PBT物性表-标准版本

- 格式:xlsx

- 大小:12.44 KB

- 文档页数:2

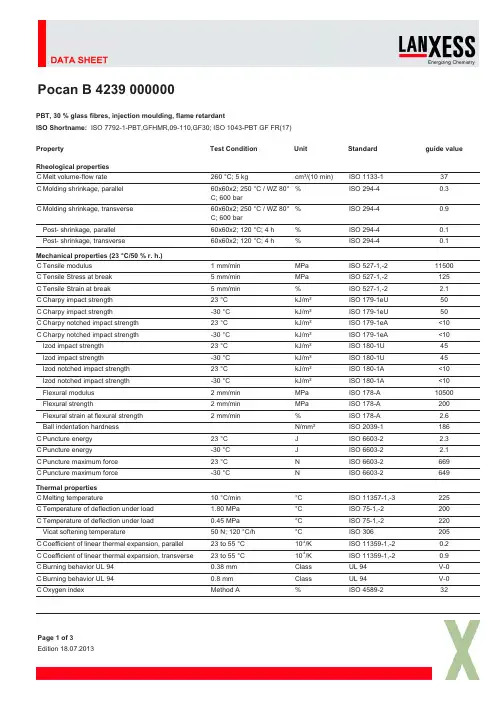

PBT,30%glass fibres,injection moulding,flame retardantISO Shortname:ISO 7792-1-PBT,GFHMR,09-110,GF30;ISO 1043-PBT GF FR(17)PropertyTest ConditionUnitStandardguide valueRheological properties C Melt volume-flow rate 260°C;5kgcm³/(10min)ISO 1133-137C Molding shrinkage,parallel 60x60x2;250°C /WZ 80°C;600bar%ISO 294-40.3C Molding shrinkage,transverse 60x60x2;250°C /WZ 80°C;600bar%ISO 294-40.9Post-shrinkage,parallel 60x60x2;120°C;4h %ISO 294-40.1Post-shrinkage,transverse60x60x2;120°C;4h%ISO 294-40.1Mechanical properties (23°C/50%r.h.)C Tensile modulus 1mm/min MPa ISO 527-1,-211500C Tensile Stress at break 5mm/min MPa ISO 527-1,-2125C Tensile Strain at break 5mm/min %ISO 527-1,-2 2.1C Charpy impact strength 23°C kJ/m²ISO 179-1eU 50C Charpy impact strength -30°C kJ/m²ISO 179-1eU 50C Charpy notched impact strength 23°C kJ/m²ISO 179-1eA <10C Charpy notched impact strength -30°C kJ/m²ISO 179-1eA <10Izod impact strength 23°C kJ/m²ISO 180-1U 45Izod impact strength -30°C kJ/m²ISO 180-1U 45Izod notched impact strength 23°C kJ/m²ISO 180-1A <10Izod notched impact strength -30°C kJ/m²ISO 180-1A <10Flexural modulus 2mm/min MPa ISO 178-A 10500Flexural strength2mm/min MPa ISO 178-A 200Flexural strain at flexural strength 2mm/min%ISO 178-A 2.6Ball indentation hardness N/mm²ISO 2039-1186C Puncture energy 23°C J ISO 6603-2 2.3C Puncture energy -30°C J ISO 6603-2 2.1C Puncture maximum force 23°C N ISO 6603-2669C Puncture maximum force -30°C NISO 6603-2649Thermal properties C Melting temperature10°C/min °C ISO 11357-1,-3225C Temperature of deflection under load 1.80MPa °C ISO 75-1,-2200C Temperature of deflection under load 0.45MPa °C ISO 75-1,-2220Vicat softening temperature50N;120°C/h °C ISO 306205C Coefficient of linear thermal expansion,parallel 23to 55°C 10-4/K ISO 11359-1,-20.2C Coefficient of linear thermal expansion,transverse 23to 55°C 10-4/K ISO 11359-1,-20.9C Burning behavior UL 940.38mm Class UL 94V-0C Burning behavior UL 940.8mm Class UL 94V-0C Oxygen indexMethod A%ISO 4589-232Pocan B 4239000000Page 1of 3PropertyTest Condition Unit Standard guide valueThermal conductivity23°CW/(m·K)ISO 83020.24Resistance to heat (ball pressure test)°C IEC 60695-10-2213Temperature index (Tensile strength)20000h °C IEC 60216-1155Halving interval (Tensile strength)°C IEC 60216-19.3Relative temperature index (Tensile strength)°C UL 746B 140Temperature index (Tensile impact strength)20000h °C IEC 60216-1130Halving interval (Tensile impact strength)°C IEC 60216-18.4Relative temperature index (Tensile impact strength)°C UL 746B 110Temperature index (Electric strength)20000h °C IEC 60216-1145Halving interval (Electric strength)°C IEC 60216-112Relative temperature index (Electric strength)°C UL 746B 125Glow wire test (GWFI)0.8mm °C IEC 60695-2-12960Glow wire test (GWIT)0.8mm °C IEC 60695-2-13725Glow wire test (GWIT) 1.6mm °C IEC 60695-2-13725Glow wire test (GWIT)3.0mm °CIEC 60695-2-13725Electrical properties (23°C/50%r.h.)C Relative permittivity 100Hz -IEC 60250 3.9C Relative permittivity 1MHz -IEC 60250 3.8C Electric strength1mm kV/mm IEC 60243-135C Comparative tracking index CTI Solution AV IEC 60112275Electrolytic corrosion RatingIEC 60426A/B 1Other properties (23°C)C Density kg/m³ISO 11831670Bulk densitykg/m³ISO 60800Processing conditions for test specimens C Injection molding-Melt temperature °C ISO 294250C Injection molding-Mold temperature °CISO 29480Processing recommendations Drying time circulating air dryer h -4-8Drying temperature circulating air dryer °C -120Residual moisture content %Acc.to Karl Fischer 0-0.02Melt temperature (Tmin -Tmax)°C -240-260Mold temperature°C-80-100C These property characteristics are taken from the CAMPUS plastics data bank and are based on the international catalogue of basic data for plastics according to ISO10350.Pocan B 4239000000Page 2of 3DisclaimerDisclaimer for sales productsThis information and our technical advice -whether verbal,in writing or by way of trials -are given in good faith but without warranty,and this also applies whereproprietary rights of third parties are involved.Our advice does not release you from the obligation to verify the information currently provided -especially that contained in our safety data and technical information sheets -and to test our products as to their suitability for the intended processes and uses.The application,use and processing of our products and the products manufactured by you on the basis of our technical advice are beyond our control and,therefore,entirely your own responsibility.Our products are sold in accordance with the current version of our General Conditions of Sale and Delivery.Test valuesUnless specified to the contrary,the values given have been established on standardized test specimens at room temperature.The figures should be regarded as guide values only and not as binding minimum values.Kindly note that,under certain conditions,the properties can be affected to a considerable extent by the design of the mould/die,the processing conditions and the coloring.Processing noteUnder the recommended processing conditions small quantities of decomposition product may be given off during processing.To preclude any risk to the health and well-being of the machine operatives,tolerance limits for the work environment must be ensured by the provision of efficient exhaust ventilation and fresh air at theworkplace in accordance with the Safety Data Sheet.In order to prevent the partial decomposition of the polymer and the generation of volatile decomposition products,the prescribed processing temperatures should not be substantially exceeded.Since excessively high temperatures are generally the result of operator error or defects in the heating system,special care and controls are essential in these areas.LANXESS DEUTSCHLAND GMBH |D -51369LEVERKUSEN ©LANXESS DeutschlandGmbHPocan B 4239000000Page 3of 3。

