ROTAN齿轮泵样

- 格式:pdf

- 大小:1.99 MB

- 文档页数:14

Benefits•Low pulsation and very gentle pumping, making the pump ideal for sensitive products.•Minimized shearing to protect end-product quality.•Low maintenance, increased process uptime.•Low contamination risk due to full material traceability and USP Class VI elastomers that reduce the risk of processcontamination from extractables.•Smooth qualification, validation and process control:material traceability, and pump supplied with the Alfa Laval Q-doc package in line with Good DocumentationPractices.Standard designAll media contacting steel components, like the rotor case, front cover, rotors and rotor nuts, are in W. 1.4404 (AISI 316L). The stainless steel gearbox provides maximum shaft rigidity and easy oil seal replacement. The gearbox design is universal, which enables the flexibility of mounting pumps with the inlet and outlet ports in either a vertical or horizontal plane by changing the foot and its position.The standard Alfa Laval SX UltraPure has four-lobe rotors rated to 150°C, facilitating use with CIP and SIP processes.Fully front-loading and fully interchangeable single, single flushed and double mechanical shaft seals are available. All media contacting elastomers are controlled compression joints, the latest technology where static and dynamic elastomer seals are used to prevent leakage of pumped media to the atmosphere.The Alfa Laval SX UltraPure can be supplied either as a bare shaft pump or mounted on a base plate complete with coupling, guard, gear motor and shroud for easy, plug-and-play installation.Working principleA gear train in the pump gearbox drives the rotors and provides accurate synchronization of the multi-lobe rotors. The movement of the counter-rotating rotors creates a partial vacuum that allows atmospheric pressure or other external pressures to force fluid into the pump chamber. As the rotors revolve, an expanding cavity forms, filling with fluid. As the blades disengage, each dwell forms a cavity. As the rotor blades engage, the cavity diminishes and fluid is displaced into the outlet port.CertificatesTECHNICAL DATAInside surface finish:Mech Ra ≤ 0.8Gearbox:Stainless steel Base plate:Stainless steel Coupling guard:Stainless steel Rotor:Four-lobeProduct wetted elastomers:EPDM - USP Class VI, 249.8°F . Chapter 88, and Chapter 87Other elastomers:FPMShaft seal:Single mechanical (R00)Rotary seal face:Silicon Carbide Stationary seal face:Silicon CarbideMax. flush pressure, single flush:Max. 0.5 bar Max. flush pressure, double mechanical:Max. 1 bar over product pressure Water consumption, flushed or double mechanical:0.5 l/min Flush connections:BSPT or NPTMedia contacting elastomersAll media contacting elastomers are controlled compression joints, the latest technology where static and dynamic elastomerseals are used to prevent pumped media leaking to atmosphere.1. Front cover compression joint.2. Spline sealing cup seal.3. Cup seal.4. Squad ring.Flows/Pressures/ConnectionsSX UltraPure 1/0070.07 1.54 1.8540 1.571001200SX UltraPure 2/0130.128 2.82 3.3840 1.5152151000SX UltraPure 2/0180.181 3.98 4.7850271001000SX UltraPure 3/0270.266 5.857.03502152151000SX UltraPure 3/0350.357.709.2565 2.571001000SX UltraPure 4/0460.4610.1212.15502152151000SX UltraPure 4/0630.6313.8616.6565 2.5101451000SX UltraPure 5/0820.8218.0421.6765 2.515215600SX UltraPure 5/115 1.1525.3030.3880310145600SX UltraPure 6/140 1.4030.8036.9980315215500SX UltraPure 6/190 1.9041.8050.20100410145500SX UltraPure 7/250 2.5055.0066.05100415215500SX UltraPure 7/380 3.8083.60100.401506101455001 These pressure ratings may vary for pumps with certain threaded connections.SX UltraPure 1/0071617SX UltraPure 2/0133233SX UltraPure 2/0183334SX UltraPure 3/0275759SX UltraPure 3/0355961SX UltraPure 4/046107110SX UltraPure 4/063113116SX UltraPure 5/082155155SX UltraPure 5/115165165SX UltraPure 6/140278278SX UltraPure 6/190290290SX UltraPure 7/250-340SX UltraPure 7/380-362Shaft Seal Options•Single or single flush/quench (steam barrier for aseptic application) R00 type mechanical seals.•Double R00 type mechanical seal for flush.All sealing options are fully front loading and fully interchangeable without the need for additional housings or pump component changes. Specialised seal setting of the mechanical seal is not required as the seal is dimensionally set on assembly. This feature further enhances fast and efficient on-site seal interchangeability.Materials for Mechanical SealsAs standard the SX UltraPure is supplied with EHEDG compliant Silicon Carbide/Silicon Carbide seal faces avoiding any risk of potential extractable contamination.Standard Specification Options•Screwed male inlet and outlet ports to DIN11851, SMS, RJT, Triclamp for ASME, DIN 32676 Clamp, DIN 11864-1 (Union) Form A, DIN 11864-2 (Flange) Form A or DIN 11864-3 (Clamp) Form A.•Heating/Cooling Jacket for Rotorcase Cover.•Product wetted surface finish electropolished to Ra ≤ 0.38 μm.•Passivated surface.•Surface finish measurement with certificate.•Hydrostatic testing with certificate.•ATEX compliance.•Complete pump unit comprising: Pump + stainless steel baseplate + coupling with guard + Geared electric motor suitable for (or supplied with) frequency speed control or manual variable speed drive (advise motor enclosure and electrical supply).•Low delta ferrite material for product wetted components.•High alloy materials for product wetted components i.e. AL6XN or Titanium.Q-docStandard documentation package:•Declaration of compliance with Regulation (EC) No.: 1935/2004.•Declaration of compliance to EN 10204 type 3.1 (MTR).•Declaration of compliance to the U.S. Food & Drug Administration CFR 21 (non-metallic parts).•Declaration of compliance to the U.S. Pharmacopeia (Elastomers and polymers).•TSE (Transmissible Spongiform Encephalopathy) / ADI (Animal Derivative Ingredient) declaration.•Declaration of surface finish compliance.•Declaration of passivation and electro polishing (if specified).•3.1 certification in accordance to EN10204.•Pump performance test certificate.Optional documentation:•Hydrostatic test certificate.•Surface measurement report.Pump SizingIn order to correctly size a rotary lobe pump some essential information is required. Provision of this information listed below enables our Technical Support personnel to obtain the optimum pump selection.Product/Fluid Data:•Fluid to be pumped.•Viscosity.•SG/Density.•Pumping temperature, minimum, normal and maximum.•Cleaning in Place temperature(s), minimum, normal and maximum.Performance Data:•Flow rate, minimum, normal and maximum.•Discharge head/pressure (closest to pump outlet).•Suction condition.Bareshaft Pump DimensionsFigure 1. Vertically portedSX UltraPure 1/0074095113208151640305294601008022114104801017423.5SX UltraPure 2/0134010514725215225032632559111100121241241001221332.5SX UltraPure 2/0185010514725215225032634166111100121241241001221332.5SX UltraPure 3/0275012517530022286140843171142155151851551251424637.5SX UltraPure 3/0356512517530022286140844777142155151851551251424637.5SX UltraPure 4/04650150213363253880631051474174200172341841501430149.5SX UltraPure 4/06365150213363253880631053381174200172341841501430149.5SX UltraPure 5/0826*******.5431.53045110701459961264200202402201801434460SX UltraPure 5/11580175256.5431.53045110701462981264200202402201801434460SX UltraPure 6/140801902954853048110701468777267260203002502101440070SX UltraPure 6/1901001902954853048110701471589267260203002502101440070SX UltraPure 7/2501002053655703060110901876394288280253302902401847581.5SX UltraPure 7/38015020536557030601109018817121288280253302902401847581.5TOP SHAFTDRIVEFigure 2. Horizontally portedAll dimensions in mmSX UltraPure 1/007409590.5189101640671143052943612480101001008010 SX UltraPure 2/0134010511523315225082.5147.5326325391311001913212410012 SX UltraPure 2/0185010511523315225082.5147.5326341461311001913212410012 SX UltraPure 3/027********.5272182860100175408431681751253018115412514 SX UltraPure 3/0356*******.5272182860100175408447741751253018115412514 SX UltraPure 4/04650150163325203880113.5212.56310514742251503520218415014 SX UltraPure 4/06365150163325203880113.5212.56310533812251503520218415014 SX UltraPure 5/0826517519537620451101352557014599462791803527521018014 SX UltraPure 5/1158017519537620451101352557014626662791803527521018014 SX UltraPure 6/1408019022542920481101552957014687782662604037022019014 SX UltraPure 6/19010019022542920481101552957014715902662604037022019014This document and its contents are subject to copyrights and other intellectual property rights owned by Alfa Laval Corporate AB. No part of this document may be copied, re-produced or transmitted in any form or by any means, or for any purpose, without Alfa Laval Corporate AB’s prior express written permission. Information and services provided in this document are made as a benefit and service to the user, and no representations or warranties are made about the accuracy or suitability of this information and these services for any purpose. All rights are reserved.200006102-1-EN-GB© Alfa Laval Corporate AB How to contact Alfa LavalUp-to-date Alfa Laval contact details for all countries are always availableon our website at 。

