台达Delta人机界面

- 格式:doc

- 大小:21.00 KB

- 文档页数:1

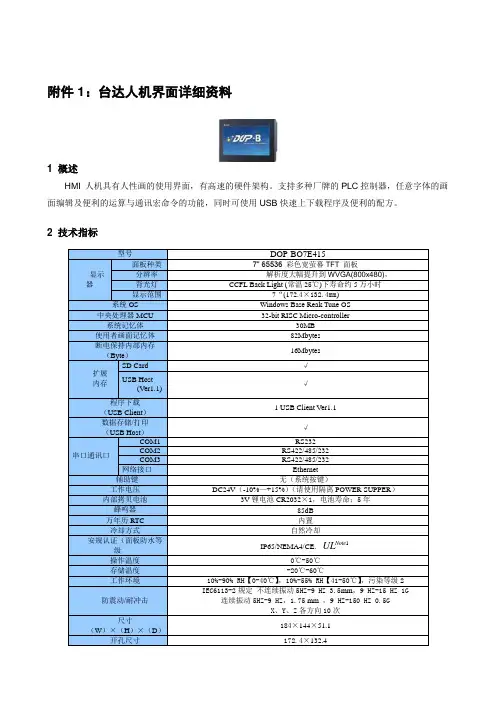

DOP -B10High Color ‧Wide Screen ‧User-Friendly HMI ProductsNo.18, Xinglong Rd., Taoyuan City33068, TaiwanB10S615 / B10E615 Instrunction Sheet(1) PrefaceThank you for purchasing DELTA’s DOP-B series. This instruction sheet will be helpful in the installation, wiring and inspection of Delta HMI. Before using the product, please read this instruction sheet to ensure correct use. You should thoroughly understand all safety precautions before proceeding with the installation, wiring and operation. Place this instruction sheet in a safe location for future reference. Please observe the following precautions: ⏹ Install the product in a clean and dry location free from corrosive and inflammable gases or liquids. ⏹ Ensure that all wiring instructions and recommendations are followed. ⏹ Ensure that HMI is correctly connected to a ground. The grounding method must comply with the electrical standard ofthe country (Please refer to NFPA 70: National Electrical Code, 2005 Ed.). ⏹ Do not disassemble HMI, modify or remove wiring when power is applied to HMI. ⏹ Do not touch the power supply during operation. Otherwise, it may cause electric shock.If you have any questions during operation, please contact our local distributors or Delta sales representatives.The content of this instruction sheet may be revised without prior notice. Please consult our distributors or download the most updated version at /ia(2) Safety PrecautionsCarefully note and observe the following safety precautions when receiving, inspecting, installing, operating, maintaining and troubleshooting. The following words, DANGER, WARNING and STOP are used to mark safety precautions when using the Delta’s HMI product. Failure to observe these precautions may void the warranty! InstallationWiringOperationD o not modify wiring during operation. Otherwise it may result in electric shock or personal injury. N ever use a hard or pointed object to hit or strike the screen as doing this may damage the screenand let the screen has not respond at all, and then cause HMI to work abnormally.Maintenance and InspectionD o not touch any internal or exposed parts of the HMI as electrical shock may result.Do not remove operation panel while power is on. Otherwise electrical shock may result. W ait at least 10 minutes after power has been removed before touching any HMI terminals orperforming any wiring and/or inspection as an electrical charge may still remain in the HMI withhazardous voltages even after power has been removed. T urn the power off before changing backup battery and check system settings after finishingchange. (all data will be cleared after changing battery). B e sure the ventilation holes are not obstructed during operation. Otherwise malfunction may resultdue to bad ventilation or overheating troubles.Wiring MethodCommunication Wiring(3) Pin Definition of Serial CommunicationDOP-B10S615 / DOP-B10E615 COM1 Port (Supports Flow Control)COM PortPINContact RS-2321 2 RXD3 TXD 45 GND 67 RTS 8 CTS9Note: Blank = No Connection.DOP-B10S615 / DOP-B10E615 COM2 Port (Supports Flow Control)COM PortPINMODE1 MODE2 MODE3 RS-232RS-422RS-4851 TXD+ D+2 RXD3 TXD 4RXD+5 GND GND GND 6TXD- D- 7 RTS 8 CTS9 RXD-Note1: Blank = No Connection.Note2: When COM2 port is used for RS-232 flow control, i.e. RTS and CTS signals are used for flow control, COM3 port will becomeincapable of being used.Note3: When COM2 port is used for RS-422 flow control, please refer to the following COM3 Port signals table for pin assignments. Thesignals, RTS+, CTS+, RTS- and CTS- shown in brackets are the signals used for flow control.DOP-B10S615 / DOP-B10E615 COM3 PortCOM PortPINMODE1 MODE2 MODE3 RS-232RS-422RS-4851 TXD+(RTS+) D+2 RXD3 TXD4 RXD+(CTS+)5 GND GND GND6 TXD-(RTS-) D-789 RXD-(CTS-)Note1: Blank = No Connection.Note2: When COM2 port is used for RS-422 flow control, please refer to the COM3 Port signals table above for pin assignments. The signals,RTS+, CTS+, RTS- and CTS- shown in brackets are the signals used for flow control.DOP-B10E615 Ethernet Interface (LAN)Ethernet Interface (LAN)PINContact Ethernet1 TX+2 TX-3 RX+ 45 6 RX-7 8Note: Blank = No Connection.(4) Parts NamesDOP-B10S615 / DOP-B10E615 (Front View): Power LED Indicator: Operation LED Indicator (Blue) : Alarm LED Indicator (Red)DOP-B10S615/DOP-B10E615 (Rear View)APower Input Terminal FEthernet Interface (LAN)BCOM2(It is provided with two LED indicators to indicate that HMI is in Read or Write status during the communication process.) GMemory Card Slot / Battery CoverCCOM3(It is provided with two LED indicators to indicate that HMI is in Read or Write status during the communication process.) HUSB HostD COM1 I Audio Output Interface EUSB SlaveJSystem KeyPIN1PIN1PIN1EFACDJG(5) DimensionsDOP-B10S615 / DOP-B106515Note:T=1.6mm(0.063")~6mm(0.24")+1.0+0.04"(6) SpecificationsDOP-B10S615DOP-B106515L C D M O D U L EDisplay Type 10.1” Widescreen TFT LCD(65536 colors)Resolution 1024 x 600 pixelsBacklight LED Back Light (less than 10,000 hours half-life at 25oC)(Note 