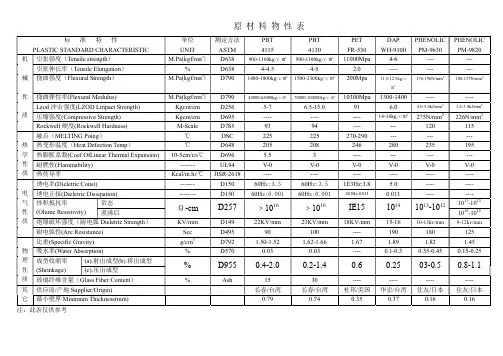

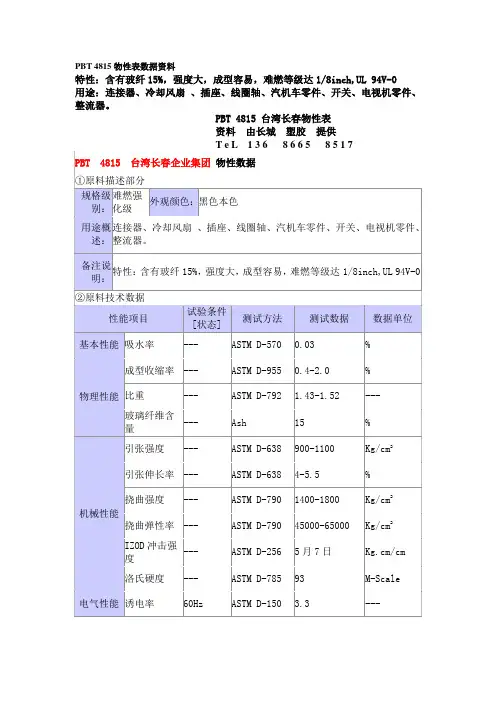

PBT 4815物性表数据资料特性:含有玻纤15%,强度大,成型容易,难燃等级达1/8inch,UL 94V-0用途:连接器、冷却风扇、插座、线圈轴、汽机车零件、开关、电视机零件、整流器。

