(精选)低压电流互感器说明书

- 格式:doc

- 大小:2.72 MB

- 文档页数:17

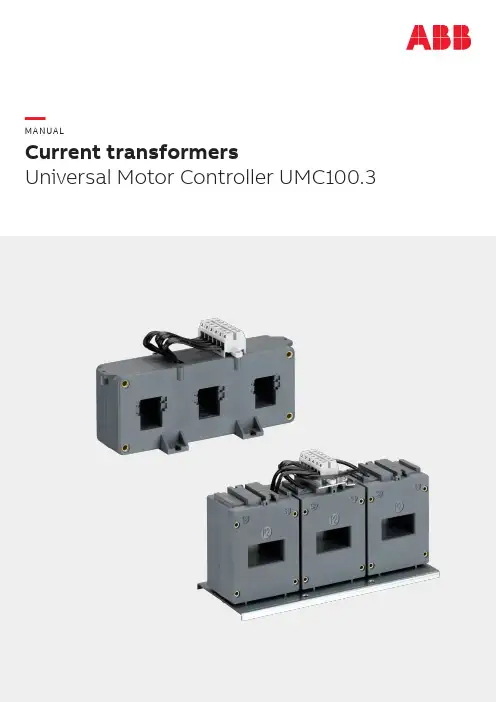

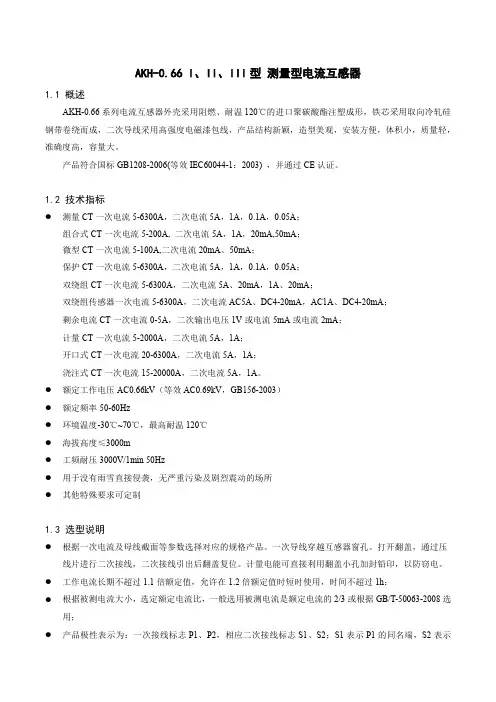

—MANUALCurrent transformersUniversal Motor Controller UMC100.3GeneralCharacteristics• CT4L185R/4, CT4L310R/4, CT5L500R/4, CT5L850R/4 three-phase current transformers for usage with UMC and nominal motor currents > 63 A• Only four types for Ie up to 850 A• CT with linear characteristicsApprovalsAll current transformers have in combination with UMC100.3 the following approvals• ABS• ATEX• CCC• cULus• DNV - GL—Order dataType Rated primary current range I e Order codeCT4L185R/460 … 185 A AC1SAJ929500R0185CT4L310R/4150 … 310 A AC1SAJ929500R0310CT5L500R/4200 … 500 A AC1SAJ929501R0500CT5L850R/4400 … 850 A AC1SAJ929501R0850—Dimensionsin mm and inches—CT4L185R/4, CT4L310R/4—CT5L500R/4, CT5L850R/42C D C 342002F 0012FunctionsApplicationThe current transformers CT4L and CT5L are accessories for the ABB Universal Motor Controllers UMCxxx. The motor current flows through the current transformer. The UMC measures the secondary current (4 A at nominal current) and calculates the real current based on the parameter setting ‚Current Factor‘.More information how to set this parameter is available in the UMC manuals.When using the current transformers together with the voltage module VI150 or VI155 the wiring schema shown below must be used to ensure proper operation of the cos φ (and thereof the power calculation) and phase sequence functions.—Wiring scheme for using current transformers with UMC and VI15xL1 L2 L3UMCCT5L500R/4CT5L850R/4L1L2CT4L185R/4CT4L310R/4L1Technical dataData at T a = 25 °C and rated values, unless otherwise indicated—GeneralType CT4L185R/4CT4L310R/4CT5L500R/4CT5L850R/4 Rated primary current range I e60 … 185 A AC150 … 310 A AC200 … 500 A AC400 … 850 A AC Rated frequency50/60 HzRated secondary current 4 ARated burden30…60 mΩPerformance under short circuit conditions:I q = 100 kA/1000 V ACCoordination type 2I q: Rated conditional short circuit currentTolerance of tripping time of UMC100 (incl. total ranges of current,temperature 0-60 °C, frequency 45-65 Hz)UMC with external current transformer: ±14 %Accuracy class of the monitored current of UMC100(range 50 % to 200 %of I e)UMC with external current transformer: 4 %—Isolation dataRated impulse withstand voltage U imp8 kVRated insulation voltage U i1000 VPollution degree3Overvoltage category III—Standards / directivesProduct standard IEC60947-1IEC60947-4-1RoHS Directive2002/95/EC—Environmental dataAmbient air temperature Operation 0 ... +60 °CStorage-25 ... +70 °CVibration (sinusoidal) acc. to IEC/EN 60068-2-6 (Fc) 5 g / 10 .... 150 HzShock (half-sine) acc. to IEC/EN 60068-2-27 (Ea)15 g / 11 ms—General DataDegree of protection IP20Dimensions (W x H x D)See dimensional drawingMounting With screws (M5/M6)Mounting position AnyAltitude2000 m; 2000 - 5000 m refer to the UMC100.3 manual 2CDC135032D0204 Duty time100 %Rated continuous thermal current (I cth) 1.2 I eWeight 1.6 kg 1.5 kg 1.7 kg 1.9 kg—Electrical Connection SecondaryTightening torque terminals 1…60.8 NmCross section terminals 1…6Max. 6 mm2—Electrical Connection PrimaryMotor wire size To be defined acc. IEC/EN 60204Max. cross section See dimension drawingD o c u m e n t n u m b e r 2C D C 135027D 0201 R e v . D (02/2020)—ABB STOTZ-KONTAKT GmbH Eppelheimer Strasse 8269123 Heidelberg, GermanyYou can find the address of your local sales organization on the ABB homepage/lowvoltageAdditional informationWe reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB AG does not accept any responsibility whatsoever for potential errors or possible lack of information in this document.We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents – in whole or in parts – is forbidden without prior written consent of ABB AG. Copyright© 2020 ABB All rights reserved。

016正常工作条件和安装条件LMK2-06650(60)Hz066kV 及以下电路中作电流、电能计量或继电保护用,并使测量、保护与高电压相隔离。

产品符合:GB/T 20840.1、GB/T 20840.2 标准。

.系列互感器为户内型电流互感器,适用于额定频率为,额定电压为.测量装置□ 5~40□ 环境湿度:≤80%□ 海拔高度:≤1000m;□ 安装场所:户内,且无金属粉尘及剧烈震动的场所;□ 安装场所的大气中无严重污秽,且介质中无足以腐蚀金属和破坏绝缘的气体与导电尘埃。

