赫斯基热流道产品指南-1

- 格式:pdf

- 大小:12.33 MB

- 文档页数:136

e-mail:**************For latest product manuals:User’s GuideKH, KHR, KHLV SERIESKapton ®Flexible HeatersShop online atGENERAL DESCRIPTIONOMEGALUX®Kapton®Insulated Flexible Heaters are available in avariety of shapes, sizes, and wattages. Wattage ratings are 2.5, 5, or 10W/in2at 115 or 28 volts. Kapton offers a high degree of resistance tochemicals, and has excellent outgasing properties in high vacuumenvironments. KH models are rectangular 115 volt units; KHLV modelsare rectangular 28 volt units, and KHR models are round 115 volt units.Contact OMEGA sales Department for specific part numbers:800-872-9436Typical construction consists of an etched foil element of 0.0005" or0.0001" thickness, which is encapsulated between two layers of 0.002"Kapton and 0.001 FEP TefIon®adhesive. Lead wires exit from theupper-right hand corner of width (W) side of heater. For 0.50" rind 1.00"wide heaters only, leads exit centrally from width (W) side. Leads exitround heaters radially. Pressure sensitive adhesive (PSA) is available asart option on heaters rated at 2.5 or 5 W/in2. The heaters can also bemechanically clamped or epoxy mounted by the user.*Kapton and Teflon are registered trademarks of DuPont.SPECIFICATIONSHeating Element Design:Etched circuit.Operating Temperature:-328°F to 392°F (-200°C to 200°C) forheaters without pressure sensitiveadhesive (PSA). Maximum operatingtemperature for heaters withpressure sensitive adhesive is 250°F(120°C)Voltage:KH, KHR Series: 115 Volts KHLVSeries: 28 VoltsWatt Density: 2.5, 5, or 10 W/in2Pressure Sensitive Optional. not available at 10Adhesive (PSA):watts/square inch watt densityLead Wire:12" of Teflon Insulated(MIL W-16878) lead wire(wire gauge varies with heater) Dielectric Strength:1260 VacMinimum Sending Radius:0.032"Heater Thickness:0.010" except at lead wife exit(thickness varies with heater)INSTALLATION AND OPERATIONUse a method of temperature control (e.g., thermostat,thermocouple and temperature controller, or variablevoltage transformer) to prevent heaters from exceedingmaximum operating temperature ratings. Place temperaturesensor close enough to the heater to sense heatertemperature.1. DO NOT immerse heaters in liquids.2. DO NOT operate heaters at a voltage higher than the specified orrated voltage.3. DO NOT cut, punch holes in or otherwise mishandle heaters.4. AVOID exposing heaters to chemicals, acids, alkalies. oils fluids orother substances that could ignite or cause damage to the heaters.5. DO NOT insulate heaters unless adequate measures are taken tocontrol heater temperature.6. DO NOT leave heaters operating unattended unless adequatecontrols are installed to insure safety.7. Heaters can be bent around curved surfaces; however, DO NOTexceed minimum banding radius.8. Exercise care in attaching heaters to flat or curved surfaces. Heaterscan be attached by mechanical clamping, by using factory appliedpressure sensitive adhesive (PSA), or with a thin layer of conductiveepoxy. Make sure that the entire heater is in contact with the surfacewith no air pockets trapped underneath. This is especially importantfor high watt density heaters, i.e. heaters with a watt density of 10watts/square inch, to prevent heater failure. DO NOT overlapheaters.9. Heaters must be attached to an appropriate heat sink and shouldNOT be mounted free-standing In air.10. Make sure heaters are installed and used by qualified personnel.DO NOT attempt to repair damaged