3 表面完整性

- 格式:ppt

- 大小:67.50 KB

- 文档页数:18

内燃机零部件“表面完整性”新概念与“表面光整加工”新技术(中国兵器集团第七O研究所岳政、刘桂莲)我国内燃机关键基础零部件与工业先进国家的相比有较大差距,为数不少的国产零件,单从外观看就像是未加工完的半成品。

而在可靠性与使用寿命方面差距就更明显,这种差距从技术层面来说有原材料、热处理、加工设备以及加工工艺等诸多方面原因。

本文仅以零件精加工工艺“微观表面质量”一个侧面做一些分析探讨,为尽快缩小差距,介绍一个机械零件“表面完整性”新概念和旨在实现“表面完整性”的实用新技术:自由磨具滚魔光整加工技术。

一、国产内燃机零部件对微观表面质量“单一性采标”是造成水平低、质量差的根本原因之一。

从某种意义上说:“货用一张皮,祸起一张皮”。

微观表面质量对机械零件的耐磨性、装配性、可靠性(抗疲劳、抗腐蚀、接触刚度)、密封性等使用性能有很大的影响。

微观表面质量又由表面的几何特性,物理、化学、力学特性两大方面的五大类诸多参数来评价、来控制。

(见本文第二部分)我国基础标准GB/T3505-2000第4条表面轮廓参数定义中对粗糙度就提出了16个参数。

而我国绝大多数内燃机零件现行技术标准和产品图样(除了平台衍磨网纹气缸套外)。

对微观表面质量都只选取了一个纵坐标幅度参数Ra来评价、来控制。

传统的车、铣、铇、磨、抛光等加工工艺,其共同特点是一道工序只能加工一个表面。

除保证实现尺寸和形状位置公差之外,就只保证实现规定的Ra,达到“符合性”要求,“单一采标”,止此而已。

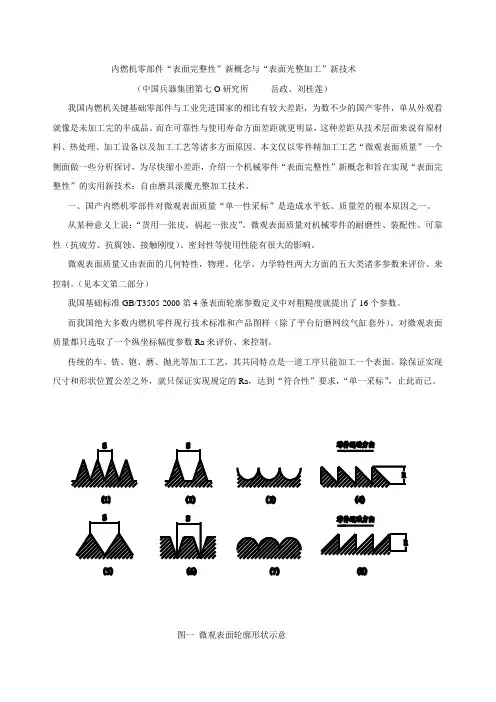

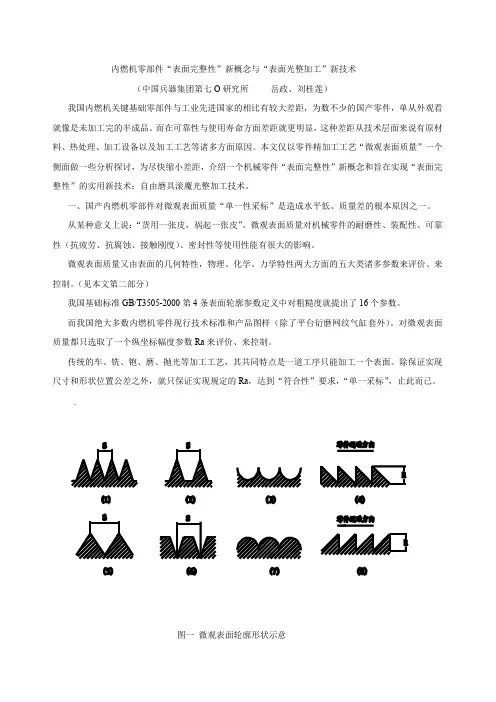

图一微观表面轮廓形状示意(1)—(4)咬合倾向大,耐磨性差。

(5)—(6)咬合倾向小,耐磨性好。

上面图一所示意的各微观表面轮廓形状,其Ra纵然可以做到相近,但表示加工纹理状态的间距参数Rsm(老标准为Sn)相差甚远,Rsm亦可以做到相近,但影响耐磨性,并用Rmp、Rmr(C)(老标准为Rmr、Rmr(c))表示的轮廓峰谷之间的形状千变万化,使配合表面实际接触面积和存油情况大相径庭,又由于表面加工纹理、方向和零件相对运动的方向不同,都对表面的耐磨性、可靠性(咬合倾向)及使用性能产生重大影响。

机械加工表面完整性研究表面完整性是描述、鉴定和控制加工过程在零件表面层内可能产生的各种变化及其对零件使用性能影响的技术。

文章着眼于传统的机械加工方法及其与表面完整性的关系,阐述了提高表面完整性的加工方法及注意事项,以满足当前的抗疲劳制造要求。

标签:机械加工;表面;完整性前言疲劳准则是航空零部件设计的基本依据,疲劳性能是航空零件使用可靠性及寿命的决定性因素。

在零件结构尺寸和材料性能一定的情况下,机械加工表面质量又是影响零件疲劳寿命的关键因素。

航空零件断裂故障的晶相分析或断口分析表明,无论是动载疲劳断裂还是静载延迟断裂,其主要原因主要是加工表面层状态不良。

为保证零件长寿命使用,六十年代中期美国率先提出了切削加工零件表面完整性的概念,将已加工的表面质量称为表面完整性。

随着航空制造业的发展及新兴材料使用的增加,表面完整性内容更为丰富,以致传统工艺切削加工的零件表面完整性的研究工作显得尤为重要。

文章着眼于传统的机械加工方法及其与表面完整性的关系,阐述了提高表面完整性的加工方法及注意事项,以满足当前的抗疲劳制造要求。

1 表面完整性概念及机制1.1 表面完整性概念表面完整性是描述、鉴定和控制加工过程在零件表面及次表面内可能产生的各种变化及其对零件使用性能影响的技术。

从广义上讲,表面完整性包括两个组成部分:(1)与零件表面纹理有关的部分,称为外部效应:其中包括表面粗糙度、波纹度、刀纹方向和宏观缺陷。

粗糙度算术平均值Ra是表面纹理构型要素中最主要的表征参数。

(2)与表面冶金层冶金物理特性变化有关的部分,即内部效应:其中包括显微结构变化:再结晶、晶间腐蚀、热影响区、显微裂纹、硬度变化、残余应力、材料非同质性和合金贫化等。