环境温度:(-)℃;;互感器主要由线圈和塑料外壳组成,为干式绝缘。

一次母线——电缆或母排——从窗孔穿过。

互感器既可以通过紧定螺钉夹持于母排上,也可通过安装板用螺钉固定安装。

LMK2-0.66的窗孔可穿过2根窄边为10mm的母排。

LMK2-0.66Ⅱ的窗孔可穿过3根窄边为10mm的母排。

结构特征产品概述选型指南LMK2-0.66LMK2-0.66Ⅱ主要技术数据1.LMK2-0.660170182.LMK2-0.66Ⅱ续上表019LMK2-0.66系列电流互感器图2图3图1互感器的外形及安装尺寸见图1、图2、图3和表1、表2外形及安装尺寸订货须知LMK2-0.66/30窗孔尺寸□ □ 请注明产品型号规格、二次负荷、相应准确级、电流比、数量。

□ 其它要求。

□ 订货举例:LMK2-0.66/40 53.75VA 0.5级 穿心匝 100只。

LMK2-0.66/60Ⅱ 5/3.75VA 0.5级 300/5 100只。

100A (含)以下电流默认穿心匝数均为多匝式。

需要订购单匝式的,请在下订单时说明。

/150/5A2表1图A-30。

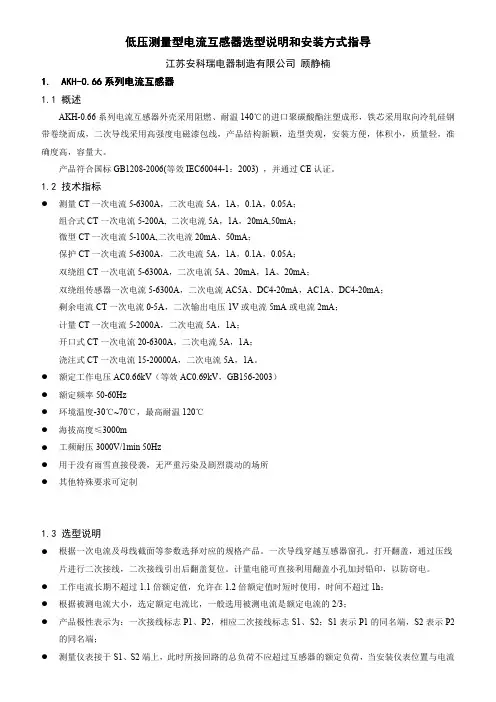

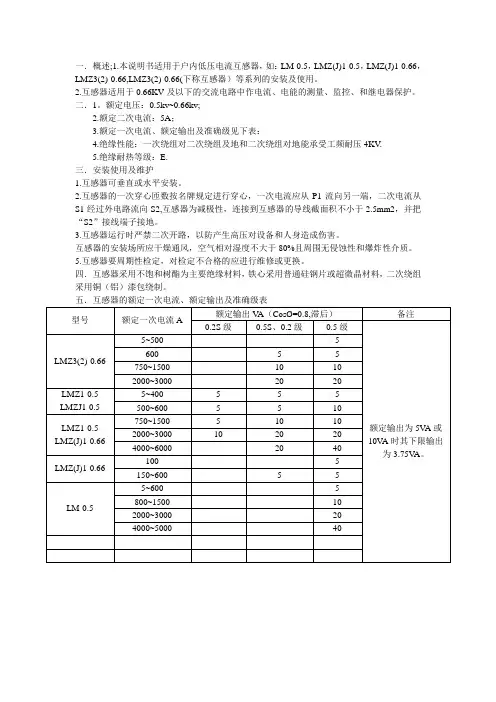

一.概述;1.本说明书适用于户内低压电流互感器,如:LM-0.5,LMZ(J)1-0.5,LMZ(J)1-0.66,LMZ3(2)-0.66,LMZ3(2)-0.66(下称互感器)等系列的安装及使用。

2.互感器适用于0.66KV及以下的交流电路中作电流、电能的测量、监控、和继电器保护。

二.1。

额定电压:0.5kv~0.66kv;2.额定二次电流:5A;3.额定一次电流、额定输出及准确级见下表:4.绝缘性能:一次绕组对二次绕组及地和二次绕组对地能承受工频耐压4KV.5.绝缘耐热等级:E.三.安装使用及维护1.互感器可垂直或水平安装。

2.互感器的一次穿心匝数按名牌规定进行穿心,一次电流应从P1流向另一端,二次电流从S1经过外电路流向S2,互感器为减极性,连接到互感器的导线截面积不小于2.5mm2,并把“S2”接线端子接地。

3.互感器运行时严禁二次开路,以防产生高压对设备和人身造成伤害。

互感器的安装场所应干燥通风,空气相对湿度不大于80%且周围无侵蚀性和爆炸性介质。

5.互感器要周期性检定,对检定不合格的应进行维修或更换。

四.互感器采用不饱和树酯为主要绝缘材料,铁心采用普通硅钢片或超微晶材料,二次绕组采用铜(铝)漆包绕制。

五.互感器的额定一次电流、额定输出及准确级表型号额定一次电流A额定输出V A(CosØ=0.8,滞后)备注0.2S级0.5S、0.2级0.5级额定输出为5V A或10V A时其下限输出为3.75V A。

LMZ3(2)-0.665~500 5 600 5 5 750~1500 10 10 2000~3000 20 20LMZ1-0.5 LMZJ1-0.55~400 5 5 5 500~600 5 5 10LMZ1-0.5 LMZ(J)1-0.66 750~1500 5 10 10 2000~3000 10 20 20 4000~6000 20 40LMZ(J)1-0.66100 5 150~600 5 5LM-0.55~600 5 800~1500 10 2000~3000 20 4000~5000 40。

220kV电流互感器使⽤说明书⼀、概述LVQB(T)-220W2(3)型电流互感器在额定频率50Hz、设备最⾼电压252kV的电⼒系统中作电⽓保护和测量⽤。

产品符合GB1208《电流互感器》国家标准。

SF6电流互感器特点:1、运⾏安全可靠,免维护、不燃烧、不爆炸;产品在线监测SF6⽓体压⼒,运⾏中可不停电补充⽓体。

2、⾼精度,计量级为0.2或0.2S。

3、动热稳定性好,低温升。

4、局部放电量在5pC以下,⽆介质损耗问题。

⼆、型号说明L V Q B (T) - □ W□污秽等级电压等级 kV带暂态保护绕组带保护绕组主绝缘介质为⽓体倒⽴式结构电流互感器三、使⽤条件1、安装场所:户外2、海拔:不超过2000m3、最⼤风速: 35m/s4、地震烈度:不超过9度5、污秽等级:Ⅲ级(Ⅳ级)及以下污秽地区6、环境温度:最低⽓温: -30℃最⾼⽓温: +40℃⽇平均⽓温不超过+30℃7、相对湿度:95%(20℃时)四、结构产品总体结构为倒⽴式结构。

