杜邦 PBT HR5330HF 物性表

- 格式:pdf

- 大小:67.31 KB

- 文档页数:2

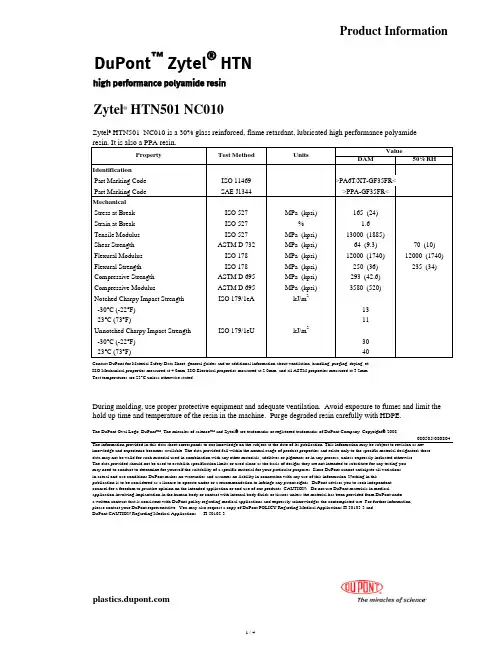

HTN501 NC010 is a 30% glass reinforced, flame retardant, lubricated high performance polyamide HTN501 NC010DuPont ™ Zytel ®HTNhigh performance polyamide resinZytel ®ValueDAM50%RHIdentification Part Marking Code ISO 11469>PA6T/XT-GF35FR< Part Marking Code SAE J1344>PPA-GF35FR<Mechanical Stress at Break ISO 527MPa (kpsi)165 (24) Strain at Break ISO 527% 1.6 Tensile Modulus ISO 527MPa (kpsi)13000 (1885) Shear Strength ASTM D 732MPa (kpsi)64 (9.3)70 (10) Flexural Modulus ISO 178MPa (kpsi)12000 (1740)12000 (1740) Flexural Strength ISO 178MPa (kpsi)250 (36)235 (34)Compressive Strength ASTM D 695MPa (kpsi)293 (42.6) Compressive ModulusASTM D 695MPa (kpsi)3580 (520)Notched Charpy Impact Strength ISO 179/1eAkJ/m2-30°C (-22°F)13 23°C (73°F)11 Unnotched Charpy Impact Strength ISO 179/1eUkJ/m2-30°C (-22°F)30 23°C (73°F)40Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Zytel® are trademarks or registered trademarks of DuPont Company. Copyright© 2008080505/080804The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in thispublication is to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: Do not use DuPont materials in medical application involving implantation in the human body or contact with internal body fluids or tissues unless the material has been provided from DuPont undera written contract that is consistent with DuPont policy regarding medical applications and expressly acknowledges the contemplated use. For further information, please contact your DuPont representative. You may also request a copy of DuPont POLICY Regarding Medical Applications H-50103-3 and DuPont CAUTION Regarding Medical Applications … H-50102-3Zytel ®resin. It is also a PPA resin.PropertyTest Method UnitsDuring molding, use proper protective equipment and adequate ventilation. Avoid exposure to fumes and limit the hold up time and temperature of the resin in the machine. Purge degraded resin carefully with HDPE.Zytel®ValueDAM50%RHThermalDeflection Temperature ISO 75-1/-2 °C (°F)0.45MPa 270 (518) 1.80MPa260 (500)Melting Temperature ISO 11357-1/-3 °C (°F)10°C/min, First Heat 300 (574)CLTE, Parallel ISO 11359-1/-2E-4/C (E-4/F)-40 - 23°C (-40 - 73°F)0.20 (0.11) 23 - 55°C (73 - 130°F)0.18 (0.10) 55 - 125°C (131 - 257°F)0.18 (0.10)CLTE, Normal ISO 11359-1/-2E-4/C (E-4/F)-40 - 23°C (-40 - 73°F)0.46 (0.26) 23 - 55°C (73 - 130°F)0.50 (0.28) 55 - 125°C (131 - 257°F)0.60 (0.33)Glass Transition Temperature DMA °C (°F)140 (284)90 (194)Electrical Surface Resistivity IEC 60093ohm 1E13 Volume Resistivity IEC 60093ohm m >1E131E13 Electric Strength IEC 60243-1kV/mm (V/mil)1.0mm34 (863)34 (863)Relative Permittivity IEC 602501E2 Hz 3.9 1E3 Hz 3.8 1E6 Hz 3.6Dissipation Factor IEC 60250E-41E2 Hz 80 1E3 Hz 130 1E6 Hz 150Arc Resistance ASTM D 495s 80 CTIIEC 60112V 525Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Zytel® are trademarks or registered trademarks of DuPont Company. Copyright© 2008080505/080804The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in thispublication is to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: Do not use DuPont materials in medical application involving implantation in the human body or contact with internal body fluids or tissues unless the material has been provided from DuPont undera written contract that is consistent with DuPont policy regarding medical applications and expressly acknowledges the contemplated use. For further information, please contact your DuPont representative. You may also request a copy of DuPont POLICY Regarding Medical Applications H-50103-3 and DuPont CAUTION Regarding Medical Applications … H-50102-3PropertyTest Method UnitsHTN501 NC010Zytel®ValueDAM50%RHFlammabilityFlammability Classification UL940.81mm V-0Oxygen Index ISO 4589-1/-2%37Hot Wire Ignition UL 746As0.81mm >150 1.5mm >150 3.0mm>150Temperature Index RTI, Electrical UL 746B°C0.81mm 150 1.5mm 150 3.0mm 150RTI, Impact UL 746B°C0.81mm 120 1.5mm 125 3.0mm 130RTI, Strength UL 746B°C0.81mm 130 1.5mm 130 3.0mm150Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Zytel® are trademarks or registered trademarks of DuPont Company. Copyright© 2008080505/080804The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in thispublication is to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: Do not use DuPont materials in medical application involving implantation in the human body or contact with internal body fluids or tissues unless the material has been provided from DuPont undera written contract that is consistent with DuPont policy regarding medical applications and expressly acknowledges the contemplated use. For further information, please contact your DuPont representative. You may also request a copy of DuPont POLICY Regarding Medical Applications H-50103-3 and DuPont CAUTION Regarding Medical Applications … H-50102-3PropertyTest Method UnitsHTN501 NC010Zytel®ValueDAM 50%RHOther DensityISO 1183kg/m 3 (g/cm 3)1680 (1.68)Hardness, Rockwell ASTM D 785Scale M 108 Scale R 124Taber AbrasionASTM D 1044mgCS-17 Wheel, 1kg, 1000 cycles 57Water Absorption ASTM D 570%Immersion 24h 0.25Molding Shrinkage ISO 294-4%Normal, 2.0mm 0.5 Parallel, 2.0mm 0.2ProcessingMelt Temperature Range °C (°F)320-330 (610-625) Mold Temperature Range °C (°F)140-160 (280-320)Drying Time, Dehumidified Dryer h 6-8 Drying Temperature°C (°F)100 (210) Processing Moisture Content%<0.10Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Zytel® are trademarks or registered trademarks of DuPont Company. Copyright© 2008080505/080804The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in thispublication is to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: Do not use DuPont materials in medical application involving implantation in the human body or contact with internal body fluids or tissues unless the material has been provided from DuPont undera written contract that is consistent with DuPont policy regarding medical applications and expressly acknowledges the contemplated use. For further information, please contact your DuPont representative. You may also request a copy of DuPont POLICY Regarding Medical Applications H-50103-3 and DuPont CAUTION Regarding Medical Applications … H-50102-3PropertyTest Method Units HTN501 NC010。

