日本岛电温控器说明书SRS13(牵引辊预热炉)

- 格式:pdf

- 大小:10.56 MB

- 文档页数:17

MR13 三回路九段可编程PID调节器中文操作指南请确认型号符合MR13选型,随表提供英文说明书和中文说明、操作流程图。

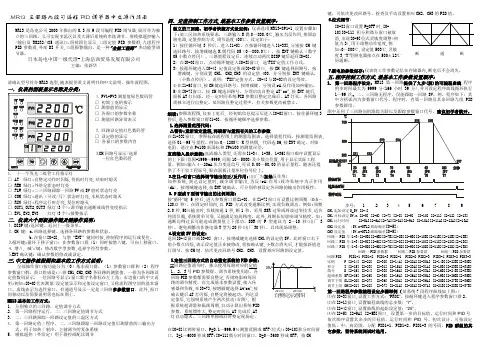

一.仪表的面板显示名称及分类:4.十一个发光二级管工作指示灯□ AT 绿灯:自整定动作时闪烁,待机时灯亮,结束时熄灭□ REM 绿灯:外给定状态时灯亮□ FLW 绿灯:二三回路跟踪一回路PV或SV值时状态灯亮□ COM 绿灯:通讯(可读/写)状态时灯亮,本机状态时熄灭□ RUN 绿灯:程序运行时灯亮,复位时熄灭□ OUT1,OUT2,OUT3 绿灯(3个):调节输出通断或线性亮度指示□ EV1,EV2,EV3 红灯(3个):报警指示二.仪表六个面板操作键及键操作说明:⒈ DISP键:返回键。

返回上一级菜单。

⒉ CH 键:a.回路选择键。

选择各回路的参数和状态。

b.在窗口[0-2], 与增“ENT”键同时按,控制程序的运行或复位。

⒊循环键:循环下移子窗口;在参数窗口群(1)同时按增∧键,可向上移窗口。

⒋增∧, 减∨键: 修改数字型参数,选择字符型参数。

⒌ENT确认键: 确认参数的修改或设定。

三.中文操作流程图和基本的工作方式说明:全部操作窗口按功能分为(0)基本窗口群,(1)参数窗口群和(2)程序参数窗口群。

窗口组成是:三排CH1,CH2,CH3各回路的测量值,一排为各回路设定值数码显示,一位回路号显示;窗口数字名称标在左上角;右边窗口的中文说明;例如:[0-0]代表测量/设定值显示和定值设定窗口,又称流程图空间的基本窗口。

虚线表示为选件窗口,有通道号显示一定是三回路多参数窗口。

此外,窗口间移动以及简要说明等也标在图上。

MR13基本的工作方式:1.分别独立的三回路,定值调节方式2.第一回路程序运行,二、三回路定值调节方式3.二、三回路跟踪一回路设定值的三温区方式4.第一回路定值/程序,二、三回路跟踪一回路设定值后测量值的三输出方式。

