电泳工艺中英文

- 格式:xls

- 大小:363.00 KB

- 文档页数:3

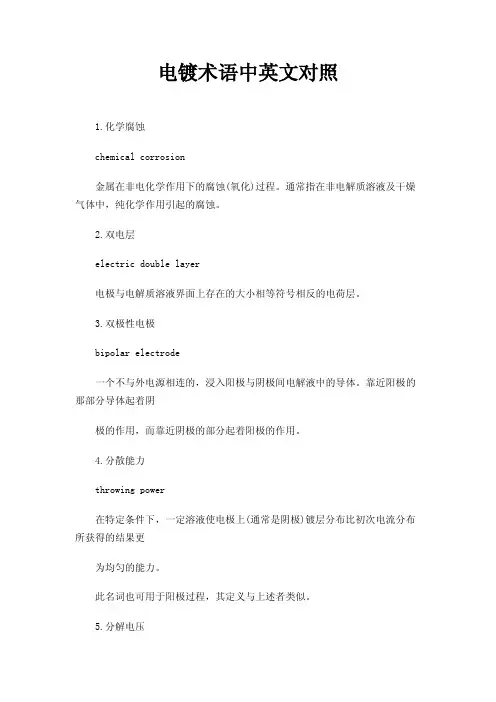

电镀术语中英文对照1.化学腐蚀chemical corrosion金属在非电化学作用下的腐蚀(氧化)过程。

通常指在非电解质溶液及干燥气体中,纯化学作用引起的腐蚀。

2.双电层electric double layer电极与电解质溶液界面上存在的大小相等符号相反的电荷层。

3.双极性电极bipolar electrode一个不与外电源相连的,浸入阳极与阴极间电解液中的导体。

靠近阳极的那部分导体起着阴极的作用,而靠近阴极的部分起着阳极的作用。

4.分散能力throwing power在特定条件下,一定溶液使电极上(通常是阴极)镀层分布比初次电流分布所获得的结果更为均匀的能力。

此名词也可用于阳极过程,其定义与上述者类似。

5.分解电压decomposition voltage其定义与上述者类似。

能使电化学反应以明显速度持续进行的最小电压(溶液的欧姆电压降不包括在内)。

6.不溶性阳极(惰性阳极)inert anode在电流通过时,不发生阳极溶解反应的阳极。

7.电化学electrochemistry研究电子导体和离子导体的接触界面性质及其所发生变化的科学。

8.电化学极化(活化极化)activation polarization由于电化学反应在进行中遇到困难而引起的极化。

9.电化学腐蚀electrochemical corrosion在卑解质溶掖中或金属表面上的液膜中,服从于电化学反应规律的金属腐蚀(氧化)过程10.电化当量electrochemical equivalent在电极上通过单位电量(例如1安时,1库仑或1法拉第时),电极反应形成产物之理论重量。

通常以克/库仑或克/安时表示。

11电导率(比电导)conductivity单位截面积和单位长度的导体之电导,通常以S/m表示。

12电泳electrophoresis液体介质中带电的胶体微粒在外电场作用下相对液体的迁移现象。

13电动势electromotive force原电池开路时两极间的电势差。

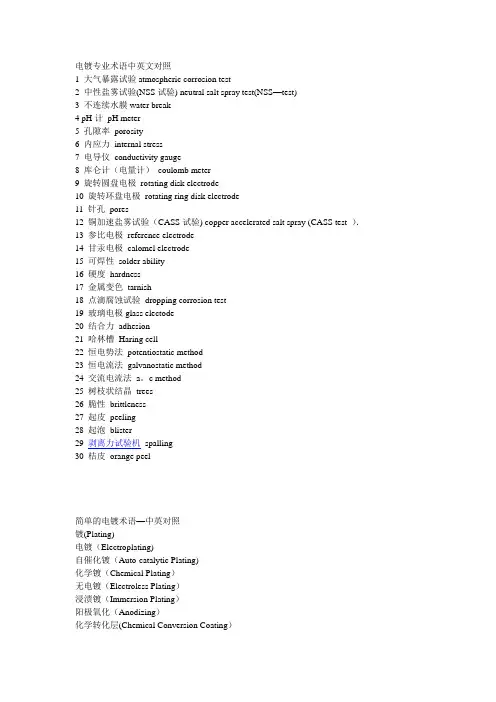

电镀专业术语中英文对照1 大气暴露试验atmospheric corrosion test2 中性盐雾试验(NSS试验) neutral salt spray test(NSS—test)3 不连续水膜water break4 pH计pH meter5 孔隙率porosity6 内应力internal stress7 电导仪conductivity gauge8 库仑计(电量计)coulomb meter9 旋转圆盘电极rotating disk electrode10 旋转环盘电极rotating ring disk electrode11 针孔pores12 铜加速盐雾试验(CASS试验) copper accelerated salt spray (CASS test ).13 参比电极reference electrode14 甘汞电极calomel electrode15 可焊性solder ability16 硬度hardness17 金属变色tarnish18 点滴腐蚀试验dropping corrosion test19 玻璃电极glass electode20 结合力adhesion21 哈林槽Haring cell22 恒电势法potentiostatic method23 恒电流法galvanostatic method24 交流电流法a。

c method25 树枝状结晶trees26 脆性brittleness27 起皮peeling28 起泡blister29 剥离力试验机spalling30 桔皮orange peel简单的电镀术语—中英对照镀(Plating)电镀(Electroplating)自催化镀(Auto-catalytic Plating)化学镀(Chemical Plating)无电镀(Electroless Plating)浸渍镀(Immersion Plating)阳极氧化(Anodizing)化学转化层(Chemical Conversion Coating)钢铁发蓝(Blackening),俗称”发黑“钢铁磷化(Phosphating)铬酸盐处理(Chromating)金属染色(Metal Colouring)涂装(Paint Finishing),包括各种涂装如手工涂装、静电涂装、电泳涂装等热浸镀(Hot dip)热浸镀锌(Galvanizing),俗称"铅水"热浸镀锡(Tinning)PVD 物理气相沈积法(Physical Vapor Deposition)真空镀(Vacuum Plating)离子镀(Ion Plating)CVD 化学气相沈积法(Chemical Vapor Deposition)电镀术语解释及英文名称ABS塑料电镀plastic plating processpH计pH meter 测定溶液pH值的仪器.螯合剂chelating agent 能与金属离子形成螯合物的物质。

金属表面电泳工艺流程英文回答:Electrophoretic deposition (EPD) is a widely used process in the coating industry to apply a thin film of metal onto a surface. It involves the use of an electric field to attract and deposit charged particles onto a conductive substrate. The process begins with the preparation of a suspension or dispersion of metalparticles in a liquid medium, known as the electrophoretic bath.The first step in the EPD process is the preparation of the metal particles. These particles are typically in the form of a powder or colloidal suspension. They can be made from various metals such as aluminum, steel, or copper. The size and shape of the particles can vary depending on the desired coating properties.After the metal particles are prepared, they aredispersed in a liquid medium to create the electrophoretic bath. This bath consists of a solvent or dispersing agent that helps to suspend the particles evenly and prevent them from settling. It may also contain additives such as binders or surfactants to improve the adhesion andstability of the coating.Once the electrophoretic bath is prepared, the substrate to be coated is carefully cleaned and prepared. This ensures that the surface is free from any contaminants or oxides that could interfere with the adhesion of the metal coating. The substrate is then immersed in the electrophoretic bath and connected to the positive terminal of a power supply.The next step is the application of an electric field. The negative terminal of the power supply is connected to a metal electrode, known as the cathode, which is immersed in the electrophoretic bath. When the power supply is turned on, an electric field is established between the anode (substrate) and the cathode. This causes the charged metal particles in the bath to migrate towards the substrate anddeposit onto its surface.The deposition process continues until a desired coating thickness is achieved. The deposition rate can be controlled by adjusting the voltage, time, and concentration of the metal particles in the electrophoretic bath. Once the desired thickness is reached, the power supply is turned off, and the coated substrate is removed from the bath.The coated substrate is then dried and cured to ensure the adhesion and durability of the metal coating. This can be done through various methods such as air drying, oven drying, or thermal curing. After the curing process, the coated substrate is ready for further finishing processes such as polishing or painting, if desired.中文回答:电泳沉积(EPD)是涂层行业中广泛使用的一种工艺,用于在金属表面上涂覆一层薄膜。