聚对苯二甲酸丁二醇酯(PBT)

聚对苯二甲酸丁二醇酯,英文名polybutylece terephthalate(简称PBT),PBT为乳白色半透明到不透明、结晶型热塑性聚酯。

具有高耐热性、韧性、耐疲劳性,自润滑、低摩擦系数,耐候性、吸水率低,仅为0.1%,在潮湿环境中仍保持各种物性(包括电性能),电绝缘性,但体积电阻、介电损耗大。

耐热水、碱类、酸类、油类、但易受卤化烃侵蚀,耐水解性差,低温下可迅速结晶,成型性良好。

缺点是缺口冲击强度低,成型收缩率大。

故大部分采用玻璃纤维增强或无机填充改性,其拉伸强度、弯曲强度可提高一倍以上,热变形温度也大幅提高。

可以在140℃下长期工作,玻纤增强后制品纵、横向收缩率不一致,易使制品发生翘曲。

PBT 结晶速度快,最适宜加工方法为注塑,其他方法还有挤出、吹塑、涂覆和各种二次加工成型,成型前需预干燥,水分含量要降至0.02%。

PBT(增强、改性PBT)主要用于汽车、电子电器、工业机械和聚合物合金、共混工业。

如作为汽车中的分配器、车体部件、点火器线圈骨架、绝缘盖、排气系统零部件、摩托车点火器、电子电器工业中如电视机的偏转线圈,显象管和电位器支架,伴音输出变压器骨架,适配器骨架,开关接插件、电风扇、电冰箱、洗衣机电机端盖、轴套。

另外还有运输机械零件,缝纫机和纺织机械零件、钟表外壳、镜筒、电熨斗罩、水银灯罩、烘烤炉部件、电动工具零件、屏蔽套等。

已商品化PBT合金有:PBT/弹性体、PBT/PC/弹性体、PBT/PPO、PBT/PE、PBT/ASA合金等。

0号锂基润滑脂参数1. 简介0号锂基润滑脂是一种常见的工业润滑脂,具有优异的润滑性能和耐高温性能。

本文将介绍0号锂基润滑脂的参数,包括其化学成分、物理性质、适用范围等方面的内容。

2. 化学成分0号锂基润滑脂主要由以下几种化学成分组成:•基础油:0号锂基润滑脂通常采用合成油或矿物油作为基础油,具有良好的稳定性和润滑性能。

•锂基皂:锂基皂是0号锂基润滑脂的主要增稠剂,能够增加脂肪润滑脂的黏度和凝固点,提高其润滑性能。

•添加剂:0号锂基润滑脂还包含了各种添加剂,如抗氧化剂、防锈剂、抗磨剂等,以提高其耐高温、抗氧化和抗磨损性能。

3. 物理性质0号锂基润滑脂具有以下物理性质:•外观:0号锂基润滑脂呈黄色或棕色均匀油膏状。

•凝固点:0号锂基润滑脂的凝固点通常在60℃以上,可以在较高温度下保持润滑性能。

•滴点:0号锂基润滑脂的滴点通常在180℃以上,表示其在高温下仍能保持稳定的润滑性能。

•针入度:0号锂基润滑脂的针入度通常在265~295之间,反映了其黏度和流动性。

4. 适用范围0号锂基润滑脂适用于以下领域和设备:•工业设备:0号锂基润滑脂可以用于各种工业设备的摩擦部位,如轴承、齿轮、链条等,提供良好的润滑和保护。

•汽车工业:0号锂基润滑脂可以用于汽车发动机、变速器、制动系统等润滑部位,具有良好的抗氧化和抗磨损性能。

•航空航天:0号锂基润滑脂适用于航空航天设备的高温润滑,如发动机、起落架等,能够在极端条件下提供可靠的润滑效果。

•轨道交通:0号锂基润滑脂也适用于轨道交通设备的润滑,如铁路机车、地铁列车等,能够提供长期稳定的润滑效果。

5. 使用注意事项在使用0号锂基润滑脂时,需要注意以下事项:•清洗:在润滑部位更换润滑脂前,应先清洗干净旧润滑脂和污垢,确保新润滑脂能够有效附着和润滑。

•适量使用:使用0号锂基润滑脂时,要根据设备的要求和工作条件合理使用适量的润滑脂,避免过量或不足。

•储存条件:0号锂基润滑脂应存放在干燥、阴凉、通风的地方,避免受潮和高温,确保其质量和性能不受影响。

化学品安全技术说明书科波西电子材料张家港有限公司按照GB/T 16483、GB/T 17519编制产品名称:MOLYKOTE® G-1068 润滑脂 / MOLYKOTE® G-1068 Grease SDS编号:4092334最初编制日期:27.04.2015发行日期:16.10.2020打印日期:22.06.2023科波西电子材料张家港有限公司鼓励并希望您能阅读和理解整份(M)SDS,该文件包括了重要的信息。

我们希望您能遵从该文件给出的预防措施,除非你的使用条件需要其他更合适的方法或措施。

一化学品及企业标识产品名称:MOLYKOTE® G-1068 润滑脂MOLYKOTE® G-1068 Grease推荐用途和限制用途已确认的各用途:润滑剂和润滑添加剂公司名称:科波西电子材料张家港有限公司扬子江国际化学工业园南京路3号215633 江苏省张家港市中国客户咨询方式:86-512-5561 1616*************************传真:86-21-3862 2896应急咨询电话24-小时应急联系电话:************国内应急电话:************二危险性概述紧急情况综述外观与性状糊狀物颜色白色至灰白色气味略微的长期吞咽或反复接触可能损害器官。

对水生生物有毒。

对水生生物有毒并具有长期持续影响。

GHS危险性类别根据法规的标准, 被列为有害品。

特异性靶器官系统毒性(反复接触) (经口):类别 2 (肾)急性(短期)水生危害:类别 2长期水生危害:类别 2GHS标签要素象形图信号词:警告!危险性说明长期吞咽或反复接触可能损害(肾)器官。

