Volvo 标准--GPDS Training To Suppliers 20120110

- 格式:pdf

- 大小:886.46 KB

- 文档页数:24

fuel efficientHow you specify and drive your truck hasa huge impact on your fuel consumption.Here is a breakdown:Driving: How you drive and in whatconditions, accounts for about 1/3 of the fuelconsumption. Resistance to roll dependsto a large extent on weather conditions andis hard to for the driver to influence.Airresistance and resistance to acceleration andgradient however, can be greatly reducedwith a fuel efficient driving style.Specifying: The specifications of the truckplay an important role for fuel consumption.Once a truck has been specified, around 2/3of its fuel-influencing factors are set and canno longer be changed. Always make sure tospecify the powertrain so that it is optimal foryour transport assignment.What affects fuelconsumption?9% Resistance to roll 10% Air resistance 18% Resistance to acceleration and gradient 3% Powertrain friction 3%Accessories 4% Engine friction 20% Heat to coolant 33% Exhaust gasesAffected by specification (60-65%)*Affected by driving (35-40%)* The figures in the slide are approximate andapplicable for 4x2 tractors , 40-tonne application.9% Resistance to rollWeather conditions and tyres are the biggest influencers on the rolling resistance.Factors that affect tyre rolling resistance:•Rib type tyres have lower rolling resistance than block type tyres. This is mainly due to less movement of the tread in the contact patch area.•Low aspect ratio tyres are stiffer, allowing for less flexing under load, thus they typically have lower rolling resistance compared to high aspect ratio tyres.•Worn tyres have less rolling resistance than new tyres -as a truck tyre wears down, the tread pattern stiffens, which leads to less flexing/deformation in the tread area.The use of fuel efficient tyres on all axle positions can make a significant difference in fuel consumption. A reduction of 10% of rolling resistance on a complete vehicle results in approximately 3% reduced fuel consumption (approximately 0.9 litres/100 km on a vehicle which consumes 30 litres/100km).Of course, a 6x4 truck will have more rolling resistance than a4x2 truck and a loaded has more resistance than an unloaded.Alongside the vehicle specification, the powertrain and aerodynamics –rolling resistance has the largest impact on fuel efficiency.To lower fuel consumption: Invest in fuel efficient tyres. Keep track of tyre pressure both on the truck and trailer.10% Air resistanceExternal accessories and speed are the factors that have the greatest impact on air resistance. Higher speed also increases tyre wear and it requires more energy to handle the longer acceleration. Going down to 85 km/h from 90 km/h reduces fuel consumption by approximately3.5%.To lower fuel consumption: Minimise external accessoriesand lower the speed.Specify the vehicle with a suitanble aerodynamic kit.18% Resistance to acceleration and gradient Driving in intense traffic and on a hilly route will of course influence the fuel consumption immensely.To lower fuel consumption: Use cruise control and predictive cruise control.Parameters that are affected by driving:3% Powertrain frictionPowertrains of today, regardless of truck brand, are very efficient but there will still be some energy losses in oil splash, gearbox and rear axle.3%AccessoriesExternally fitted parking coolers, extra lights and other accessories will give a noticeable increase in fuel consumption. They affect the aerodynamics of the trucks and therefore, require more fuel. Dif-ferent options of air compressors, alternaters and steering pumps also affect the fuel consumption.To lower fuel consumption: Minimise the number of accessories.4% Engine frictionThe fuel consumption is less at lower revs, so the driveline should be optimized for this, for example, by using a faster rear axle and down-speeding. Moving parts in the engine, like pistons, bearings, cogwheels and belts, all generate heat which results in lost energy.20% Heat to coolantDue to the low efficiency in a combustion engine, not all heat is turned into energy to move the truck forward, which is why a run-ning truck needs constant cooling.33% Exhaust gasesThe exhaust gas is basically waste heat from the engine that was not converted into kinetic energy. The higher the efficiency in the engine, the lower the temperature in the exhaust gases and the lower fuel consumption.Parameters that are affected by the specification:Did you find thisinteresting?Subscribe to get the latest blogs and content offers from the Volvo Trucks Knowledge Hub!。

V O L V O英文缩写汇总英文缩写:PS (Program start)项目开始PSC (Program strategy confirmation)项目策略确定PTCC (Program Target Compatibility Check point)项目目标分解PTC (Program Target Confirmation)项目目标确定PA (Program Approval)项目批准LR (Launch Readiness)投产准备就绪LS (Launch Sign Off)投产签收J1 (Job1)量产Use for tooling kick off.用于开模Purchasing Related Process/采购相关的流程RFQRequest for quotation which include Commercial document and ESOW. Commercial document tells the commercial items and ESOW tells the product information and requirements.询价书包括了商务文件和产品工程规范和要求(ESOW)ESOWESOW1 based on first version drawing for quotation ESOW2 based on 2nd version drawings for nominationESOW3 based on 3rd version drawing for CPAESOW1 基于第一版图纸,用于询价ESOW2 基于第二版图纸,用于确定供应商ESOW3 基于第三版图纸,用于签订CPACPACPA is a commercial contract between Volvo andsuppliers for the commodities. It is for the commoditiesprice.CPA是沃尔沃和供应商之间的关于零件价格的合同。

Warranty Training,VCCNCS, GeoMa, jma21VOLVO Warranty TrainingVSTGWarranty Training,VCCNCS, GeoMa, jma21VSTGV olvo S tandard T ime G uide 沃尔沃标准工时指导Warranty Training,VCCNCS, GeoMa, jma21VSTG 定义VSTG 是由一系列的工时代码与标准工时组成。

VSTG 包括了目前在维修方面可能发生的大部分项目,所有的工时标准在维修方案、工艺和设备进一步改进的同时会作出修改。

工时标准在不断地更新以确保高标准和实用性。

Warranty Training,VCCNCS, GeoMa, jma21VSTG 的使用条件达到标准工时的水平必须满足的条件:所有必要的工具和设备都齐备而且方便获取由经过恰当培训而且经验丰富的熟练技工进行操作在维修操作中使用VOLVO 原厂零配件、遵循规定的维修程序和正确使用专用工具。

Warranty Training,VCCNCS, GeoMa, jma21VSTG标准时间的构成VSTG 标准时间单位10个VSTG 工时等于1小时。

1 个VSTG 工时等于6分钟生产时间实际进行维修操作的时间,包括维修、获取工具和设备、获取配件、移动车辆、开具工单等项目。

Warranty Training,VCCNCS, GeoMa, jma21VSTG 标准时间的构成必要的非生产时间包括中途休息、整理工具、与车间主管沟通、等待帮手、阅读维修指引等。

该部分工时是按照生产时间的百分比来计算的,目前针对功能组1是12%,功能组2-8是18%。

针对某些特殊项目牵涉的操作替换专用工具、移动旧件等Warranty Training,VCCNCS, GeoMa, jma21解读标准工时代码章节(功能组)1 = 保养2 = 发动机系统、装配和装备3 = 电气系统和仪表4 = 动力传递系统5 = 刹车系统6 = 悬挂和转向系统7 = 弹簧、避震和车辆8 = 车身和内部X = 附件Warranty Training,VCCNCS, GeoMa, jma21解读标准工时代码组别例如:23 = 燃油系统,一般副组别例如:234 = 燃油系统,线路序列号码按序列排号码。