PBT 4815 台湾长春物性表资料由长城塑胶提供PBT 1100 高粘度,超韧性,成型表面光滑。

用于扣件组具,电脑键盘,文具外壳,旋钮开关等。

PBT 1200 高流动,表面光泽度良好。

用于扣件组具,电脑键盘,文具外壳,旋钮开关等。

PBT 2000 流动性佳,阻燃UL94V-0级。

用于汽车零件,OA器材部件,瓦斯炉零件等。

PBT 2100 流动性佳,阻燃UL94V-0级。

用于汽车零件,OA器材部件,瓦斯炉零件等。

PBT 3015 玻纤增强15%,低粘度,耐热性佳。

用于汽车零件,马达端盖,碳刷座等。

PBT 3020 玻纤增强20%,中粘度。

用于汽车零件,马达端盖,碳刷座,工业产品零件等。

PBT 3030 玻纤增强30%,高强度,耐热。

用于汽车零件,马达端盖,碳刷座,工业产品零件等。

PBT 4115 含玻璃15%,高强度,阻燃。

用于连接器,插座,线圈轴,电视机零件等。

PBT 4120 含玻璃20%,强韧耐热性佳。

用于连接器,插座,线圈轴,电视机零件等。

PBT 4130 含玻璃30%,强韧耐热性佳。

用于连接器,插座,线圈轴,电视机零件等。

PBT 4140 含玻璃40%,高强度,低翘曲。

用于连接器,插座,整流器,电视机零件等。

PBT 4815 玻纤增强15%,强度大,阻燃。

用于连接器,插座,整流器,电视机零件等。

PBT 4830 玻纤增强30%,强度大,阻燃。

用于连接器,插座,整流器,电视机零件等。

PBT 5630 玻纤增强30%,无卤阻燃。

用于连接器,线圈轴,开关,电视机零件,整流器等。

PBT 5115 玻纤增强15%,无卤阻燃,黑色规格。

用于连接器,开关,电视机零件,整流器等。

PBT 5130 玻纤增强30%,无卤阻燃,黑色规格。

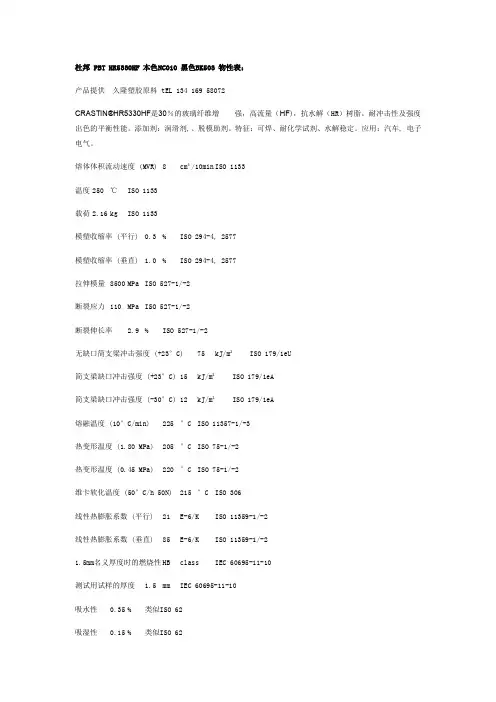

杜邦PBT HR5330HF本色NC010黑色BK503物性表:产品提供久隆塑胶原料tEL134********CRASTIN®HR5330HF是30%的玻璃纤维增强,高流量(HF),抗水解(HR)树脂。

耐冲击性及强度出色的平衡性能。

添加剂:润滑剂,、脱模助剂。

特征:可焊、耐化学试剂、水解稳定。

应用:汽车,电子电气。

熔体体积流动速度(MVR)8cm³/10min ISO1133温度250℃ISO1133载荷2.16kg ISO1133模塑收缩率(平行)0.3%ISO294-4,2577模塑收缩率(垂直) 1.0%ISO294-4,2577拉伸模量8500MPa ISO527-1/-2断裂应力110MPa ISO527-1/-2断裂伸长率 2.9%ISO527-1/-2无缺口简支梁冲击强度(+23°C)75kJ/m²ISO179/1eU简支梁缺口冲击强度(+23°C)15kJ/m²ISO179/1eA简支梁缺口冲击强度(-30°C)12kJ/m²ISO179/1eA熔融温度(10°C/min)225°C ISO11357-1/-3热变形温度(1.80MPa)205°C ISO75-1/-2热变形温度(0.45MPa)220°C ISO75-1/-2维卡软化温度(50°C/h50N)215°C ISO306线性热膨胀系数(平行)21E-6/K ISO11359-1/-2线性热膨胀系数(垂直)85E-6/K ISO11359-1/-21.5mm名义厚度时的燃烧性HB class IEC60695-11-10测试用试样的厚度 1.5mm IEC60695-11-10吸水性0.35%类似ISO62吸湿性0.15%类似ISO62密度1500kg/m³ISO1183。

