欧四欧五发动机排放培训资料

- 格式:ppt

- 大小:4.60 MB

- 文档页数:40

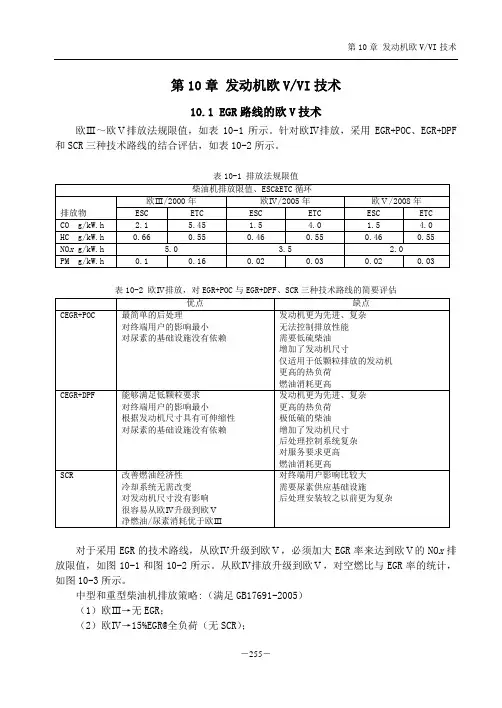

第10章发动机欧V/VI技术10.1 EGR路线的欧V技术欧Ⅲ~欧Ⅴ排放法规限值,如表10-1所示。

针对欧Ⅳ排放,采用EGR+POC、EGR+DPF 和SCR三种技术路线的结合评估,如表10-2所示。

表10-1 排放法规限值表10-2 欧Ⅳ排放,对EGR+POC与EGR+DPF、SCR三种技术路线的简要评估对于采用EGR的技术路线,从欧Ⅳ升级到欧Ⅴ,必须加大EGR率来达到欧Ⅴ的NO x排放限值,如图10-1和图10-2所示。

从欧Ⅳ排放升级到欧Ⅴ,对空燃比与EGR率的统计,如图10-3所示。

中型和重型柴油机排放策略:(满足GB17691-2005)(1)欧Ⅲ→无EGR;(2)欧Ⅳ→15%EGR@全负荷(无SCR);(3)欧Ⅴ→25%EGR@全负荷(无SCR);(4)欧Ⅵ→30%EGR@全负荷(有SCR)。

乘用车→无EGR@全负荷:(满足GB18352.3-2005)(1)欧Ⅲ→40~45%EGR低怠速,30~35% @ 2000rpm,3bar;(2)欧Ⅳ→45~50%EGR低怠速,35~40% @ 2000rpm,3bar;(3)欧Ⅴ→50~60%EGR低怠速,40~45% @ 2000rpm,3bar。

表10-3 满足各排放法规的技术评估表10-4 >300 kW级别的重型柴油机采用的技术满足各排放法规的技术评估,如表10-3所示。

重型柴油机采用的技术,如表10-4所示。

EGR技术的发展趋势为:NOx排放限值和升功率的提高相应提高了对EGR系统的要求。

不断提高EGR冷却器的换热性能,降低冷却器阻力是获得高EGR率的关键。

外形安装的限制要求应用高效的EGR冷却器,对降低EGR冷却器污垢阻力变得越来越重要。

采用外置旁通式结构以降低旁通热损失已得到了应用。

低压EGR系统正在研发之中,它有如下的优点:(1)干净的EGR(没有SOOT和HC);(2)可以在高增压压力下采用EGR;(3)即使在高流量下EGR的分布也极为均匀。

![ISF3.8欧4发动机后处理培训资料[1] 2](https://uimg.taocdn.com/73ab903d5a8102d276a22fde.webp)

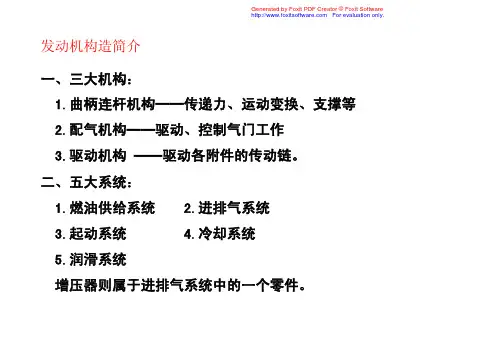

发动机构造简介一、三大机构:1.曲柄连杆机构——传递力、运动变换、支撑等2.配气机构——驱动、控制气门工作3.驱动机构——驱动各附件的传动链。

二、五大系统:1.燃油供给系统2.进排气系统3.起动系统4.冷却系统5.润滑系统增压器则属于进排气系统中的一个零件。

进、排气系统•进、排气系统作用:吐故纳新•进气部分组成:空气滤清器、进气消声器、进气管、增压器压气机、各种可变机构•排气部分组成:排气管、排气消声器、增压器涡轮机、排气净化装置、EGR系统等涡轮增压器工作原理涡轮增压器工作原理发动机测试台架-测功器•发动机测试台架功率测试-测功器。