1)Display Size 226 x 128.7mm Operation SystemDelta Real Time OS MCU 32-bit RISC Micro-controllerNOR Flash ROMFlash ROM 128 MB(OS System: 30MB / Backup: 16MB / User Application: 82MB)SDRAM 64Mbytes Backup Memory 16MbytesSound Effect OutputBuzzer Multi-Tone Frequency (2K ~ 4K Hz )/85dBAUXN/A Stereo output Ethernet Interface N/AIEEE 802.3, IEEE 802.3u10/100 Mbps auto-sensing(has built-in isolated power circuit(Note 3))USB 1 USB Host(Note 2)Ver 1.1 / 1 USB Slave Ver 2.0Memory CardSD Card (supports SDHC)Serial COM PortCOM1RS-232 (supports hardware flow control)COM2 RS-232/RS-422/RS-485 RS-232 / RS-422 / RS-485(has built-in isolated power circuit (Note 3))COM3RS-232/RS-422/RS-485RS-232 / RS-422 / RS-485(has built-in isolated power circuit (Note 3)) Function Key N/A Perpetual Calendar(RTC) Built-inCooling Method Natural air circulation Safety Approval CE /UL(Note 4)/KCC(Note 4)Waterproof Degree IP65/NEMA4Operation Voltage(Note 5)DC +24V (-10% ~ +15%)(has built-in isolated power circuit (Note 3))Voltage Endurance AC500V for 1 minute (between charging (DC24V terminal) and FG terminals)Power Consumption(Note 5)12WBackup Battery 3V lithium battery CR2032 x 1Backup Battery Life It depends on the temperature used and the conditions of usage, about 3 yearsor more at 25oC.Operation Temp. 0oC ~ 50oC Storage Temp.-20oC ~ +60oCAmbient Humidity10% ~ 90% RH [0 ~ 40o C], 10% ~ 55% RH [41 ~ 50oC]Pollution Degree 2Vibration IEC 61131-2 compliant 5Hz ≦f <8.3Hz = Continuous: 3.5mm, 8.3Hz ≦f ≦150Hz= Continuous: 1.0gShock IEC 60068-2-27 compliant 15g peak for 11 ms duration, X, Y, Z directions for 6timesDimensions(W) x (H) x (D) mm 272 x 200 x 61 Panel Cutout (W) x (H) mm261.3 X 189.3 WeightApprox.1520gThe life of LED backlight shown here is an estimated value under 25oC normal temperature and humidity conditions. 2) USB Host port can provide up to 5V/ 500mA of power.3) The withstand voltage of the isolated power circuit is 1500V peak for 1 minute.4) Some models are in the process of application to UL and KCC certification. For more information, please consult our distributors. 5)The value of the power consumption indicates the electrical power consumed by HMI only without connecting to any peripheraldevices. In order to ensure the normal operation, it is recommended to use a power supply which the capacity is 1.5 ~2 times the value of the power consumption.6)The content of this quick start may be revised without prior notice. Please consult our distributors or download the most updated version at /ia/.DOP -B10Yüksek Renk ‧Geni ş Ekran ‧Kullan ım ı Kolay HMI ÜrünleriNo.18, Xinglong Rd., Taoyuan City33068, TaiwanB10S615 / B10E615 Bilgi Döküman ı(1) ÖnsözDELTA’n ın DOP-B serisi operatör panellerini seçti ğiniz için te şekkürler. Bu bilgi döküman ı Delta HMI kurulum, ba ğlant ı, bak ım ve kontrolünde kullan ıc ıya yard ımc ı olacakt ır. Do ğru kullan ım için ürünü kullanmadan önce bu döküman ı mutlaka okuyunuz. Kurulum, ba ğlant ı ve çal ışma yapmadan önce güvenlik uyar ılar ın ı tamamen anlad ığın ızdan emin olunuz. Bu döküman ı daha sonra da kullanmak için iyi muhafaza ediniz. Lütfen a şa ğıdaki güvenlik uyar ılar ına dikkat ediniz: ⏹ Ürünün kurulumunu yan ıc ı gaz ve s ıv ılardan uzak kuru ve temiz ortamlara yap ın ız. ⏹ Ba ğlant ılar ı yaparken tüm ba ğlant ı kurallar ın ın sa ğland ığından emin olunuz.⏹ HMI’n ın toprak ba ğlant ıs ın ın do ğru yap ıld ığından emin olunuz. Topraklama metodunun ürünün kuruldu ğu ülkestandartlar ına uygun oldu ğuna emin olunuz (NFPA 70: National Electrical Code, 2005 Ed.). ⏹ HMI enerjili iken kablo ba ğlant ıs ı yapmay ın ız ya da sökmeyiniz.⏹ Çal ışma s ıras ında enerji besleme terminallerine dokunmay ın ız. Aksi halde elektrik şoku olabilir. Ürünün kullan ım ı ile ilgili sorular ın ız için, lütfen teknik servisimizle ba ğlant ıya geçiniz.Herhangi bir ihbara gerek kalmaks ız ın bu bilgi döküman ın ın içeri ği de ği ştirilebilir. Güncellenmi ş versiyonu elde etmek için teknik servise dan ışabilir veya internet adresinden indirebilirsiniz. /ia(2) Güvenlik Uyar ılar ıÜrünü al ırken, kontrol ederken, kurulumunu yaparken, çal ışt ır ırken, bak ım ve ar ıza te şhisi yaparken a şa ğıdaki güvenlik uyar ılar ına dikkat ediniz. DANGER, WARNING, ve STOP ba şl ıklar ı DELTA HMI ürününü kullan ırken yap ılmas ı gerekenleri dikkat çekmek için kullan ılm ışt ır. Ürünün garantisini muhafaza etmek için bu uyar ılara mutlaka dikkat ediniz!KurulumBa ğlant ıÇal ışmaÇal ışma s ıras ında kablo ba ğlant ılar ın ı de ği ştirmeyiniz. Aksi halde elektrik şokuna veyaki şisel zararlara sebep olabilir. D okunmatik ekrana sert ve sivri nesneler kullanarak basmay ın ız. Aksi halde HMI ekran ızarar görebilir, komutlara cevap veremeyebilir ve HMI’n ın anormal çal ışmas ına sebep olabilir.Bak ım ve KontrollerH MI içindeki devre elemanlar ına dokunmay ın ız aksi halde elektrik şoku meydana gelebilir. Enerjili iken operatör paneli ba ğlant ılar ına müdahale etmeyiniz. Aksi halde elektrik şokumeydana gelebilir. H MI enerjisi kesildikten sonra HMI üzerinde tehlikeli seviyede elektrik şarj voltaj ıkalabilece ğinden ürüne dokunmadan ve ba ğlant ılara