福特生产体系衡量指标

- 格式:ppt

- 大小:7.32 MB

- 文档页数:30

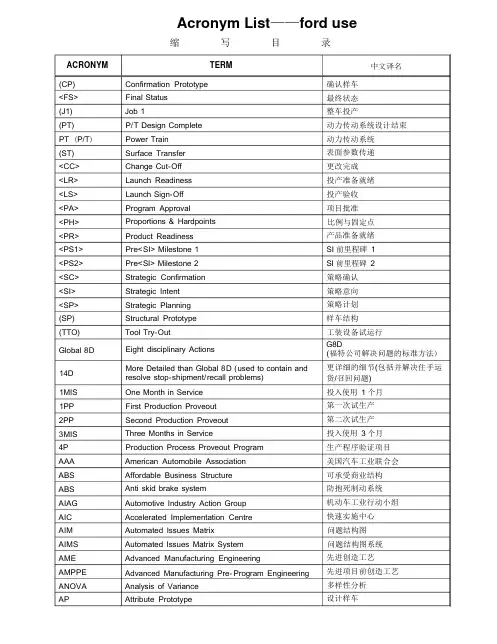

(CP)<FS>(J1) (PT)PT (P/T) (ST)<CC><LR><LS><PA><PH><PR><PS1><PS2><SC><SI><SP> (SP) (TTO) Global 8D14D1MIS1PP2PP3MIS4PAAAABSABS AIAGAICAIM AIMS AME AMPPE ANOVA AP Confirmation PrototypeFinal StatusJob 1P/T Design CompletePower TrainSurface TransferChange Cut-OffLaunch ReadinessLaunch Sign-OffProgram ApprovalProportions & HardpointsProduct ReadinessPre<SI> Milestone 1Pre<SI> Milestone 2Strategic ConfirmationStrategic IntentStrategic PlanningStructural PrototypeTool Try-OutEight disciplinary ActionsMore Detailed than Global 8D (used to contain andresolve stop-shipment/recall problems)One Month in ServiceFirst Production ProveoutSecond Production ProveoutThree Months in ServiceProduction Process Proveout ProgramAmerican Automobile AssociationAffordable Business StructureAnti skid brake systemAutomotive Industry Action GroupAccelerated Implementation CentreAutomated Issues MatrixAutomated Issues Matrix SystemAdvanced Manufacturing EngineeringAdvanced Manufacturing Pre-Program EngineeringAnalysis of VarianceAttribute Prototype确认样车最终状态整车投产动力传动系统设计结束动力传动系统表面参数传递更改完成投产准备就绪投产验收项目批准比例与固定点产品准备就绪SI 前里程碑1SI 前里程碑2策略确认策略意向策略计划样车结构工装设备试运行G8D(福特公司解决问题的标准方法)更详细的细节(包括并解决住手运货/召回问题)投入使用1 个月第一次试生产第二次试生产投入使用3 个月生产程序验证项目美国汽车工业联合会可承受商业结构防抱死制动系统机动车工业行动小组快速实施中心问题结构图问题结构图系统先进创造工艺先进项目前创造工艺多样性分析设计样车APEAL APPC APQP ASN ASQ AV AVT AWS AXOD B&A BCG BIC BIS BLI BOM BTB BTS BUR CASC/E CA CAD CAE CAP CBG CCCCCC CCC CDS CET CETs CETP CFR CIM CIWG CL CMM Automotive Performance Execution and LayoutAverage Purchased Part CapacityAdvanced Product Quality PlanningAdvanced Shipping NoticeAmerican Society for QualityAppraiser VariationAdvance Vehicle TechnologyAnalytical Warranty SystemAutomatic Transaxle Overdrive TransmissionBody & Assembly Operations (New Term: VehicleOperations)Business Consumer GroupBest in ClassBody Shop Information SystemBusiness Leadership InitiativeBill Of MaterialsBumper-to-BumperBuild-To-ScheduleBusiness Unit ReviewCapacity Analysis SheetCause & EffectCustomer AttributeComputer Aided DesignComputer Aided EngineeringCorrective Action PlanConsumer Business GroupCritical CharacteristicCourtesy CopyCarbon CopyCustomer Concern ClassificationComponent Design SpecificationCampaignable Events TeamCommon External TariffCorporate Engineering Test ProceduresConstant Failure RateComputer Integrated ManufacturingContinuous Improvement Work GroupCenterlineCoordinate Measuring Machine机动车性能实施与规划采购零件平均产能先进产品质量计划提前发货通知美国质量协会评估者的多样性先进车辆技术分析性的保修系统自动变速驱动桥超速档传动系车身与组装操作(新术语:车辆操作)消费者工作组等级中的最佳车身工作间信息系统领导层初始意向零件清单保险杠到保险杠按日程建造业务小组讨论能力分析表成因及影响消费者特性计算机辅助设计计算机辅助工程纠正行动计划消费者业务小组评价特性抄送副本客户问题分类零件设计参数召回情况小组普通关税公司工程测试程序连续故障率计算机综合创造持续改进工作组中心线协调测量设备CMMS CMMS3 Code X Code Y Concern No. CPCCPECCPUCQDC CQISCRCRTCSACSIDCODCPDDLDfDFADFM DFMEA DFRDie Casting DMADOEDOMDPDQRDTDDTDDVDVMDVP Common Material Management SystemCommon Manufacturing Management System-3Pre-build focusing on exterior componentsPre-build focusing on interior componentsConcern No.Common