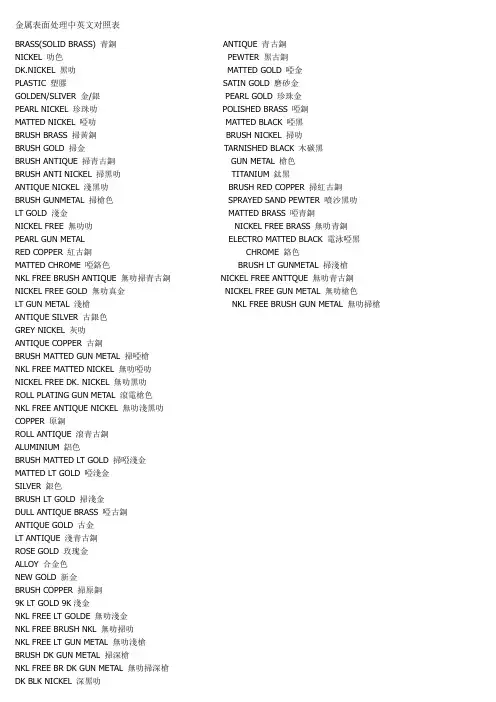

金属表面处理中英文对照表BRASS(SOLID BRASS) 青銅ANTIQUE 青古銅NICKEL 叻色PEWTER 黑古銅DK.NICKEL 黑叻MATTED GOLD 啞金PLASTIC 塑膠 SATIN GOLD 磨砂金GOLDEN/SLIVER 金/銀 PEARL GOLD 珍珠金PEARL NICKEL 珍珠叻POLISHED BRASS 啞銅MATTED NICKEL 啞叻MATTED BLACK 啞黑BRUSH BRASS 掃黃銅 BRUSH NICKEL 掃叻BRUSH GOLD 掃金TARNISHED BLACK 木碳黑BRUSH ANTIQUE 掃青古銅GUN METAL 槍色BRUSH ANTI NICKEL 掃黑叻 TITANIUM 鈦黑ANTIQUE NICKEL 淺黑叻 BRUSH RED COPPER 掃紅古銅BRUSH GUNMETAL 掃槍色SPRAYED SAND PEWTER 噴沙黑叻LT GOLD 淺金MATTED BRASS 啞青銅NICKEL FREE 無叻叻NICKEL FREE BRASS 無叻青銅PEARL GUN METAL ELECTRO MATTED BLACK 電泳啞黑RED COPPER 紅古銅CHROME 鉻色MATTED CHROME 啞鉻色 BRUSH LT GUNMETAL 掃淺槍NKL FREE BRUSH ANTIQUE 無叻掃青古銅NICKEL FREE ANTTQUE 無叻青古銅NICKEL FREE GOLD 無叻真金NICKEL FREE GUN METAL 無叻槍色LT GUN METAL 淺槍NKL FREE BRUSH GUN METAL 無叻掃槍ANTIQUE SILVER 古銀色GREY NICKEL 灰叻ANTIQUE COPPER 古銅BRUSH MATTED GUN METAL 掃啞槍NKL FREE MATTED NICKEL 無叻啞叻NICKEL FREE DK. NICKEL 無叻黑叻ROLL PLATING GUN METAL 滾電槍色NKL FREE ANTIQUE NICKEL 無叻淺黑叻COPPER 原銅ROLL ANTIQUE 滾青古銅ALUMINIUM 鋁色BRUSH MATTED LT GOLD 掃啞淺金MATTED LT GOLD 啞淺金SILVER 銀色BRUSH LT GOLD 掃淺金DULL ANTIQUE BRASS 啞古銅ANTIQUE GOLD 古金LT ANTIQUE 淺青古銅ROSE GOLD 玫瑰金ALLOY 合金色NEW GOLD 新金BRUSH COPPER 掃原銅9K LT GOLD 9K淺金NKL FREE LT GOLDE 無叻淺金NKL FREE BRUSH NKL 無叻掃叻NKL FREE LT GUN METAL 無叻淺槍BRUSH DK GUN METAL 掃深槍NKL FREE BR DK GUN METAL 無叻掃深槍DK BLK NICKEL 深黑叻DK ANTIQUE 深青古銅NKL FREE GREY NICKEL 無叻灰叻NKL FREE DK BLK NICKEL 無叻深黑叻NKL FREE ANTI SILVER 無叻古銀LT GUN METAL 淺槍(面掛電,底滾電)NKL FREE BR LT GOLD 無叻掃淺金NKL FREE BRUSH GOLD 無叻掃金NKL FREE PEARL GOLD 無叻珍珠金NEW COPPER 新原銅BIO PEWTER 古叻DULL GOLD 濁金ELECTRO BLACK 詠黑SPRAY BLACK 噴黑BRONZE BRASS 仿銅LT ANTIQUE GOLD 淺古金MATTED GUN METAL 啞槍DULL NICKEL 濁叻ROLL DK.NICKEL 滾黑叻NKL FREE ROLL DK.NICKEL 無叻滾黑叻RAW 原胚(無電鍍)SPRAY 噴色NKL FREE ELECTRO BLACK 無叻電詠黑NKL FREE BRUSH BRASS 無叻黃銅DK GUN METAL 深槍NKL FREE DK GUN METAL 無叻深槍SPRAY MATTED BLK 噴啞黑NKL FREE MATTED GOLD 无叻哑金常见的表面处理冲床工艺序号俗称(中文)英文(翻译)常见的颜色序号冲压工序英文翻译1 喷塑 powder coated 黑白军绿 1 落料 blanking2 烤漆lanking finish 2 切断 cuttingbanking varnishing 3 折弯 bendingpainting backing 4 冲字stamping letterspray painted 5 拉伸to stretch6 拉深to pull and stretch3 镀锌 zinc plated 蓝白锌彩锌 7 切边side cut /sid scrapzinc coated 8 去毛边trmming4 镀镍 iron with nickel plated 普通镍化学镍9 冲孔pierceiron covered by nickel 10 抽孔draw holesteel with nickel plated 11 深冲压deep drawing5 光亮镀镍 bright nickel-plating deep stamping6 镀铝aluminum-plated 12 折叠folding7 镀铬 chrome-plated 13 成型molding8 镀银silver-plated 14 整形plastic15 攻丝tapping9 镀金gold-plated10 镀锡tin-plated11 电泳 electrophoresis 黑色electro-coating亮铬Polished Chrome仿金Polished 24K Gold拉丝铬Brushed Chrome。

琼脂糖凝胶电泳的操作步骤琼脂糖凝胶电泳是用琼脂或琼脂糖作支持介质的一种电泳方法。

对于分子量较大的样品,如大分子核酸、病毒等,一般可采用孔径较大的琼脂糖凝胶进行电泳分离。

琼脂糖凝胶约可区分相差100bp 的DNA 片段,其分辨率虽比聚丙烯酰胺凝胶低,但它制备容易,分离范围广,尤其适于分离大片段DNA。

普通琼脂糖凝胶分离DNA 的范围为0.2-20kb,利用脉冲电泳,可分离高达10^7bp 的DNA 片段。

操作流程准备干净的配胶板和电泳槽注意DNA 酶污染的仪器可能会降解DNA,造成条带信号弱、模糊甚至缺失的现象。

选择电泳方法一般的核酸检测只需要琼脂糖凝胶电泳就可以;如果需要分辨率高的电泳,特别是只有几个bp 的差别应该选择聚丙烯酰胺凝胶电泳;用普通电泳不合适的巨大DNA 链应该使用脉冲凝胶电泳。