müdahale etmeden önce en az 10 dakika beklenilmesi tavsiye edilir. P ili de ği ştirmeden önce ürünün enerjisini kesiniz ve pili de ği ştirdikten sonra sistemayarlar ın ı kontrol ediniz. (Pil de ği ştirildikten sonra tüm datalar silinecektir). Çal ışma s ıras ında havaland ırma deliklerinin t ıkal ı olmad ığından emin olunuz. Aksi haldekötü havaland ırmadan veya a şır ı s ıcakl ıktan dolay ı ürün zarar görebilir.Ba ğlant ı MetoduHaberle şme Ba ğlant ıs ı(3) Seri Haberle şme Pin Açıklamalar ıDOP-B10S615 / DOP-B10E615 COM1 Port (Flow Control destekler)COM PortPINBa ğlantı RS-2321 2 RXD3 TXD 45 GND 67 RTS 8 CTS9Not: Bo ş pin = Ba ğlant ı yok.DOP-B10S615 / DOP-B10E615 COM2 Port (Flow Control destekler)COM PortPINMOD 1 MOD 2 MOD 3 RS-232RS-422RS-4851 TXD+ D+2 RXD3 TXD 4RXD+5 GND GND GND 6TXD- D- 7 RTS 8 CTS9 RXD-Not 1: Bo ş pin = Ba ğlant ı yap ılmaz.Not 2: COM2 portu RS-232 flow control kullan ılaca ğı zaman, RTS ve CTS sinyalleri flow control olarak kullan ıl ır, COM3 portu kullan ılamaz.Not 3: COM2 portu RS-422 flow control kullan ılaca ğı zaman, lütfen a şa ğıdaki COM3 port pin sinyal çık ışlar ın ı inceleyiniz. Paranteziçinde gösterilen RTS+, CTS+, RTS- ve CTS- sinyalleri flow control olarak kullan ıl ır .DOP-B10S615 / DOP-B10E615 COM3 PortCOM PortPINMOD 1 MOD 2 MOD 3 RS-232RS-422RS-4851 TXD+(RTS+) D+2 RXD3 TXD4 RXD+(CTS+)5 GND GND GND6 TXD-(RTS-) D-789 RXD-(CTS-)Not 1: Bo ş pin = Ba ğlant ı yap ılmaz.Not 2: COM2 portu RS-422 flow control kullan ılaca ğı zaman, lütfen yukar ıdaki COM3 port pin sinyal çık ışlar ın ı inceleyiniz.Parantez içinde gösterilen RTS+, CTS+, RTS- ve CTS- sinyalleri flow control olarak kullan ıl ır .DOP-B10E615 Ethernet Arabirim (LAN)Ethernet Arabirim (LAN)PINBa ğlant ı Ethernet1 TX+2 TX-3 RX+ 45 6 RX-7 8Not: Bo ş pin = Ba ğlant ı yap ılmaz .(4) Parça İsimleriDOP-B10S615 / DOP-B10E615 (Ön Görünüm): : : DOP-B10S615/DOP-B10E615 (Rear View)APower Giri ş TerminalFEthernet Arabirim (LAN)B COM2(Haberle şme s ıras ında HMI’n ın yazma veokuma durumunu gösteren iki LED indikator sa ğlar .)G Memory Card Slot / Pil Kapa ğıCCOM3(Haberle şme s ıras ında HMI’n ın yazma ve okuma durumunu gösteren iki LED indikator sa ğlar .)HUSB HostD COM1 I Audio Çık ış ArabirimiEUSB SlaveJSistem Tu şuPIN1PIN1PIN1EFACDJG(5) ÖlçülerDOP-B10S615 / DOP-B10E615Note:T=1.6mm(0.063")~6mm(0.24")+1.0+0.04"(6) ÖzelliklerDOP-B10S615 DOP-B10E615L C D M O D ÜLDisplay Tipi 10.1” Geni ş Ekran TFT LCD(65536 renk)Çözünürlük 1024 x 600 pikselArka I şık LED Ayd ınlatma (25oC yar ım ömürde 10,000 saatden az)(Not 1)Display Ölçüsü 226 x 128.7mm İşletim SistemiDelta Real Time OS MCU 32-bit RISC Micro-controllerNOR Flash ROMFlash ROM 128 MB(OS Sistem: 30MB / Backup: 16MB / Uygulama: 82MB)SDRAM 64Mbytes Backup Memory 16MbytesSes Efekt Çık ışı Buzzer Multi-Tone Frekans (2K ~ 4K Hz) / 85dB AUX N/A Stereo çık ışEthernet ArabirimN/A IEEE 802.3, IEEE 802.3u10/100 Mbps oto-alg ılama(dahili izole güç devresi (Not 3))USB 1 USB Host(Note 2)Ver 1.1 / 1 USB Slave Ver 2.0Memory CardSD Card (SDHC destekler)Seri COM PortCOM1RS-232 (hardware flow control destekler)COM2 RS-232/RS-422/RS-485 RS-232 / RS-422 / RS-485(dahili izole güç devresi (Not 3)) COM3RS-232/RS-422/RS-485RS-232 / RS-422 / RS-485(dahili izole güç devresi (Not 3))Fonksiyon Tu şu N/A Gerçek Zaman Saati (RTC) DahiliSo ğutma Metodu Do ğal Hava So ğutma Güvenlik Onay ı CE /UL(Note 4)/KCC(Note 4)Su geçirmezlik derecesi IP65/NEMA4Çal ışma Voltaj ı(Not 5)DC +24V (-10% ~ +15%)(dahili izole güç devresi (Not 3))Dayanma Voltaj ı 1 dakika için AC500V (DC24V terminal ve FG terminalleri aras ında)Güç Tüketimi(Not 5)12WBackup Battery 1 adet 3V lityum pil CR2032Backup BatteryÖmrü Kullan ım ko şullar ına ve ortam s ıcakl ığına ba ğl ı, 25oC’de 3 y ıl veya daha fazla.Çal ışma S ıcakl ığı 0oC ~ 50oC Saklama S ıcakl ığı-20oC ~ +60oCRutubet Oran ı 10% ~ 90% RH [0 ~ 40o C], 10% ~ 55% RH [41 ~ 50oC]Kirlenme Derecesi 2Titre şim IEC 61131-≦2 uyumlu 5Hz f <8.3Hz = Sürekli: 3.5mm,≦≦8.3Hz f 150Hz = Sürekli: 1.0gŞokIEC 60068-2-27 uyumlu 11ms süresince 15g pik,X, Y, Z yönünde 6 defaÖlçüler(W) x (H) x (D) mm 272 x 200 x 61 Panel Kesim (W) x (H) mm261.3 X 189.3 A ğırl ıkYakla şık 1520ggösterilen arka ışık LED ayd ınlatma ömrü 25 derecede normal s ıcakl ık ve rutubet ortam ında tahmin edilen de ğerlerdir. 2) USB Host port 5V/ 500mA güç sa ğlar. 3) İzoleli güç devresinin 1 dakika için peak de ğeri 1500V.4) Baz ı modeller için UL ve KCC ba şvurusu yap ılm ış ve i şlem a şamas ındad ır. Daha fazla bilgi için teknik servisimizle ba ğlant ıyageçebilirsiniz. 5) Güç tüketimi de ğeri sadece HMI için olup hiç bir harici cihaza ba ğl ı de ğilken ki de ğerdir. Normal çal ışmay ı garanti alt ına almak içinözelliklerde belirtilen güç de ğerinin 1.5 veya 2 kat ı güç tüketimini kar şılayacak bir güç kayna ğı ile kullan ılmas ı önerilir.6) Herhangi bir ihbar olmadan bu döküman ın içeri ği de ği ştirilebilir. En son güncellenmi ş halini firmam ızdan talep edebilir yada a şa ğıdakilink adresinden indirebilirsiniz /ia/.DOP-B10高彩‧寬螢幕‧友善人機介面No.18, Xinglong Rd., Taoyuan City33068, TaiwanB10S615 / B10E615安裝說明(1) 一般注意事項感謝您使用本產品,本人機介面安裝說明書提供DOP-B系列人機介面的相關資訊。

