SKF机床主轴润滑系统

- 格式:ppt

- 大小:20.48 MB

- 文档页数:26

KFG/KFGS 油脂泵使用手册斯凯孚精密机械(上海)有限公司润滑应用中心1、安全指南概述所有部件按照劳动安全和事故预防的规则生产。

使用中仍有可能引起危险、造成使用者或者第三人及财产损失,因此此部件的使用严格按照操作使用指南的技术要求。

通常,可能引起安全问题的故障应立即排除。

应用领域S KF KFG和KFGS系列泵应用于车辆、设备、机床、风力发电机的集中润滑系统。

输送油脂黏度达到NIGL2。

任何超出此应用范围的被视为不按照指定应用条件。

授权安装技师只有有资质的工程师可以安装、操作、维护和修改本指南涉及的部件。

有资质的工程师是指经过培训,由设备用户指定或委任的人员,此类人员接受培训、具有经验、了解操作指南,熟悉相关的标准、规则、事故预防、故障排除及操作运行状况。

责任免除SKF 不承担由以下原因引起的损坏:z缺少润滑剂z使用固体润滑剂或不合适的润滑剂z安装使用非SKF原装零部件z未按照正常使用用途z安装或者连接错误z电气连接错误z编程错误z对于故障排除的误操作安装当在设备上执行安装工作时,必须遵守地方性的事故预防规则和相关的操作维护说明。

电流危险只有受培训的专业人员才能进行设备电气连接并参照当地的相关规则。

(例如:DIN,VDE)不正确的连接可能会引起材料和人员受损。

承压系统危险系统可能有带压力的,所以在开始检修、调整、或进行相关操作前必须卸压。

认可的润滑剂NIGL2号或以下油脂,可选润滑剂清单会不断更新,具体可参考以下网址:/portal/skf_lub或者致电:021-********润滑剂引起的环境危害推荐的润滑剂的成分由制造商按照当前的安全规则生产,油和油脂是危害土地和水源的物质,所以在储存、处理、运输需要满足特殊的安全规则。

运输储存KFG和KFGS系列泵按照VDA6-01和DIN ISO9001及接受国的规则进行销售包装。

对于公路运输、空运、海运没有限制。

保存在摄氏-40度和70度间干燥的地方。

- 67 -工 业 技 术风电机组变桨润滑油泵、主次分配器损坏严重、变桨润滑系统失效或者变桨轴承内废旧油脂无法及时排出以及轴承内腔油脂干涸皂化,会影响新鲜油脂在滚珠表面建立油膜,并导致轴承滚珠点蚀和保持架损坏。

随着注油量逐年增加,轴承中的废润滑油将随内腔压力的增加而增加。

大部分废润滑油从密封圈溢出,油封对轴承的密封效果将会降低,灰尘等杂质就会进入变桨轴承内,导致轴承出现点蚀、撕裂等现象[1],最终损坏轴承。

大多数机组主轴轴承密封系统由迷宫密封和“V ”形密封圈组成,经过几年的运行时间,注油、温升、轴向窜动等问题就会造成主轴密封泄露。

并且主轴轴承采用的是被动废油收集方式,由于废油排出的螺杆长且内孔较细,因此废油排放时的阻力较大,主轴轴承转动时,润滑油中的基础稀油容易从油封中排出,黏滞剂则会留在轴承内[2]。