heaters.It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.WARNING: These products are not designed for use in, and should not be used for, human applications.WARRANTY/DISCLAIMEROMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANT Y adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. T his ensures that OMEGA’s customers receive maximum coverage on each product.If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification;misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted,include but are not limited to contact points, fuses, and triacs.OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential,incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s)be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY/DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.RETURN REQUESTS /INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RET URNING ANY PRODUCT (S) T O OMEGA, PURCHASER MUST OBT AIN AN AUT HORIZED RET URN (AR) NUMBER FROM OMEGA’S CUST OMER SERVICE DEPART MENT (IN ORDER T O AVOID PROCESSING DELAYS). T he assigned AR number should then be marked on the outside of the return package and on any correspondence.The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit. FOR WARRANTY RETURNS, please have the following informa-tion available BEFORE contacting OMEGA:1.Purchase Order number under which the product was PURCHASED,2.Model and serial number of the product under warranty, and3.Repair instructions and/or specific problems relative to the product.FORNON-WARRANTY REPAIRS,consult OMEGA for cur-rent repair charges. Have the following information avail-able BEFORE contacting OMEGA:1. Purchase Order number to cover the COST of the repair,2.Model and serial number of the product, and3.Repair instructions and/or specific problems relative to the product.OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.© Copyright 2005 OMEGA ENGINEERING, INC. All rights reserved. T his document may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.Servicing North America:U.S.A.:One Omega Drive, Box 4047ISO 9001 Certified Stamford, CT 06907-0047Tel: (203) 359-1660FAX: (203) 359-7700e-mail:**************Canada:976 BergarLaval (Quebec) H7L 5A1, Canada Tel: (514) 856-6928FAX: (514) 856-6886e-mail:*************For immediate technical or application assistance:U.S.A. andSales Service: 1-800-826-6342 / 1-800-TC-OMEGA Canada:Customer Service: 1-800-622-2378 / 1-800-622-BEST Engineering Service: 1-800-872-9436 / 1-800-USA-WHEN TELEX: 996404 EASYLINK: 62968934 CABLE: OMEGA Mexico:En Espan ˜ol: (001) 203-359-7803e-mail:*****************FAX: (001) 203-359-7807**************.mxServicing Europe:Benelux:Postbus 8034, 1180 LA Amstelveen, The Netherlands Tel: +31 (0)20 3472121FAX: +31 (0)20 6434643Toll Free in Benelux: 0800 0993344e-mail:*****************Czech Frystatska 184, 733 01 Karviná, Czech Republic Republic:Tel: +420 (0)59 6311899FAX: +420 (0)59 6311114Toll Free: 0800-1-66342e-mail:*****************France:11, rue Jacques Cartier, 78280 Guyancourt, France Tel: +33 (0)1 61 37 2900FAX: +33 (0)1 30 57 5427Toll Free in France: 0800 466 342e-mail:**************Germany/Daimlerstrasse 26, D-75392 Deckenpfronn, Germany Austria:Tel: +49 (0)7056 9398-0FAX: +49 (0)7056 9398-29TollFreeinGermany************e-mail:*************United One Omega Drive, River Bend Technology Centre Kingdom:Northbank, Irlam, ManchesterISO 9002 Certified M44 5BD United KingdomTel: +44 (0)161 777 6611FAX: +44 (0)161 777 6622Toll Free in United Kingdom: 0800-488-488e-mail:**************.ukM1249/0205。