由底座、瓷套、壳体及⼆次绕组等部分组成(见图1、图2)。

⼆次绕组位于壳体内,与⼀次绕组之间⽤SF6⽓体绝缘,并通过⽀持绝缘⼦固定到壳体上,其引出线通过底座内的⼆次接线端⼦引出供⽤户外接负载使⽤。

⼀次绕组通过串并联⽅式及⼆次绕组抽头可获得四种电流⽐。

壳体上⽅设置有压⼒释放装置。

瓷套采⽤⾼强瓷套(根据⽤户需要,也可采⽤硅橡胶复合绝缘套管),能够承受5倍于产品额定⽓压的内压作⽤⽽不破坏,通过瓷套的上、下法兰分别与壳体和底座牢固地联结。

瓷套外绝缘公称爬电距离为6300mm(7812mm),能适应Ⅲ级(Ⅳ级)污秽地区运⾏需要。

底座除起⽀撑设备、安装作⽤外,还设置有密度控制器、⼆次接线端⼦、SF6阀门及吸附剂等。

五、主要技术参数1、主要电⽓参数:见表⼀2、绝缘⽔平:额定短时⼯频耐受电压(⽅均根值) 460kV·1min或395kV·1min额定雷电冲击耐受电压(峰值1.2/50µs ) 1050 kV 或950 kV 3、SF 6⽓体额定压⼒ 0.40MPa (20℃) SF 6⽓体补⽓压⼒ 0.35MPa (20℃)4、产品年漏⽓率不⼤于1%5、产品内SF 6⽓体的含⽔量:出⼚值不⼤于250µL/L 运⾏值不⼤于500µL/L 6、产品局部放电⽔平:252kV (⽅均根值)下不⼤于10pC 175kV (⽅均根值)下不⼤于5pC表⼀主要电⽓参数注1、测量绕组(或保护绕组)的数量和准确级可根据⽤户需要制造,若⽆特别说明,制造⼚提供下列组合:0.5/0.5/10P15/10P15/10P15/10P15注2、测量绕组的仪表保安系数和保护绕组的准确限值系数可根据⽤户需要制造,若⽆特别说明,制造⼚提供下列参数:FS10和10P15。

低压开合式电流互感器安全操作及保养规程一、安全操作规程:1.在操作低压开合式电流互感器之前,必须确保设备通电前已经进行了完整的安全接地,并断开电源开关,确保设备不带电。

2.操作人员应配备个人防护装备,并确保装备完好。

如:绝缘手套、绝缘靴、绝缘胶布等。

3.在与低压开合式电流互感器进行接触时,应采取轻拿轻放的方式,避免碰撞、摔落和其他机械损坏。

4.严禁在湿润环境下操作低压开合式电流互感器,避免因湿润导致触电风险。

5.操作人员应遵守电压等级和额定电流的使用要求,避免使用过大或过小的电流,以免引发电器设备故障。

6.定期检查低压开合式电流互感器的接线是否牢固,是否出现松动,及时修复或更换有问题的连接件。

7.在对低压开合式电流互感器进行操作时,操作人员应保持集中注意力,不得因其他事务干扰,以免发生意外。

二、保养规程:1.每隔一段时间应对低压开合式电流互感器进行外观检查,检查是否有外部的机械损坏或表面污垢,及时清理和修复。

2.定期检查低压开合式电流互感器的连接端子是否松动,如发现松动应及时拧紧。

3.定期对低压开合式电流互感器的绝缘电阻进行检测,确保绝缘电阻符合安全要求。

4.定期检查低压开合式电流互感器的工作状态,检查是否有异常噪音或发热现象,及时更换有问题的部件。

5.如果长时间不使用低压开合式电流互感器,应将其放置在干燥通风的环境中,避免灰尘和湿气对设备的影响。

6.定期进行低压开合式电流互感器的维护保养,如更换损坏的配件、清洗污垢、润滑机械部件等。

7.在保养过程中,应遵循低压开合式电流互感器的相关维修和保养手册,按照规定的步骤进行维护工作。

综上所述,低压开合式电流互感器的安全操作和保养规程对于保证设备正常运行、延长使用寿命具有重要意义。

操作人员必须严格遵守安全操作规程,并按照保养规程进行定期保养维护,确保设备的安全可靠运行。

I C S备案号:Q/C S G 中国南方电网有限责任公司企业标准Q/C S G1209010-2016中国南方电网有限责任公司计量用低压电流互感器技术规范2016-09-01发布2016-09-01实施中国南方电网有限责任公司发布Q/C S G1209010-2016目次前言I 1范围1 2规范性引用文件1 3术语和定义1 4技术要求1 4.1结构要求1 4.2铭牌标识1 4.3额定值2 4.4绝缘要求2 4.5准确度等级和误差要求2 4.6运行变差影响3 5试验3 5.1试验类别3 5.2试验项目3 5.3试验方法4 6寿命要求5Q/C S G1209010-2016前言按照中国南方电网有限责任公司电能计量“标准化、电子化、自动化、智能化”战略要求,依据国家和行业标准,结合公司目前和未来的应用需求,组织编写了中国南方电网有限责任公司计量用低压电流互感器技术规范。

本标准对计量用低压电流互感器外形结构、使用条件、技术要求、绝缘要求和试验项目和方法等做出了规定,是中国南方电网有限责任公司计量用低压电流互感器招标采购、检验验收及质量监督等工作的技术依据。

本标准由中国南方电网有限责任公司市场营销部归口。

本标准起草单位:广东电网公司有限责任电力科学研究院。

本标准主要起草人:宋强、郑龙、石少青、林国营、胡嘉、肖勇、化振谦、林军、张鼎衢。

Q/C S G1209010-2016计量用低压电流互感器技术规范1范围本技术规范适用于中国南方电网有限责任公司范围内额定电压为0.66k V、电能计量专用电流互感器的检测与验收。

本技术规范未作明确规定的内容,必须符合相关的国家和行业标准的要求。

2规范性引用文件下列标准所包含的条文,通过在本标准中的应用而构成本标准的条文。

本标准发布时,所示版本均为有效。

所有标准都会被修订,使用时应探讨使用下列标准最新版本的可能性。

J J G1021-2007电力互感器G B20840.1-2010互感器第1部分:通用技术要求G B20840.2-2014互感器第2部分:电流互感器的补充技术要求D L/T725-2013电力用电流互感器使用技术规范3术语和定义计量用电流互感器:是指为电能计量仪表等提供电流的专用电流互感器。

L M ZJ1-0.66系列电流互感器符合标准:G B/T20840.2警告当电流互感器的一次绕组中通有电流时,严禁断开二次电路,否则电流互感器二次绕组所产生的高电压将危及设备和人身安全。

注意1 安装时,S2端应可靠接地。

2 长期工作电流不超过额定值,允许在1.2倍额定电流下作短时运行。

23 二次电路连接线截面积不小于1.5mm。

电路上的总阻抗不得超出标牌标注的二次负荷。

4 严格按照标牌标注的穿心匝数使用电流互感器。

5 避免同一互感器既作保护用又作测量用。

1 概述1.1 适用范围及主要用途L MZJ1-0.66系列为户内型电流互感器,适用于额定频率为50Hz,额定电压至0.66kV的交流电路中作电流测量、电能计量和继电保护用。