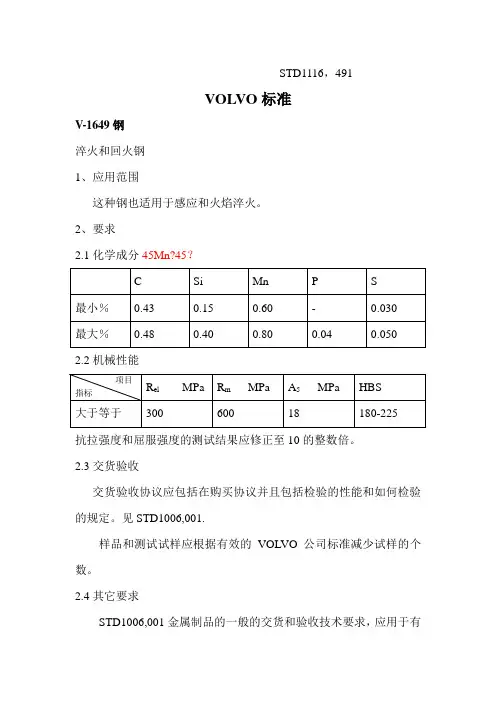

STD1116,491

VOLVO标准

V-1649钢

淬火和回火钢

1、应用范围

这种钢也适用于感应和火焰淬火。

2、要求

2.1化学成分45Mn?45?

2.2机械性能

抗拉强度和屈服强度的测试结果应修正至10的整数倍。

2.3交货验收

交货验收协议应包括在购买协议并且包括检验的性能和如何检验的规定。

见STD1006,001.