用于加热/制冷、主辅调节的复杂系统5.模拟遥控(外给定)用于群控或配比调节细读:参照流程图,仪表上电后, 经初始信息提示后进入[0-0]窗口。

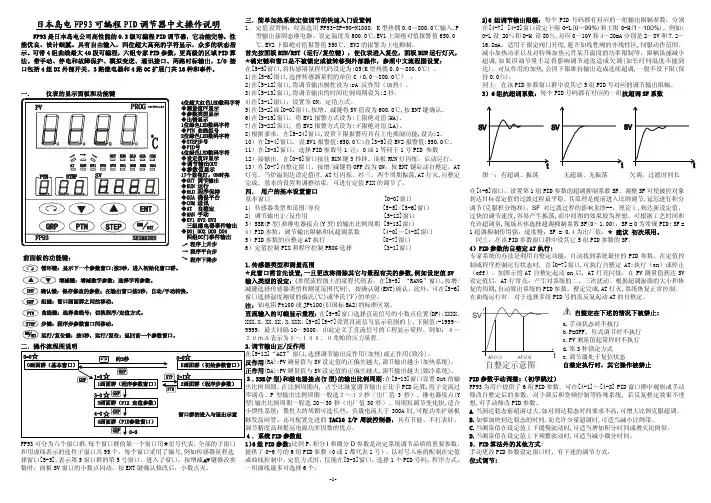

日本岛电FP93可编程PID调节器中文操作说明FP93是日本岛电公司高性能的0.3级可编程PID调节器,它功能完善,性能优良、设计细腻。

具有自由输入,四位超大高亮的字符显示,众多的状态指示。

可带4组曲线最大40段可编程,六组专家PID参数,更高级的区域PID算法。

带手动、停电和故障保护、模拟变送、通讯接口、两路时标输出,I/O接口包括4组DI外部开关、3路继电器和4路OC扩展门共16种和事件。

一. 仪表的显示面板和功能键二.操作流程图说明FP93全部的子窗口和用虚线表示的选件子窗口共95个。

每个窗口采用了编号,例如传感器量程选择窗口[5-5],表示第5窗口群的第5数时,面板SV窗口的小数点闪动,按ENT键确认修改后,小数点灭。

三.简单加热系统定值调节的快速入门设置例1. 定值设置例:仪表选用FP93-8P-90-N1000, K型热偶0.0~800.0℃输入,P型输出接固态继电器。

设定温度为600.0℃,EV1上限绝对值报警值650.0℃,EV2下限绝对值报警值550℃, EV2的报警为上电抑制。

首先按面板RUN/RST(运行/复位键),使仪表进入复位,面板RUN运行灯灭,在[5-5]窗口,将传感器量程代码设定为:05(K型热偶0.0~800.0℃) 。

1)在[5-6]窗口,选择传感器量程的单位C(0.0~800.0℃) 。

2)在[5-12]窗口,将调节输出极性设为:rA 反作用(加热)。

3)在[5-13]窗口,将调节输出的时间比例周期设为:2秒。

4)在[3-1]窗口,设置为ON,定值方式。

5)在[3-2]或[0-0]窗口,按增、减键将SV值设为600.0℃,按ENT键确认。

6)在[5-19]窗口, 将EV1报警方式设为:上限绝对值(HA)。

7)在[5-22]窗口, 将EV2报警方式设为:下限绝对值(LA)。

8)根据要求,在[5-24]窗口,设置下限报警应具有上电抑制功能,设为:2。

10)在[3-4]窗口, 设EV1报警值:650.0℃;在[3-5]设EV2报警值:550.0℃。

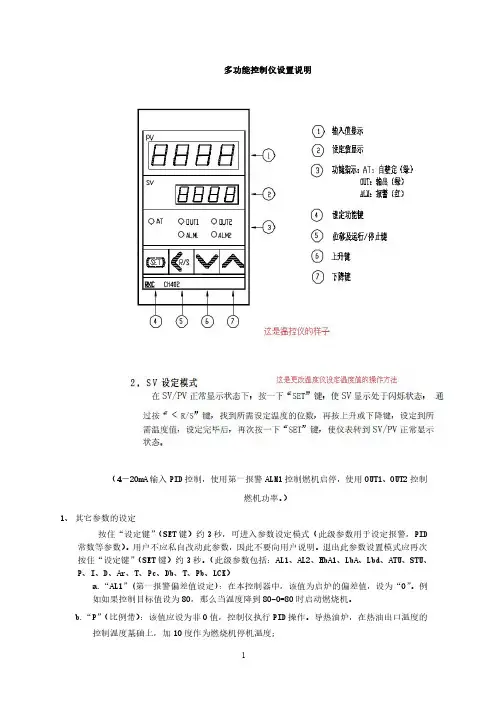

多功能控制仪设置说明(4-20mA输入PID控制,使用第一报警ALM1控制燃机启停,使用OUT1、OUT2控制燃机功率。

)1、其它参数的设定按住“设定键”(SET键)约3秒,可进入参数设定模式(此级参数用于设定报警,PID 常数等参数)。

用户不应私自改动此参数,因此不要向用户说明。

退出此参数设置模式应再次按住“设定键”(SET键)约3秒。

(此级参数包括:AL1、AL2、HbA1、LbA、Lbd、ATU、STU、P、I、D、Ar、T、Pc、Db、T、Pb、LCK)a.“AL1”(第一报警偏差值设定):在本控制器中,该值为启炉的偏差值,设为“0”。

例如如果控制目标值设为80,那么当温度降到80-0=80时启动燃烧机。

b.“P”(比例带):该值应设为非0值,控制仪执行PID操作。

导热油炉,在热油出口温度的控制温度基础上,加10度作为燃烧机停机温度;P:50I:0D:450T:20S PC:100%水套炉,在水浴温度的控制温度的基础上,加6-8度作为燃烧机的停机温度;P:88I:0D:900T:20PC:100%c.“I”(积分时间):设定积分时间以解除比例控制所发生的残留偏差(此值为0时不执行I运算)。