注意巨大的DNA 链用普通电泳可能跑不出胶孔导致缺带。

正确选择凝胶浓度对于琼脂糖凝胶电泳,浓度通常在0.5~2%之间,低浓度的用来进行大片段核酸的电泳,高浓度的用来进行小片段分析。

低浓度胶易碎,小心操作和使用质量好的琼脂糖是解决办法。

注意高浓度的胶可能使分子大小相近的DNA 带不易分辨,造成条带缺失现象。

适合的电泳缓冲液常用的缓冲液有TAE 和TBE,而TBE 比TAE 有着更好的缓冲能力。

电泳时使用新制的缓冲液可以明显提高电泳效果。

注意电泳缓冲液多次使用后,离子强度降低,PH 值上升,缓冲性能下降,可能使DNA 电泳产生条带模糊和不规则的DNA 带迁移的现象。

电泳的合适电压和温度电泳时电压不应该超过20V/cm,电泳温度应该低于30℃,对于巨大的DNA 电泳,温度应该低于15℃。

注意如果电泳时电压和温度过高,可能导致出现条带模糊和不规则的DNA 带迁移的现象。

特别是电压太大可能导致小片段跑出胶而出现缺带现象DNA 样品的纯度和状态注意样品中含盐量太高和含杂质蛋白均可以产生条带模糊和条带缺失的现象。

乙醇沉淀可以去除多余的盐,用酚可以去除蛋白。

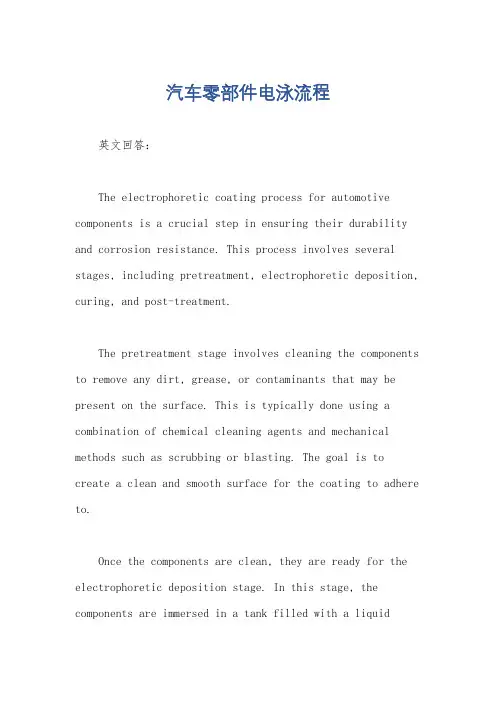

汽车零部件电泳流程英文回答:The electrophoretic coating process for automotive components is a crucial step in ensuring their durability and corrosion resistance. This process involves several stages, including pretreatment, electrophoretic deposition, curing, and post-treatment.The pretreatment stage involves cleaning the components to remove any dirt, grease, or contaminants that may be present on the surface. This is typically done using a combination of chemical cleaning agents and mechanical methods such as scrubbing or blasting. The goal is to create a clean and smooth surface for the coating to adhere to.Once the components are clean, they are ready for the electrophoretic deposition stage. In this stage, the components are immersed in a tank filled with a liquidpaint or coating material. The components are connected to an electrical circuit, with the positive terminal connected to the components and the negative terminal connected to the tank. When an electric current is applied, the coating material migrates towards the components and forms a uniform film on their surfaces. This process is known as electrophoresis.After the electrophoretic deposition, the components are cured to ensure that the coating material hardens and forms a durable finish. This is typically done by heating the components to a specific temperature for a certain period of time. The curing process may also involve the use of ultraviolet (UV) light or other methods to accelerate the drying and hardening of the coating.Once the components are cured, they undergo post-treatment to further enhance their properties. This may involve additional coating layers, such as clear coats or protective films, to provide additional protection against corrosion, UV radiation, or other environmental factors. Post-treatment may also include surface polishing orbuffing to improve the aesthetics of the components.Overall, the electrophoretic coating process for automotive components is a complex and multi-step process that requires careful attention to detail and precision. It plays a crucial role in enhancing the durability and performance of automotive parts, ensuring their longevity and resistance to corrosion.中文回答:汽车零部件的电泳涂层工艺是确保其耐久性和防腐性的关键步骤。

电镀工艺英语Electroplating ProcessElectroplating is a widely used industrial process that involves the deposition of a thin layer of metal onto the surface of an object. This process is employed in a variety of applications, ranging from decorative coatings to functional surface enhancements. The electroplating process is a complex and intricate procedure that requires careful attention to detail and precise control of various parameters.The fundamental principle behind electroplating is the use of an electric current to drive the deposition of metal ions from a solution onto the surface of the object being plated. This process is facilitated by the presence of an electrolyte solution, which contains the metal ions that will be deposited. The object to be plated, known as the cathode, is connected to the negative terminal of a power source, while the positive terminal is connected to an anode, which is typically made of the same metal that is being deposited.When an electric current is applied, the metal ions in the electrolyte solution are attracted to the negatively charged cathode, where theyare reduced and deposited onto the surface of the object. The thickness of the deposited metal layer is determined by the duration of the plating process and the strength of the electric current.The electroplating process typically involves several steps, each of which is crucial to the overall success of the operation. The first step is the preparation of the surface to be plated, which may involve cleaning, degreasing, and sometimes etching or other surface treatments to ensure proper adhesion of the deposited metal.Once the surface is prepared, the object is immersed in the electrolyte solution, which is typically a water-based solution containing the desired metal ions, as well as other additives such as brighteners, levelers, and wetting agents. These additives help to improve the quality and appearance of the plated surface.The next step is the actual plating process, where the electric current is applied, and the metal ions are deposited onto the surface of the object. The plating process can take anywhere from a few minutes to several hours, depending on the desired thickness of the deposited layer and the specific requirements of the application.After the plating process is complete, the object is removed from the electrolyte solution and rinsed thoroughly to remove any residual chemicals or contaminants. In some cases, additional post-platingtreatments, such as heat treatment or annealing, may be necessary to improve the properties of the deposited metal layer.One of the key advantages of electroplating is its versatility. The process can be used to deposit a wide range of metals, including gold, silver, copper, chrome, nickel, and zinc, among others. Each metal has its own unique properties and applications, making electroplating a valuable tool in a variety of industries.In the automotive industry, for example, electroplating is used to apply decorative chrome finishes to various components, such as bumpers, trim, and wheels. In the electronics industry, electroplating is used to deposit thin layers of copper or other metals on circuit boards, providing conductive pathways for electronic signals.In addition to its industrial applications, electroplating is also used in the manufacture of jewelry, where it is used to deposit thin layers of precious metals such as gold or silver onto less expensive base metals. This process allows for the creation of affordable, yet high-quality, jewelry pieces.Despite its widespread use, the electroplating process is not without its challenges. The handling and disposal of the hazardous chemicals used in the process, as well as the environmental impact of the process, are ongoing concerns that must be addressed by industryprofessionals. As a result, there is a growing emphasis on the development of more sustainable and eco-friendly electroplating techniques.In conclusion, the electroplating process is a complex and versatile industrial technique that plays a crucial role in a wide range of industries. By understanding the underlying principles and the various steps involved in the process, industry professionals can ensure the production of high-quality, durable, and aesthetically pleasing products that meet the demands of an ever-evolving marketplace.。