PositionRelates the allowable spread of the specificationlimits to the measure of the actual variation of theprocess.Chief Program EngineerMeasures the process variation with respect to theallowable specification, and takes into account thelocation of the process averageCost Per UnitCorporate Quality Development CenterCommon Quality Indicator SystemConcern ResponsesComponent Review TeamCorporate Security AdministratorCustomer Service IndexDuty Cycle OutputDynamic Control PlanningDirect Data LinkDegrees of FreedomDesign for AssemblyDesign for ManufacturabilityDesign Failure Mode Effects AnalysisDecreasing Failure RateDie CastingDatabase Maintenance AdministratorDesign of ExperimentDealer Operations ManagerDesign ParametersDurability Quality and ReliabilityDock to DockDesign to DeliveryDesign VerificationDesign Verification MethodDesign Verification Plan通用材料管理系统通用创造管理系统-3创造前关注的外部零件创造前关注的内部零件工程变更编号通用位置将参数限制允许限度下的展开与程序实际多样性联系起来首席项目工程师测量程序的多样性并将其考虑到程序平均性的位置中单位成本公司质量开辟中心普通质量指标系统问题回复零件讨论组公司安全管理员客户服务指数责任循环结果动态控制计划直接数据连接自由度总成设计创造能力设计故障模式影响分析设计/产品潜在失效模式与后果分析故障下降率压铸模数据库维护管理人员试验设计经销商业务经理参数设计耐久性质量与可靠性码头至码头设计到交付设计验证设计验证方式设计验证计划pk pDVP&PV DVP&R DVPR DVPV EAO EASI ECAR EDIED&T EDT EESE EMM EMS EOL EQIESESIESP ESTA ESWP EVF&T FACT FASS FA/SS FAO FAP FAQ FCPA FCSD FDVS FER FER FEU FFR FIFO FMEA Design Verification Process and ProductionValidationDesign Verification Plan & ReportDesign Verification & Product ReliabilityDesign Verification and Process VerificationEuropean Automotive OperationsEngineering And Supply InformationElectronic Connector Acceptability RatingElectronic Data InterchangeEstimated Time of DepartureElectrical and Electronic Systems EngineeringExpanded Memory ManagerEnvironmental Management SystemEnd of LineExtraordinary Quality InitiativeEngineering SpecificationsEarly Supplier InvolvementExtended Service PlanEarly Sourcing Target AgreementEarly Sourcing Work PlanEquipment VariationFacility & ToolingFacilitation and Certification TrainingField Action/Stop ShipmentField Action/Stop Shipment (Preferred Acronym)Ford Automotive OperationsFord Automotive ProcedureFrequently Asked QuestionsFord Consumer Product AuditFord Customer Service DivisionFord Design Verification SystemFresh Eyes ReviewFinal Engineering ReviewField Evaluation UnitFirst in First OutFailure Mode Effects Analysis设计验证程序和产品验证设计验证计划和结果设计验证和产品可靠性设计验证和程序验证欧洲机动车协会工程和供应信息电子连接接受比率电子数据交换设计开辟费用估计离岗时间电力及电子系统工程扩展内存管理器环境管理系统线的端点特殊初始质量工程参数早期供应商参预延期服务计划早期选点目标协议早期选点工作计划设备变更工装设备简易化及认证培训区域行动/住手运货区域行动/住手运货(优先使用缩写)福特机动车协会福特机动车程序常见问答福特客户产品审核福特客户售后服务分枝机构福特设计验证系统其它行业人员论证最终工程论证区域评估组小批量试装先进先出故障模式影响分析FMVSS FPDSFPSFPSIFPS ITFOBFQRsFRFRGFSFSICFSNFSSFTDCFTEPFTTFUNC-APPRV FVEPGAPGCGCARS GCEQGEMGIS1GPDSGPIRSGPPGQRSGRCGRCGR&R GRVWGSDBGSSMGYRHIHIC Federal Motor Vehicle Safety StandardsFord Product Development SystemFord Production SystemFord Production System InstituteFord Production System Information TechnologyFord of BritainFrequent Quality RejectsFunctional RequirementsFAO Reliability GuideFinal Sign-offFord System Integration CouncilFord Supplier NetworkFull