CQI-9中英文最新整套资料

- 格式:xlsx

- 大小:177.21 KB

- 文档页数:25

cqi-9标准英文原版CQI-9是汽车行业中用于评估热处理供应商的标准,也被称为汽车行业质量倡议第9号标准。

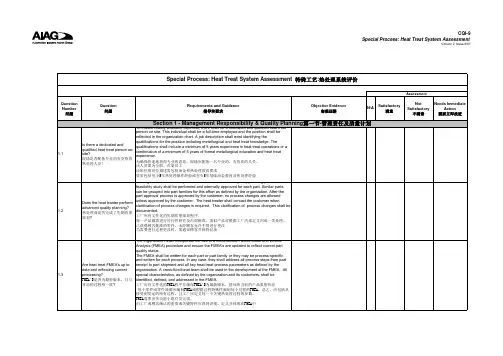

该标准的英文原版是由汽车工业行动小组(AIAG)制定的,以下是CQI-9标准的英文原版:CQI-9 Heat Treat System Assessment.1. Scope.This document defines the requirements for a Heat Treat System Assessment. The assessment is a standardized process to evaluate and improve heat treat management and control processes and is applicable to all heat treat suppliers.2. Purpose.The purpose of this assessment is to provide a common framework for heat treat suppliers to assess their systems and processes, identify areas of improvement, and implement effective actions to achieve and sustain high-quality heat-treated products.3. Definitions.Heat Treat System: The combination of equipment, procedures, and personnel used to perform heat treatment processes.Heat Treat Supplier: An organization that performs heat treatment processes on products for the automotive industry.4. Assessment Criteria.The assessment criteria are divided into 15 sections, covering various aspects of heat treat system managementand control. These sections include:Management Responsibility.Quality Planning.Customer-Specific Requirements.Design and Development.Production Part Approval Process.Control of Production and Service Provision. Control of Measuring and Monitoring Devices. Measurement System Analysis.Calibration System.Control of Nonconforming Product.Corrective Action.Preventive Action.Control of Records.Internal Audits.Training.5. Assessment Process.The assessment process involves a series of steps, including:Pre-assessment activities.On-site assessment activities.Post-assessment activities.Corrective action and continuous improvement.6. Assessment Results.The assessment results are used to identify areas of improvement and develop action plans to address anyidentified nonconformities or opportunities for improvement. The results are also used to monitor the effectiveness ofimplemented actions and track progress over time.7. Compliance.Compliance with the requirements of CQI-9 is essential for heat treat suppliers to meet the quality expectationsof the automotive industry. Non-compliance may result in corrective actions or potential disqualification as an approved supplier.It is important to note that the above is a brief summary of the CQI-9 standard in its original English version. For a comprehensive understanding and implementation of the standard, it is recommended to referto the complete and official version of the document, which can be obtained from the Automotive Industry Action Group (AIAG) or their authorized distributors.I hope this provides you with the requested information about the original English version of the CQI-9 standard.Let me know if there is anything else I can assist you with.。

