Control Safety: Electrical Components Safety: Protective Wear Terms and ConditionsLight Curtain Protective Column• A utomatically bounces back after physical shock or vibration.• R obust baseplate allows radial and vertical alignment.• Solid aluminum profileYXW-0003-000YXW-0001-000YXL-0001-000Light Curtain Mirror Columns• M ulti-sided safe guarding of danger zones• R obust protective profile• 10% reduction of operating distance for mirrorContrinex Safety Light Curtains AccessoriesDimensions mm [in]Protective columnBeam Gap DCompany Information Terminal Blocks Power Distribution Blocks Wiring Accessories ZIPLink Connection System Multi-wire Connectors Sensor Cables and Connectors M12 Junction Blocks Panel Interface Connectors Wiring Duct Cable Ties Wire BulkMulti-conductor Cables WireManagement Products Power SuppliesDC Converters Transformers and Filters Circuit Protection Tools Test Equipment Enclosures Enclosure Climate Control Safety: Electrical Components Safety: Protective Wear Terms and ConditionsContrinex Safety Light Curtains AccessoriesDimensions mm [in]Laser Alignment Tool• C lips on YBB and YCA Curtains / Barriers• H igh quality lens for narrow output beam• Up to 50m [164ft] range • <1mW output power• Standard AA batteries includedWarning: Safety products sold by AutomationDirect are Safety components only.The purchaser/installer is solely responsible for the application of these components and ensuring all necessary steps have been taken to assure each application and use meets all performance and applicable safety requirements and/or local, national and/or international safety codes as required by the application. AutomationDirect cannot certify that our products used solely or in conjunction with other AutomationDirect or other vendors’ products will assure safety for any application.Any person using or applying any products sold by AutomationDirect is responsible for learning the safety requirements for their individual application and applying them, and therefore assumes all risks, and accepts full and complete responsibility for the selection and suitability of the product for their respective application. AutomationDirect does not provide design or consulting services, and cannot advise whether any specific application or use of our products would ensure compliance with the safety requirements for any application.。

产品线 .................................F-24共通注意事项 ........................ 后-2技术指南 (465)相关信息长距离检测型安全光幕F3SL种类(交货期请向经销商咨询)本体附件(另售)专用电缆(请为发光器和受光器各定购1个)反射镜(检测距离衰减率12%)电缆长规格型号发光器用受光器用10m 连接器型F39-JL10A-L F39-JL10A-D 15m F39-JL15A-L F39-JL15A-D 30mF39-JL30A-LF39-JL30A-D镜子材质宽(mm)厚(mm)长(mm)型号玻璃镜子14532406F39-MLG0406610F39-MLG0610711F39-MLG0711914F39-MLG09141,067F39-MLG10671,219F39-MLG12191,422F39-MLG14221,626F39-MLG16261,830F39-MLG18302,134F39-MLG213420m 的长距离检测适用于大型设备及传输线侵入检测的人体检测用(4级)安全光幕■符合IEC 标准、EN 标准、北美标准,由TÜV 取得符合EC 设备指令的EC 认可,可作为符合北美劳动安全的现场所要求的OSHA 规范的安全防护装置使用■无需另备专用控制器。

通过传感器单体可实现人体侵入检测功能。

■备有防止输出自动复位的「启动/重启互锁功能」。

■备有浮动消隐功能(使不特定的1或2光轴无效化的功能)及通道选择(固定消隐:使指定光无效化功能)■内置MPCE (外部继电器)监视功能。

无需控制器便可进行反馈检测。

请参照270页的「请正确使用」。

额定值/性能*1.ESPE(Electro-Sensitive Protective Equipment)*2.AOPD(Active Opto-electronic Protective Devices)项目型号F3SL-A0351P30F3SL-A0523P30F3SL-A0700P30F3SL-A0871P30F3SL-A1046P30F3SL-A1219P30F3SL-A1394P30F3SL-A1570P30F3SL-A1746P30F3SL-A1920P30F3SL-A2095P30检测距离0.3~20m 光轴间距离22mm 光轴数1624324048566472808896检测范围351mm 523mm 700mm 871mm 1,046mm 1,219mm 1,394mm 1,570mm 1,746mm 1,920mm 2,095mm 最小检测物体不透明体φ30mm 以上(浮动消隐时为φ52/φ74)指向角发光器 受光器:各±2.5°以内(检测距离3m 以上,根据IEC61496-2)光源(发光波长)红外发光二级管(850nm)电源电压DC24V ±20%纹波(p-p )5%接通电源后启动时间3s 以下消耗电流发光器:285mA 以下, 受光器:1.4A 以下(含负载输出电流)控制输出PNP 晶体管输出X2输出,负载电流500mA 以下(残留电压2V 以下)(因电缆延长引起的电压下降除外)入光时ON 辅助输出与控制输出信号相同:PNP 晶体管输出X1输出(非安全输出),负载电流100mA 以下(残留电压1V 以下)(因电缆延长引起的电压下降除外)保护电路输出负载短路保护,电源反接保护安全相关功能・启动/重启互锁功能 [通过切换开关可以选择有效/无效]・消隐功能①通道选择(固定消隐) ②浮动消隐③无消隐(工厂出货时)[通过切换开关可进行①、②、③、的选择。

