loctite271技术参数

- 格式:pdf

- 大小:82.94 KB

- 文档页数:3

风力发电机组题库(机械专业)风力发电机组题库(机械专业)一、填空题1、XLCT 系列扳头组成包括动力头和工作头。

2XLCT 型液压扳手的旋转接头是360 度×360 度。

2、MXT 系列扳手的旋转接头是360 度×180 度;HY-230在工作时油温达到70 ℃时应停止使用,待油温降下来再继续使用;现场使用液压扳手拆松螺栓时应把泵站的压力调到10000PSI。

3、液压油每年至少更换两次,始终保证油箱满油。

4、HYTORC-230 液压泵具有四路接头,适于液压同步系统。

5、液压泵站的启动压力为140bar,停止压力为160bar,溢流压力为200bar。

6、蓄能器内冲入的气体为N2,压力为100bar,蓄能器的作用保压。

7、过滤比为βx 为上游大于直径x 的微粒数与下游大于直径x 的微粒数之比8、通常过滤器滤材可分为两大类:表面过滤介质和深度过滤介质9、增加过滤面积可以降低压差,提高使用寿命10、平行偏差(位移偏差):两个轴的中心线不同心但平行11、角度偏差(张口):两个轴的中心线不平行12、S 测量单元固定在基准端的设备上,M 测量单元固定在调整端的设备上,从调整端M 看基准端S,9 点钟在左边,右边是3 点钟,竖直方向是12 点钟。

