技术说明书-STC100温度控制器-径向

- 格式:doc

- 大小:934.50 KB

- 文档页数:8

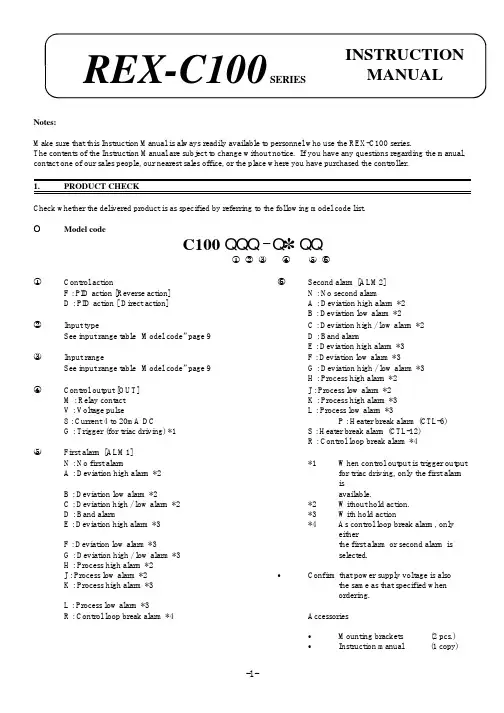

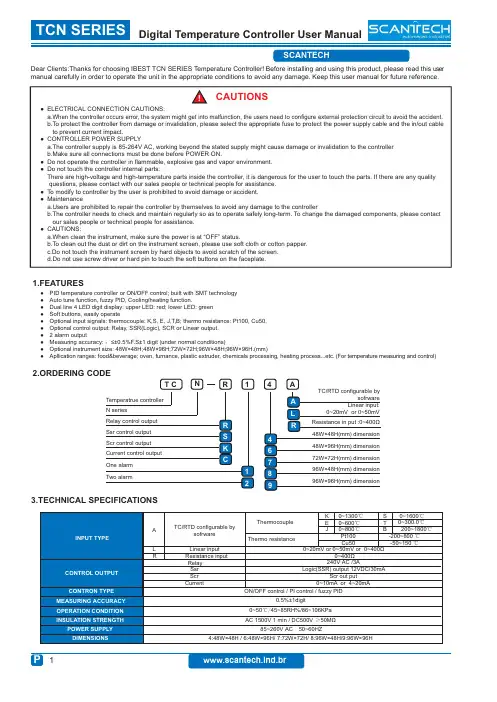

Notes:Make sure that this Instruction Manual is always readily available to personnel who use the REX-C100 series.The contents of the Instruction Manual are subject to change without notice. If you have any questions regarding the manual,contact one of our sales people, our nearest sales office, or the place where you have purchased the controller.1.PRODUCT CHECKCheck whether the delivered product is as specified by referring to the following model code list.OModel codeC100 QQQ - Q ~ QQÎ Ï Ð Ñ Ò ÓÎControl actionÓSecond alarm [ALM2]F : PID action [Reverse action]N : No second alarmD : PID action [ Direct action]A : Deviation high alarm *2B : Deviation low alarm *2ÏInput typeC : Deviation high / low alarm *2See input range table “Model code” page 9D : Band alarmE : Deviation high alarm *3ÐInput rangeF : Deviation low alarm *3See input range table “Model code” page 9G : Deviation high / low alarm *3H : Process high alarm *2ÑControl output [OUT]J : Process low alarm *2M : Relay contact K : Process high alarm *3V : Voltage pulseL : Process low alarm *38 : Current 4 to 20mA DCP : Heater break alarm (CTL-6)G : Trigger (for triac driving) *1S : Heater break alarm (CTL-12)R : Control loop break alarm *4ÒFirst alarm [ALM1]N : No first alarm*1When control output is trigger output A : Deviation high alarm *2for triac driving, only the first alarm isB : Deviation low alarm *2available.C : Deviation high / low alarm *2*2Without hold action.D : Band alarm*3With hold actionE : Deviation high alarm *3*4As control loop break alarm, only eitherF : Deviation low alarm *3the first alarm or second alarm is G : Deviation high / low alarm *3selected.H : Process high alarm *2J : Process low alarm *2CConfirm that power supply voltage is alsoK : Process high alarm *3the same as that specified when ordering.L : Process low alarm *3R : Control loop break alarm *4Accessories C Mounting brackets (2 pcs.)CInstruction manual(1 copy)REX-C100SERIESINSTRUCTION MANUALFig. 1Fig. 22.MOUNTING •DimensionsUnit : mm (inch)* Dimensions in inches are shown for reference•Mounting proceduresThickness of panel board:1 to 5mm or 5 to 9mm (0.04 to 0.20 inch or 0.20 to 0.35 inch)uWhen the controllers are mounted on panel with 1 to 5mm in thickness ÎMake a rectangular cutout corresponding to thenumber of controllers to be mounted on panel by referring to the panel cutout dimensions.ÏSince the mounting brackets are already installed onthe controller, insert the controller into the panel from the panel front without removal of the brackets (Fig. 1).uWhen the controllers are mounted on panel with 5 to 9m in thickness ÎRemove the mounting brackets from the controllerwith a slotted screwdriver.ÏEngage each mounting bracket with holes markedwith “5.9" on the housing (Fig. 2) and then insert the controller into the panel from the panel front.OCautions for mountingMo untingbracketAvoid the following location where the controller is mounted.C Location where ambient temperature is more than 50E C (122E F) or less than 0E C (32E F).C Location where humidity is high.C Location where corrosive gas is generated.C Location where strong vibration and shock exist.C Location where flooding and oil splash exist.C Location where much dust exists.CLocation where inductive disturbance is large and otherlocation where bad influence is exerted on electric instrument.3.WIRING•Rear terminalsNotes1.Terminals which are not used according to the controller type are all removed.2.For thermocouple input, no metal piece is attached to terminal No. 10. Instead, the temperature compensationelement in the internal assembly is projected through a hole at terminal No. 10.Do not damage the above temperature compensation element when the internal assembly is removed from the case.O Cautions for wiring(1)Conduct input signal wiring away from instrument, electric(3)For wiring, use wires conforming to domesticequipment power and load lines as such as possible to avoid standard of each country.noise induction.