Honeywell

- 格式:pdf

- 大小:1.04 MB

- 文档页数:14

Honeywell霍尔流量传感器广州南创谭工美国Honeywell流量传感器是一家财富100强公司发明和生产技术,以解决与全球宏观趋势,如安全性,安全性和能源的严峻挑战。

美国Honeywell流量传感器全球约132,000名员工,其中包括超过19,000名工程师和科学家,Honeywell 霍尔流量传感器的产品在多个国家设立了国外办事处及售后服务中心,并在中国设立了广州南创传感器事业部,为美国Honeywell流量传感器提供最佳的服务与解决方案。

有质量,交货,价值,和Honeywell霍尔流量传感器做的一切技术的不懈重点。

Honeywell霍尔流量传感器图片:Honeywell霍尔流量传感器自动化和控制解决方案美国Honeywell的环境控制,生命安全,安全,遥感,扫描,移动产品,以及建筑和工艺解决方案是在工作中,在150万个家庭,10万座建筑物,5000工业设施,以及数以百计的全球天然气和电力公用事业。

美国Honeywell的产品和解决方案,使客户能够捕获更多和更好的数据,更快的速度和整个无线景观,提高生产率,安全性和安全性,推动更好的决策,并降低了成本。

Honeywell霍尔流量传感器航天美国Honeywell流量传感器的航空航天产品和服务用于全球几乎所有的商业和商务飞机经营的今天,以及国防和空间应用。

美国Honeywell提供综合航空电子系统,发动机,系统和服务解决方案,认真听取美国Honeywell的客户和重点放在最能满足他们的需求,使飞行更安全,更可靠,更高效,更具成本效益的技术。

Honeywell霍尔流量传感器高性能材料和技术以开发和制造先进的材料和工艺技术,是人每天使用,以减少温室气体排放,阻止子弹,使生产的绿色燃料,增加炼油能力,加速药物发现,和保护药品的全球领先地位。

美国Honeywell的先进材料制造尼龙至计算机芯片医药包装产品,以及工艺技术由霍尼韦尔公司的UOP公司的形式大部分世界炼油厂的基础有效地生产汽油,柴油,喷气燃料,石油化工和生物燃料开发的关键。

详细资料请查看:世界500强跨国集团ૠปᆊऑႊࡼ಼ဥ1885年,Al Butz 开发了熔炉控制系统,将此系统作为产品成立公司 1886年,发明世界上第一个温控器,成立Butz 电子温度调节器公司 1893年, 更名为电子供热调节器公司(HER) 1906年,马克 · 霍尼韦尔的年轻人创立了霍尼韦尔特种加热器公司 1921年,EHR公司更名为明尼艾普利斯公斯供热调节器公司(MHR) 1927年,MHR公司和霍尼韦尔特种加热器公司合并,组成明尼艾普利斯。

霍尼韦尔 调节器公司 从此开始了在控制领域购并企业及在全球扩展业务 调节器公司,从此开始了在控制领域购并企业及在全球扩展业务 1929年,公司公司股票上市 1963年,公司正式更名为霍尼韦尔公司 1969年,霍尼韦尔的仪表帮助美国宇航员首次成功登月 1974年,霍尼韦尔研制开发了世界上第一套集散控制系统(DCS), 并成为一种 规范沿用至今 1998年,霍尼韦尔营业收入达到84亿美元 1999年,霍尼韦尔与美国联合信号公司合并,合并后公司仍称为霍尼韦尔 年 霍尼韦尔与美国联合信号公司合并 合并后公司仍称为霍尼韦尔ሚᏴࡼૠปᆊऑႊ///全球 100个国家拥有12万员工, 总部设在美国新泽西州莫里斯镇 年销售额超过346亿美元 著名 30 家道琼斯股指公司之一,“标准普尔 家道琼斯股指公司之 “标准普尔500指数”的组成部分 排列《财富》杂志前50位 被《财富》杂志(1999)评为“工作最适” Best to Work For 公司 被《工业周刊》(1999) 评为 “最佳管理公司” 最佳管理公司 Best Managed Companies, 被 《福布斯》评为 “世界第一多元化公司”●●●●●●全球超过1亿的家庭或大楼使用霍尼韦尔的楼宇控制产品 全球第一流的专利拥有者 全球第 流的专利拥有者●ጓᇗஉ৩特种材料 航空航天自动化与控制 交通与动力非常宽的、多元化的业务、技术和产品ੋహੋᄖݝDŽAerospaceDž主要产品:涡轮发动机 空中管理系统 发电系统 飞机安全系 涡轮发动机,空中管理系统,发电系统, 统,通信产品,商业数据与处理,飞机内外照明 航天 飞机导航 航 与控制系统 飞机导航,航空与控制系统,全球定位系统等。

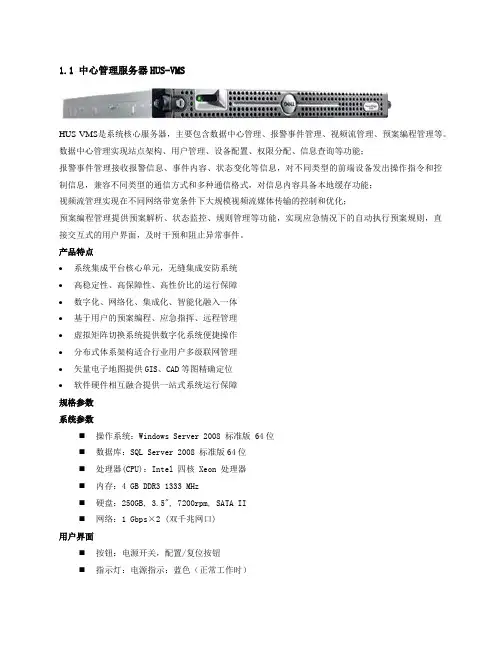

1.1中心管理服务器HUS-VMSHUS-VMS是系统核心服务器,主要包含数据中心管理、报警事件管理、视频流管理、预案编程管理等。

数据中心管理实现站点架构、用户管理、设备配置、权限分配、信息查询等功能;报警事件管理接收报警信息、事件内容、状态变化等信息,对不同类型的前端设备发出操作指令和控制信息,兼容不同类型的通信方式和多种通信格式,对信息内容具备本地缓存功能;视频流管理实现在不同网络带宽条件下大规模视频流媒体传输的控制和优化;预案编程管理提供预案解析、状态监控、规则管理等功能,实现应急情况下的自动执行预案规则,直接交互式的用户界面,及时干预和阻止异常事件。

产品特点•系统集成平台核心单元,无缝集成安防系统•高稳定性、高保障性、高性价比的运行保障•数字化、网络化、集成化、智能化融入一体•基于用户的预案编程、应急指挥、远程管理•虚拟矩阵切换系统提供数字化系统便捷操作•分布式体系架构适合行业用户多级联网管理•矢量电子地图提供GIS、CAD等图精确定位•软件硬件相互融合提供一站式系统运行保障规格参数系统参数⏹操作系统:Windows Server 2008 标准版 64位⏹数据库:SQL Server 2008 标准版64位⏹处理器(CPU):Intel 四核 Xeon 处理器⏹内存:4 GB DDR3 1333 MHz⏹硬盘:250GB, 3.5", 7200rpm, SATA II⏹网络:1 Gbps×2 (双千兆网口)用户界面⏹按钮:电源开关,配置/复位按钮⏹指示灯:电源指示:蓝色(正常工作时)HDD工作:黄色(正常工作时)网络激活:绿色(正常激活时)网络状态:绿色、琥珀色、红色(正常、拥堵、故障)尺寸重量⏹尺寸:42.90(H)×434(W)×612.6mm(D),机架安装(1U)⏹重量: 15 kg环境参数⏹电源:100~240VAC, 50~60Hz⏹工作温度:10°C ~ 35°C⏹储存温度:-40°C ~ 65°C⏹相对湿度:10% ~ 85% 非凝结⏹认证证书:CCC, CE, FCC, UL1.2网络存储系统HUS-NVRHUS-NVR是网络视频监控的存储系统,接收前端视频编码设备(如IP摄像机、编码器、DVR等)的数字化视频流,根据管理需求来实现不同类型的录像规则(计划录像、警情录像、手动录像等)。