13、写出联轴器各部位名称膜片组涨紧套中间体发电机法兰涨紧套制动盘力矩限制器测速盘14、润滑油基础油有矿物基础油和合成基础油。

15、影响润滑效率的因素:粘度、温度、载荷、滑动速度。

16、润滑剂的实际能使用的最低温度应比其倾点高10 ℃以上。

17、壳牌马力士Malleus OGH 由无机非皂基稠化剂和含有石墨的高粘度基础油组成。

18、润滑脂组成:基础油、稠化剂、添加剂。

19、高粘度指数可以确保液压油极端低温和高温下正常工作20、对于齿轮油,最突出的性能是极压性能21、如果油品颜色发黑,外观混浊,粘度增大,可能是油品氧化导致的。

22、如果油品颜色发白,外观混浊,可能是油品乳化(进水)导致的。

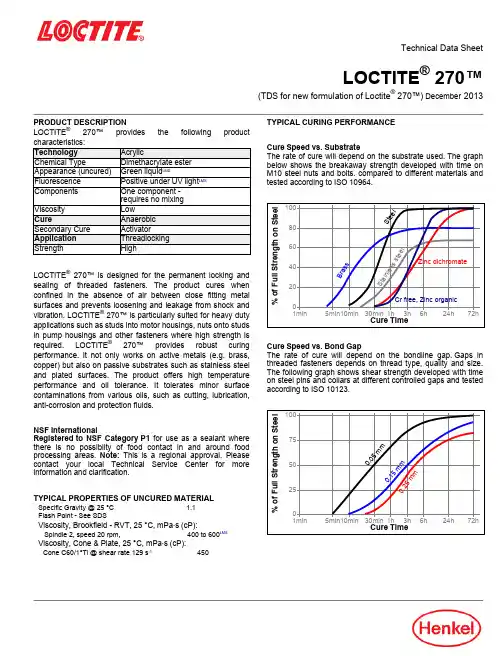

Technical Data SheetLOCTITE®270™(TDS for new formulation of Loctite®270™) December2013 PRODUCT DESCRIPTIONLOCTITE®270™provides the following productLOCTITE®270™is designed for the permanent locking andsealing of threaded fasteners.The product cures whenconfined in the absence of air between close fitting metalsurfaces and prevents loosening and leakage from shock andvibration.LOCTITE®270™is particularly suited for heavy dutyapplications such as studs into motor housings,nuts onto studsin pump housings and other fasteners where high strength isrequired.LOCTITE®270™provides robust curingperformance.It not only works on active metals(e.g.brass,copper)but also on passive substrates such as stainless steeland plated surfaces.The product offers high temperatureperformance and oil tolerance.It tolerates minor surfacecontaminations from various oils,such as cutting,lubrication,anti-corrosion and protection fluids.NSF InternationalRegistered to NSF Category P1for use as a sealant wherethere is no possibilty of food contact in and around foodprocessing areas.Note:This is a regional approval.Pleasecontact your local Technical Service Center for moreinformation and clarification.TYPICAL PROPERTIES OF UNCURED MATERIALSpecific Gravity@ 25°C 1.1Flash Point-See SDSViscosity,Brookfield -RVT, 25°C,mPa·s(cP):Spindle2,speed20rpm,400 to600LMSViscosity,Cone&Plate,25°C,mPa·s(cP):Cone C60/1°Ti@shear rate 129s-1450TYPICAL CURING PERFORMANCECure Speed vs.SubstrateThe rate of cure will depend on the substrate used. The graphbelow shows the breakaway strength developed with time onM10steel nuts and pared to different materials andtested according to ISO10964.%ofFullStrengthonSteelCure Time100806040201min5min10min30min1h3h6h24h72hBrassStainlesssteelZinc dichromateCr free, Zinc organicSteelCure Speed vs.Bond GapThe rate of cure will depend on the bondline gap. Gaps inthreaded fasteners depends on thread type,quality and size.The following graph shows shear strength developed with timeon steel pins and collars at different controlled gaps and testedaccording to ISO10123.%ofFullStrengthonSteelCure Time1007550251min5min10min30min1h3h6h24h72h.5mm.15mm.25mmCure Speed vs.TemperatureThe rate of cure will depend on the temperature.The graph below shows the breakaway strength developed with time at different temperatures on M10steel nuts and bolts and tested according to ISO 10964.% o f F u l l S t r e n g t h o n S t e e lCure Time1007550251min5min10min 30min 1h3h 6h 24h 72h5°C22 °C40 °CCure Speed vs.ActivatorWhere cure speed is unacceptably long,or large gaps are present,applying activator to the surface will improve cure speed.The graph below shows the breakaway strength developed with time on M10zinc dichromate steel nuts and bolts using Activator 7471™,7649™,7088™and 7091™and tested according to ISO 10964.% o f F u l l S t r e n g t h o n S t e e lCure Time1008060402001min5min10min 30min 1h3h6h24h 72h7471™7649™7088™7091™N oA c t iv a t o rTYPICAL PERFORMANCE OF CURED MATERIALAdhesive PropertiesCured for 24 hours @22°CBreakaway Torque,ISO 10964,Unseated:M10 steel nuts and bolts N·m 33(lb.in.) (290)M6 steel nuts and bolts N·m 5(lb.in.) (45)M16 steel nuts and bolts N·m 90(lb.in.) (800)3/8x 16steel nuts (grade 2) and bolts (grade 5) N·m 31 (lb.in.) (275)Prevail Torque @180°,ISO 10964,Unseated:M10 steel nuts and bolts N·m 33(lb.in.) (290)M6 steel nuts and bolts N·m 3(lb.in.) (26)M16 steel nuts and bolts N·m 125(lb.in.) (1,100)3/8x 16steel nuts (grade 2) and bolts (grade 5) N·m 33 (lb.in.) (290)Breakloose Torque,ISO 10964,Pre-torqued to 5N·m:M10 steel nuts and bolts N·m 39(lb.in.) (345)3/8x 16steel nuts (grade 2) and bolts (grade 5) N·m 35 (lb.in.) (310)Prevail Torque @180°,ISO 10964,Pre-torqued to 5N·m:M10 steel nuts and bolts N·m 25(lb.in.) (220)3/8x 16steel nuts (grade 2) and bolts (grade 5) N·m 31 (lb.in.) (275)Compressive Shear Strength, ISO 10123:Steel pins and collars N/mm² ≥9.0LMS(psi) (≥1,305)Cured for 1 week @22ºC,Breakloose Torque,ISO 10964,Pre-torqued to 5N·m:M10 zinc phosphate nuts and bolts N·m 46(lb.in.) (400)M10 stainless steel nuts and bolts N·m 30(lb.in.) (265)TYPICAL ENVIRONMENTAL RESISTANCECured for 1 week @22°CBreakloose Torque,ISO 10964,Pre-torqued to 5N·m:M10 zinc phosphate steel nuts and boltsHot StrengthTested at temperature% S t r e n g t h @ 22 °CTemperature, °C120100806040200050100150200Heat AgingAged at temperature indicated and tested @22°C% I n i t i a l S t r e n g t h @ 22 °CExposure Time, hours1251007550250010002000300040005000100 °C120 °C150 °C180 °C200 °CHeat Aging/Hot StrengthAged under conditions indicated and tested at temperature% I n i t i a l S t r e n g t h @ 22 °CExposure Time, hours120100806040200010002000300040005000100 °C120 °C150 °C180 °C200 °CChemical/Solvent ResistanceAged under conditions indicated and tested @22°C.%of initial strength Environment °C 500h1000h 5000h Motor oil125657575Unleaded gasoline 22909595Brake fluid 22105105100Water/glycol 50/5087758590Acetone 229595100Ethanol 22959595E85Ethanol fuel 22959595B100Bio-Diesel22100100110Breakloose Torque,ISO 10964,Pre-torqued to 5N·m:M10Stainless steel nuts and bolts%of initial strength Environment°C 500h1000h 5000h Sodium Hydroxide,20%22756555Phosphoric Acid,10%221009565GENERAL INFORMATIONThis product is not recommended for use in pure oxygen and/or oxygen rich systems and should not be selected as a sealant for chlorine or other strong oxidizing materials.For safe handling information on this product,consult the Safety Data Sheet (SDS).Where aqueous washing systems are used to clean the surfaces before bonding,it is important to check for compatibility of the washing solution with the adhesive. In some cases these aqueous washes can affect the cure and performance of the adhesive.This product is not normally recommended for use on plastics (particularly thermoplastic materials where stress cracking of the plastic could result). Users are recommended to confirm compatibility of the product with such substrates.Directions for use:For Assembly1.For best results,clean all surfaces (external and internal)with a LOCTITE ® cleaning solvent and allow to dry.2.If the cure