•测功器主要有水涡流测功器、电涡流测功器和交流电力测功器。

•交流电力测功器技术最先进、工作最可靠、功能最完善和运行成本经济。

•交流电力测功器节省了大量冷却水、可靠性高,维护费用低。

由于设备长期在有水环境下使用,水涡流和电涡流测功器设备损坏概率较高,交流电力测功器使用三相异步变频电机,运行可靠,维护方便,费用较低。

•交流电力测功器采用高速低惯量变频异步电机,是实施机动车排放污染物检测新国标的必备设备。

排放标准一、国Ⅲ、Ⅳ、Ⅴ排放标准:《车用压燃式、气体燃料点燃式发动机与汽车排气污染物排放限值及测量方法》(GB17691--2005)和《车用压燃式发动机和压燃式发动机汽车排气烟度限值及测量方法》(GB3847--2005)。

二、检测方法:•方法有ESC试验(稳态工况)和ETC、ELR试验(瞬态工况)。

•不同发动机状态和不同排放阶段应采用不同试验方法的组合。

•ESC试验(European Steady state Cycle)即稳态循环试验,包含13个稳态工况的试验循环。

•ELR(European Load Response test )即负荷烟度试验,为在恒定转速下依次改变负荷的试验循环。

•ETC (European Transient Cycle)即瞬态循环试验,包含l 800个逐秒变换工况的试验循环。

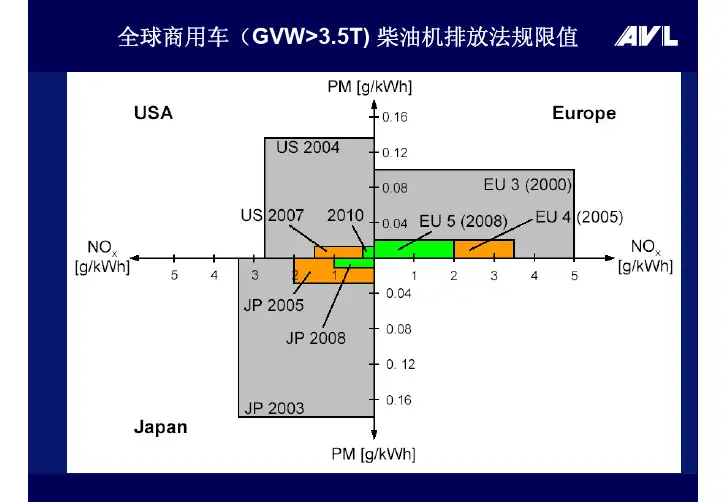

美国商用车(GVW>3.5T) 柴油机排放限值欧洲商用车(GVW>3.5T) 柴油机减排放过程欧洲商用车(GVW>3.5T) 柴油机排放限值Japan TC2008 2000欧洲柴油油品改进计划欧3发动机基本技术Direct InjectionSta n dard w aste gate t urbocharging, VGT as a n optionAir to Air IntercoolingCombustion optimisation,with o r without swirl support4 valve per cylinderAdvanced high pressure injection system ÎM multiple injection, Rate shapingElectronic Management SystemLow lube oil consumptionE GR system as an option目前欧洲发动机状态Source: BOSCHEmission control technologyEngine technologyEU3EU5EU4US10US07US04Japan NSTJapan NLT NOx [g/kWh]PM [g/kWh]0,100,022,03,55,0欧4发动机燃烧技术发展Flexiable Fuel system with > 1600 barHigh performance Cooled EGR systemHigh EGR tolerance combustion systemNew combustion bowl for low soot in oilAlternative combustion at part load for temperature managementHigh specific power require 2 stage turbochargerImprove vehicle cooling systemDifferent tuning according to the strategy applied欧4发动机主要技术发展方案Strategy 1:reduction with SCR-NOx-PM reduction with engine internal measuresStrategy 2:reduction with cooled EGR-NOx-PM reduction with DPF (e.g CRT) or POCStrategy 3:-High efficiency cooled EGR-High injection pressure-No exhaust after treatment system欧4发动机主要技术发展方案示意排放后处理装置的选择•High Effective•Reasonable cost•Optimum reliability•Stable performance and extended durability •Negligible impact on fuel economy•Optimum compatibility with engine technologies and other after-treatment systemSCR (NOX尿素还原)SCR化学反应原理SCR catalyst Urea injectionPump Air Urea-SCR ECUCAN port NOx sensor Temp. in Temp. out Urea-water TankExhaust inExhaust out Intake air Air flow sensorSCR 在ESC循环中降低NOx的实验结果1SCR 在ESC循环中降低NOx的实验结果2SCR 在ETC循环中降低NOx的实验结果1SCR 的燃油经济性(事例)Example: a 40-ton Euro-4 truckSolution:Diesel consumption Urea ConsumptionSCR29.8 L/100 kilometers, 1.5 L of urea.(5% of fuel consumption) DPF+EGR32.6 L/100 kilometers, but no urea.NOx trap5% fuel consumption penalty vs Euro 3 truck and 7% fuel consumption penalty vs Euro 3 truckSource: ACEA针对欧3欧4排放,欧洲商用车制造商决定统一采用SCR技术有关SCR的其他情况SCR催化器消音器集成SCR在欧洲的实施计划Urea InfrastructureLogistical Implementtation1st stage: Filling stations atTrucking companies2nd stage: Automotive fillingstattions at truck stopsalong the majorhighways3rd stages: Public filling stationsJoint project realized byOEMs, urea industry, oil industry,component suppliersUrea filling station at Stuttgart (Source: TOTAL)2003年西欧计划尿素的生产布置AdBule(尿素)的欧洲标准(DIN70070)AdBlue