e-mail:**************For latest product manuals:FTH SERIESIndustrial Flow Through HeatersShop online atUser’s GuideDocument: 400-00003 Revision 0: 3-23-2009FTH SERIES HEATERS INSTALLATION, OPERATION AND MAINTENANCEOmega® flow through heaters are designed primarily for providing heat that regulates liquid temperature from 90°F to 190°F. The heaters have a titanium element that resists corrosion. The 304 Stainless Steel flow through tube is 15 inches long and has 1-½ inch NPT female pipe connections. Each heater has a 6 ft SJTW 12/3 or a 6 ft SJTW 14/3 power cord. The 115 V units have a 15P plug and the 240 V units have pig tales. The safety high limit trip point for the heater is 210°F. The 7.9” x 5.7” x 3.5” enclosure is made of ABS plastic and is water resistant.WARNING:Not for use as a Spa or Hot Tub heaterWARNING:Read all instructions before installation and operation.WARNING:Heater will fail if energized without proper fluid flow – 15 GPM minimum. WARNING:Pump must be running and fluid flowing before turning on power to the Heater. WARNING:Heater must be powered down for one to five minutes before turning off the pump and stopping fluid flowWARNING:Bleed the system of any air before applying power to the heater.WARNING:Heater failures due to insufficient flow or due to dry firing the heater are not covered under warranty.WARNING:Heater should always be mounted so that the water outlet is elevated a minimum of 3 inches above the water inlet. (See Figure A)WARNING:When using piping smaller than 1-1/2 inch, the heater is to be mounted in a vertical orientation. Fluid flow is to enter at the bottom and exit out the top. (SeeFigure B)WARNING:Minimum connecting pipe diameter is ¾ inch.WARNING:Piping connections are to meet all local plumbing codes.WARNING:Electrical connections must be performed in accordance with Articles 250 and 680 of the National Electric Code and by a qualified electrician.Water Out3” Min.Figure A – Mounting Method for 1-½ Inch PipeWater InWater OutFigure B – Mounting Method for Piping less than 1-½ InchDocument: 400-00003Revision 0: 3-23-2009 Model Number Series Wattage Voltage Phase AMP DrawFTH-1500-120FTH 1500 120 1 Ø 12.5FTH-2000-240FTH 2000 240 1 Ø 8.3FTH-3000-240FTH 3000 240 1 Ø 12.5FTH-4000-240FTH 4000 240 1 Ø 16.7FTH-5000-240FTH 5000 240 1 Ø 20.8FTH-6000-240FTH 6000 240 1 Ø 25.0Chart A – Electrical SpecificationsUNPACKING AND INSPECTION UPON RECEIPTThe FTH series heaters are shipped fully assembled and ready for installation. Check for any damage sustained during shipment and report damage to seller.INSTALLATIONPrior to installation remove any packing material from inside the heater. The FTH series heaters have 1-1/2 NPT female pipe threads. The equivalent male fittings are required to plumb the heater for installation. Seal both pipe joints with an approved sealant. Although the heater assembly is equipped with a water resistant enclosure, it is not intended for direct exposure to weather or immersion in water.TROUBLESHOOTING/PRECAUTIONSMinimum guidelines for properly installed heater to achieve effective operation:1)Proper Flow Rate: 15GPM minimum.2)Thermostats are designed for heater control only and are not to be used for control of motors orother components. Heater should be turned on/off at the supply breaker or switch, not the thermostat, when heater is being serviced.3)Heater should be plumbed below the lowest operating liquid level of the piping system.4)If the heater experiences a high temperature condition, the high limit thermostat will shut down theheater. Disconnect power to the heater and check for inadequate flow (clogged filter or line), or for possible air that may have accumulated in the system. Correct the problem, start the fluid flowing,and then reconnect power to the heater.5)To reset the heater controls, disconnect power to the heater and allow the fluid temperature tocool to 90°F. Then reconnect power to the heater.6)The power supply to the heater must be disconnected before draining the piping system and donot reconnect power until the piping system is refilled and the fluid is flowing.7)The power applied to the heater must be single phase. The heater must be protected by a circuitbreaker or fused disconnect switch rated for the appropriate Amp draw. (See Chart A) A ground fault circuit must be incorporated into the system.REPLACEMENT PARTSFor heaters that are beyond factory warranty, replacement High Limit and Control Thermostats can be acquired through electrical distributors. For heaters that are covered under warranty the heater