(4)About 5 to 6 sec. are required as the(2)Conduct instrument power wiring so as not to be influenced preparation time of contact output duringby noise from the electric equipment power.power ON. Use a delay relay whenthe outputIf it is assumed that a noise generation source is located near line, is used for an external interlock circuit.the controller and the controller is influenced by noise, use anoise filter (select the filter by checking instrument power(5)The figures below show the REX-C100 circuit supply voltage.)configuration. When connecting wires, notethat the power, input, MCU and output circuitsC Sufficient effect may not be obtained depending on the are isolated independently, while the inside offilter. Therefore, select the filter by referring to its the input and outputcircuits are not isolated.frequency characteristic, etc.ÎFor instrument power wiring, if it is assumed that noiseexerts a bad influence upon the controller, shorten thedistance between twisted power supply wire pitches.(The shorter the distance between the pitches, the moreeffective for noise reduction).ÏInstall the noise filter on the panel which is alwaysgrounded and minimize the wiring distance between thenoise filter output side and the controller power terminals.Otherwise, the longer the distance between output sideand instrument power terminals, the less effective for REX-C100 circuit configurationnoise.ÐDo not install fuses and / or switches on the filter outputsignal since this may lessen filter effect.WIRING AND NAME OF PARTS•Wiring exampleREX-C100F GG-M*-~2N-HA OF PARTSÑSet-value increment keyC Used when the number needs to be increasedfor set-value change.ÒMeasured-value (PV) display unit [Green]C Displays measured-value (PV)C Displays a parameter symbol in the parametersetting mode.ÓSet-value (SV) display unit [Orange]C Displays set-value (SV)C Displays set-value corresponding to theparameter symbol displayed on the measured-value (PV) display unit.ÎSet (SET) keyC The set-value thus changed is enteredÔControl output (OUT) lamp [Green]C Parameters in the parameter setting mode are C Lights up when the control output is turnedON.selected in due order.C Can select PV / SV display mode, SV settingÕAuto-tuning (AT) lamp [Green]mode, and parameter setting modes.C Flashes during auto-tuning.ÏSetting digit shift keyÖFirst alarm (ALM1) lamp [Red]C Used when the cursor (brightly lit) is moved to C Lights up when the first alarm is turned ON.the digit whose number needs to be changed for C When a control loop break alarm (LBA) is set-value change.selected as the first alarm, this lamp lights up.ÐSet-value decrement key×Second alarm (ALM2) lamp [Red]C Used when the number needs to be decreased C Lights up when second alarm is turned ON.for set-value change.C When either a heater break alarm (HBA) orcontrol loop break alarm (LBA) is selected asthe second alarm, this lamp lights up.5.OPERATION•Calling-up procedure of each mode:Press the key.Input type code / input range displayThis controller, with the power turned ON, displaysautomatically the input type code on the measured-value (PV)display unit and the input range, on the set-value (SV) displayunit, respectively.Example : For a controller with the K thermocouple inputtype and input range from 0 to 1372E C.ÎDisplays the input type code.: Indicates input abbreviation.unit. ( : E F)input type code table).ÏDisplays the input range.< Input type code >Code Input Type Code Input typeRSBW5Re/W26RePLIIPt100JPt100PV / SV display modeC Displays measured-value (PV) on the measured-value(PV) display unit and set-value (SV) on the set-value (SV)display unit. Usually the control is set to this modeexcepting that the set-value (SV) and/or the parameter set-value are changed.PV / SV display modeC Pressing the key lights the least significant digit onvalue (SV).In order to register the value whose setting was changed,always press the key after the value is changed.sec. in the PV / SV display or SV setting mode, thecontroller is set to the parameter setting mode.C Parameters in the parameter setting mode changes in dueorder every time the key is pressed (See page 6).and keys are pressed.C In order to register the value whose setting was changed,press the key after change to shift to the nextsec.•When no key is operated for more than 1 minute.