MCO系列离心压缩机装配工艺研究

- 格式:ppt

- 大小:123.50 KB

- 文档页数:37

2MCL457离心压缩机结构设计东北大学2011年6月Design of 2MCL457 centrifugal compressorNortheastern UniversityJune 2011毕业设计(论文)任务书2MCL457离心压缩机结构设计摘要压缩机是用以提高各种气体压力的一种通用机械,是机械工业中量大面广的产品之一。

在国民经济许多部门中得到十分广泛的应用,几乎遍及工业、农业、交通运输、医疗卫生、国防、科研乃至人民生活的许多领域,尤其是在化工、合成、煤炭、石油、建筑施工、海洋工程等方面,更是必不可少的动力设备。

离心式压缩机主要应用于石油化工等领域,并且是石化装置中最关键最核心的设备之一,设备的可靠运行对整个石化装置的意义非常重大。

本课题主要是针对目前国内石化行业对离心式压缩机的需求,完成2MCL457型离心式压缩机的结构设计,并在压缩机的结构、效率等方面做一些优化和完善的工作,特别是对转子的制造和质量控制方面进行探究,以提高压缩机的性能水平和设计水平。

首先,对压缩机结构方案进行验证、选择,其中要进行压缩机结构型式的选择。

然后,完成技术选择和压力比的分配,进而确定压缩机的叶轮的主要参数。

从而确定压缩机整体的主要技术参数,再根据所得参数,计算出所需功率及电机轴功,选配电机。

根据给定的设计目标和相关标准要求,参考相关文献和资料进行设计计算,确定2MCL离心压缩机的基本参数,进而进行结构设计和强度校核。

在此基础上,完成产品的工程图纸,并完最终成产品设计。

其中,重点是对提高转子的制造质量进行探究,并在设计中予以关注。

关键词:空气压缩机;离心式;2MCL型;结构设计Design of 2MCL457 centrifugal compressorAbstractCompressor is used to increase the pressure of various gases as general machinery; the machinery industry is one of widely used products. Compressor in the national economy in many sectors are very widely used, almost every industry, agriculture, transportation, health care, national defense, scientific research and even in many areas of people's lives. Especially in the chemical, synthetic, coal, petroleum, construction, marine engineering, power equipment is essential. centrifugal compressor is mainly used in petrochemical industry, petrochemical plant and is the most critical one of the core equipment, equipment installation and reliable operation of the entire petrochemical very significant.The design should first conduct a literature search, access to relevant information and compressor references to verify the program on the compressor structure, options, including the 2MCL457 centrifugal compressor structure type selection and the choice of sports organizations. Especially in order to improve the performance level of the compressor and the design lever, experts explore the manufacture quality of the rotor.First, designers should select and validate the compressor structure program, which to conduct the selection of structure type compressor. Then, the technical choices and the distribution of pressure ratio determine the main parameters of the compressor impeller. designers calculate the required power and matching motor, then select the motor shaft power, according to the main technical parameters of the compressor as a whole and the basis of the parameters.According to a given design goals and related standards, reference documents and information related to the design calculations to determine 2MCL457 centrifugal compressor basic parameters for the structural design and strength check. On this basis, the completion of engineering drawings, and eventually into a complete product design. Also, focusing on the manufacture quality of the rotor.Key words: Air compressor; centrifugal type; 2MCL-type; structural design目录毕业设计(论文)任务书 (I)摘要 (II)Abstract (III)第1章绪论 (1)1.1 压缩机简介 (1)1.1.1 压缩机的分类 (1)1.1.2 压缩机的用途 (3)1.2 国内外发展现状 (4)1.2.1大流量离心压缩机研究现状 (4)1.2.2小流量离心压缩机研究现状 (7)1.2.3 压缩机的新发展 (7)1.3 本课题研究的意义与内容 (9)第2章工作原理与结构设计 (11)2.1 离心压缩机的工作原理 (11)2.1.1 离心压缩机的主要特点 (11)2.2 压缩机的结构设计及方案选择 (12)2.2.1离心式压缩机的主要结构 (12)第3章主要技术参数的设计与计算 (14)3.1 级数选择和各级压力比的分配 (14)3.1.1 级数的选择 (14)3.1.2流量系数的选择 (14)3.1.3理论能量头的计算 (14)3.1.4轮阻损失与漏气损失系数比的选取 (15)3.1.5总能量头的计算 (15)3.1.6多变效率ηpol的选取 (16)3.1.7各级压力比的选择 (16)3.2 叶轮主要参数的确定 (17)3.3 工作气体各个参数的确定以及电动机的选择 (17)3.3.1 各级出口压力的计算 (17)3.3.2 出口温度的计算 (18)3.3.3 各级进口流量及出口流量的计算 (18)3.3.4 等熵指数的kv2选取 (19)3.3.5 叶轮出口相对宽度的计算 (19)3.3.6 电机的选择 (20)3.4 主轴的校核 (20)第4章单轴多级离心压缩机转子的制造与质量控制研究(专题)22 4.1 转子的简介及组成 (22)4.2 叶轮的加工方案及质量控制 (22)4.2.1缺陷的类型和分析 (22)4.2.2缺陷处理方法的探讨 (23)4.2.3补焊处理 (24)4.3主轴的加工 (25)4.3.1主轴的特点 (25)4.3.2主轴的材料 (26)4.3.3主轴的加工 (26)4.3转子动平衡方案的选择 (26)4.3.1高、低速动平衡方案的确定 (27)4.3.2动平衡精度的确定 (28)第5章环保及经济性分析 (30)第6章结论 (31)参考文献 (32)致谢 (34)附录 (35)第1章绪论1.1 压缩机简介压缩机是用以提高各种气体压力的一种通用机械,是机械工业中量大面广的产品之一。