assembly must be sent back to the seller for disposition. All returned heaters are subject to the terms and conditions of the warranty.Document: 400-00003Revision 0: 3-23-2009 DIMENSION AND WIRING DIAGRAMS 120V UNITS:15”2.3”2.3”15”It is the policy of OMEGA Engineering, Inc. to comply with all worldwide safety and EMC/EMI regulations that apply. OMEGA is constantly pursuing certification of its products to the European New Approach Directives. OMEGA will add the CE mark to every appropriate device upon certification.The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.WARNING: These products are not designed for use in, and should not be used for, human applications.WARRANTY/DISCLAIMEROMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. This ensures that OMEGA’s customers receive maximum coverage on each product.If the unit malfunctions, it must be returned to the factory for evaluation. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request.Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser,including but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized modification. T his WARRANT Y is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion;or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.OMEGA is pleased to offer suggestions on the use of its various products. However, OMEGA neither assumes responsibility for any omissions or errors nor assumes liability for any damages that result from the use of its products in accordance with information provided by OMEGA, either verbal or written. OMEGA warrants only that the parts manufactured by the company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND W HATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warranty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical applications or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANTY /DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.RETURN REQUESTS/INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RET URNING ANY PRODUCT (S) T O OMEGA, PURCHASER MUST OBTAIN AN AUT HORIZED RET URN (AR) NUMBER FROM OMEGA’S CUST OMER SERVICE DEPART MENT (IN ORDER T O AVOID PROCESSING DELAYS). The assigned AR number should then be marked on the outside of the return package and on any correspondence.The purchaser is responsible for shipping charges, freight, insurance and proper packaging to prevent breakage in transit.FOR WARRANTY RETURNS, please have thefollowing information available BEFOREcontacting OMEGA:1.Purchase Order number under which the productwas PURCHASED,2.Model and serial number of the product underwarranty, and3.Repair instructions and/or specific problemsrelative to the product.FOR NON-WARRANTY REPAIRS,consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA:1. Purchase Order number to cover the COST of the repair,2.Model and serial number of the product, and 3.Repair instructions and/or specific problems relative to the product.OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a registered trademark of OMEGA ENGINEERING, INC.© Copyright 2009 OMEGA ENGINEERING, INC. All rights reserved. T his document may not be copied, photocopied,reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without theprior written consent of OMEGA ENGINEERING, INC.Where Do I Find Everything I Need for Process Measurement and Control?OMEGA…Of Course!Shop online at SMTEMPERATUREⅪߜThermocouple, RTD & Thermistor Probes, Connectors, Panels & AssembliesⅪߜWire: Thermocouple, RTD & ThermistorⅪߜCalibrators & Ice Point ReferencesⅪߜRecorders, Controllers & Process MonitorsⅪߜInfrared PyrometersPRESSURE, STRAIN AND FORCEⅪߜTransducers & Strain GagesⅪߜLoad Cells & Pressure GagesⅪߜDisplacement TransducersⅪߜInstrumentation & AccessoriesFLOW/LEVELⅪߜRotameters, Gas Mass Flowmeters & Flow ComputersⅪߜAir Velocity IndicatorsⅪߜTurbine/Paddlewheel SystemsⅪߜTotalizers & Batch ControllerspH/CONDUCTIVITYⅪߜpH Electrodes, Testers & AccessoriesⅪߜBenchtop/Laboratory MetersⅪߜControllers, Calibrators, Simulators & PumpsⅪߜIndustrial pH & Conductivity EquipmentDATA ACQUISITIONⅪߜData Acquisition & Engineering SoftwareⅪߜCommunications-Based Acquisition SystemsⅪߜPlug-in Cards for Apple, IBM & CompatiblesⅪߜData Logging SystemsⅪߜRecorders, Printers & PlottersHEATERSⅪߜHeating CableⅪߜCartridge & Strip HeatersⅪߜImmersion & Band HeatersⅪߜFlexible HeatersⅪߜLaboratory HeatersENVIRONMENTALMONITORING AND CONTROLⅪߜMetering & Control InstrumentationⅪߜRefractometersⅪߜPumps & TubingⅪߜAir, Soil & Water MonitorsⅪߜIndustrial Water & Wastewater TreatmentⅪߜpH, Conductivity & Dissolved Oxygen InstrumentsM4786/0409。