台达通讯示范程序及说明一、本试验主要完成以下功能:1〕通过RS指令完成在HMI上读写DTA温度控制器、ASDA台达伺服控制器任意地址数据;2〕通过人机HMI/PC实现伺服电机Pr模式下回原点、任意位置选择与定位控制。

二、试验用硬件和软件列表名称型号数量序号1台达温度控制器DTA9696R112台达伺服单元ASD-A0420LA13台达PLC DVP12SA11T14人机界面HMI PWS6600S-S1524V电源**15通讯线**假设干调试过程中使用的软件:1〕.P画面编程软件2〕.DeltaservoUIsoftware伺服调试工具3〕.台达PLC编程软件WPLSoft-三、资料引用描述:1〕.ADP软件使用说明.pdf2〕.ASD-A系列伺服驱动器系列手册.pdfM1000~M1014:参见P2-61~P2-63BMOV:全部传送参见P6-24RS:数据传输参见P7-81ASCI:HEX转为ASCII参见P7-97HEX:ASCII HEX参P7-102CCD:校参P7-1053〕台达温度控制器DTA系列操作手册四.程序中的关键局部编写思路1〕“二〞的算:一个8位十六制数(如**H)的二的算方法是:FFH-**H+01H=100H-**H2〕程的候参考章〔RS:数据参P7-81〕ASCII表3〕下面我以写数据例来明程思路如下所示,在PLC启正向RUN的瞬,写入初始化数〔中左列所示〕;由人机界面入16制数地址〔如4700H〕,通ASCI指令将其每一位化ASCII存放到D60〔D80〕开始的4个数据存放器中,然后通BMOV指令送到D105⋯D108〔D109⋯D112〕中。