离心压缩机生产装配工艺流程英文回答:Centrifugal compressors are widely used in various industries for compressing air, gases, and refrigerants. As a production assembly technician, my role is to ensure that the centrifugal compressors are manufactured and assembled according to the established process. Here is a step-by-step guide on the production assembly process ofcentrifugal compressors.1. Component Preparation:Before starting the assembly, all the components required for the centrifugal compressor are prepared. This includes checking the quality and quantity of each component, ensuring that they meet the specifications and standards. For example, I would inspect the impeller blades, diffuser vanes, and shafts to ensure they are free from any defects or damages.2. Assembly of Major Components:The major components of a centrifugal compressor include the impeller, diffuser, casing, and shaft. I would start by mounting the impeller onto the shaft, ensuring proper alignment and balance. Then, I would assemble the diffuser vanes onto the casing, ensuring they are positioned correctly for optimal airflow. Finally, I would attach the casing to the impeller-shaft assembly, ensuring a secure fit.3. Sealing and Lubrication:To ensure efficient operation and prevent leakage, I would apply sealing materials, such as gaskets or O-rings, at appropriate locations. Additionally, I would lubricate the bearings and other moving parts to reduce friction and wear. This step is crucial for the longevity and performance of the centrifugal compressor.4. Electrical Connections:Centrifugal compressors often require electrical connections for motor operation and control. I would carefully connect the electrical wires to the designated terminals, following the wiring diagram or instructions provided. It is important to ensure proper insulation and secure connections to avoid any electrical issues.5. Testing and Quality Assurance:Once the assembly is complete, the centrifugal compressor undergoes rigorous testing to ensure its performance and reliability. This includes conducting pressure tests, checking for any abnormal vibrations or noises, and verifying the compressor's efficiency. If any issues are identified, adjustments or repairs are made before the final product is approved for shipment.中文回答:离心压缩机广泛应用于各个行业,用于压缩空气、气体和制冷剂。