表面完整性技术把零件制造中的尺寸公差、表面纹理和冶金物理变化综合协调考虑,能使零件表面层不受(或少受)损伤甚至有所改善,从而有效地提高零件产品的使用寿命。

1.2 表面完整性的形成机制零件机械加工表面由多种要素及属性构成,如表面微观形貌、晶相结构及力学特性等。

内燃机零部件“表面完整性”新概念与“表面光整加工”新技术(中国兵器集团第七O研究所岳政、刘桂莲)我国内燃机关键基础零部件与工业先进国家的相比有较大差距,为数不少的国产零件,单从外观看就像是未加工完的半成品。

而在可靠性与使用寿命方面差距就更明显,这种差距从技术层面来说有原材料、热处理、加工设备以及加工工艺等诸多方面原因。

本文仅以零件精加工工艺“微观表面质量”一个侧面做一些分析探讨,为尽快缩小差距,介绍一个机械零件“表面完整性”新概念和旨在实现“表面完整性”的实用新技术:自由磨具滚魔光整加工技术。

一、国产内燃机零部件对微观表面质量“单一性采标”是造成水平低、质量差的根本原因之一。

从某种意义上说:“货用一张皮,祸起一张皮”。

微观表面质量对机械零件的耐磨性、装配性、可靠性(抗疲劳、抗腐蚀、接触刚度)、密封性等使用性能有很大的影响。

微观表面质量又由表面的几何特性,物理、化学、力学特性两大方面的五大类诸多参数来评价、来控制。

(见本文第二部分)我国基础标准GB/T3505-2000第4条表面轮廓参数定义中对粗糙度就提出了16个参数。

而我国绝大多数内燃机零件现行技术标准和产品图样(除了平台衍磨网纹气缸套外)。

对微观表面质量都只选取了一个纵坐标幅度参数Ra来评价、来控制。

传统的车、铣、铇、磨、抛光等加工工艺,其共同特点是一道工序只能加工一个表面。

除保证实现尺寸和形状位置公差之外,就只保证实现规定的Ra,达到“符合性”要求,“单一采标”,止此而已。

图一微观表面轮廓形状示意(1)—(4)咬合倾向大,耐磨性差。

(5)—(6)咬合倾向小,耐磨性好。

上面图一所示意的各微观表面轮廓形状,其Ra纵然可以做到相近,但表示加工纹理状态的间距参数Rsm(老标准为Sn)相差甚远,Rsm亦可以做到相近,但影响耐磨性,并用Rmp、Rmr(C)(老标准为Rmr、Rmr(c))表示的轮廓峰谷之间的形状千变万化,使配合表面实际接触面积和存油情况大相径庭,又由于表面加工纹理、方向和零件相对运动的方向不同,都对表面的耐磨性、可靠性(咬合倾向)及使用性能产生重大影响。

表面完整性检测调研报告表面完整性检测调研报告一、引言表面完整性检测是指通过一系列测试和检验手段,对物体表面的完整性进行评估和判断的过程。

在工业制造、疾病诊断、材料科学等领域中,表面完整性检测具有重要意义。

本文通过调研和分析,对表面完整性检测的相关技术和应用进行总结,以期为相关领域的研究和实践提供参考。

二、常见的表面完整性检测技术1. 视觉检测技术:通过摄像机和图像处理算法,对物体表面进行图像采集和处理,从而检测表面的缺陷、裂纹、凹凸等问题。

2. 磁粉检测技术:通过在被测物体表面涂覆磁粉,利用磁粉在表面缺陷处形成磁场不连续性的现象,通过磁场传感器检测出缺陷的存在。

3. 声波检测技术:利用超声波的传播特性,对物体表面进行扫描和检测,通过分析声波的传播时间和幅度变化,判断表面是否存在缺陷。

4. 激光检测技术:利用激光束扫描物体表面,并通过接收激光反射的信号,对物体表面的几何形态和缺陷进行检测和分析。

5. 热红外检测技术:通过测量物体表面的红外辐射,分析表面温度分布,从而判断表面是否有缺陷和异常状况。

三、表面完整性检测的应用领域1. 工业制造:在汽车、航空航天、机械制造等行业中,表面完整性检测可以帮助检测零部件表面的裂纹、划痕、气泡等问题,确保产品质量和安全性。

2. 医学诊断:在医学领域中,表面完整性检测可以应用于皮肤病、创伤伤口等方面,用于检测和评估皮肤表面的完整性,指导疾病的治疗和康复。

3. 材料科学:在材料研究和开发中,表面完整性检测可以用于评估材料表面的性能和质量,为材料的改进和优化提供支持。

四、表面完整性检测技术的发展趋势1. 自动化和智能化:随着人工智能和机器学习的发展,表面完整性检测技术将趋向自动化和智能化,提高检测效率和准确性。

2. 非接触式检测:目前大部分的表面完整性检测技术需要直接接触被测物体,未来将出现更多基于光学、声学和红外等非接触式检测技术。

3. 大数据分析:随着大数据技术的不断发展,表面完整性检测的数据量将大幅增加,大数据分析将在表面缺陷检测和预测中发挥重要作用。

总633期第三期2018年3月河南科技Henan Science and Technology表面完整性对喷丸强化疲劳性能影响的研究综述王哲(西安航空职业技术学院,陕西西安710089)摘要:从表面粗糙度、残余应力、微观组织等方面,总结表面完整性对疲劳性能影响的研究进展,分析表明:表面粗糙度、残余应力对疲劳性能影响显著;加工产生的晶粒细化、高密度位错等有助于提高疲劳寿命。

实现疲劳强度和表面完整性的互逆设计是抗疲劳制造的发展方向。

关键词:表面完整性;疲劳性能;表面粗糙度;残余应力;微观组织中图分类号:TG54文献标识码:A文章编号:1003-5168(2018)07-0052-02A Review for the Effect of Surface Integrity on Fatigue PropertiesWANG Zhe(Xi'an Aeronautical Polytechnic Institute,Xi'an Shaanxi710089)Abstract:The research progress on the effect of surface integrity on fatigue properties is reviewed in terms of surface roughness,residual stress,microstructures and so on.The analysis indicates that the surface roughness and residual stress have significant influence on fatigue performance.Besides,grain refinement and high-density dislocation produced by machining contribute to fatigue life.Realizing mutual inverse de⁃sign of fatigue strength and surface integrity is the development direction of anti-fatigue manufacturing. Keywords:surface integrity;fatigue progress;surface roughness;residual stress;microstructure1表面粗糙度保证加工表面完整性,提高疲劳强度,已经成为制造业的重要方向。

难加工金属材料磨削加工表面完整性研究进展摘要:高温合金、钛合金、不锈钢等难加工金属材料在高端装备制造特别是在国防军工领域应用广泛。

砂轮磨削是难加工金属材料零件的重要加工方式。

然而,磨削过程的力-热强耦合作用对表面完整性影响显著,而表面完整性的优劣对零件服役性能具有直接影响。

本文综述了近年来难加工金属材料磨削加工表面完整性的研究进展,全面总结了表面完整性核心要素(如表面粗糙度、残余应力、显微硬度、微观结构等)的创成机理、影响因素及其作用规律以及预测与控制,并对表面完整性控制技术的发展趋势进行了展望。

