套管强度校核全解

- 格式:ppt

- 大小:894.00 KB

- 文档页数:81

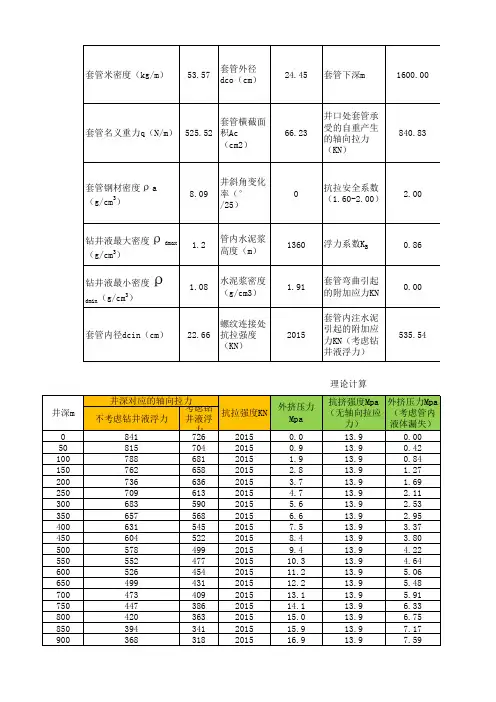

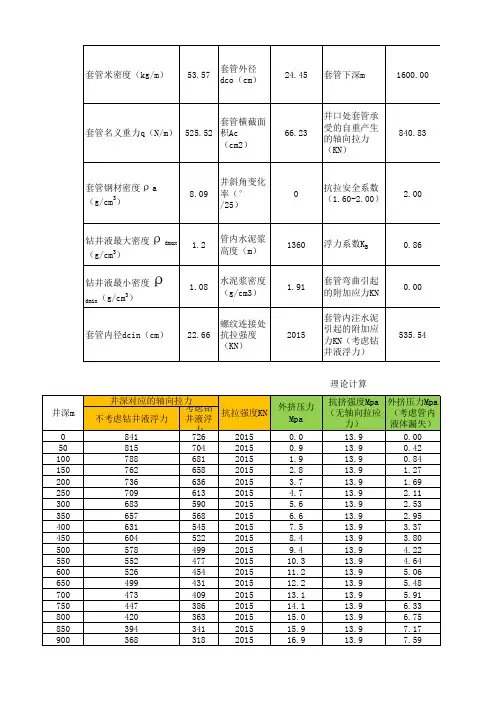

理论计算漏失液面深度1200套管底部有效外挤压力31.11732套管下深m漏失液面深度m 套管鞋处有效外挤压漏失液面处的外挤压力Mpa井口处拉力KN漏失面处的拉力KN双轴应力下井口处套管抗挤强度Mpa20000-1.9620908.109614908.109614410.68370136 19900-1.95220903.569066903.569066310.7034519 19800-1.94240899.028518899.028518310.72316264 19700-1.93260894.48797894.487970210.74283362 19600-1.92280889.947422889.947422110.76246492 19500-1.9130885.406874885.40687410.7820566 19400-1.90310880.866326880.86632610.80160872 19300-1.89330876.325778876.325777910.82112134 19200-1.88350871.78523871.785229810.84059452 19100-1.87370867.244682867.244681810.86002834 19000-1.86390862.704134862.704133710.87942284 18900-1.85410858.163586858.163585610.89877808 18800-1.84430853.623038853.623037510.91809414 18700-1.83450849.082489849.082489510.93737107 18600-1.82470844.541941844.541941410.95660892 18500-1.81490840.001393840.001393310.97580776 18400-1.8050835.460845835.460845210.99496764 18300-1.79520830.920297830.920297211.01408862 18200-1.78540826.379749826.379749111.03317076考虑双轴应力时套管下入深度和抗挤强度关系18100-1.77560821.839201821.83920111.05221412 18000-1.76580817.298653817.29865311.07121875 17900-1.7560812.758105812.758104911.09018471 17800-1.74620808.217557808.217556811.10911206 17700-1.73640803.677009803.677008711.12800084 17600-1.72660799.136461799.136460711.14685112 17500-1.71680794.595913794.595912611.16566294 17400-1.70690790.055365790.055364511.18443636 17300-1.69710785.514816785.514816511.20317144 17200-1.68730780.974268780.974268411.22186823 17100-1.67750776.43372776.433720311.24052678 17000-1.66770771.893172771.893172211.25914714 16900-1.65790767.352624767.352624211.27772936 16800-1.64810762.812076762.812076111.2962735 16700-1.63830758.271528758.27152811.31477961 16600-1.62850753.73098753.7309811.33324773 16500-1.61870749.190432749.190431911.35167792 16400-1.60880744.649884744.649883811.37007022 16300-1.5990740.109336740.109335711.38842469 16200-1.58920735.568788735.568787711.40674137 16100-1.57940731.02824731.028239611.42502032 16000-1.56960726.487692726.487691511.44326157 15900-1.55980721.947143721.947143411.46146519 15800-1.550717.406595717.406595411.4796312 15700-1.54020712.866047712.866047311.49775967 15600-1.53040708.325499708.325499211.51585064 15500-1.52060703.784951703.784951211.53390415 15400-1.51070699.244403699.244403111.55192025 15300-1.50090694.703855694.70385511.56989899 15200-1.49110690.163307690.163306911.58784041 15100-1.48130685.622759685.622758911.60574455 15000-1.47150681.082211681.082210811.62361146 14900-1.46170676.541663676.541662711.64144118 14800-1.45190672.001115672.001114711.65923375 14700-1.44210667.460567667.460566611.67698923 14600-1.43230662.920019662.920018511.69470764 14500-1.42250658.37947658.379470411.71238904 14400-1.41260653.838922653.838922411.73003346 14300-1.40280649.298374649.298374311.74764095 