speed is too slow,use appropriate activator.Please see the Cure Speed vs.Activator graph for reference.Allow the activator to dry when needed.3.To prevent the product from clogging in the nozzle,do notallow the tip to touch metal surfaces during application.4.For Thru Holes ,apply several drops of the product ontothe bolt at the nut engagement area.5.For Blind Holes ,apply several drops of the product to thelower third of the internal threads in the blind hole,or the bottom of the blind hole.6.For Sealing Applications ,apply a 360°bead of productto the leading threads of the male fitting,leaving the first thread free. For bigger threads and voids,adjust product amount accordingly and apply a 360°bead of product on the female threads also.7.Assemble and tighten as required.For Disassembly1.Remove with standard hand tools.2.In rare instances where hand tools do not work becauseof excessive engagement length,apply localized heat to nut or bolt to approximately 250°C. Disassemble while hot.3.Apply localized heat to the assembly to approximately250°C. Disassemble while hot.For Cleanup1.Cured product can be removed with a combination ofsoaking in a Loctite solvent and mechanical abrasion such as a wire brush.Loctite Material Specification LMSLMS dated June26,2009. Test reports for each batch are available for the indicated properties. LMS test reports include selected QC test parameters considered appropriate to specifications for customer use. Additionally,comprehensive controls are in place to assure product quality and consistency. Special customer specification requirements may be coordinated through Henkel Quality.StorageStore product in the unopened container in a dry location. Storage information may be indicated on the product container labeling.Optimal Storage: 8°C to21°C. Storage below8°C or greater than28°C can adversely affect product properties Material removed from containers may be contaminated during use. Do not return product to the original container. Henkel Corporation cannot assume responsibility for product which has been contaminated or stored under conditions other than those previously indicated.If additional information is required, please contact your local Technical Service Center or Customer Service Representative.Conversions(°C x1.8)+32=°FkV/mm x25.4=V/milmm/25.4=inchesµm/25.4=milN x0.225=lbN/mm x5.71=lb/inN/mm²x145=psiMPa x145=psiN·m x 8.851= lb·inN·m x0.738=lb·ftN·mm x0.142=oz·inmPa·s=cPNote:The information provided in this Technical Data Sheet(TDS)including the recommendations for use and application of the product are based on our knowledge and experience of the product as at the date of this TDS.The product can have a variety of different applications as well as differing application and working conditions in your environment that are beyond our control.Henkel is, therefore,not liable for the suitability of our product for the production processes and conditions in respect of which you use them,as well as the intended applications and results.We strongly recommend that you carry out your own prior trials to confirm such suitability of our product.Any liability in respect of the information in the Technical Data Sheet or any other written or oral recommendation(s)regarding the concerned product is excluded, except if otherwise explicitly agreed and except in relation to death or personal injury caused by our negligence and any liability under any applicable mandatory product liability law.In case products are delivered by Henkel Belgium NV,Henkel Electronic Materials NV,Henkel Nederland BV,Henkel Technologies France SAS and Henkel France SA please additionally note the following:In case Henkel would be nevertheless held liable,on whatever legal ground, Henkel’s liability will in no event exceed the amount of the concerned delivery.In case products are delivered by Henkel Colombiana,S.A.S.the following disclaimer is applicable:The information provided in this Technical Data Sheet(TDS)including the recommendations for use and application of the product are based on our knowledge and experience of the product as at the date of this TDS.Henkel is, therefore,not liable for the suitability of our product for the production processes and conditions in respect of which you use them,as well as the intended applications and results.We strongly recommend that you carry out your own prior trials to confirm such suitability of our product.Any liability in respect of the information in the Technical Data Sheet or any other written or oral recommendation(s)regarding the concerned product is excluded, except if otherwise explicitly agreed and except in relation to death or personal injury caused by our negligence and any liability under any applicable mandatory product liability law.In case products are delivered by Henkel Corporation,Resin Technology Group,Inc.,or Henkel Canada Corporation,the following disclaimer is applicable:The data contained herein are furnished for information only and are believed to be reliable.We cannot assume responsibility for the results obtained by others over whose methods we have no control.It is the user's responsibility to determine suitability for the user's purpose of any production methods mentioned herein and to adopt such precautions as may be advisable for the protection of property and of persons against any hazards that may be involved in the handling and use thereof.In light of the foregoing,Henkel Corporation specifically disclaims all warranties expressed or implied,including warranties of merchantability or fitness for a particular purpose,arising from sale or use of Henkel Corporation’s products.Henkel Corporation specifically disclaims any liability for consequential or incidental damages of any kind, including lost profits.The discussion herein of various processes or compositions is not to be interpreted as representation that they are free from domination of patents owned by others or as a license under any Henkel Corporation patents that may cover such processes or compositions.We recommend that each prospective user test his proposed application before repetitive use,using this data as a guide.This product may be covered by one or more United States or foreign patents or patent applications.Trademark usageExcept as otherwise noted,all trademarks in this document are trademarks of Henkel Corporation in the U.S.and elsewhere. ®denotes a trademark registered in the U.S.Patent and Trademark Office.Reference0.2。