关键词:磨削;表面完整性;金属材料高温合金、钛合金、不锈钢等难加工金属材料在国民经济各行各业,尤其是国防军工领域具有极其广泛且重要的应用。

镍基高温合金(如变形高温合金GH4169、铸造高温合金K424 及粉末冶金高温合金FGH96 等)由于优良的抗热疲劳性能、高温强度、耐腐蚀性、抗冲击性以及抗蠕变性能被广泛应用于燃气轮机与航空发动机热端部件以及核反应堆部件等;钛材料(如钛合金TC4、TC6;钛铝金属间化合物Ti2AlNb、γ-TiAl 等)具有密度低、强度高、抗腐蚀性好等优良特性,大量应用于航空发动机叶片、叶轮、叶盘和机匣等重要部件;超高强度钢(如300M)兼顾高强度、高韧性以及优异的耐蚀性能,应用于飞机起落架、核电设施等[1-3]。

目前我国航空航天、国防军工领域正处于攻坚克难的关键时期,发动机各个部件的加工方式在一定程度上决定了我国航空发动机的性能。

然而航空发动机所用的材料多为难加工材料,这些材料由于强度和硬度高、导热系数低等,在加工过程中往往会产生较大的切削力和切削温度,造成加工过程完成后表面完整性难以保证[4-5]。

其中,磨削是难加工材料及其零件的重要加工方式,具有加工表面粗糙度低、加工精度高等优点,尤其是现代磨削技术(如高速磨削、超高速磨削等)的加工效率也大幅提高[6],改变了粗切精磨的传统加工方式。