数据入以后,从地址ADR1/0开始,两个一依次相加算校〔程序明〕。

在一个PLC描周期,需要将数据写入指定的地址当中去,以免生,但是在人机界面上,在同一只能写入一个数据,解决个矛盾,我采用先把数据写入PLC的数据存放器中,待地址和数据都写好以后,人地一个触信号,将数据同写入。

Delta DOP HMI实用通信实例Applied Example Of Delta DOP HMI Communication摘要:本文介绍了Delta DOP触摸屏的一些通信特点合不同情况下的一些通信选择关键词:触摸屏通信 PLC MODBUSAbstract: The paper introduces several advantages and several choices under different situations of Delta DOPKey words: HMI(Human Machine Interface) Communication PLC MODBUS_______________________________________________________________________________一引言众所周知,DOP系列触摸屏的优良特性使它受到众多用户的青睐。

而历史原因造成大量控制设备的开放性很差、通信能力弱,一些厂家的产品(或系统)因保密需要也不会采用公开的通信协议,许多产品设计初期未曾考虑过通信连接,等等,这些都使触摸屏与之通信连接面临许多困难。

然而,市场需求推动技术进步,产品的更新换代使越来越多产品采用高文件控制器,从单片机到PLC再到PC机,通信能力越来越强,而用单片机的系统也开始集成通信协议,所以,强大的通信能力将保证触摸屏的广阔应用前景。

这篇文章中,笔者特别将DOP的各种可能通信汇集在一起,图文并茂,供广大的初学者使用,也可供对DOP熟悉的技术人员参考。

二DOP的通信介绍DOP A系列产品本身集成两个串行通信接口(如图),分别标记为COM1, COM2。

其中COM1为RS232, COM2为RS232/RS485(可选)。

AE系列提供三个串行通信口,本文以A系列DOP为例进行说明。

要实现DOP触摸屏与外部其它设备的通信,除了通信口物理特性匹配外,还需要通信各方采用相同的通信规约(即通信协议),从OSI七层模型看,这部分属于数据链路层(复杂的通信协议还与网络层密切相关),主要体现在信息帧传送协议(包括差错控制)上。

目录台达 CODESYS 运动控制方案产品介绍运动控制器现场装置人机界面软件硬件规格选型说明产品信息台达 CODESYS 运动控制方案自动化和数字化在智能制造时代中扮演重要的角色。

机械制造商为了增加竞争力,积极寻找可以快速扩展设备开发和应用的方法,以减少机台建造所需投入的时间和人力。

台达和 CODESYS 集团合作,开发以CODESYS 平台为基础的全新运动控制解决方案。

CODESYS 平台为一符合IEC 61131-3标准且容易上手的整合平台。

此平台丰富的运动控制功能可以支持全球使用者多样化的应用,并方便落实到现有设备。

台达 CODESYS 运动控制方案整合PLC 、HMI 、和运动控制器的控制功能,并将其运用在不同的新产品中,包括PC-Based 运动控制器AX-864E 系列和PLC-Based 运动控制器AX-308E 系列。

此方案通过EtherCAT 运动总线,可同步控制台达交流伺服驱动器ASDA-A3-E 、ASDA-B3-E 、ASDA-A2-E 等系列、精巧标准型矢量控制变频器MS300 / MH300系列、泛用型矢量控制变频器C2000 Plus 系列、远端模块R1-EC 系列和DVP EtherCAT 远端I/O 模块。