d.“D”(微分时间):设定微分时间以防止输出的波动提高控制安定(此值为0不执行D运算)。

注:如果燃机采用两段火工作方式应将P值设为0,此时仪表不执行PID运算。

上述三个参数“P”“I”“D”的设定值应根据现场实际经验设定或启自动演算。

e.“T”比例周期:设定加热侧比例周期(即动作周期)数值范围1-100,不能为零值。

“T”越小OUT1动作越频繁。

f.“Pc”比例带(制冷侧):数值范围1-1000,设置制冷侧比例带(控制OUT2闪烁输出关断时间),“Pc”越大关断时间越长。

g.“t”比例周期(制冷侧):数值范围1-100,设置制冷侧输出周期,“t”越小OUT2动作越频繁。

注:“P”、“I”、“D”、“T”、“t”配合调节控制OUT1、OUT2输出频率和接通关断时间。

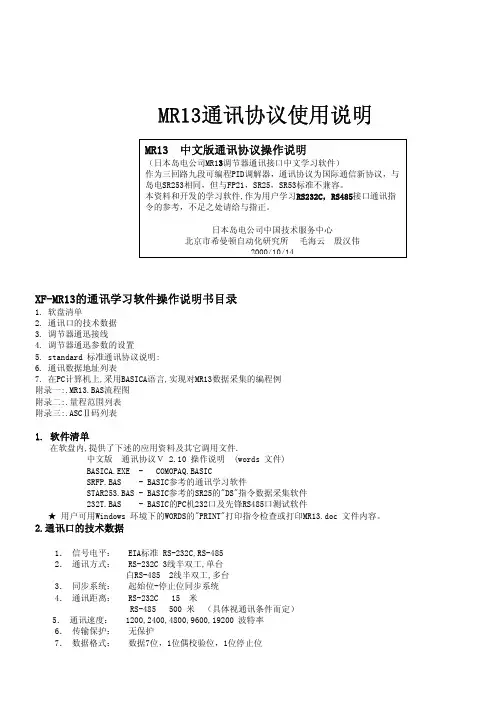

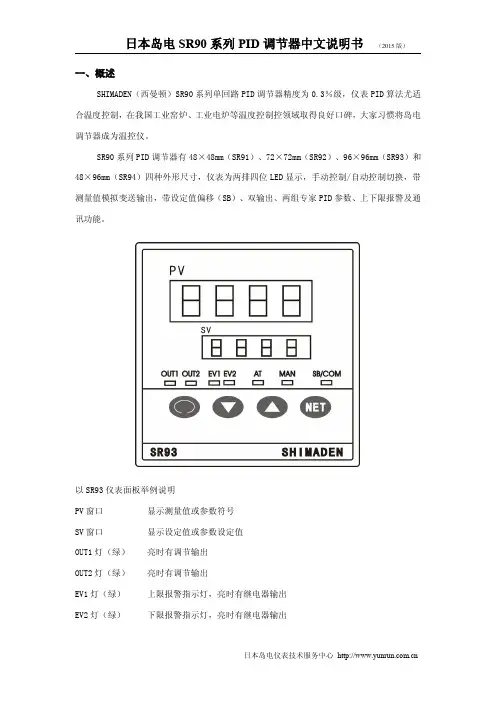

一、概述SHIMADEN(西曼顿)SR90系列单回路PID调节器精度为0.3%级,仪表PID算法尤适合温度控制,在我国工业窑炉、工业电炉等温度控制控领域取得良好口碑,大家习惯将岛电调节器成为温控仪。

SR90系列PID调节器有48×48mm(SR91)、72×72mm(SR92)、96×96mm(SR93)和48×96mm(SR94)四种外形尺寸,仪表为两排四位LED显示,手动控制/自动控制切换,带测量值模拟变送输出,带设定值偏移(SB)、双输出、两组专家PID参数、上下限报警及通讯功能。

以SR93仪表面板举例说明PV窗口显示测量值或参数符号SV窗口显示设定值或参数设定值OUT1灯(绿)亮时有调节输出OUT2灯(绿)亮时有调节输出EV1灯(绿)上限报警指示灯,亮时有继电器输出EV2灯(绿)下限报警指示灯,亮时有继电器输出AT灯(绿)闪烁时自整定MAN灯(绿)闪烁时为手动状态SB/COM灯(绿)闪烁时为SB或COM状态之一循环键选择各子窗口和0、1窗口群之间的切换增加键增加数字或修改字符参数减少键增加数字或修改字符参数确认键数字或参数修改后的确认二、SR90系列PID调节器参数设置及代码SR90系列PID调节器所有参数窗口可分为两个窗口群(0-×窗口群和1-×窗口群)共60个选件窗口,每个窗口可设置一个参数。

每个窗口采用了编号,例如传感器量程选择窗口[1-48],表示1号窗口群的第48号窗口。

按增减键修改参数时,面板SV窗口的小数点闪动,按“ENT”键确认修改后,小数点灭。

(一)[0-×]窗口参数设置及操作SR90系列PID调节器上电完成自检完成后自动进入显示状态(PV显示测量值,SV显示控制目标值),仪表测量显示状态就是[0-0]窗口。

1、[0-0]窗口设定值SV(控制目标值)设定用增减键修改SV值,按“NET”键确认即完成控制目标值设定。

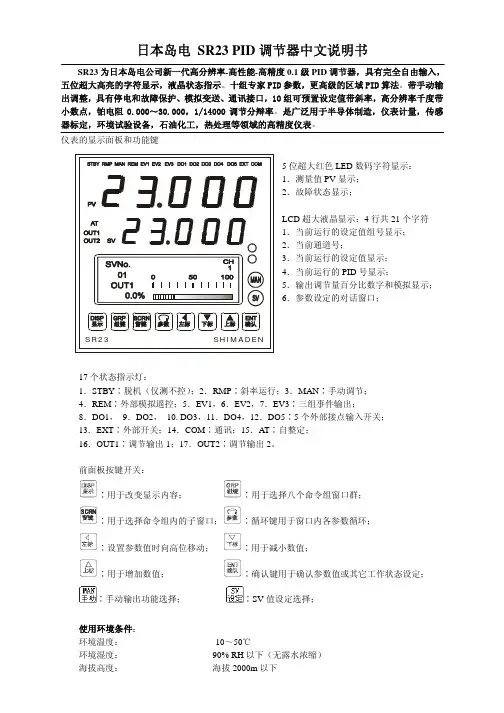

日本岛电 SR23 PID 调节器中文说明书SR23为日本岛电公司新一代高分辨率-高性能-高精度0.1级PID 调节器,具有完全自由输入,五位超大高亮的字符显示,液晶状态指示。

十组专家PID 参数,更高级的区域PID 算法。

带手动输出调整,具有停电和故障保护、模拟变送、通讯接口,10组可预置设定值带斜率,高分辨率千度带小数点,铂电阻0.000~30.000,1/14000调节分辩率。