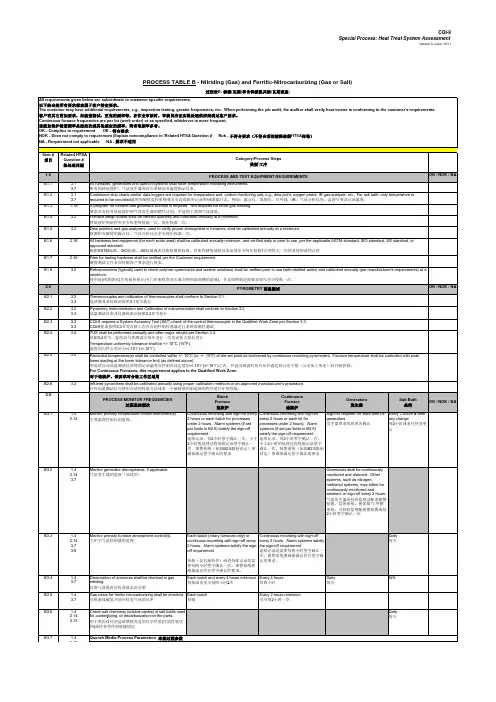

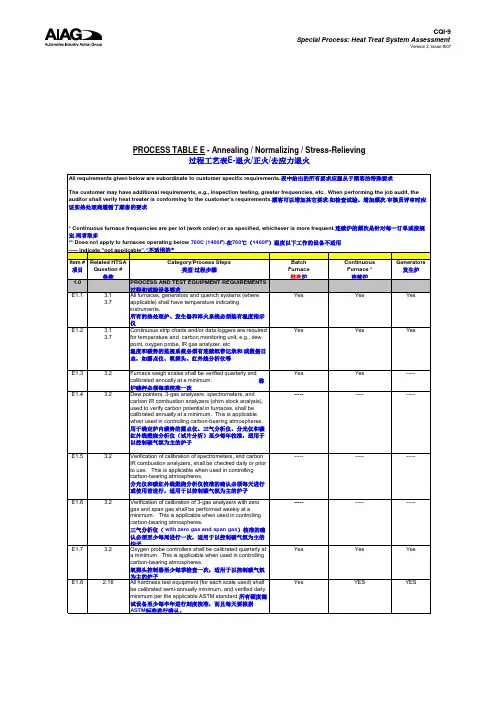

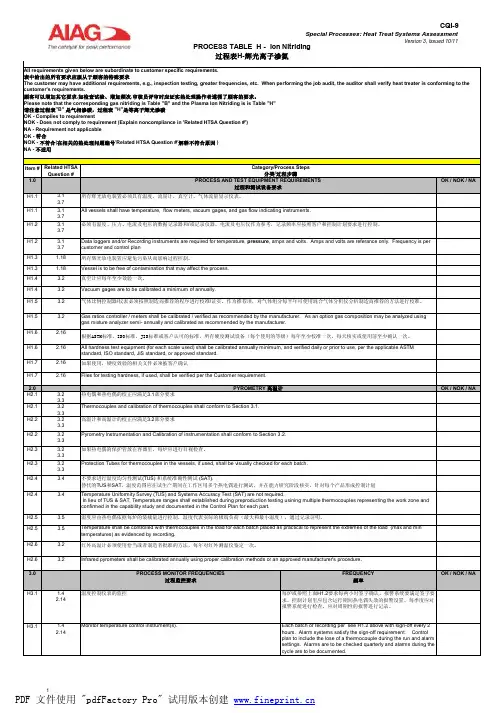

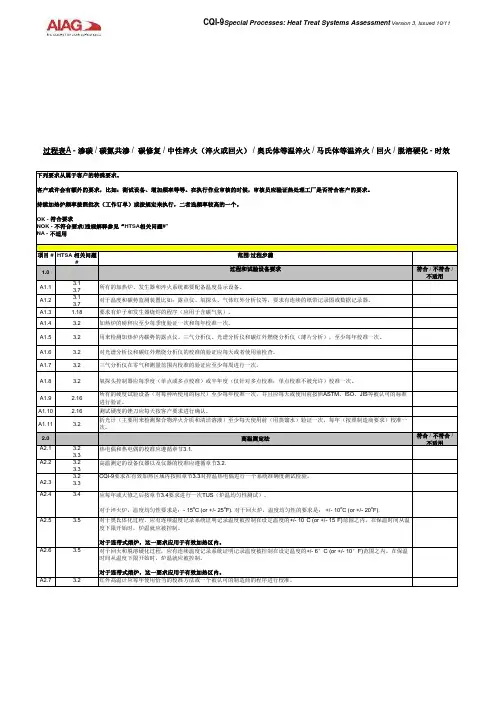

Version 3, Issued 10/11Item #Related HTSAQuestion #1.0OK / NOK / NAH1.1 3.13.7H1.1 3.13.7H1.2 3.13.7H1.2 3.13.7H1.3 1.18H1.3 1.18H1.4 3.2H1.4 3.2H1.5 3.2H1.5 3.2H1.6 2.16H1.6 2.16H1.7 2.16H1.7 2.162.0OK / NOK / NAH2.1 3.23.3H2.1 3.23.3H2.2 3.23.3H2.2 3.23.3H2.3 3.23.3H2.3 3.23.3H2.4 3.4H2.43.4H2.5 3.5H2.5 3.5H2.6 3.2H2.6 3.23.0OK / NOK / NA H3.11.42.14H3.11.42.14温度控制仪表的监控每炉或参照上面H1.2要求每两小时签字确认,报警系统要满足签字要求。