对水生生物有毒并具有长期持续影响。

防范说明预防措施不要吸入粉尘/ 烟/ 气体/ 烟雾/ 蒸气/ 喷雾。

避免释放到环境中。

事故响应如感觉不适,须求医/就诊。

收集溢出物。

废弃处置将内装物/容器送到批准的废物处理厂处理。

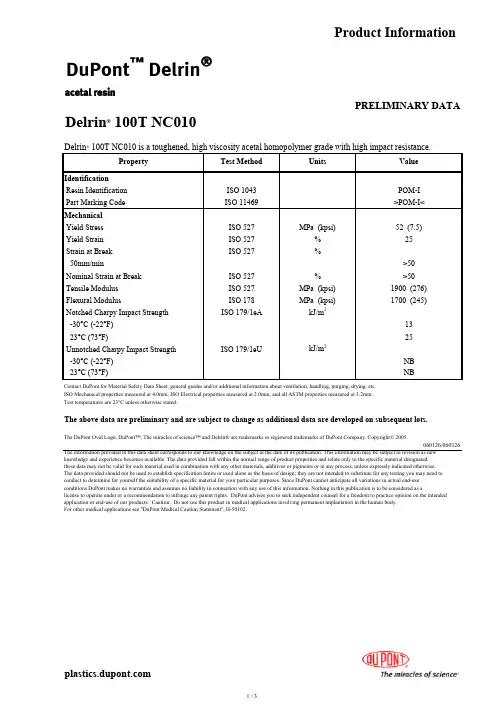

DuPont ™ Delrin®acetal resinPRELIMINARY DATADelrin ®100T NC010IdentificationResin Identification ISO 1043POM-I Part Marking Code ISO 11469>POM-I<Mechanical Yield Stress ISO 527MPa (kpsi)52 (7.5) Yield Strain ISO 527%25 Strain at Break ISO 527%50mm/min>50Nominal Strain at Break ISO 527%>50 Tensile Modulus ISO 527MPa (kpsi)1900 (276) Flexural ModulusISO 178MPa (kpsi)1700 (245)Notched Charpy Impact Strength ISO 179/1eAkJ/m2-30°C (-22°F)13 23°C (73°F)25Unnotched Charpy Impact Strength ISO 179/1eUkJ/m 2-30°C (-22°F)NB 23°C (73°F)NBContact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The above data are preliminary and are subject to change as additional data are developed on subsequent lots.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2005.060126/060126The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise. The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publication is to be considered as alicense to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. Caution: Do not use this product in medical applications involving permanent implantation in the human body. For other medical applications see "DuPont Medical Caution Statement", H-50102.Delrin ® 100T NC010 is a toughened, high viscosity acetal homopolymer grade with high impact resistance.PropertyTest Method Units ValueDelrin ®100T NC010ThermalDeflection TemperatureISO 75f °C (°F)0.45MPa 130 (265) 1.80MPa72 (160)Melting Temperature ISO 11357-1/-3 °C (°F)10°C/min 178 (352)CLTE, Parallel ISO 11359-1/-2E-4/C (E-4/F)23 - 55°C (73 - 130°F) 1.2 (0.67)Rheological Melt Mass-Flow Rate ISO 1133g/10 min190°C, 2.16kg 2.0ElectricalRelative Permittivity IEC 602501E6 Hz 3.1Dissipation Factor IEC 60250E-41E6 Hz 90CTI IEC 60112V 600Other DensityISO 1183kg/m 3 (g/cm 3)1370 (1.37)Hardness, Rockwell ISO 2039/2Scale M 59 Scale R 113Water Absorption ISO 62, Similar to%Equilibrium 50%RH 0.3 Saturation, immersed 0.9Molding Shrinkage ISO 294-4%Normal, 2.0mm 1.9 Parallel, 2.0mm2.1Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The above data are preliminary and are subject to change as additional data are developed on subsequent lots.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2005.060126/060126The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise. The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publication is to be considered as alicense to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. Caution: Do not use this product in medical applications involving permanent implantation in the human body. For other medical applications see "DuPont Medical Caution Statement", H-50102.PropertyTest Method Units ValueDelrin ®100T NC010ProcessingMelt Temperature Range °C (°F)200-210 (390-410)Melt Temperature Optimum °C (°F)205 (400) Mold Temperature Range °C (°F)40-60 (100-140)Mold Temperature Optimum °C (°F)50 (122) Drying Time, Dehumidified Dryer h 2-4 Drying Temperature °C (°F)80 (175) Processing Moisture Content %<0.05 Hold Pressure RangeMPa (kpsi)60-80 (9-12)Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm. Test temperatures are 23°C unless otherwise stated.The above data are preliminary and are subject to change as additional data are developed on subsequent lots.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2005.060126/060126The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; these data may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise. The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you may need to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variations in actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publication is to be considered as alicense to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. Caution: Do not use this product in medical applications involving permanent implantation in the human body. For other medical applications see "DuPont Medical Caution Statement", H-50102.PropertyTest Method Units Value。