•Parameter typesThe following parameter symbols are displayed one by one every time the key is pressed.Current transformer input (CT)Setting is not possible.Set heater break alarm value byreferring to this value.Display input value from thecurrent transformerCTSecond alarm Set alarm set-value of second alarm.AL2Control loopbreak alarm (LBA)0.0 to 200.0 min.Set control loop break alarmset-value.Cannot be set to “0.0".8.0LbAAuto-tuning (AT)0 : Auto-tuning end or stop1 : Auto-tuning startTurns the auto-tuningON/OFF.ATUIntegral time (I)1 to 3600 sec.Eliminates offset occurringcontrol is performed. I actionturns OFF with I set to “0".240IAnti-reset windup (ARW)1 to 100% of proportional band.Prevents overshoot and/orundershoot caused by integralaction. I action turns OFFwith this action set to “0".100ArSet data lock 0100 : No set data locked (Allparameters changeable)0101 : Set data locked (All parametersnot changeable)0110 : Only the set-value (SV) ischangeable with the set data locked.Performs set data changeenable / disable.0100LCK* The second alarm (or first alarm), heater break alarm, control loop break alarm parameter symbols are not simultaneously displayed. * Heater break alarm is not available on a current output.C Parameter setting procedure Setting set-value (SV)Following is an example of setting the set-value (SV) to 200E C. (PV : 30E C)Î Set to the set modeÏ Shift of the digit brightly litÐ Set-value increase or decrease ÑSet-value entryPress the key to Press the key to shift Press the key to set “2".After finishing the setting,enter the SV setting mode.the digit which lights brightlypress thekey. All ofController returns to the PV/SV display mode.Example : When a temperature of 199E C is changed to 200E C.Set-value increase or decreasePress the key to shift the digit brightly lit to the least significant digit. Press the key to change “9" to “0", therebyobtaining 200E C. The same applies to set-value decrease.Example : For changing 200 to -100.Minus (-) value settingPress the key to shift the digit brightly lit to the hundreds digit. Press the key to decrement figures in order of÷ 0 ÷ -1.Setting parameters other than set-value In the PV/SV display modeIn the parameter setting modeKey operational cautions CFor this controller, the value whose setting was changed is not registered. It is registered for the first time it is shifted to the next parameter by pressing the key.setting mode, set data lock is activated.In this case, change the “” parameter set-value to “0100".the parameter setting mode.Press thekey by the required number of times untilkey after the setting is finished in the parameters).When no parameter setting is required, return the controller to the PV/SV display mode.¬Pay attention to the following when the parameters described below are set.Auto-tuning (AT)C Prior to starting the auto-tuning function, end all the parameter settings other than PID and control loop break alarm(LBA).Heater break alarm (HBA)C Set heater break alarm set-value to a value about 85% current transformer input value. However, when power supplyvariations are large, set the alarm to a slightly smaller value.In addition, when two or more heaters are connected in parallel, set the alarm to a slightly larger value so that it is activated even with only one heater is broken. (However, within the value of a current transformer input value).C When the heater break alarm set-value is set to “0.0" or the current transformer is not connected, the heater breakalarm is turned ON.Control loop break alarm (LBA)C Usually set the set-value of the LBA to a value twice the integral time (I).O Set data locking procedureThis controller is provided with a set data locking function which disables each set-value change by the front key and also the auto-tuning function. Use this function for malfunction prevention at the end of each setting.C Press the key by the required number of(PV) display unit.C Press the , and keys to set the•Display at error occurrence< Heater break alarm >Display CauseMeasure(Lights)C Controlled object trouble (No power supply,incorrect wiring, etc).C Sensor trouble (Sensor disconnected, shorted, etc).C Actuator trouble (Weld relay contact, incorrectwiring, relay contact not closed, etc).C Output circuit trouble (Weld internal relay contact,relay contact not opened or closed, etc).C Input circuit trouble (The measured-value does notchange even if input changes, etc).Control system check(Error cause cannot bespecified)Check whether there is no effectby disturbances (Other heatsource, etc).LBA set time check< Overscale, Underscale >Input type Input display rangeTCK-30 to +1372E C -30 to +2502E F J-30 to +1200E C -30 to +2192E F R, S-30 to +1769E C -30 to +3216E F B-30 to +1820E C -30 to +3308E F E-30 to +1000E C -30 to +1832E F T-199.9 to +400.0E C -199.9 to +752.0E F N-30 to +1300E C -30 to +2372E F PLII-30 to +1390E C -30 to +2534E F L-30 to +800E C -30 to +1600E F U-199.9 to +600.0E C -199.9 to +999.9E F W5Re/W26Re-30 to +2320E C -30 to +4000E FRTDPt100JPT100-199.9 to +649.0E C Pt100-199.9 to +999.9E F。