样品和测试试样应根据有效的VOLVO公司标准减少试样的个数。

2.4其它要求

STD1006,001金属制品的一般的交货和验收技术要求,应用于有

关的工厂。

STD1006,235应用于钢棒材、锻件、连铸钢棒和锻件。

STD1006,237也适用。

3、补充资料

此标题下面的信息是非标的并且不必考虑遵守。

更多的信息可以从有关文献和制造商处获得。

3.1锻件

对锤锻来说,最高的温度应在1250℃,其它锻件可以到1300℃,工件温度超过1000℃时停留时间应尽可能短。

因为过热和脱碳的危险,最高温度只能在很短的期间使用。

冷却不用控制。

3.2热处理

3.2.1正火

840-860℃,不控制冷却。

3.2.2淬火和回火

油淬850-870℃,水淬840-860℃。

淬火后应立即回火,回火温度大约600℃,保温时间大约1小时。

3.2.3表面淬火

钢材适用于感应和火焰淬火,淬火后的硬度应在55-60HRC,随后的回火温度150-200℃。

V o l v o -C a r s -C u s t o m e r -S p e c i f i c -R e q u i r e m e n t s -I A T F 16949-2018.01.01沃尔沃I A T F 16949顾客特殊要求(共10页)VOLVO CAR GROUPCustomer-Specific Requirements For use with IATF 16949Unless waived in writing by Volvo Car Group, "Tier 1 suppliers" and directed 2nd Tier Suppliers to Volvo Car Group for production or service parts or services shall be third party registered to IATF16949 and ISO14001.Volvo Car Supplier Quality Office 01/01/2018 --本页仅作为文档封面,使用时请直接删除即可-- --内页可以根据需求调整合适字体及大小--Effective from 1st April 2018Per IATF 16949, an "organization" is the manufacturing facility being registered to IATF subcontractor is the manufacturing facility directly contracted by the organization to ship product to the organization in support of a Volvo Car contract. A subcontractor hired by the organization to perform services not directly related to a Volvo Car contract . floor cleaning or grass cutting) is not impacted in any way by the subcontractor development or other subcontractor requirements stated in IATF 16949. In this document, the terms "organization" and "supplier" are interchangeable, both representing the company (or site) being registered to IATF 16949.0. GeneralUnless waived in writing by Volvo Car, "Tier 1 suppliers"* to Volvo Car for production or service parts or services shall be third party registered to IATF16949:2016, ISO 9001:2015 and ISO 14001:2015.The Scope (section 1) of IATF 16949 specifies the types of organizations appropriate for an IATF16949 registration.* Note: In this context, "Tier 1 supplier" refers to an organization's manufacturing site directly contracted by Volvo Car. (Tier1 and Directed Tier2)While it is technically feasible to register only one part of an organization's facility (one product line or area) to IATF 16949, this type of limited scope is not permitted.Note: Requirements in this document do not supersede any regulatory requirements.1. ScopeIATF 16949 and this document define the fundamental quality system requirements for Volvo Car suppliers. This document contains the company-specific requirements supplemental to IATF 16949. These supplemental requirements shall be included in the scope of the registration/certification audit in order to be recognized as satisfying the Volvo Car supplier criteria for third-party certification by an IATF recognized and contracted certification body.IATF 16949 is applicable to manufacturing sites of suppliers to Volvo Car (production and service parts and materials), and to assemblers of production parts or materials supplying to Volvo Car Vehicle Assembly Plants.All IATF 16949 requirements and the requirements of this document shall be addressed by the organization’s quality system.The English language version of this document shall be the official version if translated.For purposes of third party registration.Any translations of this document shall:•Be for reference only,•Reference the English (AIAG) version as the official language,•Be acceptable only if translated by organizations authorized by IATF Oversight (see and include Volvo Car in the copyright statement.Copies of this document are available from Volvo Car at Volvo Cars Supplier Portal and IATF Homepage Note: unless otherwise noted, all references listed throughout these Volvo Car Group Specific Requirements refer to the latest edition.2. Terms and DefinitionsWhere inconsistent terminology exists between IATF 16949 and this document, this document shall take precedence. Otherwise the definitions from IATF 16949 apply to this document.2.1 Active PartAn active part is one currently being supplied to the customer for original equipment or service applications. The part remains active until tooling scrap authorization is given by Volvo Car Procurement. For parts with no customer-owned tooling or situations where multiple parts are made from the same tool, written confirmation from the Buyer is required to deactivate a part.2.2 Capacity verificationA verification methodology to demonstrate that an organization can meet the weekly volume requirements as defined in the Purchasing Request for Quote (RFQ), Commercial Program Agreement (CPA) or Tool Order.2.3 CustomerFor the purposes of IATF16949, references to “customer” in this document shall be interpreted as the entity, . Volvo Car, which is both purchasing and receiving product from the organization complyingwith IATF 16949.2.4 Gauge familiesGauge families are measurement devices of the same type, make, and model that are used in a similar environment (temperature, humidity, range, method of measurement, etc.).2.5 OrganizationFacility adding manufacturing value to production materials: providers of production or service parts, heat treating, plating, painting or other finishing services, sourced by Volvo CarNote 1: For the purposes of registration under ISO/TS 16949, the "organization" is the entity normally referred to by Volvo Car as the "Tier 1 supplier". Volvo Car will continue to use that term when negotiating with the organization.Note 2: To avoid additional confusion, although the term "supplier" is used by IATF 16949 to indicate "subcontractor", Volvo Car will use the term "Tier 2 Supplier".Note 3: "Design responsible Suppliers" also provide engineering services. Program specific Engineering Statement Of Work (ESOW) defines engineering responsibilities.Note 4: Sequencing warehouses and other facilities not adding manufacturing value to the product arenot eligible for stand-alone registration to IATF16949.Note 5: For the purposes of registration under IATF16949, the "organization" is a direct sourced supplieris normally referred to by Volvo Car as the "Directed Tier 2 supplier".2.6 Supplier Request for Customer Approval SREA /SRICASREA - Supplier Request for Engineering Approval.SRICA - Supplier Request for Industrial Change Approval.Detailed information when to use is available through Volvo Cars Supplier portal2.7 SQM (Supplier Quality Management)Supplier Quality Management - Volvo Car team dedicated to evaluation of potential suppliers in the sourcing process, preparation and approval of new processes and parts in new projects, and supplier development in running production.2.8 Subcontractor (Tier X Supplier)Provider of production materials, production or service parts, directly to an organization contracted by Volvo Car. Also included are providers of heat treating, painting, plating or other finishing services.N ote: “Directed Tier x supplier" refers to an organization's subcontractor directly contracted by Volvo Car.2.9 SCASpecial Characteristics Agreement SCA is an agreement what characteristics are the most important to control, what control methods and frequencies to use and also a summary of the capabilities reached during R@R.2.10 Volvo CarThe names "Volvo Car” refer to the corporate entity comprising all departments under Volvo Car Group.2.11 Volvo Car Engineering (PD)Volvo Car Product Development Engineering, including Program and Non-Program organizations.2.12 VSIMVolvo Supplier Improvement Metrics – supplier performance measurements available through Volvo Cars Supplier portal2.13 Quality WallQuality Wall is a tool to protect Volvo Cars production plants from quality disturbances. This extra inspection is manned with additional supplier resources. When requested, 100% inspection of all material must be performed using the Quality Wall Checklist available at the Volvo Car Supplier Portal.4 Context of the organizationCustomer satisfaction - supplementalCertification Body / Registrar NotificationThe organization shall notify its certification body/registrar in writing within ten (10) working days after request from Volvo Cars. This notification of the registrar will constitute a "customer claim"as defined by the IATF Rules. This step will initiate the decertification process of theorganization's IATF 16949 certification.In case of withdrawal of ISO 9001, 14001 or IATF 16949 certificate, the organisation shall inform Volvo Cars within ten (10) working days.5 LeadershipCustomer focusThe organization shall demonstrate enhanced customer satisfaction by meeting the continuous improvement requirements of VQE.6 PlanningNo Volvo Car Corporation Customer Specific Requirements for this section7 SupportPlant, facility and equipment planningThe organisation shall keep Volvo Car system for recording of production line capacities (Line Capacity Reporting LCR) updated, as requested.Environment for the operation of processesThere are monthly audits of 5S for continuous improvement of plant cleanliness, housekeeping and working conditions. Packaging material is included in this requirement. Management team shall continuously monitor improvement plans.Measurement system analysisMeasurement systems used to verify Special Characteristics identified in the SCA document shall show Total Gauge R&R values lower than or equal to 10% (evaluated towards tolerance band). Volvo Cars Supplier Quality Management organisation can in special cases approve use of measurement systems with Total Gauge R&R values between 10% and 30% but the tolerance range used by the organisation must in those cases be decreased to assure that all parts released fulfil Volvo Cars specification.For further details see Customer-Specific Requirements for use with AIAG PPAPInternal LaboratoryThe organization’s Internal Laboratory shall be accepted by the customer, if specified by Volvo Cars7.5.3.2 Control of