Views&CommentsRecent Progress in Surface Integrity Research andDevelopmentFengzhou Fang a,b,Chunyang Gu a,Ran Hao a,Kaiyuan You a,Siyu Huang aa State Key Laboratory of Precision Measuring Technology and Instruments,Center of Micro/Nano Manufacturing Technology(MNMT),Tianjin University,Tianjin300072,Chinab Center of Micro/Nano Manufacturing Technology(MNMT-Dublin),School of Mechanical and Materials Engineering,University College Dublin,Belfield D04V1W8,Ireland1.IntroductionSurface integrity has great significance for the quality and performance of machined components,and has therefore been increasingly recognized by industry.In particular,within certain industries that require high reliability,such as the aerospace industry,surface integrity is one of the most relevant indexes used to evaluate the quality of machined parts.Thus,obtaining updated knowledge on surface integrity is of great interest to both the academic community and industry[1].Surface integrity not only comprises surface topographical features[2,3],but also includes all of their physical,mechanical,metallurgical,chemical,and biological properties and characteristics[4].Since most manufacturing operations directly affect these properties,the objective of studying surface integrity is to ensure the required service properties of surfaces in part and product manufacturing. Focused research activities in surface integrity are widespread due to increasing demands for surface integrity application in industry,which are caused by industry’s need for a better understanding of the functional performance of components and that performance’s dependence on the surface integrity generated from various manufacturing processes.The CIRP Conference on Surface Integrity(CSI)discusses recent technical and scientific advancements,and future trends.This event aims to provide an international forum for researchers to present and exchange the latest achievements in surface-integrity-related research that have great significance in manufacturing and product quality,and that give insight into scientific knowledge on the formation and evolution of surface integrity in various surface processes.The conference includes keynote speeches,an expert panel discussion,oral presentations, posters,and more.More than200researchers participated in the CIRP Conference on CSI(2018)from various countries and regions,including China,France,Germany,Ireland,Japan,Poland, Singapore,Sweden,the United Kingdom,and the United States.This paper comments on the CSI2018keynote speeches,which reported on recent progress and achievements in theoretical and experimental investigations on surface integrity in manufacturing processes.The topics covered here include subsurface damage from machining hard and brittle materials,three-dimensional (3D)-printed hydrogel structures,residual stress in metal additive manufacturing(AM),process signatures,predictive modeling,and multiscale modeling.2.Machining hard and brittle materialsIn recent years,hard and brittle materials have been used in an increasing number of applications in variousfields such as commu-nication,optics,and aerospace.Due to their poor machinability, surface and subsurface damage tend to be left on workpieces that are composed of hard and brittle material,making it necessary to analyze their surface integrity.Ductile regime machining assesses brittle materials in terms of their mechanics and materials.If the machined surfaces of a brittle material are free of cracks and chips, the machining process is considered to be within the ductile regime;if not,the process is considered to be within the brittle regime[5].Several influential factors,including material proper-ties,machining conditions,and tool parameters,have a major influence on the dislocation and slip of materials during the machining process[6].Material-removal mechanisms vary in terms of their strain rates[7],and cutting speed has a significant effect on the surface quality of variable compliance parts[8].When the strain rate increases,the material-removal mechanism shifts from the ductile regime into the brittle regime.Strain rate has a strong influence on a material’s brittleness and micro-hardness;a higher strain rate always results in a more brittle material[9].Furthermore,as the cutting speed increases,the hardening depth also increases[10]. When working with brittle materials,it is inevitable for micro-cracks to be generated during machining;however,if a micro-crack is small enough and does not extend beyond the cutting depth,no subsurface damage occurs.Therefore,it is important to choose machine parameters to control the crack scale,which is easily influenced.Moreover,as a workpiece’s brittleness increases,the damage depth decreases[9].A change in strain rate can influence a material’s brittleness,following the rule that brittleness increases with an increase in strain rate,and that a higher strain rate can result in a larger pulverization area.Thus,damage suppression in high-speed machining is an important and urgent task.During a machining process,the material deformation mechanism transforms from isothermal deformation to adiabatic shear/ductilefracture and then to brittle fracture,due to increased cutting speed. Meanwhile,the clip morphology transforms from continuous to serrated and then to fragmented.This phenomenon has been ver-ified:When the cutting speed of machining Inconel718increases from800to7000mÁminÀ1,the surface roughness increases from 0.237to0.902l m,as shown in Fig.1[7].It is worth noting that material pile-up in machining is generally thought to be the sign of plastic(ductile)deformation; however,it has been verified that pile-up does not always indicate plastic deformation.Brittle regime machining can also generate pile-up with no visible cracks;however,examination of the subsurface would reveal a pulverization area underneath the machined surface[11].3.Surface integrity in additive manufacturingAM has been a fast-developing area in the past few years.Since AM is different from the traditional processing of materials,the factors that affect the surface integrity of parts made by AM should be discussed separately.AM techniques can be classified into seven categories based on international standards;these categories include vat photopolymerization,powder-bed fusion,material extrusion,and material jetting,among others[12].AM enables the freeform fabrication of complex structures,and has a wide range of applications in tissue fabrication.Both metals and bioma-terials can be used in AM,which expands the scope of applications[13].A metal AM process,such as selective laser melting(SLM),can be used to produce functional components directly.The surface integrity of products made through metal AM has become a research focus.In particular,residual stress in combination with some of the new characteristics of AM has ignited great interest among researchers.Residual stress may cause certain adverse effects in metal AM,including examples such as part distortion and cracks.Therefore,a great deal of research focuses on reducing its influence[14,15].The residual stress generated in manufacturing processes is related to many factors.Relevant research indicates that the most important parameters determining the magnitude and shape of residual stress profiles are the material properties,sample and sub-strate height,laser-scanning strategy,and heating conditions. Therefore,various specific residual stress mitigation and control methods are being investigated in order to address the abovemen-tioned issues.In situ feedback control is an effective method of dealing with residual stress;this method creates a closed-loop feedback of process parameters and controls the thermography. Thermal gradient control is another practical method,which can be realized by preheating the feedstock material and substrate.In addition to controlling manufacturing processes,residual stress can be controlled by post-processing,such as magneticfield-assisted polishing and burnishing.Due to donor shortages and transplant rejection,the medical profession is encountering organ-transplant challenges.Thus, envisioned organ printing is highly recommended,since it can be used to directly manufacture nonconventional parts based on a computer-aided design(CAD)model built by using computed tomography(CT)to scan patients’actual organs.It is the emergence of AM technology that has made it possible to print organs.Among the seven AM techniques mentioned above[12], extrusion-based printing is the most widely used process in bioprinting due to its easy implementation and high efficiency, as well as the wide range of extrudable materials available[16]. Because of the layer-by-layer fabrication process,mechanical and biological properties of tissue-like structures are potentially affected by interfacial features,which vary as a result of factors such as the concentration of hydrogel,concentration of crosslinking agent,gelation temperature,and gelation time.Experimental samples with interfaces in two orientations are fabricated by inkjet printing,and control samples with and without interfaces are fabricated by extrusion printing and casting,as shown in Fig.2[17].Conventional mechanical testing methods for AM,including quasi-static tensile testing,compression testing,and needle inser-tion(indentation),are still widely used to quantify mechanical behavior[17,18].Digital image correlation(DIC)is also used as an optical method to quantify interfacial deformation.In order to eliminate interfacial features thoroughly,a novel printing-then-solidification AM approach has been developed,which benefits from the yield-stress property of a nano-clay suspension.With this approach,the liquid state and shape of hydrogel structures can be retained during inside-bath printing(with nano-clay as a support bath)[16]or in-air printing(with nano-clay as an internal scaffold) [19],and then solidified simultaneously.The printing efficiency and accuracy of this approach may be investigated further in future.4.Predictive models for process-induced surface integrityAn increasing number of researchfindings are revealing prob-lems with conventional processing;for example,conventional flood cooling during processing may be prejudicial to surface integ-rity as well as to product life,operator health,and energy con-sumption.Therefore,sustainable processing is emerging as a relevantfield.Sustainable processing of a range of aerospace,auto-motive,and biomedical alloys can achieve enhanced product qual-ity,life performance,and sustainability,as well as improved process sustainability.Predictive modeling for process-induced surface integrity is of great significance to sustainable machining. The optimal processing parameters,which can be obtainedby Fig.1.The effect of cutting speed on machining Inconel718with10mm depth of cut.