参数表齿轮泵R25/2.5 至 R105/2400TB3-NNNN-111_CN • 00出版人RICKMEIER GmbHLangenholthauser Straße 20-22D-58802 Balve电话 +49 (0) 23 75 / 9 27-0传真 +49 (0) 23 75 / 9 27-26********************www.rickmeier.de© 2019, RICKMEIER GmbH保留所有权利。

未经 RICKMEIER 有限责任公司书面许可,既不允许传播、复制、编辑,也不允许向第三方转发这些内容。

在标题页展示了示例配置。

因此,提供的产品可能与插图不同。

2 / 48TB3-NNNN-111_CN • 00目录1概述 (5)2应用领域 (6)3说明描述 (7)3.1结构 (7)3.2产品说明 (7)4工作原理 (8)5旋转和输送方向 (9)5.1确定旋转方向 (9)5.2更改旋转和输送方向 (9)6指令和验收 (9)7标准规格和派生型 (10)7.1材料 (10)7.2固定法兰 (11)7.3接口 (12)7.4轴端 (13)7.5轴密封件 (14)7.5.1径向轴密封圈 (RWDR) (14)7.5.2滑环密封件 (GLRD) (15)7.6限压阀 (DB) (15)7.7换向阀 (UNI 功能) (16)7.8辅助轴承 (17)7.9双联泵 (17)7.10集成加热装置 (17)7.11噪声优化 (18)8名称和配置 (18)8.1型号代码 (18)8.2泵选择 (18)8.2.1结构尺寸(型号)/ 几何排量 Vg (19)8.2.2结构型式 (19)8.2.3轴端 (19)8.2.4限压阀 (20)8.2.5限压阀 - 压力范围 / 预设 (20)8.2.6轴密封件 (20)8.2.7接口 / 接口尺寸 (21)8.2.8旋转方向(往轴端看) (21)8.2.9材料 (21)8.2.10其它选装件 (22)8.3泵设计 (23)9技术参数 (24)9.1使用限制 (24)9.2运行数据 (25)10齿轮泵尺寸表 (29)10.1结构尺寸 R25 (29)10.2结构尺寸 R35 (30)TB3-NNNN-111_CN • 00 3 / 4810.3结构尺寸 R45 (31)10.4结构尺寸 R65 (32)10.5结构尺寸 R95 (33)11泵组尺寸表 (34)11.1结构尺寸 R25 (34)11.1.1结构型式 IM B35 (34)11.1.2带泵支架底座的 IM B5 结构型式 (35)11.1.3结构型式 IM V1/B5 (36)11.2结构尺寸 R35 (37)11.2.1结构型式 IM B35 (37)11.2.2带泵支架底座的 IM B5 结构型式 (38)11.2.3结构型式 IM V1/B5 (39)11.3结构尺寸 R45 (40)11.3.1结构型式 IM B35 (40)11.3.2带泵支架底座的 IM B5 结构型式 (41)11.3.3结构型式 IM V1/B5 (42)11.4结构尺寸 R65 (43)11.4.1结构型式 IM B35 (43)11.4.2带泵支架底座的 IM B5 结构型式 (44)11.4.3结构型式 IM V1/B5 (45)11.5结构尺寸 R95 (46)11.5.1结构型式 IM B35 (46)11.5.2带泵支架底座的 IM B5 结构型式 (47)11.5.3结构型式 IM V1/B5 (48)4 / 48TB3-NNNN-111_CN • 00TB3-NNNN-111_CN • 00 5 / 481概述本目录中的技术说明用作常规信息。