documentsWhere the organization uses Volvo Car documents / instructions or other documents of external origin, the organization ensures that the appropriate revision level is used•Standards & Forms - Latest revision•Design records - Revision valid at PSW approvalNote: Engineering Standards & Forms are obtained from Volvo Cars Supplier PortalIf any standards are not available through the above source, organizations should contact Volvo Car Engineering).7.5.3.2.1 Records retentionThe organization shall retain the documents below in a safe and confidential way for the following timesDevelopment Documentation L+20e. g. CAE Reports, Laboratory Reports, Measurement Data, Measurement Protocols andTest ReportsProduct Documentation for Legal and Safety Requirement related parts L+20 (These are identified by consequence class 1, CR or RT requirements or Emission Related Components ERC marking) e. g. Purchase orders and amendments, Tooling orders, PPAP documents, Set-up verification results, Running Production Inspection, Running Production Testing, Annual Layout Inspection and Log-books showing modifications and changes to production process.Product Documentation for non-Legal nor Safety Requirement related parts L+1e. g. Purchase orders and amendments, Tooling orders, PPAP documents, Set-upverification results, Running Production Inspection, Running Production Testing, Annual Layout Inspection and Log-books showing modifications and changes to production process.Remark: L stands for Vehicle Life representing the date when the product which the documentation is related to, is not produced any more including spare parts. Add twenty (20) or one (1) year to the year when the product is not produced any more in order to calculate the destruction date for the record.7.5.3.2.2 Engineering SpecificationsPart folder RequirementsThe Part folder define the Engineering Specifications describing the requirement for the part .•2D Drawings•3D Models•Technical RegulationsHeat Treat Assessment Requirements•For supplier processes defined by SQM, supplier shall demonstrate compliance to CQI-9 "Special Process: Heat Treat System Assessment" available through AIAG.Assessment is done yearly and is valid also for sub-suppliers.•The heat treat assessment can be either 1st or 2nd party, but must be conducted by a qualified assessor as defined in AIAG Heat Treat System Assessment CQI-9.Note:•Heat Treat assessments conducted by the organization, heat treat suppliers, or Volvo Car demonstrating compliance to CQI-9 requirements do not relieve theorganization of full responsibility for the quality of supplied product.•To reduce the risk of embrittlement, heat-treated steel components shall conform to the requirements in VCSDesign and development reviewUnless agreed with Volvo Cars, design responsible suppliers shall include Volvo Car Engineering, Assembly and / or Manufacturing in design reviews for all Volvo Car parts.8.3.3.2 Manufacturing process design inputVolvo Cars Commodity Specific Assessments (CSA) shall be used as manufacturing process design input. Available through Volvo Cars Supplier Portal.8.3.3.3 Special characteristicsDesignated Special CharacteristicsThe organization shall together with Volvo Cars identify and agree with Volvo Car Engineering and SQM organization regarding which characteristics are the most important to control, how to control them and appropriate control frequency.Measurement points from Measurement Point Drawings shall be included in the special characteristics.The form "Special Characteristics Agreement (SCA) available from Volvo Cars supplier portal shall be used and approved. The SCA shall be completed and updated as required by the customer.Design FMEA(s), Process FMEA(s) and Control plan(s) for parts with characteristics influencing Health, Safety and Legislation Requirements prepared by design responsible organization require Volvo Car Engineering approval. Approval signoff shall be made on the SCA document. Product approval processThe organization shall comply with the AIAG PPAP, Volvo Car PPAP Requirement Handbook and Customer Specific Requirements for PPAP.PPAP package for subcontractors to be available upon request.Supplier verifies PPAP compliance of requirements by on-site visit of high impact/new projects subcontractor’s facilities.Capacity Verification shall be submitted to Volvo Cars. Changes in capacity shall be communicated to Volvo Cars.All PPAP documents are available in English.Manufacturing process design outputAIAG FMEA handbook must be followed.Supplier quality management system developmentSubcontractors shall have an accredited third party certification to current version of IATF 16949 or VDA6 unless otherwise agreed by Volvo Cars. The organization shall have a list of its subcontractors available to Volvo Cars.Control planSpecial characteristics identified in the SCA document shall be included and marked in the control plans.All Gauges used for measuring and evaluating of Volvo Cars components/parts according to the control plan shall have a Gauge R&R performed in accordance with the appropriate methods described by the latest AIAG Measurement Systems Analysis manual. Gauges should be regularly verified (quick check on top of yearly calibration) before use. New Gauge R&R shall be done after each Gauge calibration or as agreed with SQM.When consequence class 1&3 have been defined in the SCA document, Attribute Gauges are not accepted.Technical Regulation testing frequency requirements shall be clearly noted in the Control Plan and PFMEA. Any revisions to these frequencies require Volvo Car SQM concurrence.The control plan shall include the needed increased inspection frequency related to tools . dies, moulds and cutting tools) coming close to their estimated life time.If requested the organization shall reinforce the control plan (“Quality Wall”) by increasing the frequencies and scope of controls and inspections in order to avoid parts out of specification during the launch phase. The reinforced control plan shall be used for all deliveries until otherwise is decided by Volvo Cars.Volvo Cars reserves the right to require the use of an independent third party inspector to ensure that only compliant products are shipped to Volvo Car facilities.Identification and traceabilitySupplier shall have a traceability system in place for products, including sub components shipped to customer. Traceability data has to support Customer retention timings.Total Productive MaintenanceGauge and Measurement equipment shall be subject to recalibration and verification after maintenance activities.Tool and equipment maintenance plans shall contain those special characteristics identified in the SCA document.Error-proofing and “Poka Yoke” methods shall be defined in preventive maintenance plans.Control of changesFor Supplier initiated changes, Volvo Cars change processes (see below) at Volvo Cars supplier portal have to be used.Process, site and subcontractor changes:SRICA Supplier Request for Industrial Change ApprovalProduct changes:SREA Supplier Request for Engineering ApprovalIn order to give the Customer needed time to review change requests, the Organization shall ensure that required Customer approvals are attained in due time prior to any changes.A new PPAP approval is required after any change initiated by SRICA/SREAchange of process controlsIn case of temporary process change(s) the organisation shall ask for a Temporary Part Deviation (TPD) approval.Layout inspection and functional testingUnless otherwise agreed with Volvo Car’s Supplier Quality Management (SQM), all PartFolder requirements, including all applicable legal and homologation requirements, shall be verified and documented annually and described in the Control Plan.Control of nonconforming productIn case of need of shipping parts outside Technical Specification the organisation shall ask for a Temporary Part Deviation (TPD) approval. All affected Volvo Car facilities shall be informed in case of shipping non-conforming material.The organization shall immediately notify Volvo Car Engineering, SQM and the receiving Volvo Car facility of test failure (including Technical Regulation activities), suspension of shipments, and identification of any suspect lots shippedCustomer notificationCustomer Deviation Permit is managed by the TPD Process /PPAP processSubmission of PPAPThe organization shall submit PPAP per Volvo Car's Phased PPAP Handbook, available through the Volvo Cars Supplier Portal.PPAP submissions can only be approved according to released (not “Preliminary”) PartFolder for Suppliers.9.1.2.1 Customer satisfactionThe organization management has a defined organization and a systematic process •to monitor VSIM metrics monthly in o rder to meet VQE requirements.•to update VSIM with relevant information continuously . Supplier contacts, 8D reports, APQP, PPAP, Line Capacity Report).•to collect and evaluate continuously progress of new projects . APQP reporting and PPAP planning).•to collect and evaluate regularly "customer satisfaction" . interviewing Volvo Cars Manufacturing, Logistic, SQM, Buyer, Volvo Car Engineering, Customer Service andother customer representatives).•to have a process to determine what drives reduction in warranty costs and improvement in customer satisfaction.10.2.5 Warranty management systemsFurther information will be found on VSIM.10.2.6 Customer complaints and field failure test analysisAny non-conforming product or process output shall be analysed using the 8D methodology to identify Root Cause and implement robust Permanent Corrective actions.Organizations shall respond to Quality Rejects and Administrative Rejects with an 8D and in Volvo Car reporting system as specified by customer.A Yearly review of Volvo Cars customer complaints shall be performed in order to find common systemic Root Causes.Change Log:9。