说明书设计题目温控器设计姓名:张龙学号: 2011071128 专业:机械工程及自动化目录摘要 (3)1 设计内容与设计要求 (4)2、方案选择 (4)2.1 单片机的选择方案 (4)2.2显示器的选择方案 (4)2.3 模数转换芯片的选择 (5)3、元器件介绍 (5)3.1 AT89C51 (5)3.2 LCD1602液晶屏 (6)3.3 ADC0804 (8)3.4 NPN型三极管 (9)4.系统硬件设计 (10)4.1时钟电路 (11)4.2 复位电路 (12)4.3 ADC转换电路 (14)4.4 LCD1602液晶显示器 (14)4.5 独立按键控制电路 (15)4.6 继电器控制电路 (15)5.软件设计 (16)总结 (17)摘要温控器(Thermostat),根据工作环境的温度变化,在开关内部发生物理形变,从而产生某些特殊效应,产生导通或者断开动作的一系列自动控制元件,也叫温控开关、温度保护器、温度控制器,简称温控器。

或是通过温度保护器将温度传到温度控制器,温度控制器发出开关命令,从而控制设备的运行以达到理想的温度及节能效果,其应用范围非常广泛,根据不同种类的温控器应用在家电、电机、制冷或制热等众多产品中。

其工作原理是通过温度传感器对环境温度自动进行采样、即时监控,当环境温度高于控制设定上限值时控制电路启动,温度下降。

当环境温度低于控制设定下限值时,控制电路不工作,温度上升。

主要应用于电力部门使用的各种高低压开关柜、干式变压器、箱式变电站及其他相关的温度使用领域。

关键词:温控器温度采样上限值下限值1 设计内容与设计要求基本内容:设计一个简易温控器基本要求:①可以设定上限温度和下限温度,温度高于上限温度上,主电路不工作,温度降低,温度低于下限控制电路时,主电路继续工作,温度升高。