符合标准:GB/T20840.2 《第二部分:电流互感器的补充技术要求》。

1.2 使用环境条件a) 环境温度:(-5~40)。

b) 环境湿度:≤80%。

c ) 海拔高度:≤1000m 。

d ) 安装场所:户内,且无金属粉尘及剧烈震动的场所。

1.3 型号含义2 结构特征与工作原理2.1 结构互感器由树脂混合料将二次线圈、嵌装螺母等零部件固化成型。

中间窗孔供母排穿过。

二次线圈由高磁导率的优质取向硅钢带或纳米晶软磁合金带制作的环形或矩形铁芯与聚酯漆包圆线制作而成。

2.2 工作原理电流互感器是一种交流电流变换的电气设备,它串接在用电线路上,利用电磁互感的工作原理,将大小不一的电流变成一定大小的电流,便于用统一规格的电气仪表进行测量。

3 技术参数3.1 额定电压:0.66kV 。

3.2 额定频率:50Hz 。

3.3 额定安匝范围:50A t ~6000At 。

3.4 额定二次电流:5A ,1A 。

L M Z J 1 - 0.66额定电压(kV )电流互感器母线式绕注绝缘设计序号加强绝缘4 外形、窗孔及安装尺寸见图1、图2、图3、图4和表1。

图1 规格:30、40图2 规格:50、60图3图1、图2左视图 图4 规格:80、100、140、1803.5 二次负荷功率因数:0.8(滞后)。

低压电能计量用电流互感器0.5S级0.2S级安科瑞电气股份有限公司张小莉工业计量高精度电流互感器分为0.5S和0.2S级普通配电用电流互感器分为0.5级和0.2级其区别在于:0.5S(0.2S)级的精度比0.5(0.2)级高。

带S的是特殊的电流互感器,要求在1%-120%负荷范围内精度足够高,一般取5个负荷点测量其误差小于规定的范围。

精度高指S型能在更宽的电流范围内保证准确度,主要指下线电流。

一般的电流互感器要求在0.02In~Imax 范围内建成误差,见GB/T17215和15283;而S型的电流互感器则要求在0.01In~Imax范围内建成误差,见GB17883-19990.2S 0.5S交流静止式有功电度表。

目前国家标准中只规定了检测范围,并未指定具体负荷电流点。

最近正在起草国家的电能表型式评价大纲,规定大约如下:平衡负载1:Imax, In, 0.5In, 0.05In, 0.01In 0.5L和0.8C :Imax, In, 0.5In, 0.1In, 0.02In 不平衡负载1Imax, In, 0.5In, 0.05In 0.5LImax, In, 0.5In, 0.1In实际上,在小量程时仪表的误差有可能是很大的一个值,这也是要求仪表检测时,常用量程要用到满量程的2/3左右的最好的原因。

而0.5S(0.2S)是要求每一点的相对误差都要在0.5(0.2)级,即每一点的绝对误差与这一点的测量范围的比值要达到0.5%(0.2%),而不是每一点的绝对误差与满量程的比值达到0.5%(0.2%)。

前者就是0.5S(0.2S)级,后者就是0.5(0.2)级。

如果不对,还请各位指教按GB/T 17883的注解:IEC 60185对测量范围在0.05In~1.2 In或0.05In~1.5 In或0.05In~2 In的互感器以及准确度等级为0.2S和0.5S表与所连接互感器的测量范围必须是相同的,且只有等级为0.2S和0.5S的互感器具有本标准中工作仪表的准确度要求时,仪表的测量范围才能是0.01In~1.2 In。