(a)800mÁminÀ1cutting speed;(b)7000mÁminÀ1cutting speed[7].F.Fang et al./Engineering4(2018)754–758755multiple operations and optimal processing of the model,can be used to realize sustainable machining.Several forward models,both analytic [20–22]and numerical [23,24],have been estab-lished in the past decade or more.Forward modeling does not solve the problem of near-infinite iterative experimentation,but merely replaces it with near-infinitive iterative computation.Modeling needs that have been proposed involve hybrid reverse modeling,from product performance to the prediction of process conditions.The desired functional performance would be input as the initial parameter in order to achieve a performance-based product and process prediction design,as shown in Fig.3[25].Reverse model-ing is a paradigm shift toward true surface engineering that would enable the production of novel products with unprecedented func-tional performance and sustainability.Physics-based convergent (multidisciplinary)models for the optimization of manufacturing processes should ultimately be process agnostic.Regardless of the manufacturing process,the external thermal,mechanical,and chemical loads that occur during the process cause specific internal material loads such as temperature and stress fields (see Fig.4,correlation 2[26]),and thus lead to modification of the material.Based on this knowl-edge,process signatures have been proposed [27],which link internal material loads with the resulting material modifications,and determine the underlying mechanisms in order to solve the inverse problem and pre-determine the required machining parameters.Thus far,outstanding progress has been achieved in process sig-natures [27–31].One prominent result is the uniform notation that has been developed for process signatures and their components.Fig.5[26]demonstrates that a process signature includes many Process Signature Components (PSCs)for different scale levels and different types of material modification.For each PSC box,one unified formula M =f (L )is used to embody the correlation between an internal material load (L )and a material modification (M )by involving numerical and analytical models as auxiliary means.Once the physics-based correlations are known,use of the knowledge-based approach to predict machining parameters under a desired functional property becomes feasible.In future,underlying mechanisms at the microstructural and polycrystalline level will become a highlight of process signatures.The impacts of the initial material state of a workpiece and of multi-stage process-ing and process chains are also beginning to attract attention [26].In order to apply theoretical models or inverse models to guide actual industrial production,more complex situations should be considered in industrial applications.Industrial manufacturing processes cover diversified multiscale and multi-physics industrial problems that require modeling and analysis in order to be flexible.In recent years,applications of ultra-precision productsareFig.2.Representative stress–strain curves for (a)inkjet-printed samples with longitudinal and transverse printing orientations and (b)a casting sample [17].Fig.3.The predictive product design process [25].PM,M,U,and PU refer to the pre-manufacturing,manufacturing,use,and post-use stages in life-cycle product,respectively.756 F.Fang et al./Engineering 4(2018)754–758becoming increasingly extensive;these include various optical lenses and other ultra-precision machining components whose geometrical accuracy can be as precise as 100nm.Moreover,human hand-held devices,which have a scale of centimeters,take up such a large market share that industry has put a great deal of effort into improving their efficiency while guaranteeing product quality.Therefore,the scale of industrial cases ranges widely,from a centimeter scale to micrometer and nanometer scales.A top-down modeling approach based on multiscale and multi-physics methods has been proposed in order to analyze this kind of indus-trial ultra-precision multiscale phenomenon [32,33].To date,multiscale and multi-physics modeling and analysis have been shown to be feasible and have been used in simulations of an aerofoil components manufacturing system.The next level will involve work using digital twins combined with smart machining and intelligent analysis,along with advanced precision machining,which can be a powerful tool for process optimization [34].Moreover,work with the simulation approach in digital smart machining has been verified by industrial cases and is believed to be capable of improving the ultra-precision machining process.5.Conclusions and outlookThrough reverse modeling,it is possible to establish the rela-tionship between machining parameters and functional perfor-mance in order to realize sustainable machining for better environmental friendliness,personnel health,and operational safety,and to achieve low machining cost and waste reduction.Given the current processing methods,the focus should be on con-trolling and optimizing the influencing factors with the greatest weights,and reflecting them in the model.In a specific machining process,particularly when machining hard and brittle materials,damage suppression for high-speed machining should be takeninto account,because the surface roughness increases as the cut-ting speed of machining increases.In general,surface integrity covers a wide range of research fields from modeling to metrology,and from manufacturing to pro-cess signatures;thus,it is a bridge that combines scientific research with specific applications.Surface integrity has come far beyond its initial concept—which originally focused on the five main areas of surface roughness,micro-hardness,microstructure,residual stress,and features—and is now much more comprehen-sive in concept than conventional surface metrology.However,no clear definition of surface integrity has been established as yet,so more details must be investigated in order to determine the essential commonalities within this field.In future work in surface integrity,more attention should be paid to interdisciplinary intersection and the practical needs of industry.Deep integration of manufacturing,measurement,mate-rial science,mathematics,and fundamental physics in surface and subsurface research would yield many promising achievements.The use of various processing methods that complement each other,in addition to new technologies,will allow us to further develop surface-integrity-related parameters to meet functional demands.AcknowledgementsThe CIRP Conference on Surface Integrity (CSI)in 2018was sponsored by the Chinese Academy of Engineering and the Tianjin Development Programme for International Academic Exchange Platform.References[1]Brinksmeier E.CSI Bremen 2012preface.Procedia Eng 2011;19:1–2.[2]Krolczyka GM,Marudab RW,Krolczyka JB,Nieslony P,Wojciechowski S,Legutko S.Parametric and nonparametric description of the surface topography in the dry and MQCL cutting conditions.Measurement 2018;121:225–39.[3]Krolczyk GM,Legutko S.Experimental analysis by measurement of surfaceroughness variations in turning process of duplex stainless steel.Metrol Meas Syst 2014;21(4):759–70.[4]Fang FZ,Xu FF.Recent advances in micro/nano-cutting:effect of tool edge andmaterial properties.Nanomanuf Metrol 2018;1:4–31.[5]Zhang B.Machining of hard and brittle materials:‘‘ductile regime”or ‘‘brittleregime”?[presentation].In:Proceedings of the 4th CIRP Conference on Surface Integrity;2018Jul 11–13;Tianjin,China;2018.[6]Fang F,Wu H,Zhou W,Hu X.A study on mechanism of nano-cutting singlecrystal silicon.J Mater Process Technol 2007;184(1):407–10.[7]Wang B,Liu Z,Su G,Ai X.Brittle removal mechanism of ductile materials withultrahigh-speed machining.J Manuf Sci Eng 2015;137(6):061002.[8]Nieslony P,Krolczyk GM,Wojciechowski S,Chudy R,Zak K,Maruda RW.Surface quality and topographic inspection of variable compliance part after precise turning.Appl Surf Sci 2018;434:91–101.[9]Zhang B,Howes TD.Subsurface evaluation of ground ceramics.CIRP Ann1995;44(1):263–6.[10]Krolczyk G,Legutko S,Nieslony P,Gajek M.Study of the surface integritymicrohardness of austenitic stainless steel after turning.Teh Vjesn 2014;21(6):1307–11.[11]Zhang B,Tokura H,Yoshikawa M.Study on surface cracking of aluminascratched by single-point diamonds.J Mater Sci 1988;23(9):3214–24.[12]Ringeisen BR,Pirlo RK,Wu PK,Boland T,Huang Y,Sun W,et al.Cell and organprinting turns 15:diverse research to commercial transitions.MRS Bull 2013;38(10):834–43.[13]Huang Y.Interfacial strength of layer-by-layer manufactured soft structures[presentation].In:Proceedings of the 4th CIRP Conference on Surface Integrity;2018Jul 11–13;Tianjin,China;2018.[14]Li C,Liu Z,Fang X,Guo Y.Residual stress in metal additive manufacturing.Procedia CIRP 2018;71:348–53.[15]Li C,Guo Y,Fang X,Fang F.A scalable predictive model and validation forresidual stress and distortion in selective laser melting.CIRP Ann 2018;67(1):249–52.[16]Jin Y,Compaan A,Chai W,Huang Y.Functional nanoclay suspension forprinting-then-solidification of liquid materials.ACS Appl Mater Interfaces 2017;9(23):20057–66.[17]Christensen K,Davis B,Jin Y,Huang Y.Effects of printing-induced interfaces onlocalized strain within 3D printed hydrogel structures.Mater Sci Eng C 2018;89:65–74.Fig.4.The causal sequence of manufacturing processes [26].Fig.5.Notation of a process signature with its single component [26].F.Fang et al./Engineering 4(2018)754–758757[18]Kaklamani G,Cheneler D,Grover L,Adams MJ,Bowen J.Mechanical propertiesof alginate hydrogels manufactured using external gelation.J Mech Behav Biomed Mater2014;36:135–42.[19]Jin Y,Liu C,Chai W,Compaan A,Huang Y.Self-supporting nanoclay as internalscaffold material for direct printing of soft hydrogel composite structures in air.ACS Appl Mater Interfaces2017;9(20):17456.[20]Wang X,Jawahir IS.Recent advances in plasticity applications in metalmachining:slip-line models for machining with rounded cutting edge restricted contact grooved tools.Int J Mach Machinabil Mater2007;2(3):347–60.[21]Ulutan D,Alaca BE,Lazoglu I.Analytical modeling of residual stresses inmachining.J Mater Process Technol2007;183(1):77–87.[22]Lazoglu I,Ulutan D,Alaca BE,Engin S,Kaftanoglu B.An enhanced analyticalmodel for residual stress prediction in machining.CIRP Ann2008;57(1):81–4.[23]Umbrello D,Outeiro JC,M’Saoubi R,Jayal AD,Jawahir IS.A numerical modelincorporating the microstructure alteration for predicting residual stresses in hard machining of AISI52100steel.CIRP Ann2010;59(1):113–6.[24]Pu Z,Dillon OW,Jawahir IS,Puleo DA.Microstructural changes of AZ31magnesium alloys induced by cryogenic machining and its influence on corrosion resistance in simulated bodyfluid for biomedical applications.In: Proceedings of the ASME2010International Manufacturing Science and Engineering Conference;2010Oct12–15;Erie,PA,USA.New York:ASME;2010.p.271–7.[25]Jawahir IS.Predictive models for process-induced surface integrity to achievedesirable functional performance in manufactured components [presentation].In:Proceedings of the4th CIRP Conference on Surface Integrity;2018Jul11–13;Tianjin,China;2018.[26]Brinksmeier E,Meyer D,Heinzel C,Lübben T,Sölter J,Langenhorst L,et al.Process signatures—the missing link to predict surface integrity in machining.Procedia CIRP2018;71:3–10.[27]Brinksmeier E,Gläbe R,Klocke F,Lucca DA.Process signatures—an alternativeapproach to predicting functional workpiece properties.Procedia Eng2011;19(1):44–52.[28]Brinksmeier E,Klocke F,Lucca DA,Sölter J,Meyer D.Process signatures—a newapproach to solve the inverse surface integrity problem in machining processes.Procedia CIRP2014;13:429–34.[29]Zhu X,Zhang F,Lei M,Guo D.Material loading in inverse surface integrityproblem solution of cemented carbide component manufacturing by surface modification.Procedia CIRP2016;45:235–8.[30]Lei M,Zhu X,Guo D.Reducing geometrical,physical and chemical constraintsin surface integrity of high performance stainless steel components by surface modification.J Manuf Sci Eng2016;138(4):044501.[31]Sealy MP,Liu Z,Guo Y,Liu Z.Energy based process signature for surfaceintegrity in hard milling.J Mater Process Technol2016;238:284–9.[32]Cheng K.Multi-scale multi-physics modelling and analysis with theapplication to precision manufacturing of aerospace structures and components[presentation].In:Proceedings of the4th CIRP Conference on Surface Integrity;2018Jul11–13;Tianjin,China;2018.[33]Qin S,Cheng K.Future digital design and manufacturing:embracing industry4.0and beyond.Chin J Mech Eng2017;30(5):1047–9.[34]Cheng K,Niu Z,Wang R,Rakowski R,Bateman R.Smart cutting tools and smartmachining:development approaches,and their implementation and application perspectives.Chin J Mech Eng2017;30(5):1162–76.758 F.Fang et al./Engineering4(2018)754–758Engineering 2 (2016) xxx–xxxViews & Comments表面完整性研究的进展与展望房丰洲a ,b ,顾春阳 a ,郝然 a ,游开元 a ,黄思雨 aaState Key Laboratory of Precision Measuring Technology and Instruments, Center of Micro/Nano Manufacturing Technology (MNMT), Tianjin University, Tianjin 300072, China bCenter of Micro/Nano Manufacturing Technology (MNMT-Dublin), School of Mechanical and Materials Engineering, University College Dublin, Belfield D04 V1W8, Ireland1.引言工件的表面完整性影响着其使用性能,这一点已经逐渐受到工业界的广泛重视,尤其是对产品可靠性要求较高的行业,如航空工业中表面完整性是评价工件加工表面质量最重要的指标之一。