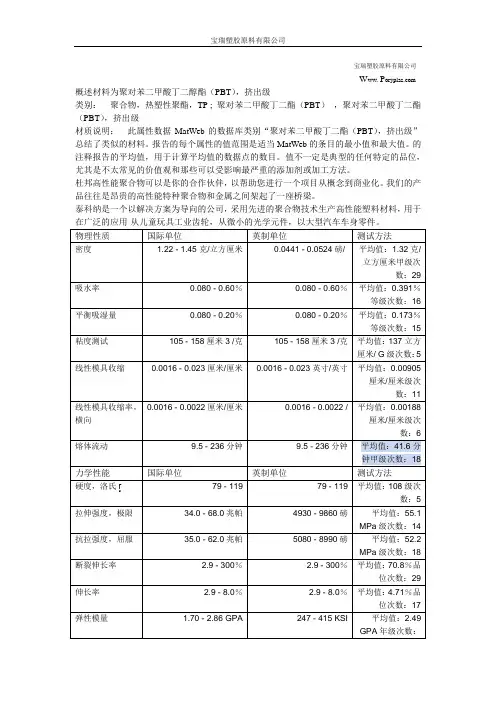

宝瑞塑胶原料有限公司

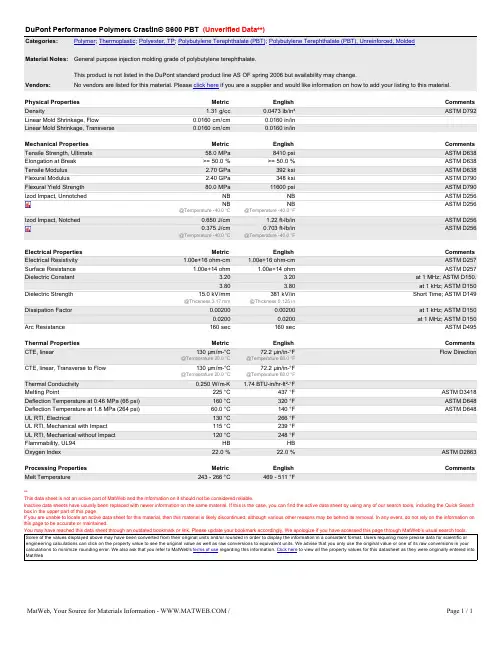

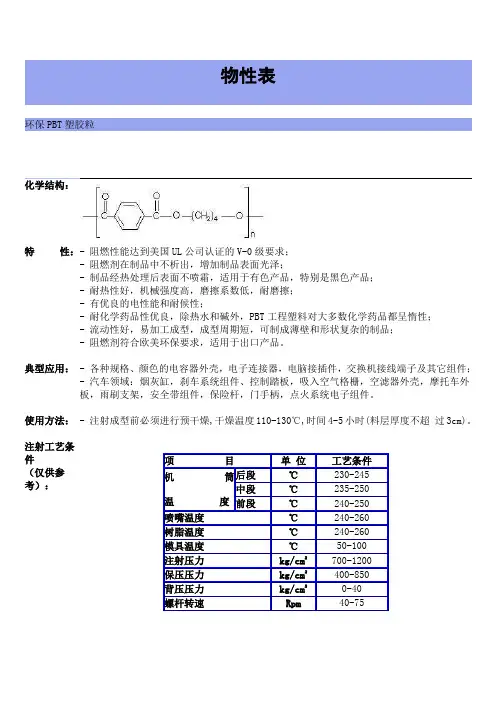

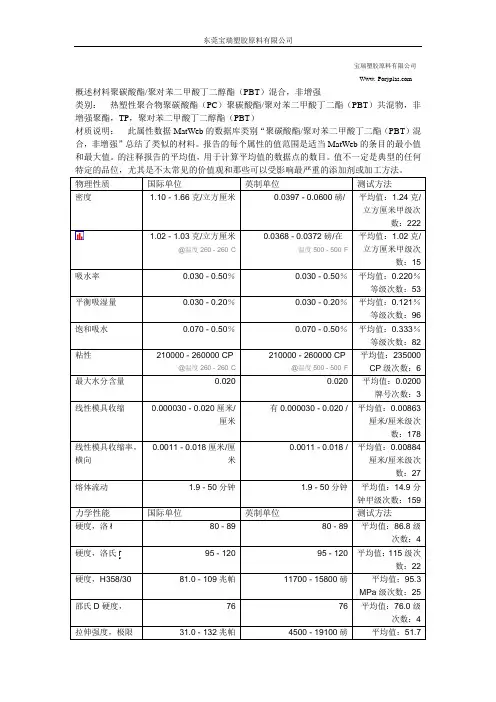

概述材料聚碳酸酯/聚对苯二甲酸丁二醇酯(PBT)混合,非增强

类别:热塑性聚合物聚碳酸酯(PC)聚碳酸酯/聚对苯二甲酸丁二酯(PBT)共混物,非增强聚酯,TP,聚对苯二甲酸丁二醇酯(PBT)