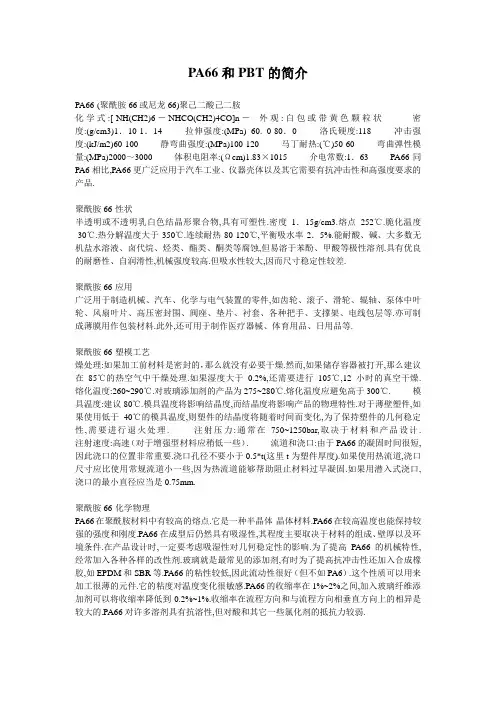

PA66和PBT的简介PA66-(聚酰胺66或尼龙66)聚己二酸己二胺化学式:[-NH(CH2)6-NHCO(CH2)4CO]n-外观:白包或带黄色颗粒状密度:(g/cm3)1.10-1.14 拉伸强度:(MPa) 60. 0-80.0 洛氏硬度:118 冲击强度:(kJ/m2)60-100 静弯曲强度:(MPa)100-120 马丁耐热:(℃)50-60 弯曲弹性模量:(MPa)2000~3000 体积电阻率:(Ωcm)1.83×1015 介电常数:1.63 PA66同PA6相比,PA66更广泛应用于汽车工业、仪器壳体以及其它需要有抗冲击性和高强度要求的产品.聚酰胺66-性状半透明或不透明乳白色结晶形聚合物,具有可塑性.密度1.15g/cm3.熔点252℃.脆化温度-30℃.热分解温度大于350℃.连续耐热80-120℃,平衡吸水率2.5%.能耐酸、碱、大多数无机盐水溶液、卤代烷、烃类、酯类、酮类等腐蚀,但易溶于苯酚、甲酸等极性溶剂.具有优良的耐磨性、自润滑性,机械强度较高.但吸水性较大,因而尺寸稳定性较差.聚酰胺66-应用广泛用于制造机械、汽车、化学与电气装置的零件,如齿轮、滚子、滑轮、辊轴、泵体中叶轮、风扇叶片、高压密封围、阀座、垫片、衬套、各种把手、支撑架、电线包层等.亦可制成薄膜用作包装材料.此外,还可用于制作医疗器械、体育用品、日用品等.聚酰胺66-塑模工艺燥处理:如果加工前材料是密封的,那么就没有必要干燥.然而,如果储存容器被打开,那么建议在85℃的热空气中干燥处理.如果湿度大于0.2%,还需要进行105℃,12小时的真空干燥.熔化温度:260~290℃.对玻璃添加剂的产品为275~280℃.熔化温度应避免高于300℃. 模具温度:建议80℃.模具温度将影响结晶度,而结晶度将影响产品的物理特性.对于薄壁塑件,如果使用低于40℃的模具温度,则塑件的结晶度将随着时间而变化,为了保持塑件的几何稳定性,需要进行退火处理. 注射压力:通常在750~1250bar,取决于材料和产品设计.注射速度:高速(对于增强型材料应稍低一些). 流道和浇口:由于PA66的凝固时间很短,因此浇口的位置非常重要.浇口孔径不要小于0.5*t(这里t为塑件厚度).如果使用热流道,浇口尺寸应比使用常规流道小一些,因为热流道能够帮助阻止材料过早凝固.如果用潜入式浇口,浇口的最小直径应当是0.75mm.聚酰胺66-化学物理PA66在聚酰胺材料中有较高的熔点.它是一种半晶体-晶体材料.PA66在较高温度也能保持较强的强度和刚度.PA66在成型后仍然具有吸湿性,其程度主要取决于材料的组成、壁厚以及环境条件.在产品设计时,一定要考虑吸湿性对几何稳定性的影响.为了提高PA66的机械特性,经常加入各种各样的改性剂.玻璃就是最常见的添加剂,有时为了提高抗冲击性还加入合成橡胶,如EPDM和SBR等.PA66的粘性较低,因此流动性很好(但不如PA6).这个性质可以用来加工很薄的元件.它的粘度对温度变化很敏感.PA66的收缩率在1%~2%之间,加入玻璃纤维添加剂可以将收缩率降低到0.2%~1%.收缩率在流程方向和与流程方向相垂直方向上的相异是较大的.PA66对许多溶剂具有抗溶性,但对酸和其它一些氯化剂的抵抗力较弱.PBT-聚对苯二甲酸丁二醇酯属于聚酯系列,是由1.4-pbt丁二醇(1.4-Butyleneglycol)与对苯二甲酸(PTA)或者对苯二甲酸酯(DMT)聚缩合而成,并经由混炼程序制成的乳白色半透明到不透明、结晶型热塑性聚酯树脂.与PET一起统称为热塑性聚酯,或饱和聚酯. PBT为乳白色半透明到不透明、结晶型热塑性聚酯.具有高耐热性、韧性、耐疲劳性,自润滑、低摩擦系数,耐候性、吸水率低,仅为0.1%,在潮湿环境中仍保持各种物性(包括电性能),电绝缘性,但体积电阻、介电损耗大.耐热水、碱类、酸类、油类、但易受卤化烃侵蚀,耐水解性差,低温下可迅速结晶,成型性良好.缺点是缺口冲击强度低,成型收缩率大.故大部分采用玻璃纤维增强或无机填充改性,其拉伸强度、弯曲强度可提高一倍以上,热变形温度也大幅提高.可以在140℃下长期工作,玻纤增强后制品纵、横向收缩率不一致,易使制品发生翘曲. PBT燃烧鉴别:不易燃烧,燃烧时无液体流下,离开火焰后在5秒钟内熄灭,相似于PC.PBT注塑参数1.注射温度:PBT的分解温度为280℃,所以实际生产中一般控制在240-260℃之间.2.注射压力:注射压力一般为50~100MPa.3.注射速率:PBT冷却速度快,因此要采用较快的注射速率.4.螺杆转速和背压:成型PBT的螺杆转速不宜超过80r/min,一般在25~60r/min之间.背压一般为注射压力的10%~15%.5.模具温度:一般控制在70~80℃,各部位的温度差不超过10℃.6.成型周期:一般情况下为15~60s.PBT注意事项1.再生料使用:再生料与新料的比例一般在25%~75%.2.脱模剂使用:一般情况下不使用脱模剂,必要时可采用有机硅脱模剂.3.停机处理:PBT停机时间在30min以内,可将温度降到200℃时停机.长期停机后再生产时,要将料筒内的料排空,再加入新料才能进行正常生产.PA66\PBT厂家东莞湘樟塑化公司,美国杜邦公司,美国杜邦公司,美国液氮公司,基础创新塑料(美国)公司,美国赫斯特公司,美国泰科纳公司,美国普立万公司,美国Chem Polymer公司,美国舒尔曼公司,美国TEKNOR APEX公司,美国RTP公司,德国朗盛公司,美国巴斯夫公司,美国巴斯夫公司,瑞士EMS,台湾耐特,广州金发。

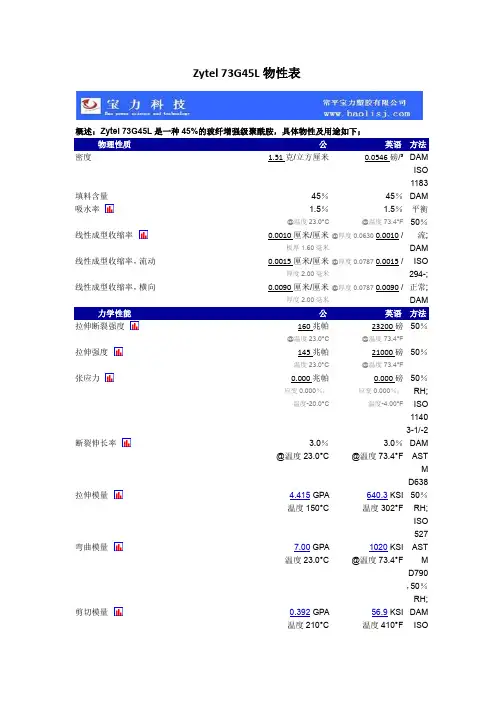

Zytel 73G45L物性表概述:Zytel 73G45L是一种45%的玻纤增强级聚酰胺,具体物性及用途如下;物理性质公英语方法密度 1.51克/立方厘米0.0546磅/³DAMISO1183 填料含量45%45%DAM吸水率 1.5%@温度23.0°C1.5%@温度73.4°F平衡50%线性成型收缩率0.0010厘米/厘米板厚1.60毫米@厚度0.0630 0.0010 / 流;DAM线性成型收缩率,流动0.0015厘米/厘米厚度2.00毫米@厚度0.0787 0.0015 / ISO294-;线性成型收缩率,横向0.0090厘米/厘米厚度2.00毫米@厚度0.0787 0.0090 / 正常;DAM力学性能公英语方法拉伸断裂强度160兆帕@温度23.0°C23200磅@温度73.4°F50%拉伸强度145兆帕温度23.0°C21000磅@温度73.4°F50%张应力0.000兆帕应变0.000%,温度-20.0°C0.000磅应变0.000%,温度-4.00°F50%RH;ISO11403-1/-2断裂伸长率 3.0%@温度23.0°C3.0%@温度73.4°FDAMASTMD638拉伸模量 4.415 GPA温度150°C640.3 KSI温度302°F50%RH;ISO527弯曲模量7.00 GPA温度23.0°C1020 KSI@温度73.4°FASTMD790,50%RH;剪切模量0.392 GPA温度210°C56.9 KSI温度410°FDAMISO6721梁缺口冲击强度,缺口 1.85焦耳/平方厘米温度23.0°C3.47 ft-lb/in温度73.4°FDAMASTMD256梁缺口冲击强度,无缺口14.9 J /厘米温度23.0°C27.9 ft-lb/in温度73.4°FDAMASTMD4812梁缺口冲击强度,缺口(ISO)15.0千焦/平方米@温度-30.0°C7.14 ft-lb/in²@温度-22.0°FDAMISO180/1A简支梁冲击缺口10.1 J /平方厘米@温度-30.0°C48.1 ft-lb/in²@温度-22.0°F50%RH;ISO179/1eU无简支梁冲击,缺口 1.90焦耳/平方厘米@温度-30.0°C9.04 ft-lb/in²@温度-22.0°FDAMISO179/1eA简拉伸蠕变模量,1小时9400兆帕温度23.0°C1.36e +6 PSI@温度73.4°F50%RH;ISO899拉伸蠕变模量,1000小时7300兆帕温度23.0°C1.06E +6 PSI@温度73.4°F50%RH;ISO899热性能公英语方法热膨胀系数,线性,并行的流500μm/m-°C温度23.0 - 55.0°C278μin/in-°F温度73.4 - 131°FDAM ASTM E 831500μm/m-°C温度23.0 - 55.0°C278μin/in-°F温度73.4 - 131°FDAM ISO 11359-1/-2热膨胀系数,线性,横向流动100μm/m-°C温度23.0 - 55.0°C55.6μin/in-°F温度73.4 - 131°FDAM ASTM E 831100μm/m-°C温度23.0 - 55.0°C55.6μin/in-°F温度73.4 - 131°FDAM ISO 11359-1/-2在0.46兆帕的热变形温度221 °C 430 °F DAM ISO 75-1/-2无冲击易燃性,UL94。