简析大型离心压缩机的安装工艺及质量控制摘要:随着我国经济的快速发展,各种科学技术也得到了优化,工业化水平也得到了快速的提升,越来越多的科学技术被运用于工业生产之中,而大型的离心压缩机是现代工业生产当中最普遍的设备之一。

大型离心压缩机成为现代石油化工业的重要设备,在工业生产当中,发挥着越来越重要的作用。

本文阐述了大型离心压缩机概念,分析了大型离心压缩机安装的工艺,基于此,探究了大型离心压缩机的质量管控措施。

关键词:大型离心压缩机安装工艺质量控制前言:大型离心压缩机成为石油化工行业的重要生产设备。

由于大型离心压缩机功率大、转速高、一次性投资高,因此,在使用过程当中是以单机配置的状态没有备用机,一旦发生了故障,将会导致企业生产停滞。

为此,大型压缩机的制造、组建、安装以及试运行等多个环节都要进行严格的把控,这些将直接关系到设备的后期运行。

一、大型离心压缩机概述离心式压缩机是一个非常精密和复杂的设备,其主要的作用是能对气体介质进行加压,并匹配相对应的装置工艺。

压缩机通常通常由两个部分组成:转子和定子共同组成,其中转子包括了平衡板、主轴和叶轮等部件;而定子则包括了蜜封、隔板和机壳等,而电动机或者汽轮机会带动着压缩机进行旋转,那么,旋转的过程当中就会产生离心力的作用,气体随着叶轮和扩压器刘速增加,使得气体能够快速的流畅通过,而失去了大量气体后就会变得十分的稀薄,由此,增加压缩机自身的压力,在气体快速转动的过程当中,离开叶伦。

而气体在扩压器的作用之下进行能量转换,使得转速在不断的减慢,这样,气体的转动动能就被转换成了压缩机本身的静止的压缩能,进而提高气体介质压力[1]。

大型离心压缩机主要利用叶轮来控制气流,由此产生的气体,使得被压缩的气体速度、压力以及温度得到良好的控制。

当气体进入到扩压器之后,会大大降低机器的运行效率,由此增大了压力。

而运行的过程需要多级结构并运用规范的方式进行操作,装配之前需要检测仪器设备的配件是否完好,压缩机的中各项零件是否符合压缩机的结构要求。

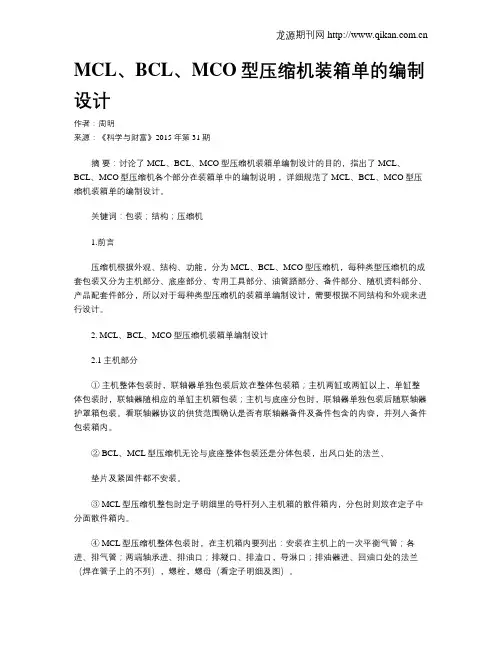

MCL、BCL、MCO型压缩机装箱单的编制设计作者:周明来源:《科学与财富》2015年第31期摘要:讨论了MCL、BCL、MCO型压缩机装箱单编制设计的目的,指出了MCL、BCL、MCO型压缩机各个部分在装箱单中的编制说明,详细规范了MCL、BCL、MCO型压缩机装箱单的编制设计。

