LN20042Q1使用手册

- 格式:docx

- 大小:12.08 KB

- 文档页数:1

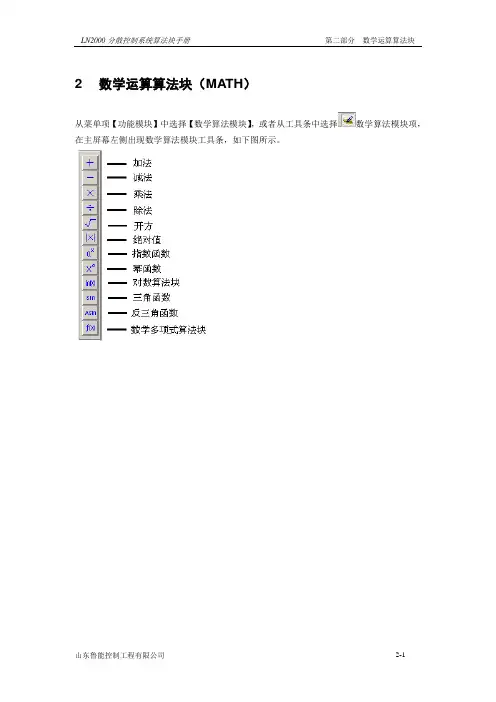

2 数学运算算法块(MATH)从菜单项【功能模块】中选择【数学算法模块】,或者从工具条中选择数学算法模块项,在主屏幕左侧出现数学算法模块工具条,如下图所示。

2.1加法算法块(ADD)Addition1、算法块图例2、算法块设置界面有外部连接的模拟量输入端无法手动修改初值,如上图中AI1和AI3两处;没有外部连接的输入端则可以修改初值,如上图中AI2和AI4两处。

3、算法块参数4、功能说明该算法完成加权加法的浮点运算,最多可以使用4个输入端。

5、算法说明悬空的输入端AI(i)初值默认为0。

AO=AI1*k1+AI2*k2+ AI3*k3+ AI4*k4。

2.2减法算法块(SUB)Subtraction1、算法块图例2、算法块设置界面有外部连接的模拟量输入端用户无法手动修改初值,如上图中AI1处;没有外部连接的输入端则可以修改初值,如上图中AI2处。

3、算法块参数4、功能说明该算法完成加权减法的浮点运算。

5、算法说明悬空的输入端AI(i)初值默认为0。

AO=AI1*k1-AI2*k22.3乘法算法块(MULT)Multiplication1、算法块图例2、算法块设置界面有外部连接的模拟量输入端用户无法手动修改初值,如上图中AI1处;没有外部连接的输入端则可以修改初值,如上图中AI2处。

3、算法块参数4、功能说明该算法完成加权乘法的浮点运算。

5、算法说明AO=(AI1*k1)*(AI2*k2)+Bias2.4除法算法块(DIV)Division1、算法块图例2、算法块设置界面3、算法块参数4、功能说明该算法完成加权除法的浮点运算。

5、算法说明AI2初值默认为1;初始化AI1,AI2,AO;若AI2=0,AO=AO(n-1)若AI2≠0,AO=(AI1*k1)/(AI2*k2)+Bias 注:AO(n-1)为前一采样时刻输出。

2.5开方算法块(SQRT)Square Root1、算法块图例2、算法块设置界面3、算法块参数4、功能说明该算法完成加权开方的浮点运算。

Using an adjustable frequency drive with a soft starter bypassToday’s most complete drive packages oftencombine several different solutions together inorder to provide the most reliable and robust sys-tem available. This application paper will discussthe advantages of using a drive with a soft starterbuilt into the bypass.Contactors, soft starters, and drives aredifferent devices that can be used to control amotor. A contactor simply connects the motordirectly across the AC line. A motor connectedto the AC line will accelerate very quickly to fullspeed and draw a large amount of current duringacceleration. A soft starter is a device used toslowly ramp up a motor to full speed, and/orslowly ramp down the motor to a stop. Reducingboth current draw and the mechanical strain onthe system are big advantages of using a softstarter in place of a contactor. Many large pumpsand fans require at least a 30-second ramp timeto prevent mechanical damage to the system.Soft starters are more common on larger horse-power systems. An adjustable frequency drivenot only has the ramping ability of a soft starter,but also allows the speed to be varied, whileoffering more flexibility and features.Enclosed adjustable frequency drives ofteninclude a bypass when used in applications thatcan not afford downtime. A bypass configurationconsists of three contactors: one contactordisconnects the drive from AC power, anotherdisconnects the motor from the drive, and thelast contactor connects the motor directly to theAC line. See Figure 1 on the next page for atypical three-contactor bypass configuration.A bypass provides peace of mind guaranteeingthat the system will continue to run, even in theevent of a drive failure. However, many designersoverlook the possibility of adding a soft starterinto the bypass. A soft starter can be added inline with the bypass contactor that connects themotor directly across the line. See Figure 2 on thenext page for a typical three-contactor bypasswith an integral soft starter.If an application is using an adjustable frequencydrive because a contactor is not acceptable, thena contactor-only bypass should not be acceptableeither. Adding a soft starter to the bypass allowsthe motor to be ramped up to full speed, thusreducing the mechanical and electrical stress onthe system.The best overall motor control package starts witha drive to provide the greatest amount of control,flexibility, and protection. Adding a bypass withan integral soft starter provides a backup systemto run the motor should the drive fail. Large drivesystems should have soft starters in the bypass,otherwise the application risks negatively affect-ing the power system, damaged bearings, or bentshafts once the bypass is engaged.Eaton Corporation Electrical Sector 1111 Superior Ave.Cleveland, OH 44114United States877-ETN-CARE (877-386-2273)© 2009 Eaton Corporation All Rights Reserved Printed in USAPublication No. AP03902004E / Z9003August 2009PowerChain Management is a registered trademark of Eaton Corporation. All other trademarks are property of theirrespective owners.Product Application AP03902004EEffective August 2009Using an adjustable frequency drivewith a soft starter bypassFigure 1. Typical Three-Contactor Bypass ConfigurationFigure 2. Typical Three-Contactor Bypass with Integral Soft Starter。