是广泛用于半导体制造,仪表计量,传感器标定,环境试验设备,石油化工,热处理等领域的高精度仪表。

仪表的显示面板和功能键5位超大红色LED 数码字符显示: 1.测量值PV 显示; 2.故障状态显示;LCD 超大液晶显示:4行共21个字符 1.当前运行的设定值组号显示; 2.当前通道号;3.当前运行的设定值显示; 4.当前运行的PID 号显示;5.输出调节量百分比数字和模拟显示; 6.参数设定的对话窗口;17个状态指示灯:1.STBY ∶脱机(仅测不控);2.RMP ∶斜率运行;3.MAN ∶手动调节; 4.REM ∶外部模拟遥控;5.EV1,6.EV2,7.EV3∶三组事件输出; 8.DO1, 9.DO2, 10. DO3,11.DO4,12.DO5∶5个外部接点输入开关; 13.EXT ∶外部开关;14.COM ∶通讯;15.AT ∶自整定; 16.OUT1∶调节输出1;17.OUT2∶调节输出2。

前面板按键开关:∶手动输出功能选择;∶SV 值设定选择;使用环境条件:环境温度: -10~50℃提供电压:100~240V AC ±10% 50/60Hz功耗:15V A以下输入噪声变化率:正常模式 40dB min(50/60Hz)普通模式 120dB min(50/60Hz)可应用标准:安全 IEC 6101-1 和 EN 61010-1EMC(电磁兼容性) EN 61326防护等级:前面板防尘、防水(相当于IP66,NEMA4X)NEMA-国际电气制造业协会外壳材料:PC树脂模(相当于UL94-1)(UL-(美国)保险商实验所)外形尺寸:高96×宽96×深110(mm)仪表板厚度: 1.0~4.0mm之间开孔尺寸:高92×宽92mm重量: 600g以下尊敬的用户,在使用前请确认SR23的选型型号是否符合您的系统要求。