无密封的离心泵分为屏蔽电机驱动和磁力驱动两种结构形式,并有着多年的使用经验。

然而无密封的转子泵,只在近几年才开始使用。

本文将就正排量泵与磁力驱动技术相结合后所具有的结构和优势加以讨论。

在流程工业中,磁力驱动泵正在得到越来越广泛的应用。

在选择磁力驱动泵时,不仅要考虑安全方面的因素,而且还需考虑其防止泄漏的能力和减少维修的要求正逐渐成为重要的因素。

在计算泵的全寿命费用(Total Life Cycle Cost)时,一台磁力驱动泵往往能提供最为经济的解决方案。

每当讨论磁力驱动泵时,与机械密封泵相比,以下几点经常被认为是缺点而提出:结构复杂;不能超过其最大扭矩,哪怕是短时间内;更加昂贵;尤其在第一次介绍磁力驱动泵时,经常会提及以上观点。

一个相关的问题是,在推广阶段,磁力驱动技术到底取得了哪些进展?从越来越多的使用磁力驱动泵这一事实来看,我们可以推断磁力驱动技术已经有了长足的发展。

设计目前的设计都是在应用经验的基础上发展而来的。

这使得泵具有相当简单和坚固的结构,使磁力驱动泵具有与机械密封泵完全一样的可靠性。

尽可能地延长两次大修之间的间隔时间是十分重要的,所以可靠性成为现在设计开发中的一个基本焦点。

减少两个磁力偶合器之间的磨损,同时加强冷却,意味着磁力驱动泵可以比以前在更多的应用中提供最优化的方案。

典型的例子,就是有一家制造商已经采用了一种被证实有效的专利技术,克服了内轴承室的阻力损失、过热以及磨损等问题。

这是通过平衡泵内液体和以下的工作原理来获得的:转子上有一些径向孔与中空泵轴相连。

在运行过程中,离心力作用于径向孔中的液体,使得与磁力驱动部分相连的中空轴中产生负压。

其压差推动转子后面两个独立的腔体内的液体循环,从而有效地带走因为摩擦和磁力损失所产生的热量。

这些腔体分别与入口和出口相连。

与其他磁力驱动泵相比,这种系统保留了泵原有的良好自吸能力,因为冷却液体并没有直接将入口和出口短接。

足够的冷却液体的产生与进出口压差,粘度和轴转速无关。

DESMI ROTAN是DESMI公司内啮合齿轮泵的注册商标,并已拥有逾100年的制造和应用经验,特别是在输送状况比较恶劣的工况下,苏州埃立特流体设备有限公司专业为客户提供高品质进口化工泵。

1、Rotan齿轮泵的主要结构和零件特点:

泵体,齿轮,轴承,轴承套,轴承盖,密封组件,泵座,主轴,主轴套等组成。

这款泵的内外转子:具有无脉动输送,磨损小,转子使用寿命长。

合金机械密封:磨损小,润滑性能强。

铜套:具有耐磨损,耐高温,耐腐蚀,润滑性能强。

月牙板:是由高精度全自动数控铣加工。

2、Rotan齿轮泵的工作原理:

在泵腔内分为小齿轮在大齿轮的一边,月牙板在大齿轮的另一边,小齿轮转动,带动大齿轮,由月牙板把泵腔内分为吸入腔和排出腔,当轮齿相互分开形成压力吸入液体,当齿轮啮合时把液体挤压由排出腔排出。

3、Rotan齿轮泵的特点:

这款泵采用的是内啮合齿轮,因此齿轮运转时内外齿轮也是同方向运转,输送杂质少或有润滑性的液体时,转子泵比普通齿轮泵的齿轮使用寿命长。

这种泵齿廓

磨损小,无脉动,噪音低等特性。

4、Rotan齿轮泵的适用介质:

铸铁材质:适用于不含金属颗粒和纤维的高粘度流体,适用输送温度为200以内的液体,粘度为300000CST以内的液体。

例如:锂基脂,油漆,原油等。

不锈钢材质:适用于不含金属颗粒和纤维的液体介质,适用于化工加工和食品加工,不锈钢材质的转子泵具有耐腐蚀性。

Rotan高粘度齿轮油泵根据它无脉动,耐腐蚀,磨损小,噪音低的特点,广泛适用在石油工业,化工工业,医药行业,食品行业等。

齿轮泵科技名词定义中文名称:齿轮泵英文名称:gear pump定义:依靠密封在一个壳体中的两个或两个以上齿轮,在相互啮合过程中所产生的工作空间容积变化来输送液体的泵。