PA 123/PA 145 Current transformer Installation and operation manualYour safety first!This is the reason why our instruction begins with the following guidelines:−Use the transformer for its intended purpose.−Observe the technical data given in the rating plate and in the specification.−To facilitate and ensure high quality standards, the installation should be carried out by trained personnel or supervised by the service department of ABB.−Operations have to be carried out by specially trained electri-cians who are familiar with the following instructions.−It is recommended to observe the standards (DIN VDE/IEC) and local H&S regulations as well as the requirements of the local electric authority.−Transformer work should be changed over in accordance with the instructions in the manual.−All documentation should be available to all persons involved in installation, maintenance and operation.−Operating personnel shall bear all responsibility for all aspects related to the operational safety as stated in EN 50110 (VDE 0105) and national regulations.−Observe the safety rules, which are compliant with EN 50110 (VDE 0105) standard on ensuring a dead state at the site of works carried out on a transformer.If you have any questions regarding the information contained in this manual, our organisation will provide the necessary information.Important informationThis manual is intended to explain the mode of operation andinstallation of the product.Operating the device without reading the manual may entail prop-erty damage, serious injury or death. The person responsible for the installation of the device should read the following instructions and follow the recommendations contained herein.For your own safety:−Make sure that all installation, service and maintenance works are performed by professionals.−Make sure that during all the phases (installation, service, up-keeping) all applicable regulations will be preserved.−Ensure that the guidelines contained in this manual are followed.Basic guidelines for this manualRead the relevant chapters of this manual to provide adequate operation. Chapters are marked according to their significance.2 PA 123/PA 145 Current transformerTable of contents1. Introduction (4)2. Transformer delivery (4)3. Transportation, unpacking, lifting (4)4. Storage (5)5. Installation (5)5.1. Earthing terminals (5)5.2. Primary terminals (5)5.3. Secondary terminals (5)6. Bolt tightening torques (6)7. Operation and maintenance (6)7.1. Operation (6)7.2. Corrosion protection (8)8. Transformer construction (8)9. Disposal (9)9.1. Recycling and disposal proceedings (9)10. Check list (10)10.1. Before first energising (10)10.2. After first energising (10)11. End (11)PA 123/PA 145 Current transformer 3PA 123/PA 145 Current transformer1. IntroductionThe subject of this manual are type PA 123 and PA 145 overhead current transformers. These transformers are used for feeding measurement and protection systems in power networks with maximum system voltage of 123 kV and 145 kV or lower (the greatest effective value of phase-to-phase voltage) and 50 Hz fre-quency. They are designed either to operate in grids with effectively earthed or insulated neutral points or in compensated networks.2. Transformer deliveryTypically, the transformers are delivered in bulk packaging (3 pcs) where they are stacked vertically. The packaging is in the form of a complete crate.The delivered transformers are fully assembled, tested and ready for direct use. Product testing protocols are delivered together with the transformers.Immediately after delivery, check whether the transformer has not been damaged during transportation. Check the transport pack-aging. Damaged packing may point out to careless handling of the transformer. Next, check the transformer itself. Special atten-tion should be paid to possible damage of sheds and binder at insulator flanges, to the tightness of the transformer and the cor-rect oil level indication in the device.One should ensure that technical parameters of the transformer given in the rating plate are in accordance with the parameters given when submitting the order and in accordance with the design documentation parameters.Any damage found or other error should be immediately notified to the manufacturer, and, if appropriate, the carrier. Sending pho-tos of damage will be helpful in its assessment.3. Transportation, unpacking, liftingTransformers may be transported in either vertical or horizontal position.In the case of horizontal transportation, transformers should be transported on a special bed in accordance with the method as shown in Figure 1. Additionally, before laying the transformer, restrain its compensation bellows by inserting a flexible disc made of, for example, polyurethane foam, under the bellows cover. Dur-ing horizontal transportation, the compensation bellows cannot have any freedom of movement due to their flexibility and possibil-ity of damage.In vertical transportation, due to the high position of the centre of gravity, the transformer should be transported on arms or plat-forms expanding spacing of the base. Those elements shall be removed before setting the transformer on the support structure (in the working location).Transformers should be lifted with a crane with appropriate load capacity using two slings of the same length (min. 1.5 m). Hooks should be attached to the openings designed for that purpose located in the transformer head enclosure (see Fig. 1).Packing method for horizontal transformer transport4 PA 123/PA 145 Current transformer4. StorageTransformers should be stored on a levelled and hardened surface, preferably in the original packaging. In the case of long-term storage, it is recommended to protect contact surfaces against corrosion.Transformers can be stored in the open air for up to two years. If this period is exceeded, it is recommended to place transformers in a well-ventilated room or under a roof, and to insert silica gel or another moisture absorbent into terminal boxes.5. InstallationThe support structure should be flat and horizontal. Levelling correction can be performed using distance washers, placing them between the transformer and the structure. Observe the notes given in item 3 while shifting the transformer. It should be fastened to the structure with screw elements of an adequate size. The support structure and fastening elements are not included in the delivery.The transformer should be placed in the vertical position at least 24 h before energising.5.1. Earthing terminalsTwo earthing terminals are found on the base of the transformer across its diagonal. Prior to connection, the contact surface of the terminals should be thoroughly cleaned from oxide layers so it becomes uniform and smooth. Additionally, a thin layer of con-ducting grease can be applied in order to improve contact. The earthing should be connected with stainless bolts.5.2. Primary terminalsPrimary terminals of the transformer, marked as P1 and P2, are placed on the opposite sides of the head. In the case of recon-nectable transformer, up to 3 P2 terminals can be found on the primary side, marked with respective values of the rated primary current.Reconnection of the primary winding to the required current range is performed by placing a detachable terminal (bolt or flat) in the location marked with the respective current value. These terminals should be fastened to the transformer with four supplied M12 bolts. Contact surfaces should be cleaned beforehand.All contact surfaces of the primary terminals should be even and cleaned from the oxide layer before connecting. In the case of copper terminals, use of extraction naphtha is usually sufficient. Conducting grease can be applied in order to improve contact. The line cable terminals should be tightened with M12 bolts (stainless bolts are recommended) to such prepared terminals. An incorrectly performed primary connection will lead to excessive heating of the transformer, which can cause its damaging. Primary connections should be made in such a way so as to minimise mechanical static loads of the transformer terminals. It is recom-mended to use flexible elements as rigid connections may cause damage of the transformer. The maximum allowable static load of each transformer terminal is equal to 3,600 N in any direction. At the same time, only one terminal can be loaded with such force. Also, it is recommended to maintain the sum of the loads acting on the primary terminals during normal operation of the trans-former below 50% of such a value.5.3. Secondary terminalsSecondary windings are connected to terminal blocks placed in the terminal box on the bottom of the transformer. These are typi-cally Phoenix ST spring connectors with terminals adapted to connection of cables of cross-section up to 10 mm2 or up to 6 mm2. Each terminal is described in accordance with winding markings given on the rating and schematic diagram plates. Yellow-green terminals (with the earthing mark) are intended for earthing secondary windings with the use of pushed crosswise bridges. The crosswise bridge can be removed with a screwdriver, by inserting it in the slit and levering.Optionally, the connectors to which metering windings are led may be adapted for sealing with use of a transparent cover.The current coil screen is led out with a pin through the resin bushing (tg δ terminal).A rating plate is placed on the external side of the door, while the schematic diagram plate is placed inside.In the bottom wall of the terminal box, there is a plate with open-ings for glands for secondary circuits’ connection cables. In the typical execution, they are two M40 glands with the choking range of Ф19 mm – Ф28 mm.An example of a terminal box for secondary windings of the trans-former is shown in Figure 2.PA 123/PA 145 Current transformer 56 PA 123/PA 145 Current transformerConnect external circuits to secondary terminals of the voltage module of the transformer pursuant to the design documents and wiring shown on the schematic diagram plate.The current coil screen terminal (tg δ) should be earthed with a jumper during normal transformer operation.Connectors inside the terminal box are arranged so that, when using crosswise bridges, earthing is possible for any secondary terminal of a given winding.−Transformer with taps on the secondary side:In the case of a transformer with reconnection on the secondary side, unused taps should remain unearthed, and only one of the terminals, to which circuits are connected for a given secondary winding, should be earthed. −Unused windings:Utmost terminals (with reconnection on the secondary site, these are terminals corresponding to the highest ratio) of the unused secondary winding should be shorted with each other (with a cable of minimum cross section of 6 mm 2) and earthed with a crosswise bridge. Each unused winding should beearthed in only one point.6. Bolt tightening torquesPrimary terminal bolts M1260 Nm Bolts fastening the transformer to the support structure280 Nm7. Operation and maintenance7.1. OperationTransformers do not require special servicing. Visual inspection is usually sufficient. The check-list is placed at the end of this manual.Visual inspection:Visual inspection should be based on:−the position of the oil level indicator,−tightness of the transformer,−lack of mechanical damage,−condition of the insulator and binder connecting the insulator with flanges.Occasionally, check the tightening degree of the primary terminals.The transformer tightness is a particularly important criterion as in the case of oil leaks moisture can penetrate the device. Small insulator damage may be repaired on site.Oil level indicator:Changes of the position of the oil level indicator depend on oil temperature in the transformer. The position of the indicator should be in the green field range. Shifting of the indicator to the upper or bottom red field points out to incorrect transformer oper-ation. In such a case, the transformer should be put out of service, and the manufacturer should be contacted.On the lid covering the head stainless steel expansion bellows (1) are placed, used for compensation of oil volume thermal changes in the transformer. The oil level indicator (2) is placed on the upper surface of the bellows. The bellows are placed in a metal cover (3) equipped with a view-finder (4). Cover removal does not result is unsealing of the transformer. The whole compensation system is shown in Figure 3.Position of the oil level indicator Interpretation Indicator in the green area Correct transformer operationIndicator on the upper red fieldOil pressure too highTransformer over heatingOil gasification(insulation failure)Further inspection necessary Indicator on the lower red fieldOil level too lowSuspicion of oil leakage (moisturemay penetrate inside)Further inspection necessaryMeasurement of the dielectric loss factor tgδ:During measurement of the dielectric loss factor tg δ, the measur-ing bridge should be connected to the correct terminal marked with the tg δ symbol. One should remember to earth it after per-forming the measurement. Usually, the test voltage should equal 10 kV RMS, and it should be applied across transformer primary terminals and earth.1243Fig. 3. Construction of the compensation systemPA 123/PA 145 Current transformer 78 PA 123/PA 145 Current transformerOil sampling:Due to the fact that transformers are air-tight, they do not require periodical oil checking. Oil used in the transformer meets the requirements of the PN-EN 60296 (IEC 60296) standard.It is recommended to check the oil after 15–20 years of operation or after a non-conformity state if there are suspicions as to trans-former efficiency.Contact the manufacturer in order to obtain necessary instructions concerning oil sampling. If oil samples are taken during the guar-antee period without the manufacturer’s permission, the device loses its guarantee.7.2. Corrosion protectionExternal elements of the transformer casing are made in the form of aluminium alloy casts, resistant to corrosion. Casts can be unpainted or painted. Typical colours in the case of painted casts include light-grey (RAL 7035) or grey-green (RAL 7033). While remaining metal elements, such as bolts, are made of stainless steel.8. Transformer constructionPA 123 or PA 145 type current transformer comprises a current coil in a tight enclosure filled with transformer oil.This is a "top core" type structure where the magnetic toroidal cores are located in the transformer head. The cores withsecondary windings are additionally encapsulated in a metal can connected via a tube to terminal box tg δ terminal. Both the metal can as well as the tube are insulated with oil impregnatedelectrical grade paper. The distribution of electric stresses in the paper insulation is capacitor controlled. En exterior screen is located external to the coil, connected to the primary terminal inside the head.Such a coil structure provides the following advantages:protection of devices connected to the terminal in the event of primary insulation perforation, equalisation of electrical stresses in primary insulation and a facility for measuring the tg δ coefficient on the primary insulation only.Fig. 4. PA 123 and PA 145 current transformers structure 1. base2. hollow insulator3. head4. e xpansion bellows in casing5. opening coil6. s econdary coils terminal box7. P2 primary terminals8. P1 primary terminal9. m ounts for fastening thetransformer 10. h oles for lifting the unit 11. oil level indicator1234567981011The transformer primary insulation constitutes electric grade paper dried at a high temperature and high vacuum impregnated with transformer oil. The free spaces inside the transformer are filled with transformer oil.External insulation comprises a hollow insulator made out of elec-trical porcelain with brown enamel or a glass reinforced plastic (FRP) tube coated with grey silicon rubber.The seals in the transformer are of the o-ring type, and they are made of NBR oil-resistant rubber.If calibration of measuring windings has been performed, addi-tional respective markings (designations) have been placed on the transformer and the rating plate (where required).9. DisposalDuring correct operation and when no mechanical damage occurs, the transformer should operate over 30 years. Once this period of time has expired or if operation is no longer required, it is recommended to dispose of the transformer.Primary materials used in the transformer:Item Material Quantity [kg] 1Copper (Cu – ETP)20 2Aluminium alloy AC-Al Si10Mg (Cu)80 3Steel20 4Transformer plate50 – 150 5Permalloy (iron-nickel alloy)10 6Mineral transformer oil120 7Electrical grade paper25 8Solid insulation materials (epoxy resin, bakelitepaper)10 9Porcelain80 10Composite insulator20 Items 9 and 10 alternatively.Above values are approximate.9.1. Recycling and disposal proceedingsRecycling and disposal should meet national (or local) regulations. On the territory of the Republic of Poland, the manner by which the transformer should be recycled and disposed is defined in the Waste Act of 14 December 2012, published in Journal of Laws, 2013, item 21, as amended.PA 123/PA 145 Current transformer 910. Check list10.1. Before first energisingWhat to check:When Check: 1. E xternal packing appearance A No signs of careless handling2. Transformer tightness A, B, CNo visible oil leaks or greasy stains (even if the packing is intact)3. Transformer housing B, C Insulator, terminals and housing of the transformer show no signs ofmechanical damage.4. Oil level B, C Oil level indicator is in the proper position5. Quality and correctness of performed connections C Performed connections are reliable and in accordance with the design10.2. After first energisingWhat to check:When Check: 6. Transformer tightness D, E No visible oil leaks or greasy stains7. Transformer housingD, E Insulator, terminals and housing of the transformer show no signs of mechanicaldamage.8. Oil level D, E Oil level indicator is in the proper position9. S econdary winding insulation test (measurement methoddepends on local practices)E Values dependent on age, voltage level, measurement method and temperature10. D ielectric loss factor tg δ (measurement method dependson local practices)E Values dependent on age, voltage level, measurement method and temperatureRespective terminals are marked as: …tg δ”11. O il sampling: gas analysis (DGA), tg δ, water content EMeasurements did not indicate exceeding of permissible limitsWhenA After arrival of the transformer to the final locationB After unpackingC Directly before applying voltageD During routine inspection in accordance with the schedule determined for the stationE After 15–20 years or inspection of efficiency after the non-conformity state if there are suspicions as to transformer efficiency11. EndFor additional information concerning the operation and mainte-nance of type PA 123 and PA 145 transformers, please contactthe transformer manufacturer.10 PA 123/PA 145 Current transformerNotesPA 123/PA 145 Current transformer 112129P L 969-W 1-e n . E d i t i o n 01.2014For more information, please contact:ABB Contact Center Phone: +48 22 22 37 777e-mail:**************.comABB Sp. z o.o.Branch Office in Przasnysz ul. Leszno 5906-300 PrzasnyszPhone: +48 22 22 38 931, +48 22 22 39 255 Fax.: +48 22 22 38 958www.abb.plWe reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB Sp. z o.o. does not accept any responsibilitywhatsoever for potential errors or possible lack of information in this document.We reserve all rights in this document and in the subject matter and illustrations contained herein. Any reproduction, disclosure to third parties or utilisation of its contents – in whole or in parts – is forbidden without prior written consent of ABB Sp. z o.o.© Copyright 2014 ABB All rights reserved。