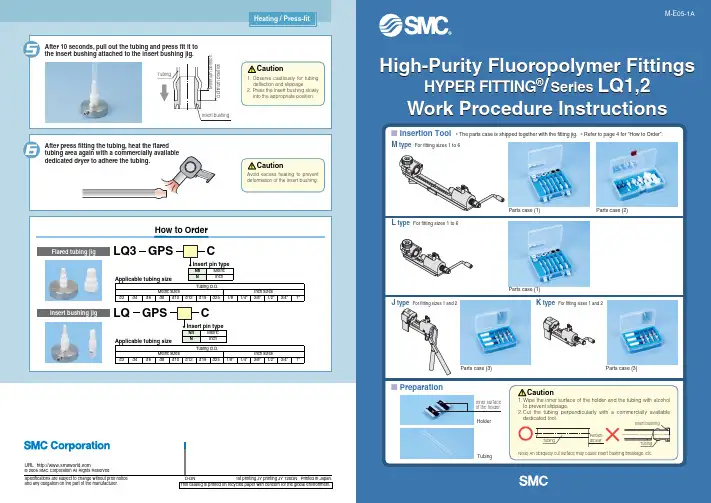

PreparationParts case (1)Parts case (1)Parts case (3)Parts case (3)Parts case (2)Inner surfaceof the holderSET POS.Clamp so that the gap is equal on both sides.G a pSize reductionAttach the collar to the insert bushing for size reduction.Note)A collar cannot be attached afterinstallation has been completed.CollarInsert bushingTurn the lever to SET POS and fix it with the insert pin replacement screw.Fix the holder into the clamp with screws.Place the tubing on the holder and fix it.Attach the insert bushing to the insert pin.Attach the insert pin to the base.Press fit an insert bushingInsert bushingCollarInsert pin replacement screwInsert bushingInsert pinInsert pinHolderBaseInsert bushing for size reductionCollar (for size reduction)HolderScrew (attached both on top and bottom)ClampCautionTurn the handle slowly and press fit the insert bushing into the tubing.∗Dismantle the handle, slide the clamp until thetubing end touches the insert bushing, and fix it. Note)Note) J and K type clamps do not move.J type K typeToo much tubing protrusionBent tubingInsert bushing press fitted into tubingTubing finished by press-fittingon both sidesOptimum position Minimum positionInsert bushingTubingHandleNote) Too much tubing protrusion may cause breakage.Tubing length1. Do not allow the tubing to pro-trude too much from the holder when fixing the tubing position.2. Check the tubing for bending.1. Observe cautiously for tubing deflection and slippage.2. Press the insert bushing slowly into the appropriate position.CautionCaution∗ J-type clamps have a lever.Press fit an insert bushing∗ Before press-fitting, be sure to move the clamp to the appropriate position. (Refer to P2 .)Insert pin for short pipingNutTubing finished by press-fittingInsert pinInsert pinInsert pin for short pipingInsert bushingNut NutClamp Insert pin for short pipingClampHow to Order Insertion ToolsNote1)Replacement part type J is the part for LQ-GJ and LQ-GK.Replacement part type L is the part for LQ-GL and LQ-GM.Insert bushing press fitted into tubingNut tightening tool (LQ1 only) ∗ Use a commercially available tool to tighten the nut for an LQ2 fitting.Flared tubing jigInsert bushing jigNut tightening toolSeatSeatInsert bushing。