Service SuppliersFairlane Training and Development CenterFord Technical Educational ProgramFirst Time ThroughFunctional ApprovalsFinished Vehicle Evaluation ProgramGlobal Architecture ProcessGlobal CraftsmanshipGlobal Craftsmanship Attribute Rating SystemGlobal Core Engineering QualityGeneric Electronic ModuleGlobal Information StandardsGlobal Products Development SystemGlobal Prototype Inventory Requisition andSchedulingGlobal Parts PricingGlobal Quality Research SystemUN-ECE Group des Raporteurs de CeinturesGovernment Regulations CoordinatorGage Repeatability and ReproducibilityGross Vehicle WeightGlobal Supplier DatabaseGlobal Sourcing Stakeholders MeetingGreen-Yellow-RedHigh-ImpactHigh-Impact Characteristics美国联邦机动车安全标准福特产品开辟系统福特生产系统福特产品系统学院福特产品系统信息技术福特英国时常性质量不合格品功能要求FAO (福特机动车运作) 可靠性指导最终验收福特系统综合委员会福特供应商网络全方位服务供应商培训和发展中心福特技术培训项目首次通过功能批准下线车辆评估项目全球建造设计程序全球技术工艺全球技术特性评分系统全球核心工程质量通用电子模块全球信息标准全球产品研发系统全球样车库存及控制安排全球零件定价全球质量调查系统欧盟ECE 安全带规划小组政府法规协调员量具重复性和再现性车辆质量全球供应商数据库全球选点股东大会绿-黄-红重大影响重大影响特性HRHTFB HVACICAICCD ICCD CRS IEIFRILVSIMIPIPDIQIQS2IRISOISPCJITJPHJSAKKKKLTKOLCL LDEM LOALP&TLRLRRLSLSLLTDB MBJ1 MBOMEMIS MMOG Human ResourcesHard Tooled Functional BuildHeating Ventilating and Air ConditioningInterim Containment ActionIntensified Customer Concern DatabaseIntensified Customer Concern Database ConcernResolution SpecialistIndustrial EngineerIncreasing Failure RateIn-Line Vehicle SequencingIndustrial MaterialsInstrument PanelIn Plant DateIncoming QualityInitial Quality StudyInternal RejectInternational Organization for StandardizationIn-Station Process ControlsJust in TimeJobs Per HourJob Safety AnalysisPSW not ready for inspectionKey Life TestKickoffLower Control LimitLean Design Evaluation MatrixLetter of AgreementLaunch Planning & TrainingLaunch ReadinessLaunch Readiness ReviewLaunch Sign-OffLower Specification LimitLight Truck Data BaseMonths Before Job OneManufacturing Business OfficeManufacturing EngineeringMonths in ServiceMaterial Management Operations Guideline人力资源成形机功能建造加热通风和空调过渡性补救措施强化的客户问题数据库强化的客户问题数据库解决问题专员产业工程师故障率增长车辆顺序工业材料仪表板进厂日进货质量初始质量研究内部不合格品国际标准化组织过程质量控制及时每小时工作量工作安全分析PSW (零件质量合格验收) 未做好检测准备关键使用寿命测试起动低控制限值设计评估表协议书投产计划和培训投产准备就绪投产准备就绪论证投产验收低参数限制轻型卡车数据库Job1 (投产)前 1 个月创造办公室创造工程使用中的月份物料管理操作指南MMSAMP&L MPPC MPPS MODMRBMRDMSMS3(MSIII) MTCMYNAAO NFMNIST NMPDC Nova C NTEINVHOCMOEEOEMONPOSOTGP Diagrams PAPAGPALPATPCAPCIPDPDLPD Q1 PDSA PFMEAPI Material Management System AssessmentMaterials, Planning and LogisticsMaximum Purchased Part CapacityManufacturing Process Planning SystemModuleMaterial Review BoardMaterial Required DateMaterial SpecificationsMaterial Supply Version IIIManage the ChangeModel YearNorth American Automotive OperationsNoise Factor ManagementNational Institute of Standards and TestingNew Model Program Development CenterNew Overall Vehicle AuditNew Tooled End ItemsNoise, Vibration, HarshnessOperating Committee MeetingOverall Equipment EfficiencyOriginal Equipment ManufacturerOwner Notification ProgramOperator SafetyOpen to GoParameter DiagramsProgram ApprovalPremier Automotive