GET ASOLUTIONS.COMPETITIVE EDGE WITH ROBOTIC SOLUTIONSSMART ROBOTICS SMARTER DC SMARTEST DECISIONRESULTS-DRIVEN ROBOTICS Scalable robotic solutions increasingly deliver significant competitive advantages to modern distribution centers. By leveraging advanced robotic technology with extensive material handling experience, warehouse automation solutions from Honeywell Robotics offer fully integrated, end-to-end strategies designed specifically for the unique needs and challanges of DCs. These solutions provide the speed, accuracy and efficiency to satisfy a broad and growing range of operational requirements.Innovative designs, application expertiseand committed support ensure maximumdependability and round-the-clockproductivity. A diverse robotics portfolioensures these systems can be customizedto your unique needs. Robotic solutionsalso relieve workers of some of the mostarduous, repetitive and injury-pronetasks, freeing up limited labor for morerewarding, higher-value jobs.Honeywell Intelligrated is recognized bythe Association for Advancing Automation(A3) as a Certified Robot Integrator, withmore than a quarter-century of experienceproviding single-source robotic solutionsfor high-performance distribution andmanufacturing operations. From systemconcepting, simulation, fabricationand integration to installation andcommissioning, training and ongoingsupport, each solution is approachedwith a comprehensive lifecycle view tomaximize the value of your system.PRODUCTIVITY AND PRECISIONIN ANY APPLICATIONMultiple solutions from HoneywellRobotics provide flexible, scalable optionsfor a variety of applications, including:• Smart flexible depalletizing — Quicklyunload mixed-SKU or single-SKUpallets in any sequence with nopre-programming.• Mobile robotics — Transport loads,handle carts, and perform machinetending jobs with autonomous mobilerobots (AMRs).• Loading and unloading — Autonomouslyload and unload trailers with minimaloperator supervision or intervention.• Palletizing — Efficiently build stablepallet loads according to operationalrequirements.CERTIFIED FOR SEAMLESSINTEGRATIONHoneywell Intelligrated is an A3-CertifiedRobot Integrator, with extensive experienceimplementing robotic solutions that workseamlessly with existing automationequipment. Robotic systems come withintegrated software and controls, enablingeasy training, simple daily use andstraightforward maintenance.EVALUATE PERFORMANCEBEFORE YOU BUYWhile automation and robotics offerlogical solutions to the challenges facedby many DCs, robotic technology presentsa lot of confusing choices. Worse, manyof the solutions that exist today can’tCreating a smart, productive and profitable distribution center (DC) requires expert system integration. You know how your facility works. Smart robotics can make it work better. From our end-to-end distribution center experience comes smart automation processes that help you push what’s possible. Robotics from a DC expert? That’s smart.ROBOTICS2 | | Get a Competitive Edge With Robotic SolutionsGet a Competitive Edge With Robotic Solutions | | 3address the unique demands of modern distribution centers. The majority ofexisting logistics solutions providers fail to meet the market or technical requirements critical to DCs, or lack the infrastructure necessary for full-scale implementation.To help DCs develop robotic solutions that really work for the logistics industry, Honeywell Robotics offers a full suite of Robotic Solution Design Services. From robotic cells to full-system designs, tools like simulation, software and feature analysis, prototype designs, system modeling and more can help you to find robotic solutions that meet your unique needs — before you break ground or begin site integration.Using these tools, you can determine how different solutions will perform and learn how quickly you’ll see return on your investment. You’ll get estimates of rates and throughputs based on your own unique product mix.Simulations can identify where robots will provide the greatest benefit and show where conveyors, storage systems or other solutions might be most effective. You also can calculate how manypeople automation will free up for safer and higher-value jobs. These powerful development tools ensure that you get the right solution, without having to rely on trial and error.ROBOTIC PALLETIZING AND DEPALLETIZING SOLUTIONSRobotic palletizing and depalletizing solutions from Honeywell Robotics increase throughput and improve ergonomics while reducing your operational costs. Robotic solutions automate the labor-intensive tasks of stacking and unstacking a broad range of products, packaging types and configurations. SKU proliferation, international markets or other complexities are easily accommodated. Modular designs offer compact footprints and can scale from a single robot to large multi-arm systems as your future growth demands.ROBOTIC PALLETIZING SOLUTIONSIntelliGen™ palletizing software — Enables easy adaptation of pallet load configurations and stacking patterns based on product size, packaging changes or other variables.Mixed-load or mixed-case order fulfillment — Efficient replenishment and delivery with less-than-full pallet loads of mixed product and labels-out configurations for retail display.Stack-and-wrap robotic palletizing cell — Builds pallet loads with increased stability and higher sustained throughput, while allowing a single operator to monitor multiple functions.Pallet and sheet handling — Boost speeds and reduce costs by automating the insertion of slip sheets, tier sheets and empty palletsinto robotic palletizing cells.4 | | Get a Competitive Edge With Robotic SolutionsDepalletizing is a physically demanding, injury-prone job with high turnover. Honeywell Robotics is meeting the challenges of this arduous task with a fully automated solution, driven by sophisticated machine learning (ML) plus advances in perception and gripping technologies.Capable of handling a wide range of product shapes and sizes, depalletizing robots can seamlessly transition from mixed-SKU to single-SKU pallets in any sequence — from a single work cell to an integrated system — without requiring additional programming or operator intervention. A soft, efficient grippingunit delivers faster, more consistent throughput with less product damage. The robot’s logic optimizes lifting force to each item’s weight and automatically adjusts the gripping angle to safely handle items that don’t lie flat on the pallet.SMART FLEXIBLE DEPALLETIZINGANY PATTERN ANY SEQUENCE NO PAUSING NO PRE-PROGRAMMINGKEY FEATURES OF THE SMART FLEXIBLE DEPALLETIZER• Multi-pick• Constant pallet mode • 8' pallet handling*• Automatic speed adjustment • Automatic height adjustment • Box on ground detection • Slip sheet handling • Empty pallet detection* Layers above 72" must be consistent SKUs.Get a Competitive Edge With Robotic Solutions | | 5Several flexible configuration options will ensure this turnkey system integrates seamlessly into your existing workflows. In addition toovercoming a common operational bottleneck, the system will help you to reduce worker injuries, schedule more accurately, and lower logistics costs while reducing exposure to a challenging labor market.Integration with AMRsSingle-side optionsAutomatic pallet stacking Automatic infeed and discharge optionsRobotic pallet handlingManual feed6 | | Get a Competitive Edge With Robotic SolutionsMOBILE ROBOTICSAutonomous mobile robots (AMRs) are among the fastest-growing automation strategies available to the logistics and manufacturing industries today. Supplied in strategic collaboration with OTTO Motors, AMRs are smart enough to interact safely with human co-workers and other vehicles, find a different route if their original path is blocked, and respond to rapid changes in orders or logistics needs — all without human intervention.AMRs are also highly cost-effective, requiring minimal information technology (IT) or infrastructural changes. No tape, markers or wires are needed for navigation, and the robots require only a short set-up period to learn their surroundings.AMRs can be deployed to ease labor burdens, improve productivity, reduceor eliminate errors, lower costs, and help your operation to stay nimble in constantly changing market conditions.PALLET CONVEYANCE Autonomous forklifts can perform many of the same transport tasks as a traditional forklift without supervision or additional equipment. Other AMRs can be loaded or unloaded directly with a forklift, move loads independently between compact pick-up and delivery (P&D) stands, or interact autonomously with conveyor systems.Common pallet conveyance applications include:• Warehouse transport — AMRs move palletized products to storage locations after unloading.• Cross-docking — Robots carrypallets routed from inbound trailers or containers directly to the respective outbound trailer.• Connecting islands of automation — Completed pallet loads are transported between various warehouse operations, such as palletizers, wrappers or pallet cranes.• Creating and clearing staging lanes —OTTO Lifter autonomously creates orclears lanes of pallets (end-to-end orside-by-side) with a single command,automatically compensating forchanging positions or gaps in the lane.• Trash removal — Robots collect andtransport corrugate, dunnage andrecyclables to processing areas.In addition, pallet conveyance AMRsincrease operational savings by reducingthe number of traditional forklifts andoperators needed for transport, enablingoperators to be repurposed for othervalue-added operations.PICKING AND CARTTRANSPORTMobile robots can provide significantproductivity benefits by automating themovement of carts used to transportpicked orders, returns or kits. AMRs cantravel over any floor surface smoothenough to handle a traditional cartpushed by a worker. Instead of spendingmore than half the day walking, workerscan simply park carts in designatedpick-up locations and call robots to comepick them up. In this way, carts can betransported virtually anywhere in a facilitywith little or no human intervention.AUTOMATED MACHINE TENDINGAMRs with the in-line conveyor optioncan be used to transport parts and goodsbetween automated manufacturingequipment, replenish automated storageand retrieval systems (AS/RS), or handleitems that can’t easily be moved byconveyors. They can also provide a flexible“bridge” between different conveyorsystems.MAXIMIZING UPTIMESome OTTO AMRs can operate for anentire shift or longer on a 90% charge, andautonomously dock with optional chargingstations when not needed for other tasks,extending their effective run time withouthuman supervision.ROBOTIC UNLOADERIn situations where trailers transport stacked products of a consistent size, robotic unloaders can fully automate the unloading of trucks, trailers and containers. These robots operate quickly and require minimal operator supervision or intervention, with no need to change processes or add supporting equipment.SOLUTIONS OVERVIEW Intelligent automated material handling solutions from Honeywell Intelligrated optimize processes, increase efficiency, and give businesses a competitive edge. Honeywell Intelligrated designs, manufactures, integrates and installscomplete warehouse automation and software solutions, including:• Automated storage and retrieval solutions (AS/RS)• Conveyor and pallet conveyor systems • Fulfillment technologies• Honeywell Robotics• Labor management software• Lifecycle Support Services• Machine controls• Palletizing and depalletizing• Sortation systems• Voice solutions• Warehouse execution systems LIFECYCLE SUPPORT SERVICESLifecycle Support Services employs aconsultative, data-driven approach toachieve your critical business outcomes.By delivering proactive, value-addedservices and solutions, we can helpyou to reduce the risk of downtime andincrease system availability, longevityand dependability. Drawing from a fullspectrum of strategic services, we offermultiple engagement models, tailoredto your business, culture and strategy.Our comprehensive portfolio constitutesthe key building blocks of a successfullifecycle asset management plan. Byconducting assessments of both yourequipment condition and operationalefficiency, we can determine how tooptimize your operations with:• Engineered Solutions• Technical Services• Contract Services• Training•Honeywell Intelligrated Spare PartsGet a Competitive Edge With Robotic Solutions | | 7Honeywell Intelligrated +1 866.936.7300********************** Follow us on Twitter: /intelligrated Learn more on YouTube:Honeywell Intelligrated GCEBR (EN/US) | REV 4 | 5/22© 2022 Honeywell International Inc.THE CONNECTED DISTRIBUTION CENTERThe pace of change in modern commerce is putting tremendous pressure on fulfillment operations. To stay competitive and protect profits, companies need solutions that help them achieve maximum throughput, day-to-day flexibility, future-proof scalability and intelligence to make informed decisions.The Connected Distribution Center helps companies make the digital transformation necessary to increase reliability, improve utilization and maximize productivity through:• Intelligent, data-driven, high-speed execution• Automated, adaptable processes for machines and workers• Optimized utilization with the ability to seamlessly adapt and expand• Insights and predictive analytics, from sensors to the cloud。