应用学科:齿轮泵是依靠泵缸与啮合齿轮间所形成的工作容积变化和移动来输送液体或使之增压的回转泵。

由两个齿轮、泵体与前后盖组成两个封闭空间,当齿轮转动时,齿轮脱开侧的空间的体积从小变大,形成真空,将液体吸入,齿轮啮合侧的空间的体积从大变小,而将液体挤入管路中去。

吸入腔与排出腔是靠两个齿轮的啮合线来隔开的。

齿轮泵的排出口的压力完全取决于泵出处阻力的大小。

编辑本段齿轮泵工作原理分析外啮合双齿轮泵的结构。

一对相互啮合的齿轮和泵缸把吸入腔和排出腔隔开。

齿轮转动时,吸入腔侧轮齿相互脱开处的齿间容积逐渐增大,压力降低,液体在压差作用下进入齿间。

随着齿轮的转动,一个个齿间的液体被带至排出腔。

这时排出腔侧轮齿啮合处的齿间容积逐渐缩小,而将液体排出。

齿轮泵适用于输送不含固体颗粒、无腐蚀性、粘度范围较大的润滑性液体。

泵的流量可至300米3/时,压力可达3×107帕。

它通常用作液压泵和输送各类油品。

齿轮泵结构简单紧凑,制造容易,维护方便,有自吸能力,但流量、压力脉动较大且噪声大。

齿轮泵必须配带安全阀,以防止由于某种原因如排出管堵塞使泵的出口压力超过容许值而损坏泵或原动机编辑本段齿轮泵的工作原理简介齿轮泵的概念是很简单的,即它的最基本形式就是两个尺寸相同的齿轮在一个紧密配合的壳体内相互齿轮泵啮合旋转,这个壳体的内部类似“8”字形,两个齿轮装在里面,齿轮的外径及两侧与壳体紧密配合。