TM是SCR系统的必要元素Urea –as the active component in AdBlue, is a productlargely used in agriculture and industryAdBlue TM-A 32.5% urea solution in watermeeting the DIN 70070 standardAdBlue TM–is by far the best reagent since it is clear, non-toxic and non-hazardous product and there are norestrictions for its transport on rails, road andships.AdBlue TM –is trade mark of aqueous urea solution forautomotive applicationAccurate dosing system of AdBlue and appropriate strategies is necessary to provide the correct amount of reductant during all driving conditions and prevent ammonia (NH3) slip预测的西欧AdBule的需求量Source: ACEA欧洲AdBule的价格According to new ACEA report 2003,urea at retail should cost about 40 Euro-cents per liter, versus about 79 Euro-cents/liter for diesel fuelSCR结论2ADVANTAGES:Most effective NO x reduction technologyfor HD trucks in the long rangeCombustion adjusted for best fuel efficiency and lowest particulatesCHALLENGES:High system costPackaging of dosage system, urea tank, SCR catalyst and modified exhaust mufflerLong term field testingLogistics for urea-water solution is a prerequisiteOBD is indispensable.EGR 对过量空气系数和烟度的影响2.0 1.6 1.2 15% EGR 0.8 8% EGR Current engine technology Development target 15% EGRSmoke – FSN0.40 1.40% EGR 1.5 1.6 1.7 1.81.9Air excess ratio – [-]冷却EGR的布置1(高压式) 1 2 3 4 5 6 7 8NOx sensor Particulate trap ∆p sensor Air flow meter Air filter Modulated EGR-Rate control valve Intake manifoldEngineExhaust manifold EGR cooler EGR valveVenturiCheck valve (optional)Air / Air Intercooler高压冷却EGR的使用Modulated EGR-Rate control valve2 3 4 5 6 7 8 Particulate trap is optionalAir filterEngineExhaust manifold Air flow meter EGR cooler EGR valveVenturiCheck valve (optional)Problems:NOx sensor System contamination Increased soot-in-oilParticulate trap ∆p sensor Transport losses increase with improved TC efficiency VTG - EGR controlRequirements: Durable particulate filter with reliable regeneration, durable and insensitive controlAir / Air Intercooler1Advantages:Intake manifold冷却EGR的布置2(低压式) 1 2 3 4 5 6 7 8NOx sensor EGR valve Air filterEngineExhaust manifoldEGR coolerPartic ulate trap ∆p sensorEGR coolerAir / Air IntercoolerIntake manifold低压冷却EGR的使用 1 2 3 4 5 6 7 8Advantages: Reduced control complexityEGR valve Air filter Air / Air Intercooler Intake manifoldEngineExhaust manifold Fuel economyEGR coolerProblems:NOx sensorPartic ulate trap ∆p sensor Reliability of particulate filter Recirculated NO2 may form corrosive nitrous acidRequirements: Low sulfur fuel (<50 ppm S) Durable particulate filter with reliable regeneration冷却EGR系统示意1冷却EGR系统示意2颗粒扑捉器(DPF)- 穿墙式连续被动再生颗粒扑捉器(CRT)Filter Section Catalyst Section Inlet HeadOutlet HeadWall Flow Filter Conversion of Soot stored: Pt - Oxidation Catalyst Oxidation of NO to NO2: 2 NO + O2 2 NO2 C + 2 NO2 CO2 + 2 NO at temp. 200 - 550 deg C CO2 C + O2 at temp. > 550 deg CSource: Johnson Matthey49202010-21氧化燃烧颗粒-1C + 2NO2 C + O2CO2 + 2NO CO2at temp. 200 - 550 deg C at temp. > 550 deg C。