Series: WS-13 and WS-15ST(C) Service ManualWarming StationsWarranty InformationLIMITED TWO YEAR WARRANTYBKI(The “Company”) warrants to the original purchaser/user, that at time of shipment from the Company factory, this equipment will be free from defect in materials and workmanship. Written notice of a claim under this Warranty must be given within TWO YEARS AND THREE MONTHS from date of shipment from the factory. Defective conditions caused by abnormal use or misuse, lack of maintenance, damage by third parties, alterations by unauthorized personnel, acts of God, failure to follow installation instructions or any other events beyond the control of the company will NOT be covered under Warranty. The obligation of the Company under this Warranty shall be limited to repairing or replacing (at the option of the company) any part which is defective in reasonable opinion of the Company. The user will have the responsibility of removing and returning the defective part to the Company and installing the replacement part.IN NO EVENT SHALL THE COMPANY BE LIABLE FOR LOSS OF USE, LOSS OF REVENUE OR LOSS OF PRODUCT OR PROFIT OR FOR INDIRECT OR CONSEQUENTIAL DAMAGES INCLUDING BUT NOT LIMITED TO, FOOD SPOILAGE OR PRODUCT LOSS. WARRANTY DOES NOT COVER GLASS BREAKAGE. THE ABOVE WARRANTY IS EXCLUSIVE AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, ARE EXCLUDED INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY SHALL APPLY ONLY WITHIN THE CONTINENTAL UNITED STATES, ITS TERRITORIES, AND POSSESSIONS AND IN CANADA.LIMITED TWO YEAR LABOR WARRANTYAll labor necessary to repair or replace factory defective parts will be performed, without charge, to the end user, by service personnel of a BKI Authorized Distributor during the first ninety days after the date of installation of the new equipment.Replacement parts: Any appliance replacement part, except lamps and fuses, which proves to be defective in material or workmanship within 90 days from date of original installation will be repaired or replaced without charge F.O.B. Factory, Simpsonville, S.C. or F.O.B. authorized distributor.Table of ContentsTable of Contents (3)Introduction (4)Safety Precautions (4)Safety Signs and Messages (4)Safe Work Practices (4)Safety Labels (6)Operation (8)Models (8)Unit Shutdown (8)Operational Guidelines (8)Installation (9)Instructions For Shipping Damage (9)Electrical Information (9)Maintenance (10)Scheduled Maintenance (10)Troubleshooting (11)Repair (11)Replacement Parts (12)WS-13 Wiring Diagram (13)WS-15ST(C) (14)Notes (15)BKI Worldwide is a wholly owned subsidiary of Standex International Corporation.IntroductionCongratulations! You have chosen a Warming Station that will give you many years of fine service from the original manufacturer, BKI .The BKI name and trademark on this unit assures you of the finest in design and engineering — that it has been built with care and dedication — using the best materials available. Attention to the operating instructions regarding proper installation, operation, and maintenance will result in long lasting dependability to insure the highest profitable return on your investment.PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If you have any questions, please contact your BKI Distributor. If they are unable to answer your questions, contact the BKI Technical Service Department, toll free: 1-800-927-6887. Outside the U.S., call 1-864-963-3471.Safety PrecautionsAlways follow recommended safety precautions listed in this manual. Below is the safety alert symbol. When you see this symbol on your equipment, be alert to the potential for personal injury or property damage.Safety Signs and MessagesThe following Safety signs and messages are placed in this manual to provide instructions and identify specific areas where potential hazards exist and special precautions should be taken. Know and understand the meaning of these instructions, signs, and messages. Damage to the equipment, death or serious injury to you or other persons may result if these messages are not followed.This message indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.This message indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury.This message indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate injury. It may also be used to alert against unsafe practices. This message is used when special information, instructions or identification are required relating to procedures, equipment, tools, capacities and other special data.Safe Work PracticesBeware of High VoltageThis equipment uses high voltage. Serious injury can occur if you or any untrained or unauthorized person installs, services, or repairs this equipment. Always Use an Authorized Service agent to Service Your Equipment.California Residents Only. This product can expose you to chemicals including chromium, and lead which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to .Keep this manual with the EquipmentThis manual is an important part of your equipment. Always keep it near for easy access. If you need to replace this manual, contact:BKITechnical Services Department2812 Grandview DriveSimpsonville, S.C. 29681Or call toll free: 1-800-927-6887Outside the U.S., call 864-963-3471Protect ChildrenKeep children away from this equipment. Children may not understand that this equipment is dangerous for them and others.NEVER allow children to play near or operate your equipment.Keep Safety Labels Clean and in Good ConditionDo not remove or cover any safety labels on your equipment. Keep all safety labels clean and in good condition. Replace any damaged or missing safety labels. Refer to the Safety Labels section for illustration and location of safety labels on this unit. If you need a new safety label, obtain the number of the specific label illustrated on page 6, then contact:BKITechnical Services Department2812 Grandview DriveSimpsonville, S.C. 29681Or call toll free: 1-800-927-6887Outside the U.S., call 864-963-3471Be Prepared for EmergenciesBe prepared for fires, injuries, or other emergencies.Keep a first aid kit and a fire extinguisher near the equipment. You must use a 40-pound Type BC fire extinguisher and keep it within 25 feet of your equipment. Keep emergency numbers for doctors, ambulance services, hospitals, and the fire department near your telephone.Know your responsibilities as an Employer•Make certain your employees know how to operate the equipment.•Make certain your employees are aware of the safety precautions on the equipment and in this manual.•Make certain that you have thoroughly trained your employees about operating the equipment safely.•Make certain the equipment is in proper working condition. If you make unauthorized modifications to the equipment, you will reduce the function and safety of the equipment.Safety LabelsModels WS-13On Back of UnitModel WS-15ST(C)OperationModelsOnce the unit is plugged in to the appropriate receptacle with the appropriate overcurrent protection (see rating tag), press the “I” portion of the power switch. Switch will illuminate, and the unit will begin to heat. IMPORTANT: Allow 20 minutes to preheat before loading product into Warming Station.Unit Shutdown1. Press the “O” portion of the power switch.2. Allow the equipment to cool to room temperature.Operational Guidelines•Foods should be a minimum of 160︒ F. before being placed in the warmer.•Foods loaded in first should be served first as much as is practical.•Check Federal and State Health and Sanitation Regulations for internal temperature required for holding cooked foods for sale. Maintaining these temperatures often tends to continue to cook certain products.Therefore, smaller amounts of bulk foods should be displayed at non-peak periods and the warmerrefilled as needed.•For WS-15ST(C) Models Only: Top swivels to allow room todump product into pan.This equipment is designed to hold foods for a short period of time only.InstallationSerious injury, equipment damage or death could result if attempting to install this unityourself. Ensure that an authorized BKI service agent installs the unit.Instructions for Shipping DamageYou are responsible for filing all freight claims with the delivering truck line. Inspect all cartons and crates for damage when they arrive. If there is damage noted to shipping crates or cartons, or, if a shortage is found, note this on the bill of lading (all copies) before signing.If damage is detected when the equipment is uncrated, immediately call the delivering truck line and follow up the call with a written report indicating concealed damage to your equipment. Ask for an immediate inspection of your concealed damage item. Crating material MUST be retained to show the inspector from the truck line. Electrical InformationElectrocution, equipment failure or property damage could result if an unlicensedelectrician performs the electrical installation. Ensure that a licensed electrician performthe electrical installation in accordance with local codes, or in the absence of local codes,with the National Electrical Code, ANSI NFPA 70-20XX.This unit, when installed by an authorized BKI service agent, must be wired for use in accordance with all applicable local, state, and federal codes. For specific electrical requirements and connections refer to the wiring diagram attached to the unit or provided in the Service Manual.MaintenanceFailure to comply with the maintenance below could result in a serious accident.Electrocution, equipment failure or property damage could result if an unlicensedelectrician performs electrical repair. Ensure that a licensed electrician performs electricalrepair.Scheduled MaintenanceThis unit should be cleaned at the end of each working day. Use the following procedure:Failure to remove power from this unit may cause severe electrical shock. This unit mayhave more than one disconnect switch.Never use abrasive cleaners that may damage the finish.Never steam clean the interior.Avoid getting excess water in the interior of the unit.Do not leave this unit on and unattended after business hours.1. Remove all food from the unit.2. Remove power from the unit by following the shutdown procedures in the Operation section.3. Allow the equipment to cool to room temperature.4. Sponge the inside and outside of the unit with a mild soap and water solution, being sure to clean allareas. Avoid getting water in the interior of the unit.5. Wipe the parts and unit dry with a soft, clean cloth.TroubleshootingProblem Cause Possible SolutionUnit will not turn on. Power cords notconnected or circuitbreaker supplying powerto the unit has tripped. Make sure power cords are connected and circuit breaker is on. If problem persists, contact a licensed electrician.Product is not holding its temperature Product temperature istoo low when loaded.OrFaulty component inheating circuitMake sure product is above 160 F when loaded.Contact an authorized BKI service agent forcorrective action.Unit is not heating No power to unitOrFaulty component inheating circuit. Make sure power cords are connected and circuit breaker is on. If problem persists, contact licensed electrician.Contact an authorized BKI service agent for corrective action.RepairBefore replacing any parts, make sure the power has been turned off and the unit hascooled down.Replacement PartsPart # Description PictureCS0005Cord SetFor WS-13 & WS-15ST(C)C0346Element – Top HeatFor WS-13 & WS-15ST(C)S0356Power SwitchFor WS-13 & WS-15ST(C)C0348Foil Element – Bottom Heat For WS-15ST(C) OnlyWS-13 Wiring DiagramWS-15ST(C) Wiring DiagramNotes2812 Grandview Drive, Simpsonville, S.C. 29681, USA Made and printed in the U.S.ALI0174/0704。