JING KE40.5 〜550kVSF6电流互感器安装、运行、维护使用说明书M C13000001中国江苏精科智能电气股份有限公司1.适用范围和产品用途1.1适用范围本安装使用说明书对SF6电流互感器的使用条件、技术参数、产品结构、交接、安装、使用与维护等方面作出了具体规定,敬请您在安装之前详细阅读。

1.2产品用途本公司制造的SF6电流互感器适用于额定电压分别为35、110、220、500kV,额定频率为50Hz的交流电力系统中作电流、电能计量、测量及母差保护、过流保护、距离保护等作用。

1.3型号说明如220kV SF6气体绝缘电流互感器:L V Q B T --- 252(220)(GY)W2(3)」皿级防污(W级防污)咼原型设备最高电压(额定电压)kV -------------------- 带暂态保护绕组稳态保护气体绝缘--------------------------------------------- 倒置式结构电流互感器2.使用条件2.1设备种类户外2.2环境温度最高温度+45 C日平均最高温度+35 C2.3海拔<2000m (特殊产品不超过3500m )2.4 大气条件 大气中无严重影响互感器绝缘的污秽、侵蚀性和爆炸性介质2.6 最大风速35m/s8 度(水平加速度 0.25g 、垂直加速度 0.125g ) 1.673. 技术参数设备最高电压: 40.5、126、252、550 kV 额定电压: 35、110、220、500kV额定一次电流:100 〜5000、2 X50 〜2 X 2000 A(500kV 产品可满足w 2 X 5000 A ) 额定二次电流:1 、 5 A额定负荷:20 /准确限值系数: 100VA 10 〜 40 仪表保安系数: FS5、 FS10测量绕组的准确级: 0.2S 、0.5S 、0.2、0.5 稳态保护绕组的准确级: 5P 、10P 、5PR 、10PR 暂态保护绕组的准确级: TPS 、 TPY二次绕组个数: 1〜8个各准确级的误差限值见 GB1208 — 2006《电流互感器》、GB16847-1997《保 护用电流互感器暂态特性技术要求》 。

电流互感器使用说明

一、总述:

GLQ-1电流互感器适用于海拔不超过1000m,-20℃~75℃的环境温度范围的非暴露安装场合。

工作环境无明显灰尘、烟、腐蚀性气体、蒸气或盐等污秽。

无异常振动。

GLQ-1电流互感器适用于三相300A以内的一次系统,将一次系统的高电压和大电流按比例变换成低电压和小电流,供给测量仪表和保护装置使用。

二、额定值:

2.1 额定一次电流范围: 150~300A

2.2 最大允许电流: 1000A 瞬间

2.3额定二次电流范围: 18.8±0.1 ~ 37.5±0.1mA

2.4三相不平衡度: <2% (0.1mAMax)

2.5额定负载: 30欧姆

2.6匝间绝缘: 4500V~

2.7相间绝缘: 3000V~

三、安装及使用注意:

3.1、电流互感器工作时二次回路不得开路;不能装设熔断器;一般不进行切换,若需要切换时,应有防止开路的可靠措施。

3.2、二次侧有一端必须接地。

3.3、连接时要注意次级极性,使二次电流产生的磁通势对一次电流产生的磁通势起去磁作用,励磁电流甚小,以保证互感器铁芯中的总磁通很小。

本电流互感器一次回路高端接输入,低端为输出。

上海光通电器厂有限公司

2010/3/10。

低压电流互感器招标文件(专用和通用2部分)技术规范专用部分1.总则1.1本技术规范书适用于低压电流互感器的采购。

1.2本技术规范书参照现行的国家、行业标准及规程和公司的有关规定提出。

对没有提到的技术条件及内容,均应满足0.2S级计费用低压电流互感器执行标准的要求。

若其中某一指标在各标准中有不同规定时,则选取其中最高值。

2.引用标准GB20840.2-2014互感器第2部分:电流互感器的补充技术要求JJG313-2010测量用电流互感器检定规程JB/T5472仪用电流互感器DL/T725-2013 电力用电流互感器使用技术规范DL/T 448-2000 电能计量装置技术管理规程GB/T16927.1高电压技术(第一部分)GB/T16927.2高电压技术(第二部分)GB/T15239 孤立批计数抽样检验程序及抽样表Q/GDW572-2010 计量用低压电流互感器技术规范《计量器具条码编码规则》3.技术要求(不特别声明时,环境类别和严酷等级按P级(普通级)对待)产品应根据使用环境类别满足各自的严酷等级要求,并按海拔、环境温度、湿热、日照辐射、霉菌、盐雾等类别的等级标注,P级(普通级)项目不必标注, A级(提高级)项目必须标注。

3.1准确度等级: 0.2S级;3.2额定电压:0.66 kV3.3额定绝缘水平:0.72 kV /3kV ;3.4 额定电流:(50~800)A /5A3.5绝缘要求:3.5.1工频耐压一次绕组(或可能与一次导体接触的外壳表面)对二次绕组及接地底板、二次绕组对接地底板的工频耐受电压为3kV,试验时间1min,互感器应无击穿或闪络发生。

3.5.2匝间绝缘强度二次绕组开路,一次绕组通以额定最大一次电流并维持1min,互感器二次绕组的匝间绝缘无损坏。

3.5.3绝缘电阻用500V兆欧表测量各个绕组之间和个绕组对地的绝缘电阻,应符合JB/T5472第6.7款要求,一次绕组(若有)与二次绕组及接地端子之间的绝缘电阻不低于100MΩ;二次绕组对接地的金属外壳绝缘电阻不低于30MΩ。

低压电能计量用电流互感器0.5S级0.2S级安科瑞电气股份有限公司张小莉工业计量高精度电流互感器分为0.5S和0.2S级普通配电用电流互感器分为0.5级和0.2级其区别在于:0.5S(0.2S)级的精度比0.5(0.2)级高。

带S的是特殊的电流互感器,要求在1%-120%负荷范围内精度足够高,一般取5个负荷点测量其误差小于规定的范围。

精度高指S型能在更宽的电流范围内保证准确度,主要指下线电流。

一般的电流互感器要求在0.02In~Imax 范围内建成误差,见GB/T17215和15283;而S型的电流互感器则要求在0.01In~Imax范围内建成误差,见GB17883-19990.2S 0.5S交流静止式有功电度表。

目前国家标准中只规定了检测范围,并未指定具体负荷电流点。

最近正在起草国家的电能表型式评价大纲,规定大约如下:平衡负载1:Imax, In, 0.5In, 0.05In, 0.01In 0.5L和0.8C :Imax, In, 0.5In, 0.1In, 0.02In 不平衡负载1Imax, In, 0.5In, 0.05In 0.5LImax, In, 0.5In, 0.1In实际上,在小量程时仪表的误差有可能是很大的一个值,这也是要求仪表检测时,常用量程要用到满量程的2/3左右的最好的原因。

而0.5S(0.2S)是要求每一点的相对误差都要在0.5(0.2)级,即每一点的绝对误差与这一点的测量范围的比值要达到0.5%(0.2%),而不是每一点的绝对误差与满量程的比值达到0.5%(0.2%)。

前者就是0.5S(0.2S)级,后者就是0.5(0.2)级。

如果不对,还请各位指教按GB/T 17883的注解:IEC 60185对测量范围在0.05In~1.2 In或0.05In~1.5 In或0.05In~2 In的互感器以及准确度等级为0.2S和0.5S表与所连接互感器的测量范围必须是相同的,且只有等级为0.2S和0.5S的互感器具有本标准中工作仪表的准确度要求时,仪表的测量范围才能是0.01In~1.2 In。

LMZ,LMK,SDH,LQZ系列电流互感器产品说明书保定尚源电力科技有限公司目录1,LMZ1/LMZJ1-0.5型电流互感器2,(BH)LMK2-0.66型电流互感器3,LMZ1-0.66型电流互感器4,SDH-0.66型电流互感器5,LQZ-0.66型电流互感器LMZ1/LMZJ1-0.5型电流互感器一,概述LMZ1-0.5 系列电流互感器供额定频率为50Hz、额定电压为0.5kV 及以下的交流线路中作电流、电能测量或继电保护用. 本型互感器为浇注绝缘式,穿心母线型电流互感器,下部有底座,供固定安装之用。

二.型号含义L M Z 1 J-0.5额定电压(KV)加大容量设计序号浇注式母线(排)型电流互感器三,使用环境条件1,互感器安装海拔高度不超过1000米2,环境温度:-5℃~40℃且平均不超过30℃3,额定电压:0.5KV 0.66KV4,互感器安装场所应干燥通风,空气相对湿度不大于80%且周围无侵蚀性和爆炸性的介质四,主要技术参数和安装尺寸图1 图2型号¢ A B L A1 C H 外形图LMZ1-0.530 --90 85 45 115 图135 --90 85 45 115 图140 --97 85 45 120 图145 --97 85 45 120 图1 LMZJ1-0.530 38 8 90 85 45 115 图240 52 10 100 85 45 130 图250 62 12 115 85 50 140 图2-100 50 171 85 36 152 图3-140 70 216 150 43 181 图3图3安装尺寸主要技术参数型号额定电流比(A)额定电压(KV)准确级额定负荷(V A)一次穿心匝数LMZ1-0.55/50.5 0.5 53010/5 15 15~20/5 10 30~40/5 5 50/5 3 75~100/5 2 150~200/51 250~300/5400/5LMZJ1-0.55/50.5 0.5 53010/5 15 15~20/5 10 30~40/5 5 50/5 3 75~100/5 2 150/51 200/5300/5400/5500~600/50.5 0.510800/51000~1500/5 20我公司特别推荐高精度S 级电流互感器(BH)LMK 2-0.66型电流互感器 一,概述LMK-0.66系列产品适用于额定频率50Hz ,额定电压0.66kV 及以下电力系统中作电能计量、电流测量和继电保护用。