Honeywell楼宇控制系统简介1. 系统概述2. EBI系统的特点3. EBI系统的操作界面4. 数据报表5. 实时数据库6. 报警管理7. 趋势图8. EBI系统结构9. EBI系统和Excel 5000楼宇自控系统的关系10.Excel 5000楼宇自控系统的优点11. 现场控制器的特点Honeywell楼宇控制系统简介美国HONEYWELL公司在1975年开发的世界第一套集散控制系统TDC-2000,引起了自动控制领域的一场革命,集散系统已成为控制技术的主流。

集散系统的主要特点是在现场控制域内的通信总线是无主式的,点对点的同层通信。

HONEYWELL公司EXCEL5000建筑物自动化系统的控制总线(分站总线)就是这种结构,它与其他类型产品(大多采用所谓主从式的线路结构)有很大的不同,也可以说,HONEYWELL 公司建筑物自动化系统是符合中国国家标准规定的集散型控制系统。

EXCEL5000控制总线的特点是所有现场的分站(控制器),直接挂在分站总线上,中央站也挂在这条总线上,它们之间没有主控制器,网络控制器之类设备环节,从而保证了现场控制器的独立工作能力,实现了集散系统的控制分散,提高了建筑物自动化系统的可靠性。

1.系统概述美国Honeywell公司推出的EBI系统是一套应用于楼宇集成管理的组件。

EBI的模块化设计方案不论大型楼宇系统还是小型用户都能提供对对其系统的彻底控制,EBI的开放性使其具有提供对各种现有系统及过程的强大组合集成能力。

EBI包含有功能强大的组件,它们是:楼宇控制管理系统(Building Automatic Control System)、生命保障(火灾报警)管理系统(Life &Safety Management System)、安保管理系统(Security Management System)。