Purpose of today 目的Focus Group讲解对象 Suppliers 供应商Purpose目的: Provide comprehensive knowledge of Volvo Cars Purchasing Terms andConditions 增进供应商对沃尔沃《生产采购全球性条款与细则》的了解PPGTC= Production Purchasing Global Terms & Conditions 《生产采购全球性条款与细则》>PPGT&C STA>,<Purchasing>,<Christian Wulfsberg>,<cwulfsb1> Issue date: <2010->, Security Class: <Proprietary> Page 2Provide comprehensive knowledge of Volvo Cars Purchasing Terms and Conditions 增进供应商对沃尔沃《生产采购全球性条款与细则》 的了解>PPGT&C STA>,<Purchasing>,<Christian Wulfsberg>,<cwulfsb1> Issue date: <2010->, Security Class: <Proprietary> Page 3Different Agreement and conditions Production Purchasing 生产性采购所需的协议及条款条件列表Terms and conditions•Volvo Production Purchasing Global Terms & Conditions PPGTC July 1. 2011Agreements•Confidentiality agreement•Development/Technology agreement•Sourcing agreement/Commercial & Program agreement. Tier 1 and Tier 2•Commercial and Program Agreement Pricing Agreement •Directed Tier 2 Responsibility Agreement incl Schedule A •Current-year pricing agreement (Non Design) •Multi year agreement •Bailment agreement Production material •Contingent liability agreement •Supplier letter (Agreement for supplier usage of VCC owned tooling)hhttttppss::////ssuupppp供 lliieer应rppo商orrtt平aall..台vvoollvvooccaarrss..bbiizz>PPGT&C STA>,<Purchasing>,<Christian Wulfsberg>,<cwulfsb1> Issue date: <2010->, Security Class: <Proprietary> Page 4The Purchase Order采购订单>PPGT&C STA>,<Purchasing>,<Christian Wulfsberg>,<cwulfsb1> Issue date: <2010->, Security Class: <Proprietary> Page 5Example: Purchase Order for PartsPurchase Order 采购订单>PPGT&C STA>,<Purchasing>,<Christian Wulfsberg>,<cwulfsb1> Issue date: <2010->, Security Class: <Proprietary> Page 6PPGTC 《生产采购全球性条款与细则》解释>PPGT&C STA>,<Purchasing>,<Christian Wulfsberg>,<cwulfsb1> Issue date: <2010->, Security Class: <Proprietary> Page 7Section 1. What is Covered应用范围We should apply these Terms and Conditions for everything that is related to production purchasingE.g. production parts, tools, spare parts etc. 该条款与细则适用于所有生产性采购Section 2. Documents used in the production purchasing 生产性采购所需的合同性文件RFQ SA/CPA ESOW Production Order Second Tier Responsibility Agreement …>PPGT&C STA>,<Purchasing>,<Christian Wulfsberg>,<cwulfsb1> Issue date: <2010->, Security Class: <Proprietary> Page 8Section 3 Web-Guides and Supplemental Terms and Conditions 网上指南和补充条例与细则Web-Guides contains special conditions but PPGT&C takes precedence in case of conflict网上指南包含一些具体的要求,如与PPGTC不一致,应以PPGTC为准Supplemental Terms and Conditions add special terms for special parts/markets and take precedence over PPQT&C in case of conflict补充条款与细则包含了针对特殊产品或当地市场要求的具体规定,如与PPGTC不一致,应以PPGTC为准https:// Section 4. The Terms and Conditions that Apply适用的条款与条件Only agreements referring to PPGT&C is valid UNLESS the deviation has been in writing and approved by the President and Chief Executive Officer of Volvo Car Corporation.任何对PPGTC的改动必须以书面形式作出并经过沃尔沃汽车公司主席和首席执行 官批准>PPGT&C STA>,<Purchasing>,<Christian Wulfsberg>,<cwulfsb1> Issue date: <2010->, Security Class: <Proprietary> Page 9Section 5 When the Contract is Formed 合同成立An agreement is formed between VCC and the supplier when the supplier accept the buyers PO which can be done in two ways供应商接受采购订单有两种方式:1) The supplier starts to work on what we have ordered 供应商开始按照采购订单的要求展开工作2) The supplier informs us that they have accepted our PO. 供应商通知沃尔沃他们已经接受了沃尔沃采购订单Section 7 Volume Projections 产量计划VCC can give volume forecasts to the supplier but these are only forecasts nothing else. 沃尔沃可以提供产量计划,只是计划,对沃尔沃并不具有约束力。