14200-1.3930644.757826644.757826211.76521155 14100-1.38320640.217278640.217278211.7827453 14000-1.37340635.67673635.676730111.80024223 13900-1.36360631.136182631.13618211.81770239 13800-1.35380626.595634626.595633911.83512583 13700-1.3440622.055086622.055085911.85251257 13600-1.33420617.514538617.514537811.86986265 13500-1.32440612.97399612.973989711.88717612 13400-1.31450608.433442608.433441611.90445302 13300-1.30470603.892894603.892893611.92169337 13200-1.29490599.352346599.352345511.93889723 13100-1.28510594.811797594.811797411.95606462 13000-1.27530590.271249590.271249411.97319559 12900-1.26550585.730701585.730701311.99029016 12800-1.25570581.190153581.190153212.0073483812700-1.24590576.649605576.649605112.02437028 12600-1.23610572.109057572.109057112.0413559地层水密度1.03漏失面深度m0(g/cm3)管体屈服强2508.8水泥浆密度 1.91度KN漏失系数0固井时钻井1.1液密度最大抗外挤13.9强度Mpa抗拉强度KN2015双轴应力下漏失面处的抗挤强度套管鞋处抗挤安全系数漏失面处抗挤安全系数10.6837014-7.08460754#DIV/0!10.7034519-7.12020859#DIV/0!10.7231626-7.15616924#DIV/0!10.7428336-7.19249497#DIV/0!10.7624649-7.22919137#DIV/0!10.7820566-7.26626415#DIV/0!10.8016087-7.30371912#DIV/0!10.8211213-7.34156222#DIV/0!10.8405945-7.37979952#DIV/0!10.8600283-7.41843722#DIV/0!10.8794228-7.45748162#DIV/0!10.8987781-7.4969392#DIV/0!10.9180941-7.53681654#DIV/0!10.9373711-7.57712037#DIV/0!10.9566089-7.61785757#DIV/0!10.9758078-7.65903518#DIV/0!10.9949676-7.70066037#DIV/0!11.0140886-7.74274048#DIV/0!11.0331708-7.78528301#DIV/0!11.0901847-7.91576262#DIV/0!11.1091121-7.96023319#DIV/0!11.1280008-8.00520626#DIV/0!11.1468511-8.05069039#DIV/0!11.1656629-8.09669434#DIV/0!11.1844364-8.14322706#DIV/0!11.2031714-8.19029774#DIV/0!11.2218682-8.23791575#DIV/0!11.2405268-8.28609069#DIV/0!11.2591471-8.3348324#DIV/0!11.2777294-8.38415094#DIV/0!11.2962735-8.4340566#DIV/0!11.3147796-8.48455993#DIV/0!11.3332477-8.53567174#DIV/0!11.3516779-8.58740308#DIV/0!11.3700702-8.6397653#DIV/0!11.3884247-8.69276999#DIV/0!11.4067414-8.74642907#DIV/0!11.4250203-8.80075471#DIV/0!11.4432616-8.85575943#DIV/0!11.4614652-8.91145603#DIV/0!11.4796312-8.96785765#DIV/0!11.4977597-9.02497776#DIV/0!11.5158506-9.08283018#DIV/0!11.5339042-9.14142909#DIV/0!11.5519203-9.20078902#DIV/0!11.569899-9.26092489#DIV/0!11.5878404-9.32185203#DIV/0!11.6057445-9.38358615#DIV/0!11.6236115-9.44614339#DIV/0!11.6414412-9.50954033#DIV/0!11.6592338-9.57379398#DIV/0!11.6769892-9.63892183#DIV/0!11.6947076-9.70494184#DIV/0!11.712389-9.77187247#DIV/0!11.7300335-9.8397327#DIV/0!11.747641-9.90854202#DIV/0!11.7652116-9.97832048#DIV/0!11.7827453-10.0490887#DIV/0!11.8002422-10.1208679#DIV/0!11.8177024-10.1936799#DIV/0!11.8351258-10.2675472#DIV/0!11.8525126-10.3424928#DIV/0!11.8698627-10.4185405#DIV/0!11.8871761-10.4957149#DIV/0!11.904453-10.5740411#DIV/0!11.9216934-10.6535452#DIV/0!11.9388972-10.7342539#DIV/0!11.9560646-10.8161947#DIV/0!11.9731956-10.8993962#DIV/0!11.9902902-10.9838877#DIV/0!12.0073484-11.0696993#DIV/0!。