Series WE04 2-Piece Flanged Stainless Steel Ball ValveSpecifications - Installation and Operating InstructionsBulletin V-WE04The SERIES WE04 incorporates a full port 2-piece flanged SS ball valve for great flow rates with minimal pressure drop. The valve features a blowout proof stem for added safety, reinforced PTFE seats and seals for longer life, and a 316 SS (ASTM CF8M) ball for better performance. Actuators are direct mounted creating a compact assembly for tight spaces. Limit switches are able to be mounted directly to the valves allowing for remote position indication.The Series WE04 can be configured with either a pneumatic or electric actuator. Electric actuators are available in weatherproof or explosion-proof, a variety of supply voltages, and two-position or modulating control. Two-position actuators use the supply voltage to drive the valve open or closed, while the modulating actuator accepts a 4 to 20 mA input for valve positioning. Actuators feature thermal overload protection and permanently lubricated gear train.The pneumatic double acting actuator uses an air supply to drive the valve open and closed. The actuator has two supply ports, with one driving the valve open, and the other driving the valve closed. Spring return pneumatic actuators use the air supply to open the valve, and internally loaded springs return the valve to the closed position. Also available is the SN solenoid valve to electrically switch the air supply pressure between the air supply ports for opening and closing the valve. Actuators are constructed of anodized and epoxy coated aluminum for years of corrosion freeservice.WE04-DHD00WE04-DTD01-AWE04-DDA02-NN09WE04-CTI01-ABy DwyerVALVE BILL OF MATERIALSVALVE DIMENSIONAL DRAWINGAUTOMATED VALVE DRAWINGSW/ PNEUMATIC ACTUATORW/ ELECTRIC ACTUATORW/ EXPLOSION-PROOF ELECTRIC ACTUATORPNEUMATIC ACTUATORNote: For optimal operation, pneumatic actuators should be run with a supply of clean, lubricated air.Spring Return Actuator OperationAir to PORT 2 (the left hand port) causes the actuator to turn counterclockwise (CCW). Loss of air to PORT 2 causes air to exhaust and the actuator turns clockwise (CW). This is the FAIL CLOSE operation.Double Acting Actuators OperationAir to PORT 2 (the left hand port) causes the actuator to turn counterclockwise (CCW). Air to PORT 1 (the right hand port) causes the actuator to turn clockwise (CW).Pneumatic Actuator MaintenanceRoutine maintenance of pneumatic actuator:• Keep the air supply dry and clean• Keep the actuator surface clean and free from dust• Periodic checks should be done to make sure all fittings are tight• Pneumatic actuators are supplied with lubrication to last the entire life span of the actuator under normal operating conditions.The outer surface of the pneumatic actuator should be clean to avoid friction or corrosion. All fittings and connections should be tight to prevent leaks during operation. Check the bolts mounting the valve to the actuator to make sure they have not come loose during shipping or installation. Make sure the valve and actuator are not rubbing or jamming against other components during operation. The actuator should be inspected annually to make sure all fittings and bolts are tight and nothing has come loose during operation.Disassembling Pneumatic ActuatorsBefore beginning disassembly, ensure that the air supply to the actuator has been disconnected, all accessories have beenremoved, and that the actuator has been disassembled from the valve.1. Loosen the end cap fasteners (23) with a wrench (size varies depending on actuator model). On the spring return actuator, alternate 3 to 5 turns on each fastener until the springs are completely decompressed. Use caution when removing the cap since the springs are under load until the fasteners are fully extended.2. Remove the pinion snap ring (13) with a lock ring tool. The indicator (12) may now be removed.3. Turn the pinion shaft (2) counter clockwise until the pistons are at the full end of travel. Disengage the pistons (15) from the pinion. (Note: Low pressure air--3 to 5 psi MAXIMUM--might be required to force the pistons completely from the body.) Note the position of the pistons before removing them from the actuator body.4. Remove the pinion through the bottom of the actuator. The actuator is now completely disassembled.Be sure the actuator surfaces are free of debris and scratches before reassembling.1. Apply a light film of grease to all O-rings and the pinion before replacing.2. Put the pinion (2) back through the actuator with the flats of the pinion shaft running parallel with the body.3. When reassembling the actuator, make sure that the piston racks are square to the actuator body and returned to their original orientation. (Note: The normal operation of all spring return pneumatic actuators is FAIL CLOSED. To change the orientation to FAIL OPEN, rotate the racks 180º to create a reverse operation.4. When replacing springs in a spring return actuator, ensure that the springs are replaced in their identical position in the end cap from which they were removed. (Note: In some circumstances, you might want to change the standard 80 pound spring set to fit your application and available air pressure.5. Seal the end caps with a petroleum lubricant and bolt to actuator body.6. Check the seal of the actuator by covering seal areas (pinion, end caps) with soapy water and using low pressure air to the actuator to ensure that no bubbles are produced.Pneumatic Actuators Bill of MaterialsReassembling Pneumatic ActuatorsELECTRIC ACTUATORSElectric Installation1. Operate valve manually and place in the open position.2. Remove any mechanical stops the valve might have. (DO NOT REMOVE ANY PARTS NECESSARY FOR THE PROPER OPERATION OF THE VALVE, SUCH AS THE PACKING GLAND, PACKING NUT, ETC.)3. Ensure that the actuator output shaft and valve stem are aligned properly. If they are not, operate the valve manually until they are correct.4. Remove actuator cover.5. Bring power to the actuator. CAUTION: Make sure power is OFF at the main box.6. Wire the actuator per the diagram attached to the inside of the cover. Special actuators (those with positioner boards, etc.) will have diagrams enclosed inside the cover.7. Securely tighten bolts used to mount the actuator to a mounting bracket or directly to the valve mounting pad if it is ISO5211 compliant.8. Cycle the unit several times and check the open and closed positions of the valve. Cams are pre-adjusted at the factory; due to the variety of valve designs and types however, slight adjustments might be required.9. Replace cover and tighten screws.To Set The Open Position1. Cycle the valve to the open position by applying power to terminals. The top cam and switch control this position. In the open position, the set screw in the top cam will be accessible.2. If the valve is not open completely:A. Slightly loosen the set screw on the top cam.B. Rotate the cam clockwise (CW) by hand until the switch makes contact. Contact is made when a slight click can be heard. By making incremental CW movements of the top cam, the valve can be positioned precisely in the desired position.C. When the top cam is set, tighten the set screw securely.3. If the valve opens too far:A. Apply power to terminals. This will begin to rotate valve CW. When valve is fully open and in the exact position desired, remove power from actuator.B. Loosen the set screw in the top cam.C. Rotate the top cam counterclockwise (CCW) until the switch arm drops off the round portion of the cam onto the flat section. A slight click can be heard as the switch changes state.D. Continue applying power to terminals until valve is in the desired position.To Set The Closed Position1. Apply power to terminals to move the valve toward the closed position. The bottom cam and switch control the closed position. In the closed position, the set screw in the bottom cam will be accessible.2. If the valve is not closed completely:A. Slightly loosen the set screw on the bottom cam.B. Rotate the cam counterclockwise (CCW) by hand until the switch makes contact. Contact is made when a slight click can be heard. By making incremental CCW movements of the bottom cam, the valve can be positioned precisely in the desired position.C. When the top cam is set, tighten the set screw securely.3. If the valve closes too far:A. Apply power to terminals. This will begin to rotate valve CCW. When valve is fully closed and in the exact position desired, remove power from actuator.B. Loosen the set screw in the top cam.C. Rotate the top cam clockwise (CW) until the switch arm drops off the round portion of the cam onto the flat section. A slight click can be heard as the switch is no longer making contact with the round part of the cam.D. Continue applying power to terminals until valve is in the desired position.Electric Actuators Wiring Diagram: ACT-TI & ACT-MIWiring Diagrams forTI01-A to TI05-A: 110 VAC, TI01-B to TI05-B: 220 VAC, TI01-C to TI05-C: 24 VACHOTALVE ALVEWiring Diagrams for TI01-D to TI05-D: 24 VDCOPERATION:POWER TO 1 & 2 FOR CCW ROTATION POWER TO 3 & 4 FOR CW ROTATION TERMINALS 5 & 6 FOR FIELD LIGHT INDICATION CONNECTIONSW.#1 SW.#2SWITCH #1 OPEN SWITCH SWITCH #2 CLOSE SWITCHWiring Diagrams forMI01-A to MI05-A: 110 VAC, MI01-B to MI05-B: 220 VAC, MI01-C to MI05-C: 24 VACSW. 1, CLOSESW. 2, OPEN .SW. 3, CLOSE SW. 4, OPEN Wiring Diagrams forMI01-D to MI05-D: 24 VDCSW. 1, CLOSESW. 2, OPEN .SW. 3, CLOSE SW. 4, OPENElectric Actuators Wiring Diagram: ACT-TD & ACT-MDWiring Diagrams forTD01-A to TD03-A: 110 VAC, TD01-B to TD03-B: 220 VAC,TD01-C to TD03-C: 24 VACWiring Diagrams forTD01-D to TD03-D: 24 VDCWiring Diagrams forMD01-A to MD03-A: 110 VAC, MD01-B to MD03-B: 220 VAC,MD01-C to MD03-C: 24 VACNote: To speed up installation of the control wires to the ACT-MDXX modulating actuator, it is recommended to remove the control module from the actuator. The control module can be removed by removing the two mounting screws on the left and right of the control module. Install the control wires to the correct terminal points and then reinstall the control module.Electric Actuator MaintenanceOnce the actuator has been properly installed, it requires no maintenance. The gear train has been lubricated and in most cases will never be opened. Duty Cycle Definition“Duty Cycle” means the starting frequency.Formula: Running Time ÷ (Running Time + Rest Time) x 100% = duty cycle –> Rest Time = Running Time x (1 - duty cycle) ÷ duty cycleFor example: The running time is 15 seconds30% duty cycle 15 x [(1 - 30%) / 30%] = 35 –> The rest time will be 35 seconds 75% duty cycle 15 x [(1 - 75%) / 75%] = 5 –> The rest time will be 5 seconds If the duty cycle is higher, the rest time will be shortened, which means the starting frequency will be higher.Thermal OverloadAll actuators are equipped with thermal overload protection to guard the motor against damage due to overheating.Mechanical OverloadAll actuators are designed to withstand stall conditions. It is not recommended to subject the unit to repeated stall conditions.Explosion-Proof Electric Actuators1. DO NOT under any circumstances remove the cover of the actuator while in a hazardous location. Removal of the coverwhile in a hazardous location could cause ignition of hazardous atmospheres.2. DO NOT under any circumstances use an explosion-proof electric actuator in a hazardous location that does not meet the specifications for which the actuator was designed.3. Always verify that all electrical circuits are de-energized before opening the ac -tuator.4. Always mount and cycle test the actuator on the valve in a non-hazardous loca -tion.5. When removing the cover, care must be taken not to scratch, scar of deform the flame path of the cover and base of the actuator, since this will negate the NEMA rating of the enclosure.6. When replacing the cover, take care that the gasket is in place to assure proper clearance after the cover is secured.7. All electrical connections must be in accordance with the specifications for which the unit is being used.8. Should the unit ever require maintenance, remove from the hazardous location before attempting to work on the unit.If the actuator is in a critical application, it is advisable to have a standby unit in stock.Electric Actuators Performance Rating MAINTENANCE/REPAIRUpon final installation of the Series WE, only routine maintenance is required. The Series WE is not field serviceable and should be returned if repair is needed. Field repair should not be attempted and may void warranty.WARRANTY/RETURNRefer to “Terms and Conditions of Sale” in our catalog and on our website. Contact customer service to receive a Return Goods Authorization number before shipping the product back for repair. Be sure to include a brief description of the problem plus any additional application notes.10©Copyright 2015 Dwyer Instruments, Inc.Printed in U.S.A. 10/15FR# 444175-00 Rev. 11。