关键词:包装;结构;压缩机1.前言压缩机根据外观、结构、功能,分为MCL、BCL、MCO型压缩机,每种类型压缩机的成套包装又分为主机部分、底座部分、专用工具部分、油管路部分、备件部分、随机资料部分、产品配套件部分,所以对于每种类型压缩机的装箱单编制设计,需要根据不同结构和外观来进行设计。

2. MCL、BCL、MCO型压缩机装箱单编制设计2.1主机部分①主机整体包装时,联轴器单独包装后放在整体包装箱;主机两缸或两缸以上,单缸整体包装时,联轴器随相应的单缸主机箱包装;主机与底座分包时,联轴器单独包装后随联轴器护罩箱包装。

看联轴器协议的供货范围确认是否有联轴器备件及备件包含的内容,并列入备件包装箱内。

② BCL、MCL型压缩机无论与底座整体包装还是分体包装,出风口处的法兰、垫片及紧固件都不安装。

③ MCL型压缩机整包时定子明细里的导杆列入主机箱的散件箱内,分包时则放在定子中分面散件箱内。

④ MCL型压缩机整体包装时,在主机箱内要列出:安装在主机上的一次平衡气管;各进、排气管;两端轴承进、排油口;排凝口、排渣口,导淋口;排油器进、回油口处的法兰(焊在管子上的不列),螺栓,螺母(看定子明细及图)。

各管口处的垫片除了椭圆垫、凸面石棉垫片及(SH3403-96)钢垫片安装在主机上以外,其它的都放在主机箱内的散件箱。

⑤ MCL型压缩机上、下定子分包时,定子明细里中分面零件与定子轴承区的零件分两箱包装,定子中分面零件箱或定子轴承区零件箱的净重不能超过2吨,若超出分箱包装。

Ⅰ定子中分面零件箱:包括导杆及所有的中分面拆下的散件,端盖箱,若有保护盖,列保护盖箱。

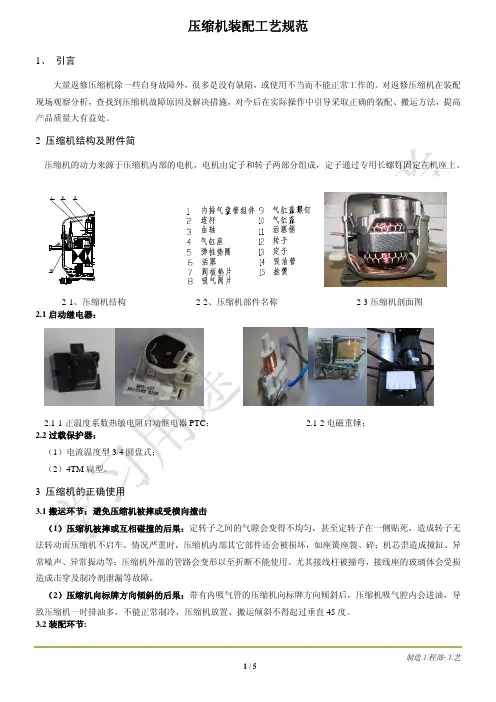

1、引言大量返修压缩机除一些自身故障外,很多是没有缺陷,或使用不当而不能正常工作的。

对返修压缩机在装配现场观察分析,查找到压缩机故障原因及解决措施,对今后在实际操作中引导采取正确的装配、搬运方法,提高产品质量大有益处。

2 压缩机结构及附件简介2.1-1正温度系数热敏电阻启动继电器PTC 2.1-2电磁重锤;2.2过载保护器:(1)电流温度型3/4圆盘式;(2)4TM扁型。

常噪声、异常振动等;压缩机外部的管路会变形以至折断不能使用。

尤其接线柱被撞弯,接线座的玻璃体会受损造成击穿及制冷剂泄漏等故障。

(2)压缩机向标牌方向倾斜的后果:带有内吸气管的压缩机向标牌方向倾斜后,压缩机吸气腔内会进油,导致压缩机一时排油多,不能正常制冷,压缩机放置、搬运倾斜不得起过垂直45度。