对机械加工中零部件表面完整性的研究作者:李成梁马磊来源:《中国科技博览》2014年第29期[摘要]在机械加工中,表面质量是加工中的一个重要方面,而表面完整性又是影响表面质量的一个方面。

本文首先对表面完整性的判定要素和评价指标体系进行了介绍,在此基础上说明机械加工工艺对零部件表面完整性的影响。

[关键词]机械;加工工艺;零部件表面完整性;影响中图分类号:TH161.1 文献标识码:A 文章编号:1009-914X(2014)29-0023-011 零部件表面完整性零件的加工表面完整性是指:在机械工艺加工过程中,由于受控制的加工方法的影响,导致成品的表面状态或性能没有任何损伤,甚至有所加强的结果。

于是,机械零件“表面完整性”要求零件经过机械加工后表面层完整无损,零件表面层的机械物理性能、金相组织等均能满足使用要求,并确保具有一定的使用寿命。

1.1 机械零件“表面完整性”要素任何零件在加工后,都不能到达预期的完美效果。

在此针对表面纹理的形式、方向对密封性的影响总会存在着微观的偏差。

为此,在机械工艺加工过程中,我们提出了零件的“表面完整性”.其有两点点判定要素:一是加工表面的几何特征。

如粗糙度,加工表面缺陷。

缺陷的种类很多,在切削过程中产生最多的就是毛刺。

二是加工表层材料的性能。

如反映表层的塑性变形与加工硬化、表层的残余应力及表层的金相组织变化等方面的物理力学性;反映表面锈蚀、光学性能等要求及其特殊性能。

都是机械零件“表面完整性”的重要要素。

对于某一单一零件,应根据具体要求选取评价要素内容作为具体评价指标。

1.2 机械零件“表面完整性”评价指标体系表面完整性是从加工表面的几何纹理状态和表面受扰材料区的物理、化学、力学性能变化两个方面来评价和控制表面质量。

其评价指标可归纳为如下五类:一是表面的纹理形貌:包括表面粗糙中欧的、表面波度和表面纹理方向。

二是表面缺陷:包括加工毛刺、飞边、宏观裂纹、表面撕裂和皱折等缺陷。

金属材料与零件的表面完整性与疲劳断裂抗力间的关系王仁智(北京航空材料研究院,北京100095)摘要:本文论述了金属材料/零件的表面完整性与其疲劳断裂抗力之间的关系。

试验结果表明,表面完整性中的残余应力、组织结构与表面粗糙度这三个因素对疲劳断裂抗力是最有影响力的三个因素。

关键词:表面完整性,组织结构,残余应力,疲劳断裂抗力Review on the Relationship between Surface Integrity and Fatigue Fracture Resistance of Metallic Materials and ComponentsWang Renzhi(Institute of Aeronautical Materials, Beijing, 100095)Abstract: The relationship between surface integrity (SI) of metal materials and fatigue fracture resistance (FFR) are discussed. The experiments have been shown that the three factors of residual stress microstructure as well as surface roughness including in the all factors of SI have the most influence on the FFR.Keywords:Surface integrity; Microstructure; Residual stress; Fatigue fracture resistance.引言任何一种金属材料及其零部件的疲劳断裂(高周或低周疲劳),其疲劳源绝大多数情况下萌生于表面。

因此,金属材料/零件的疲劳断裂抗力(Fatigue fracture resistance –FFR),首先取决于表面完整性(Surface integrity - SI)。

第15卷第6期精密成形工程贺柏涵1,周文龙1,2,程旭3,盖鹏涛4,李春艳1,陈国清1,付雪松1,2(1.大连理工大学材料科学与工程学院,辽宁大连 116024;2.大连理工(营口)新材料工程中心有限公司,辽宁营口 115004;3.空装驻沈阳地区第一军事代表室,沈阳 110850;4.中国航空制造技术研究院,北京 100024)摘要:目的以7A65高强度铝合金为研究对象,研究喷丸强度、弹丸介质(铸钢丸和陶瓷丸)对靶材疲劳性能的影响规律。

方法利用扫描电镜、激光共聚焦显微镜、X射线衍射仪等仪器表征喷丸强化7A65铝合金表面完整性和疲劳失效断口,分析喷丸工艺参数与疲劳性能、断裂模式的相关性。

结果喷丸强化后铝合金表面粗糙化严重,表面粗糙度从初始0.622 μm增加至4.736 μm(铸钢丸、喷丸强度为0.22 mmA),并出现褶皱损伤;在相同喷丸强度下陶瓷丸喷丸表面粗糙度较低,无褶皱损伤。

2种弹丸在金属表面引入的残余应力场基本相同,残余压应力层深约300 μm,最大残余压应力值为−480.6 MPa,其产生位置为距离表面75 μm 处(喷丸强度为0.22 mmA)。