LGVV-CONE FLOW METERLGV型V型内锥流量测量节流装置使用说明书LGV-DT-JS-1028-2018(A)感谢您选择丹东通博电器(集团)有限公司的产品。

本使用说明书给您提供有关安装、连接和调试以及针对维护、故障排除和贮存方面的重要信息。

请在安装调试前仔细阅读并将它作为产品的组成部分保存在仪表的近旁,供随时翻阅。

并可通过下载本说明书。

如未遵照本说明书进行操作,则本仪表所提供的防护可能会被破坏。

商标、版权和限制说明通博、通博电器、通博泵业、DDTOP、均为公司的注册商标。

本仪表的性能规格自发布之日起生效,如有更改,恕不另行通知。

丹东通博电器(集团)有限公司有权在任何时候对本说明书所述的产品进行修改,恕不另行通知。

质保丹东通博电器(集团)有限公司保证所有产品自出厂之日起,一年之内无材料和制造工艺方面的缺陷。

在质保期内,如产品出现质量问题而返回,提出的索赔要求经制造厂检验后确定属于质保范围内,则丹东通博电器(集团)有限公司负责免费为买方(或业主)维修或更换。

丹东通博电器(集团)有限公司对因设备使用不当,劳动力索赔、直接或后续损伤以及安装和使用设备所引起的费用概不负责。

除了关于丹东通博电器(集团)有限公司某些产品的特殊书面保修证明,丹东通博电器(集团)有限公司不提供任何明示或暗示的质量保证。

质量丹东通博电器(集团)有限公司通过了ISO9001质量体系认证,产品生产的全过程均严格依照质量体系的规定范围执行,对产品和服务质量提供最强有力的保证。

1 安全提示 (5)1.1爆炸可能会导致死亡或严重伤害。

(5)1.2过程泄漏可能导致严重伤害或死亡。

(5)1.3不遵守安全安装准则可能导致死亡或严重受伤。

(5)2概要 (5)2.1 介绍 (5)2.2 工作原理 (5)2.3 重塑速度剖面 (6)3特点 (6)3.1 高精确度 (6)3.2 重复性 (6)3.3 量程 (6)3.4 安装要求 (6)3.5 长期性能 (7)3.6 信号稳定 (7)3.7 低永久压力损失 (7)3.8 范围 (7)3.9 无停滞的区域 (7)3.10 结构支撑 (7)4V锥流量测量系统 (7)4.1 应用数据 (7)4.2 流量计算 (8)4.3 应用尺寸 (8)4.4 校准 (8)4.5 结构材料 (8)4.6 阀组 (9)4.7 二级和三级仪表 (9)4.8 流量计铭牌 (9)5安装 (9)5.1 拆包 (9)5.2 方向 (10)5.3 管道要求 (10)5.4 安装 (10)5.5 取压管线:通用 (10)5.6 取压管线:过程工业 (10)5.7 取压管线:蒸汽应用 (11)5.8 水平管道安装:气体 (11)5.9 水平管道安装:液体 (11)5.10 水平管道安装:冷凝蒸汽 (12)5.11 垂直管道安装:通用 (12)5.12 垂直管道安装:气体 (12)5.13 垂直管道安装:液体 (13)5.14 安装后DP压力传送器调零,在蒸汽流量应用 (14)5.15 安装后DP压力传送器调零,在环境温度液体应用 (15)5.16 安装后DP压力传送器调零,在气体应用 (15)5.17 差压测量 (16)6维护 (16)6.1 定期维护 (16)7故障排除 (16)7.1 现场V锥系统故障排除 (16)8产品认证 (18)1 安全提示出于安全的原因,明确禁止擅自改装或改变产品,维修或替换只允许使用由制造商指定的配件。