GroupProject Attribute LeadershipProgram Activity Team, Program Attribute Team, orProgram Action TeamPermanent Corrective ActionProduct Change InformationProduct DevelopmentProgram Design LanguageProduct Development Q1Plan, Do, Study, ActProcess Failure Mode Effects AnalysisProcess Improvement物料管理系统评定材料、计划与物流采购零件最大产能创造程序计划系统模块物料论证板物料要求到厂日物料参数物料供应(第三版)管理变更年度车型北美汽车工业协会噪声管理全国标准和测试协会新车型项目开辟中心新车总评审新工具加工成品噪声、振动、控制平顺性工作委员会会议总体设备效率设备最初创造厂车主告知程序操作者安全可进行参数图表项目批准首要机动车项目组项目特性领导层项目促进小组、项目特性小组和项目行动小组持续改进行动产品变更信息产品开辟项目设计语言产品开辟Q1计划、实践、研讨、实施程序故障模式影响分析/过程潜在失效模式与后果分析程序改进PIPC PIST PM PMA PMT PO POC POT PPPAP PPPL PPM PPPM PR PR PR PSO PSS PST PSW PTO PTR PV PV PV PVBR PVM PVP PVT QA QC QCT QFD Percentage of PpkIndices Process CapablePercentage of Inspection Point That SatisfyToleranceProgram MangerProject Management AnalystProgram Management Team or Program ModuleTeamPurchase OrderPoint of ContactProcess Ownership TeamProcess PotentialProduct Planning & TechnologyProduction Part Approval ProcessProcess CapabilityProduct Planning CommitteeProgram Parts ListParts per Million (applied to defective Supplier parts)Program and Pre-Production ManagementPublic RelationsProduct RequirementProduct Readiness MilestoneProduction Standard OrderPrivate Switching ServiceProgram Steering TeamPart Submission WarrantPowertrain OperationsPlatinum Resistance ThermometerProduction ValidationProcess VariablesPart VariationPrototype Vehicle Build RequirementsProduction Validation MethodPowertrain Validation ProgramProduct Vehicle Team or Plant Vehicle TeamQuality AssuranceQuality ControlQuality Cost TimingQuality Function DeploymentP 指数程序能力百分比满足公差要求的检查点百分比项目经理项目管理分析项目管理组或者项目模式组采购定单联系点程序所有者小组程序潜力产品计划和技术生产零件批准程序程序能力产品计划委员会项目零件清单零件的百万分比率(合用于供应商不合格零件)程序和投产前管理公共关系产品要求产品就绪时间节点创造标准定单私人转接服务项目指导小组零件质量合格验收传动系统控制件铂金电阻温度计产品验证程序变更零件变更样车创造要求产品验证方法传动系统验证程序产品车辆组或者工厂车辆组质量保证质量控制质量成本时机选择质量功能配备pPP&TpkPPCpkQFTF QLSQMS QOP QOS QOE QPMQPSQRQS-9000 QSA-PD QTMQVARRDCR&M RMSR&RR&RR&VTR/1000 RAP REDPEPR RIEROA ROCOF RPN RRCL RRDM RRR RWUPS2SCSCs/CCs SCAC SCTs SDS Quality Focused Test FleetQuality Leadership SystemQuality Management SystemQuote one paperQuality Operating SystemQuality of EventQuality Program ManagerQuality Process SystemQuality RejectQuality Systems – 9000Quality System Assessment for ProductDevelopmentQuality Team MemberQuality-Focused Value Analysis WorkshopRangeRegional Distribution CenterReliability and MaintainabilityResource Management SystemRepeatability and ReproducibilityRoles and ResponsibilitiesResearch & Vehicle TechnologyRepairs per thousandRemote Anti-theft Personality moduleRobust Engineering Design Process Enabler ProjectReliability Improvement EngineerReturn on AssetsRate of Occurrence of FailureRisk Priority NumberReliability and Robustness Check ListReliability and Robustness Demonstration MatrixPSW rejectedReal World Usage ProfileStandard deviationVarianceSignificant CharacteristicsSignificant Characteristics/Critical CharacteristicsSupplier Craftsmanship Advisory CommitteeStrategic Commodity TeamsSystem Design