铝合金疲劳性能对铸钢丸介质敏感性较高,当喷丸强度较低(0.11 mmA)时喷丸强化效果最佳,疲劳寿命是原始寿命的5倍多,疲劳源从表面转移至次表面(500 μm);当喷丸强度增至0.22 mmA时,裂纹源向表面靠近,疲劳寿命为原始寿命的2倍。

铝合金疲劳性能对陶瓷丸介质敏感性较低,在喷丸强度为0.11~0.22 mmA时疲劳寿命较为稳定,在喷丸强度为0.11 mmA时疲劳寿命最高,为原始寿命的7倍。

结论7A65高强度铝合金经喷丸强化后疲劳寿命显著提升,强化效果受弹丸介质影响,陶瓷丸介质强化效果更好、喷丸强化工艺窗口更宽。

关键词:7A65铝合金;疲劳寿命;喷丸强化;表面完整性;表面粗糙度;残余应力DOI:10.3969/j.issn.1674-6457.2023.06.001中图分类号:TG174.4 文献标识码:A 文章编号:1674-6457(2023)06-0001-10Surface Integrity and Fatigue Properties of Shot PeeningStrengthened 7A65 Aluminum AlloyHE Bai-han1, ZHOU Wen-long1,2, CHENG Xu3, GAI Peng-tao4, LI Chun-yan1, CHEN Guo-qing1, FU Xue-song1,2(1. School of Materials Science and Engineering, Dalian University of Technology, Liaoning Dalian 116024, China;2. Dalian Technology (Yingkou) New Material Engineering Center Limited Company, Liaoning Yingkou 115004, China;收稿日期:2023–03–16Received:2023-03-16基金项目:国家自然科学基金(51975084);辽宁省自然科学基金(2022–YKLH–04);中央高校基本科研业务费专项(DUT19LAB16);辽宁省“兴辽英才计划”(XLYC1902084)Fund:National Natural Science Foundation of China(51975084); Natural Science Foundation of Liaoning Prov-ince(2022-YKLH-04); Basic Research Funds for Central Universities(DUT19LAB16); Supported by "Xingliao Talents Program" of Liaoning Province(XLYC1902084)作者简介:贺柏涵(1997—),男,硕士生,主要研究方向为铝合金表面强化。

网络教育学院本科生毕业论文(设计)题目:切削加工表面完整性研究现状学习中心:层次:专科起点本科专业:机械设计制造及其自动化年级:年季学号:学生:指导教师:完成日期:年月日内容摘要机械加工得到的零件表面完整性特征可分为三类:(1)表面形貌特征:表面缺陷、表面纹理和表面粗糙度等;(2)表面机械性能:残余应力和显微硬度等;(3)金相组织变化:加工变质层、白层、夹杂物等。

本文围绕切削加工后零件表面完整性三类特征指标,系统论述了各自的研究发展历程,重点对表面粗糙度、残余应力、显微硬度、白层及变质层进行了归纳,概括了各自的研究方案、技术手段及研究成果。

关键词:切削加工;表面完整性;研究现状目录内容摘要 (I)前言 (1)1 切削加工表面完整性研究的发展 (2)1.1 表面完整性的提出及发展 (2)1.2 表面完整性研究意义 (2)2 表面粗糙度研究 (3)3 残余应力研究 (4)3.1 残余应力的生成机理研究 (4)3.2 残余应力影响因素的实验研究 (4)4 加工硬化研究 (5)4.1加工硬化的影响因素研究 (5)4.2 材料特性对工件加工硬化的影响 (5)4.3 显微硬度沿工件深度方向的分布规律研究 (5)5 切削加工白层研究 (6)5.1 白层的形成机制 (6)5.2 白层的影响因素研究 (6)5.2.1 切削参数对白层的影响 (6)5.2.2 工件材料特性对白层的影响 (7)6 变质层研究 (8)6.1 变质层的组织特点 (8)6.2 切削参数对变质层的影响 (8)参考文献 (9)前言机械加工得到的零件表面完整性特征可分为三类:(1)表面形貌特征:表面缺陷,表面纹理和表面粗糙度等;(2)表面机械性能:残余应力和显微硬度等;(3)金相组织变化:加工变质层,白层、夹杂物等。

零件的表面完整性影响着零件的后续加工以及最终使用性能,尤其在航空航天领域对关键零件的耐磨性能和耐疲劳性能要求很高。

表面完整性中的残余应力如果是残余压应力可以减小零件表面裂纹的扩展,提高耐疲劳性能,而拉伸残余应力则会加速表面裂纹的扩展,加速了零件的疲劳破坏,且在有应力集中或者有腐蚀性介质存在的工况下,残余拉应力对零件疲劳强度的影响更为突出;加工硬化会降低零件表面的塑形和韧性,对零件的疲劳强度和疲劳寿命不利,但是均匀的加工硬化有利于提高零件的硬度和耐磨性;白层有耐蚀和硬度高的特点,但是其内部常常含有裂纹,脆性大且与基体结合不牢固,容易发生早期剥落脱离;变质层的产生会引起加工表面产生残余应力和微观组织结构的改变,由于其组织均匀性较差且伴有裂纹,容易降低零件的耐磨性和耐疲劳性能。

2016•9(上)《科技传播》164创新与应用技术在机械加工领域当中,对于零部件的表面质量,有着很高的要求。

在零部件的加工当中,采用一定的机械加工工艺,使零部件成品表面不存在任何损伤,甚至有所加强的结果,就是零部件表面完整性。

目前,在很多国家的工业生产当中,零部件表面完整性都得到了广泛的重视,在对零部件加工过程中的性能、表面状况等进行控制与评价的过程中,都发挥了重要的作用。

1 机械加工工艺1.1 机械加工工艺的概念在机械加工工艺当中,作为一门科学,经验是十分重要的,能够提升这门科学的实用性。

在进行加工的过程中,机械加工工艺是一个重要依据。

通过机械加工,对毛坯的性质、尺寸、形状等进行改变,从而使其成为合格零件。

在零部件的加工当中,机械加工工艺是重要的步骤。

在流程的基础上,利用机械加工工艺,加工毛坯成为半成品或成品,最终实现零部件的应用。

1.2 机械加工工艺的技术在机械加工工艺当中,包含了柔性自动化加工、难加工材料切削加工、花键加工、齿轮加工、螺纹加工、特种加工、超精密加工、精密加工、磨削、拉削、镗削、钻削、铣削、车削、规程制定、机械加工质量、毛坯及余量、材料及热处理、金属切削原理等技术与工艺数据资料[1]。