TWN4 MULTITECH 2 LEGIC USER MANUALTABLE OF CONTENTS1INTRODUCTION (3)1.1ABOUT THIS MANUAL (3)1.2SCOPE OF DELIVERY (3)1.3ELATEC SUPPORT (3)2INTENDED USE (4)3SAFETY INFORMATION (5)4TECHNICAL DATA (7)4.1TECHNICAL SPECIFICATIONS (7)4.2FIRMWARE (7)4.3ANTENNAS (7)5MODE OF OPERATION (8)5.1OPERATING MODE (8)5.2POWER UP (8)5.3ENUMERATION (8)5.4INITIALIZATION (8)5.5NORMAL OPERATION (8)5.6DETECTION OF A TRANSPONDER (8)5.7SUSPEND MODE (9)6COMPLIANCE STATEMENTS (10)6.1EU (10)6.2FCC (10)6.3ISED CANADA (10)6.4RF EXPOSURE COMPLIANCE (11)6.5SINGAPORE (11)6.6THAILAND / ประเทศไทย (11)6.7UNITED KINGDOM (11)APPENDIX (12)A – RELEVANT DOCUMENTATION (12)B – TERMS AND ABBREVIATIONS (12)C – REVISION HISTORY (12)1INTRODUCTION1.1ABOUT THIS MANUALThis user manual is intended for the user and enables a safe and appropriate handling of the product. It gives a general overview, as well as important technical data and safety information about the product. Before using the product, the user should read and understand the content of this user manual.For the sake of better understanding and readability, this user manual might contain exemplary pictures, drawings and other illustrations. Depending on your product configuration, these pictures might differ from the actual design of your product.The original version of this user manual has been written in English. Wherever the user manual is available in another language, it is considered as a translation of the original document for information purposes only. In case of discrepancy, the original version in English will prevail.1.2SCOPE OF DELIVERYDepending on your product configuration, the product can be delivered alone or with different components and accessories, such as cables or wall holders, as part of a kit. For more information about the delivered components and accessories, refer to your delivery note, consult the ELATEC website or contact ELATEC.1.3ELATEC SUPPORTIn case of any technical questions or product malfunction, refer to the ELATEC website () or contact ELATEC technical support at***********************In case of questions regarding your product order, contact your Sales representative or ELATEC customer service at********************2INTENDED USEThe contactless RFID readers and modules of the ELATEC TWN4 MultiTech 2 LEGIC family are a direct enhancement of the TWN4 MultiTech LEGIC readers with the same form factors (PCB modules and desktop readers with housing). During the development of the TWN4 MultiTech 2 LEGIC family, special emphasis has been placed on optimizing the HF performance (13.56 MHz). Compared to the predecessor TWN4 MultiTech LEGIC, the read range could be increased by more than 50% for LEGIC transponders and even doubled for some HF transponders.TWN4 MultiTech 2 LEGIC key features include a powerful SDK for writing apps that are executed directly on the reader, the possibility to upgrade the firmware in the field, a direct chip-commands support and an optimized BLE module. Additionally, the reader can simultaneously read more than 60 RFID technologies from low (LF) and high frequency (HF) bands, including NFC. This gives the option to select as many of the technologies required instead of being forced to select just a few ones.The product is for indoor use and may not be used outdoor.Any use other than the intended use described in this section, as well as any failure to comply with the safety information given in this document, is considered improper use. ELATEC excludes any liability in case of improper use or faulty product installation.3SAFETY INFORMATIONTransport and storage•Observe carefully the transport and storage conditions described on the product packaging or other relevant product documents(e.g. data sheet).Unpacking and installation•Before unpacking and installing the product, this user manual and all relevant installation instructions must be read and understood carefully.•The product is equipped with a cable.o Do not twist or pull the cable.o Do not replace the cable and do not use a cable extension.ELATEC excludes any liability for damages or injuries resulting from the use of the product with a cable extension or a replaced cable.Handling•Depending on your product configuration, the product might be equipped with one or more light-emitting diodes (LED).Avoid direct eye contact with the blinking or steady light of the light-emitting diodes.•The product has been designed for a use under specific conditions, e.g. in a specific temperature range (refer to the product data sheet).Any use of the product under different conditions might damage the product or alter its reading performance.•The use of other RFID readers or reader modules in direct vicinity to the product, or in combination with the product might damage the product or alter its reading performance. In case of doubts, contact ELATEC for more information.•The user is liable for the use of spare parts or accessories other than the ones sold or recommended by ELATEC.ELATEC excludes any liability for damages or injuries resulting from the use of spare parts or accessories other than the ones sold or recommended by ELATEC.•Like most electronic devices, RFID systems generate electromagnetic waves that can vary in amplitude and frequency. It is generally known and accepted that some RFID devices might potentially interfere with personal medical devices, like pacemakers or hearing aids.TWN4 MultiTech 2 LEGIC fulfills general radio and EMC requirements. However, users with a pacemaker or any other medical device should use TWN4 MultiTech 2 LEGIC carefully and refer to the information given by the manufacturer of their medical devices before using TWN4 MultiTech 2 LEGIC or any host device containing TWN4 MultiTech 2 LEGIC.Maintenance and cleaning•Any repair or maintenance work should be done by a trained and qualified personnel only.Do not try to repair or carry out any maintenance work on the product by yourself.Do not allow any repair or maintenance work on the product by an unqualified or unauthorized third party.•The product does not need any special cleaning. However, the housing may be carefully cleaned up with a soft, dry cloth and a non-aggressive or non-halogenated cleaning agent on the outer surface only.Make sure that the used cloth and cleaning agent do not damage the product or its components (e.g. label(s)).Disposal•The product must be disposed of in accordance with the EU directive on waste electrical and electronic equipment (WEEE) or any applicable local regulations.Product modifications•The product has been designed, manufactured and certified as defined by ELATEC.Any product modification without prior written approval from ELATEC is prohibited and considered improper use of the product. Unauthorized product modifications may also result in the loss of product certifications.If you are unsure about any part of the safety information above, contact ELATEC support.Any failure to comply with the safety information given in this document is considered improper use. ELATEC excludes any liability in case of improper use or faulty product installation.4TECHNICAL DATA4.1TECHNICAL SPECIFICATIONSFREQUENCY 125 KHZ (LF) / 13.56 MHZ (HF) / 2.4 GHZ (BLE) ANTENNA(S) IntegratedHOUSING Material: ABS UL94-V0 Color: black or whiteDIMENSIONS (L X W X H) Approx. 88.00 x 56.00 x 18.50 mm / 3.46 x 2.20 x 0.73 inchPOWER USB: 4.3 V - 5.5 VRS-232: requires 5 V external power supplyPS2 classified power source according to IEC 62368-1, short-circuit current < 8 ACURRENT CONSUMPTION RF field on: 140 mA typicallyTEMPERATURE RANGE Operating: -25 °C up to +70 °C (-13 °F up to +158 °F) Storage: -40 °C up to +75 °C (-40 °F up to +167 °F)RELATIVE HUMIDITY 5% to 95% non-condensingREAD/WRITE DISTANCE LF and HF: up to 100 mm / 4 inch, depending on environment and transponder BLE: up to several meters/feetWEIGHT Approx. 