来自于挤出机的物料在吸入口进入两个齿轮中间,并充满这一空间,随着齿的旋转沿壳体运动,最后在两齿啮合时排出。

在术语上讲,齿轮泵也叫正排量装置,即像一个缸筒内的活塞,当一个齿进入另一个齿的流体空间时,液体就被机械性地挤排出来。

因为液体是不可压缩的,所以液体和齿就不能在同一时间占据同一空间,这样,液体就被排除了。

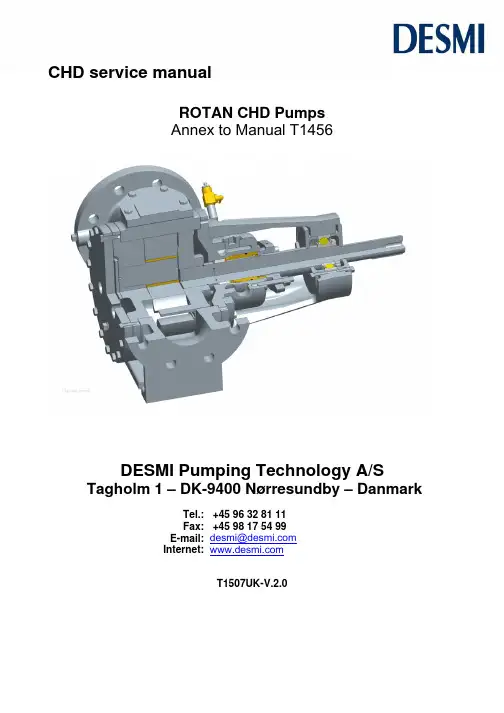

CHD service manualROTAN CHD PumpsAnnex to Manual T1456DESMI Pumping Technology A/S Tagholm 1 – DK-9400 Nørresundby – DanmarkTel.: +45 96 32 81 11Fax: +45 98 17 54 99E-mail: ***************Internet: T1507UK-V.2.01. INTRODUCTIONS .................................................................................................................................... ‐ 2 ‐2. BEFORE START‐UP .................................................................................................................................. ‐ 7 ‐3. MAINTENANCE ..................................................................................................................................... ‐ 10 ‐4. REPLACEMENT OF SOFT PACKING RINGS .............................................................................................. ‐ 11 ‐5. REPLACEMENT OF LIP SEAL ................................................................................................................... ‐ 12 ‐6. INSPECTION OF IDLER PIN/BUSHING ..................................................................................................... ‐ 14 ‐7. INSPECTION/ADJUSTMENT OF AXIAL CLEARANCE ................................................................................. ‐ 16 ‐8. SPARE PARTS LIST ................................................................................................................................. ‐ 17 ‐9. ASSEMBLY DRAWINGS ......................................................................................................................... ‐ 18 ‐10. SERVICE CENTRES – DENMARK ......................................................................................................... ‐ 21 ‐11. SUBSIDIARY COMPANIES – DESMI PUMPING TECHNOLOGY A/S ....................................................... ‐ 22 ‐ Illustrations in this manual are only used to demonstrate the different working procedures. To a degree they are dependent on the size of the pump as there are different model constructions used for different applicationsWhen ordering spare parts the following information must be provided:- The pump serial number- The pump SX number- The spare part Position numberThe above information can be found on the pump flanges or the pump’s nameplate1. IntroductionsThis service manual only contains information about startup, service and maintains of Rotan CHD pumps.For general information about Rotan pumps please refer to manual T1456Rotan pumps are designed for pumping media with high viscosity such as chocolate, Cocoa Mass , Cocoa Butter, sugar powder etc. The Pump are equipped with heating jacket on the front and rear end. The Rotor, Idler and idler bushing are with special clearances.The Rotan CHD pumps are not Pressure or flow tested from the factory.The front cover and rear cover is pressure tested separately.CHD pumps are preserved with vegetable oil.Rotan CHD pumps are not approved for pumping foods requiring FDA and 3 A approval.DESMI Pumping Technology A/SDESMI Pumping Technology A/SEC Declaration of Conformity The Machinery Directive 2006/42/ECManufacturer: DESMI Pumping Technology A/SAddress: Tagholm 1, DK-9400 Nørresundby, Denmark Tel.: +45 96 32 81 11 E-mail:***************DESMI Pumping Technology A/S hereby declares that the product in question has been produced in accordance with the following essential health and safety requirements of the Machinery Directive 2006/42/EC Annex I.Product: ROTAN pumps complete with motor Type: HD, CD, PD, GP, CC, ED(MD) Serial No: From 10000-xx-xx to 999999-xx-xxThe following harmonized standards have been applied:EN 809 + A1/AC:2010 Pumps and pump units for liquids DS/EN 12162 + A1:2009 Procedures for hydrostatic testing of liquid pumpsNørresundby 2015Claus Dietz Hansen Technical DirectorDESMI Pumping Technology A/SDESMI Pumping Technology A/SDeclaration of Incorporation”Manufacturer: DESMI Pumping Technology A/S Address: Tagholm 1, DK-9400 Nørresundby, Denmark. Tel.: +45 96 32 81 11 E-mail: ***************Product: ROTAN pumps Type: HD, CD, PD, GP, CC, ED(MD) Serial No: From 10000-xx-xx to 999999-xx-xxDESMI Pumping Technology A/S hereby declares that the product in question has been produced in accordance with the following essential health and safety requirements of the Machinery Directive 2006/42/EC Annex I:The following harmonized standards have been applied:EN 809:2002 + AC – Pumps and pump units for liquidsEN 12162 + A1:2009 – Procedures for hydrostatic testing of liquid pumpsThe pump must not be put into service until the final machinery into which the pump has been incorporated into, is declared in conformity with the provisions of the machinery directive 2006/42/EC.Nørresundby 2015Claus Dietz Hansen Technical DirectorDESMI Pumping Technology A/SDESMI Pumping Technology A/SEC Declaration of ConformityATEX – 94/9/ECManufacturer: DESMI Pumping Technology A/S Address: Tagholm 1, DK-9400 Nørresundby, Denmark. Tel.: +45 96 32 81 11 E-mail: ***************Product: ROTAN pumps Type: HD, CD, PD, GP, CC, ED(MD) which are marked: II category 2 or 3, ”c” X and with temperature class andinstalled and applied in conformity with DESMI Pumping Technology A/S’ user manualThe entire user manual must be read thoroughly before a ROTAN ATEX pump is installed and put into useD E S M I P u m p i n g T e c h n o l o g y A /S h e r e b y d e c l a r e s t h a t t h e p r o d u c t i n q u e s t i o n h a s b e e n p r o d u c e d i n a c c o r d a n c e w i t h A T E X D i r e c t i v e 94/9/E C .T h e f o l l o w i n g h a r m o n i s e d s t a n d a r d s h a v e b e e n a p p l i e d : E N 13463-1:2009 E N 13463-5:2011T h e p r o d u c t i s d e s i g n e d f o r u s e w h e n c o n n e c t e d t o a n e l e c t r i c m o t o r , w i t h t h e a i m o f c r e a t i n g a j o i n t m a c h i n e . T h e c o n f o r m i t y a l s o a p p l i e s t o c o m p l e t e p u m p s w i t h m o t o r i f , a c c o r d i n g t o t h e m a n u f a c t u r e r , t h e m o t o r c o n f o r m s t o a c o r r e s p o n d i n g c a t e g o r y a n d t e m p e r a t u r e c l a s s a n d h a s b e e n f i t t e d i n c o n f o r m i t y w i t h D E S M I P u m p i n g T e c h n o l o g y A /S ’ u s e r g u i d e .If DESMI Pumping Technology A/S supplies pump and electric motor connected, the EC Declaration of Conformity and user manual for the electric motor will be attached.Nørresundby 2015Claus Dietz Hansen Technical DirectorDESMI Pumping Technology A/SDESMI Pumping Technology A/SDESMI Pumping Technology A/S2. Before start-upRotan CHD pumps are preserved with vegetable oil at the factory, If this oil is not compatible with the media that is pumped, the pump should be cleaned before startup.Rotan CHD pumps is fitted with a special shaft seal, and may not be mistaken for a standard soft shaft packing (see Figure 1)The main bushing and the soft packing rings are not lubricated from the factory.The main bushing and the soft packing is to be lubricated before startup. Make sure that the lubrication media is compatible with the media that’s is pumpedWhen lubricating the main bushing and the soft packing, the lubrication pressure must notexceed 20 bar / 290 psi. If the lubrication pressure exceeds this, there is a risk of damaging the Lip seal and the packing gland.Prelubrication amounts of main bearingPrelubrication amount for main bearingPump sizeHD - CDGrease in cm3 (cubic centimeters)33 5,0 41 7,5 51/66 25,5 81/101 27,0 126 24,0 151 28,0 152 42,0Remember to close the pet cock valve after lubricationFigure 1. Shows Construction of CHD shaft seal DESMI Pumping Technology A/SDESMI Pumping Technology A/SBefore starting the pump, check:∙ That the main bushing and soft packing is lubricated with Food grade grease That the pump is correctly aligned with the gear and motor. See chapter: “Aligning the ∙ pump and gear/motor” Main manual T1456∙ That the pump is heated, to secure a free rotation of the shaft∙ That the ball bearings maximum service life is observed See main manual T1456 ∙ That all isolating valves in the suction and pressure pipe are fully open, to avoid thepressure being too high, and the pump running dry ∙ That there is no coagulated liquid in the pump or pipe system, after last operation,that can cause blockage or breakdown ∙ That all necessary monitoring and safety system are connected and adjustedaccording to the operation conditionsAfter starting the pump, check:∙ That the pump is drawing the liquid∙ That there are no signs of cavitation i.e. excessive noise and or vibration ∙ That the speed is correct∙ That the direction of rotation is correct ∙ That there is no leakage from the pump ∙ That the shaft seal not leaking(the shaft seal on a CHD pump is a isolated construction and