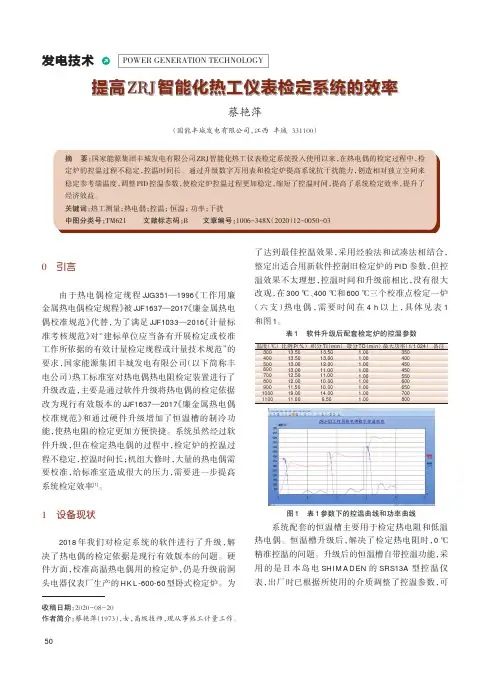

发电技术POWER GENERATION TECHNOLOGY提高ZRJ智能化热工仪表检定系统的效率蔡艳萍(国能丰城发电有限公司,江西丰城331100)摘要:国家能源集团丰城发电有限公司ZRJ智能化热工仪表检定系统投入使用以来,在热电偶的检定过程中,检定炉的控温过程不稳定,控温时间长。

通过升级数字万用表和检定炉提高系统抗干扰能力,创造相对独立空间来稳定参考端温度,调整PID控温参数,使检定炉控温过程更加稳定,缩短了控温时间,提高了系统检定效率,提升了经济效益。

关键词:热工测量;热电偶;控温;恒温;功率;干扰中图分类号:TM621文献标志码:B文章编号:1006-348X(2020)12-0050-030引言由于热电偶检定规程JJG351—1996《工作用廉金属热电偶检定规程》被JJF1637—2017《廉金属热电偶校准规范》代替,为了满足JJF1033—2016《计量标准考核规范》对“建标单位应当备有开展检定或校准工作所依据的有效计量检定规程或计量技术规范”的要求,国家能源集团丰城发电有限公司(以下简称丰电公司)热工标准室对热电偶热电阻检定装置进行了升级改造,主要是通过软件升级将热电偶的检定依据改为现行有效版本的JJF1637—2017《廉金属热电偶校准规范》和通过硬件升级增加了恒温槽的制冷功能,使热电阻的检定更加方便快捷。

系统虽然经过软件升级,但在检定热电偶的过程中,检定炉的控温过程不稳定,控温时间长;机组大修时,大量的热电偶需要校准,给标准室造成很大的压力,需要进一步提高系统检定效率[1]。

1设备现状2018年我们对检定系统的软件进行了升级,解决了热电偶的检定依据是现行有效版本的问题。

硬件方面,校准高温热电偶用的检定炉,仍是升级前洞头电器仪表厂生产的HKL-600-60型卧式检定炉。

为了达到最佳控温效果,采用经验法和试凑法相结合,整定出适合用新软件控制旧检定炉的PID参数,但控温效果不太理想,控温时间和升级前相比,没有很大改观,在300℃、400℃和600℃三个校准点检定一炉(六支)热电偶,需要时间在4h以上,具体见表1和图1。

日本岛电SR90 系列PID 调节器中文操作说明 SR90系列是在全面总结SR70、SR73A 及SR60基础上的高性能的单回路调节器。

0.3级精度、四种外形尺寸、四位超大LED 显示,带手动和模拟变送、设定值偏移(SB)、双输出及二组专家PID 参数、一组外部开关、两路报警和事件输出,以及通讯功能。

一.仪表的显示面板和功能键四位超大红色LED和四位绿色LED 1:测量值PV和设定值SV2:参数窗口3:错误信息七位指示灯OUT1:(绿)OUT2:(绿) 亮时有调节输出EV1:(红)EV2:(红)亮时事件报警输出AT:(绿)闪烁时自整定MAN:(绿)闪烁时为手动状态SB/COM:(绿) 亮时为两者之一的状态二.操作流程图说明SR90系列所有参数窗口可分为两个窗口群(0-X 窗口群和1-X),子窗口和虚线表示的选件窗口共60个。