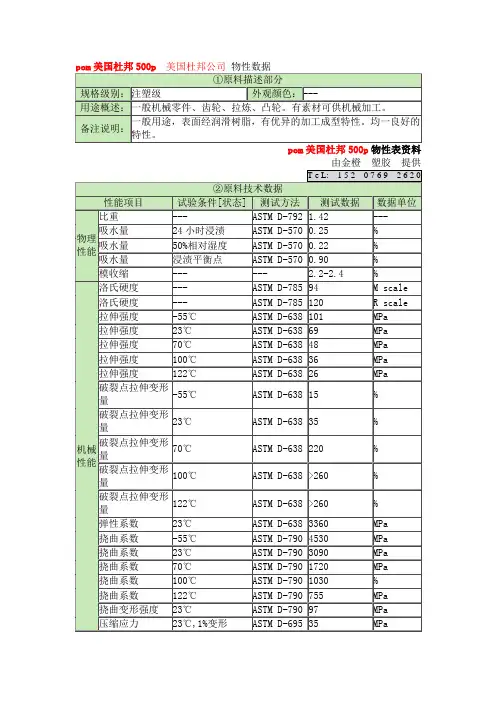

pom美国杜邦500p美国杜邦公司物性数据①原料描述部分规格级别:注塑级外观颜色:---用途概述:一般机械零件、齿轮、拉炼、凸轮。

有素材可供机械加工。

备注说明:一般用途,表面经润滑树脂,有优异的加工成型特性。

均一良好的特性。

pom美国杜邦500p物性表资料由金橙塑胶提供T e L: 1 5 2 0 7 6 9 2 6 2 0②原料技术数据性能项目试验条件[状态] 测试方法测试数据数据单位物理性能比重--- ASTM D-792 1.42 --- 吸水量24小时浸渍ASTM D-570 0.25 % 吸水量50%相对湿度ASTM D-570 0.22 % 吸水量浸渍平衡点ASTM D-570 0.90 % 模收缩--- --- 2.2-2.4 %机械性能洛氏硬度--- ASTM D-785 94 M scale 洛氏硬度--- ASTM D-785 120 R scale 拉伸强度-55℃ ASTM D-638 101 MPa拉伸强度23℃ ASTM D-638 69 MPa拉伸强度70℃ ASTM D-638 48 MPa拉伸强度100℃ ASTM D-638 36 MPa拉伸强度122℃ ASTM D-638 26 MPa破裂点拉伸变形量-55℃ ASTM D-638 15 %破裂点拉伸变形量23℃ ASTM D-638 35 %破裂点拉伸变形量70℃ ASTM D-638 220 %破裂点拉伸变形量100℃ ASTM D-638 >260 %破裂点拉伸变形量122℃ ASTM D-638 >260 %弹性系数23℃ ASTM D-638 3360 MPa挠曲系数-55℃ ASTM D-790 4530 MPa挠曲系数23℃ ASTM D-790 3090 MPa挠曲系数70℃ ASTM D-790 1720 MPa挠曲系数100℃ ASTM D-790 1030 %挠曲系数122℃ ASTM D-790 755 MPa挠曲变形强度23℃ ASTM D-790 97 MPa压缩应力23℃,1%变形ASTM D-695 35 MPa压缩应力23℃,10%变形ASTM D-695 123 MPa 抗剪强度23℃ ASTM D-732 66 MPa挠曲疲劳忍耐限度50%RH,23℃,106周期ASTM D-671 31 MPa负载变形量140kg/cm2,50℃ ASTM D-621 0.5 % 抗拉伸冲击强度长试片23℃ ASTM D-1822 420 kj/m2 IZOD冲击试验无缺口23℃ ASTM D-256 2160 j/m IZOD冲击试验缺口-40℃ ASTM D-256 66 j/m IZOD冲击试验23℃ ASTM D-256 81 j/m电气性能抗电弧 3.1mm ASTM D-495 220 sec 介电强度瞬间Shorttime(2.3mm)ASTM D-149 19.7 kv/mm 容积电阻率23℃,0.2%含水量A STM D-257 1×1015Ω.cm 介电常数50%RH,23℃,102~106HzASTM D-150 3.7 Ω.cm 介电因数50%RH,23℃,106Hz ASTM D-150 0.005 ---热性能线性热膨胀系数60~104℃ ASTM D-696 13.7 10-5m/m℃ 线性热膨胀系数104~160℃ ASTM D-696 14.9 10-5m/m℃ 自燃性--- UL-94 HB ---热畸变温度 1.8MPa ASTM D-648 136 ℃热畸变温度0.5MPa ASTM D-648 172 ℃熔点--- ASTM D-2133 175 ℃热传导系数--- --- 0.37 W/mk线性热膨胀系数-40~29℃ ASTM D-696 10.4 10-5m/m℃ 线性热膨胀系数29~60℃ ASTM D-696 12.2 10-5m/m℃如果对pom美国杜邦500p方面还有什么疑问,请与我们详谈!1:美国杜邦系列(聚甲醛)POM:美国杜邦POM 100AF 20%铁氟龙增强合金低磨耗高粘度高韧性POM美国杜邦POM 500AF 20%TEFLON3纤维增强高流动低磨耗聚甲醛美国杜邦POM 100P 注塑级高粘度高韧性POM美国杜邦POM 500P 高流动性表面经润滑树脂美国杜邦POM 900P 高流动性低黏度表面经润滑树脂厨卫网美国杜邦POM 1700P 超高流动级POM 超低粘度均一物性美国杜邦POM 100T 坚韧高粘性美国杜邦POM 100ST 高黏度表面经润滑,超强韧性聚甲醛树脂美国杜邦POM 500T 低磨耗高流动POM美国杜邦POM 100 高粘度,具有最坚韧的硬度,优良的热稳定性美国杜邦POM 500 高流动高抗冲抗蠕变美国杜邦POM 500CL 高流动抗磨耗POM美国杜邦POM 500AL 高流动抗磨耗级美国杜邦POM 107 强度、刚度、热稳定性能好、硬度好。

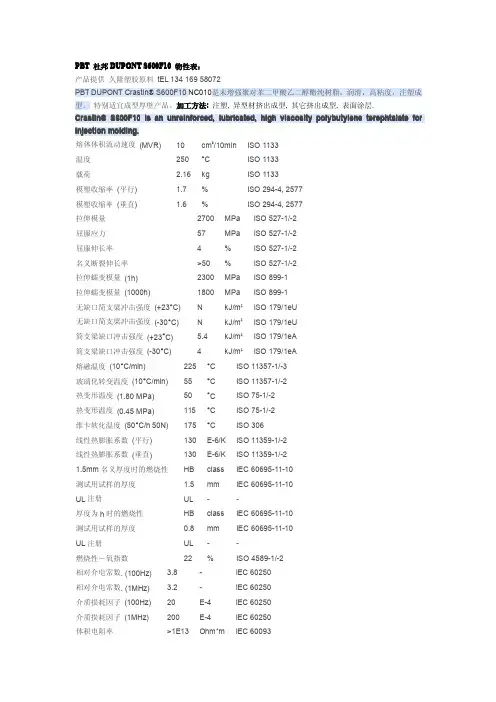

PBT杜邦DUPONT S600F10物性表:产品提供久隆塑胶原料tEL134********PBT DUPONT Crastin®S600F10NC010是未增强聚对苯二甲酸乙二醇酯纯树脂,润滑,高粘度,注塑成型。