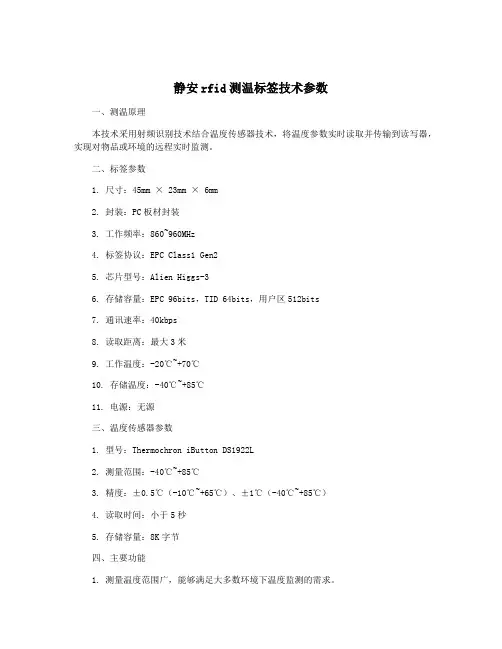

静安rfid测温标签技术参数一、测温原理本技术采用射频识别技术结合温度传感器技术,将温度参数实时读取并传输到读写器,实现对物品或环境的远程实时监测。

二、标签参数1. 尺寸:45mm × 23mm × 6mm2. 封装:PC板材封装3. 工作频率:860~960MHz4. 标签协议:EPC Class1 Gen25. 芯片型号:Alien Higgs-36. 存储容量:EPC 96bits,TID 64bits,用户区512bits7. 通讯速率:40kbps8. 读取距离:最大3米9. 工作温度:-20℃~+70℃10. 存储温度:-40℃~+85℃11. 电源:无源三、温度传感器参数1. 型号:Thermochron iButton DS1922L2. 测量范围:-40℃~+85℃3. 精度:±0.5℃(-10℃~+65℃)、±1℃(-40℃~+85℃)4. 读取时间:小于5秒5. 存储容量:8K字节四、主要功能1. 测量温度范围广,能够满足大多数环境下温度监测的需求。