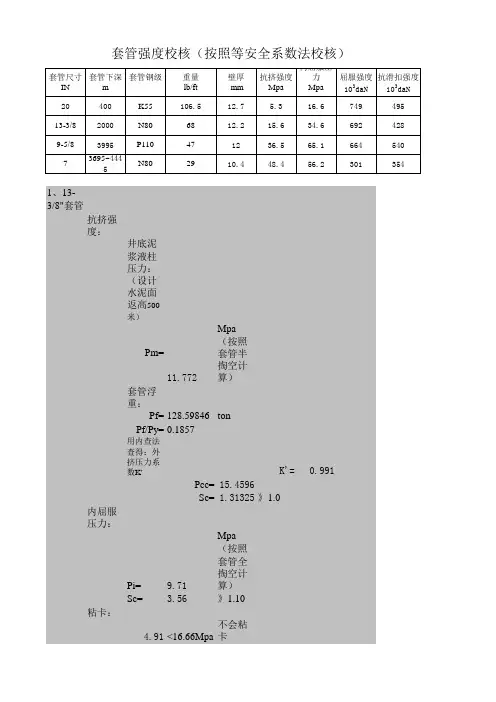

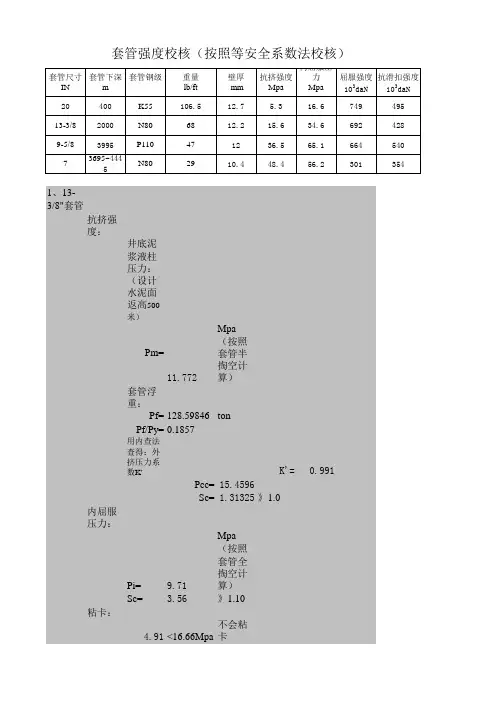

套管强度校核(按照等安全系数法校核)1、13-3/8"套管抗挤强度:井底泥浆液柱压力:(设计水泥面返高500米)Pm=11.772Mpa(按照套管半掏空计算)套管浮重:Pf=128.59846tonPf/Py=0.1857用内查法查得:外挤压力系数K'K'=0.991Pcc=15.4596Sc=1.31325》1.0内屈服压力:Pi=9.71Mpa(按照套管全掏空计算)Sc= 3.56》1.10粘卡:4.91<16.66Mpa不会粘卡结论:该套管安全。