③设定温度时,液晶屏上显示设定状态,设定完显示正常模式,并且设定的上下限温度,在液晶屏上都有显示。

⑤采集温度信号,转换成数字信号。

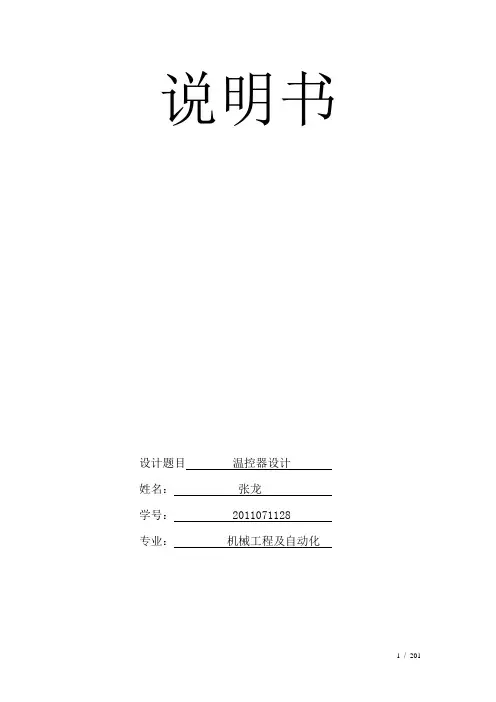

ECS100温度控制器功能说明书型号继电器接点最大电流配置传感器配置蜂鸣音Serial code 制冷除霜风机灯光调温除霜冷凝器门开关ECS100 30A5A 5A ☆√●●●●A(30.05.05.00)S234.B √:必配●:选配☆:未来配置外边框有黑黄绿三种颜色可选。

第一部分:技术信息1、技术参数1.1、测量范围:-50℃~90℃(注①)1.2、温度分辨率:0.1℃1.3、测温精度:-40℃~50℃时±1℃,50℃~70℃时±2℃,其它段±3℃1.4、最大控温范围:-50℃~50℃;1.5、电源电压: 230±10%(VAC)1.6、整机功耗:<1.5W1.7、显示器前面板防护等级:IP651.8、显示器后壳体防护等级:无1.9、工作环境温度:0℃~55℃;1.10、存储温度:-25℃~75℃;1.11、相对湿度:20%~85%(无结露)注①:仅指传感器校正值设置为0时。

2、显示界面3、规格尺寸3.1安装尺寸:(71mm)×(29mm)3.2整机尺寸:(78.5mm)×(34.5mm)×(82mm)4、指示灯状态说明指示灯符号状态表示意义制冷指示灯亮制冷工作灭制冷停止闪烁制冷延时除霜指示灯亮化霜工作灭化霜停止风机指示灯亮冷却风机启动灭冷却风机关闭除霜滴水指示灯亮除霜滴水启动灭除霜滴水结束一键还原亮执行参数一键还原亮参数设置设置指示灯灭测控状态门信号指示灯亮柜门打开5、按键功能5.1、按键名称按键名称作用进入参数设置状态;切换菜单和参数;调整菜单及参数;启动或者关闭灯光输出(注①)调整菜单及参数;持续10秒执行参数一键还原;退出参数设置状态;查看除霜传感器温度值(注②)持续3秒则强制启动除霜5.2、按键操作5.2.1 控制器通电状态下按键后,则显示St代码,再次按下后显示St参数值,此时可通过操作或修改温度控制点。

STULZ精密空调简易操作资料C1002控制器中文操作资料空调常见故障判断及处理STULZ C1002精密空调操作资料1STULZ C1002精密空调操作资料2STULZ C1002精密空调操作资料3STULZ C1002精密空调操作资料4STULZ C1002精密空调操作资料5STULZ C1002精密空调操作资料6STULZ C1002精密空调操作资料空调常见故障判断及处理1、更换热保护器2、清洗或更换滤网3、调整或更换皮带1、热保护器坏2、过滤网脏3、风机皮带太松电加热故障HEA 1、倒换相序2、检查三相电源是否正常3、闭合空开/更换保险管4、调整皮带,清洗滤网5、调整、更换气流开关6、改造回风1、AC 电源反相2、AC 电源缺相/不正常3、风机空开未闭合/保险管坏4、皮带松,滤网脏5、气流开关失灵6、回风不好气流报警FLO11、查漏后补氟里昂2、更换膨胀阀3、清洗过滤网4、改造回风5、更换低压保护开关6、更换干燥过滤器7、更换管路电磁阀或线圈8、修改设定值1、A/C 系统缺氟漏氟2、膨胀阀失灵3、过滤网脏4、回风不好5、低压保护开关坏6、干燥过滤器脏堵7、管路电磁阀或线圈坏8、温度设置太低低压报警LOP1清洗或更换过滤网1、清洗室外机2、更换室外风机3、检查线路及开关4、高压开关复位5、更换高压保护开关故障处理过滤网脏1、室外机太脏2、室外风机堵转3、室外机无电源4、高压开关未复位5、高压保护开关坏原因过滤网脏堵FIL 压缩机高压报警HIP1报警内容7STULZ C1002精密空调操作资料8STULZ C1002精密空调操作资料9。