其中的任何一个组件都能使您更好地管理大楼中的每一个细节,而它们的强力组合提供了企业楼宇自控管理的“全景图”。

Speed Sensors Product Range GuideWith more than 50,000 products ranging from snap-action, limit, toggle, and pressure switches to position, speed, pressure, and airflow sensors, Honeywell has one of the broadest sensing and switching portfolios.Honeywell sensor, switch, and control components are tailored to exact specifications for stronger performance, longer productivity, and increased safety. Enhanced accuracy and durability are built into every part, improving output and endurance. For our customers, this can reduce expenditures and operational costs. Our global footprint and channels help to competitively price such components for your chosen application and provide immediate technical support.While Honeywell’s switch and sensor solutions are suitable for a wide array of basic and complex applications, our custom-engineered solutions offer enhanced precision, repeatability, and ruggedness. We offer domain knowledge and technology resources, along with a close working relationship, to develop and deliver cost-effective, individually tailored solutions. Whether clean-slate development or simple modifications to an existing design are needed, our expertly engineered solutions help to meet the most stringent requirements with world-class product designs, technology integration, and customer-specific manufacturing.Global service, sourcing, and manufacturing. Industry-leading engineers. Value-added assemblies and solutions. A one-stop, full-service, globally competitive supplier.For innovation that’s well apart, there’s only HoneywellTable of ContentsMagnetoresistive Sensor ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3Hall-effect Digital Sensor ICs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5Hall-effect Digital and Linear Sensor ICs . . . . . . . . . . . . . . . . . . . . . . . . . . .6Value Added Magnetic Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8Active Speed Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10Passive Speed Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113NanopowerSeriesStandardPowerSeries2SS52MSeriesVF401APS00BDescription omnipolar MRsensor IComnipolar MRsensor IComnipolar MRdigital sensor IC2-wire MRfine pitch ringmagnet sensor IChigh resolutionmagneticdisplacementMagnetic Sensors |Magnetoresistive Sensor ICs1Dimensions:• SOT-23: 2,8 mm x 2,9 mm [0.11 in x 0.11 in]• Flat TO-92-style: 3,0 mm x 4,0 mm [0.12 in x 0.16 in] (not including leads)• VF-401 flat TO-92-style: 3,0 mm x 4,06 mm [0.12 in x 0.16 in] (not including leads)• SOT-89B: 4,2 mm x 4,5 mm [0.16 in x 0.18 in]• U-Pack: 4,5 mm x 4,5 mm [0.18 in x 0.18 in] (not including leads)• SOIC-8: 4,9 mm x 6,0 mm [0.19 in x 0.24 in]SL353SS30AT,SS40A,SS50ATSS311PT,SS411PSS340RT,SS440RSeriesDescriptionmicropower omnipolarHall-effect digitalsensor IClow-cost bipolarHall-effect digitalsensor IClow-cost bipolarHall-effect digital sensorIC with built-in pull-uplow-cost unipolarHall-effect digitalsensor ICFeaturescombined with very lowaverage current reducespower consumptionspeed capability, reversepolarity protectionlow voltage, enhancedsensitivityNorth pole (SS340RT)or South pole (SS440R),multiple magneticsensitivities (high,medium, and low) Magnetic Sensors |Hall-effect Digital Sensor ICs1Dimensions:• SOT-23: 2,8 mm x 2,9 mm [0.11 in x 0.11 in]• Flat TO-92-style: 3,0 mm x 4,0 mm [0.12 in x 0.16 in] (not including leads)• SOT-89B: 4,2 mm x 4,5 mm [0.16 in x 0.18 in]5SS345PT, SS445PSS351AT, SS451A, SS551ATSS360NT , SS360ST , SS360ST-10K, SS460S, SS460S-T2 VF360NT , VF360ST , VF460SSS360PT, SS460P, SS460P-T2unipolar Hall-effect digital sensor IC with built-in pull-up resistor low-cost omnipolarHall-effect digital sensor IC high sensitivity, latching Hall-effect digital sensor IC high sensitivity, latching Hall-effect digital sensor IC high sensitivity latching digital Hall-effect sensor IC with built-in pull-up resistor pole (SS345PT) or a South pole (SS445P)protection, typical operating point of 85 G at 25°C [77°F]no chopper stabilizationstandard for potential use in automotive applications, fastest response time in its class class, no chopper stabilization, operates from only 30 Gausstypical, at 25°C [77°F]Magnetic Sensors |Hall-effect Digital and Linear Sensor ICsDigitalVF526DTLinearSS490 SeriesSS39ET, SS49E, SS49E-F, SS49E-L, SS49E-T2, SS49E-T3, SS59ET1Dimensions:• 4-Pin SIP: 3,6 mm x 5,1 mm [0.14 in x 0.20 in]• SOT-89B: 4,2 mm x 4,5 mm [0.16 in x 0.18 in]• Flat TO-92-style:3,0 mm x 4,0 mm [0.12 in x 0.16 in] (not including leads)7Series103SR (digital)103SR (linear)Magnetic Sensors | Value AddedSeries SR16/SR17SR3SR4Description low-cost Hall-effect vane sensor Hall-effect digital position sensor magnetoresistive digitalMagnetic Sensors |Value Added9Series SNG-Q SNDH-T SNDH-HDescription quadrature speed and direction quadrature speed and direction single Hall-effect speed sensorFeaturesplatform-based approachenables cost-competitivenessand mechanical and electricalconfigurability; designed forpotential applications whereenhanced accuracy is required todetect small target featuresoffset self calibration, short circuitand reverse voltage protection,low jitter output, near zero speedavailable, zero speed sensingversions available, range of con-nector options Speed Sensors |ActiveSpeed Sensors |ActiveSeries584XXFeaturesproduces constant amplitude output signals suitable for direct use in many digital andlogic control applications, internal digital signal conditioningSeriesLCZZH10Featuresomni-directional sensor to target, low power consumption, zero speed, digital outputomni-directional sensor to target, low powerconsumption, zero speed, digital output11SeriesVRS General PurposeVRS Hazardous LocationVRS High OutputDescription/potential applicationsused where medium to high speeds or in electrically noisy environments with relatively small air gaps existused where explosion-proof or intrinsically safe sensors are requiredused where higher output voltages are needed, perform best at low to mediumspeeds with medium to high impedance loads (sealed front-end versions for use where the sensor is exposed to fluids, lubricants or adverseSeriesVRS High ResolutionVRS High TemperatureVRS Power OutputDescription/potential applicationsused where precise timing pulse is required, and/or fine pitch gears are usedused where the sensor is exposed to temperatures up to 260ºC [450ºF] (sealed front-end versions for use where the sensor is exposed to fluids, lubricants or adverse used where driving lowresistance loads at large air gaps is required, and larger actuators are usedSpeed Sensors |PassiveWarranty/RemedyHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period . Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgement or consult your local sales office for specific warranty details . If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective . The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.While Honeywell may provide application assistance personally, through our literature and the Honeywell web site, it is buyer’s sole responsibility to determine the suitability of the product in the application .Specifications may change without notice . The information we supply is believed to be accurate and reliable as of this writing . However, Honeywell assumes no responsibility for its use .005911-11-EN IL50 GLO Printed in USA May 2017© 2017 Honeywell International Inc . All rights reserved .Find out moreTo learn more about Honeywell’s sens-ing and switching products, call +1-815-235-6847, email inquiries to *********************, or visit Honeywell Sensing and Internet of Things 9680 Old Bailes Road Fort Mill, SC 29707 honeywell .com。

常用型号选型样本霍尼韦尔电位器Best Seller of Evectric Materials领导地位的跨国公司。

在全球,其业务涉及航空产品、技术及服务;住宅和商业楼宇控制、工业控制技术、产品和服务以及自动化产品和服务;特种化学、纤维、塑料、电子和先进材料技术、以及产品和服务;交通和动力技术、产品和服务等领域。

霍尼韦尔在全球95个国家拥有10万员工,总部设在美国新泽西州莫里斯镇。

在纽约、伦敦、芝加哥和太平洋证券市场的交易代码为HON,为道琼斯工业指数的30家构成公司之一,也是“标准普尔500指数”的组成部分。

2002年,霍尼韦尔的销售额为223亿美元;在全球财富500强排名榜中列第195位。

传感与控制元件部霍尼韦尔公司(Honeywell)创立于1885年,从楼宇恒温控制装置开始,经过110余年的发展。

已经成为一个拥有120,000多名员工,年销售额达240亿多美元的全球化集团公司。

为工业楼宇设备和航天、航空应用提供各类传感器、控制产品和系统。

目前在全世界九十多个国家设有工厂、研究机构、销售和服务中心,在全球控制领域中处于领先地位。

Mircro Switch(微型开关公司)创立于1935,后加入霍尼韦尔成为霍尼韦尔传感与控制战略单元。

目前共有20多个系列近六万种产品,在全世界拥有三十万用户。

近半个世纪以来,霍尼韦尔公司的传感与控制分部以其优秀的产品质量和可靠性,以及不断的技术创新,不仅在北美、而且在全世界赢得了很高的声誉。

霍尼韦尔电位器 21.编码器 Encoder388E系列 (3)510系列 (4)350E11/350E16系列 (6)600系列 (8)2.电位器Potentiometers(1) 陶瓷电位器309系列 (9)409系列 (10)591系列 (11)(2)导电塑料电位器308系列 (13)408系列 (14)380系列 (15)381系列 (16)392和RV6系列 (18)53C和RV4系列 (20)574系列 (22)575系列576系列(3) 绕线电位器43系列 RA20 (24)58系列 RA30 (26)(4) 碳膜电位器585系列 (28)586系列(5) 合成碳膜电位器 (29)(6) 开关电位器 (42)(7) 电动工具专用型 (46)(8) 精密电位器Precision Potentiometers578系列 (47)73系列 ..................... (48)MKV系列 (49)MK11系列 (50)Sensor Cube (51)(10) 预调电位器 (52)(11) 玻璃釉预调电位器 (56)3. 微调电位器Trimmers Arthur343系列 (60)363系列 (61)364系列 (62)530B系列 (63)4. 绕线电阻Wirewound Resistors wMark SongCMC系列 (65)SC系列 (66)VC系列 (67)VK系列 (68)VP线绕电阻系列 (69)VP可调线绕电阻系列 (70)VPR系列 (71)5. 绕线电位器53B010/53B/030/53B050 (72)53B13/53B14/53B11 (72)57B3/57B7 (72)3霍尼韦尔电位器 4特点●小体积●防尘●模块化结构高性能,●机械寿命超过100,00转有4脉冲16定位和6脉冲24 定位两种●2位格莱码输出可扩展与推-推、推-拉和自复位开 关●配合宽泛的温度使用范围 -40°C~100°C应用●液位控制●指针控制●频率控制●温度控制●时间控制●位置反馈订货文件填写388EN-4P 388EN-6P-DJ其中: 388EN 为系列号4P, 6P 表示每周脉冲数,DJ 表示Dome Switch接触电阻2.5K Ohms max.额定电压/电流 5 Vdc at 5 mA绝缘电阻100 MOhms at 50 Vdc耐电压900 Vac at ATM机械行程/速度/寿命连续, 最大30转/分钟,寿命100000转定位数16, 24转动力矩0,007 Nm to 0,39 Nm工作温度-40 ℃ to 100 ℃ [-40 0F to 212 0F]冲击振动100 G, MIL-STD-202Dome Switch 类型SPST 自复位Dome Switch 触点容量125 mA at 28 Vdc Dome Switch 机械寿命25,000 次Dome Switch 接触电阻小于 10 Ohms Dome Switch 绝缘电阻 1 MOhmDome Switch 耐电压对地750 V; 300 V across terminalsUNSPSC Code 0,34 kg [12 oz], nominal Dome Switch 长度of Throw0,381 mm [0.015 in] nominal UNSPSC Code30211929UNSPSC Commodity30211929 Encoders产品波形频率L频率R等幅波循环388E 尺寸(仅供参考) MM[IN]配件表层直径配件表层最大限度代表性数值尺寸(仅供参考) MM[IN]螺纹直径轴衬轴连接388E 机械的编码器,4或6fe 电子脉冲并瞬间与单轴接通直径直径5特点●提供一个2-bit 格莱码表示相对位置,或者4-bit格莱码表示绝对位置。