电镀专业术语中英文对照1 大气暴露试验atmospheric corrosion test2 中性盐雾试验(NSS试验) neutral salt spray test(NSS-test)3 不连续水膜water break4 pH计 pH meter5 孔隙率 porosity6 内应力 internal stress7 电导仪 conductivity gauge8 库仑计(电量计) coulomb meter9 旋转圆盘电极 rotating disk electrode10 旋转环盘电极 rotating ring disk electrode11 针孔 pores12 铜加速盐雾试验(CASS试验) copper accelerated salt spray (CASS test ).13 参比电极 reference electrode14 甘汞电极 calomel electrode15 可焊性 solder ability16 硬度 hardness17 金属变色 tarnish18 点滴腐蚀试验 dropping corrosion test19 玻璃电极glass electode20 结合力 adhesion21 哈林槽 Haring cell22 恒电势法 potentiostatic method23 恒电流法 galvanostatic method24 交流电流法 a.c method25 树枝状结晶 trees26 脆性 brittleness27 起皮 peeling28 起泡 blister29 剥离 spalling30 桔皮 orange peel简单的电镀术语-中英对照/article/428110.html 镀(Plating)电镀(Electroplating)自催化镀(Auto-catalytic Plating)化学镀(Chemical Plating)无电镀(Electroless Plating)浸渍镀(Immersion Plating)阳极氧化(Anodizing)化学转化层(Chemical Conversion Coating)钢铁发蓝(Blackening),俗称”发黑“钢铁磷化(Phosphating)铬酸盐处理(Chromating)金属染色(Metal Colouring)涂装(Paint Finishing),包括各种涂装如手工涂装、静电涂装、电泳涂装等热浸镀(Hot dip)热浸镀锌(Galvanizing),俗称"铅水"热浸镀锡(Tinning)PVD 物理气相沈积法(Physical Vapor Deposition)真空镀(Vacuum Plating)离子镀(Ion Plating)CVD 化学气相沈积法(Chemical Vapor Deposition)电镀术语解释及英文名称 /article/3897/art_information.htmlABS塑料电镀 plastic plating processpH计 pH meter 测定溶液pH值的仪器。

铸件及产品表面处理工艺:压铸件:Die castingsZinc Die castings 电铸件:Electrical castings不锈钢铸件:stainless steel castings铸件表面处理Surface finish for the castings: 做黑:blacking镀锌:Zinc plating镀铬:chrome plating镀镍:nickel plating磨砂面处理:grit satin finishSatin finish titanium抛光处理:tumble bright手工拉丝(圆形拉丝,放射线拉丝, 对角线拉丝):brushed metal surface/drawbench(circular metal brushed texture, radius metal brushed texture, diagonal metal brushed texture)Cell phone with brushed metal surface哑光面处理:hand dull polished finish镜面抛光处理:mirror polished finish金属孔:metallic holes氧化铬钝化处理:passivation treatment电抛光处理:electrolytic polished喷砂处理(玻璃砂,钢玉沙,石英砂):sandblasting(glass bead blasting, corundum-sand blasting, quartz-sand blasting)Satin finished surfaceTPU或橡胶凹刻:TPU,rubber text intaglioCell phone TPU text intaglioCD纹样:CD patternCell phone navigation key used CD pattern镀枪色:gun color platinggun color plated真空镀:PVD vacuum plating(PVD: Physical vapor deposition)PVDtechnics UV coating+PVD technics紫外固化(增加表面耐磨层及使用寿命):UV curingUV coating字符镭雕:Laser carving textSilicone rubber keypad numbers by laser carving technics 字符丝印:Silk-screen printingPhone text silkscreen printed一般电镀:electroplating effectsElectroplated mobile手机壳使用材料:ABS+PC(塑料)Zinc Alloy(锌合金),Aluminum Alloy(铝合金)ABS+PC Zinc AlloyAlumium Alloy按键材料: Keypad made of PC plasticPC plastic镜片屏幕材料:Lens, screen made of PMMA(亚克力),PVC plasticPMMA material Clear PVC FilmUSB软胶塞材料:USB stopper made of Rubber, TPUTPO material cover电镀可用在ABS和金属材料,真空镀可用在PMMA和任何材料上,真空镀价格相对便宜:Electroplating can be done by ABS and metal materials, PVD vaccum plating can be donw on any other materila such as PMMA亚克力,PVD plating cheaper不导电真空镀处理:Non conductive PVD vacuum platingNon conductive PVD plated注塑材料:injection molding plastic喷漆处理:paint sprayingPaint-spraying+UV coating模具蚀纹(手机壳花纹工艺):in-mould metal etching techniqueComputer cover etching不锈钢拉丝电镀处理:stainless steel brushed surface by chrome plating阳极氧化处理:anodic oxidation treatmentAluminum Anoidc oxidation treatment on surface 表面电镀:surface electroplating电泳处理:Electrophoresis不导电真空溅镀工艺(和电镀效果一样都是在塑料表面镀金属色,但是有镜面效果非常亮):Non conductive vacuum metallization technics(It is similar to electroplating effects, but colors can be mirror finish)PVD vacuum metallization不锈钢表面进行处理(表面本色白化处理,表面镜石光亮处,表面着色处理,光亮处理方法,喷砂处理法,机械抛光,化学抛光,电化学抛光):Stainless steel surface treatment(color bleaching treatment, mirror finish treatment, sand blasting, mechanical polishing finish, chemical polishing finish, electrochemical polishing finish).Chemical polished喇叭网,布织网:Speaker mesh,netting双色注塑:two-color injection molding technics底面镀膜:underside coating with thin film钢板花纹镭雕:Steel sheet with laser engraving treatmentLaser Engraving texture部分纹理突起:Texture bump不锈钢冲压:Precision stainless steel stamping part.彩镀:color plating电池盖常用材料:battery cap made of aluminum alloy, ABS+PCAlumium Alloy cap表面腐蚀纹:Electrochemisty corrosion pattern finishLighter metal corrosion texture表面氧化处理:Surface oxidation treatment沙面处理:satin finish亮面处理:glossy finishHigh glossy finish car body with black paint spray+UV coating 哑光面处理:matte finish批花纹处理:radiation pattern功能键镀膜效果:function keys made of transparent PC with coating effect手机壳体分件:上壳:Front Housing壳上装饰件:cap decorative pieces中壳:middle cover后壳:Rear Housing按键:keypad天线:Antenna电池盖:battery cover侧按键:side function key导航键:navigation key功能键:function key喇叭孔:Mic振动器:Vibrater测试端口:Test port and 嗡鸣器:Buzzer常用材料及应用ABS:汽车(仪表板,工具舱门,车轮盖,反光镜,冰箱,大强度工具如头发烘干机,搅拌器,食品加工机,割草机,电话机壳体,打字机键盘,娱乐用车辆如高尔夫球手推车,喷气式雪橇车。