2、9-5/8"套管抗挤强度:井底泥浆液柱压力:(设计水泥面返高500米)Pm=29.43Mpa(按照套管半掏空计算)套管浮重:Pf=111.68ton按照环空封固800米计算Pf/Py=0.37用内查法查得:外挤压力系数K'K'=0.979Pcc=35.7335Sc=3.03547》1.0内屈服压力:Pi=17.45Mpa(按照套管全掏空计算)Sc= 3.73》1.10粘卡:19.60<21.66MPa不会粘卡3、7"尾管粘卡:13.08<16.66MPa不会粘卡4. 7"CSG抗挤强度:井底泥浆液柱压力:(设计水泥面返高500米)Pm=45.9108Mpa(按照套管半掏空计算)Safety:套管浮重:Pf=129.63ton按照环空封固800米计算Tensile:Py/Pf=2.09用内查法查得:外挤压力系数K'K'=0.979Pcc=0Sc=0》1.0内屈服压力:Pi=16.06Mpa(按照套管全掏空计算)Sc= 1.35》1.10粘卡:10.59<21.66MPa不会粘卡1.160671。

2014-2015学年第二学期《完井工程》《套管柱强度校核》上机报告班级:石油工程12级1班姓名:李国锋学号:教师:一、欲解决问题的说明某井177.8毫米油层套管下至井深3600m,ρ=1.6g/cm3,水泥返到地面,预计气层深度3700m处七层压力Pp=59Mpa,尾管射孔完井,油管不带封隔器生产。

试对井段套管柱强度校核。

二、问题求解分析过程①设计方法按照各段所选套管钢级壁厚,查找套管对应抗挤强度,丝扣连接强度,以及抗内压强度,计算各段套管段底外挤力,段顶拉力,以及天然气充满井时的内压力。

从而求得抗挤、抗拉、抗内压系数。

②主要公式Sc=Pc/ρgHSt=Fst/Fm 其中Fm=qgLSi=Pi/(Pp/e1.1155×10-4GD)③符号说明程序中出现符号主要有:Pc——套管受到的外挤力Fm——套管收到的下部套管重力之和Fs——套管的屈服强度Fst——套管的丝扣滑脱强度Sc——套管抗挤系数St——套管抗拉系数Si——套管抗内压系数D——表示某段套管下入深度L——表示某段套管长度三、程序功能介绍及代码①程序功能本程序可以代替人工进行某一井段套管柱强度校核,通过程序可以查看各个井段套管柱是否符合各个安全系数要求。