在一些较为复杂的工艺过程当中,需要利用相应的工具、技术等进行辅助。

例如,计算机辅助工艺设计系统,作为一种高效、实用的机选及系统,能够实现自动化的信息处理,计算机化的工艺设计过程。

通过对相应技术的合理搭配与应用,能够对零部件的质量进行更为有效的确保。

2 零部件表面完整性2.1 零部件表面完整性的概念随着科技的发展,零部件的运行和工作环境日益恶劣,因此对零部件的质量提出了更高的要求[2]。

而零部件的表面完整性,将会对其性能产生直接的影响。

在零部件表面完整性当中,要求在经过机械加工之后,零部件应当满足无损、完整的表面层,使其表面的金相组织、机械物理性能等,满足实际的应用需求,并且确保良好的使用寿命。

2.2 零部件表面完整性的要素就目前的机械加工工艺水平来看,都不能达到完美的效果。

机械加工零件表面完整性表征模型研究曾泉人 刘 更 刘 岚西北工业大学,西安,710072摘要:总结了机械加工零件表面完整性的发展及其表征与测量的已有方法和标准。

针对零件精加工的表面完整性要求,借鉴美国表面完整性切削加工数据组,提出了表面完整性表征模型,并明确给出了表征模型中各特征的主要表征参数。

考虑具体被加工零件及其工艺,同时结合表面完整性内涵,初步构建了机械加工零件的表面完整性概念模型,为机械加工零件表面完整性的控制及其疲劳寿命的提高,提供了理论基础和实施途径。

关键词:表面完整性;表征模型;表面形貌;疲劳寿命中图分类号:T H 123;TH 161.1 文章编号:1004 132X(2010)24 2995 05Quantitative Description Model of Surface Integrity for Machined PartsZeng Quanren Liu Geng Liu LanNo rthw estern Po lytechnical University,Xi an,710072Abstract :The existing standar d and development about description and measurement of surface integrity for machined parts were summarized.According to the requir em ents of sur face integrity fo r the par ts w ith precision m achining,a quantitative m odel of descriptio n fo r sur face integrity w as pro posed and the parameter s of characteristics w ithin the description model were definitely detailed.Co nsidering the specific parts and corresponding machining pro cesses,a co nceptual m odel of surface integrity for machined parts w as established by co mbining the natures of surface integr ity.T his resear ch o ffer s theoretical basis and feasible operational fram ew ork for the contr ol of sur face integ rity and improvement of the fatigue life fo r m achined parts.Key words :surface integrity;description m odel;surface topogr aphy;fatigue life收稿日期:2010 03 22基金项目:国家自然科学基金资助项目(50975232);国家重点基础研究发展计划(973计划)资助项目0 引言材料的强度及疲劳寿命准则是机械加工航空零件的设计依据,疲劳性能是航空零件可靠性及使用寿命的决定性因素。

表面完整性评价与检测方法研究作者:宋策来源:《科学与财富》2019年第19期摘要:本文以航空发动机领域表面完整性技术为重点,详细介绍了表面完整性数据检测的方法手段病做了简单的对比,为后续系统开展表面完整性检测、评价研究提供技术基础。

关键词:表面完整性数据组;表面完整性评价方法;表面特征检测方法1 引言美国最先提出了三个级别表面完整性数据组,颁布了表面完整性国家标准,建立了完善的表面完整性表征与检测体系,西方先进航空发动机企业,如RR、GE等,在前期大龄数据积累的基础上,已经形成了比较完善的标准规范体系,采用验收标准+实验室检测的方式,详细规定了零件表面完整性表征数据的验收标准、检测方法及操作规范,因此可以在最大程度上保证检测结果的准确性和一致性,使零件表面完整性控制具备良好的研究基础。

2 表面完整性评价方法Field和Kahles 在1972年详细论述了表面完整性的定义以及它的重要性,总结了被加工零件当时所面临的诸多表面完整性问题,并首次强调指出:传统或非传统加工工艺将会使合金表面和表层产生塑性变形、微观裂纹、相变、显微硬度、撕裂和裂纹、残余应力等冶金学变化。

他们提出了三个级别表面完整性数据组,包括最小数据组标准数据组和扩展数据组。

其中,最小数据组是一种最经济的表面完整性描述方式;标准数据组为重要的应用提供详细的数据;扩展数据组增加了疲劳试验、应力腐蚀以及补充的机械试验等。

3 表面特征测量方法3.1 表面粗糙度表面粗糙度的主要测量方法有比较法、印模法、接触测量和非接触测量。

以TR240表面轮廓仪测量为例。

当采用表面轮廓仪测量试件表面粗糙度时,取样长度L=0.8MM,评定长度LN=5XL=4.0MM。

取样长度L是用于判别具有表面粗糙度特征的一段基准线长度,等于表面轮廓仪的截取长度,它可以限制和减弱表面波纹度对表面粗糙度测量结果的影响。

长度LN是评定轮廓所必须的一段长度,通常包括5个取样长度。

采用接触式测量时更要注意,只显示粗糙度值得电子仪器对于不同特征的表面轮廓所测到的粗糙度值却几乎相同。

复合材料加工中多物理场耦合作用下的表面完整性复合材料因其优异的力学性能、轻质高强以及可设计性,在航空航天、汽车制造、体育器材等领域得到了广泛应用。

然而,在复合材料的加工过程中,由于材料的多相性和各向异性,加工过程中的多物理场耦合作用对材料的表面完整性产生了显著影响。

本文将探讨复合材料加工中多物理场耦合作用下的表面完整性问题。

一、复合材料加工中的多物理场耦合现象在复合材料的加工过程中,如切削、磨削、激光加工等,材料受到力、热、电、化学等多种物理场的共同作用。

这些物理场之间相互影响、相互制约,形成了复杂的耦合作用。

例如,在切削过程中,切削力会导致材料的弹性变形和塑性变形,同时切削热会使材料表面温度升高,进而影响材料的力学性能和加工质量。

此外,切削液的化学作用也会对材料表面产生影响。

1.1 力场耦合作用在复合材料加工中,力场耦合作用主要表现为切削力、磨削力等对材料表面的影响。

这些力的作用会导致材料表面的塑性变形、裂纹的形成和扩展,从而影响表面完整性。

力场耦合作用的研究对于优化加工参数、提高加工质量具有重要意义。

1.2 热场耦合作用热场耦合作用在复合材料加工中同样重要。

加工过程中产生的切削热、磨削热等会使材料表面温度升高,导致材料热膨胀、热应力的产生,进而影响材料的表面完整性。

热场耦合作用的研究有助于控制加工过程中的热影响,提高加工精度和表面质量。

1.3 电场耦合作用在某些特殊加工过程中,如电火花加工、激光加工等,电场耦合作用对复合材料的表面完整性也有显著影响。

电场的作用会导致材料表面的电蚀、熔化和气化等现象,从而影响加工表面的粗糙度和完整性。

1.4 化学场耦合作用化学场耦合作用主要体现在加工过程中使用的切削液、磨削液等化学介质对材料表面的影响。

这些化学介质可能会与材料表面发生化学反应,导致材料表面腐蚀、氧化等现象,影响表面完整性。

二、表面完整性的影响因素复合材料加工中的表面完整性受到多种因素的影响,包括材料特性、加工方法、加工参数等。