2. 可根据具体应用场景选择不同的读写器,实现远距离读取,并可联网传输温度数据。

3. 小巧的封装使标签易于安装,可粘贴或挂钩在物品表面。

4. 高精度的温度传感器将温度读数传输到标签芯片,提高了温度数据的准确性和可靠性。

5. 标签芯片存储容量大,可以存储设备和环境的编号、位置、时间和温度信息等关键数据。

6. 可实现对多个标签的批量读取,提高温度监测的效率和精度。

五、应用领域本技术适用于温度监测领域,如食品、药品、化妆品、医疗器械、冷链物流等行业。

可以实现对产品的全程温度监测,保证产品的质量和安全,提高客户体验。

六、应用案例1. 食品安全监测在食品行业中,餐饮、食品制造、生鲜物流等环节的温度监测是确保食品质量安全的关键。

利用静安RFID测温标签技术,可以实现对食品全程温度监测,对食品历史温度进行回溯分析,保证食品质量和安全性,提高食品行业的信誉度。

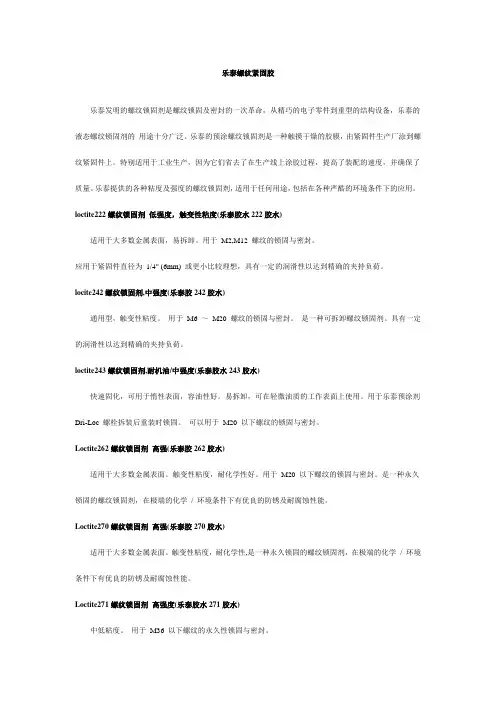

乐泰螺纹紧固胶乐泰发明的螺纹锁固剂是螺纹锁固及密封的一次革命,从精巧的电子零件到重型的结构设备,乐泰的液态螺纹锁固剂的用途十分广泛。

乐泰的预涂螺纹锁固剂是一种触摸干燥的胶膜,由紧固件生产厂涂到螺纹紧固件上。

特别适用于工业生产,因为它们省去了在生产线上涂胶过程,提高了装配的速度,并确保了质量。

乐泰提供的各种粘度及强度的螺纹锁固剂,适用于任何用途,包括在各种严酷的环境条件下的应用。

loctite222螺纹锁固剂低强度,触变性粘度(乐泰胶水222胶水)适用于大多数金属表面,易拆卸。

用于M2,M12 螺纹的锁固与密封。

应用于紧固件直径为1/4" (6mm) 或更小比较理想,具有一定的润滑性以达到精确的夹持负荷。

locite242螺纹锁固剂,中强度(乐泰胶242胶水)通用型,触变性粘度。

用于M6 ~M20 螺纹的锁固与密封。

是一种可拆卸螺纹锁固剂。

具有一定的润滑性以达到精确的夹持负荷。

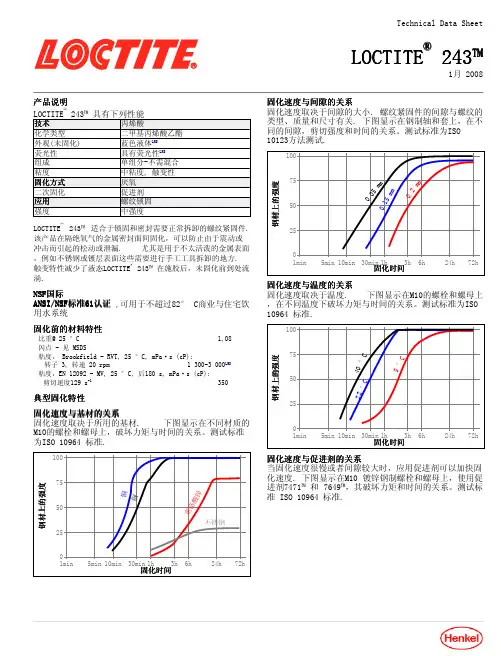

loctite243螺纹锁固剂,耐机油/中强度(乐泰胶水243胶水)快速固化,可用于惰性表面,容油性好。

易拆卸,可在轻微油质的工作表面上使用。

用于乐泰预涂剂Dri-Loc 螺栓拆装后重装时锁固。

可以用于M20 以下螺纹的锁固与密封。

Loctite262螺纹锁固剂高强(乐泰胶262胶水)适用于大多数金属表面。

触变性粘度,耐化学性好。

用于M20 以下螺纹的锁固与密封。

是一种永久锁固的螺纹锁固剂,在极端的化学/ 环境条件下有优良的防锈及耐腐蚀性能。

Loctite270螺纹锁固剂高强(乐泰胶270胶水)适用于大多数金属表面。

触变性粘度,耐化学性,是一种永久锁固的螺纹锁固剂,在极端的化学/ 环境条件下有优良的防锈及耐腐蚀性能。

Loctite271螺纹锁固剂高强度(乐泰胶水271胶水)中低粘度。

用于M36 以下螺纹的永久性锁固与密封。

Loctite272螺纹锁固剂高温高强度(乐泰胶272胶水)耐高温达230 ℃。

可用于汽缸头双头螺纹锁固。

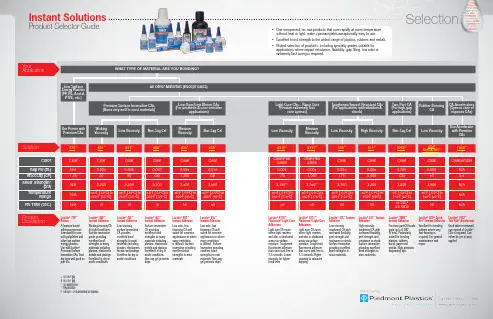

Instant SolutionsProduct Selector GuideSelectionLoctite ® 3092™ Instant Adhesive Fast two-part CA bonds gaps up to 0.200” (5 mm). Particularly suited for bonding plastics, rubbers, wood, paper andmetals. High precision dispensing tips.Loctite ® 454™ Instant Adhesive Surface insensitive CA providing excellent bond strengths to many materials including plastics, elastomers, metals and platings. Excellent for dry or acidic conditions. Non-sag gel prevents drips.Loctite ® 435™ Instant AdhesiveLow viscositytoughened CA with increased flexibility, peel strength and resistance to shock. Surface insensitive providing excellent bond strengths to most materials.Loctite ® 411™ Instant AdhesiveHigh viscosity toughened CA with increased flexibility, peel strength and resistance to shock. Surface insensitive providing excellent bond strengths to most materials.Loctite ® 406™ Instant Adhesive Wicking viscosity CA for tight bond lines. Surface insensitive grade providing excellent bond strengths to many materials including plastics, elastomers metals and platings. Excellent for dry or acidic conditions.Loctite ® 401™ Instant Adhesive Low viscosity surface insensitive CA provides excellent bond strengths to most materials including plastics, elastomers metals and platings. Excellent for dry or acidic conditions.What type of materIal are you bondIng?low Surface energy plastics (pp , pe, acetal, ptfe, etc.)all other materials (except glass)premium Surface Insensitive Cas (bond very well to most materials)low odor/low bloom Cas (for aesthetic & odor sensitiveapplications) light Cure Cas – rapid Cure (provide extremely fastcure speeds) toughened/Impact resistant Cas (for applications with vibration &shock)two-part Ca (for high gap applications)rubber bondingCaCa accelerators (Speeds cure of exposed Cas)use primer with premium Cas Wicking Viscositylow Viscosity non-Sag gelmedium Viscositynon-Sag gel low Viscositymedium Viscositylow Viscosity high Viscosity non-Sag gel low Viscosityuse accelerator with premiumCas770™406™401™454™403™455™4310™4311™435™411™3092™404®Quick Set ™7452™Color Clear Clear Clear Clear Clear Clear Clear/Pale Green Clear/Pale Green Clear Clear Clear Clear Clear/Ambergap fill (in.)N/A 0.0040.0050.0100.0080.0100.0040.0080.0060.0080.2000.005N/A Viscosity (cp) 1.252090Gel 1,200Gel 1751,0501755,000Gel 800.4Shear Strength*(psi)N/A 3,2003,2003,2002,6002,6003,190**3,760**2,7003,2003,2003,500N/A temperaturerange N/A -65°F (-54°C) to 250°F (121°C)-65°F (-54°C) to 250°F (121°C)-65°F (-54°C) to 250°F (121°C)-65°F (-54°C) to 200°F (93°C)-65°F (-54°C) to 200°F (93°C)-65°F (-54°C) to 240°F (116°C)-65°F (-54°C) to 240°F (116°C)-65°F (-54°C) to 225°F (107°C)-65°F (-54°C) to 210°F (99°C)-4°F (-20°C) to 176°F (80°C)-65°F (-54°C) to 180°F (82°C)N/A fix time (sec.)N/A1515155040<5µ<5µ303015 sec.¥ 3.5 min.§30N/ASolutionProduct Description•One-component, no-mix products that cure rapidly at room temperature without heat or light, make cyanoacrylates exceptionally easy to use.•Excellent bond strength to the widest range of plastics, rubbers and metals.•Widest selection of products, including specialty grades suitable for applications where impact resistance, flexibility, gap filling, low odor or extremely fast curing is required.Loctite ® 403™ Instant Adhesive Low odor, low blooming CA well suited for cosmetic applications or where vapor ventilation is difficult. Surface insensitive providing excellent bond strengths to most materials.Loctite ® 455™ Instant Adhesive Low odor, low blooming CA well suited for cosmetic applications or where vapor ventilation is difficult. Surface insensitive providing excellent bond strengths to most materials. Non-sag gel prevents drips.Loctite ® 4310™Flashcure ® Light Cure AdhesivesLight cure CA cures where light reaches and also in shadowed areas via surface moisture. Toughened, fluorescent adhesive that cures tack free in 2-5 seconds. Lower viscosity for tighter bond lines.¥At 0.002" gap.§At 0.200" gap.* Grit-blasted steel.** Polycarbonate.µFull cure = 24 hours without UV exposure.Loctite ® 4311™Flashcure ® Light Cure AdhesivesLight cure CA cures where light reaches and also in shadowed areas via surface moisture. Toughened, fluorescent adhesive that cures tack free in 2-5 seconds. Higher viscosity to minimize dripping.Loctite ® 404® Quick Set ™ Instant Adhesive Excellent for bonding rubbers where very fast fixturing isrequired. For general maintenance and repair.Loctite ® 7452™Tak Pak ® Accelerator Used where increased cure speed of Loctite ® CAs is required. Can either be pre or post applied.Loctite ® 770™ PrimerA heptane based adhesion promoter formulated for use with polyolefins and other low surface energy plastics. Use with Loctite ® Premium Surface Insensitive CAs. Fast dry time and good on part life.YourApplication。