随着温度升高,基础稀油被分离,废油将会发生皂化变质,从而造成油路堵塞,进而导致新的润滑油脂难以注入,主轴轴承的使用寿命降低。

只有定期吸出废油,加注新鲜润滑油,才能延长轴承使用寿命。

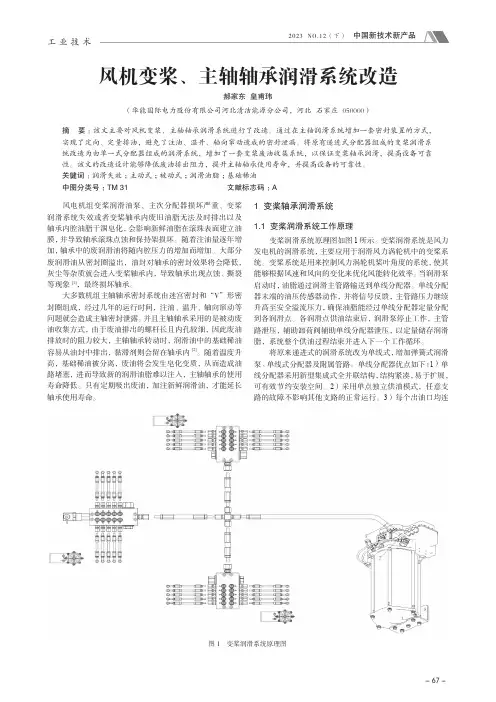

1 变桨轴承润滑系统1.1 变桨润滑系统工作原理变桨润滑系统原理图如图1所示。

变桨润滑系统是风力发电机的润滑系统,主要应用于润滑风力涡轮机中的变桨系统。

变桨系统是用来控制风力涡轮机桨叶角度的系统,使其能够根据风速和风向的变化来优化风能转化效率。

当润滑泵启动时,油脂通过润滑主管路输送到单线分配器。

单线分配器末端的油压传感器动作,并将信号反馈,主管路压力继续升高至安全溢流压力,确保油脂能经过单线分配器定量分配到各润滑点。

各润滑点供油结束后,润滑泵停止工作,主管路泄压,辅助卸荷阀辅助单线分配器泄压,以定量储存润滑脂,系统整个供油过程结束并进入下一个工作循环。

将原来递进式的润滑系统改为单线式,增加弹簧式润滑泵、单线式分配器及附属管路。

单线分配器优点如下:1)单线分配器采用新型集成式全并联结构,结构紧凑,易于扩展,可有效节约安装空间。

CLP pump – a new standard in lubrication performanceSKF eLube – next generation lubrication systemsBe smart. Be connected.Be prepared.SKF eLube – next generation lubrication systemsSKF eLube is a new generation of connected automatic lubrication solutions – a complete line of smart and user-friendly components that you combine in a system to best fit your needs. eLube can help you identify issues at a glance, track machine health data, get early warning of potential failures and take preventive action. Connect it to SKF Enlight Centre and receive machine perfor-mance insights based on data from both your lubrication system and your bearings. SKF eLube products are compact, fit-for-purpose and easy to integrate into your equipment.Availability andflexibilityThe SKF eLube family offers a pre-selected range of pack-ages to provide quick availability and flexibility for different demands and applications. You can either choose one of these packages or configure the eLube products according to your special needs.Easy to learn, quick toget startedYou will find that eLube products are intuitive to install and configure. Easy-to-use interfaces help you set up the proper parameters and take appropriate action to solve issues.Cut costs by keepingtrack of your dataThe integrated datalogging functionality of eLube products enables planned pump refills through pre-warning signals and refill indicators. This information can also help you identify maintenance issues to accept or reject warranty claims. By keeping track of lubrication data, you can ultimately reduce machine downtime.Safer operationSKF eLube systems help you reduce the risk of accidents via remote monitoring of lubrication equipment without the need to access hazardous areas.Reduce environmentalimpactAutomatic lubrication systems reduce the use of lubricants, resulting in decreased emissions of up to 2.2 kg CO2 per kilo-gram of grease. With SKF eLube you can get an overview of your lubricant consumption, helping you take yet another step towards environmentally sound lubrication management.2EASY AND INTUITIVE TO USEThe new pump series CLP is the first of the new SKF eLube generation. It works in small progressive lubrication systems. The lightweight, simple and easy-to-use pump stands out with its compact design and reliable functionality in mobile and industrial applications.Available now:CLP Basic and Basic PlusBasic variants provide visual level monitoring, while Basic Plus models feature integrated empty-level monitoring and a manual lubrication button for mobile applications to start an extra lubrication cycle.A new standard in lubrication performanceSKF Lincoln Compact Lubrication Progressive pump series CLPTo come during the next months:Intuitive lubrication controlCLP Touch versions come with an intuitive touch control panel with datalogging functionality.Remote monitoring at its easiestCLP Smart pumps can remotely be monitored, controlled and set using the SKF eLube App.Lubrication management at a glanceCLP Online versions connect to the SKF Enlight Centre. There a dashboard provides an overview of all connected pumps, allowing for fleet management in real time. CLP Online ver-sions can be remotely controlled with the SKF eLube App.Example layout of a progressive system with CLP Basic pump, SSV metering devices and LMC301 controller3CLP Basic / Basic PlusReinforced steel bracketWithstands vibrations in mobile applicationsCLP BasicCLP Basic PlusStandard pump element 6Maximum two pump elements to provide up to 3 cm 3 lubricant per minute and per pump elementFollower plate T o ensure continu-ous grease flowElectrical connectionBayonet plug for mobile use or square plug for industrial useManual lubrication button T o start additional lubrication cycleVisual level monitoringIntegrated empty-level monitoringFilling connectionWith standard filling nippleAll CLP models are suitable for fluid grease and grease applications and come with a follower plate to ensure con-tinuous grease flow. T o refill the pumps easily, they are equipped with a standard grease nipple at the bottom. The fill level can be visually monitored at each pump model. Basic Plus variants feature integrated empty-level monitor-ing that informs the user before the pump runs out of lubri-cant. Both Basic and Basic Plus variants can be controlled via an external lubrication controller or the machine control system.Basic Plus variants for mobile use come with a manual lubrication button to start an extra lubrication cycle. This helps to quickly check proper function of the system.CLP Basic / Basic Plus common main features• Lubricant: greases NLGI 000 to 2• Filling from bottom by grease nipple • Visual-level monitoring • Follower plate• Control via external lubrication controller or machine control system• Pump element 6 mounted on the right side, providing a delivery volume of ~3 cm 3/min Features depending on model *• Power supply 12 / 24 V DC• Additional electrical empty-level monitoring• Additional manual lubrication button • Electrical connections on the left side: –Bayonet plug, 7 pole A coded (power, signal and manual lubrication)–Bayonet plug, 4 pole A coded (power supply)–Square plug, A coded (power supply)• Electrical connection on the right side: –M12×1, 4 pole A coded (signal output) • Reinforced mounting bracket to withstand vibrations* Double check the description per model4CLP Basic12 V for mobile use CLP Basic24 V for mobile use CLP Basic Plus24V for industrial useCLP Basic24 V for industrial useCLP Basic Plus12V for mobile use CLP Basic Plus24V for mobile use Material number CLP-EGXXX1-0000020 • 12 V DC• Compliance E1/ CE • Pump element 6• Reinforced mounting bracket+Bayonet plug, 4 pole A coded (power sup-ply), on the left sideMaterial number CLP-EGXXX2-0000020 • 24 V DC• Compliance E1/ CE • Pump element 6• Reinforced mounting bracket+Bayonet plug, 4 pole A coded (power sup-ply), on the left sideMaterial number CLP-XGXXX2-0000022 • 24 V DC• Compliance CE • Pump element 6+Square plug, A coded (power supply), on the left sideMaterial number CLP-EG1XY1-0000021 • 12 V DC• Compliance E1/ CE • Pump element 6• Reinforced mounting bracket+Empty-level monitoring+Bayonet plug, 7 pole A coded (power, signal and manual lubrication), on the left side +Additional manual lubrication button mounted on the right sideMaterial number CLP-EG1XY2-0000021 • 24 V DC• Compliance E1/ CE • Pump element 6• Reinforced mounting bracket+Empty-level monitoring+Bayonet plug, 7 pole A coded (power, signal and manual lubrication), on the left side +Additional manual lubrication button mounted on the right sideMaterial number CLP-XG1XX2-0000023 • 24 V DC• Compliance CE • Pump element 6+Empty-level monitoring+Square plug, A coded (power supply), on the left side+M12×1, 4 pole A coded (signal output) on the right sidePre-defined models make ordering easy and improve lead timeThe easiest and fastest way to order the new CLP pumps is to choose a pre-defined package. By ordering a pre-defined, standard model, you get a fully equipped pump specifically configured for mobile or industrial use. These packages meet all standard requirements of these applications.5Comparison CLP model featuresCLP BasicCLP Basic Plus Material number CLP-EGXXX1-0000020CLP-EGXXX2-0000020CLP-XGXXX2-0000022CLP-EG1XY1-0000021CLP-EG1XY2-0000021CLP-XG1XX2-0000023Application Mobile Mobile Industry Mobile Mobile Industry Voltage 12 V DC 24 V DC 24 V DC 12 V DC 24 V DC 24 V DC ComplianceE1/CE E1/CE CE E1/CE E1/CE CE Reinforcement bracket ••-••-Visual level monitoring ••••••Electrical empty-level monitoring---•••Manual lubrication button---••-Electrical connection left Bayonet plug 4 pole A coded (power)••----7 pole A coded (power, signal, manual lubrication)---••-Square plug A coded (power)--•--•Electrical connection right M12×1 4 pole A coded (signal)-----•Grease NLGI 000 to 2••••••Standard filling from front ••••••Follower plate••••••Pump element 6 (left)••••••Dimensions max. [mm]218.5×187×154.5218.5×187×154.5212×187×152218.5×187×154.5218.5×187×154.5235×187×152Dimensions max. [in]8.6×7.36×6.088.6×7.36×6.088.34×7.36×5.988.6×7.36×6.088.6×7.36×6.089.25×7.36×5.981The spare parts assemblies may be used exclusively for replacement of identical defective parts. Modifications with spare parts on existing products are not allowed. Exceptions to this are the pump elements and the optional filling connection.2 Gasket always included 3 Chisel pasteTechnical data for all CLP Basic and Basic plus models Function principle Electrically operated lubrication pump LubricantsGreases: NLGI 000 to NLGI 2Max. working pressure 270 bar 3 916 psi Operating temperature -25 to +65°C -13 to +149°F Usable reservoir volume 1 l 0.26 gal Number of pump elementsmax. 2Pump element 1)6Lubricant output 2)~3 cm 3/min IP-protection class 3)IP 6K9K Corrosion class C3Voltages12 / 24 V DCOperating current up to 3 A (max. peak), nominal 1,2 A Relative duty cycle15% ED S3 30 minutes Electrical protection class III Outlet connection G 1/4Mounting positionAnyDimensions depending on model (max. H×D×W)CLP Basic mobile 218.5×187×154.5 mm 8.6×7.36×6.08 in CLP Basic industry 212×187×152 mm 8.34×7.36×5.98 in CLP Basic Plus mobile 218.5×187×154.5 mm 8.6×7.36×6.08 in CLP Basic Plus industry 235×187×152 mm 9.25×7.36×5.98 in Weight (empty)5 kg11 lb1Pump element 6 is included in the standard packages (→page 5).Other pump elements can be ordered using the spare part / additional component list (→page 6/7)2 Lubricant output depending on pump element3 Protection class depending on electrical connection6How to order individually configured pump variants7 | /eLube-clp® SKF and Lincoln are registered trademarks of the SKF Group.™ eLube is a trademark of the SKF Group.© SKF Group 2020The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein. PUB LS/P2 18918 EN · June 2020Certain image(s) used under license from .。