Alkali degreasing 碱液脱脂法alkali cleaner 碱液脱脂剂ion exchange 离子交换法solution control, both control 槽液管理emulsion edgreasing(cleaner) 乳化脱脂法(剂)chemical decaling ;chemical derusting 化学除锈剂chemical degreasing 化学脱脂法chemical conversion coating 化学成膜rust cause on phosphate coating 黄锈〔磷化处理中〕chromate coaring, chronating 铬酸处理〔钝化〕chromate coating chromating 铬酸盐处理sodium silicate 硅酸钠descaling 打锈descaling,derusting 除锈〔同酸洗、酸蚀〕acid pickling,pickling 酸洗〔同除锈〕acid pickling in hibitor 酸性阻蚀剂sankblasting ,blast cleaning 喷砂deionized water (rinsing) 纯水〔洗〕shot blasting 喷丸fresh water rinsing 新鲜水洗steam phosphating 蒸气磷化处理spray pretreatment system 喷射式前处理total acid 总酸度accelerator 促进剂degreasing 脱脂cleaner 脱脂剂phosphoric acid cleaning 脱脂,除锈二个合一处理剂blue color 灰蓝色vapor degreasing 三氯乙烯脱脂〔蒸气〕trichloroethylene 三氯乙烯parchlorlerhylene,carbontetrachlchlcride 四氯乙烯half dip pretreatment system 半浸式前处理P ratio P比phosphating chemicals 磷化处理剂chemical conversion coating 皮膜处理coating weight 膜重surface treatment 外表预处理surface conditioning 外表调整surface conditioner 外表调整剂flood spray pretreatment system 溢流喷射式前处理full dip pretreatment system 全浸式前处理pretreatment 前处理pretreament chemicals 前处理剂drying off 烘干水份free acid 游离酸度solvent degreasing 溶剂脱脂precleaning 预洗净hot water prerinsing 预热水洗ziue phosphating phosphatetreatment 锌盐磷化处理zinc phosphating coating 锌盐磷化膜iron phosphating coating 铁盐磷化膜anodic electro deposition 阳极电泳anode earth method 阳极接地法spitting spray ,fluttering 气喘、喷流连续wet on wet 湿碰湿top coat 涂面漆air spraying 空气喷涂air blow 吹风airless spraying 无空气喷涂over spray 过喷涂membrane system electro deposition 隔膜〔电极〕电泳涂装over coating 重叠涂装wet sanding with gasoline 汽油打磨cathodic electro deposition 阴极电泳涂装dry sanding 干打磨gun distance 喷枪距离spray gun velocity 喷枪移动速度mechanical sanding 机械打磨surface preparation 外表准备〔同底材面调整〕electrostatic air atomixing spray metode 空气雾化式静电涂装mill scale 黑皮〔黑色氧化皮〕finish sanding 修饰性打磨substrate 底材〔基底〕primer coating 涂底漆dipping,dip coating 浸涂spraying ,spray coating 喷涂(atomizing) fan pattern 喷涂影spot repair 局部修补three coat three bake 涂三次烘三次slipper dipping 拖式浸涂electrostatic coating 静电涂装electrostatic powder coating 静电粉末涂装electrostatic rotary atomizing spray method 静电雾化式静电涂装法all pattying 统刮腻子application trial 试涂装turn-over 更新期pad application,padding 揩涂(paint) mixing 调制color matching 调色throwing power 泳透力electro phoresis 电泳electro osmosis 电渗electrodeposition,electrocoating (ED) 电泳涂装sanding,grinding 打磨painting,coating ,finishing 涂装interval between coats,coat interval 涂装间隔paint system ,coating system 涂装体系paint process 涂装工艺painting sepctification 涂装技术要求transfer efficiency 涂着效率color sealer 同色封底涂层surface coating ,sealer coating 涂中涂层repainting 重新涂装spreading rate 涂布面积比brush application ,brushing,brush coating 刷涂work 被涂物atomizing 雾化detail sanding ,defect sanding 局部打磨flow coating 淋涂electrophorectic powder coating 粉末电泳涂装法knifing ,knife application 刮涂touch up 修补涂装hot spraying ,hot spray coating 热喷涂masking 遮盖polishing 抛光mettalic coating 金属闪光漆涂装utra filtration(UF) 超滤flridized powder bed coating 流化床涂装application by roller,roller coating 辊涂(dark)infrared drying ,infrarde drying,infrarde baking 〔暗〕红外枯燥wet film 湿涂膜sand dry ,surface dry 表干baking,thermosetting 加热枯燥drying 枯燥forced drying 强制枯燥dry-hard,dry-through,hard dry,dry through,baking 完全枯燥,完全固化ultra violer curing 紫外线固化枯燥set to touch ,dust free,dry to touch 触指枯燥air drying cold curing 自然枯燥〔常温枯燥〕curing by polymerization 聚合枯燥drying by evaporation 蒸发枯燥〔同挥发枯燥〕setting ,flash off 晾干electoro beem curing ,radiation curing 电子束固化〔辐射枯燥〕hot air drying couvection drying 热风枯燥,对流枯燥tack free ,tack dry 半固化枯燥〔指触枯燥〕baking stoving 烘干acrylic resin paint 丙烯酸树脂涂料acryl lacquer 热塑性丙烯酸涂料application solid 施工固体份amine content 胺浓度alkyd resin paint 醇酸树脂涂料cobwebbing 拉丝现象etching grimer 腐蚀底漆〔同磷化底漆,活性底漆〕enamel 磁漆non aqueous dispersion paint 非水分散型涂料oil surfacer 油性二道浆ash content 灰分cathodic electrod eoposition 阴极电泳涂料flexibility 弹性,可弯曲性nonvolatile content(matter),solids content,heating residue 不挥发分skinning 结皮性bake schedule 枯燥时间pigment volume,pigment volume concentration 颜料体积比率pigment content 颜料分〔P、W、C〕dilution stability 稀释稳定性redueed paint 稀释好的涂料caking 凝结性coulomb efficiency 库仑效率clear 清漆clear lacquer 硝基清漆synthetic resin paint 合成树脂涂料guide coat 二道浆anticorrosive coating ,rust inhibiting paint ,corrosion resistant coating,antirust paint防锈涂料primer 底漆涂料chassis black paint 底盘黑涂料zinc rich primer 富锌底漆water borne paint 水性粉笔料〔水系涂料〕water soluble resin paint ,water soluble resin coating 水溶性树脂涂料stomeguard coating 抗石击性涂料patiblity ,potible 相溶性spray mist patibiliity 抗漆雾污染性touch up primer 局部修补底漆thixotropic ,thixotropy 触变性antichippimg paint,chip resistant paint 抗崩裂性shelf life ,storage stability,canstability 贮藏稳定性grainning,bitty,seed 细度、粒度flat paint ,flat oikl paint ,mat paint 无光涂料electrocoating ,coating for electrodeposition 电泳涂料film forming agent ,film forming ingredient ,film former,film forming material 涂膜主要成分color surfacer 同色涂料coating ,paint 涂料virgin paint ,UN-cut paint 原漆two ponent paint 双组份涂料nitrocellulose lacquer,nitrocellulose coating 硝基漆thermosetting〔themoplastic〕 acrylic paint 热固(塑)性丙烯酸树脂涂料consistency 稠度viscosity 粘度high solid lacquer 高固体份硝基漆high solid paint 高固体分型涂料binder 基料putty 腻子light curing coating 光固化涂料vehicle 漆料phenolic coating ,phenolic resin paint 酚醛树脂涂料unsaturated polyester paint 不饱和聚脂涂料primer surfacer 底漆二道浆blocking 粘结、结块powder paint 粉末涂料anti-corrosion wax ,anti-rust wax 防锈蜡pot life ,pot stability 活化期、活化寿命polyester putty 聚酯腻子water dispersible paint 水分散型涂料millbase ,milling base 研磨色浆solventless coating ,solvent free paint 无溶剂型涂料metallic enamel,metallic paint ,metallic pigmented paint 金属闪光色磁漆thermosetting paint 烘烤型涂料oil paint 油性涂料oil length 油度lacquer 硝基清漆lacquer enamel 硝基磁漆bituminous paint 沥青涂料leveling 流平性varnish 清漆acrylate resins 丙烯酸系树脂acrylic acid 丙烯酸acryl modified slkyd resin 丙烯酸改性的醇酸树脂asphalt (bitumen) 沥青amino resin 氨基树脂alkyd resin 醇酸树脂epoxy resin 环氧树脂oil free alkyd resin 无油醇酸树脂external plastici zation 外部增塑化drying oil 干性油hilsonite 天然硬沥青glycerin 甘油gel time ,time for gelation 胶化时间saponification value ,saponification number 皂化价safflower oil 红花油carbooxyl acid 脂肪酸nitrocellulose 硝化棉silicone resin 有机硅树脂polybasic acid 多元酸polyhydric alcohol polyol 多元醇natural resin 〔oil〕天然树脂(油)internal plasticization 部塑化thermisettig property 热固性thermoplastic ,thermoplasticity,thermal plasticity 热泪盈眶可塑性castor oil 蓖麻油phenol resin 酚醛树脂nondrying oil 不干性油blown asphalt 氧化沥青ployester 聚醋polybutadience 聚丁二烯methacrylic acid 甲基丙烯酸iodine value ,iodine number 碘值asbestin 石棉粉aluminium flake powder,aluminium pigment powder 铝粉aluminium flake paste,aluminium pigment paste 铝粉膏tint(ing) shade,reduce shade 色光、色头red lead 红丹carbon black 碳黑pigment 颜料oil absorption value 吸油量clay 白土、土rust preventing pigment, rust inhibiting pigment 防锈颜料extender filler ,extender pigment 填料、体质颜料talc 滑石粉white tiianium pigment 钛白color pigment (strength) 着色颜料〔力〕lead pigment 铅系颜料titanum dioxide 二氧化钛permanent red 永固红fast yellow 耐晒黄dispersion 分散red iron oxide 铁红inorganic pigment 无机颜料organic (color) pigment 有同颜料leafing 漂浮sellosolves (solvent) 醇醚溶剂alcohols(solvent) 醇系溶剂isopropyl alcohol 异丙醇ethers(solvent ) 醚系熔剂esters (solvent) 酯系溶剂ethyl alochol 乙醇diluent 稀释剂xylene 二甲苯ketones (solvent) 酮系溶剂high boiling point solvent, high boiler ,slow solvent 高沸点溶剂ethyl acetate 乙酸乙酯aliphatic hydrocarbons (solvent) 脂肪族系碳氢化合物溶剂cosolvent 助溶剂cellosolve 溶纤剂cellosolve acetate 乙酸溶纤剂solvent naphtha 煤焦油溶剂kerosene ,kerosine 煤油toluene 甲苯butyl alcohol ,butanol 丁醇mineral spirit,petroleum spirit 白醇methyl ethyl ketone 甲乙酮amine 胺surface active agent surfactant 外表活性剂plasticizer 增塑剂reducidility 稀释剂metallic soap ,metal soap 金属皂harder ,curing abent 固化剂antioxdant ,oxidant inhibitor 防止氧化剂ultrviolet absorber 紫外线吸收剂dibutyl phthalate 苯甲酸二丁酯thinner 稀料antistatic agent 静电防止剂antisag agent 