特别适宜成型厚壁产品。

加工方法:注塑,异型材挤出成型,其它挤出成型,表面涂层.Crastin®S600F10is an unreinforced,lubricated,high viscosity polybutylene terephtalate for injection molding.熔体体积流动速度(MVR)10cm³/10min ISO1133温度250°C ISO1133载荷 2.16kg ISO1133模塑收缩率(平行) 1.7%ISO294-4,2577模塑收缩率(垂直) 1.6%ISO294-4,2577拉伸模量2700MPa ISO527-1/-2屈服应力57MPa ISO527-1/-2屈服伸长率4%ISO527-1/-2名义断裂伸长率>50%ISO527-1/-2拉伸蠕变模量(1h)2300MPa ISO899-1拉伸蠕变模量(1000h)1800MPa ISO899-1无缺口简支梁冲击强度(+23°C)N kJ/m²ISO179/1eU无缺口简支梁冲击强度(-30°C)N kJ/m²ISO179/1eU简支梁缺口冲击强度(+23°C) 5.4kJ/m²ISO179/1eA简支梁缺口冲击强度(-30°C)4kJ/m²ISO179/1eA熔融温度(10°C/min)225°C ISO11357-1/-3玻璃化转变温度(10°C/min)55°C ISO11357-1/-2热变形温度(1.80MPa)50°C ISO75-1/-2热变形温度(0.45MPa)115°C ISO75-1/-2维卡软化温度(50°C/h50N)175°C ISO306线性热膨胀系数(平行)130E-6/K ISO11359-1/-2线性热膨胀系数(垂直)130E-6/K ISO11359-1/-21.5mm名义厚度时的燃烧性HB class IEC60695-11-10测试用试样的厚度 1.5mm IEC60695-11-10UL注册UL--厚度为h时的燃烧性HB class IEC60695-11-10测试用试样的厚度0.8mm IEC60695-11-10UL注册UL--燃烧性-氧指数22%ISO4589-1/-2相对介电常数.(100Hz) 3.8-IEC60250相对介电常数.(1MHz) 3.2-IEC60250介质损耗因子(100Hz)20E-4IEC60250介质损耗因子(1MHz)200E-4IEC60250体积电阻率>1E13Ohm*m IEC60093表面电阻率1E15Ohm IEC60093介电强度26kV/mm IEC60243-1相对漏电起痕指数600-IEC60112吸水性0.5%类似ISO62吸湿性0.2%类似ISO62密度1300kg/m³ISO1183熔体密度1110kg/m³-熔体0.21W/(m K)-熔体的比热2100J/(kg K)-注塑成型参数:干燥温度110-130°C干燥时间,除湿机=2-4小时处理水分含量<0.04%熔体温度处理最佳=250°C熔体温度范围240-260°C模具温度最佳=80°C模具温度范围30-130°C型材挤出参数:干燥温度110-130°C干燥时间,除湿机=2-4小时处理水分含量<0.04%熔体温度处理最佳=250°C熔融温度范围为240-260°C。

宝瑞塑胶原料有限公司

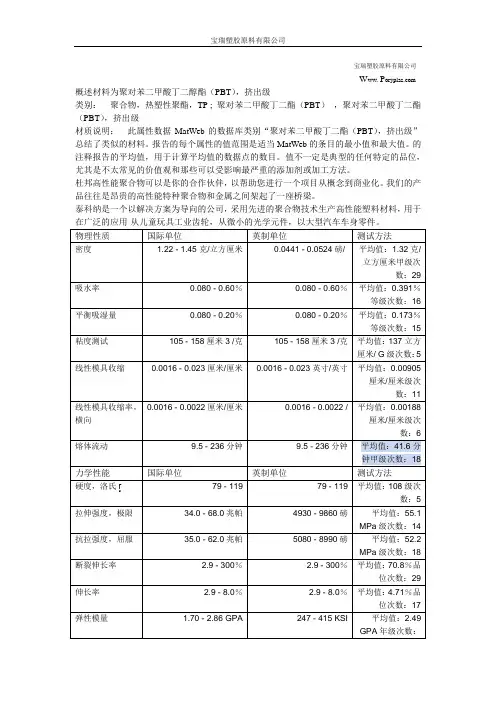

W ww. P 概述材料为聚对苯二甲酸丁二醇酯(PBT),挤出级

类别:聚合物,热塑性聚酯,TP ; 聚对苯二甲酸丁二酯(PBT),聚对苯二甲酸丁二酯(PBT),挤出级

材质说明:此属性数据MatWeb的数据库类别“聚对苯二甲酸丁二酯(PBT),挤出级”总结了类似的材料。

报告的每个属性的值范围是适当MatWeb的条目的最小值和最大值。

的注释报告的平均值,用于计算平均值的数据点的数目。

值不一定是典型的任何特定的品位,尤其是不太常见的价值观和那些可以受影响最严重的添加剂或加工方法。

杜邦高性能聚合物可以是你的合作伙伴,以帮助您进行一个项目从概念到商业化。

我们的产品往往是昂贵的高性能特种聚合物和金属之间架起了一座桥梁。

泰科纳是一个以解决方案为导向的公司,采用先进的聚合物技术生产高性能塑料材料,用于。

通用尼龙物性表尼龙(PA)材料的特性一尼龙简介尼龙(Nylon,Polyamide,简称PA)是指由聚酰胺类树脂构成的塑料。

此类树脂可由二元胺与二元酸通过缩聚制得,也可由氨基酸脱水后形成的内酰胺通过开环聚合制得,与PS、PE、PP等不同,PA不随受热温度的升高而逐渐软化,而是在一个靠近熔点的窄的温度范围内软化,熔点很明显,熔点:215-225℃。

温度一旦达到就出现流动。

PA的品种很多,主要有PA6、PA66、PA610、PA11、PA12、PA1010、PA612、PA46、PA6T、PA9T、MXD-6芳香醯胺等.以PA6、PA66、PA610、PA11、PA12最为常用.尼龙类工程塑料外观上都呈现为角质、韧性、表层光亮、白色(或乳白色)或微黄色、透明或半透明的结晶性树脂,它容易被著成任一种颜色。

作为工程塑料的尼龙分子量一般为1.5-3万。

它们的密度均稍大于1,密度:1.14-1.15g/cm3。

拉伸强度:>60.0Mpa。

伸长率:>30%。

弯曲强度:90.0Mpa 。

缺口冲击强度:(KJ/m2) >5。

尼龙的收缩率为1%~2%. 需注意成型后吸湿的尺寸变化。

吸水率100% 相对吸湿饱和时能吸8%.使用温度可-40~105℃之间。

熔点:215-225℃。

合適壁厚2-3.5mm. PA的机械性能中如抗拉抗压强度随温度和吸湿量而改变,所以水相对是PA的增塑剂,加入玻纤后,其抗拉抗压强度可提高2倍左右,耐温能力也相应提高,PA本身的耐磨能力非常高,所以可在无润滑下不停操作,如想得到特別的润滑效果,可在PA中加入硫化物。