Sensors and Switches for Valves and Flow Meters An Application NoteBackgroundFlow meters can measure and regulate volumetric flow, velocity from which the volumetric flow is determined, and mass flow. Valves control or regulate the flow of gases or fluids by partially obstructing, opening or closing the pipeline that carries the media. In many applications, they are operated manually by a lever, pedal, or wheel. Valves are often used in oil and gas, chemical manufacturing, water reticulation and mining applications. Automatic valves with diaphragms or pistons are often actuated by changes in pressure, temperature or flow.SolutionsHoneywell manufactures a wide range of sensors and switches, from simple on/off switches to electronic sensors designed to deliver system control, fluid level indication, temperature regulation, along with protection from overheating and starting/stopping the compressor. Honeywell components provide enhanced reliability, minimize down time, and improve robustness in most harsh environments.Various package options are available, including stainless steel, and those designed for hazardous and harsh-duty applications.Hazardous-location limit switches – These specialized switches perform a number of functions, including monitoring the position ofthe valve stem, actuator or wheel position, providing on-off position on manual process valves, providing real-time valve status information for improved productivity and safety. As these limit switches are enclosedin an explosion-proof housing, any flame path is extinguished inside which mitigates the risk of causing an explosion at the switch part.These switch components provide feedback for the user to take actionin order to prevent explosions in hazardous environments. Hazardous-location switches are employed in valves in outdoor, above-ground, potentially explosive environments such as oil and gas or water treatment applications.Limit Switches – Employed to monitor the position of the valve stemor actuator, limit switches are primarily used on valves in non-explosive environments such as waste water treatment plants, power generation plant or other factory applications. They also allows users to remotely monitor the valve stem, actuator lever, or wheel position for improved productivity and reduced total installed cost in hazardous locations.Figure 1. Industrial Valve ApplicationValves serve a variety of purposes in industrial applications, although their main purpose is to control media through a system.Wireless Limit Switches – Allows users to remotely monitor valve stem, actuator lever, or wheel position for improved productivity and safety, while reducing total installed cost with an economical wireless point-to-point solution.Basic Switches –Snap-action switches monitor the position of the valve handle by indicatingif the switch is actuated. These switches are employed on valves used in both non-explosive environments such as waste water treatment plants and/or other factory applications and also explosive/hazardous applications. Invalve monitoring applications, basic switches perform position sensing on cams with no power consumption. In addition to valves, Honeywell’s V15W2 Series is suitable for use in hazardous environments such as refrigeration, HVAC,appliances, and paint booths.Hall-effect Speed Sensors and Sensor ICs – In flow meter applications Honeywell’s speed sensors measure flow by monitoring revolutions of the impeller (an inside propeller). Eachrevolution of the impeller equates to the delivery of a certain amount of fluid. For example, if the user sets a fluid level of five gallons per minute,the speed sensor counts the impeller rotation so that the correct amount of fluid is delivered. Invalve monitoring application, Hall-effect sensor ICS measure position sensing on cams.Position Sensors – In flow meter applications, Hall-effect magnetic position sensors are usedto determine valve position. In valve monitors, position sensors deliver continuous position status with enhanced reliability and accuracy.Pressure Transducers and Switches – In valve actuator applications, pressure transducers and switches measure the pressure of the diaphragm to help regulate and control the flow within the pipeline. The sensors can measure differential pressure by comparing values across the valve. They can also give an indication of valve position related to opening and closing by measuring the pressure value at that time.Snap-Action SwitchPosition SensorSMART Position SensorHall-Effect Position Sensor ICwith Actuatorsin hazardous locationsLimit SwitchLearn more aboutthe XYR6000OneWireless™ SensorClick here to view Hazardous Area Limit SwitchesRead more about MICRO SWITCH Limit Switches12Explosion-Proof Valve Position IndicatorMICRO SWITCH VPX • Valve position indicator in explosion-proof housing2334Basic SwitchMICRO SWITCH BZ, V7, V15, V15W2, and ZW Series • Large, miniature, and subminiature basic switchesHazardous Location Limit SwitchMICRO SWITCH LSX, CX, and BX Series • Premium limit switches in explosion-proof housingLimit SwitchMICRO SWITCH HDLS, GL, and Double Break Series • Premium heavy duty and standard global limit switches14Figure 4. Switches in Valve Actuators and PositionersClick here to view VPX Series Valve Position IndicatorsGet details on the SMART PositionSensor familyFigure 5. Sensing and Switching Products Used in Valve ActuatorsHazardous Location Position Sensor XYR6000 OneWireless™ SeriesAllows users to remotely monitor valve stem, actuator lever, or wheel position for improved productivity and safety, while reducing total installed cost in hazardous locations; part of a scalable ISA100 mesh networkHazardous Area Limit SwitchMICRO SWITCH™ LSX/CX/BX/EX SeriesMonitors valve stem, actuator lever, or wheel position, providing real-time position status for improved productivity and safety in hazardous locationsLimit SwitchMICRO SWITCH™ HDLS, GLS, and Double Break SeriesMonitors valve stem, actuator lever, or wheel position, providing real-time position status for improved productivity and safetyPosition SensorSMART Position Sensor, SPS Series 75 mm Linear Monitors valve stem or actuator position1234Stainless Steel Media Isolated Pressure Sensor or Pressure Switch MLH, PX2, or PX3 Series Pressure Sensor or HP, HE, ME, LP, or LE Series Pressure SwitchMeasures diaphragm pressure6Valve Actuator(Kammer valve actuator photoused with permission of Flowserve.)Wireless Limit SwitchMICRO SWITCH™ HDLS and GLS SeriesAllows users to remotely monitor valve stem, actuator lever, or wheel position for improved productivity and safety, while reducing total installed cost with an economical wireless point-to-point solution5Learn more about MICRO SWITCH Basic SwitchesReview Limitless™ Wireless SwitchesFind out more on Hall-effect Speed SensorsFigure 6. Sensing and Switching Products Used in Valves and Flow MetersSMART Position Sensor SPS Series75mm analog and 225 mm analog and digital linear configuration Position Sensor SR SeriesDigital position sensorHall-Effect Sensor LCZ or 3000 SeriesSingle, zero speed sensor (LCZ) or high resolution VRS sensor (3000)Basic SwitchMICRO SWITCH BZ, V7, V15, V15W2, and ZW SeriesLarge, miniature, and subminiature basic switchesHazardous Location Limit Switch MICRO SWITCH VPX, CX, LSX, and BX SeriesPremium limit switches in explosion-proof housingLimit SwitchMICRO SWITCH HDLS, GLS,and Double Break SeriesPremium heavy duty and standard global limit switchesFlow MeterClick here to view Pressure TransducersMore information available here on Hall-effect Sensor ICsTypes of ValvesSpecifically, there are several main types of valves: 1) Manual process valves, 2) Valve actuators/positioners, 3) Valve monitors/indicators, 4) Valves and flowmeters, and 5) Sanitary and food/beverage valves.Manual Process Valves – Manual process valves in industrial facilities control the flow of liquid, gas, slurry, or steam. Eighty percent require operators to manually open, close, or otherwise control the valve. At any given time, users may not know the actual position of the valve. Process plants, including refineries, chemical, pharmaceutical, and water treatment plants as well as power generation installations, all need a better way to verify status with or without human intervention, especially in hazardous or hard-to-reach locations. (See Figures 2 and 3)Valve Actuators/Positioners – A valve actuator is a pneumatic or electric mechanism used in process control systems to automatically open or close valves. Actuators can be used with either linear or rotary valves in industrial, medical, food/beverage, and transportation applications. In standard valves, when the valveis given a command to open to a certain point, there is no feedback to verify that it has opened to that position. Valve positioners utilize a source of power to operate and continuously adjust a valve. The power source can be a manual gearbox or an electronic device with control and measuring devices; Available with hydraulic, pneumatic, and electric operating mechanics, these are often used in pipelines, process plants and in remote areas. Postioners can be used for opening or closing a valve to control the rate of fluid flow based on a signal from a central control system. With a valve positioner, the command is given and the valve positioner reads the opening, verifies position, and readjusts (if necessary) to the exact position needed which allows for excellent precision in the valve setting. (See Figures 4 and 5)Valve Monitors/Indicators – Mechanical or electrical valve monitors and indicators are used in process control to show valve position. They provide an electrical signal, and sometimes visual feedback, to accurately monitor and verify that a valve is in the correct position. Valve monitors are mostly used in conjunction with a valve positioner/actuator to provide information from remote locations that are not easilyaccessed, or where power isn’t readily available. Potential applications include chemical, pharmaceutical, power generation and oil and gas processes. (See Figures 4 and 5)Valves and Flowmeters – Valves control or regulate the flow of gasses or fluids by partially obstructing, opening or closing the pipeline that carries the media. Valves are often usedin oil and gas, chemical manufacturing, water reticulation and mining applications. In many of these applications, the valves are operated manually by a lever, pedal or wheel. Automatic valves with diaphragms or pistons are often actuated by changes in pressure, temperature or flow.Flow meters can measure and regulate volumetric flow, velocity from which the volumetric flow is determined, and mass flow. The turbine flow meter translates the mechanical action of the turbine rotating in the liquid flow around an axis into a user-readable rate of flow (gpm, lpm, etc.). The turbine wheel is set in the path of a fluid stream. The flowing fluid impinges on the turbine blades, imparting a force to the blade surface and setting the rotor in motion. Nearly all flow meters mustbe installed so that there is a significant runof straight pipe before and after the locationof the flow meter. This is intended to allow the straight pipe run to “smooth out” any turbulence produced by the presence of valves, chemical injectors and diffusers, and changes in pipe direction. (See Figure 5)Sanitary and Food/Beverage Valves – Sanitary and food and beverage valves are engineered for pressure control in sanitary (or “clean”) environments. They are usually manufactured with stainless steel for sanitary and high-purity applications. These valves are often constructed as a ball valve around a fullbore design that ensures the product passes through the valve with no restrictions on the flow with minimal pressure drop.Sanitary and food and beverage valves are often found in pharmaceutical, biotechnology, food and beverage, cosmetics, chemical and other industries where sanitary process control is required for steam, gases, and liquids such as water-for-injection systems.000697-7-EN | 7 | 04/21© 2021 Honeywell International Inc.Honeywell Advanced Sensing Technologies830 East Arapaho Road Richardson, TX 75081 /astFor more informationHoneywell Advanced Sensing Technol-ogies services its customers through a worldwide network of sales offices and distributors. For application assistance, current specifications, pricing or the nearest Authorized Distributor, visit /ast or call:Asia Pacific +65 6355-2828Europe +44 (0) 1698 481481USA/Canada+1-800-537-6945Warranty/RemedyHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment orconsult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the peri-od of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole dis-cretion, finds defective. The foregoing is buyer’s sole rem-edy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.While Honeywell may provide application assistance per-sonally, through our literature and the Honeywell web site, it is buyer’s sole responsibility to determine the suitability of the product in the application.Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this writing. However, Honeywell assumes no responsibility for its use.m WARNINGPERSONAL INJURYDO NOT USE these products as safety or emergency stop devices or in any other application where failure of the product could result in personal injury.Failure to comply with these instructions could result in death or serious injury.m WARNINGMISUSE OF DOCUMENTATION• The information presented in this product sheet is for reference only. Do not use this document as a product installation guide.•Complete installation, operation, and maintenance information is provided in the instructions supplied with each product.Failure to comply with these instructions could result in death or serious injury.。