流挂防止剂antisetlle agent 沉淀防止剂flatting agent 消光剂paint thinner 涂料用稀料lacquer thinner 硝基漆用稀料retarder ,retarder solvent 防潮剂rheology control 流变性控性paper tack stick 粘性纸胶带dry sandpaper 干打磨用砂纸crape masking 纸质遮盖用胶带abrasive paper sandpaper 打磨砂纸abrasive colth ,sanding cloth 打磨砂布washing solvent (flame retarding solvent ) 清洗用溶剂water proof abrasion sandpaper 耐水性砂纸heat stabe maskingtape 耐热遮盖用胶带tack rag 粘性纱布tackrag varnish 粘灰清漆paint remover 脱漆剂polishing pound 抛光剂poly net 打磨网masking tape 遮盖用胶带hiding power,obiterating power ,covering power ,opacity 遮盖力top coat,finish coat ,finishing coat 面漆层overcoatability 涂面漆的适应性recoatability 重复涂装的适应性glass transition point 玻璃化点specular gloss,specular reflection 镜面光泽度grindability 打磨性pentrability 浸透性distinctness of image 鲜映性alkaliproof ,alkali resistance 耐碱性overbake resistance 耐过烘性salt water resistance 耐盐水性gasoline resistance 耐挥发油性durability 耐久性flexibility ,elasticity 耐弯曲性weather resistance, weathering property,weatherproof 耐候性acidproof ,acid resistance 耐酸性impact resisrance 耐冲击性corrosion resistance 耐蚀性water resistance,waterproof 耐水性washability 耐洗净性chiping resistance 耐崩裂性heat resistance 耐热性boiling water resistance 耐沸水性abrasion resistance 耐摩耗性chemical resistance 耐药品性oil resistance ,oilproof 耐油性solvent resistance 耐溶剂性gloss 光泽flat 无光泽stain resistance 涂膜污染性appearance of paint film,paint film appearance 涂膜的外观surface of paint film 涂面semigloss 半光泽abhesion 附着力elusion ,bleeding 溶出degradation 裂解ageing 老化oildeaetting,oil cratering 油缩孔water slaining (marke) 雨水痕迹bubble ,bubbling (bubble trace on ED film) 气泡〔电泳气泡〕peeling off wet Ed film 电泳湿漆膜脱落ED cratering 电泳缩孔pinpole on ED film 电泳针孔discollration 掉色off color 色差mottling 色不均flooding 色别离wet contamination 湿污染pecking 啄伤gas checking,gas crazing 气体裂纹blushing 白化pigment sedimentation 颜料沉降sanding scratch 打磨器纹sealing failure 涂密封胶不良bleeding 底层污染stain,spot,spotting 粘污crinkling,shrivelling,wrinkling,rivelling 起皱suction ,absorption 吸收water bubbling 水泡hiding failure 遮盖不良scrack 划伤low distinctness of image 鲜映性低intercoat adhesion failure 层间剥落fading 退色dripping 流痕sagging run curtaining 下沉sag 流挂wrinkle 皱纹起皱chipping 碎落chalking 粉化thin Edcoating ,no ED coating 泳透性差dulling,loss of gloss,matting 失光flashing 光泽不匀sand scratch 打磨划伤too much film thickness 涂膜过厚peeling 涂膜剥落dry contamination 干污染dirt ,seed 涂料颗粒cratering,fish eye 涂料缩孔,鱼眼sagging,runing 流淌bleeding 渗色thin paint 涂得太薄skips 漏涂peeling 剥离crawling,fish eye,cratering 缩孔鱼眼ding and dent 钣金凹凸soldering pinhole 焊药针孔pinhole 针孔blistering 膨泡bunp,cluster 颗粒blushing 发白blistering 起泡mar 触伤痕hair cracking 鬓状裂纹sanding scratch 砂纸纹cratering 凹坑discorloration 变色swelling 膨润shading 模糊〔阴影〕et star pineple 星状不平break line failure 保护不良metallic seeding 金属颗粒after tack 返粘under baking 未烘干透grinding scratch 锉刀纹orange peel 桔皮solvent popping ,pin holes 气泡孔cracking,hair craching,checking ,craging,alligateying crocodiling 裂纹鬓状裂纹浅裂纹龟裂鳄鱼皮裂纹filiform corrosion test 丝状腐蚀性试验hiding chart 遮盖力试验纸wet film thickness gauge 湿漆膜厚度量远规Erichsen film distensibility meter 杯突试验机Eleter 永久磁性测厚仪salt spray testing ,salt spray test 盐水喷雾试验pencil hardness test 铅硬度试验carbon arc 碳弧灯appearance inspection 外观检查dilution stability test 稀释稳定性试验dilytion test,reducibility test 稀释试验xenone lamp 氙气灯coulomb efficiency test 库仑效率试验bending test 弯曲试验gravelometer 石击崩裂试验法cryptoneter 遮盖力测验法Krebs -Stomer viseter,Stomer viseter 斯端马粘度计cross cut 穿插横割constant temperature and humidity cabinet 恒温恒湿箱gloss meter 光泽计color difference meter 色差计test panel 试验板test piece,coupon,specimen 试验样板outdoor wethering test ,outdoor exposure test 自然曝晒试验imact test,impact testing ,chip test 冲击试验impact tester 冲击试验仪sampler 取样器Sward hardness rocker 斯惠特硬度计scab corrosion test 疤形腐蚀试验accelerated weathering test,accelerated weathering ,artificial weathering 人工耐候性试验accelerated weathering tester 人工耐候性试验机over bake resistance test 耐过烘性试验hot water resistance test 耐温水试验weathering test ,weathering 耐候性试验humidity resistance test 耐湿试验humidity box 耐湿试验盒chemical resistance test 耐药品性试验diamond shot test 金刚石冲击试验法throwing power 泳透性试验grind gauge ,fineness gauge 细度刮板Du-pot impact tester 杜邦式冲击试验heat cycle test 热循环试验exposure rack 曝晒试验Broodfield viseter B型粘度计portable distinctness of image glossmeter 鲜映测计〔PGD〕specific gravity cup 比重杯specified achromatic light 标准光源film applicator 涂膜涂布器Ford cup ,Ford viscosity cup 福特杯pound corrosion test 复合腐蚀试验〔CCT〕tack free test ,print test 不粘性试验film thickness gauge 漆膜厚度计pressure feed type spray gun 压送式喷枪pressurw tank ,pressure feed paint container 油漆增压箱rubber patten 子橡胶磨块patten 木质磨块colors changer 换色装置water curtain 水幕air cap 空气帽air cleaner 空气静化器air pressor 空气压缩机air sander 气动打磨机air duster 气动除尘器air transformer 空气压力调整器airless spray gun 无气喷枪airless apraying equipment 无气喷涂装置auto roll filter 自动滚筒式过滤器auto absorber 自动吸水器orbital sander 眼眶形打磨机pressure cup 加压杯rotary air sander 转动型气动打磨机reverser clean 转动式清洁器stirring equipment 搅拌装置rotary atomizing electrostatic spraying equipment 旋杯式静电喷涂装置steel spatrla 钢刮刀heating oil separater 加热油水别离装置dryspray booth 干式喷漆室wood spatula 木刮勺supply duct 供气风管supplying fan 供气风机air supply house 空调装置high voltage regulator 高压发生器surge chamber 缓冲容器side room 侧调漆间robot by C.Pteaching method CP式机械手automatic air duster 自动吹风装置automatic solution machine 自动溶液管理装置automatic sanding machine 自动湿打磨装置automatic washing machine 自动水洗装置automatic apray machine 自动喷涂机automatic electrostatic spray machine 自动静电涂装装置automatic dust off machine 自动除尘装置automatic spray 自动涂装装置bravity spray gun 重力式喷枪deionized water generator 纯水装置pad 托盘〔板〕dipping tank 浸槽water washing spray booth 水洗式喷漆室scraper 刀spray gun 喷枪spray system pretreatment equipment 喷射式前处理装置spray booth 喷漆室electrostatic coating equipment 静电涂装装置electrostatic powder coating equipment 静电粉末涂装装置semifolw sealing 半浮动涂密封胶side reciprocator 侧喷机duct 风筒〔管〕touching tracer 修整追踪装置double action sander 双动打磨机DC power equipment 直流电源disc sander 盘式打磨机hand electrostatic spray gun 手提式静电喷枪hand electrostatic spray equipment 手提式静电喷涂装置ceiling filter 顶棚过滤器electrocoating equipment 电泳涂装装置painting robot 涂装机械手cup of spray gun 涂料杯paint circulating system 涂料循环输漆系统mixing room 调漆室spray gum tip 涂料喷嘴needle 针阀exhaust air washing system 排气洗净装置brush 刷子robot by P.T.P.teaching method PTP 式机械手full dip pretreatment system equipment 全浸式前处理装置top reciprocator 平面涂装机knife,spatula 刮刀ultra filtration equipment 超滤装置〔UF〕light projector 光投影器robot by remoto teaching method 远距离式教式机械手continuous settling equipment 连续沉淀装置dark(far) infrared oven 暗〔远〕红外线烘干室air seal 风幕oven 炉枯燥机indirect hot air oven 间接加热式热风烘干室drying oven 枯燥室infrared oven 红外线枯燥室enthalpy heat exchanger 全热泪盈眶交换器hot air converction oven 对流炉direct hot airoven ] 直接加热式热风烘干炉hot air oven 热风炉hot air circulating equipment 热风循环装置burner house 燃烧室heat pump 热泵radiation panel heater 辐射板setting room 晾干室baking oven 烘干室cooling unit 强冷室color specification 色的规格colorrendition 演色color chart 色卡cool color 冷色saturation ,chroma 彩色度〔鲜艳度、饱和度或纯度〕brightness 亮度shade 修色color difference 色差color scheme 色彩设计hue 色相metamerism 条件等色solid color 本色master color 造型色板warm color 暖色tinting 调色tint 着色tone analysis 色调分类color standard (panel) 标准颜色板flip-flop 闪光spectrophotometer 分光光度计spectral reflection faetor 分光反射率relative spectral distribution 分光分布achromatic color 无彩色value of lightness 明度metallic color 金属闪光色chromatic color 有彩色ionomer resin 离子树脂acrylic resin 丙烯酸树脂acrylonitrile butadiene styrene frepolymer resin 丙烯腈,丁二烯苯乙烯树脂〔ABS〕urethane resin 聚氨酯树脂fiberglass reinforced plastics 玻璃纤维增强树脂〔FRP〕polyvinyl chloride resin 聚氯乙烯树脂〔PVC〕vigid polypropylene resin 硬质聚丙烯树脂〔硬PP〕hotrolled steel sheet 热轧钢板polyamide resin 聚酰氨树脂〔PA〕polystyrene resin 聚苯乙烯树脂〔PS〕zinc fusing glavanized steel sheet 热镀锌钢板zinc alloy fusing galvanized steel sheet 热熔合金化镀锌钢板high tensile coldrolled steel sheet 冷轧高强度钢板〔SAPH〕coldrolled steel sheet 冷轧普通碳素构造钢板〔SPCCR〕。