材质说明:此属性数据MatWeb的数据库类别“聚碳酸酯/聚对苯二甲酸丁二酯(PBT)混合,非增强”总结了类似的材料。

报告的每个属性的值范围是适当MatWeb的条目的最小值和最大值。

的注释报告的平均值,用于计算平均值的数据点的数目。

值不一定是典型的任何特定的品位,尤其是不太常见的价值观和那些可以受影响最严重的添加剂或加工方法。

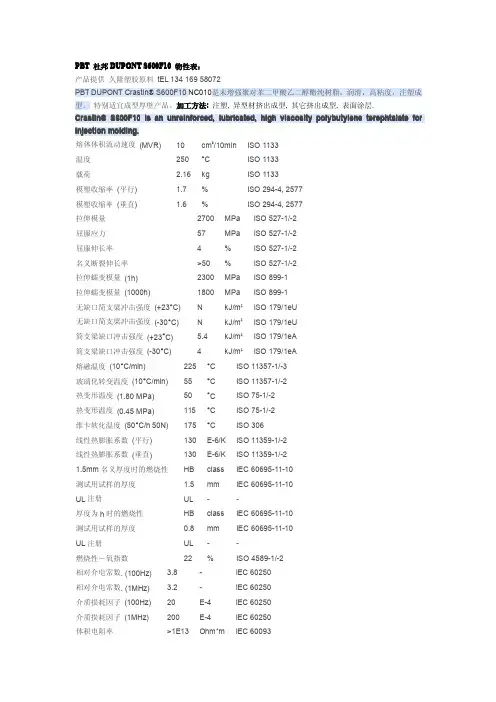

PBT杜邦DUPONT S600F10物性表:产品提供久隆塑胶原料tEL134********PBT DUPONT Crastin®S600F10NC010是未增强聚对苯二甲酸乙二醇酯纯树脂,润滑,高粘度,注塑成型。

特别适宜成型厚壁产品。

加工方法:注塑,异型材挤出成型,其它挤出成型,表面涂层.Crastin®S600F10is an unreinforced,lubricated,high viscosity polybutylene terephtalate for injection molding.熔体体积流动速度(MVR)10cm³/10min ISO1133温度250°C ISO1133载荷 2.16kg ISO1133模塑收缩率(平行) 1.7%ISO294-4,2577模塑收缩率(垂直) 1.6%ISO294-4,2577拉伸模量2700MPa ISO527-1/-2屈服应力57MPa ISO527-1/-2屈服伸长率4%ISO527-1/-2名义断裂伸长率>50%ISO527-1/-2拉伸蠕变模量(1h)2300MPa ISO899-1拉伸蠕变模量(1000h)1800MPa ISO899-1无缺口简支梁冲击强度(+23°C)N kJ/m²ISO179/1eU无缺口简支梁冲击强度(-30°C)N kJ/m²ISO179/1eU简支梁缺口冲击强度(+23°C) 5.4kJ/m²ISO179/1eA简支梁缺口冲击强度(-30°C)4kJ/m²ISO179/1eA熔融温度(10°C/min)225°C ISO11357-1/-3玻璃化转变温度(10°C/min)55°C ISO11357-1/-2热变形温度(1.80MPa)50°C ISO75-1/-2热变形温度(0.45MPa)115°C ISO75-1/-2维卡软化温度(50°C/h50N)175°C ISO306线性热膨胀系数(平行)130E-6/K ISO11359-1/-2线性热膨胀系数(垂直)130E-6/K ISO11359-1/-21.5mm名义厚度时的燃烧性HB class IEC60695-11-10测试用试样的厚度 1.5mm IEC60695-11-10UL注册UL--厚度为h时的燃烧性HB class IEC60695-11-10测试用试样的厚度0.8mm IEC60695-11-10UL注册UL--燃烧性-氧指数22%ISO4589-1/-2相对介电常数.(100Hz) 3.8-IEC60250相对介电常数.(1MHz) 3.2-IEC60250介质损耗因子(100Hz)20E-4IEC60250介质损耗因子(1MHz)200E-4IEC60250体积电阻率>1E13Ohm*m IEC60093表面电阻率1E15Ohm IEC60093介电强度26kV/mm IEC60243-1相对漏电起痕指数600-IEC60112吸水性0.5%类似ISO62吸湿性0.2%类似ISO62密度1300kg/m³ISO1183熔体密度1110kg/m³-熔体0.21W/(m K)-熔体的比热2100J/(kg K)-注塑成型参数:干燥温度110-130°C干燥时间,除湿机=2-4小时处理水分含量<0.04%熔体温度处理最佳=250°C熔体温度范围240-260°C模具温度最佳=80°C模具温度范围30-130°C型材挤出参数:干燥温度110-130°C干燥时间,除湿机=2-4小时处理水分含量<0.04%熔体温度处理最佳=250°C熔融温度范围为240-260°C。