3.2装配环节:(1)防止焊堵:焊接压缩机排气管与系统管路时,插接深度不宜过浅;避免任意扩大外管;不要用大火长时间地加热;避免焊料熔化后从焊接间隙流下造成排气管焊堵。

一旦排气管路焊堵,压缩机工作产生的高压会造成密封垫破、吸气阀片断等缺陷,造成压缩机不排气。

(2)防止烘烤不当:焊接火焰不要长时间烘烤压缩机外壳,以避免高热使压缩机内的塑料消音器及绝缘材料变形、熔化。

(3)防止吸潮气或杂质:压缩机拔去胶堵后,应尽快焊接,包括对因箱体问题拆下的压缩机。

避免让压缩机管敞口时间过长,避免将大气做工质或在潮湿环境中运行,尤其是使用R134a工质的压缩机。

否则,容易造成潮气或杂质侵入,造成油吸潮变质,符合R134a要求的零件被污染、阀组积碳等缺陷,使系统不能正常工作。

(4)压缩机的减振:为获得良好的安装效果,应保证螺母和衬套之间的间隙,使压缩机传到底板上的振动减弱,另外还应保证橡胶垫和平垫片之间的间隙。

把橡胶减震块夹在与压机排气管相连的冷凝管上那一部分。

(5)TSD 的正确使用:TSD不能应用在带有与温控器并联元件的制冷系统中,即必须保证在温控器断开后,TSD不再通电。

离心压缩机生产装配工艺流程英文回答:Centrifugal compressors are widely used in various industries for compressing gases. The production and assembly process of centrifugal compressors involves several steps to ensure the final product meets the required specifications and quality standards.Firstly, the manufacturing process begins with the procurement of raw materials. This includes sourcing high-quality metals, such as steel or aluminum, for the compressor components. The raw materials are carefully inspected to ensure they meet the necessary standards for strength and durability.Once the raw materials are obtained, the next step is to prepare them for the assembly process. This involves cutting, shaping, and machining the materials into the required shapes and sizes. For example, the compressorimpellers, which are crucial components for compressing the gas, are carefully machined to achieve the desired dimensions and surface finish.After the components are prepared, they are then assembled together to form the compressor unit. This involves fitting the impellers, diffusers, and other components into the compressor casing. The assembly process requires precision and attention to detail to ensure all the components are properly aligned and secured.Once the compressor unit is assembled, it undergoes rigorous testing to ensure its performance and reliability. This includes testing the compressor's efficiency, pressure ratio, and overall performance under different operating conditions. Any issues or defects identified during the testing phase are addressed and resolved before the final product is released for use.In addition to the production and assembly process, quality control plays a crucial role in ensuring the reliability and performance of centrifugal compressors.Quality control measures include regular inspections, testing, and adherence to industry standards and regulations. This helps to identify any potential defectsor deviations from the required specifications and allowsfor corrective actions to be taken.Overall, the production and assembly process of centrifugal compressors involves careful planning,precision machining, meticulous assembly, and thorough testing. This ensures the final product meets the necessary quality standards and performs reliably in variousindustrial applications.中文回答:离心压缩机的生产装配过程包括多个步骤,以确保最终产品符合所需的规格和质量标准。

MCL型离心压缩机装置

1、MCL型离心压缩机的用途

●MCL型离心压缩机:主要应用与各种中低压工业装置。

(类似

这样)

●适用领域:炼油乙烯、合成氨尿素、甲醇、煤化工、化工等领

域。

(类似这样)

2、MCL型离心压缩机特点

●应用范围

流量:

入口压力:

入口温度:

转速范围:

●主要典型结构图

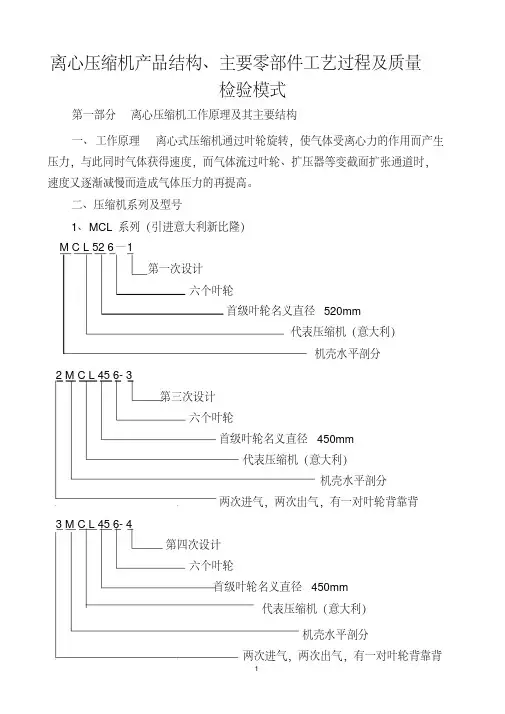

●命名说明(型号示例)(样本第四页)

●结构特点(样本第四页)

●配置特点

●技术特点

选型、密封、静叶、有限元分析等技术特点

●技术水平

设计、制造、加工水平符合国际有关通用标准及技术规范,具有与国外同类产品竞争的实力。

(类似这样的话)

3、产品的业绩

1)截至2012年为止,沈鼓已先后设计制造MCL型离心压缩机共?台套。

2)目前具有研制多大机组的能力?

4、订货说明

●用户需提供信息

●说明

可根据用户选型需要提供其他内容,如性能曲线等。

离心式压缩机装配工艺流程下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!离心式压缩机是一种高速旋转的机械设备,广泛应用于石油、化工、冶金、电力等领域。

离心压缩机装配工艺流程英文回答:As a manufacturing engineer, I am responsible for developing the assembly process for centrifugal compressors. The assembly process plays a crucial role in ensuring the quality and efficiency of the final product. Here, I will outline the steps involved in the assembly process for a centrifugal compressor.1. Preparation: Before starting the assembly process,it is important to gather all the necessary components and tools. This includes the compressor housing, impellers, bearings, seals, and various fasteners. Additionally, specialized tools such as torque wrenches and alignment fixtures are required for precise assembly.2. Inspection and cleaning: Each component isthoroughly inspected for any defects or damage. Any debrisor contaminants are removed through a cleaning process.This ensures that only high-quality components are used in the assembly.3. Housing assembly: The first step in the assembly process is to mount the compressor housing. This involves aligning the housing with the mounting points and securing it with appropriate fasteners. The housing provides the structure and support for the compressor.4. Impeller installation: The impellers are carefully installed inside the housing. They are aligned and secured using specific techniques to ensure proper functioning. The impellers play a crucial role in compressing the fluid and generating the desired pressure.5. Bearing and seal installation: The next step involves installing the bearings and seals. These components provide smooth rotation and prevent leakage of the compressed fluid. Proper alignment and lubrication are essential for their optimal performance.6. Connection of auxiliary components: Variousauxiliary components, such as sensors, control valves, and piping, are connected to the compressor. These components enable the monitoring and control of the compressor's operation.7. Testing and quality assurance: Once the assembly is complete, the compressor undergoes rigorous testing to ensure its performance and reliability. This includestesting for leakage, vibration, and overall efficiency. Any issues identified during testing are addressed andrectified.8. Final packaging and shipment: After passing all the quality checks, the compressor is packaged according to the specified requirements. It is then prepared for shipment to the customer.中文回答:作为一名制造工程师,我负责制定离心压缩机的装配工艺流程。