ASHRAE Handbook 2010 Refrigeration 中文目录2009版的基础知识部分让人叹为观止,2010版的制冷部分只能用无言以对。

真郁闷,昨天被人拉到公司打酱油,所以只能先翻到二级标题。

以后有时间慢慢把三级标题翻出来。

光目录就弄出几十页的动静,何以堪啊。

2 2010 Refrigeration 46Dedication 46编著人员 46技术委员会、工作组、和技术资源组 46ASHRAE 研究:提高生活品质 46序 46系统和方法(Systems and Practices) 462.1.1 卤代烃制冷系统 462.1.2 氨制冷系统 472.1.3 二氧化碳制冷系统 472.1.4 过量充液系统(Liquid Overfeed Systems) 482.1.5 制冷系统的部件匹配(Component Balancing in Refrigeration Systems) 482.1.6 制冷剂系统的化学 482.1.7 制冷剂系统内水分和其它杂质的控制 482.1.8 设备和系统脱水、充注和试验 492.1.9 制冷剂的密封、恢复、回收和再利用 49部件和设备 492.1.10 制冷剂管路的绝热系统 492.1.11 制冷剂控制元件 502.1.12 制冷剂系统内的润滑油 502.1.13 制冷系统的载冷剂 512.1.14 受迫对流空气冷却器 512.1.15 零售食品存储冷冻和设备 512.1.16 食品服务和一般商业冷冻设备 522.1.17 家用冰箱和冷冻机 522.1.18 吸收设备 52食品冷却和储藏 522.1.19 食品的热力性质 522.1.20 食品的冷却和冷冻时间 532.1.21 日用品储藏设备 532.1.22 食品微生物和冷藏 532.1.23 冷藏设备设计 542.1.24 冷藏设备负荷 54冷冻运输 542.1.25 货运集装箱、轨道运输、拖车和卡车 542.1.26 海运冷冻 552.1.27 航空运输 55食品、饮料和花卉应用 552.1.28 水果、蔬菜和鲜花的预冷 552.1.29 工业食品冷冻系统 562.1.30 肉类产品 562.1.31 禽类产品 562.1.32 鱼类产品 572.1.33 乳类产品 572.1.34 蛋和蛋类产品 572.1.35 阔叶树和藤类水果 582.1.36 柑橘类水果、香蕉和亚热带水果 582.1.37 蔬菜 592.1.38 果汁浓缩物和冷藏果汁产品 592.1.39 饮料 592.1.40 已处理食品,预加工过的食品和精制食品 60 2.1.41 烘焙食品 602.1.42 巧克力、糖果、坚果、干果和干燥蔬菜 61 工业应用 612.1.43 制冰 612.1.44 溜冰场 612.1.45 混凝土坝和次表土 622.1.46 化工中的制冷 622.1.47 低温应用 622.1.48 超低温制冷 632.1.49 生物医学应用和低温制冷 632.1.50 制冷术语 632.1.51 规范和标准 63ASHRAE Handbook 2009 Fundamental 中文目录花了三天的业余时间才把《ASHRAE Handbook 2009 Fundamental》目录翻译成中文,因为涉及的学科太多,很多专业名称采用的是直译,后续如果在阅读过程中有新发现我会修改过来。