Productivity Products FEATURED PRODUCT GUIDEHoneywell Safety and Productivity Solutions (S&PS) provides comprehensivesolutions that enhance workplace safety and incident response, improve enterpriseperformance and enable greater product design innovation. Customers rely on Honeywell's connected solutions to provide real-time safety intelligence, increase worker productivity and enrich operational intelligence with data-driven insights. Honeywell servescustomers in aerospace, automotive, commercial building, first responder, field service, healthcare, logistics, manufacturing, oil & gas, power and utilities, medical, retail, supply chain, test & measurement andtransportation markets.Precision That Yields PerformanceWearable Solution CK3R/ CK3X Tecton CS CK71Multiple 1.2 m (4 ft)Multiple 1.5 m (5 ft)/Multiple 1.2 m (4 ft)Multiple 1.5 m (5 ft),Multiple 1.8 m (6 ft)with protective bootMultiple 2.4 m (8 ft)>*********> 1,000 tumbles @ 1 m> 2,000 tumbles @ 1 m-10°C to +50°C -20°C to +60°CCK75CN75/75e Dolphin 60s Dolphin 70e Dolphin 75e Multiple 2.4 m (8 ft)Multiple 2.4 m (8 ft)Multiple 1.2 m (4 ft)Multiple 1.2 m (4 ft)Multiple 1.2 m (4 ft)> 2,000 tumbles @ 1 m> 2000 tumbles @ 1 m> 800 tumbles @ 1 m >1,***************standard battery>***************extended battery> 1,000 tumbles @ .5 mstandard battery> 300 tumbles @ .5 mextended batteryIP 67IP67EDA50/EDA50K CT50CN51i.roc Ci70 -Ex*Dolphin 99EX/ 99EX NI* Multiple 1.2 m (4 ft)Multiple 2.4m (8ft)Multiple 1.5 m (5 ft)Multiple 1.2 m (4 ft)Multiple 1.8 m (6 ft)00 tumbles at 0.5 m(1.64 ft)> 1,000 tumbles @ 1 m>1,***************> 2,000 tumbles @ 1 mIP54IP65IP67-10°C to +50°C (+14°F to +122°F) -20° to +50°C(-4°F to +122°F)-10° C to +50° C(+14° F to +122° F)-20°C to +50°C(-4°F to +122°F)-20°C to +50°C(-4°F to +122°F)IP30CN70/ CN70E RFID IF2IV7Fixed Mount Vehicle MountISO1800-6B/ 6C EPC global UHFClass 1 Gen 2ISO1800-6C EPC global UHFClass 1 ISO1800-6B/ 6C EPC globalUHFClass 1 Gen 2ISO1800-6B EPC globalUHFClass 1 Gen 2-15°C to +50°C -20°C to +60°C-20°C to +50°C-25°C to +55°C Linear (70-deg cone)Internal, orientation insensitiveSL42 iPhone 6/ iPhone 6+Captuvo SL22/ SL22h Captuvo SL42/ SL42h Captuvo SL62 Multiple 1.2 m (4 ft)Multiple 1.2 m (4 ft)Multiple 1.2 m (4 ft)Multiple 1.2 m (4 ft)Optional OptionalTouch OnlyThor CV31Thor VM1/ CV41Thor VM2Thor VM3IP66IP66-30°C to +50°C (-22°F to +122°F)efroster units: -30°C to +50°C(-22°F to +122°F );tandard units: -20°C to +50°C(-4°F to +122°F)-20°C to +50°C(-4°F to +122°F)-30°C to +50°C(-22°F to +122°F)16.5 cm (6.5”), VGA (640 x 480I-Class MK II203/300/600 dpi 300 mm/s (12 ips)Direct ThermalPM23cPD43 / PD43c203/300/406 dpi 203/300 dpi 300 mm/s (12 ips)203 mm/s (8 ips)Direct Thermal, Thermal TransferDirect Thermal, Thermal TransferProducts with a Star () represent the APAC Focus Models.PC43d/tPC42d4.1"203/300 dpi203 dpi203 mm/s (8 ips) 4 ips* M-4210 / M4308Connecitvity Key Bluetooth ®Ethernet Parallel Serial USB WifiNEWNEWRL3e/4e PB22/32 /50101 mm/s (4 ips)Products with a Star () represent the APAC Focus Models.MF4te PB21/31 /51PR2/3Receipt Receipt Receipt2.2”,3.3”,4.4” 2.2” ,3.3”203/300 dpi203 dpi203 dpiBasic: 101 mm/s (4 ips)Advanced: 127 mm/s (5 ips)101 mm/s (4 ips)101 mm/s (4 ips)152 mm/s (6 ips)Direct ThermalProducts with a Star () represent the APAC Focus Models.Eclipse 5145Voyager 1250gHH360TetheredCordedSingle-Line Laser Scanner with CodeGate®Linear Laser Area-Imaging Scanner Multiple 1.5 m (5 ft)Multiple 1.5 m (5 ft)Granit 1280i/ 1910i/ 1911i/ 1980i/ 1981iAutocube 8200Bluetooth® TetheredTetheredFull-Range Laser Scanner,Area-Imaging Scanner with Adaptus ®,Full-Range Area-Imaging Scanner 3D depth sensing technology -30°C to 50°C Multiple 2 m (6.5 ft)Xenon 1900g/1902g Voyager 1450g/1452gHH660Enhanced Xenon1900h/ 1902h Voyager 1602gBluetooth® Tethered Bluetooth® Tethered Tethered Bluetooth® Tethered Bluetooth®Area-Imaging Scanner with Adaptus®Linear/ Area-ImagingScannerArea-Imaging ScannerArea-Imaging Scannerwith Adaptus®Area Imaging RingScannerMultiple 1.8 m (6 ft)Multiple 1.5 m (5 ft)Multiple 1.5 m (5 ft)50 drops 1.8 m (6 ft)8670 Bluetooth Ring ScannerBluetooth® Area-Imaging30 drops to concrete from 5' (1.5m)IP541D, PDF417,2D Bluetooth®Scan WedgeStratos 2400Stratos 2700HH400TetheredTetheredOmnidirectional Laser Omnidirectional Laser + Area-Imaging Scanner Area ImagerDesigned to withstand 1m drop to concreteOrbit 7120/OrbitCG 7180Orbit 7190YJ5900Genesis 7580HF600 Tethered Tethered Tethered Tethered TetheredOmnidirectional Laser Scanner with CodeGate®Hybrid,Omnidirectional Laserand Area-Imaging ScannerOmnidirectional LaserArea-Imaging Scannerwith Adaptus®Area Imager1.2 m (4 ft)Multiple 1.2 m (4 ft) 2 times 1m (3.3ft) 1.2 m (4 ft) 2 times 1m (3.3ft)Sealed to resist airborne particulate contaminants Sealed to resist airborneparticulate contaminantsSealed to resist airborneparticulate contaminantsSealed to resist airborneparticulate contaminantsLaser:Reads standard 1D,Vuquest 3320g HF500Solaris 7980 Tethered Tethered TetheredArea-Imaging Scanner Area-Imager Area-Imaging Scanner 1.5 m (5 ft) 2 times 1.5m (5ft)Multiple 1.5 m (5 ft)IP401D, PDF, 2D,1D, 2D1D, PDF417, 2DUSB HID** 1 day turn on select scannersWith Honeywell Repair Services, it’s easy to get the level of repair coverage and protection that makes the most sense for your business.Honeywell Repair Services not only protect your device investment, but also provide predictable repair costs for the duration of your agreement.You can take advantage of multiple services programs, including either the Full Comprehensive Program or the Limited Comprehensive Program based on the product category and product type (general duty, rugged orspecialty) of your devices. Or you may prefer the Wear & Tear Program for your Honeywell devices. With each program, you also get comprehensive telephone support and access to the Honeywell Scanning & Mobility online Technical Support Portal for product information.Ensure business continuity, workflow performance and protection of your technology investments with Honeywell Repair Services — now available in over 70 countries with global pricing and global standards of quality.Honeywell Repair Services© Copyright 2017, Honeywell International Inc. All rights reserved. Honeywell and its product names are among the trademarks and/or service marks owned by Honeywell International Inc., or its subsidiaries.All other trademarks are property of their respective owners.Featured-Product-Guide | Rev01 | 01/17© 2017 Honeywell International Inc.For more informationHoneywell Safety and Productivity Solutions17 Changi Business Park Central 1Honeywell Building Singapore 486093Service Programs at a GlanceFeaturesFull ComprehensiveComprehensive coverage up to and including device replacement that covers accidental damage, wear and tear, damaged accessories, product defects, failures, and any other damage sustained when the device is used as intended in the work environment (Coverage for eligible accessories includes damaged styluses, battery door covers, screen protectors, and hand straps or clips when included with equipment for service).Limited ComprehensiveComprehensive coverage as described above, excluding device replacement.Wear & TearUplifts warranty and provides coverage for reasonable wear and tear and hardware manufacturing defects.Work Performance Assurance。