确保套管柱安全。

②程序运行界面见图1③附源程序代码Private Sub Command1_Click()Dim L1, L2, L3, L4, L5 As Integer Dim D1, D2, D3, D4, D5 As Integer Dim Sc1, Sc2, Sc3, Sc4, Sc5 As Single Dim St1, St2, St3, St4, St5 As Single Dim Si1, Si2, Si3, Si4, Si5 As Single Dim bh1, bh2, bh3, bh4, bh5 As Single Dim ρ As SingleD1 = Val(Text26.Text)ρ = Val(Text27.Text)Pp = Val(Text28.Text)L1 = Val(Text5.Text)L2 = Val(Text4.Text)L3 = Val(Text3.Text)L4 = Val(Text2.Text)L5 = Val(Text1.Text)bh1 = Text20.Textbh2 = Text19.Textbh3 = Text18.Textbh4 = Text17.Text图1 bh5 = Text16.Text'根据段长自动计算井段'Text15.Text = D1Text14.Text = D1 - L1Text13.Text = Text14.TextD2 = Text13.TextText12.Text = D2 - L2Text11.Text = Text12.TextD3 = Text11.TextText10.Text = D3 - L3Text9.Text = Text10.TextD4 = Text9.TextText8.Text = D4 - L4Text7.Text = Text8.TextD5 = Text7.TextText6.Text = D5 - L5'第一段校核'If bh1 = 8.05 Thenq1 = 34.22: Pc1 = 26400000: Pi1 = 43710000: Fst1 = 1966000ElseIf bh1 = 9.19 Thenq1 = 38.69: Pc1 = 37296000: Pi1 = 49918000: Fst1 = 2308000ElseIf bh1 = 10.36 Thenq1 = 43.15: Pc1 = 48398000: Pi1 = 56253000: Fst1 = 2656000ElseIf bh1 = 11.51 Thenq1 = 47.62: Pc1 = 59293000: Pi1 = 62461000: Fst1 = 2989000ElseIf bh1 = 12.65 Thenq1 = 52.08: Pc1 = 70189000: Pi1 = 63706000: Fst1 = 3319000End IfSc1 = Round((Pc1 / (ρ * 9810 * D1)), 2)Label30.Caption = Sc1Fm1 = 9.81 * q1 * L1St1 = Round((Fst1 / Fm1), 2)Label35.Caption = St1Si1 = Round((Pi1 * (2.7183 ^ (0.00011155 * 0.55 * D1)) / (Pp * 1000000)), 2)Label40.Caption = Si1'第二段校核'If bh2 = 8.05 Thenq2 = 34.22: Pc2 = 26400000: Pi2 = 43710000: Fst2 = 1966000ElseIf bh2 = 9.19 Thenq2 = 38.69: Pc2 = 37296000: Pi2 = 49918000: Fst2 = 2308000ElseIf bh2 = 10.36 Thenq2 = 43.15: Pc2 = 48398000: Pi2 = 56253000: Fst2 = 2656000ElseIf bh2 = 11.51 Thenq2 = 47.62: Pc2 = 59293000: Pi2 = 62461000: Fst2 = 2989000ElseIf bh2 = 12.65 Thenq2 = 52.08: Pc2 = 70189000: Pi2 = 63706000: Fst2 = 3319000End IfSc2 = Round((Pc2 / (ρ * 9810 * D2)), 2)Label29.Caption = Sc2Fm2 = (9.81 * q2 * L2) + Fm1St2 = Round((Fst2 / Fm2), 2)Label34.Caption = St2Si2 = Round((Pi2 * (2.7183 ^ (0.00011155 * 0.55 * D2)) / (Pp * 1000000)), 2)Label39.Caption = Si2'第三段校核'If bh3 = 8.05 Thenq3 = 34.22: Pc3 = 26400000: Pi3 = 43710000: Fst3 = 1966000ElseIf bh3 = 9.19 Thenq3 = 38.69: Pc3 = 37296000: Pi3 = 49918000: Fst3 = 2308000ElseIf bh3 = 10.36 Thenq3 = 43.15: Pc3 = 48398000: Pi3 = 56253000: Fst3 = 2656000ElseIf bh3 = 11.51 Thenq3 = 47.62: Pc3 = 59293000: Pi3 = 62461000: Fst3 = 2989000ElseIf bh3 = 12.65 Thenq3 = 52.08: Pc3 = 70189000: Pi3 = 63706000: Fst3 = 3319000End IfSc3 = Round((Pc3 / (ρ * 9810 * D3)), 2)Label28.Caption = Sc3Fm3 = (9.81 * q3 * L3) + Fm2St3 = Round((Fst3 / Fm3), 2)Label33.Caption = St3Si3 = Round((Pi3 * (2.7183 ^ (0.00011155 * 0.55 * D3)) / (Pp * 1000000)), 2)Label38.Caption = Si3'第四段校核'If bh4 = 8.05 Thenq4 = 34.22: Pc4 = 26400000: Pi4 = 43710000: Fst4 = 1966000ElseIf bh4 = 9.19 Thenq4 = 38.69: Pc4 = 37296000: Pi4 = 49918000: Fst4 = 2308000ElseIf bh4 = 10.36 Thenq4 = 43.15: Pc4 = 48398000: Pi4 = 56253000: Fst4 = 2656000ElseIf bh4 = 11.51 Thenq4 = 47.62: Pc4 = 59293000: Pi4 = 62461000: Fst4 = 2989000ElseIf bh4 = 12.65 Thenq4 = 52.08: Pc4 = 70189000: Pi4 = 63706000: Fst4 = 3319000End IfSc4 = Round((Pc4 / (ρ * 9810 * D4)), 2)Label27.Caption = Sc4Fm4 = (9.81 * q4 * L4) + Fm3St4 = Round((Fst4 / Fm4), 2)Label32.Caption = St4Si4 = Round((Pi4 * (2.7183 ^ (0.00011155 * 0.55 * D4)) / (Pp * 1000000)), 2)Label37.Caption = Si4'第五段校核'If bh5 = 8.05 Thenq5 = 34.22: Pc5 = 26400000: Pi5 = 43710000: Fst5 = 1966000ElseIf bh5 = 9.19 Thenq5 = 38.69: Pc5 = 37296000: Pi5 = 49918000: Fst5 = 2308000ElseIf bh5 = 10.36 Thenq5 = 43.15: Pc5 = 48398000: Pi5 = 56253000: Fst5 = 2656000ElseIf bh5 = 11.51 Thenq5 = 47.62: Pc5 = 59293000: Pi5 = 62461000: Fst5 = 2989000ElseIf bh5 = 12.65 Thenq5 = 52.08: Pc5 = 70189000: Pi5 = 63706000: Fst5 = 3319000End IfSc5 = Round((Pc5 / (ρ * 9810 * D5)), 2)Label26.Caption = Sc5Fm5 = (9.81 * q5 * L5) + Fm4St5 = Round((Fst5 / Fm5), 2)Label31.Caption = St5Si5 = Round((Pi5 * (2.7183 ^ (0.00011155 * 0.55 * D5)) / (Pp * 1000000)), 2)Label36.Caption = Si5End Sub四、应用举例为了检验程序是否可用,是否可以准确无误的达到预期设计效果,代入数据检验程序是否可以准确无误的达到目的要求。