二 PA性能的主要优点有:1. 机械强度高,韧性好,有较高的抗拉、抗压强度。

比拉伸强度高于金属,比压缩强度与金属不相上下,但它的刚性不及金属。

抗拉强度接近于屈服强度,比ABS 高一倍多。

对冲击、应力振动的吸收能力强,冲击强度比一般塑料高了许多,并优于缩醛树脂。

2. 耐疲劳性能突出,制件经多次反复屈折仍能保持原有机械强度。

产品资料PBT-G30增强聚对苯二甲酸丁二醇酯Glass Fiber Reinforced PBT 主要特征FEATURES主要应用 APPLICATIONS●尺寸稳定性好●优异的综合性能,高强度●高耐温●●注塑成型●家电部件●车拉手●门插销性 能[1] Properties 测试标准ASTM测试条件Test Condition国际单位S.I.Units典型值S.I.[2]Typical Values机械性能Mechanical拉伸强度Tensile Strength D638 10mm/min MPa 135 伸长率Elongation at break D638 10mm/min % 2.8 弯曲强度Flexural Strength D790 2mm/min MPa 190 弯曲模量Flexural Modulus D790 2mm/min MPa 8000 悬臂梁缺口冲击强度Impact Strength, IZOD notchedD256 3.2mm, 23℃J/m 110 洛氏硬度Rockwell Hardness D785 R-Scale - 120 热性能Thermal热变形温度Heat Distortion Temp. D6480.45MPa, 6.4mm ℃2201.8MPa, 6.4mm ℃212电性能Electrical体积电阻率V olume Resistivity D257 - · cm 1016其他Others比重Specific Gravity D792 23℃g/cm3 1.53 玻纤含量Glass Fibre Content - - % 30 收缩率Mold Shrinkage D955 23℃% 0.3/0.9 吸水率Water Absorption D570 23℃,24hr % 0.06阻燃性Flammability UL94 1.5mm Class HB 3.0mm Class HB[1] 染色料的性能可能与以上数值有不同。

PBT,30%glass fibres,injection moulding,flame retardantISO Shortname:ISO 7792-1-PBT,GFHMR,09-110,GF30;ISO 1043-PBT GF FR(17)PropertyTest ConditionUnitStandardguide valueRheological properties C Melt volume-flow rate 260°C;5kgcm³/(10min)ISO 1133-137C Molding shrinkage,parallel 60x60x2;250°C /WZ 80°C;600bar%ISO 294-40.3C Molding shrinkage,transverse 60x60x2;250°C /WZ 80°C;600bar%ISO 294-40.9Post-shrinkage,parallel 60x60x2;120°C;4h %ISO 294-40.1Post-shrinkage,transverse60x60x2;120°C;4h%ISO 294-40.1Mechanical properties (23°C/50%r.h.)C Tensile modulus 1mm/min MPa ISO 527-1,-211500C Tensile Stress at break 5mm/min MPa ISO 527-1,-2125C Tensile Strain at break 5mm/min %ISO 527-1,-2 2.1C Charpy impact strength 23°C kJ/m²ISO 179-1eU 50C Charpy impact strength -30°C kJ/m²ISO 179-1eU 50C Charpy notched impact strength 23°C kJ/m²ISO 179-1eA <10C Charpy notched impact strength -30°C kJ/m²ISO 179-1eA <10Izod impact strength 23°C kJ/m²ISO 180-1U 45Izod impact strength -30°C kJ/m²ISO 180-1U 45Izod notched impact strength 23°C kJ/m²ISO 180-1A <10Izod notched impact strength -30°C kJ/m²ISO 180-1A <10Flexural modulus 2mm/min MPa ISO 178-A 10500Flexural strength2mm/min MPa ISO 178-A 200Flexural strain at flexural strength 2mm/min%ISO 178-A 2.6Ball indentation hardness N/mm²ISO 2039-1186C Puncture energy 23°C J ISO 6603-2 2.3C Puncture energy -30°C J ISO 6603-2 2.1C Puncture maximum force 23°C N ISO 6603-2669C Puncture maximum force -30°C NISO 6603-2649Thermal properties C Melting temperature10°C/min °C ISO 11357-1,-3225C Temperature of deflection under load 1.80MPa °C ISO 75-1,-2200C Temperature of deflection under load 0.45MPa °C ISO 75-1,-2220Vicat softening temperature50N;120°C/h °C ISO 306205C Coefficient of linear thermal expansion,parallel 23to 55°C 10-4/K ISO 11359-1,-20.2C Coefficient of linear thermal expansion,transverse 23to 55°C 10-4/K ISO 11359-1,-20.9C Burning behavior UL 940.38mm Class UL 94V-0C Burning behavior UL 940.8mm Class UL 94V-0C Oxygen indexMethod A%ISO 4589-232Pocan B 4239000000Page 1of 3PropertyTest Condition Unit Standard guide valueThermal conductivity23°CW/(m·K)ISO 83020.24Resistance to heat (ball pressure test)°C IEC 60695-10-2213Temperature index (Tensile strength)20000h °C IEC 60216-1155Halving interval (Tensile strength)°C IEC 60216-19.3Relative temperature index (Tensile strength)°C UL 746B 140Temperature index (Tensile impact strength)20000h °C IEC 60216-1130Halving interval (Tensile impact strength)°C IEC 60216-18.4Relative temperature index (Tensile impact strength)°C UL 746B 110Temperature index (Electric strength)20000h °C IEC 60216-1145Halving interval (Electric strength)°C IEC 60216-112Relative temperature index (Electric strength)°C UL 746B 125Glow wire test (GWFI)0.8mm °C IEC 60695-2-12960Glow wire test (GWIT)0.8mm °C IEC 60695-2-13725Glow wire test (GWIT) 1.6mm °C IEC 60695-2-13725Glow wire test (GWIT)3.0mm °CIEC 60695-2-13725Electrical properties (23°C/50%r.h.)C Relative permittivity 100Hz -IEC 60250 3.9C Relative permittivity 1MHz -IEC 60250 3.8C Electric strength1mm kV/mm IEC 60243-135C Comparative tracking index CTI Solution AV IEC 60112275Electrolytic corrosion RatingIEC 60426A/B 1Other properties (23°C)C Density kg/m³ISO 11831670Bulk densitykg/m³ISO 60800Processing conditions for test specimens C Injection molding-Melt temperature °C ISO 294250C Injection molding-Mold temperature °CISO 29480Processing recommendations Drying time circulating air dryer h -4-8Drying temperature circulating air dryer °C -120Residual moisture content %Acc.to Karl Fischer 0-0.02Melt temperature (Tmin -Tmax)°C -240-260Mold temperature°C-80-100C These property characteristics are taken from the CAMPUS plastics data bank and are based on the international catalogue of basic data for plastics according to ISO10350.Pocan B 4239000000Page 2of 3DisclaimerDisclaimer for sales productsThis information and our technical advice -whether verbal,in writing or by way of trials -are given in good faith but without warranty,and this also applies whereproprietary rights of third parties are involved.Our advice does not release you from the obligation to verify the information currently provided -especially that contained in our safety data and technical information sheets -and to test our products as to their suitability for the intended processes and uses.The application,use and processing of our products and the products manufactured by you on the basis of our technical advice are beyond our control and,therefore,entirely your own responsibility.Our products are sold in accordance with the current version of our General Conditions of Sale and Delivery.Test valuesUnless specified to the contrary,the values given have been established on standardized test specimens at room temperature.The figures should be regarded as guide values only and not as binding minimum values.Kindly note that,under certain conditions,the properties can be affected to a considerable extent by the design of the mould/die,the processing conditions and the coloring.Processing noteUnder the recommended processing conditions small quantities of decomposition product may be given off during processing.To preclude any risk to the health and well-being of the machine operatives,tolerance limits for the work environment must be ensured by the provision of efficient exhaust ventilation and fresh air at theworkplace in accordance with the Safety Data Sheet.In order to prevent the partial decomposition of the polymer and the generation of volatile decomposition products,the prescribed processing temperatures should not be substantially exceeded.Since excessively high temperatures are generally the result of operator error or defects in the heating system,special care and controls are essential in these areas.LANXESS DEUTSCHLAND GMBH |D -51369LEVERKUSEN ©LANXESS DeutschlandGmbHPocan B 4239000000Page 3of 3。