霍尼韦尔(HoneyWeH)智能家居系统解决方案具有120多年历史的霍尼韦尔(honeywe11)是世界自动化控制技术的领导者。

霍尼韦尔自1980年代起推出智能家居解决方案,陆续推出高集成社区规模智能家居系统家庭网关,可视对讲系统、无线灯光控制系统等,迄今为止,韩国已有200,000多户住宅使用霍尼韦尔的智能家居产品,在亚太其他地区,我们的集成智能家居解决方案也开创了许多成功案例,包括中国首个及最大的顶级智能社区深圳红树西岸、华北首个全集成智慧住宅天津赛顿中心、华东首个高集成智慧住宅杭州东方润园和中东迪拜的OIdTownCommercia1Is1and,我们的可视对讲系统也正被广泛采用事实上,全球有超过一亿个家庭和500多万幢大型建筑在使用霍尼韦尔的楼宇和住宅产品与技术。

一、智能住宅随着国民经济和科学技术水平的提高,特别是计算机技术、通信技术、网络技术、控制技术、信息技术的迅猛发展与提高,促使了家庭生活的现代化,衣食住行的舒适化,居住环境的安全化。

这些高科技已经影响到人们生活的方方面面,改变了人们生活习惯,提高了人们的生活质量,人类技术发展的最终目的和方向是服务于生活所需,智能住宅也正是在这种形势下应运而生的。

智能住宅是将家庭中各种与信息相关的通讯设备、家用电器、环境调节设备和家庭保安装置等,通过有线或无线网络连接到一个家庭智能化系统上进行集中的监视和智能控制,同时可以支持远程的监控,实现信息化家庭事务管理,并保持这些家用设施与住宅环境的和谐与协调。

二、系统介绍Honeywe11HRIS-1000系统是基于TCP/IP协议和Ethernet网络平台的全数字化智能家居平台。

在这个平台上集成了丰富的居住环境控制及安防功能,各种功能协调统一,有机融合。

家庭网关是户内控制和网络协议转换的中心,利用家庭网关使所有可能的设备信息互通,实现环境自动控制、就地集中监控、网络远程监控。

在这个有充足软硬件冗余的平台上可以轻松搭建一个未来型的智能住宅和智能社区空间。

目录技术部分 (1)一、霍尼韦尔安防(Honeywell Security)简介 (1)1、霍尼韦尔公司简介 (1)2、霍尼韦尔安防(Honeywell Security)发展历程 (2)3、典型项目案例 (3)二、门禁控制系统设计 (7)1、门禁系统构成 (7)2、门禁控制管理软件(Winpak Pro) (10)3、门禁设备参数 (14)技术部分一、霍尼韦尔安防(Honeywell Security)简介1、霍尼韦尔公司简介霍尼韦尔是一家营业额达到340亿美元的财富100强企业,而安防事业在其多元化经营中占据着特殊的地位。

过去两年,霍尼韦尔战略投资中相当一部分用于发展安防事业。

我们还致力于将其他霍尼韦尔业务中的资源与安防事业整合起来,我们提供给您的是霍尼韦尔全部的品牌优势!霍尼韦尔安防是全世界最大及最富经验的电子保安系列产品制造商之一,其产品正保护着全球数百万的家庭、企业单位、商业单位及政府机关的安全。