金属表面处理中英文对照表BRASS(SOLID BRASS) 青铜ANTIQUE 青古铜NICKEL 叻色PEWTER 黑古铜黑叻 MATTED GOLD 哑金PLASTIC 塑胶SATIN GOLD 磨砂金GOLDEN/SLIVER 金/银PEARL GOLD 珍珠金PEARL NICKEL 珍珠叻POLISHED BRASS 哑铜MATTED NICKEL 哑叻MATTED BLACK 哑黑BRUSH BRASS 扫黄铜BRUSH NICKEL 扫叻BRUSH GOLD 扫金TARNISHED BLACK 木碳黑BRUSH ANTIQUE 扫青古铜GUN METAL 枪色BRUSH ANTI NICKEL 扫黑叻TITANIUM 钛黑ANTIQUE NICKEL 浅黑叻BRUSH RED COPPER 扫红古铜BRUSH GUNMETAL 扫枪色 SPRAYED SAND PEWTER 喷沙黑叻LT GOLD 浅金MATTED BRASS 哑青铜NICKEL FREE 无叻叻NICKEL FREE BRASS 无叻青铜PEARL GUN METAL ELECTRO MATTED BLACK 电泳哑黑RED COPPER 红古铜CHROME 铬色MATTED CHROME 哑铬色BRUSH LT GUNMETAL 扫浅枪NKL FREE BRUSH ANTIQUE 无叻扫青古铜NICKEL FREE ANTTQUE 无叻青古铜NICKEL FREE GOLD 无叻真金NICKEL FREE GUN METAL 无叻枪色LT GUN METAL 浅枪NKL FREE BRUSH GUN METAL 无叻扫枪ANTIQUE SILVER 古银色GREY NICKEL 灰叻ANTIQUE COPPER 古铜BRUSH MATTED GUN METAL 扫哑枪NKL FREE MATTED NICKEL 无叻哑叻NICKEL FREE DK. NICKEL 无叻黑叻ROLL PLATING GUN METAL 滚电枪色NKL FREE ANTIQUE NICKEL 无叻浅黑叻COPPER 原铜ROLL ANTIQUE 滚青古铜ALUMINIUM 铝色BRUSH MATTED LT GOLD 扫哑浅金MATTED LT GOLD 哑浅金SILVER 银色BRUSH LT GOLD 扫浅金DULL ANTIQUE BRASS 哑古铜ANTIQUE GOLD 古金LT ANTIQUE 浅青古铜ROSE GOLD 玫瑰金ALLOY 合金色NEW GOLD 新金BRUSH COPPER 扫原铜9K LT GOLD 9K浅金NKL FREE LT GOLDE 无叻浅金NKL FREE BRUSH NKL 无叻扫叻NKL FREE LT GUN METAL 无叻浅枪BRUSH DK GUN METAL 扫深枪NKL FREE BR DK GUN METAL 无叻扫深枪DK BLK NICKEL 深黑叻DK ANTIQUE 深青古铜NKL FREE GREY NICKEL 无叻灰叻NKL FREE DK BLK NICKEL 无叻深黑叻NKL FREE ANTI SILVER 无叻古银LT GUN METAL 浅枪(面挂电,底滚电) NKL FREE BR LT GOLD 无叻扫浅金NKL FREE BRUSH GOLD 无叻扫金NKL FREE PEARL GOLD 无叻珍珠金NEW COPPER 新原铜BIO PEWTER 古叻DULL GOLD 浊金ELECTRO BLACK 咏黑SPRAY BLACK 喷黑BRONZE BRASS 仿铜LT ANTIQUE GOLD 浅古金MATTED GUN METAL 哑枪DULL NICKEL 浊叻ROLL 滚黑叻NKL FREE ROLL 无叻滚黑叻RAW 原胚(无电镀)SPRAY 喷色NKL FREE ELECTRO BLACK 无叻电咏黑NKL FREE BRUSH BRASS 无叻黄铜DK GUN METAL 深枪NKL FREE DK GUN METAL 无叻深枪SPRAY MATTED BLK 喷哑黑NKL FREE MATTED GOLD 无叻哑金常见的表面处理冲床工艺序号俗称(中文)英文(翻译)常见的颜色序号冲压工序英文翻译1 喷塑 powder coated 黑白军绿 1 落料 blanking2 烤漆 lanking finish 2 切断 cuttingbanking varnishing 3 折弯 bendingpainting backing 4 冲字 stamping letter spray painted 5 拉伸 to stretch6 拉深 to pull and stretch3 镀锌 zinc plated 蓝白锌彩锌 7 切边 side cut/sid scrapzinc coated 8 去毛边 trmming4 镀镍 iron with nickel plated 普通镍化学镍9 冲孔 pierceiron covered by nickel 10 抽孔 draw holesteel with nickel plated 11 深冲压 deep drawing5 光亮镀镍 bright nickel-plating deep stamping6 镀铝 aluminum-plated 12 折叠 folding7 镀铬 chrome-plated 13 成型 molding8 镀银 silver-plated 14 整形 plastic15 攻丝 tapping9 镀金 gold-plated10 镀锡 tin-plated11 电泳 electrophoresis 黑色electro-coating亮铬 Polished Chrome仿金 Polished 24K Gold拉丝铬Brushed Chrome。