Specifications质量节点测试行动组质量领导体系质量管理体系报价记录单质量运作体系质量事件质量项目经理质量程序系统质量不合格质量体系-9000产品开辟质量体系评估质量小组成员车间质量重点价值分析范围区域配送中心可靠性及可维护性资源管理系统重复性和再现性职务与责任研究与车辆技术修理千分率防盗遥控器个性化模式积极的工程设计程序计划可靠性改进工程师资产回报率故障发生率优先处理风险号码可靠性与强有力的核对表可靠性与强有力的演示图表PSW (零件质量合格验收) 不合格现实生活使用记录标准偏差多样性重要特性重要特性/评价特性供应商技术顾问委员会策略性商品组系统设计参数sSDSSEVASHARPSISIMSMARTSMESMFSOWSOPSP/APSP&PISPCSPCSPROM SREASRISSISSMSTSTASTARSSVCSWOTTATAPTCMTEDTEGTEMTGRTGWTISTOCTPMTPPSTQCTRIZ (Russian) TRMC Subsystem Design SpecificationSystems Engineering Value AnalysisSafety and Health Assessment Review ProcessSystem International des UnitSupplier Improvement MetricsSynchronous Material and Replenishment TriggerSubject Matter ExpertSynchronous Material FlowStatement of WorkStructural Prototype/Attribute PrototypeStrategic Process & Product ImprovementSpecial Product CommitteeStatistical Process ControlSample Promise DateSupplier Request for Engineering ApprovalSupplier Responsible IssuesSales Satisfaction IndexStrategic Sourcing MeetingSurface TransferSupplier Technical AssistanceSupplier Tracking and Reporting SystemSmall Vehicle CenterTarget AgreementTarget Achievement PlanTotal Cost ManagementThings Engineers DoTooling and Equipment GroupTotal Equipment ManagementThings Gone RightThings Gone WrongTime in ServiceTable of ContentsTotal Productive MaintenanceTorque Process Potential StudyTrue Quality CharacteristicsTheory of Inventive Problem SolvingTiming, Release and Material Control (also known as子系统设计参数系统工程价值分析安全和健康评估讨论程序国际单位制供应商改进步骤同步物料与补给触发器主题专家同步物料流程工作陈述批量上量时间结构原形/特性原形策略性程序和产品改进特殊产品委员会统计程序控制承诺的样品到货日供应商要求工程批准供应商责任销售满意度指标策略选点会议表面转移供应商技术支持供应商跟踪及汇报系统小型车中心竞争对手情况目标协议目标完成计划总成本管理工程师任务工装及设备组全部设备管理事态发展正确事态发展错误服务期限目录全部生产维护扭矩程序潜力研究真实质量特性创造性解决问题的理论(俄罗斯)时效性、发布和物料控制 (同Acronym List——ford use 缩写目录ACRONYMTS-16949 TSPUCLUSLV/CVCVC Buyer VDIVDSVDSVERVFGVINVLDVOVOVOGOVPVPMCVPPVQLVQRVRTVRTVRTWASWCR WERSWIPWMIWPRCYS/YCTERMTar-Mac)Technical Specification – 16949Technical Skills ProgramUpper Control LimitUpper Specification LimitVery or Completely SatisfiedVehicle CenterVehicle Center Buyer (now Consumer BusinessGroup Buyer)Vehicle Dependability IndexVehicle Design SpecificationsVehicle Descriptor SectionVehicle Evaluation RatingsVehicle Function GroupVehicle Identification NumberVehicle Line DirectorVehicle OfficeVehicle OperationsVehicle Operations General OfficeVice PresidentVehicle Project Management CoordinatorVehicle Program PlanVehicle Quality LevelVehicle Quality ReviewVehicle Review TeamVariability Reduction TeamVehicle Reduction TeamWork Analysis SheetWorldwide Customer RequirementsWorldwide Engineering Release SystemWork In ProgressWorld Manufacturing IdentifierWarranty Parts Return CenterPotential Significant and Critical Characteristics中文译名Tar-Mac)技术规范-16949技术性技能项目上限控制参数上限非常或者彻底满意汽车中心车辆中心客户(现在为商务集团购买客户)车辆可靠性指标车辆设计参数车辆描述组车辆评估等级车辆功能组车辆识别代码车辆生产线总监车辆办公室车辆运作车辆运作综合办公室副总裁车辆项目管理协调员车辆项目计划车辆质量级别车辆质量研讨车辆研讨小组减少差异小组车辆减产小组工作分析表全球客户需求全球工程发布系统进行中的工作世界创造商识别代码维修部件回收中心潜在的重要和评价特性Remark: Editor adds the content in shadow. 备注:阴影部份的内容为编者增加。

![福特质量体系[1]](https://uimg.taocdn.com/2e6800bacc17552706220853.webp)