there for leak free) ∙That the operation pressure is correct∙ That the pressure in the heating jackets not exceeds 10 bar∙ That the magnetic clutch (type ED) is not slipping and then causing an inadequateflow. And that the temperature in the magnetic clutch does not exceed the permitted l ∙ That the power consumption is correct∙ That all surveillance equipment is working correctly∙ That any pressurized water pipes, Heating/cooling and lubricating systems, etc. are working correctlyDESMI Pumping Technology A/S3. MaintenanceNormal Maintenance of the Rotan CHD pumps will typically include the following.1. Lubrication of the soft shaft seal and main bushing2. Inspection of leakage from the lip seal (the lip seal is leak free)3. Inspection of wear on the idler pin and idler bushingThe implementation of the above mentioned maintenance points, can vary a lot, depending of the operations conditions.DESMI Pumping Technology A/S recommend that the soft packing and main bushing islubricated at an 8 hour intervals (see diagram below) it is important that the lubrication interval is adjusted to the operations conditions, so that the media is kept away from the main bushing and lip seal. Automatic grease pots may be fittedAfter roughly one month operation it is recommended that the front cover is removed forinspection for wear on the idler pin/bushing, and disassembly of the rear end for inspection of wear on the shaft – main bushing and the lip seal if there is traces of the pumped media in the main bushing, it is recommended that the lubrication interval is adjusted.The operating conditions, can be very different, so it is recommended that the company work out a procedure for servicing the pumps (lubrications interval, inspection of wear) that is adjusted to the pump operation conditions.Lubrication of slide bearings CHDFat quantity in grams Pump type:HD – CD – EDRelubrication intervalin hoursMain bearing33 8 hours 141 1 51 1,5 66 1,581 2101 2,5 126 4 151 6 152 10DESMI Pumping Technology A/S4. Replacement of soft packing ringsThe Rotan CHD pumps are constructed with a split packing gland follower, which allows the main bearing bushing to be pulled out of the pump and the soft packing rings can be replaced.Remove the nut (pos. BE) and pull back the packing gland (pos. BB) along with the mainbushing (pos. BC). Remove the bolts in the packing gland (pos. EJ), pull the main bushing as far back as possible. Gently Use a Flexible Packing Extractor for pulling out the soft packing rings (poss. CJ). Clean the area before, replacing them with new ones.If the nuts (pos. BE) are tightened too hard it can result in high heat generation, and poor lubrication of the soft packing rings. Under these conditions there is a very high risk of damaging the soft packing rings and the shaftDESMI Pumping Technology A/S5. Replacement of Lip sealWhen replacing the Lip seal (pos. EG) in the main bushing The rear end is to be dismantled. See figure 2Rotan pumps are constructed with a back pull out systemthat allows the pump casing to remain in the pipe systemWhilst the rear end is removed as show in figure. aRemove the bolts pos. F Remove the rear end.The rear end is now ready to be dismantled.The Lip seal pos. EG. Can be replaced.Use the proper tools to remove the ball bearing.Clean all components before assembling them.The rear end is now ready to be mounted in the pump casing, Remember to check/adjust the axial clearance see chapter “Inspection/adjustment of axial clearance”.Remember to lubricate the soft packing and main bushing before starting up the pump.Figure. aDESMI Pumping Technology A/SFigure. 2 Exploded view of rear endDESMI Pumping Technology A/S6. Inspection of Idler pin/BushingRemove the bolts pos. E. and gently pull out the front cover including the Heating jackets (figure. 3)Be careful that the idler doesn’t fall down when removing the front coverPump size 81 to 201 use proper lifting equipment.Clean the front cover, and inspect the idler pin Poss. AC For Wear (figure. 4)Clean the idler busing pos. AD and inspect it for wear (figure. 5) See figure 7 for measuring wear on idler pin and busingClean the packing surface on the front cover and pump before mounting the front cover on the pump againFrom the size 81 to 152 the Idler is manufactured with a tapered surface between the teeth, the idler is placed on the idler pin with the tapered surface pointing against the front cover. See Figure 6Figure. 3 Removing of front cover Figure.4 Front coverFigure. 6Figure. 5 IdlerDESMI Pumping Technology A/SMeasuring of wearMeasure the diameter on the idler pin and the diameter on the idler bushing the clearance must not exceed measurements stated in the above table (Figure 8)Pump Size RecommendedClearance after wearD+D max(mm)41 1,5 51 1,7 66 1,7 81 1,7 101 1,7 126 1,8 151 1,8 152 1,8Figure. 7Figure. 8DESMI Pumping Technology A/S7. Inspection/adjustment of axial clearanceThe axial clearance is the distance between rotor and front coverType ED: Adjustments screws pos. E/NMThe adjustments screws is to be turned in pairs and in the same angle. Figure:11 Show the axial clearance in mm for the different pump sizes.** Pumps in stainless steel is to be adjusted with 0,10mm larger clearance than stated above. Pumps in stainless steel is recognized by a 3 in the pump code example: CD26EFCHD-3M22BAxial clearence CHDPump size26/33 41 51/66 81/101 126/151 152 CHD*Min.0,20 0,250,20 0,300,30 0,400,40 0,500,60 0,750,70 0,90Max.Stainless pumps**Is adjusted with 0,10mm larger clearance than stated aboveIdler°DESMI Pumping Technology A/S8. Spare parts ListPosition numberA = Pump casingB = GasketC = GasketD = BoltE = BoltF = BoltG = Pipe plugJ = Drive screwS = Blind coverAA = Front coverAB = IdlerAC = Idler pinAD = Idler bushingAF = GasketAJ = Heating jacket AK = Bolt AL = Pipe plug BA = Rear cover BB = Packing gland BC = Main bearing bushing BD = Stud bolt BE = Nut BF = Washer BG = Pipe plug BH = Pipe plug BJ = Bolt BK = Pipe plug BL = Lubrication sign CHD BU = Rotor BV = ShaftBY = Ball bearing nutBZ = Ball bearing lock ring CA = Key CB = KeyCE = Snap ring CJ = Packing coil CQ = BracketCR = Bearing cover CS = Bearing cover CT = BoltCU = Ball bearing EF = O-ring EG = Seal ring EJ = BoltEK = Nipple EK = Nipple EL = BibcockEM = lubricating nipple ER = Support ring FP = Welding sleeve HE = BoltHG = Cover plate for idler pin HH = Screw HE = Bolt HF = Washer HR = Gasket JL = GasketKM = Spacer ringWhen ordering spare parts the following information must be provided: - The pumps serial number - The pumps SX number - The spare part Possession number The above information can be found on the pump flanges or the pump’s nameplateDESMI Pumping Technology A/S9. Assembly drawingsAssembly drawings for Rotan CHD pumps Size 33 to 201DESMI Pumping Technology A/SDESMI Pumping Technology A/SDESMI Pumping Technology A/S10. Service centres – DenmarkService center - DenmarkNøresundby Tagholm 1DK-9400 Nørresundby Tel: +45 70236363Fax: +45 9817 5499Kolding Albuen 18 CDK-6000 Kolding Tel: +45 7023 6363 Fax: +45 75 58 34 65ÅrhusLilleringvej 20 DK-8462 Harlev JTel: +45 7023 6363 Fax: +45 8694 2292HvidovreStamholmen 173 DK-2650 Hvidovre Tel: +45 70236363 Fax: +45 3677 3399OdenseHestehaven 61 DK-5260 Odense S Tel: +45 70236363 Fax: +45 6595 7565DESMI Pumping Technology A/S11. Subsidiary companies – DESMI Pumping Technology A/SSubsidiary companies – DESMI Pumping Technology A/SDESMI Denmark A/SAddress: Tagholm 1,DK-9400 NørresundbyDenmarkTel: +45 7244 0250 Fax: +45 9817 5499DESMI Inc.Address: 4021 Holland Blvd, Chesapeake Virginia 23323, USA Tel.: +1 757 857 7041 Fax.: +1 757 857 6989DESMI Contracting A/SAddress: Tagholm 1,DK-9400 NørresundbyDenmarkTel.: +45 96 32 81 11 Fax: +45 98 17 54 99DESMI Pumping Technology (Suzhou) Co., Ltd Address: No 740 Fengting avenue,Weiting Sub-District 215122 SIP Suzhou, ChinaTel.: +86 512 6274 0400 Fax.: +86 512 6274 0418DESMI GmbHAddress: An der Reitbahn 1521218 Seevetal, Germany Tel.: +49 40 7519 847 Fax: +49 40 7522 040DESMI KoreaAddress: 905 ,Western Tower I, Janghang-dong 867, Ilsandong-gu, Goyang, Gyeonggi 410-838, Korea Tel.: +82 31 931 5701 Fax.: +82 31 931 5702DESMI Ltd.Address: “Norman House” RosevaleBusiness Park, Parkhouse industrial Estate (West) Newcasle, Staffordshire ST5 7UB, EnglandTel.: +44 1782 566 900 Fax.: +44 1782 563 666DESMI Singapore Pte.LtdAddress: No. 8 Kaki Bukit Road 2, Ruby Warehouse ComplexUnit no: # 02-16 Singapore 417841 Tel.: +65 6748 2481 Fax.: +65 6747 6172DESMI B.VAddress: Texasdreef 7,3565 CL Utrech NetherlandsTel.: +31 3026 610 024 Fax.: +31 302 623 314DESMI IndiaAddress: 413,Adity Trade CentreAmeerpet, Hyderabad - 500016 Tel.: +91 9949339054DESMI Norge ASAddress: Vigevejen 46,4633 Kristiansand S, Norway Tel.: +47 38 122 180 Fax.: +47 38 122 181DESMI AfricaAddress: Plot No.1848 Yarht Club RoadMsasani Peninsular, Dar esSalaam,TanzaniaTel. +255 769756919DESMI Pumping Technology A/S。