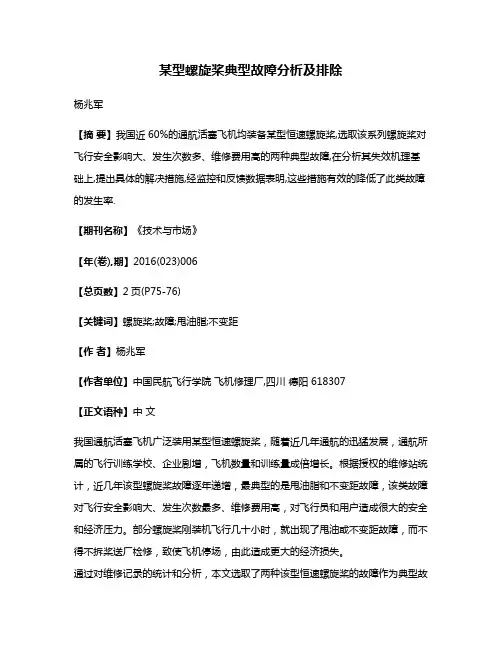

某型螺旋桨典型故障分析及排除杨兆军【摘要】我国近60%的通航活塞飞机均装备某型恒速螺旋桨,选取该系列螺旋桨对飞行安全影响大、发生次数多、维修费用高的两种典型故障,在分析其失效机理基础上,提出具体的解决措施,经监控和反馈数据表明,这些措施有效的降低了此类故障的发生率.【期刊名称】《技术与市场》【年(卷),期】2016(023)006【总页数】2页(P75-76)【关键词】螺旋桨;故障;甩油脂;不变距【作者】杨兆军【作者单位】中国民航飞行学院飞机修理厂,四川德阳 618307【正文语种】中文我国通航活塞飞机广泛装用某型恒速螺旋桨,随着近几年通航的迅猛发展,通航所属的飞行训练学校、企业剧增,飞机数量和训练量成倍增长。

根据授权的维修站统计,近几年该型螺旋桨故障逐年递增,最典型的是甩油脂和不变距故障,该类故障对飞行安全影响大、发生次数最多、维修费用高,对飞行员和用户造成很大的安全和经济压力。

部分螺旋桨刚装机飞行几十小时,就出现了甩油或不变距故障,而不得不拆桨送厂检修,致使飞机停场,由此造成更大的经济损失。

通过对维修记录的统计和分析,本文选取了两种该型恒速螺旋桨的故障作为典型故障来分析和研究,并期望该型螺旋桨用户能够利用本文的研究成果,降低螺旋桨的故障率,以降低训练费用,确保飞行安全。