完善、整合性高的台达 CODESYS 运动控制方案,可满足多样的应用需求。

PC-Based 运动控制器AX-864E 系列PLC-Based 运动控制器AX-308E 系列伺服驱动器PC-Based PLC-Based人机界面远端I/O 模块變頻器ASDA-A2-EASDA-A3-EASDA-B3-EAX-864EAX-308EDOP-100R1-ECDVP(EtherCAT 远端I/O 模块)C2000 PlusMH300MS300软件运动控制器现场装置●使用符合国际 IEC 61131-3 规范的CODESYS SoftPLC 开发软件和SoftMotion ●最多可支持 64 轴●无排线、无风扇的标准工业计算机等级架构 ●Intel x86 CPU●内置安全IC 系统,提升软硬件安全性 ●低电压检测机制和资料覆写功能 ●内置8组高速输入/输出接口●适合运用于工业机器人、木工、印刷、包装、印刷等行业●AX-308E CPU 最多可支持 8 轴 EtherCAT 伺服 (最短同步时间: 8轴 / 2 ms )●支持台达PLC AS 系列电源、数字IO 、模拟IO 和温度扩展模块 ●高效能: 基本指令的最短执行时间为5 ns●提供常用指令如位置、速度、扭矩、多轴补间、E-gear 、ECAM 等指令●内置16组DI 、8组DO 、2组增量编码器、SSI 绝对型编码器、RS232/485、Ethernet 和EtherCAT 通讯接口PC-Based 运动控制器AX-864E支持EtherCAT 通讯协议和基于CODESYS 的编辑软件,提供全面和整合的运动控制解决方案PLC-Based 运动控制器AX-308E支持 EtherCAT 通讯协议和基于CODESYS 的编辑软件,提供不同行业实时弹性的运动控制解决方案运动控制器现场装置交流伺服系统符合IEC 61158和IEC 61800-7现场总线标准;支持CiA402规格中所有CoE 模式和各项EtherCAT 命令模式ASDA-A2-EASDA-B3-EASDA-A3-E●CODESYS 原厂认证●通过ETG (EtherCAT Technology Group)兼容性测试认证 ●支持绝对型和增量型编码器伺服电机 ●支持高速位置抓取功能●ASDA-A3-E 和ASDA-A2-E 内置符合SIL2 (IEC EN 61508 & IEC 62016) / Cat. 3 PL=d (ISO 13894-1)标准的安全扭矩停止功能 (STO, Safe Torque Off)●高阶交流伺服驱动器●同步周期短,适用于多轴高速同步控制 ●支持绝对型和增量型ECMA 系列电机●电机功率范围: 200 V 100 W ~ 3 kW 、400 V 400 W ~ 7.5 kW●标准型交流伺服驱动器●3.1 kHz 速度响应频宽,缩短40%整定时间 ●高速轴间资料交换,提供简易龙门控制功能 ●兼容 A2 / B2 / A 3 系列电机,替换方便●电机功率范围: 200 V 100 W ~ 3 kW●高效能运动控制型交流伺服系统 ●3.1 kHz 速度响应频宽,提升设备产能●全新的挠性结构补偿和低频抑制功能,确保机台稳定度和缩短整定时间●薄型化设计,节省电器柜安装空间●电机功率范围: 200 V50 W ~ 15 kW台达 CODESYS 运动控制方案产品介绍精巧高效型 / 标准型矢量控制变频器MH300 / MS300体积精巧,内置安全扭矩停止功能STO 和EMC 滤波器,整合PLC ,支持多样的通讯协定和I/O 扩展模块高效能泛用型矢量控制变频器C2000 Plus精准的速度/扭矩/位置控制模式,内置PLC ,适用于有感测器/无传感器的同步与异步电机●功率范围: 115 V 0.2 kW ~ 0.75 kW 、230 V 0.2 kW ~ 15 kW 、460 V 0.4 kW ~ 22 kW●支持感应电机与永磁电机,开环/闭环控制 ●最高输出频率: 最高 2000 Hz / 1500 Hz●内置符合SIL2 (IEC EN 61508 & IEC 62016) /Cat.3 PL d (ISO 13894-1)标准的安全扭矩停止功能 STO (Safe Torque Off) ●內建PLC (5K / 2K steps)● 支持多样的通讯协定: Modbus 、CANopen 、EtherCAT 、PROFIBUS DP 、DeviceNet 、Modbus TCP 、EtherNet/IP●电源模块: 连接EtherCAT 从站模块与100 BASE-TX EtherCAT 网络 ●数字输入模块: 16点Sink/Source 数字输入模块; 1 ms 和2 ms 的反应时间●数字输出模块: 6点数字输出模块; 输出电流:sink 型模块每点0.5 A ,source 型模块每点0.25 A ●ADC 模块: 4通道16-bit A / D 输入; DAC 模块: 4通道16-bit D / A 输出 ●运动模块: 单轴脉冲输出●手轮模块: 单通道手轮输入,4 / 6轴控制●EtherCAT 耦合器RTU-ECAT :内置2个EtherCAT 通讯端口,最多可支持8个DVP 薄型I/O 模块●数字输入模块: 支持8 / 16 / 32点NPN / PNP 输入 ●数字输出模块: 支持8 / 16/ 32点NPN / PNP/继电器输出●数字I/O 模块: 8点数字输入和8点数字输出,支持不同型态的输入/输出格式 ●模拟输入模块: 4 / 6通道,支持mA / V 输入 ●模拟输出模块: 2 / 4通道,支持mA / V 输出●数字I/O 模块: 4通道数字输入和2通道数字输出模块,支持mA / V 输入/输出型式●温度模块: 2 / 4 / 6 / 8通道,支持RTD 、热电偶和NTC 输入(注:详细信息请参照DVP 系列PLC 型录)●功率范围: 230 V 0.75 kW ~ 90 kW 、460 V 0.75 kW ~ 560 kW ●高过载承受度: 150 % / 60 秒和180 % / 3 秒,适用于恒定转矩应用 ●内置PLC (10k steps) ●支持点对点位置控制●采用3C3标准PCB 涂层,可确保变频器在恶劣环境下安全可靠运行●内置Modbus ,支持通讯扩展卡: CANopen 、EtherCAT 、ROFINET 、PROFIBUS DP 、DeviceNet 、Modbus TCP 、EtherNet/IP远端I/O 模块R1-EC ( AX-864E 适用)耐用精巧的E-bus 从站模块,适用于高精度和高需求的产业应用远端I/O 模块RTU-ECAT (PLC DVP 薄型RTU 方案)适合多种应用的精巧EtherCAT 远端I/O模块方案现场装置台达 CODESYS运动控制方案产品介绍1 ms(sink/source)反应时间(sink/source) 反应时间制造设备程序控制第三方控制器AX-864EAX-308EEthernet运动控制编程软件 - Softmotion●支持单轴和多轴运动(主/从轴运动和凸轮控制) ●使用PLCopen 认证的POU库,编辑运动控制功能●图形化CAM 编辑软件整合配置、编程、编译、和调适功能; 无缝整合传统和系统性的编程方式●在SoftPLC 和控制器的runtime 模拟模式下显示应用资料 ●在监视列表中监看指定的数值●直接在对应的编辑器中读、写、和强制设定变量●单步或单周期执行程序码支持标准 IEC 61131-3 编程●结构化文本 (ST)●梯形图 (LD)工作与除错●功能块 (FBD)●顺序功能图 (SFC)产品信息电源输入接口DC 24 V (±15 %)SSI编码器输入接口SD 卡槽HDMI输出接口Gigabit LAN 接口(Modbus TCP / OPC UA)USB EtherCAT接口连接现场装置电源输入接口DC 24 V (±15 %)8组数字输入 / 8组数字输出OA / OB / OZ signalINC 编码器输入接口ABS SSI编码器输入接口外观说明外观说明137.4166.8141164153.2R2.5X2R1.4X2554.2PC-Based 运动控制器AX-864EPLC-Based 运动控制器AX-308E产品尺寸单位: mm产品尺寸单位: mm16组数字输入8组数字输出MicroSD 卡槽RS232 / 485接口EtherCAT接口增量型编码器输入接口 (×2)Ethernet接口连接现场装置硬件规格2021型号说明AX-864E P0MB1T产品类型AX - 3 系列AX - 8 系列I/O: (晶体管) T: NPN可控制轴数。