GROUPE DE FONCTIONS 9功能组9ÉQUIPEMENTS AUXILIAIRES ET FONCTIONSSPÉCIALES附属设备与特殊功能Types de carrosseries et domaines d'utilisation上装的种类及应用领域Les camions actuels sont des outils de transport polyvalents. Il existe de nombreux types de carrosseries, ce qui permet d'adapter chaque camion à l'utilisation et au type de transport auxquels il est destiné. Le transport routier de marchandises représente un volume quotidien énorme et très variéet implique donc de nombreuses exigences auxquelles les camions actuels doivent être en mesure de répondre. Les aliments frais, par exemple, requièrent une manipulation spécifique et, la plupart du temps, une réfrigération. Le transport du bois de l'exploitation forestière à la scierie implique, quant à lui, des exigences totalement différentes.现实中的卡车都是多功能的运输工具。

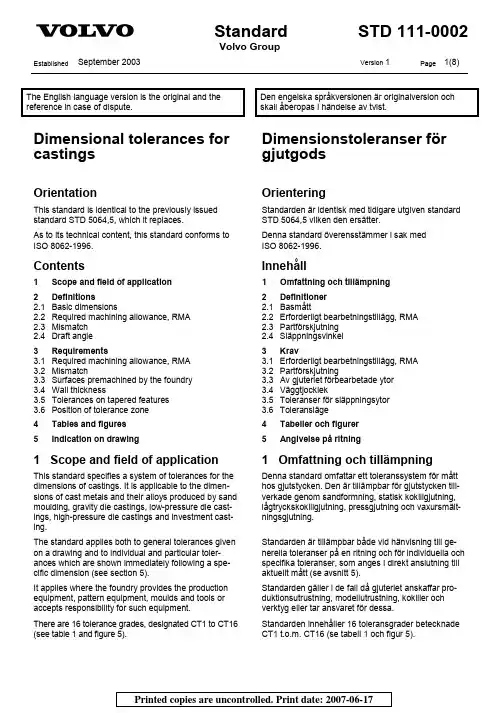

Standard STD 111-0002Volvo GroupEstablished September 2003 Version 1 Page1(8)The English language version is the original and thereference in case of dispute.Den engelska språkversionen är originalversion ochskall åberopas i händelse av tvist.Dimensional tolerances forcastingsDimensionstoleranser förgjutgodsOrientation Orientering This standard is identical to the previously issuedstandard STD 5064,5, which it replaces.Standarden är identisk med tidigare utgiven standardSTD 5064,5 vilken den ersätter.As to its technical content, this standard conforms toISO 8062-1996.Denna standard överensstämmer i sak medISO 8062-1996.Contents Innehåll1 Scope and field of application 1 Omfattning och tillämpning2 Definitions 2 Definitioner2.1 Basic dimensions 2.1 Basmått2.2 Required machining allowance, RMA 2.2 Erforderligt bearbetningstillägg, RMA2.3 Mismatch 2.3 Partförskjutning2.4 Draft angle 2.4 Släppningsvinkel3 Requirements 3 Krav3.1 Required machining allowance, RMA 3.1 Erforderligt bearbetningstillägg, RMA3.2 Mismatch 3.2 Partförskjutning3.3 Surfaces premachined by the foundry 3.3 Av gjuteriet förbearbetade ytor3.4 Wall thickness 3.4 Väggtjocklek3.5 Tolerances on tapered features 3.5 Toleranser för släppningsytor3.6 Position of tolerance zone 3.6 Toleransläge4 Tables and figures 4 Tabeller och figurer5 Indication on drawing 5 Angivelse på ritning1 Scope and field of application 1 Omfattning och tillämpningThis standard specifies a system of tolerances for thedimensions of castings. It is applicable to the dimen-sions of cast metals and their alloys produced by sandmoulding, gravity die castings, low-pressure die cast-ings, high-pressure die castings and investment cast-ing.Denna standard omfattar ett toleranssystem för måtthos gjutstycken. Den är tillämpbar för gjutstycken till-verkade genom sandformning, statisk kokillgjutning,lågtryckskokillgjutning, pressgjutning och vaxursmält-ningsgjutning.The standard applies both to general tolerances givenon a drawing and to individual and particular toler-ances which are shown immediately following a spe-cific dimension (see section 5).Standarden är tillämpbar både vid hänvisning till ge-nerella toleranser på en ritning och för individuella ochspecifika toleranser, som anges i direkt anslutning tillaktuellt mått (se avsnitt 5).It applies where the foundry provides the productionequipment, pattern equipment, moulds and tools oraccepts responsibility for such equipment.Standarden gäller i de fall då gjuteriet anskaffar pro-duktionsutrustning, modellutrustning, kokiller ochverktyg eller tar ansvaret för dessa.There are 16 tolerance grades, designated CT1 to CT16(see table 1 and figure 5).Standarden innehåller 16 toleransgrader betecknadeCT1 t.o.m. CT16 (se tabell 1 och figur 5).2 Definitions 2 Definitioner 2.1 Basic dimensions 2.1 BasmåttDimension of a raw casting before machining (see fig-ure 3), the necessary machining allowance being included (see figure 4). Mått för obearbetat gjutgods före bearbetning (se figur 3) med nödvändigt bearbetningstillägg (arbetsmån) inkluderat (se figur 4).2.2 Required machining allowance, RMA 2.2 Erforderligt bearbetningstillägg,RMAOn raw castings, a material allowance to permit the re-moval of the defects of casting on the surface by subse-quent machining and to allow the achievement of the desired surface texture and the necessary accuracy of dimension. På obearbetat gjutgods, materialtillägg som medger avlägsnande av gjutdefekter på godsytan genom ef-terföljande bearbetning och som möjliggör önskad ytstruktur och nödvändig måttnoggrannhet.2.3 Mismatch 2.3 PartförskjutningRelative displacement of surfaces of a casting owing to inaccuracies in the constituent parts of multipart moulds. Relativ förskjutning av ytor på ett gjutstycke beroende på onoggrannheter hos de ingående delarna i flerde-taljformar.2.4 Draft angle 2.4 SläppningsvinkelAdditional slope of shaping elements (e.g. on envelop-ing surfaces) necessary to facilitate the removal of a casting from a mould or die, or a pattern from a mould, or the parts of a permanent mould from each other. Lutning på formade element (t.ex. på omslutande ytor) nödvändig för att underlätta avlägsnande av gjutgods ur en form eller verktyg eller en modell ur en form, eller delarna i en permanent form från varandra.3 Requirements 3 Krav3.1 Required machining allowance, RMA 3.1 Erforderligt bearbetningstillägg,RMAUnless otherwise specified, the required machining al-lowance is valid for the entire raw casting, i.e. only one value is specified for all surfaces to be machined and this shall be selected from the appropriate dimension range according to the largest overall dimension of the finished casting after final machining. Om inget annat anges, gäller erforderligt bearbet-ningstillägg hela det obearbetade gjutgodset dvs en-dast ett värde anges för alla ytor som skall bearbetas, och detta värde väljs utgående från ett lämpligt di-mensionsområde baserat på det största måttet på det färdiga gjutstycket efter slutbearbetning.The maximum dimension of a feature, as cast, shall not exceed the finished dimension plus the required ma-chining allowance plus the total casting tolerance. When applicable, the taper shall be considered additionally. Maximala mått, i gjuttillståndet, skall inte överstiga det färdiga måttet plus erforderligt bearbetningstillägg plus den totala gjutgodstoleransen. Om släppning före-ligger, skall denna läggas till.There are 10 grades of required machining allowance, designated A to K (see table 2). Det finns 10 grader för bearbetningstillägg betecknade A t.o.m. K (se tabell 2).3.2 Mismatch 3.2 PartförskjutningMismatch (see figure 6) shall lie within the tolerance shown in table 1. This means that the mismatch shall lie within the limits of size shown in figure 5. When it is im-portant to restrict further the value of mismatch, it shall be stated on the drawing (see section 5). This value shall not be added to the tolerance given in table 1. Partförskjutning (se figur 6) skall ligga inom de tole-ranser som anges i tabell 1. Detta innebär att partför-skjutning skall ligga inom de i figur 5 visade tolerans-gränserna. När det är nödvändigt att begränsa part-förskjutningens storlek ytterligare, skall detta anges på ritningen (se avsnitt 5). Detta värde på partförskjut-ningen skall ej adderas till toleransvärdena angivna i tabell 1.3.3 Surfaces premachined by thefoundry3.3 Av gjuteriet förbearbetade ytorAny surfaces to be pre-machined by the foundry and the necessary machining allowances for the final machining shall be stipulated on the drawing in accordance with STD 5068,04. Ytor som skall förbearbetas av gjuteriet, och nödvän-digt bearbetningstillägg för den slutgiltiga bearbet-ningen, skall anges på ritningen i överensstämmelse med STD 5068,04.The required machining allowances necessary for the achievement of the pre-machined condition shall be the responsibility of the foundry, independent of the values given i table 2. För erforderligt bearbetningstillägg, som är nödvändigt för att uppnå det förbearbetade