120 g / 4.23 oz (with cable)4.2FIRMWAREThe product is delivered ex-works with a specific firmware version. Refer to the label attached to the product to find the firmware version installed ex-works.4.3ANTENNASThe reader is equipped with the following antennas:HF antenna (13.56 MHz)Dimensions: 42 x 47 mm / 1.65 x 1.85 inchNumber of turns: 3LF antenna (125 kHz)Diameter: 16 mm / 0.63 inchNumber of turns: 120BLE (2.4 GHz)The reader is equipped with a BLE SAM card*.* It is strictly prohibited to take the BLE SAM card out of the SAM slot. Removing the BLE SAM card is considered as an unauthorized product modification and improper use of the product, which may result in the loss of product certifications. ELATEC excludes any liability in case of unauthorized product modification or improper use of the product.For more information, refer to the related product data sheet or other technical documents.5MODE OF OPERATIONThe mode of operation described in the following chapter is based on a standard ELATEC RFID reader equipped with two LEDs. Depending on your product (number of LEDs, installed firmware, etc.) and in case the product settings have been modified with the AppBlaster tool, the information below might differ from your product configuration when in operation. In particular, the color and sequence of the LEDs on your product might be different.5.1OPERATING MODEIn order to start operating TWN4 MultiTech 2 LEGIC, it simply has to be connected directly to a host device.5.2POWER UPOnce TWN4 MultiTech 2 LEGIC is connected to the host device, it detects the type of communications cable (e.g. USB or RS-232), with which it is connected to the host.In case of RS-232:• A version string is sent via RS-232 to the host device.• A 5 V external power supply is required and must meet the following conditions:o PS2 classified power source according to IEC 62368-1o Short-circuit current < 8 A5.3ENUMERATIONThis is only applicable for the USB version: Once the device has been powered up, it is waiting for completion of the enumeration by the USB host. As long as the device is not enumerated, it is entering a minimum power consumption mode, where both LEDs are turned off.5.4INITIALIZATIONAfter powering up and enumeration (in USB mode), the device is turning on the built-in transponder reader logic. The green LED is turned on permanently. Some RFID readers need some kind of initialization, which is performed in this step. After successful initialization, the device sounds a short sequence, which consists of a lower tone followed by a higher tone.5.5NORMAL OPERATIONAs soon as the reader has completed the initialization, it is entering normal operation. During normal operation, the reader is searching for a transponder continuously.5.6DETECTION OF A TRANSPONDERIf a transponder is detected by the reader, following actions are performed:•Send the ID to the host. By default, the USB device sends by emulating keystrokes of a keyboard. An RS-232 device sends the ASCII code of an ID.•Sound a beep.•Turn off the green LED.•Blink the red LED for two seconds.•Turn on the green LED.Within the two seconds timeout, where the red LED is blinking, the transponder, which just has been recognized will not be accepted again. This prevents the reader from sending identical IDs more than one time to the host.If during the two seconds timeout of the red LED a different transponder is detected, the complete sequence restarts immediately. 5.7SUSPEND MODEThe USB version of the reader supports the USB suspend mode. If the USB host is signaling suspend via the USB bus, the reader is turning off most of its power consuming peripherals. During this operation mode, no detection of transponders is possible and all LEDs are turned off. Once the host is resuming to normal operation mode, this is also signaled via the USB bus. Therefore, the reader will resume to normal operation too.6COMPLIANCE STATEMENTS6.1EUHereby, ELATEC GmbH declares that TWN4 MultiTech 2 LEGIC is in compliance with Directive 2014/53/EU. The full text of the EU declaration of conformity is available at the following internet address: /approvals6.2FCCContains FCC ID: WP5TWN4F22Contains FCC ID: QOQ-BGM220S2This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:(1) this device may not cause harmful interference, and(2) this device must accept any interference received, including interference that may cause undesired operation. (except receivers associated with operation of a licensed radio service and stand-alone devices).CautionThe Federal Communications Commission (FCC) warns the users that changes or modifications to the unit not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.FCC §15.105 (b)Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures: •Reorient or relocate the receiving antenna.•Increase the separation between the equipment and receiver.•Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.•Consult the dealer or an experienced radio/TV technician for help.6.3ISED CANADAContains IC: 7948A-TWN4F22Contains IC: 5123A-BMG220S2This device contains licence-exempt transmitter(s)/receiver(s) that comply with Innovation, Science and Economic Development Canada’s licence-exempt RSS(s). Operation is subject to the following two conditions:1. This device may not cause interference.2. This device must accept any interference, including interference that may cause undesired operation of the device.L’émetteur/récepteur exempt de licence contenu dans le présent appareil est conforme aux CNR d’Innovation, Sciences et Développement économique Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux conditions suivantes:1. L’appareil ne doit pas produire de brouillage;2. L’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre le fonctionnement.6.4RF EXPOSURE COMPLIANCERF exposure statement (mobile and fixed devices)This device complies with the RF exposure requirements for mobile and fixed devices. However, the device shall be used in such a manner that the potential for human contact during normal operation is minimized. 6.5 SINGAPOREComplies with IMDA Standard [DA 103787]6.6 THAILAND / ประเทศไทย6.7UNITED KINGDOMTWN4 MultiTech 2 LEGIC complies with the requirements of the UK legislations and other regulations as listed in the respective UK declaration of conformity. The importer is responsible for applying the following information to the packaging of the product:• the importer company’s details, including the company’s name and a contact address in the UnitedKingdom.• UKCA markingAPPENDIXA – RELEVANT DOCUMENTATIONELATEC documentation•ELATEC quick start guide•TWN4 MultiTech 2 LEGIC data sheet•TWN4 MultiTech 2 LEGIC functional description•TWN4 MultiTech 2 technical handbookB – TERMS AND ABBREVIATIONSTERM EXPLANATION BLE Bluetooth Low EnergyFCC Federal Communications CommissionHF high frequencyISED Innovation, Science and Economic Development Canada LED light-emitting diodeLF low frequencyNFC near field communicationPCB printed circuit boardRFID radio frequency identificationSDK software development kitUKCA UK conformity assessedWEEE Waste of electrical and electronic equipment.Refers to Directive 2012/19/EU of the European Parliament and of the Council of the European UnionC – REVISION HISTORYVERSION CHANGE DESCRIPTION EDITION 02 Editorial changes, chapters “Technical Data” and “Compliance Statements” updated 07/202301 First edition 05/2023Elatec reserves the right to change any information or data in this document without prior notice. Elatec declines all responsibility for the use of this product with any other specification but the one mentioned above. Any additional requirement for a specific customer application has to be validated by the customer himself at his own responsibility. Where application information is given, it is only advisory and does not form part of the specification. Disclaimer: All names used in this document are registered trademarks of their respective owners.EMEA AMERICAS ASIA JAPANPuchheim, Germany Palm City, Florida, USA Shenzhen, China Tokyo, Japan +49 89 552 9961 0 +1 772 210 2263+86 755 23946014 +81 90 1846 6900 **************************************************************************************。