DuPont™ Delrin®acetal resinDelrin® 500P NC010Delrin® 500P NC010 is a medium viscosity acetal homopolymer resin for injection molding. Delrin® 500P has improved processing thermal stability.Property Test Method Units ValueIdentificationResin Identification ISO 1043POMPart Marking Code ISO 11469>POM< MechanicalYield Stress ISO 527MPa (kpsi)70 (10.1)Yield Strain ISO 527%17Strain at Break ISO 527%50mm/min40Nominal Strain at Break ISO 527%30Tensile Modulus ISO 527MPa (kpsi)3100 (450)Tensile Creep Modulus ISO 899MPa (kpsi)1h2800 (406)1000h1600 (232)Flexural Modulus ISO 178MPa (kpsi)2900 (420)Flexural Stress ISO 178MPa (kpsi)@ 3.5% Strain80 (11.6)Notched Charpy Impact Strength ISO 179/1eA kJ/m2-30°C (-22°F)823°C (73°F)9Unnotched Charpy Impact Strength ISO 179/1eU kJ/m2-30°C (-22°F)22023°C (73°F)300Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm.Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.061121/061121 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; thesedata may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise.The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you mayneed to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variationsin actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publicationis to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: This product is not permitted to be sold for use in medical applicationsinvolving any implantation in the human body or where contact with internal body fluids or tissues will equal or exceed 24 hours. For applications involvingcontact of less than 24 hours, see “DuPont Medical Caution Statement", H-50102 and contact your DuPont sales representative.Delrin® 500P NC010Property Test Method Units ValueThermalDeflection Temperature ISO 75-1/-2 °C (°F)0.45MPa158 (316)1.80MPa94 (201)Melting Temperature ISO 11357-1/-3 °C (°F)10°C/min178 (352)CLTE, Parallel ISO 11359-1/-2E-4/C (E-4/F)-40 - 23°C (-40 - 73°F) 1.0 (0.56)23 - 55°C (73 - 130°F) 1.1 (0.61)55 - 100°C (130 - 212°F) 1.5 (0.82)CLTE, Normal ISO 11359-1/-2E-4/C (E-4/F)-40 - 23°C (-40 - 73°F) 1.0 (0.56)23 - 55°C (73 - 130°F) 1.1 (0.61)55 - 100°C (130 - 212°F) 1.6 (0.9)Vicat Softening Temperature ISO 306 °C (°F)50N157 (315) RheologicalMelt Mass-Flow Rate ISO 1133g/10 min190°C, 2.16kg15ElectricalSurface Resistivity IEC 60093ohm1E15Volume Resistivity IEC 60093ohm m1E12Electric Strength IEC 60243-1kV/mm (V/mil)1.0mm33 (838)Relative Permittivity IEC 602501E2 Hz 3.91E6 Hz 3.9Dissipation Factor IEC 60250E-41E2 Hz2001E6 Hz60CTI IEC 60112V600Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm.Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.061121/061121 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; thesedata may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise.The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you mayneed to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variationsin actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publicationis to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: This product is not permitted to be sold for use in medical applicationsinvolving any implantation in the human body or where contact with internal body fluids or tissues will equal or exceed 24 hours. For applications involvingcontact of less than 24 hours, see “DuPont Medical Caution Statement", H-50102 and contact your DuPont sales representative.Delrin® 500P NC010Property Test Method Units ValueFlammabilityFlammability Classification IEC 60695-11-100.75mm HBFlammability Classification UL940.75mm HBOxygen Index ISO 4589-1/-2%22High Amperage Arc Ignition Resistance UL 746A arcs0.75mm200Hot Wire Ignition UL 746A s0.75mm81.5mm113.0mm15 Temperature IndexRTI, Electrical UL 746B°C0.75mm501.5mm1103.0mm110RTI, Impact UL 746B°C0.75mm501.5mm853.0mm90RTI, Strength UL 746B°C0.75mm501.5mm903.0mm95Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm.Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.061121/061121 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; thesedata may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise.The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you mayneed to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variationsin actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publicationis to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: This product is not permitted to be sold for use in medical applicationsinvolving any implantation in the human body or where contact with internal body fluids or tissues will equal or exceed 24 hours. For applications involvingcontact of less than 24 hours, see “DuPont Medical Caution Statement", H-50102 and contact your DuPont sales representative.Delrin® 500P NC010Property Test Method Units ValueOtherDensity ISO 1183kg/m3 (g/cm3)1420 (1.42)Hardness, Rockwell ISO 2039/2Scale M92Scale R120Water Absorption ISO 62, Similar to%Equilibrium 50%RH0.3Immersion 24h0.6Saturation, immersed 1.4Molding Shrinkage ISO 294-4%Normal, 2.0mm 1.9Parallel, 2.0mm 2.0ProcessingMelt Temperature Range °C (°F)210-220 (410-430)Melt Temperature Optimum °C (°F)215 (420)Mold Temperature Range °C (°F)80-100 (175-210)Mold Temperature Optimum °C (°F)90 (195)Drying Time, Dehumidified Dryer h2-4Drying Temperature °C (°F)80 (175)Processing Moisture Content%<0.2Hold Pressure Range MPa (kpsi)80-100 (12-15)Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etc.ISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm.Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont™, The miracles of science™ and Delrin® are trademarks or registered trademarks of DuPont Company. Copyright© 2006.061121/061121 The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as new knowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; thesedata may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise.The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you mayneed to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variationsin actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publicationis to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practice opinion on the intended application or end-use of our products. CAUTION: This product is not permitted to be sold for use in medical applicationsinvolving any implantation in the human body or where contact with internal body fluids or tissues will equal or exceed 24 hours. For applications involvingcontact of less than 24 hours, see “DuPont Medical Caution Statement", H-50102 and contact your DuPont sales representative.。

杜邦PBT HR5330HF本色NC010黑色BK503物性表:

产品提供久隆塑胶原料tEL134********

CRASTIN®HR5330HF是30%的玻璃纤维增强,高流量(HF),抗水解(HR)树脂。

耐冲击性及强度出色的平衡性能。

添加剂:润滑剂,、脱模助剂。

特征:可焊、耐化学试剂、水解稳定。

应用:汽车,电子电气。

熔体体积流动速度(MVR)8cm³/10min ISO1133

温度250℃ISO1133

载荷2.16kg ISO1133

模塑收缩率(平行)0.3%ISO294-4,2577

模塑收缩率(垂直) 1.0%ISO294-4,2577

拉伸模量8500MPa ISO527-1/-2

断裂应力110MPa ISO527-1/-2

断裂伸长率 2.9%ISO527-1/-2

无缺口简支梁冲击强度(+23°C)75kJ/m²ISO179/1eU

简支梁缺口冲击强度(+23°C)15kJ/m²ISO179/1eA

简支梁缺口冲击强度(-30°C)12kJ/m²ISO179/1eA

熔融温度(10°C/min)225°C ISO11357-1/-3

热变形温度(1.80MPa)205°C ISO75-1/-2

热变形温度(0.45MPa)220°C ISO75-1/-2

维卡软化温度(50°C/h50N)215°C ISO306

线性热膨胀系数(平行)21E-6/K ISO11359-1/-2

线性热膨胀系数(垂直)85E-6/K ISO11359-1/-2

1.5mm名义厚度时的燃烧性HB class IEC60695-11-10

测试用试样的厚度 1.5mm IEC60695-11-10

吸水性0.35%类似ISO62

吸湿性0.15%类似ISO62

密度1500kg/m³ISO1183。