每个窗口采用了编号,例如传感器量程选择窗口[1-48],表示第1窗口群的第48号窗口。

按增减健修改参数时,面板SV 窗口的小数点闪动,按ENT 键确认修改后,小数点灭。

三.入门的快速设置例(简单加热系统)某加热系统,仪表选用SR93-1P-N-90-1000000, K 型热偶0.0~800.0℃输入,P 型输出接固态继电器。

单设定值,设定温度为600.0℃,EV1上限绝对值报警值650.0℃,EV2下限绝对值报警值550℃, 报警为上电抑制。

设置步骤如下:1)在[1-48]窗口,将传感器量程代码设定为:05(K 型热偶0.0~800.0℃) 。

2)在[1-49]窗口,选择传感器量程的单位C(0.0~800.0℃) 。

3)在[1-42]窗口,将调节输出极性设为:rA 反作用(加热)。

4)在[1-10] 窗口,将调节输出的时间比例周期设为:2秒。

5)在[0-0]窗口,按增、减键将SV 值设为600.0℃,按ENT 键确认。

6)在[1-20]窗口, 将EV1报警方式设为:上限绝对值(HA)。

日本岛电SR1/SR3/SR4 PID调节器中文操作说明SR1/SR3/SR4是高性能价格比的新型单回路调节器。

0.3级精度、PID自整定,48×48mm和96×96mm以及96×48mm三种外形尺寸、四位超大LED显示,带手动、输出限幅、独立的两路事件报警继电器。

最重要的是采用了岛电在热处理应用方面享有盛名的专家PID算法。

一.仪表的显示面板和功能键二.操作流程图说明SR1/SR3/SR4所有参数窗口可分为两个窗口群(0-X和1-X窗口群),子窗口和虚线表示的选件窗口共32个。

每个窗口采用了编号,例如传感器量程选择窗口[1-22],表示第1窗口群的第23号窗口。

按增减健修改参数时,面板SV窗口的小数点闪动,按ENT键确认修改后,小数点熄灭。

三.入门的快速设置例(简单加热系统)某加热系统,仪表选用SR3-8P-1, K型热偶0.0~800.0℃输入,P型输出接固态继电器。

设定温度为600.0℃,EV1上限绝对值报警值650.0℃,EV2下限绝对值报警值550℃, 报警为上电抑制。

设置步骤如下:1)在[1-22]窗口,将传感器量程代码设定为:05(K型热偶0.0~800.0℃) 。

2)在[1-23]窗口,选择传感器量程的单位C(摄氏度℃)。

3)在[1-17]窗口,将调节输出极性设为:rA 反作用(加热)。

4)在[1-10] 窗口,将调节输出的时间比例周期设为:2秒。

5)在[0-0]窗口,按增、减键将SV值设为600.0℃,按ENT键确认。

6)在[1-11]窗口, 将EV1报警方式设为:上限绝对值(HA)。

7)在[1-14]窗口, 将EV2报警方式设为:下限绝对值(LA)。

8)在[1-16]窗口,下限报警应具有上电抑制功能,设为:2。

9)在[0-3]窗口, 设EV1报警值:650.0℃;在[0-4]设EV2报警值:550.0℃。

10)系统接成闭环后,在[0-2] AT功能窗口按增/减键将OFF改为ON状态后,按ENT键确认启动自整定,AT灯闪烁自整定起动。

日本岛电FP93可编程PID调节器中文操作说明FP93是日本岛电公司高性能的0.3级可编程PID调节器,它功能完善,性能优良、设计细腻。

具有自由输入,四位超大高亮的字符显示,众多的状态指示。

可带4组曲线最大40段可编程,六组专家PID参数,更高级的区域PID算法。

带手动、停电和故障保护、模拟变送、通讯接口、两路时标输出,I/O接口包括4组DI外部开关、3路继电器和4路OC扩展门共16种和事件。

一. 仪表的显示面板和功能键二.操作流程图说明FP93全部的子窗口和用虚线表示的选件子窗口共95个。

每个窗口采用了编号,例如传感器量程选择窗口[5-5],表示第5窗口群的第5数时,面板SV窗口的小数点闪动,按ENT键确认修改后,小数点灭。

三.简单加热系统定值调节的快速入门设置例1. 定值设置例:仪表选用FP93-8P-90-N1000, K型热偶0.0~800.0℃输入,P型输出接固态继电器。

设定温度为600.0℃,EV1上限绝对值报警值650.0℃,EV2下限绝对值报警值550℃, EV2的报警为上电抑制。

首先按面板RUN/RST(运行/复位键),使仪表进入复位,面板RUN运行灯灭,在[5-5]窗口,将传感器量程代码设定为:05(K型热偶0.0~800.0℃) 。

1)在[5-6]窗口,选择传感器量程的单位C(0.0~800.0℃) 。

2)在[5-12]窗口,将调节输出极性设为:rA 反作用(加热)。

3)在[5-13]窗口,将调节输出的时间比例周期设为:2秒。

4)在[3-1]窗口,设置为ON,定值方式。

5)在[3-2]或[0-0]窗口,按增、减键将SV值设为600.0℃,按ENT键确认。

6)在[5-19]窗口, 将EV1报警方式设为:上限绝对值(HA)。