1)甩油脂故障,又分为:桨叶根部与桨毂配合处甩油脂;前、后两半桨毂桨根接缝处甩油脂,如图1。

2)不变距故障,是指螺旋桨不变距或变距范围小于厂家规定值。

1)由于螺旋桨在高速旋转中会与空气中小的尘埃、杂质以及跑道上沙粒碰撞,加之螺旋桨本身的振动,这样会在桨叶表面上产生小的损伤和疲劳层。

翻修螺旋桨时,必须对桨叶表面进行打磨抛光处理,去除一定桨叶材料,并且对桨根部分进行滚压,致使桨根直径变小。

多次翻修后导致桨叶根部与桨毂之间配合间隙增大,密封件的拉伸量和压缩率减小,密封失效。

螺旋桨高速旋转时,桨根轴承内的润滑脂在离心力的作用下,在该处向外甩出。

LumiTop 2700/4000 Spectrally enhanced imaging colorimeter\\ L ab specs meet production speedThe LumiTop 2700/4000 combines the accuracy of Instrument Systems’ well-known spectroradiometers of the CAS series with the obvious advantages of imaging colorimetry. Principle: Fast and accurate With the help of a polarization insensitive, three-way beam splitter, the LumiTop 2700/4000 mergesan RGB CCD/CMOS camera anda flicker diode with the high-end spectroradiometer of the CAS series. This innovative design allows for simultaneous measurements of all components, which may result in significant time-savings.At the same time, the extremely accurate spectral information of the spectroradiometer measurement is used as reference for the camera measurement. This guarantees spectroradiometric accuracy across the whole 2D image.As a result, the LumiTop 2700/4000 not only performs fast 2D measurements with unprecedented accuracy but also offers all the advantages of classical imaging colorimetry. Perfect for productionBecause of this combination, theLumiTop 2700/4000 is perfectfor use in display productionlines or quality control, where thebenefits and capabilities of both,the accurate spot measurement ofspectroradiometers and the lateralresolution of camera measurementsare highly valued.All-in-one solutionMany different test applications cannow be organized in a single teststation:y M easurement of luminance andcolory E valuation of color and luminanceuniformity or Mura effectsy P ixel metrology including pixeldefect analysisy C ontrast measurementy A nalysis of white balance or colorgamuty F licker and luminance modulationmeasurementy A nalysis of the acquired spectraEasy to integrate intoproduction linesThe LumiTop 2700/4000 isintegrated in Instrument Systems’comprehensive new software“LumiSuite”, which comes witha user-friendly GUI for laboratoryapplications and a powerfulsoftware development kit for easyimplementation into any productionline. The spectra measured asreference for the camera can beanalyzed in more detail usingInstrument Systems’ well-knownsoftware SpecWin Pro.Independent of displaytechnologyDue to the high absolute accuracyof the CAS spectroradiometer thatis used as reference during eachmeasurement, the performanceof the solution is excellent for anydisplay technology (or any otherhomogeneous samples). Moreoverno golden sample or user calibrationsare needed. This makes the solutionparticularly favorable when OLEDs orother narrow-banded light sourceshave to be investigated where classicalimaging colorimeters based on XYZfilter technologies reach their limits.ModularityThe LumiTop 2700/4000 is designedas a modular accessory to any of thespectroradiometers of the CAS series.Thus the same spectroradiometerscan also be used with the telescopicoptics TOP 150 or TOP 200.\\Technical specifications1)Inclusive lens and fiber exit.2)Without CAS, with mode mixer.3)E xternal neutral density filters on the lens (OD 0.3/0.6/0.9) are available for increasingthe upper measurement limit or measuring modulated light sources.4)L ower measurement limit based on a signal to noise ratio of 10:1 for maximumexposure time (60 seconds LumiTop 2700 / 10 seconds LumiTop 4000). Uppermeasurement limit based on a signal level < 80 % for a white (non-modulated) LED light source using for minimum exposure time (1 ms LumiTop 2700 / 27 µs LumiTop 4000).5)T ypical value for maximum deviation over the FOV relative to the CAS spot;calculated for an image with 16 pixels (LumiTop 2700) / 21 pixels (LumiTop 4000) cropped at each edge and 10 by 10 pixels (LumiTop 2700) / 13 by 13 pixels(LumiTop 4000) binning (34 averages) immediately after calibration with reference used for flat-field correction.6)2σ of repeated measurements of one instrument (L ≈ 100 cd/m2, autoexposure).7)R NU (response non-uniformity) is defined as 99.7 % percentile of the deviationof the mean image value; calculated for an image with 16 pixels (LumiTop 2700) /21 pixels (LumiTop 4000) cropped at each edge and 10 by 10 pixels (LumiTop 2700) /13 by 13 pixels (LumiTop 4000) binning (34 averages) immediately after calibrationwith reference used for flat-field correction.8)T ime between beginning of two subsequent measurements using the SDK;determined with a camera exposure time of 20 ms and CAS exposure time of200 ms for a white LED (L ≈ 500 cd/m2). Depends mainly on PC processing capability.9)L ower measurement limit based on a signal to noise ratio of 10:1 for maximumexposure times 65 s for CAS 140D and CAS 140CT, 20 s for CAS 120. Uppermeasurement limit based on a signal level < 80 % for a white (non-modulated) LED light source using a CAS internal optical density filter OD4 and minimum exposure time (10 ms CAS 140CT / 4 ms CAS 140D and CAS 120). Values valid for CAS 140CT, CAS 120 with 100 μm and CAS 140D with 250 μm slit width.10)I mmediately after calibration relative to calibration standard.11)I mmediately after calibration.12)M aximum deviation from average of repeated CAS measurements with a linearpolarized light source and varying polarization angle.13)L ≈ 150 cd/m2, 30 Hz, 10 % sine wave.14) 2σ of repeated measurements of one instrument.15)Distance between DUT and front plate of LumiTop.We bring quality to light.Instrument Systems GmbH Kastenbauerstr. 281677 Munich, Germany ph: +49 (0)89 45 49 43-58 fax: +49 (0)89 45 49 43-11 **************************b _L u m i T o p _e n _V 1.7Instrument Systems is continually working on the further development of its products. Technical changes, errors and misprints do not justify claims for damages. For all other purposes, our Terms and Conditions of Business shall be applicable.。

技术数据表LOCTITE® 401™2月2012产品描述:®本技术数据表适用于“生产日期参考”部分提及的日期后生产的LOCTITE® 401™401™.LOCTITE® 401™适合于难粘基材的粘接,且能使应力均匀分布并具有很强的拉伸力和/或剪切力.该产品适用范围广,可用于大多数金属,塑料或弹性材料的快速粘接.LOCTITE® 401™尤其适合于粘接多孔或吸收材料,例如木材,纸,皮革或织物.NSF国际认可NSF P1注册认可可在不和食物及周围食品加工领域接触的地方作为密封剂使用。

注意: 这是一个区域性认可。

如需更多资料和说明请与当地的技术服务中心联系。

固化前的材料特性密度@25°C 1.1闪点-见MSDS粘度测量仪,mPa.s(cp):温度: 25°C,剪切速率:3,000s-170至110LMS布氏粘度, -LVF, 25°C,mPa.s(cp):转子1, 转速30rpm100至120典型固化特性一般情况下,材料表面的湿气会引发本产品的固化反应。

尽管本产品在相当短的时间内就可达到应用强度,但是至少要固化24小时才能具有完全的耐化学/溶剂性能。

固化速度与基材的关系固化速度取决于被粘接的基材,下表表明在22°C/ 50%相对湿度的情况下,不同基材的初固时间。

初固时间是定义样件的剪切强度达到0.1N/mm² 的时间初固时间,秒:钢材<5铝<5氯丁橡胶<5丁腈橡胶<5ABS<5PVC<5聚碳酸酯5至10酚醛树脂<5木材 (巴尔沙木)<5木材 (橡木)15至30木材(松树)木材(松)15至20硬纸板<5织物10至20皮革15至30纸<5固化速度与粘接间隙的关系固化速度取决于粘接间隙。