宝瑞塑胶原料有限公司

W ww. P 概述材料为聚对苯二甲酸丁二醇酯(PBT),挤出级

类别:聚合物,热塑性聚酯,TP ; 聚对苯二甲酸丁二酯(PBT),聚对苯二甲酸丁二酯(PBT),挤出级

材质说明:此属性数据MatWeb的数据库类别“聚对苯二甲酸丁二酯(PBT),挤出级”总结了类似的材料。

报告的每个属性的值范围是适当MatWeb的条目的最小值和最大值。

的注释报告的平均值,用于计算平均值的数据点的数目。

值不一定是典型的任何特定的品位,尤其是不太常见的价值观和那些可以受影响最严重的添加剂或加工方法。

杜邦高性能聚合物可以是你的合作伙伴,以帮助您进行一个项目从概念到商业化。

我们的产品往往是昂贵的高性能特种聚合物和金属之间架起了一座桥梁。

泰科纳是一个以解决方案为导向的公司,采用先进的聚合物技术生产高性能塑料材料,用于。

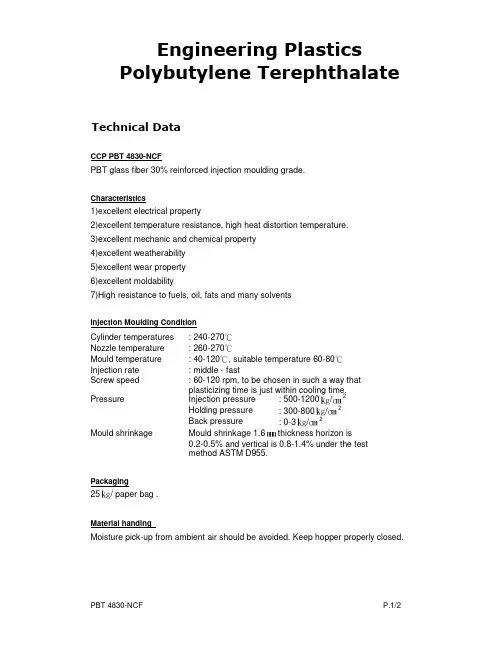

Engineering Plastics Polybutylene Terephthalate Technical DataCCP PBT 4830-NCFPBT glass fiber 30% reinforced injection moulding grade.Characteristics1)excellent electrical property2)excellent temperature resistance, high heat distortion temperature.3)excellent mechanic and chemical property4)excellent weatherability5)excellent wear property6)excellent moldability7)High resistance to fuels, oil, fats and many solventsInjection Moulding ConditionCylinder temperatures : 240-270℃Nozzle temperature : 260-270℃Mould temperature : 40-120℃, suitable temperature 60-80℃Injection rate : middle - fastScrew speed : 60-120 rpm, to be chosen in such a way thatplasticizing time is just within cooling time.Pressure Injection pressure : 500-1200㎏/㎝2Holding pressure : 300-800㎏/㎝2Back pressure : 0-3㎏/㎝2Mould shrinkage Mould shrinkage 1.6㎜thickness horizon is0.2-0.5% and vertical is 0.8-1.4% under the testmethod ASTM D955.Packaging25㎏/ paper bag .Material handingMoisture pick-up from ambient air should be avoided. Keep hopper properly closed. PBT 4830-NCF P.1/2CCP PBT 4830-NCFProperty Value Unit Test methodASTMGlass Fiber Content 30 %Specific gravity 1.63 - D792 Melting point 225 ℃DSC Coef. of linear thermal expansion 3 10-5㎝/㎝℃D696 Heat deflection temperature under load--- 18.6㎏/㎝2200 ℃D648--- 4.6㎏/㎝2218 ℃D648 Moisture absorption (24h) 0.03 %D570 Flammability acc. to UL94, 3.2㎜thickness V-0 - UL94Tensile strength 1200 ㎏/㎝2D638 Tensile elongation 3.2 %D638 Flexural strength 1800 ㎏/㎝2D790 Flexural modulus 85000 ㎏/㎝2D790 Izod impact strength - notched 1/4” 8.0 ㎏-㎝/㎝D256 Hardness - rockwell 121 R D785Dielectric strength, 2㎜thickness 22 KV/㎜D149 Volume resistivity 1015Ω-㎝D257 Surface resistivity 1013ΩD257 Dielectric constant 3.5 60Hz D150 Dielectric dissipation factor 0.001 60Hz D150 Arc resistance 100 SEC D495(1)For reference only(2)All data in the table are the typical values of the material and not the minimumvalues of the material specifications.P.2/2。

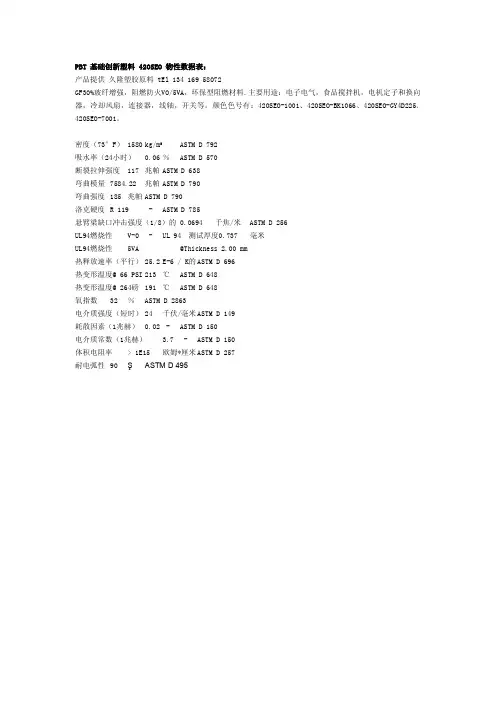

PBT基础创新塑料420SEO物性数据表:

产品提供久隆塑胶原料tEl134********

GF30%玻纤增强,阻燃防火VO/5VA,环保型阻燃材料.主要用途:电子电气,食品搅拌机,电机定子和换向器,冷却风扇,连接器,线轴,开关等。

颜色色号有:420SEO-1001、420SEO-BK1066、420SEO-GY4D225、420SEO-7001。

密度(73°F)1580kg/m³ASTM D792

吸水率(24小时)0.06%ASTM D570

断裂拉伸强度117兆帕ASTM D638

弯曲模量7584.22兆帕ASTM D790

弯曲强度185兆帕ASTM D790

洛克硬度R119-ASTM D785

悬臂梁缺口冲击强度(1/8)的0.0694千焦/米ASTM D256

UL94燃烧性V-0-UL94测试厚度0.737毫米

UL94燃烧性5VA@Thickness 2.00mm

热释放速率(平行)25.2E-6/K的ASTM D696

热变形温度@66PSI213℃ASTM D648

热变形温度@264磅191℃ASTM D648

氧指数32%ASTM D2863

电介质强度(短时)24千伏/毫米ASTM D149

耗散因素(1兆赫)0.02-ASTM D150

电介质常数(1兆赫) 3.7-ASTM D150

体积电阻率>1E15欧姆*厘米ASTM D257

耐电弧性90ŞASTM D495。

PBT3316泰科纳Ticona物性数据表:产品提供久隆塑胶原料tEl134********Celanex3316是一种30%玻璃纤维增强的非渗出性阻燃级(UL和CSA核准的V-0(在1/32英寸时)和5V(在1/16英寸时))聚对苯二甲酸丁二醇酯,其在机械性能和加工性能方面实现了优异平衡。

它非常适合电插座、连接器、电子电气用途。

其中其UL核准的50%再研磨使用能力使得所购买的产品得到最大利用。

熔体体积流动速度,MVR7cm³/10min250℃ 2.16kg ISO1133拉伸模量10700MPa ISO527-1/-2断裂应力135MPa ISO527-1/-2断裂伸长率 2.5%ISO527-1/-2无缺口简支梁冲击强度,+23℃59kJ/m²ISO179/1eU无缺口简支梁冲击强度,-30℃42kJ/m²ISO179/1eU简支梁缺口冲击强度,+23℃8.5kJ/m²ISO179/1eA简支梁缺口冲击强度,-30°C8.5kJ/m²ISO179/1eA熔融温度,10°C/min225℃ISO11357-1/-3热变形温度, 1.80MPa208℃ISO75-1/-2热变形温度,8.00MPa165℃ISO75-1/-2维卡软化温度,50°C/h50N225℃ISO306厚度为h时的燃烧性V-0class测试用试样的厚度0.4mm IEC60695-11-10燃烧性-氧指数30%ISO4589-1/-2介质损耗因子,100Hz33E-4IEC60250介质损耗因子,1MHz145E-4IEC60250体积电阻率1E13Ohm*m IEC60093表面电阻率1E15Ohm IEC60093介电强度34kV/mm IEC60243-1吸水性0.4%类似ISO62吸湿性0.16%类似ISO62密度1660kg/m³ISO1183PBT3316泰科纳Ticona注塑成型参数:为了避免CELANEX树脂在加工过程中发生水解降解,需将其干燥到水分含量等于或小于0.02%。