High consistency• Non ferrous hydraulic circuit. Stainless steel tank, evaporator, and water pump maintain the quality of the coolant.• Very precise outlet water temperature control with two hot gas valves (± 0,5 °C)• PID software developed and tested to give the highest temperatureconsistency even at variable loads.• High pressure pumps supply constant water flow and pressure to the systemPerfect solution, easy to install and manage• Hydraulic circuit: storage and filling tank, with evaporator and pump provide a compact solution, easy to use and install.• Electronic controllers with proprietary software provide access to all the vital parameters of the unit and allow special management for specific needs, with remote monitoring available.• Condensers filters• Independent condensing plenum • Full access and easy service designHyperchill LaserIndustrial Process Chillers for Precision CoolingPrecision chilled water with non-ferrous hydraulic circuitHyperchill Laser is designed to meet the needs of many applications re-quiring stable working conditions with maximum quality and cleanli-ness of the process fluid.Compact and reliable machines de-signed for industrial applications and manufactured with the highest qual-ity and safety standards.Laser marking, cutting and weld-ing are typical industrial processes where the characteristics of Hyper-chill Laser are vital to obtain the de-sired product quality and to optimisethe production process.Low power consumption• Very low power consumptionthanks to oversized condensers and evaporators, and use of compliant scroll compressors (from ICEP007 onwards).High reliability• Maximum working ambienttemperatue up to 48 °C for ICEP models, up to 45 °C for HLS models, prevents downtime even under extremely harsh conditions.Product Features:Microprocessors: allow complete control of the unit parameters. Proprietary software from ICEP007 onwards allows and wide range of programming and remote monitoring options.Compliant scroll compressors: (from ICEP007 onwards) with less moving parts and compliant technology provide excellent efficiency, high reliability, and very low noise levels.Water and refrigerantmanometers permit easy control of the working conditions.Stainless steel plateevaporators, compact and efficient, external to the tank.Water tank: generouslydimensioned guarantee high reliability and improved temperature control.Differential pressure switch: protects pump and evaporator in case of flow shut down.Mesh filters: (from ICEP007 onwards) condenser protection from dirt and contamination, reduces maintenance costs and the risk of downtime.Water pump: available with different head pressures to fit the end user application, can be also configured as twin system for redundancy.MODBUS interface fitted on ICEP models (from ICEP007); optionalfor HLS modelsThe performance of high-powered lasers depends on effective cool-ing. High-powered lasers generate a significant amount of heat that must b e removed from the laser system to avoid overheating critical Versions:• Low ambient temperature (from ICEP007 onwards): additional condensing control for continuous operation in cold ambients (nega-tive temperature). Available for air cooled versions with axial fans.Options:• Water by-pass: externally adjust-able allowing the correct flow throught the system to be set.• Flow switch: to be used as an alarm signal in case of water flow shut down.components. Carbon dioxide (CO 2) lasers, excimer lasers, ion lasers, solid-state lasers, and dye lasers all use liquid cooling to remove excess heat. Laser liquid cooling can help accomplish three goals: maintain-• Precision control: when very precise water temperature is re-quired (± 0,5 °C).• Special and multiple pumps: higher (P50-5bar) or lower (P15-1,5bar) head pressure available to suit different hydraulic cir-• Check valves: external non-return valve + solenoid valve to separate the hydraulic circuit when the unit is switched off.• Wheels (ICEP002-ICEP014): for easy of transport.ing a precise laser wavelength and higher output efficiency, achieving desired b eam quality, and reduc-ing thermal stress on a laser sys-tem.cuits. Double stand- by pump for higher reliability.• Antifeeze heating (from ICEP007 onwards): avoids freezing when the unit is switched off. Can also be used as a heater to warm up the system.• Remote control kits: base version for remote ON/OFF and general alarm monitoring or advanced version for complete unit manage-ment via remote monitoring.• Water filters for circuit cleanli-ness and machinery protection.Technical dataTo obtain the required cooling capacity multiply the value at nominal conditions by the above correction factors (i.e. cooling capacity = Pxf1xf2xf3, where P is the cooling capacity at conditions (1). Hyperchill Laser, in its standard configuration, can operate up to ambient temperatures of max 48 °C for ICEP models, 45 °C for HLS models and min 5 °C and water temperatures of max 30 °C inlet and min. 0 °C outlet. The above correction factors are approximative: for a precise selection always refer to the software selection program.(1) at water inlet/outlet temperature = 20/15 °C, glycol 0 %, ambient temperature 25 °C. (2) at water inlet/outlet temperature = 25/20 °C, glycol 0 %, ambient temperature 35 °C.(3) referred to free field conditions at a distance of 10m from unit, measured on condenser side, 1 m from ground.ICEP002ICEP003-005ICEP007-060HLS076-116As the manufacturer of process chillers delivering water at a design temperature of 15 °C, Parker Hannifin Manufacturing s.r .l., Gas Separation and Filtration Division EMEA, declares that Parker chillers are exempt from Ecodesign EU regulation 2016/2281.Correction factorsBULHLS-04-ENYour local authorized Parker distributor© 2018 Parker Hannifin Corporation. All rights reserved.Europe, Middle East, AfricaAE – United Arab Emirates, DubaiTel: +971 4 8127100 ********************AT – Austria, Wiener Neustadt Tel: +43 (0)2622 23501-0 *************************AT – Eastern Europe, Wiener NeustadtTel: +43 (0)2622 23501 900 ****************************AZ – Azerbaijan, Baku Tel: +994 50 2233 458****************************BE/LU – Belgium, Nivelles Tel: +32 (0)67 280 900*************************BG – Bulgaria, Sofia Tel: +359 2 980 1344**************************BY – Belarus, Minsk Tel: +48 (0)22 573 24 00 ************************CH – Switzerland, Etoy Tel: +41 (0)21 821 87 00*****************************CZ – Czech Republic, Klecany Tel: +420 284 083 111*******************************DE – Germany, Kaarst Tel: +49 (0)2131 4016 0*************************DK – Denmark, Ballerup Tel: +45 43 56 04 00*************************ES – Spain, Madrid Tel: +34 902 330 001 ***********************FI – Finland, Vantaa Tel: +358 (0)20 753 2500 *************************FR – France, Contamine s/Arve Tel: +33 (0)4 50 25 80 25 ************************GR – Greece, Piraeus Tel: +30 210 933 6450 ************************HU – Hungary, Budaörs Tel: +36 23 885 470*************************IE – Ireland, Dublin Tel: +353 (0)1 466 6370 *************************IL – IsraelTel: +39 02 45 19 21************************IT – Italy, Corsico (MI) Tel: +39 02 45 19 21 ***********************KZ – Kazakhstan, Almaty Tel: +7 7273 561 000****************************NL – The Netherlands, Oldenzaal Tel: +31 (0)541 585 000 ********************NO – Norway, Asker Tel: +47 66 75 34 00************************PL – Poland, Warsaw Tel: +48 (0)22 573 24 00 ************************PT – PortugalTel: +351 22 999 7360**************************RO – Romania, Bucharest Tel: +40 21 252 1382*************************RU – Russia, Moscow Tel: +7 495 645-2156************************SE – Sweden, Spånga Tel: +46 (0)8 59 79 50 00 ************************SK – Slovakia, Banská Bystrica Tel: +421 484 162 252**************************SL – Slovenia, Novo Mesto Tel: +386 7 337 6650**************************TR – Turkey, Istanbul Tel: +90 216 4997081 ************************UA – Ukraine, Kiev Tel: +48 (0)22 573 24 00 ************************Parker WorldwideUK – United Kingdom, Warwick Tel: +44 (0)1926 317 878 ********************ZA – South Africa, Kempton Park Tel: +27 (0)11 961 0700*****************************North AmericaCA – Canada, Milton, Ontario Tel: +1 905 693 3000US – USA, Cleveland Tel: +1 216 896 3000Asia PacificAU – Australia, Castle Hill Tel: +61 (0)2-9634 7777CN – China, Shanghai Tel: +86 21 2899 5000HK – Hong Kong Tel: +852 2428 8008IN – India, MumbaiTel: +91 22 6513 7081-85JP – Japan, Tokyo Tel: +81 (0)3 6408 3901KR – South Korea, Seoul Tel: +82 2 559 0400MY – Malaysia, Shah Alam Tel: +60 3 7849 0800NZ – New Zealand, Mt Wellington Tel: +64 9 574 1744SG – Singapore Tel: +65 6887 6300TH – Thailand, Bangkok Tel: +662 186 7000TW – Taiwan, Taipei Tel: +886 2 2298 8987South AmericaAR – Argentina, Buenos Aires Tel: +54 3327 44 4129BR – Brazil, Sao Jose dos Campos Tel: +55 800 727 5374 CL – Chile, Santiago Tel: +56 2 623 1216MX – Mexico, Toluca Tel: +52 72 2275 4200EMEA Product Information Centre Free phone: 00 800 27 27 5374(from AT , BE, CH, CZ, DE, DK, EE, ES, FI, FR, IE, IL, IS, IT , LU, MT , NL, NO, PL, PT , RU, SE, SK, UK, ZA) US Product Information Centre Toll-free number: 1-800-27 27 537/gsfe。