SKF轴承润滑油的粘度参数使用注意事项瑞典SKF轴承自1907年以来SKF一直是全球领先的技术供应商。

我们的根本实力是不断研发新技术的能力——然后运用它们来生产可为我们客户提供具有竞争力的优势产品。

通过结合在40多个行业的实际经验,以及在SKF技术平台的专业知识,我们实现了这一目标。

这五个技术平台是:轴承及轴承单元、密封件、机电一体化、服务和润滑系统。

我们的成功源自我们的知识、我们的员工以及我们一直坚持的SKF关爱原则。

如今SKF技术研发的重点是在我们及客户的运营中减少在其资产生命周期对环境的影响。

SKF 超越零( BeyondZero)产品组合是SKF在此领域要提供的最新范例。

SKF的全称是“Svenska Kullager-Fabriken”中文音译名称为“斯凯孚”;SKF集团总部设立于瑞典哥特堡,是轴承科技与制造的领导者。

Sven Wingquist在1905年发明了双列自动对心滚珠轴承,随即于1907年创立Svenska Kullargerfabriken瑞典滚珠轴承制造公司,简称SKF,不断发展,服务世界。

SKF执世界滚动轴承业之牛耳,经营的触角已遍及全球,业务遍及世界130个国家,每年生产五亿多个轴承,销售网遍布全球。

此外,SKF集团亦持续致力于轴承工业的研究与发展,平均每两天就有一项新的专利问世。

SKF集团也是第一家通过ISO14001环保认证的轴承公司,此项认证涵盖17个国家共60多个制造单位。

SKF 在全球的轴承行业,保持领导地位的同时,多年来努力不懈的开发多个领域的技术,产品和服务,已发展成为真正以供应解决方案为主导的轴承企业,为用户创造更大的价值。

这些解决方案可以帮助用户提高整体的生产能力,除了通过特殊应用的创新SKF轴承产品以外,还有尖端的模拟系统、咨询服务、设备效率化服务,以及轴承行业最先进的供应管理技术等。