霍尼韦尔安防不仅在工业领域,同时在商业领域也凭借其最先进的技术保护着各类场所的安全,通过提供品质卓越的视频监控系统、防盗控制系统、门禁控制系统及功能完善的集成系统,使霍尼韦尔安防产品能够配合不同的安装需求。

确保着全球工业的未来并令我们的商业环境、生活环境更加安全!霍尼韦尔安防产品品牌处于全球领先地位。

全球安防行业的权威性杂志《安全与自动化》在2004年1月进行的广泛的网络调查的基础上评选出十大安防品牌,霍尼韦尔安防是唯一一家在三大产品类别中评选得分领先并排名前五位的品牌。

霍尼韦尔安防信守对经销商、系统集成商的承诺。

我们关注如何促进合作伙伴的业务增长,并投资于那些可助您成长的项目。

我们不断深入挖掘市场需求并创造需求,为您搭建成功的舞台。

我们深深懂得:只有您成功,我们才能成功!霍尼韦尔安防不断追求创新,提供新技术、新产品。

霍尼韦尔安防每年在研发方面投入超过4000万美元,通过设在中国、美国、韩国、印度、苏格兰和法国的研发基地,我们能为您提供全球最好的技术。

参考答案系统操作1、HM的复位和启动HM的复位:1)进入系统状态画面将HM SHUTDOWN两次使HM处于FAIL状态.2)按节点电源上的复位(RESET)按钮。

HM的启动:1)打开节点卡件箱的交流电源。

2)打开HM节点电源。

3)由于HM具有自启动功能,因此,HM上电后可以自行启动。

4)等待一段时间,直到该HM的LCN地址显示正确后查看系统状态画面,若HM状态OK说明HM已启动完毕。

2、US的复位通过按US操作员键盘上的复位(RESET)按钮。

从HM启动一台US的方法1)打开US卡件箱的交流电源。

2)打开该US的节点电源,等待直到该节点的LCN地址显示正确。

3)按一下操作员键盘上的LOAD键,此时CRT上出现:“N,1,2,3,4,X?”询问启动文件从哪里存取?4)输入N后按ENTER键5)等待一会后CRT上出现“OPR,ENG,UNP,X?”询问该US装载何种属性?6)输入O(OPR)为操作员属性或E(ENG)为工程师属性或U(UNP)为万能属性,然后ENTER。

7)等待一段时间,直到操作台状态显示画面中相应的US状态为OK则该US启动完毕。

从快速启动盘启动一台US的方法1)打开US卡件箱的交流电源。

2)打开该US的节点电源,等待直到该节点的LCN地址显示正确。

3)将快速启动盘插入ZIP驱动器4)按一下操作员键盘上的LOAD键,此时CRT上出现:“N,1,2,3,4,X?”5)输入插有快速启动盘的ZIP驱动器号后按ENTER键6)等待一会后CRT上出现“OPR,ENG,UNP,X?”询问该US装载何种属性?7)输入O(OPR)为操作员属性或E(ENG)为工程师属性或U(UNP)为万能属性,然后ENTER。

8)等待一段时间,直到操作台状态显示画面中相应的US状态为OK则该US启动完毕。

从一台US上启动另一台US的方法1)按CONSOLE STATUS键进入控制台状态显示画面。

2)选择需启动的US节点确认该US节点处于POW ON状态。

Honeywell传感器广州南创房工Honeywell是一家财富100强公司发明和生产技术,以解决与全球宏观趋势,如安全性,安全性和能源的严峻挑战。

Honeywell传感器全球约132,000名员工,其中包括超过19,000名工程师和科学家,Honeywell传感器的产品在多个国家设立了国外办事处及售后服务中心,并在中国设立了广州南创传感器事业部,为Honeywell传感器提供最佳的服务与解决方案。

有质量,交货,价值,和美国Honeywell传感器做的一切技术的不懈重点。

Honeywell传感器的能力不断提高,来自成功实现两个看似竞争的一次任务 - 生产力和经济增长。

Honeywell传感器公司的核心内部业务流程,传动效率和服务质量。

促成带来世界一流的产品和服务更快地推向市场和更具成本效益自动化和控制解决方案美国Honeywell的环境控制,生命安全,安全,遥感,扫描,移动产品,以及建筑和工艺解决方案是在工作中,在150万个家庭,10万座建筑物,5000工业设施,以及数以百计的全球天然气和电力公用事业。

美国Honeywell的产品和解决方案,使客户能够捕获更多和更好的数据,更快的速度和整个无线景观,提高生产率,安全性和安全性,推动更好的决策,并降低了成本。

航天美国Honeywell流量传感器的航空航天产品和服务用于全球几乎所有的商业和商务飞机经营的今天,以及国防和空间应用。

美国Honeywell提供综合航空电子系统,发动机,系统和服务解决方案,认真听取美国Honeywell的客户和重点放在最能满足他们的需求,使飞行更安全,更可靠,更高效,更具成本效益的技术。

高性能材料和技术以开发和制造先进的材料和工艺技术,是人每天使用,以减少温室气体排放,阻止子弹,使生产的绿色燃料,增加炼油能力,加速药物发现,和保护药品的全球领先地位。

美国Honeywell的先进材料制造尼龙至计算机芯片医药包装产品,以及工艺技术由霍尼韦尔公司的UOP公司的形式大部分世界炼油厂的基础有效地生产汽油,柴油,喷气燃料,石油化工和生物燃料开发的关键。

Honeywell(霍尼韦尔)18000空气净化器美国霍尼韦尔是最专业的空气净化器品牌能快速的净化空气质量。

1.双向进风口设计专利;活性碳滤网-True HEPA滤网双层过滤系统2.活性炭过滤网可去除多种异味3.360度环状True HEPA,能去除99.97%,0.3微米以上4.CADR比率221,适用于19-35平方米面积7.轻触式按钮,有3档模式选择风速8.耗材更换监测装置9.原装进口,5年保固Honeywell(霍尼韦尔)18400 空气净化器美国霍尼韦尔是最专业的空气净化器品牌能快速的净化空气质量。

1.双向进风口设计专利;活性碳滤网-True HEPA滤网双层过滤系统2.活性炭过滤网可去除多种异味3.360度环状True HEPA,能去除99.97%,0.3微米以上4.CADR比率374,适用于32-65平方米面积7.轻触式按钮,有3档模式选择风速8.耗材更换监测装置9.原装进口,5年保固Honeywell(霍尼韦尔)18250 空气净化器美国霍尼韦尔是最专业的空气净化器品牌,能快速的净化空气质量。

1.美国原装进口的机器,5年保固2.双向进风口设计专利;活性碳滤网-True HEPA滤网-CPZ滤网三层过滤系统,除甲醛的专用机效果显著3.高效HEPA过滤网能去除99.97%,0.3微米以上的微粒,给室内带来清新的空气4.特有CPZ滤网有效祛除甲醛甲苯等有害气体5.活性炭过滤网可去除多种异味6.耗材更换监测装置7.轻触式按钮,有3档模式选择8.CARD(洁净空气输出量)比率229,适用20-40平米Honeywell(霍尼韦尔)18450 空气净化器美国霍尼韦尔是最专业的空气净化器品牌,能快速的净化空气质量。

1.美国原装进口的机器,5年保固2.双向进风口设计专利;活性碳滤网-True HEPA滤网-CPZ滤网三层过滤系统,除甲醛的专用机效果显著3.高效HEPA过滤网能去除99.97%,0.3微米以上的微粒,给室内带来清新的空气4.特有CPZ滤网有效祛除甲醛甲苯等有害气体5.活性炭过滤网可去除多种异味6.耗材更换监测装置7.轻触式按钮,有3档模式选择8.CARD(洁净空气输出量)比率331,适用28-60平米Honeywell(霍尼韦尔)HAP-801APCN空气净化器产品特性:1.双进风口设计(专利),双滤网过滤2.有3档模式选择3.高效HEPA过滤网4.适用于25~35平方米面积5.CADR比率170,每小时循环空气次数3-5次6.活性炭过滤网可去除多种异味7.触控面板操作平台,简单便捷8.耗材更换监测装置9.UV紫外线杀菌功能10.高效除甲醛滤网CZ(活性炭+沸石)11.光触媒能有效地降解空气中有毒有害气体;能有效杀灭多种细菌,并能将细菌或真菌释放出的毒素分解及无害化处理;同时还具备除臭、抗污等功能。