150型全回转全套管钻机中平台强度校核Abstract: Full rotary casing drilling rig platform is main stress component while working. According to working characteristics of middle platform of full rotary casing drilling rig,two kinds of working situations―lifting and lining, and underdraught, are analyzed on statics by using ANSYS software,which provides theoretical analysis for improving structural stress and structural optimization design.0 引言全回转套管钻机是就地灌注的施工机械之一。

在易塌孔和复杂地层地层,采用全回转全套管钻进工艺,配合如冲锤、抓斗等钻具,钻进岩石层和卵砾石层,对防滑坡和基础桩桩的进行施工。

近几年,在城市一次开发利用的地区多次处理原有的基桩。

施工时装有带回转钻头的套管,垂直钻入地基。

旋进施工中套管一边保持孔壁,一边作往复圆周回转以及垂直钻进,进行强力钻削并压入地基。

全回转套管钻机工作时首先由夹紧油缸加紧套管,然后回转马达驱动套管对土进行360°旋转切削,最后由起拔油缸带动套管上下运动。

夹紧油缸在夹紧套管时有两种基本形式。

一种是中平台固定夹紧油缸带动上平台上下运动进行夹紧。

另一种是上平台固定夹紧油缸带动中平台上下运动进行夹紧。

本文以中平台固定上平台随动的全回转套管钻机为研究对象,对其上中下平台进行强度分析,为结构的进一步改进提供基础。

1 全回转套管钻机的组成全回转套管钻机主要由全套管钻机机架本体、夹持装置、回转装置、压入起拔装置四部分构成。

圆钢、钢管的强度校核一、纯拉伸圆钢的强度校核已知:有一根45号圆钢,外径50mm ,长300 mm。

受力情况如下图:P=500Kgf 求:校核圆钢强度。

解:1、分析危险截面。

危险截面是截面最小的面,显然圆钢的任意截面相等。

2、危险截面所受的拉力为:P=9.8×500=4900N危险截面受拉力作用下的正应力:表1-1-95,在1-125页。

Pσ= ?σ pAσ--------正应力。

P--------拉力。

2A--------截面面积。

A=πR222σ= F?S= 4900?(πR) =4900?(3.14×25) =2.5N/mm =2.5 (Mpa)σ--------许用正应力。

查表4-1-57,在4-59页。

p查得σ=600Mpa pσ?σ p圆钢强度足够。

二、纯拉伸钢管的强度校核已知:有一根45号钢管,外径50mm ,内径40 mm ,长300 mm。

受力情况如下图:P=500Kgf求:校核钢管强度。

解:1、分析危险截面。

危险截面是截面最小的面,显然钢管的任意截面相等。

2、危险截面所受的拉力为:P=9.8×500=4900N危险截面受拉力作用下的正应力Pσ= ?σ pAσ--------正应力。

P--------拉力。

22A --------面积。

A=π(R- R) 122222σ= F?S= 4900?,π(R- R) ,=4900?,3.14(25- 20), 12=6.94 (Mpa)σ--------许用正应力。

查表4-1-57,在4-59页。

p查得σ=600Mpa pσ?σ p钢管强度足够。

三、纯弯曲圆钢的强度校核已知:有一根45号圆钢,外径50mm ,长900 mm。

受力情况如下图:F=500Kgf 求:校核圆钢强度。

解:1、分析危险截面。

危险截面是弯矩最大的面,显然是管得中心处,F处的截面。

2、危险截面所受的弯矩为:M=(F?2)×(820?2)=(9.8×500?2)×(820?2)=1004500N.mm弯矩作用下的正应力Mσ= ?σ pW公式在表1-1-95,在1-125页。