产品介绍SKF依然标志着最优质的滚动轴承.1989年元月31日投审会通过SKF集团旗下的台湾子公司─斯凯孚股份有限公司的投资案,同年2月18日取得营利事业登记证,随即在台北、台中和高雄设立分公司以及成立位在三重的中心仓库,负责货物配销。

风电主轴轴承维护目录主轴轴承的贮存主轴轴承的安装主轴轴承的润滑选择主轴轴承初次润滑主轴轴承涉及的齿轮箱与发电机对中主轴轴承的补充润滑主轴轴承的状态监测主轴轴承的润滑分析主轴轴承的贮存一、贮藏室要求A、室内温度控制存放主轴轴承仓库的室温4~28℃的温度范围,存放轴承的仓库内应设有空调和除湿设备。

室温过低,防锈油会在低温下硬化收缩并产生裂纹,湿气等有害物质会通过裂纹直接接触轴承表面而使其锈蚀;室温过高,防锈油会熔化变薄,防锈性能下降,失去对轴承表面的保护作用;日夜温差过大或温度变幅度过大,大气中湿气会在轴承表面上凝结成水珠,从而引起轴承锈蚀。

如果温度低于4℃时应使用空调或其它加热方式升温,如远红外电炉,但要注意加热时,不能产生有害气体损坏轴承,引起轴承生锈。

加热设备的数量与分布应以保证轴承存放处温度能比较均匀地升高为原则。

在高于28℃时,最好用自然对流法降温,避免使用易扬起灰尘或带来潮气的强制电扇风冷法,如果必须使用电扇,宜用高处安装百页窗式排风扇,风扇的数量和分布的选择原则应使室内存放轴承处尽可能温度均匀地冷却,同时气流无涡旋死角。

切忌对着轴承吹风,在门户经常开启的进口处应尤其要注意,因为较高温度的轴承陡遇冷风也会凝结水滴,凝结的水滴可能引起轴承生锈,这一点在早上入库调换房间空气时也应注意。

B、仓库湿度控制存放轴承的仓库,其室内相对湿度应保持在45%~60%,当湿度超过60%时应采取去湿措施。

最好在通风道的入口端设置去湿装置。

过高的湿度,易导致轴承的锈蚀,缩短轴承的“库存寿命”在库存安全期,阴雨天禁止雨衣、湿鞋等入室。

以下时温度、湿度对轴承仓贮的影响:相对湿度,% 环境温度,℃轴承最长仓贮时间,年60 25-30 1075 25-30 575 35-40 3典型的对贮存环境状态不控制的方法 1对已填充润滑脂的密封轴承最长的贮存期限为3年因此,对轴承仓库的控制对轴承使用会产生较大的影响!C、室内空气条件存放主轴轴承的仓库,其室内空气应洁净、无尘、干燥、不含酸碱性气体、水蒸气或其他腐蚀性气体。

主轴轴承油润滑结构

主轴轴承在机械设备中起到支撑和转动的作用,因此需要适当的润滑来减少摩擦和磨损。

以下是主轴轴承常见的油润滑结构:

1.润滑脂润滑:主轴轴承可以使用润滑脂进行润滑。

润滑脂是一种半固态润滑剂,由基础油和增稠剂混合而成。

它的粘度适中,能够在高速旋转下保持稳定的润滑膜,并提供持久的润滑效果。

2.油气润滑:主轴轴承可以采用油气润滑系统进行润滑。

这种系统使用润滑油通过喷嘴或喷雾器以气体形式送入轴承,形成气膜润滑。

油气润滑系统能够在高速旋转下提供均匀的润滑,并有效冷却轴承。

3.循环油润滑:主轴轴承可以使用循环油润滑系统进行润滑。

这种系统通过油泵将润滑油送入轴承,然后通过油槽或管道回流到油箱。

循环油润滑系统能够提供持续的油膜润滑和冷却效果,适用于高速、高温和重载的工作条件。

4.润滑剂供给:在主轴轴承上,润滑剂可以通过直接滴注、喷射或浸润等方式供给。

这些供给方式可根据轴承的类型、工作条件和润滑要求来选择。

无论使用哪种润滑结构,确保正确选择和应用适当的润滑剂,并根据设备的要求进行定期检查和维护,以确保主轴轴承的正常运行和寿命。

1/ 1。