tillståndet, är gjuteriet ansvarigt, oberoende av de värden som anges i tabell 2.3.4 Wall thickness 3.4 VäggtjocklekUnless otherwise specified, the tolerance for wall thick-ness in grades CT1 to CT15 will be one grade coarser than the general tolerance for other dimensions; for ex-ample, if there is a general tolerance on a drawing of CT10, the tolerance on wall thickness will be CT11. För väggtjockleksmått skall vid toleransgraderna CT1 t.o.m CT15, om inget annat anges, en toleransgrad högre än den allmänna toleransgrad som anges för övriga mått tillämpas. Om exempelvis den generella toleransen på ritningen är CT10, så gäller CT11 för väggtjockleksmått.3.5 Tolerances on tapered features 3.5 Toleranser för släppningsytorWhere a design requires a tapered feature, the tolerance shall be applied symmetrically along the surface (see figure 2). När gjutstyckets konstruktiva utformning kräver ytor med släppning, skall toleransen vara symmetrisk ut-efter släppningsytan (se figur 2).The drawing shall specify generally whether the draft shall be added to, subtracted from or averaged to the material, e.g. Ritningen skall generellt ange om släppningen skall läggas till, dras ifrån eller fördelas på båda sidor, t.ex.taper + taper −taper ±See figure 1. släppning + släppning −släppning ±Se figur 1.Tapers for particular surfaces which deviate from the general indication on the drawing shall be indicated individually. Släppning på specifika ytor som avviker från den ge-nerella angivelsen på ritningen, skall anges individuellt på ritningen.For dimensions to be machined, “taper +” shall be ap-plied, irrespective of the general indication of taper, in order that the finished dimensions can be achievable. För måttsatta ytor som skall bearbetas, skall ”släpp-ning +” tillämpas, oberoende av den generella an-givelsen för släppning, för att det färdiga måttet skall kunna erhållas.Nominal dimensionNominal dimension Nominal dimension Fig. 1 Tapers / SläppningarFig. 2 Tapered feature (see section 5) / Släppningsyta (se avsnitt 5)3.6 Position of tolerance zone 3.6 ToleranslägeThe tolerance zone, unless otherwise stated, is to be symmetrically disposed with respect to the basic dimen-sion, i.e. with one half on the positive side and one half on the negative side (see figure 5). However, when agreed by both manufacturer and purchaser for specific reasons, the tolerance zone may be asymmetric, e.g. on either the positive or negative side. Toleransen skall, om inget annat anges, vara sym-metrisk med avseende på basmåttet, d.v.s. lika för-delad på plus- och minussidan (se figur 5). Dock kan, om speciella skäl föreligger och om överenskommelse härom träffats mellan gjuteri och kund, toleransen vara asymmetrisk, t.ex. antingen på plus- eller minus-sidan.4 Tables and figures 4 Tabeller och figurer Table 1 Casting tolerancesTabell 1 GjutgodstoleranserCasting basic dimension Total casting tolerance mm 1) Total toleransvidd mm 1)Gjutstyckets basmått Casting tolerance grade CT Toleransgrad CTover över up to andincl.t.o.m1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16– 10 0,09 0,13 0,180,26 0,36 0,52 0,741,0 1,5 2,0 2,8 4,2 – – – – 10 16 0,10 0,14 0,200,28 0,38 0,54 0,781,1 1,6 2,2 3,0 4,4 – – – – 16 25 0,11 0,15 0,220,30 0,42 0,58 0,821,2 1,7 2,4 3,2 4,6 6 8 10 12 25 40 0,12 0,17 0,240,32 0,46 0,64 0,901,3 1,8 2,6 3,6 5,0 7 9 11 14 40 63 0,13 0,18 0,260,36 0,50 0,70 1,0 1,4 2,0 2,8 4,0 5,6 8 10 12 16 63 100 0,14 0,20 0,280,40 0,56 0,78 1,1 1,6 2,2 3,2 4,4 6 9 11 14 18 100 160 0,15 0,22 0,300,44 0,62 0,88 1,2 1,8 2,5 3,6 5,0 7 10 12 16 20 160 250 0,24 0,340,50 0,70 1,0 1,4 2,0 2,8 4,0 5,6 8 11 14 18 22 250 400 0,400,56 0,78 1,1 1,6 2,2 3,2 4,4 6,2 9 12 16 20 25 400 630 0,640,901,2 1,82,63,6 5 7 10 14182228 630 1000 1,0 1,4 2,02,84,0 6 8 11 16202532 1000 1600 1,6 2,23,24,6 7 9 13 18232937 1600 2500 2,63,85,4 8 1015 21263342 2500 4000 4,46,2 9 1217 24303849 4000 6300 7,0101420 28354456 630010000 111623 324050641) See section 6. 1) Se avsnitt 6.Notes:Anmärkningar:1 For wall thicknesses in grades CT1 to CT15, onegrade coarser applies (see section 3.4). 1 För väggtjockleksmått med toleransgraderna CT1t.o.m. CT15, gäller en toleransgrad högre (se av-snitt 3.4).2 For basic dimensions up to and including 16 mm,general tolerances from CT13 to CT16 are notavailable. For these sizes, individual tolerances shall be indicated. 2 För basmått t.o.m. 16 mm föreligger inga generellatoleranser från CT13 t.o.m. CT16. För dessa mått skall individuella toleranser anges.Table 2 Required machining allowances (RMA)Tabell 2 Erforderligt bearbetningstillägg (RMA)Largest dimension 1)Required machining allowances (RMA) mmErforderligt bearbetningstillägg (RMA) mm Största mått 1)Required machining allowance gradeGrad för bearbetningstilläggöver over t o mup to andinclA 2)B 2)CDEFGH J K– 40 0,1 0,1 0,2 0,3 0,4 0,5 0,5 0,7 1 1,440 63 0,1 0,2 0,3 0,3 0,4 0,5 0,7 1 1,4 263 100 0,2 0,3 0,4 0,5 0,7 1 1,4 2 2,8 4100 160 0,3 0,4 0,5 0,8 1,1 1,5 2,2 3 4 6 160 250 0,3 0,5 0,7 1 1,4 2 2,8 4 5,5 8 250 400 0,4 0,7 0,9 1,3 1,8 2,5 3,5 5 7 10 400 630 0,54 0,8 1,1 1,5 2,2 3 4 6 9 12 630 1000 0,6 0,9 1,2 1,8 2,5 3,5 5 7 10 14 1000 1600 0,7 1 1,4 2 2,8 4 5,5 8 11 16 1600 2500 0,8 1,1 1,6 2,2 3,2 4,5 6 9 13 18 2500 4000 0,9 1,3 1,8 2,5 3,5 5 7 10 14 20 4000 6300 1 1,4 2 2,8 4 5,5 8 11 16 22 6300 10000 1,1 1,5 2,2 3 4,5 6 9 12 17 24 1) Largest overall dimension of the casting after finalmachining.1) Största mått hos gjutstycket efter slutbearbetning.2) Grades A and B shall only be applied in specialcases, for example with series production in which the pattern equipment, the casting procedure and the machining procedure with regard to clamping surfaces and datum surfaces or targets have been agreed between the customer and the foundry. 2) Graderna A och B skall endast användas i speci-ella fall, t.ex. vid serieproduktion där överenskom-melse har träffats mellan kund och gjuteri beträf-fande modellutrustning, gjutprocess, maskinbear-betning med hänsyn till fastspänningsytor ochreferensytor.Fig. 3 Drawing indications (see section 2.1)Ritningsangivning (se avsnitt 2.1)Fig. 4 Relationship of casting with machining al-lowance showing the tolerance symmetricallydisposed about the basic dimensionGjutstycke med bearbetningstillägg. Figurenvisar toleransen symmetriskt förlagd omkringbasmåttetFig. 5 Tolerance limits / Toleransgränser Fig. 6 Examples of mismatch (see section 2.3)Exempel på partförskjutning (se avsnitt 2.3) NOTE - Any mismatch shall lie within the limits of sizeshown (see sections 1 and 2).ANM.: Eventuell partförskjutning skall ligga inom de ifiguren visade toleransgränserna (se avsnitt 1 och 2).5 Indication on drawing 5 Angivelse på ritningTolerances according to this standard shall be stated on the drawing in the following ways: Toleranser enligt denna standard anges på ritning enligt följande:a) with general reference to tolerance grade, for exam-ple,a) med generell hänvisning till toleransgrad, t.ex.Casting tolerances ISO 8062-CT16, STD 111-0002or ellerb) if further restriction of the mismatch is required (seesection 2.3), for example, b) om ytterligare krav gäller beträffande partför-skjutning (se avsnitt 2.3), t.ex.Casting tolerances ISO 8062-CT16, STD 111-0002. Maximum mismatch 2,5or eller c) following the basic dimension, in millimetres, for ex-ample,c) i anslutning till basmåttet, i mm, t.ex.95 ± 1,1or ellerd) following the basic dimension for one or more dimen-sions and according to tolerance grade for the rest of the dimensions, for example, d) i anslutning till basmåttet för något eller några måttoch enligt toleransgrad för övriga mått,t.ex.Casting tolerances ISO 8062-CT16, STD 111-0002 unless otherwise stated. Ex 1: CASTING TOLERANCES ISO 8062-CT16, STD 111-0002 Ex 2: CASTING TOLERANCES ISO 8062-CT16, STD 111-0002.MAX MISMATCH 2,5Ex 3: CASTING TOLERANCES ISO 8062-CT16, STD 111-0002 UNLESS OTHERWISE STATED。