V1.0.64FY2004图形五防系统产品使用说明书长园共创电力安全技术股份2014年11月04日1.系统简介FY2004图形五防系统(以下简称FY2004)是根据我国电力安全领域发展的实际需要,总结和归纳了国不同地区电力系统运行的不同方式及其特点,用于倒闸操作防误管理的智能化系统。

1.1文件清单(1)、语音dll: WaveDll.dll、Err00.wav(2)、打印dll: userprt.dll 和Ravesolo.dll.(3)、图形文件dll: gdiplus.dll.(4)、图形文件:main.prj.(5)、数据库文件:FY2004.mdb.(6)、打印报表文件:czp.rav.(7)、启动Logo文件:car.avi.(8)、制图程序:Draw2004.exe.1.2功能说明该程序兼容了FY2004系统先前版本的所有功能,具有单任务操作、多任务操作,实现了检修逻辑、流程操作、操作票格式的个性设置、规约特殊功能扩充、Ⅴ型联机等项功能,同时支持23、24、25、26、27、31版电脑钥匙和现有的通讯适配器。

2.登录2.1登录运行FY2004主程序,在FY2004的“登录”菜单点击登录选项,系统弹出对话框。

如图:选择用户名并输入密码后并确认,进入一次主接线图界面。

2.2浮动式菜单用鼠标左键或右键点击空白处可以隐藏主菜单,登录后鼠标左键同时按下或者敲“ALT”键可以调出主菜单,同时支持右键功能弹出主菜单,还可以按住“Ctrl”键不放,用鼠标拖动主菜单条移动。

2.3菜单功能2.3.1菜单说明点击进入操作票目录,可以进行典型票开票、修改操作票等;点击进入对位环境,可以对设备进行手工强制对位,整订设备状态;点击进入模拟开票;点击进入手工开票;点击打印操作票;点击可以放大一次接线图;点击缩小一次接线图;点击将一次图返回实际大小;点击切换至上一副图;点击切换至下一副图;点击切换到首图;点击进入导航窗口;点击注销当前用户,再操作时需重新登录。

ITQ电动执行器安装使用手册(ITQ-0100, 0160, 0240, 0350, 0500, 0800 1100, 1500, 2000 & 3000)目录2.ITQ 执行器1)外部部件ITQ0100 ~ ITQ1100CAPACITOR TERMINAL BLOCKASSEMBLYMOTORTORQUE SWITCHASSEMBLYLIMIT SWITCHASSEMBLYPOTENTIOMETERASSEMBLYITQ0160 ~ ITQ1100ITQ1500 ~ ITQ30003) 参数(开关式)CAPACIT TERMINAL BLOCK ASSEMBLYMOTORITQ1500, ITQ2000 & ITQ3000ITQ0350, ITQ0500 ITQ0800, ITQ1100连接用可拆卸式驱动轴瓦3. 选型与应用VALVE BUTTERFLY BUTTERFLY 2-WAY BALL 2-WAY BALL 3-WAY BALLITQ0100 ITQ0160, 0240 ITQ0350, 0500 ITQ0800,ITQ1100 ITQ1500, ITQ2000 & ITQ3000ITQ0100 ITQ0160, ITQ0240注 : 1. 上表仅供参考,不承担任何责任!2. 应详细咨询阀门厂温度、流体特性等后再选型。

3. 特殊条件如高温、低温、海水、恶劣腐蚀性条件、高振动下的应用,在选定执行器前请咨询我们技术部门。

4. 对用户无视我们的劝告所做的决定,我们有权力回避任何责任。

人工操作向手轮方向拉动手柄,直到手柄竖直。

如果手柄未直立,再次拉,缓慢转动手轮。

在手轮上有标志指示转动方向。

顺时针为关闭方向,逆时针为打开方向。

电动运行时不必把手柄恢复原位。

ITQ0100 ITQ0160~ITQ1100 ITQ1500~ITQ30005.执行器在管道上的推荐安装1)执行器在管道上的位置10. 维修保养1)润滑因为工厂已经充分供应了润滑油,正常运行中一般不必再注入润滑油。