粘接间隙小固化速度快,粘接间隙增大将降低固化速度.固化速度与湿度的关系固化速率取决于环境相对湿度。

Loctite222—低强度螺纹锁固剂低强度、可拆卸,触变性粘度。

适用于大多数金属表面,易拆卸。

用于M2,M12螺纹的锁固与密封。

应用于直径不大于1/4"的紧固件时效果最好,具有一定的润滑性以达到精确的夹持负荷。

Applications低强度、可拆卸Loctite242—中强度螺纹锁固剂通用型,触变性粘度。

用于M6—M20螺纹的锁固与密封。

是一种可用普通工具拆卸的螺纹锁固剂。

具有一定的润滑性以达到精确的夹持负荷。

Applications中强度,可拆卸。

Specifications颜色:蓝色;粘度(mPa.s):1200~5000;平均拆卸力矩(N.m):4.9;平均破坏力矩(N.m):12.4;温度范围(℃):-18~150;固化速度钢@25℃:24小时;推荐促进剂:7649/7471;比重:1Loctite243—中强度螺纹锁固剂中强度、容油性好快速固化,可用于惰性表面,容油性好。

易拆卸,可在轻微油质污染的工作表面上使用。

用于乐泰预涂剂Dri—Loc螺栓拆装后重装时锁固。

可以用于M20以下螺纹的锁固与密封。

Applications大到19mm螺钉,轻微油膜表面Specifications颜色:蓝色;粘度(mPa.s):1300~3000;平均拆卸力矩(N.m):7;平均破坏力矩(N.m):20;温度范围(℃):-18~150;固化速度钢@25℃:3小时;推荐促进剂:7649/7471;比重:1.08Loctite262—高强度螺纹锁固剂高强度、耐溶剂性能优良适用于大多数金属表面。

触变性粘度,耐化学性好用于M20以下螺纹的锁固与密封。

是一种永久锁固的螺纹锁固剂,在极端的化学/环境条件下有优良的防锈及耐腐蚀性能。

Applications大到19mm螺钉,永久锁固Specifications颜色:红色;粘度(mPa.s):1200~2400;平均拆卸力矩(N.m):32;平均破坏力矩(N.m):22;温度范围(℃):-18~150;固化速度钢@25℃:10小时;推荐促进剂:7649/7471;比重:1.1Loctite271—高强度螺纹锁固剂高强度、中低粘度用于M36以下螺纹的永久锁固与密封。

1.产品简介产品乐泰271是一种单组分,触变性,高强度,厌氧型螺纹锁固胶。

本产品在隔绝空气的条件下,在两个紧密配合的金属面间固化。

颜色粘度(mPa.s)平均拆卸力矩(N.m)平均破坏力矩(N.m)温度范围(℃)固化速度钢@25℃推荐促进剂比重红色400~60025-4017-40-18~15024小时7649/74711.12.典型用途典型应用:大到25.4mm直径螺钉,避免螺纹紧固件的松动和渗漏,尤其适用于不移动的场合,如汽缸衬垫螺柱,汽车前端悬挂螺栓或液压系统中的螺柱。

乐泰Loctite®271—高强度螺纹锁固剂.高强度、中低粘度用于M36以下螺纹的永久锁固与密封。

3应用范围螺纹密封剂防止气体和液体从管道接头泄漏。

由于振动、压力或温度不断变化,所有这些接头都是动态的。

乐泰厌氧密封剂固化成不溶性硬塑料螺纹填料,无论是否施加扭矩该填料都可用来防止泄漏。

螺纹锁固剂是单组分厌氧锁固剂,它完全填补了界面连接螺纹之间的微小间隙。

在没有空气的情况下接触金属时,锁固剂聚合成坚硬的固体。

3.1正排量系统乐泰®品牌正排量ID孔径涂料系统可有效地应用螺纹锁固剂、固齿胶和其它低粘度至中等粘度的厌氧材料(具有内孔直径)。

根据产品粘度,每分钟可达到120个周期。

可为每位客户的过程需求选择多种旋压封头。

乐泰®品牌正排量泵具有专利无密封设计。

气动泵提供了可重复、一致的产品交付。

3.2压力时间贮存器点胶系统根据产品粘度,乐泰®品牌压力时间ID孔径涂层系统将有效适用于厌氧高达每分钟60个周期。

压力容器装置由重型拉伸成形单件钢制成,配备了压力调节器、量规、安全卸压阀和产品输送线连接器。

更多信息请上网查询

L-GAGE ® LH

LH系列高精度激光位移(及测厚)传感器

LH系列为一款基于三角测量法的高精度激光位移传感器。

可高速,非接触,及可靠地测量各种目标物如:金属, 木材, 陶瓷, 纸张和上漆目标物。

其1024像素CMOS线性光学组件可克服以往PSD激光位移传感器因为颜色变化和材料不同而过多影响其测量精度。

• 超高精度,坚固外壳 • 一体式的激光位移传感器 • 精密集束的红色激光光癍

• 精确可靠地测量各种目标物金属, 木材, 陶瓷, 纸张和上漆目标物 • 非接触式激光精确测量用于检测移动目标物,热零件,加工工件, 粘性柔软物体 • 4-20 mA 模拟量输出 • 即插即用设置• 1024 像素 CMOS 线性图像接收器• 高级图像处理算法

• 能可靠测量黑色及反光物体 • 两台LH可自行同步作为测厚仪 • 无需外部控制器

• 精确的厚度测量而无需担心震动变化;如印刷机械中纸带颤动器纸 张厚度的测量

• 测厚数据可通过4-20 mA 或 RS-485 串口数据输出 •

IP67防护等级

更多信息请上网查询

产品选型:

®

SMBLH1。