7)在[5-22]窗口, 将EV2报警方式设为:下限绝对值(LA)。

8)根据要求,在[5-24]窗口,设置下限报警应具有上电抑制功能,设为:2。

10)在[3-4]窗口, 设EV1报警值:650.0℃;在[3-5]设EV2报警值:550.0℃。

日本岛电SR90 系列PID 调节器中文操作说明 SR90系列是在全面总结SR70、SR73A 及SR60基础上的高性能的单回路调节器。

0.3级精度、四种外形尺寸、四位超大LED 显示,带手动和模拟变送、设定值偏移(SB)、双输出及二组专家PID 参数、一组外部开关、两路报警和事件输出,以及通讯功能。

一.仪表的显示面板和功能键四位超大红色LED和四位绿色LED 1:测量值PV和设定值SV2:参数窗口3:错误信息七位指示灯OUT1:(绿)OUT2:(绿) 亮时有调节输出EV1:(红)EV2:(红)亮时事件报警输出AT:(绿)闪烁时自整定MAN:(绿)闪烁时为手动状态SB/COM:(绿) 亮时为两者之一的状态二.操作流程图说明SR90系列所有参数窗口可分为两个窗口群(0-X 窗口群和1-X),子窗口和虚线表示的选件窗口共60个。

每个窗口采用了编号,例如传感器量程选择窗口[1-48],表示第1窗口群的第48号窗口。

按增减健修改参数时,面板SV 窗口的小数点闪动,按ENT 键确认修改后,小数点灭。

三.入门的快速设置例(简单加热系统)某加热系统,仪表选用SR93-1P-N-90-1000000, K 型热偶0.0~800.0℃输入,P 型输出接固态继电器。

单设定值,设定温度为600.0℃,EV1上限绝对值报警值650.0℃,EV2下限绝对值报警值550℃, 报警为上电抑制。

设置步骤如下:1)在[1-48]窗口,将传感器量程代码设定为:05(K 型热偶0.0~800.0℃) 。

2)在[1-49]窗口,选择传感器量程的单位C(0.0~800.0℃) 。

3)在[1-42]窗口,将调节输出极性设为:rA 反作用(加热)。

4)在[1-10] 窗口,将调节输出的时间比例周期设为:2秒。

5)在[0-0]窗口,按增、减键将SV 值设为600.0℃,按ENT 键确认。

6)在[1-20]窗口, 将EV1报警方式设为:上限绝对值(HA)。

日本SHIMADEN(岛电)FP23可编程PID调节器中文操作说明一.日本岛电公司型FP230。

1%高精度高分辨率完全自由输入20组曲线(共400步)可编程单双通道,大液晶双排LED5位醒目显示,多DI/DO接口,常用通讯及MODBUS协议,支持用户灵活方便编译的计算机USB接口软硬件,功能极大集成。

可广泛用于半导体制造,计量仪表,传感器标定,航空航天,石油化工,冶金等自控领域二.仪表的显示面板和功能键∶调节输出2两个工作点:红外线通讯收发。

前面板按键开关:∶用于选择八个命令组窗口群;请尊敬的用户在使用前确认FP23的选型型号与系统要求无误。

三.选择FP23规格,设定FP23工作模式用户可根据实际需求,选择单输入或双输入两种规格之一。

选择单输入规格有下面两种工作模式∶SS模式∶单路输入,单路调节输出;SD模式∶单路输入,双路调节输出。

选择双输入规格有下面四种工作模式∶DL模式∶双路输入,独立两通道调节;DS模式∶双路输入,单路输出调节;DD模式∶双路输入,双路输出调节。

四.单通道FP23加热系统的定值控制快速设定例调节器选定型号为:FP23-SSPN-0000000系统要求:烘箱加热器K型热电偶0.0—800.0℃,固态继电器输出设定值为600.0℃,EV1事件输出为上限绝对值报警,报警值为700.0℃。

具体设置如下:1.在UNIT/RANGE【7-3】窗口依次设定量程RANG:06(0.0—800.0℃)单位UNIT:℃在该窗口改变量程后,用户退出该窗口群时调节器会出现此画面,让用户确认。

将NO改为YES,ENT键确认,量程改变并确认。

2.在CTRL OUT【6-1】窗口确认调节极性OUT1ACT:反极性Reverce,调节输出周期CYC:设为2秒3.CTRL EXEC窗口群的【1-6】窗口FIX SV设定控制值为:600。

0℃4.在CTRL EXEC窗口群的【1-6】窗口FIX MOVE设定为:EXE方式5.在EVENT/DO窗口群的【4-0-②】窗口EV1MD报警方式:设为PV Hi上限绝对值报警;在该窗口的ACT选择报警接点的NO常开或NC常闭方式6.在CTRL EXEC窗口群的【1-7】窗口FIX EV1:具体报警值:700.0℃;7.CTRL EXEC窗口群的【1-6】窗口FIX MODE设定为:ON方式,FIX指示灯亮8.【0-0】窗口,同时按ENT和DISP两键,RUN指示灯亮,FIX定值控制方式随即开始9.在CTRL EXEC窗口群的【1-1】窗口启动AT自整定功能:OFF变为ON,按ENT确认键,AT灯闪亮。