控制计划里应包含运行期间热电偶失效的报警设置。

每季度应对报警系统进行检查,应对周期性的报警进行记录。

所有辉光放电装置必须具有温度,流量计,真空计,气体流量显示仪表。

热电偶和热电偶的校正应满足3.1部分要求高温计和高温计的校正应满足3.2部分要求如果热电偶的保护管放在容器里,每炉应进行目视检查。

不要求进行温度均匀性测试(TUS) 和系统准确性测试 (SAT).替代的TUS 和SAT ,温度范围应在试生产期间在工作区用多个热电偶进行测试,并在能力研究阶段核实,针对每个产品形成控制计划温度应由热电偶依据每炉的装载量进行控制,温度代表实际的极端负荷(最大和最小温度),通过记录证明。

Each batch or recording per see H1.2 above with sign-off every 2hours. Alarm systems satisfy the sign-off requirement. Control plan to include the lose of a thermocouple during the run and alarm settings. Alarms are to be checked quarterly and alarms during the cycle are to be documented.Monitor temperature control instrument(s).红外高温计必须使用恰当或者制造者批准的方法,每年对红外测温仪鉴定一次。

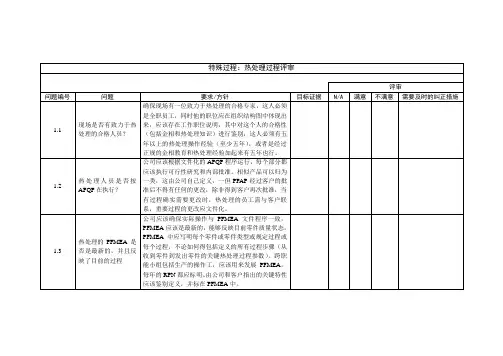

cqi-9 条款解释CQI-9是汽车供应链质量要求的一种标准,主要涉及汽车热处理体系。

它是由美国汽车工程师协会(AIAG)制定的,旨在确保汽车热处理过程的质量和一致性。

CQI-9热处理体系标准包括以下内容:1.热处理管理体系:要建立和维护一个有效的热处理质量管理体系,包括组织结构、职责、程序和资源等。

2.热处理工艺控制:要制定和执行符合汽车制造要求的热处理工艺流程,包括加热、保温、冷却等环节。

3.设备管理:要确保热处理设备符合要求,包括设备选型、安装、调试、维护和保养等。

4.质量检验:要对热处理后的产品质量进行检验,包括外观、尺寸、性能等方面的检测。

5.记录管理:要对热处理过程中的各项数据进行记录和分析,以便追溯和改进。

CQI-9适用于整个汽车供应链中从原材料供应商到零部件生产商再到最终组装商的所有环节。

对于汽车热处理过程,CQI-9的目的是确保其质量和一致性,以提升汽车的整体性能和安全性。

CQI-9是美国三大汽车针对热处理供应商的审核,其基本流程和TS16949流程一样,但更注重与热处理工艺相关的内容。

在CQI-9的条款中,需要准备以下资料:1.设备炉温均匀性测定记录,最好是符合SAE 2750D。

2.热电偶管理方法,包括台帐、定期校验、强制报废等。

3.仪表的管理,包括台帐、定期检定、报警功能的定期触发等。

此外,CQI-9的审核主要涉及以下内容:1.设备炉温均匀性测定记录。

2.热电偶管理方法。

3.仪表的管理。

此外,CQI-9还要求企业建立和维护一个有效的热处理质量管理体系,包括组织结构、职责、程序和资源等,以确保企业能够有效地管理和控制热处理过程,提高产品质量和客户满意度。

总之,CQI-9旨在确保汽车热处理过程的质量和一致性,以提升汽车的整体性能和安全性。