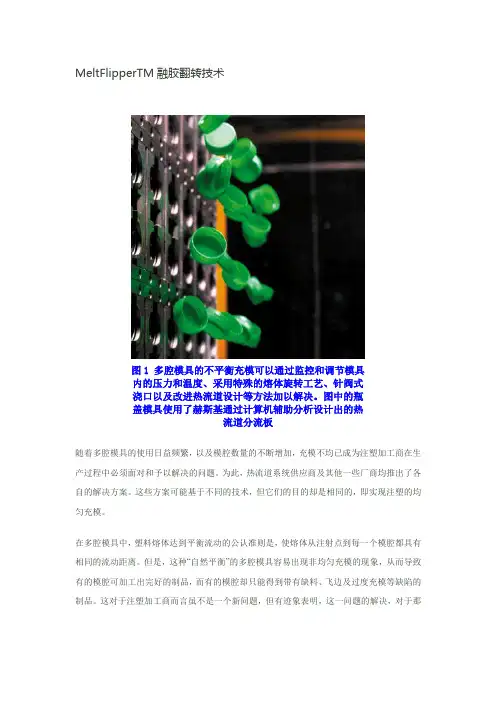

MeltFlipperTM融胶翻转技术图1 多腔模具的不平衡充模可以通过监控和调节模具内的压力和温度、采用特殊的熔体旋转工艺、针阀式浇口以及改进热流道设计等方法加以解决。

图中的瓶盖模具使用了赫斯基通过计算机辅助分析设计出的热流道分流板随着多腔模具的使用日益频繁,以及模腔数量的不断增加,充模不均已成为注塑加工商在生产过程中必须面对和予以解决的问题。

为此,热流道系统供应商及其他一些厂商均推出了各自的解决方案。

这些方案可能基于不同的技术,但它们的目的却是相同的,即实现注塑的均匀充模。

在多腔模具中,塑料熔体达到平衡流动的公认准则是,使熔体从注射点到每一个模腔都具有相同的流动距离。

但是,这种“自然平衡”的多腔模具容易出现非均匀充模的现象,从而导致有的模腔可加工出完好的制品,而有的模腔却只能得到带有缺料、飞边及过度充模等缺陷的制品。

这对于注塑加工商而言虽不是一个新问题,但有迹象表明,这一问题的解决,对于那些原本使用简单模具的注塑加工商而言显得非常重要,因为他们已开始使用更复杂的多腔模具。

然而,并非所有的被访者都同意上述观点。

热流道供应商D-M-E公司的发言人说:“我们看不出更多的充模不平衡问题,主要是因为我们避免了浇口尺寸的改变。

”D-M-E公司为预防制品出现潜在的缺陷,在一套几何形状均衡的模具上反复运用Moldflow软件进行了分析,他们得出的结论是:“即使运用了Moldflow分析软件,你所能做的也只是这些。