红外扫描光幕说明书

一、指示灯说明

LED指示灯用于指示产品的工作状态和故障状态,发射器和接收器配置有相同数量的指示灯。

LED指示灯置于发射器和接收器的上端,其布置图见图4.1。

图4.1 指示灯布置

表4.1 指示灯说明(工作状态、加热玻璃指示灯)

注:* 光幕工作异常时,有报警输出;** 遮挡光轴数超过触发物体大小时,有检测输出。

表4.2 指示灯说明(接收光束强弱指示灯)

二、光幕外形尺寸和接线图

1、光幕外形尺寸如图5.1;

2、光幕接线图如图5.2。

图5.1 发射器和接收器外形尺寸

第 1 页。

介电强度:≥AC 1500V 有效探测高度:1670 mm 标准最大工作距离:3000 mm 标称寿命:≥100 万次抗光指标:50000 Lux

六、安装、使用注意事项

1、检查光幕型号以及电源组件是否与订购的一致。

2、按照指定的标记打开一个端盖,小心取出全部部件。

3、安装好发射装置、接收装置、电源组件和专用连接电缆后,接通交

流电源。

此时光幕若未被遮挡,接收装置内的绿色电源指示灯应亮,同时电源组件内的红色动作指示灯熄灭,输出继电器吸合。

4、连接电缆应固定好,保证轿厢门机在开、关门过程中不会被拉紧、

折断或挂断。

5、观察光幕的动作,当光幕若被遮挡时,接收装置内的红色状态指示

灯应亮。

6、当发射装置或接收装置内的某个光管损坏时,光幕动作。

30秒后,

光幕进入冗余运行方式,将屏蔽该光管恢复作业。

但红色状态指示灯会闪烁,以提醒维修人员尽快排除故障。

为安全起见,冗余运行方式只允许一只光管损坏。

七、排除故障

1、接通交流电源后,如电源组件内绿色电源指示灯不亮,请检查外电

源是否接好,电压是否正确,保险丝是否熔断。

2、接收装置如无指示,请检查连接电缆是否接好或连接电缆是否已被

拉紧、折断或挂断。

3、接收装置指示正常,但不能控制门机。

请检查继电器是否有吸合声,

信号线连接是否正确。

4、光幕出现误动作,请检查发射装置、接收装置、电源组件接地是否

良好,连接电缆屏蔽层是否脱落,光幕安装位置是否合适,门机关门晃动是否过大。

X L – G M 系列电梯光幕使用说明书

上海鑫菱机电设备有限公司

一、概述

XL - GM系列电梯光幕由红外线发射装置、接收装置、电源组件和专用连接电缆四部分组成。

XL光幕采用自动探测技术,由MCU控制发射和接收装置依次开启,在轿门区域自上而下连续扫描,轿厢门机系统根据红外光线是否被阻挡,来控制轿厢门做相应的关或开门操作。

二、安装

标准型光幕安装开孔孔径和孔距如下图所示:

其它类型光幕只是主体厚度不同,孔径和孔距是一样的。

长度为m时开8孔,2 m 时开10孔。

侧开门时,光幕主体其中一根安装方式不变,另一根为侧开门特配的主体,一般采用胶带灵活固定在轿厢上。

三、接线

电源组件为AC220V的光幕电气连接按图1所示,安装尺寸按图2所示。

6接AC电源190

5 180

电源指示灯4

○接地

3 信号输出R3 ○○

60

○2

动作指示灯1

图2

图1

其中4#端、6#端接AC220V,5#端接地。

1# ~3#为信号输出端。

电源组件为DC24V时,3#端接电源+,1#端接电源﹣,2#端接地。

4# ~

6#为信号输出端。

不论哪类电源,信号输出为继电器无源接点,其状态如下

表所示。

光幕状态

种类电源

无遮挡遮挡AC220V适用917A-D、H、J1/3接通;2/3断开1/3断开;2/3接通

DC24V适用917A-D、H、J4/6接通;5/6断开4/6断开;5/6接通

四、主要性能

光幕类型光幕型号扫描

光路

扫描光束响应

时间

水平

误差

垂直

误差

最小检出物高

度标准型XL-GM/A31945mm35 mm50 mm 增强型XL-GM-D9412865 ms5mm25 mm25 mm 加厚型XL-GM-B9412865 ms5mm25 mm25 mm 二合一型XL-GM-C31945mm35 mm50 mm

五、技术参数

标称功率:≤3W 信号输出接点容量:1 A。