离心压缩机生产装配工艺流程英文回答:Centrifugal compressors are widely used in various industries for compressing gases. As a production assembly technician, my role is to ensure the smooth and efficient production of centrifugal compressors. The production assembly process involves several steps, which I will explain in detail.Firstly, we receive the necessary components and parts for the compressor. These parts include the impeller, diffuser, casing, bearings, and seals. Each component is carefully inspected for quality and compatibility before proceeding to the assembly stage.Next, the assembly process begins by attaching the impeller to the shaft. This requires precision andattention to detail to ensure proper alignment and balance. Once the impeller is securely attached, the diffuser isinstalled around it to direct the airflow.After the impeller and diffuser are in place, the casing is assembled around them. The casing provides support and protection for the internal components. It is crucial to ensure a tight and secure fit to prevent any leaks or inefficiencies.Once the casing is assembled, the bearings and seals are installed. The bearings allow the shaft to rotate smoothly, while the seals prevent any gas leakage. These components are carefully lubricated to reduce friction and increase the lifespan of the compressor.After the main components are assembled, the electrical and control systems are integrated into the compressor. This includes connecting the wiring, sensors, and control panels. The electrical systems are tested to ensure proper functionality and safety.Finally, the completed compressor undergoes a series of performance tests to ensure it meets the requiredspecifications. This includes testing the compression efficiency, flow rate, and pressure levels. Any adjustments or fine-tuning are made at this stage to optimize the compressor's performance.中文回答:离心压缩机在各个行业中被广泛应用于气体压缩。

离心式压缩机安装工序介绍

以及由转轴、多个叶轮、平衡鼓和止推环组成的转子部件等组成。

该压缩机的特点是:水平剖分式,进气管、排气管、润滑油管等都布置在下半部分机壳上,这样布置的好处是,只需拆去连接螺栓将上半部分机壳吊起,就可检修压缩机内部构件。

4.1 隔板束

隔板是静止部件,它构成了前级扩压器的半个壁面、部分回流器弯道和后级扩压器的半个壁面。

由于它使气体的压力升高,所以隔板既是结构部件,

又是一个气动力部件。

由于通过扩压器截面时气体

的速度很高,因而其表面光洁度对机组的整体效率有着重要的影响。

叶轮和隔板表面的堆积物会严重堵塞扩压器通道,将会导致压力损失增大,从而降低压缩机的总效率。

4.2 转子

转子由轮毂驱动,由止推轴承实现轴向定位,并由前后径向轴承支撑。

转子上装配有迷宫密封,。

单轴悬臂多级离心压缩机的研制

王军;郑志国;印明洋;李耀祖

【期刊名称】《风机技术》

【年(卷),期】2008(000)002

【摘要】阐述了MCO系列单轴悬臂多级离心压缩机的特点,在同种设计参数条件下,该机与常规单缸压缩机设计方案相比,提高了工作效率,降低了运行成本;与常规双缸压缩机方案相比不仅降低了制造成本、运行成本,而且减少了故障点,使机组运转更安全稳定,更易维护.

【总页数】4页(P5-8)

【作者】王军;郑志国;印明洋;李耀祖

【作者单位】沈阳鼓风机(集团)有限公司,沈阳市,110142;沈阳鼓风机(集团)有限公司,沈阳市,110142;沈阳鼓风机(集团)有限公司,沈阳市,110142;沈阳鼓风机(集团)有限公司,沈阳市,110142

【正文语种】中文

【中图分类】TH452

【相关文献】

1.1.5MW紧凑式单轴多级离心压气机设计 [J], 王永生;林峰

2.3万8空分单轴悬臂多级离心压缩机的研制 [J], 张玉珠;齐智勇

3.多轴组装式与传统单轴离心压缩机的比较 [J], 王广兰

4.SIC705单轴等温离心压缩机的结构特点 [J], 李国贵;梁启荣

5.煤制乙二醇现状及单级悬臂组装式酯化循环气离心压缩机的研制 [J], 孙家姝;亢天明

因版权原因,仅展示原文概要,查看原文内容请购买。