RCKCB100温控器操作使用说明RKC CB100温控器操作使用说明1 操作接口及指示灯说明;(图 1)PV:显示测量值或参数名称SV: 显示设定值或参数值AT:自动演算指示灯,档进行自动演算时AT指示闪烁,演算完成后,指示灯熄灭.OUT1:加热控制输出指示.OUT2:冷却控制输出指示.ALM1:第一组报警指示当输入点接热电欧时(即温度型输入时)所发生的报警1.温度偏移时报警2.过程报警3.设置值SV报警.ALM2: 第二组报警指示当输入点接4~20mADC或1~5VDC时(即标准信号输入时)所发生的报警1.温度偏移时报警2.过程报警3.设置值SV报警SET:设置键及参数设置,修改后的确认键,按SET键2秒后进入参数设置界面,参数设置完毕后按SET键确认.再按SET 键2秒后跳出参数设置见面.R/S:移位键,用来选择要改动的数据 ,RUN/STOP功能选择ˇ:数据递减数据递增2参数设置及说明;长按SET键两秒就可进入参数设置界面.AL1: 设置第一组报警值范围(图2)例如:设定值SV 设定为50度,AL1设定为5度,当检测值PV 超过55度时,则显示AL1报警ATU(Autotuning):PID自动演算如图3所示0:执行自动演算1:不执行自动演算STU(Self-tuning):自我演算(图4)0 :执行自我演算1:不执行自我演算P:设定比例时间 (30s)如图5所示(图5)I:设定积分时间(240s)如图6所示(图6)D:设定微分时间(60s)如图7所示PID控制在温控其中的应用R2输入输出关系;U0(t)=R2*Ui(T1)/R1I(intergral)积分控制电路; R电路输入输出关系;Uo=RC*dUi/dtX X XX AR:设定加热周期的比例 (100%)如图8所示(图8)T:设定加热周期(8s)如图9所示(图9)PB:设定PV补正值(2)如图10所示(图10)LCK:数据锁定功能如图11所示(图11)LCK 数据锁定功能参数0000 初始设定模式锁住 1000始设定模式打开0000 设定值(SV)及参数皆可设定0011只有设定值(SV)可设定0001 只有设定际报警可设置 0101只有报警值可设定0010 除了报警不能设定外,其余捷可设定0110除了设定之及报警不能设定外,其余可设定0100 除了设定值外,其余可设定 0111设定值及参数皆无法设定初是设定方式;将LCK 数值设置为1000后,同时按住SET键及R/S键5 秒终即可进入初始模式设定1;COD为0000时可设置SL1~SL11;COD为0001时可设置SLH 按set键SLL按set键OH按set键AH1 按set键AH2按set键DF按set键STTM按set键STPK按set 键STIK其具体意义如下表所示。

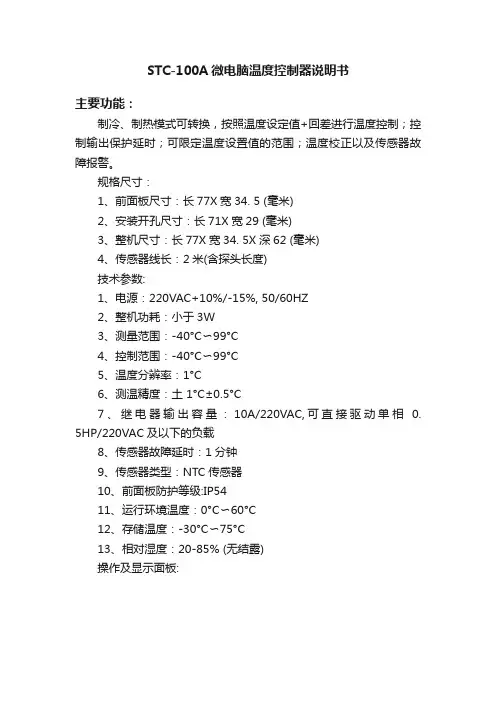

STC-100A微电脑温度控制器说明书主要功能:制冷、制热模式可转换,按照温度设定值+回差进行温度控制;控制输出保护延时;可限定温度设置值的范围;温度校正以及传感器故障报警。