系列人机与各厂牌连线说明Delta Controller ASCII/RTU(适用台达变频器、伺服驱动器、PLC、温度控制器)人机默认值通讯速率:9600, 7, None, 2 (ASCII); 9600, 8, None, 2 (RTU)控制器站号:1控制区/状态区:None/None控制器接线的说明Delta Servoa. RS-232(DOP-A/AE/AS, DOP-B系列适用)b. RS-422(DOP-A/AE系列适用)系列人机与各厂牌连线说明c. RS-422(DOP-AS35/AS38/AS57系列适用)e. RS-485(DOP-A/AE系列适用)系列人机与各厂牌连线说明g. RS-485(DOP-AS35/AS38系列适用)h. RS-485(DOP-B系列适用)系列人机与各厂牌连线说明Delta 变频器a. RS-485(DOP-A/AE系列适用)系列人机与各厂牌连线说明Temperature Controllera. RS-485(DOP-A/AE系列适用)系列人机与各厂牌连线说明d. RS-485(DOP-B机种适用)控制器 Read/Write 地址的定义a.寄存器符号格式寄存器种类Word No.(n)读写地址范围数据长度注伺服通讯地址SERVO-n SERVO-0 – SERVO-FFFF Word 16进位变频器通讯地址INVERTER-n INVERTER-0 –INVERTER-FFFFWord 16进位温控器通讯地址TEMP_CTRL-n TEMP_CTRL-0 –TEMP_CTRL-6000Word 16进位PLC通讯地址X PLC_X n PLC_X0 – PLC_X360 Word 8进位, 1 PLC通讯地址Y PLC_Y n PLC_Y0 – PLC_Y360 Word 8进位, 1PLC通讯地址M PLC_M n PLC_M0 – PLC_M1520,PLC_M1536 – PLC_M4080Word 1PLC通讯地址S PLC_S n PLC_S0 – PLC_S1008 Word 1PLC通讯地址T PLC_T n PLC_T0 – PLC_T255Word PLC通讯地址C PLC_C n PLC_C0 – PLC_C199 Word PLC通讯地址D PLC_D n PLC_D0 – PLC_D9999 Word PLC通讯地址HC PLC_HC n PLC_HC200 – PLC_HC255Double Word系列人机与各厂牌连线说明符号格式寄存器种类读写地址范围数据长度注Word No.(n)PLC通讯地址Module PLC_Module n PLC_Module4000 –PLC_Module4499Word 16进位Output Registers RW-n RW-0 – RW-FFFF Word16进位Input Registers R-n R-0 – R-FFFF Word16进位Output Registers W n W40001 – W50000 WordInput Registers W n W30001 – W40000 Wordb.接点符号格式接点种类Word No.(n);Bits No.(b)读写地址范围注伺服通讯地址SERVO-n.b SERVO-0.0 – SERVO-FFFF.F 16进位变频器通讯地址INVERTER-n.b INVERTER-0.0 – INVERTER-FFFF.F 16进位温控器通讯地址TEMP_CTRL-n.b TEMP_CTRL-0.0 –TEMP_CTRL-6000.F16进位Servo Digital Input SERVO_DI-b SERVO_DI-1 – SERVO_DI-8 2 Servo Digital Output SERVO_DO-b SERVO_DO-1 – SERVO_DO-52 PLC 通讯地址 X PLC_X b PLC_X0 – PLC_X377 8进位PLC 通讯地址 Y PLC_Y b PLC_Y0 – PLC_Y377 8进位PLC 通讯地址 M PLC_M b PLC_M0 – PLC_M1535, PLC_M1536 – PLC_M4095PLC 通讯地址 S PLC_S b PLC_S0 – PLC_S1023 PLC 通讯地址 T PLC_T b PLC_T0 – PLC_T255 PLC 通讯地址 C PLC_C b PLC_C0 – PLC_C255温控器 Bit 通讯地址TEMP_CTRLB-b TEMP_CTRLB-800 –TEMP_CTRLB-8FF16进位Discrete Outputs RWB-b RWB-0 – RWB-FFFF 16进位Discrete Inputs RB-b RB-0 – RB-FFFF 16进位Discrete Outputs B b B1 – B10000Discrete Inputs B b B10001 – B20000注1元件地址必须是16的倍数。

深度挖掘-台达DOP人机界面“一机多屏”的实现前言:随着人机界面的发展及用户对高功能的追求,人机界面“一机多屏”的使用方式越来越频繁。

本文用清晰的图示结合一个样例详细的说明台达DOP是如何实现“一机多屏”功能的。

关键字:人机界面宏指令问题的引出与解答:现在市面上很多的人机界面(HMI)都提供了方便的一台控制器连接两台或者更多人机的功能,也就是大家常说的“一机多屏”,如WeinView、Hitech等都可以实现。