本型互感 器用于户内配电柜、箱内部型,电流互感器为母线型塑料壳式绝缘,产品下部有安装板供固定安装用,中间窗孔供一次母线排通过用。

本产品是绿色环保型 。

二,型号含义L M K 2- 0.66额定电压(KV)设计序号2000~2500/53000/530型 号 额定电流比(A ) 额定电压(KV ) 准确级 额定负荷(V A )一次穿心匝数LMZ 1-0.55/50.50.2530 10/5 1515~20/5 10 30~40/5 5 50~75/5 1 2.5 1100/5 0.5S 5 150~200/5 0.2 300~400/5 0.2S500~600/510外壳为开口式母线(排)型电流互感器三,使用环境条件1,互感器安装海拔高度不超过1000米2,环境温度:-5℃~40℃且平均不超过30℃3,额定电压:0.5KV 0.66KV4,互感器安装场所应干燥通风,空气相对湿度不大于80%且周围无侵蚀性和爆炸性的介质四,主要技术参数和安装尺寸图1 图2图3安装尺寸型号¢ AB A1 A2 CH 外形图LMK 2-0.66/302330.5 11 33 59 30 78 图2 30 - - 33 59 30 78 图123 30.5 11 28 59 42 78 图2 23 30.5 11 36 68 37 82 图223 30.5 11 46 75 43 96 图2 LMK 2-0.66/40 30.5 42 11 43 78 4497 图2LMK 2-0.66/6045 61.5 20.5 43101 45 127 图2 LMK 2-0.66/805282 10 60118 44 134 图3LMK 2-0.66/100 62 102 128014444137图3型 号 额定电流比(A ) 额定电压(KV ) 准确级 额定负荷(V A ) 一次穿心匝数LMK2~0.66/305/50.661 2.515 10/5 10 15/5520/5 4 30/5 3 40~60/5275~100/5 1 150/5 0.5 200~300/55LMk2~0.66/40 5/50.66 12.5 1510/510 15/5 5 20/54 30/5 340~60/52 75~100/5 1150/5 0.5 200~400/5 5 500~800/5 10 LMK2~0.66/60 200~400/5 0.66 0.5 5 1500~800/510主要技术参数LMZ1-0.66型电流互感器一,概述LMZ1-0.66系列电流互感器供额定频率为50Hz、额定电压为0.66kV及以下的交流线路中作电流、电能测量或继电保护用. 本型互感器为浇注绝缘式,穿心母排型电流互感器,上端有安装螺丝供固定用二.型号含义L M Z 1- 0.661000/50.2151200~1500/5 202000~2500/5 40LMK2~0.66/80600~800/50.660.5 1011000/50.2151200~1500/5 202000~2500/5 40LMK2~0.66/100800/50.660.5 1011000/50.2151200~1500/5 202000~3000/5 40额定电压(KV)设计序号浇注绝缘式母排式电流互感器三,使用环境条件1,互感器安装海拔高度不超过1000米2,环境温度:-5℃~40℃且平均不超过30℃3,额定电压:0.5KV 0.66KV4,互感器安装场所应干燥通风,空气相对湿度不大于80%且周围无侵蚀性和爆炸性的介质四,主要技术参数和安装尺寸安装尺寸型号 A B A2 C HLMZ1-0.66 34 15 92 90 115 42 16 97 90 116 52 20 102 90 120 62 20 102 90 120 102 25 153 90 127 122 32 184 90 133LMZ1-0.66 34 34 92 90 135 64 25 124 90 135 137 40 207 90 150 204 40 274 90 150技术参数型号额定电流比(A)额定电压(KV)准确级额定负荷(VA)LMZ1-0.66150~200/50.66 0.55 250/5300/5400500~600/510800~51000~1600/5 15LMZ1-0.66200~400/50.66 0.510 500~800/51000~1250/515 1000~3000/51500/52000~3150/5 20SDH-0.66型电流互感器一,概述SDH-0.66系列产品适用于额定频率50Hz,额定电压0.66kV及以下电力系统中作电能计量、电流测量和继电保护用。

本型互感器用于户内配电柜、箱内部型,电流互感器为母线型塑料壳式绝缘,产品下部有安装板供固定安装用,中间窗孔供一次母线排通过用。

本产品是绿色环保型。

二,型号含义S D H 0.66额定电压(KV)互感器电流塑料外壳三,使用环境条件1,互感器安装海拔高度不超过1000米2,环境温度:-5℃~40℃且平均不超过30℃3,额定电压:0.5KV -0.66KV4,互感器安装场所应干燥通风,空气相对湿度不大于80%且周围无侵蚀性和爆炸性的介质四,主要技术参数和安装尺寸安装尺寸型号 A B A1 A2 H h C SDH-1 42 32 45 79 104 44 4652 32 54 87 106 45 45SDH-2 62 32 42 102 111 44 4562 52 50 100 141 63 46SDH-3 82 32 60 122 118 50 4582 52 60 119 141 63 46SDH-4 102 32 74 140 123 51 50102 52 80 141 150 67 50 SDH-5 122 52 54 168 153 69 49132 52 81 177 150 67 49 SDH-6 170 50 160 250 160 77 51200 60 180 245 150 70 55型号额定电流比(A)额定电压(KV)准确级额定负荷(V A) SDH-1 200~400/50.66 0.5 5500~800/510SDH-2 300~400/50.66 0.5 5500~800/50.5 101000/5 0.2 15SDH-3 600~800/50.66 0.5 101000~1200/50.2 15SDH-41000~1200/50.660.2151500/5 15SDH-51500~2000/50.660.2202500~3000/530SDH-6 2500~3000/50.660.230技术参数4000~5000/540LQZ-0.66型电流互感器一,概述LQZ-0.66型电流互感器用于户内,供额定电压660V,额定频率50Hz 的交流电路中作电流、电能测量和继电保护用。

LQG(LQZ)-0.66电流互感器是我公司为小电流(5~150A)免去用户穿心多匝的麻烦而新开发的产品,具有用铜排布线能直接连接、安装方便、容量大等特点。

二,型号含义L Q Z 0.66额定电压(KV)浇注式图片2 带铜排电流互感器三,使用环境条件1,互感器安装海拔高度不超过1000米2,环境温度:-5℃~40℃且平均不超过30℃3,额定电压:0.5KV -0.66KV4,互感器安装场所应干燥通风,空气相对湿度不大于80%且周围无侵蚀性和爆炸性的介质四,主要技术参数和安装尺寸图1额定电压:0.66kV额定频率:50Hz额定一次电流:5-125A 额定二次电流:5A 准确级:0.5S,0.2级,0.5级二次输出:5VA, 10VA.图2额定电压:0.66kV额定频率:50Hz额定一次电流: 5-2000A 额定二次电流:5A准确级:0.2S,0.2级 ,0.5级,0.5S级二次输出:5VA,10VA,20VA(注:文档可能无法思考全面,请浏览后下载,供参考。

可复制、编制,期待你的好评与关注)。