电泳的工艺流程铝合金电泳电泳的工艺流程铝合金电泳首先:电泳涂装(electro-coating)是利用外加电场使悬浮于电泳液中的颜料和树脂等微粒定向迁移并沉积于电极之一的基底表面的涂装方法。

电泳涂装的原理发明于是20世纪30年代末,但开发这一技术并获得工业应用是在1963年以后,电泳涂装是近30年来发展起来的一种特殊涂膜形成方法,是对水性涂料最具有实际意义的施工工艺。

具有水溶性、无毒、易于自动化控制等特点,迅速在汽车、建材、五金、家电等行业得到广泛的应用。

电泳涂装是把工件和对应的电极放入水溶性涂料中,接上电源后,依靠电场所产生的物理化学作用,使涂料中的树脂、颜填料在以被涂物为电极的表面上均匀析出沉积形成不溶于水的漆膜的一种涂装方法。

电泳涂装是一个极为复杂的电化学反应过程,其中至少包括电泳、电沉积、电渗、电解四个过程。

电泳涂装按沉积性能可分为阳极电泳(工件是阳极,涂料是阴离子型)和阴极电泳(工件是阴极,涂料是阳离子型);按电源可分为直流电泳和交流电泳;按工艺方法又有定电压和定电流法。

目前在工业上较为广泛采用的是直流电源定电压法的阳极电泳。

1-经表面处理后的工件;2-电源;3-工件;4-喷水冲洗;5-槽液过滤;6-沉积槽;7-循环泵电泳涂装与其他涂装方法相比较,具有下述特点:(1)采用水溶性涂料,以水为溶解介质,节省了大量有机溶剂,大大降低了大气污染和环境危害,安全卫生,同时避免了火灾的隐患;(2)涂装效率高,涂料损失小,涂料的利用率可达90%,95%;(3)涂膜厚度均匀,附着力强,涂装质量好,工件各个部位如内层、凹陷、焊缝等处都能获得均匀、平滑的漆膜,解决了其他涂装方法对复杂形状工件的涂装难题;(4)生产效率高,施工可实现自动化连续生产,大大提高劳动效率;(5)设备复杂,投资费用高,耗电量大,其烘干固化要求的温度较高,涂料、涂装的管理复杂,施工条件严格,并需进行废水处理;(6)只能采用水溶性涂料,在涂装过程中不能改变颜色,涂料贮存过久稳定性不易控制。

汽车零部件电泳流程英文回答:The electrophoretic coating process for automotive parts involves several steps to ensure a high-quality finish and corrosion protection. Here is a brief overview of the process:1. Pretreatment: The parts are thoroughly cleaned and prepared before the coating process. This usually involves removing any dirt, oil, or rust from the surface of the parts. Various cleaning methods such as degreasing, acid cleaning, and phosphate treatment may be used.2. Electrodeposition: The parts are then immersed in a tank filled with a water-based paint solution. An electric current is applied, causing the paint particles to migrate and adhere to the surface of the parts. This process is known as electrodeposition or electrophoresis.3. Curing: After the parts have been coated, they are heated to cure the paint. This helps to create a durable and long-lasting finish. The curing process can be done using ovens or infrared heat.4. Inspection: Once the parts have been cured, they are inspected for any defects or imperfections. This may include checking for uneven coating, drips, or bubbles. Any issues are addressed before the parts move on to the next stage.5. Topcoat: In some cases, a topcoat may be applied to further enhance the appearance and protection of the parts. This can include clear coats, color coats, or additional layers of paint.6. Quality control: Throughout the entire process, quality control measures are in place to ensure that the coating meets the required standards. This may involve testing the thickness of the coating, conducting adhesion tests, and checking for any visual defects.7. Packaging and shipping: Once the parts have passedthe quality control checks, they are carefully packaged and prepared for shipping to the automotive assembly plants or distribution centers.中文回答:汽车零部件电泳涂装流程包括几个步骤,以确保涂层具有高质量的表面和防腐蚀性能。