![沃尔沃培训内训教材[优质PPT]](https://uimg.taocdn.com/ec315b55b52acfc788ebc949.webp)

volvo服务包装要求Volvo's service packaging requirements for suppliers encompass several key areas, ensuring that all aspects of delivery, quality, business principles, and formal requirements are met. These standards are designed to maintain the integrity and efficiency of Volvo's supply chain and operations. Here is a detailed overview:1.Delivery Requirements:⏹Suppliers are responsible for determiningthe Regional Value Content of theirproducts when shipping to a countryoutside of their own.⏹ A Certificate of Origin must be submittedfor goods annually and with each shipmentin regions where it is required.2.Quality Assurance:⏹Volvo expects suppliers to take completeresponsibility for the environmentalimpact of their products and services.⏹ A holistic approach towards materialhandling and information exchange isrequired.⏹Suppliers must be proficient in moderntools and methods for effective continuousimprovement.⏹Specific requirements are detailed in theSupply Partner Quality Assurance Manual(SPQAM).3.Business Principles:⏹Volvo emphasizes the importance ofresponsible business practices andsustainable behavior, as outlined in theirCode of Conduct.⏹Compliance with principles including anti-corruption, competition law, sanctions,and other business-related issues iscrucial.⏹The Supply Partner Code of Conduct (KEP 6)defines minimum sustainabilityrequirements in areas such as humanrights, working conditions, health andsafety, responsible sourcing of rawmaterials, environmental performance, andbusiness ethics.4.Formal Requirements:⏹After initial screening, suppliers undergoa Supplier Evaluation process.⏹They must comply with Key ElementsProcedures (KEP), which cover requirementsapplicable to all supply types.These requirements reflect Volvo's commitmentto sustainability, ethical business practices, and high standards of quality and compliance. By adhering to these standards, suppliers can effectively contribute to Volvo's supply chainwhile aligning with the company's core values and operational principles.。

The English language version is the original and the reference in case of dispute.此英文版为初始版,如有争议,以英文版为准。

TEST METHOD 试验方法Odour of trim materials in vehicles汽车装饰材料气味Organic materials有机材料Orentation引言This standard is a further development of standard STD 1027,2712, issue 1, which it replaces and from which it differs in that the requirements under section 3.1 ”Conditioning of test pieces” have been changed.本标准是标准STD 1027,2712,版本1的延伸,该标准在章节3.1:测试件条件做了更改,区别并代替以前版本。

This standard conforms to VDA 270, Versions A2, B2 and C2, with the exception that the test has been extended to include placing a set of test pieces in a test vessel without water.除了该实验扩展到了在无水试验容器中包含一套试验样件外,本标准和VDA 270, 版本 A2, B2 和 C2是一致的。

Contents 内容1 Scope and field of application范围和适用性2 Apparatus 设备3 Test pieces 测试件3.1 Conditioning of test pieces测试件条件3.2 Quantity of materials for testing测试材料数量4 Testing 测试5 Evaluation评估6 Test report 试验报告1Scope and field of application 范围和适用性The purpose of the test is to assess odour under the influence of temperature and moisture. The test is performed on materials from the interior of vehicles and on components that come into contact with the air flow supplied to the interior of vehicles.本试验目的在于在温度和湿度影响下评估气味。

Issue date: 2/15/2012Volvo GPDS Training 沃尔沃GPDS培训

VCTC R&D Miao Weimin

研发缪伟民

2012-01-10

Issue date: 2/15/2012

Training Purpose/培训目的

•Let suppliers have a initial understanding of Volvo vehicle development process

给供应商一个有关沃尔沃产品开发流程的简单介绍•Let suppliers understand all the activities which relate to suppliers

让供应商理解所与供应商有关的活动

Issue date: 2/15/2012

GPDS/GPDS 的定义

•GPDS: Global Product Development System •GPDS :全球产品开发体系

Issue date: 2/15/2012

•GPDS get the engineering, design, purchasing, manufacturing , marketing (customer) and suppliers to work together to deliver a good vehicle.

•GPDS将工程,造型,采购,制造,市场和供应商整合在一起,为客户开发一个好的车型。

Issue date: 2/15/2012

Powertrain / 动力总成Under body / 下车体Upper body /上车体

Issue date: 2/15/2012VPP (supplier related)/供应商相关的VPP

Issue date: 2/15/2012

VPP (supplier related)/供应商相关的VPP

•PS (Program start)

项目开始

•PSC (Program strategy confirmation)

项目策略确定

•PTCC (Program Target Compatibility Check point)项目目标分解

•PTC (Program Target Confirmation)

项目目标确定

Issue date: 2/15/2012

•PA (Program Approval)

项目批准

•LR (Launch Readiness)

投产准备就绪

•LS (Launch Sign Off)

投产签收

•J1 (Job1)

量产

VPP (supplier related)/供应商相关的VPP

Issue date: 2/15/2012

Builds/装车活动

M1 build

M1 build is to verify under body. So under body related parts are affected.

M1装车是为了验证下车的设计,所以只有下车体的零件影响到。

L421 program already finished the M1 build. All related parts have been provided by related suppliers.

L421 项目的M1装车活动已经结束,所有相关零件已经有各个供应商提供。

Issue date: 2/15/2012

Builds/装车活动

E3/E4 build / E3/E4装车

E3/E4 build is to verify electrical parts’function (no dimension requirement). All body electrical parts are affected. Chassis and PT electrical parts are not affected.

E3/E4装车是为了验证车身电子零件的性能(对几何尺寸没有要求),车身电子相关零件需要支持该装车。

底盘和动力系统的电气相关的零件不需要支持。

Support needed from suppliers/需要供应商支持-Provide qualified parts on time/准时提供合格零件-On site support the builds for key parts/关键零件供应商现场支持装车。

-Resolve the issue found in the builds/解决装车问题

Issue date: 2/15/2012

MTO Build (Machine Try Out Build)

MTO build is to verify BIW (body in white) and body shop process. All stamping parts are affected. No any trim parts are needed. Build will only in body shop. Parts must be from job1 tooling. This build is before VP

MTO 是为了验证白车身和焊装工艺的一次装车,只在焊装车间进行,只有冲压件会影响到,总装零件不需要支持。

所有零件必须是量产模具制作的。

MTO 装车发生在VP 装车之前。

Support needed from suppliers/需要供应商支持-Provide qualified parts on time/准时提供合格零件-On site support the builds for key parts/关键零件供应商现场支持装车。

-Resolve the issue found in the builds/解决装车问题Builds/装车活动

Issue date: 2/15/2012PCF Definition/PCF 定义

PCF: Body Parts Coordination

PCF: 焊装零件几何尺寸检查

PCF Methods/TPC 方法

Use fixtures to simulate standard body then check the body parts dimension.

用检具来模拟标准车身,以此来检查焊装零件的几何尺寸。

PCF Plan

Refer to VPP

参考VPP

PCF Related Parts/PCF 相关零件

All body parts

所有焊装的零件

Builds/装车活动

Issue date: 2/15/2012

Support needed from suppliers of PCF/需要供应商支持

1.Provide the parts in time

及时提供样品

2.Provide the date of the sample parts

按要求提供样品的检测数据

3.Arrange the engineers to be in Chengdu plant when the PCF build happens

安排工程师到场参与PCF 的建造

4.Take actions for the issues which are found in the PCF builds

采取改善行动来改善PCF 所发现的问题

Builds/装车活动

Issue date: 2/15/2012Support needed from suppliers of TPC/需要供应商支持

1.Provide the parts in time

及时提供样品

2.Provide the date of the sample parts

按要求提供样品的检测数据

3.Arrange the engineers to be in Chengdu plant when the TPC build happens

安排工程师到场参与TPC 的建造

4.Take actions for the issues which are found in the TPC builds

采取改善行动来改善TPC 所发现的问题

Builds/装车活动。