规格尺寸:1、前面板尺寸:长77X宽34. 5 (毫米)2、安装开孔尺寸:长71X宽29 (毫米)3、整机尺寸:长77X宽34. 5X深62 (毫米)4、传感器线长:2米(含探头长度)技术参数:1、电源:220VAC+10%/-15%, 50/60HZ2、整机功耗:小于3W3、测量范围:-40°C〜99°C4、控制范围:-40°C〜99°C5、温度分辨率:1°C6、测温精度:土1°C±0.5°C7、继电器输出容量:10A/220VAC,可直接驱动单相0. 5HP/220VAC及以下的负载8、传感器故障延时:1分钟9、传感器类型:NTC传感器10、前面板防护等级:IP5411、运行环境温度:0°C〜60°C12、存储温度:-30°C〜75°C13、相对湿度:20-85% (无结露)操作及显示面板:显示说明:两位红色数码管显示温度等信息。

按键说明:▲键:上调键;▼键:下调键;set键:设置键。

指示灯状态说明:按键操作说明:1、修改温度设定值:控制器正常工作时,按下set键显示当前温度设定值,此时按▲键或▼键可上调或下调并显示温度设定值。

4秒内没有任何按键操作则保存参数修改并返回正常显示状态。

保存参数时如果出现错误则显示'Er',3秒后返回正常显示状态。

2、修改参数设定值:控制器正常工作时,按住set键持续4秒以上进入修改参数模式,显示第一个菜单项的代码'HC'。

按▲键或▼键可上翻或下翻菜单项并显示菜单项的代码,按set键显示当前菜单的参数设定值。

按住set键不放,再按▲键或▼键可上调或下调并显示当前菜单的参数设定值。

KST10160型温度控制器使用说明书一、概述:本温度控制器为常闭触点型(即通常输出触点是闭合的,当温度升到设定值时触点断开)温控器,它采用高灵敏、高精度的双金属片为感温器,具有结构简单,设置温度精度高,控温范围连续可调等特点,广泛应用于加热设备的控制、超温度告警等。

二、主要技术指标:1、 温度调节范围:0℃~60℃。

2、温度控制精度:±4℃。

3、温度通断差:<7K。

4、接点容量:10A AC250V/15A AC120V5、绝缘电阻:≥50MΩ。

6、接触电阻:≤50mΩ。

7、电气强度:带电端子与露出非带电金属部件之间 1500V历时1min 1800V历时1s同极端子间(非连续触点) 600V历时1min 720V历时1s三、安装要求:1、 本温度控制器应安装在尽可能远离加热器或其它发热体上方的地区,以确保控制温度的准确。

2、 本温度控制器的安装方式为卡装在35mm宽的DIN导轨上。

周围应保持空气流通,任何时候温控器的通气孔都不能被覆盖。

3、 由于使用条件范围很宽,因此在用户最终使用时应对产品的安全运行进行验证。

四、温度设置举例:本温度控制器在设置控制温度时应考虑到产品的最大温度控制偏差,在最低工作温度的基础上再加上最大温度控制偏差,才是温控器的设定温度。

如:最低工作温度为5℃,最大温度控制偏差为11K(4+7),那么温控器的设定温度就应是16℃。

福建省南平市安达电器制造有限公司地址:福建省南平市沙门路28号电话:0599-*******传真:0599-*******网址:E-Mail:npanda@合格证比例:1:1。