齿轮泵型号大全齿轮泵型号大全2CY型齿轮泵:主要由齿轮、轴、泵体、泵盖、轴承套、轴端密封等部件组成。

齿轮及轴均经热处理,有较高的硬度和耐磨度。

泵内所有运转部件均利用其输送的介质润滑。

LB型冷冻机专用齿轮泵:适用于输送不含固体颗粒和纤维、无腐蚀性、温度不高于80℃、粘度为5~1500ST的润滑油或性质类似润滑油的其它液体。

CHY型齿轮泵:CH、CHY型齿轮泵是用来输送粘度在200E(1500mpa.s)以下各种不含固体颗粒杂质的机械油、汽轮机油等有润滑性能及性质类似的其它介质,温度不高于120。

CH、CHY型齿轮油泵属容积式泵。

其独特的结构方式具有自吸能力,输送油料时脉动平稳,压力较高、磨损小、使用寿命长、应用广泛、效率高。

WCB型齿轮泵: WCB型齿轮油泵属于低压力里微型手提式节能输油泵,适用于无动力电源的出售单位油桶转油,也适用于炼油厂、电厂、变电所及油库输油。

稀油润滑性系统的稀油治作稀油转运。

K1P型齿轮泵:油泵排量:cm3/r。

效率高,能耗小,操作方便、便于修理,结构牢固,寿命长。

HGP型齿轮泵:QT内啮合齿轮泵内部齿轮触点平滑,静音连转。

其卓越特性为特别齿轮制定,使用时其声音极低,即使在高速运转,音频仍然平稳平和。

kcb齿轮泵:本产品广泛用于国防、科研、石油、化工、冶金、纺织、交通、制药、食品、造纸等工业部门。

适用于输送各种有润滑性的液体,温度不高于80℃,粘度为5-1500mm2/S,工作压力在0.28-1.45MPa。

不合适输送强腐蚀性及含硬颗粒或纤维液体。

2齿轮泵型号齿轮泵的型号一般有ycb齿轮泵、nyp转子泵、kcb齿轮泵等常规产品,一般来说在前面的字母型号就推断出这种泵的各项指标性能和大小参数,在这例举一个如ycb4/0.6的齿轮油泵的工作参数就是,这台齿轮泵的流量是4m/h,工况压力是0.6mpa,只要符合这个工作环境就可以使用。