PBT,30%glass fibres,injection moulding,flame retardantISO Shortname:ISO 7792-1-PBT,GFHMR,09-110,GF30;ISO 1043-PBT GF FR(17)PropertyTest ConditionUnitStandardguide valueRheological properties C Melt volume-flow rate 260°C;5kgcm³/(10min)ISO 1133-137C Molding shrinkage,parallel 60x60x2;250°C /WZ 80°C;600bar%ISO 294-40.3C Molding shrinkage,transverse 60x60x2;250°C /WZ 80°C;600bar%ISO 294-40.9Post-shrinkage,parallel 60x60x2;120°C;4h %ISO 294-40.1Post-shrinkage,transverse60x60x2;120°C;4h%ISO 294-40.1Mechanical properties (23°C/50%r.h.)C Tensile modulus 1mm/min MPa ISO 527-1,-211500C Tensile Stress at break 5mm/min MPa ISO 527-1,-2125C Tensile Strain at break 5mm/min %ISO 527-1,-2 2.1C Charpy impact strength 23°C kJ/m²ISO 179-1eU 50C Charpy impact strength -30°C kJ/m²ISO 179-1eU 50C Charpy notched impact strength 23°C kJ/m²ISO 179-1eA <10C Charpy notched impact strength -30°C kJ/m²ISO 179-1eA <10Izod impact strength 23°C kJ/m²ISO 180-1U 45Izod impact strength -30°C kJ/m²ISO 180-1U 45Izod notched impact strength 23°C kJ/m²ISO 180-1A <10Izod notched impact strength -30°C kJ/m²ISO 180-1A <10Flexural modulus 2mm/min MPa ISO 178-A 10500Flexural strength2mm/min MPa ISO 178-A 200Flexural strain at flexural strength 2mm/min%ISO 178-A 2.6Ball indentation hardness N/mm²ISO 2039-1186C Puncture energy 23°C J ISO 6603-2 2.3C Puncture energy -30°C J ISO 6603-2 2.1C Puncture maximum force 23°C N ISO 6603-2669C Puncture maximum force -30°C NISO 6603-2649Thermal properties C Melting temperature10°C/min °C ISO 11357-1,-3225C Temperature of deflection under load 1.80MPa °C ISO 75-1,-2200C Temperature of deflection under load 0.45MPa °C ISO 75-1,-2220Vicat softening temperature50N;120°C/h °C ISO 306205C Coefficient of linear thermal expansion,parallel 23to 55°C 10-4/K ISO 11359-1,-20.2C Coefficient of linear thermal expansion,transverse 23to 55°C 10-4/K ISO 11359-1,-20.9C Burning behavior UL 940.38mm Class UL 94V-0C Burning behavior UL 940.8mm Class UL 94V-0C Oxygen indexMethod A%ISO 4589-232Pocan B 4239000000Page 1of 3PropertyTest Condition Unit Standard guide valueThermal conductivity23°CW/(m·K)ISO 83020.24Resistance to heat (ball pressure test)°C IEC 60695-10-2213Temperature index (Tensile strength)20000h °C IEC 60216-1155Halving interval (Tensile strength)°C IEC 60216-19.3Relative temperature index (Tensile strength)°C UL 746B 140Temperature index (Tensile impact strength)20000h °C IEC 60216-1130Halving interval (Tensile impact strength)°C IEC 60216-18.4Relative temperature index (Tensile impact strength)°C UL 746B 110Temperature index (Electric strength)20000h °C IEC 60216-1145Halving interval (Electric strength)°C IEC 60216-112Relative temperature index (Electric strength)°C UL 746B 125Glow wire test (GWFI)0.8mm °C IEC 60695-2-12960Glow wire test (GWIT)0.8mm °C IEC 60695-2-13725Glow wire test (GWIT) 1.6mm °C IEC 60695-2-13725Glow wire test (GWIT)3.0mm °CIEC 60695-2-13725Electrical properties (23°C/50%r.h.)C Relative permittivity 100Hz -IEC 60250 3.9C Relative permittivity 1MHz -IEC 60250 3.8C Electric strength1mm kV/mm IEC 60243-135C Comparative tracking index CTI Solution AV IEC 60112275Electrolytic corrosion RatingIEC 60426A/B 1Other properties (23°C)C Density kg/m³ISO 11831670Bulk densitykg/m³ISO 60800Processing conditions for test specimens C Injection molding-Melt temperature °C ISO 294250C Injection molding-Mold temperature °CISO 29480Processing recommendations Drying time circulating air dryer h -4-8Drying temperature circulating air dryer °C -120Residual moisture content %Acc.to Karl Fischer 0-0.02Melt temperature (Tmin -Tmax)°C -240-260Mold temperature°C-80-100C These property characteristics are taken from the CAMPUS plastics data bank and are based on the international catalogue of basic data for plastics according to ISO10350.Pocan B 4239000000Page 2of 3DisclaimerDisclaimer for sales productsThis information and our technical advice -whether verbal,in writing or by way of trials -are given in good faith but without warranty,and this also applies whereproprietary rights of third parties are involved.Our advice does not release you from the obligation to verify the information currently provided -especially that contained in our safety data and technical information sheets -and to test our products as to their suitability for the intended processes and uses.The application,use and processing of our products and the products manufactured by you on the basis of our technical advice are beyond our control and,therefore,entirely your own responsibility.Our products are sold in accordance with the current version of our General Conditions of Sale and Delivery.Test valuesUnless specified to the contrary,the values given have been established on standardized test specimens at room temperature.The figures should be regarded as guide values only and not as binding minimum values.Kindly note that,under certain conditions,the properties can be affected to a considerable extent by the design of the mould/die,the processing conditions and the coloring.Processing noteUnder the recommended processing conditions small quantities of decomposition product may be given off during processing.To preclude any risk to the health and well-being of the machine operatives,tolerance limits for the work environment must be ensured by the provision of efficient exhaust ventilation and fresh air at theworkplace in accordance with the Safety Data Sheet.In order to prevent the partial decomposition of the polymer and the generation of volatile decomposition products,the prescribed processing temperatures should not be substantially exceeded.Since excessively high temperatures are generally the result of operator error or defects in the heating system,special care and controls are essential in these areas.LANXESS DEUTSCHLAND GMBH |D -51369LEVERKUSEN ©LANXESS DeutschlandGmbHPocan B 4239000000Page 3of 3。