台达的人机功能很强,但在Screen Editor编辑软件中并没有提供这样的功能。

那么如果用户想使用“一机多屏”就没有办法了吗?当然不是这样,台达人机很好的一个特点就是提供了2个通讯口,而且2个通讯口可以独立使用。

这样,我们就可以用一个通讯口连接控制器,另一个通讯口连接第二台或者第三台触摸屏了。

解决方法有了,下面我们就结合一个样例来看一看DOP是怎么做到的。

系统图:如上面这样的系统图,我们可以用一个人机作为Master HMI,其余若干个人机作为Slave HMI,分别为2#、3#......。

Master HMI的COM1与一台EH PLC通过RS232连接,COM2与各个Slave HMI通过RS485连接。

这样,Master HMI作为两条线路上的主站,负责交换两条线路上的数据。

本例我们采用两台HMI同一个PLC连接,所以将上面的系统图简化并作个变形,以形成我们熟悉的样子。

两台人机直接通过MODBUS ASCII来连接。

如下图:样例要实现的功能:1、两台人同时显示PLC的数据变化。

2、当其中任意一台人机修改PLC寄存器的数值时,同时能在另一台人机上一起变化。

3、当一台人机切换画面时,另一台人机也会自动切换。

功能分析与框图:DOP有个很大的特点就是支持宏指令功能,所以这些功能都要依靠宏来实现。

我们先设功能1中PLC用到的寄存器地址为D200, D201。

2#Slave HMI与之对应的地址设为$109, $110,根据下表DOP内部与MODBUS的对应关系可以知道对应MODBUS的地址为W40110, W40111。

v1.0 可编辑可修改新编台达人机界面实用问题101例0、台达人机目前有哪些系列有什么不同A,AS,AE,BA 标准型,提供5.7”~10.4”AS 简易型,提供3.5”,3.8”,5.7”单色,彩色;3个通讯口,可以接U盘AE 高端型提供5.7”~10.4”, 3个通讯口,可以接U盘,各种扩展模块B 真彩,高亮 5.7”,7” TFT, 3个通讯口,可以接U盘1、台达新机种A80THTD1,A10THTD1是3个通讯口吗是的,都是64K TFT,有3个独立通讯口2、台达哪款机种可以接以太网,支持哪些协议?目前可以通过AE系列+EXLNHJ1AE模块上以太网,支持MODBUS TCP/IP协议2009年将会推出集成以太网的B07E机种3、台达人机有I/O点吗有的,有14点,28点两种模块,插在AE系列的扩展口上。

4、 EXIO PLC扩展卡如何编程人机软件内嵌了一个编程界面,与台达PLC的软件操作一模一样,可以用梯形图的方式。

5、用了一个DOP-AS57CSTD,需要2个RS485口,一个台达的变频器,一个连我自己开发的单片机,不知道是否可以可以,AS57C有2个独立的485通讯口。

6用了一个B系列的触摸屏,但程序是原来用A系列软件做的,B系列软件可以打开吗可以,B系列的软件可以兼容A系列的程序;但反过来不可以。

7、由于手自动操作比较频繁,想通过PLC输入口来控制画面的切换,却不知道如何下手没有思路、方法,请指教!利用PLC的输入点来做为画面切换的控制信号,利用【系统控制区】来切换8 选用台达触摸屏与西门子S7-200通讯,控制堆取料机的自动运转,触摸屏界面突然不能切换了,从堆料界面能进入取料界面,但取料界面却无法进入堆料界面,请教大侠们问题是出在什么地方了“从堆料界面能进入取料界面,但取料界面却无法进入堆料界面”从这句上可以看出触摸屏硬件没有问题。

想到2个可能,第一个是操作等级被升高了,所有“取料界面却无法进入堆料界面”。

台 达 人 机 界 面 实用问题集中达电通股份有限公司人机产品开发处目录硬件篇 (9)1、Q:台达的A系列HMI最多有几个通讯口,可以独立使用吗? (9)2、Q:台达触摸屏RS232通讯口与计算机连接的下载线怎么焊接? (9)3、Q:我的USB经常出现使用不正常,不能下载的问题。

重新插拔或者重新启动电脑又正常,请问是什么原因? (9)4、Q:程序的容量有多大啊,会不会我的程序过大不能下载呢? (9)5、Q:DOP-A的历史缓存区数据若存于掉电保持的SRAM中,可占用240K字节,我最多能存多少笔掉电保存的数据呢? (9)6、Q:DOP提供的256K掉电保存和64K配方空间是集成的还是要另外买配件呢? (10)7、Q:DOP人机界面的使用温度是多少?能用到零下吗?另外我使用在室外可以吗? (10)8、Q:DOP人机界面屏幕的最大显示范围是多大? (10)9、Q:台达哪款机种可以接以太网,支持哪些协议? (10)10、Q:我的触摸屏怎么一半有显示,一半没有了? (10)11、Q:我要做背光节能吗?这样有什么好处? (10)12、Q:这几天很冷,屏在现场显示的速度很慢,还有些拖影,有什么办法吗? (10)13、Q:DOP人机的记忆体备份电池没电了,可以充电吗? (10)14、Q:我看你们的人机要24V电源供电,我用PLC上的可以吗? (10)15、Q:各个型号的开孔尺寸是多少? (11)16、Q:工作时机器的电控柜有60摄氏度,贵公司人机能正常工作吗? (11)17、Q:台达人机目前有哪些系列?有什么不同? (11)18、Q:台达新机种A80THTD1,A10THTD1是3个通讯口吗? (11)19、Q:台达人机有I/O点吗? (11)20、Q:U盘支持即插即用吗? (11)21、Q:我现在开始用B系列触摸屏,感觉这个屏做工很好,功能很强。

可是屏幕太小,只有7”,你们将来会做更大的吗? (12)22、Q:我一直使用DOP-A10TCTD这个型号,最近停产了,是真的吗?如果用AE10THTD替代好贵啊! (12)23、Q:厂里的设备要用到东北去,冬天有零下20多度,台达人机可以用吗? (12)24、Q:HMI在高温下使用会有问题吗? (12)25、Q:我在用B07S200,不知道前面的三个指示灯都做什么的? (12)26、Q:B07S200的COM口旁的指示灯做什么用? (12)27、Q:台达哪些触摸屏可以接鼠标? (12)28、Q:HMI上电黑屏。