还有几种常见的齿轮油泵是kcb齿轮泵,kcb代表的是,带安全阀的齿轮泵,kcb200,是指此种齿轮泵的流量是200l/min。

低温泵和压缩机品牌Cryomec的多极离心泵相当有竞争能力,性价比高;在LNG行业有长足的制造工艺泵的经验,针对LNG的特性特别开发出VSMP(Vertical Sealess Motor Pump)系列泵。

该泵的最大的特点是罐外安装,无需氮气密封(与通常氮气密封泵相比,省去消耗氮气费用),铠装全密封,O泄漏。

该款泵在中国有较多的使用业绩,使用情况非常好。

上海塞普机电技术有限公司提供该产品,有意者可来电咨询。

Cryostar,法国品牌,应该说在低温泵领域,算是老大了,产品质量相当比较稳定,常规的低温泵,使用广泛;Sefco,瑞士品牌,离心泵价格比较高!产品质量还是不错的,很多钢厂都使用它们的作为流程泵和增压泵,同样的,柱塞泵价格太高,国内也比较难接受;ACD,美国品牌,在低温泵方面,应该算是后来之秀,特别在国内,知名度还算比较高的,他们的产品线比较全面;性价比还不错;福斯(flowsever),美国品牌,非常大的一个泵阀类企业,在低温泵方面,相对来说,比较少,一般都是早期使用和一些大型项目使用,对于空分类的低温介质,介入相对较少;他们多级泵,应该说还是可以考虑,但价格也比较高,需要根据项目和型号来确定;联合泵业(union),美国品牌,专门做流程内泵的,在低温内,也是少量业绩,和福斯有些类似;在低温泵的领域,还有几个其他的品牌,比如EBARA、NIKKISO、J.C.Carter、CS&P、Vanzetti等,顺带也介绍一下这几家;Ebara,日本品牌,在大型水泵领域非常出名,在低温泵方面,主要是低温潜液电机泵,生产和测试地在美国,低温潜液泵,全球第一品牌;Nikkiso,日本品牌,屏蔽泵方面的牛人,在低温泵方面,也和Nikkiso类似,主要为潜液泵式电机泵,生产和测试地也在美国;J.C.Carter,美国品牌,主要生产低温潜液式电机泵,和现代集团合作,主要在LNG船载方面非常有名气;但在空分介质方面,没有什么特别的名气;CS&P,美国品牌,主要生产低温柱塞泵,用于油田领域,很有名气,其生产的柱塞泵,用于液氮介质,其压力可以达到180MPa;但在空方方面,也没有什么名气;Vanzetti,意大利品牌,主要生产低温离心泵和柱塞泵,从二氧化碳泵开始进入的,有自己的生产和测试工厂,在欧洲的空分领域,有一定的名气,在国内,还没有什么名气。

2020年度国内泵行业十大多级泵厂家品牌榜单1.上海阳光泵业制造有限公司上海阳光泵业制造有限公司座落于上海市金山工业园区,是国内一家著名的集研制、开发、生产、销售、服务于一体的大型多元化企业,注册资本1100万元。

主导产品包括:螺杆泵、隔膜泵、液下泵、磁力泵、排污泵、化工泵、多级泵、自吸泵、齿轮油泵、计量泵、卫生泵、真空泵、潜水泵、转子泵等类别。

产品以优越的性能,精良的品质已获得各项专业认证证书及客户的认可。

公司拥有多名水泵专家和各类中高级工程师,不断的开发制造,升级换代产品年年都有问世。

2.威乐水泵(山东)有限公司威乐水泵(山东)有限公司主要经营进口品牌德国WILO威乐水泵、Grundfos格兰富?泵、Ebara荏原?泵、美国帕斯菲达PULSAFEEDER计量泵、米顿罗milton?roy计量泵、;国产品牌合作厂家:上海凯泉泵业(集团)有限公司、上海连城泵业有限公司、威乐水泵(上海)有限公司、苏州登丰泵业有限公司等优质国产水泵。

{变量3} 4.河北鸿海泵业有限公司泊头市鸿海泵业有限公司是以开发、制造各种齿轮泵、导热油泵、容积泵、不锈钢泵、离心泵、螺杆泵为主的专业生产厂家,具有完善的生产体系和质量保证体系。

产品广泛应用于国家石油、化工、船舶、电力、粮油、建材、冶金、国防及科研等行业,并有部分产品销往国际市场。

主要产品有KCB、2CY型输油泵,KCB型铜轮泵,RY型高温热油泵,BCB型摆线内啮合燃油泵,ZYB型渣油泵,NYP型稠油泵,BWB型保温泵,CB-B型齿轮泵,CYZ型自吸式离心油泵,BRY型离心式高温热油泵,YHB型立、卧式润滑齿轮泵,三螺杆泵,焦油专用泵,电动齿轮泵等十五大系列300多种规格,规格齐全,适用范围广。

我公司拥有一支经验丰富的齿轮泵设计、制造、测试的专业技术队伍,具有较强的开发、研制生产齿轮油泵的能力,可根据用户的需要专门设计、制造各种类型的特种齿轮油泵产品。

5.上海金胜泵阀有限公司本公司是一家专从事泵、阀产品、变频供水设备集生产、销售、科研、开发、服务于一体的私营有限责任公司。