安全措施1.对安装或维修人员的技能要求①具有从事CCTV系统安装或维修的资格证书。

②具有从事高空作业的资格证书。

③具有低压布线和低压电子线路接线的基础知识和操作技能。

④了解并熟悉本产品使用说明。

2.对升降设备的要求①使用适合安装地点和球机安装方式的安全升降设备。

②升降设备具有到达安装位置的足够的举升高度。

③升降设备具有良好的安全性能。

注意事项1.小心运输运输及保管过程中要防止重压、剧烈振动和浸泡等对产品造成的损坏。

本产品必须采用分体包装形式运输,无论工程商发货还是返回工厂维修,若因未采用安全包装而运输,造成的任何产品损坏,不属保修范围。

2.发生故障时如果本机出现冒烟、异常气味或功能不正常,应立即关闭电源并断开电源线,停止使用本机,然后与制造商联系。

3.切勿拆开或改装切勿打开壳体,否则可能会导致危险或引起本机损坏。

如果进行内部设定或维修,请与制造商联系。

4.切勿把别的物品放入本机确认摄像机内没有金属物或易燃物。

如果机内有异物,可能会引起着火、短路或损伤。

如果水或液体流入摄像机,请立即关闭电源并断开电源线,然后与制造商商谈。

小心地保护摄像机,避免雨水、海水侵蚀。

5.小心提放本机为了避免损伤,切勿使摄像机掉落或遭受强烈的震动或冲击。

6.设置在远离电场和磁场的场所如果设置在电视机、无线电发射机、电磁装置、变压器、扬声器附近,它们产生的电磁场将会干扰图像。

7.避免湿气和灰尘为了避免摄像机损坏,切勿把摄像机设置在有油烟或水蒸气、温度过高或有很多灰尘的场所。

8.避免高温切勿设置在取暖炉或其他热源的附近,如聚光灯。

也不要设置在易受阳光照射的地方,否则会引起摄像机的变形、褪色或其他损伤。

当设置在天花板、厨房或锅炉房附近时,温度可能会升得很高。

9.清洁用软布擦拭能去掉壳体上的脏物。

要除去污垢,可用软布沾上洗涤剂溶液并拧干后擦拭,然后再用干的软布擦干。

切勿使用汽油、涂料稀释剂或其他化学品清洁壳体,否则可能会引起变形和涂漆剥落。

温度控制器说明书温度控制器说明书1. 简介温度控制器(Temperature Controller)是一种用于测量和控制温度的设备。

它广泛应用于工业、科研、农业等领域,用于保持恒定的温度环境以满足特定的需求。

本说明书将介绍温度控制器的基本使用方法和注意事项。

2. 功能特点- 温度测量:温度控制器可以精确测量环境或物体的温度,并实时显示在屏幕上。

- 温度设定:用户可以通过温度控制器设置所需的温度值。

- 温度控制:温度控制器可以根据用户设定的温度值自动控制加热或制冷设备,以保持温度稳定。

- 报警功能:当温度超过或低于设定的阈值时,温度控制器会发出警报以提醒用户。

- 数据记录:温度控制器可以记录温度数据,并提供导出或打印功能。

3. 使用方法3.1 连接将温度探头插入温度控制器的探头接口,并确保连接牢固。

3.2 开机按下温度控制器的电源按钮,待显示屏上出现启动画面后,即表示温度控制器已成功开机。

3.3 设定温度使用温度控制器上的设定按钮或旋钮,调整显示屏上的温度数值,以设定所需的目标温度。

3.4 启动控制在设定好目标温度后,按下温度控制器上的启动按钮,控制器将开始控制加热或制冷设备以维持目标温度。

3.5 报警功能如果温度超过或低于设定的阈值,温度控制器将发出警报声。

在警报触发时,及时采取相应措施以避免温度波动过大。

4. 注意事项- 请勿在温度控制器受潮或温度较高的环境中使用,以免损坏设备。

- 在使用过程中请注意安全,避免触摸温度探头以免烫伤。

- 调节温度时,请逐步调整,避免温度波动过大。

- 定期校准温度控制器以确保测量的准确性和稳定性。

- 在长时间不使用温度控制器时,请断开电源并存放在干燥通风的地方。

5. 维护和保养- 温度探头需要定期清洁和校准,以保证测量的准确性。

- 定期检查温度控制器的电源线和连接线是否损坏。

- 如有任何故障或异常情况,请及时联系售后服务。

6. 常见问题解答问:温度控制器无法开机怎么办?答:请检查电源线是否连接正常,并确保电源插座有电。