假如你改变了浇口位置,之后制品的熔接缝位置也有所变化,这可能是因为剪切力不平衡而导致的变化,因此你不得不改变浇口尺寸来予以补偿。

”然而,D-M-E公司建议,尽量不要进行这样的改动,因为改变浇口尺寸意味着模具加工窗口的缩小。

图2 Beaumont公司的MeltFlipper技术专用于解决模具不平衡的问题。

iMARC是其最新型号,可通过对模具分型线的简单调节来改变熔体的旋转程度大多数被访者都认为,多腔模具的不平衡充模确实已成为近年来的一个热议话题。

2、缩短成型周期,提高机器效率3、改善制品表面质量和力学性能。

4、不必用三板式模具即可以使用点浇口。

5、可经济地以侧浇口成型单个制品。

6、提高自动化程度。

7、可用针阀式浇口控制浇口封冻。

8、多模腔模具的注塑件质量一致。

9、提高注塑制品表面美观度。

但是,每一项技术都会有自身的缺点存在,热流道技术也不例外:1、模具结构复杂,造价高,维护费用高。

2、开机需要一段时间工艺才会稳定,造成开价废品较多。

3、出现熔体泄露、加热元件故障时,对产品质量和生产进度影响较大。

上面第三项缺点,格外需要注意,通过采购质量上等的加热元件、热流道板以及喷嘴并且使用时精心维护,可以减少这些不利情况的出现。

三、热流道系统的组成1、热流道板:热流道分流板其主要任务是恒温地将熔体从主流道送入各个单独喷嘴,在熔体传送过程中,熔体的压力降尽可能减小,并不允许材料降解。

常用热流道板的形式有:一字型,H型,Y型,X字型;结构上有外加热热流道板和内加热热流道板两大类。

2、喷嘴:热流道喷嘴热流道模具按喷嘴结构形式不同有多种形式,类型均大同小异,但各个厂家加工工艺和实施方法有很大区别,这决定了热流道系统的质量和价格的差异。

一般有开放式、针阀式和其他几种特殊形式。

针阀式喷嘴技术上较先进,优点有:a.在制品上不留下进浇口残痕,进浇口处痕迹平滑;b.能使用较大直径的浇口,可使型腔填充加快,并进一步降低注射压力,减小产品变形。

C.可防止开模时出现牵丝现象及流涎现象;d.当注塑机螺杆后退时,可有效地防止从模腔中反吸物料;e.能配合顺序控制以减少制品熔接痕。

3、加热元件热流道加热元件加热元件是热流道系统的重要组成部分,其加热精度和使用寿命对于注塑工艺的控制和热流道系统的工作稳定影响重大。

一般有加热棒、加热圈、管式加热器、螺旋式加热器(加热盘条)等等。

4、温控器热流道温控器温控器就是对热流道系统的各个位置进行温度控制的仪器,由底端向高端分别有通断位式,积分微分比例控制式和新型智能化温控器等种类,根据需要用户可以同其它模内组件配合使用。

热流道系统漏料问题及解决热流道的发明和应用,为模具制造商带来了更多发展机会;从通用塑料如聚丙烯和聚乙烯,到工程塑料如聚碳酸脂以及玻璃纤维增强尼龙等,许多不同的材料都可以通过热流道系统进行加工。

然而,这种技术和设备也常为模具制造商带来一些烦恼,漏料就是问题之一。

1成功应用热流道系统的先决条件赫斯基注塑系统上海有限公司热流道及模具事业部亚太区总经理迪尼士指出,要成功运用热流道系统,最关键的因素是模具制造商需按自身的需要,选择合适的热流道产品。

各种热流道系统之间的重要区别之一是熔料的加热方式,可分为内部和外部加热两种。

顾名思义,内部加热系统是把加热器直接安装在熔道中,从内部加热;而外部加热系统即是在外部加热原料,使原料在没有障碍的情况下流过通道。

外部加热系统解决了熔料通道中的死点问题,并使熔道内的剪切曲线更为合理。

热流道系统是注塑机注口的延伸,要均匀地将原料传送到每个注料口,最有效的方法是安装一个平衡的分流板,以确保从注射点到每一个膜腔的熔流长度和流道尺寸相等。

这种机械平衡设计,能确保各个产品的均衡充填,同时可避免飞边和短射的发生。

不同的熔道尺寸会直接影响热流道的性能。

不合适的熔道尺寸,会导致塑料降解,或者造成注塑件的不均匀或者充填不完整,以及换色缓慢等。

模具制造商在确定熔道尺寸时,要考虑压力降、停留时间、温升、剪切速率和换色频率等因素。

在决定了系统类型之后,接着就要选择合适的浇口类型及其填充速度。

浇口类型林林总总,要考虑的因素包括:允许的浇口痕迹、浇口位置和注塑的原料类型。

无论是非结晶或结晶塑料,不同的浇口类型都对特定原料有所限制。

大部分热流道系统都能匹配不同尺寸的热嘴,每种热嘴可提供特定的填充速度。

浇口太小将会限制塑料填充,并可能产生过大的剪切导致材料降解。

2漏料原因分析与对策其中一个最让模具制造商叫苦的问题,就是热流道系统中熔料泄漏后会流到分流板槽中。

这也是造成模具损坏和停用的主要原因之一。

迪尼士指出,大部分的漏料情况,并不是因为系统设计不良,而是由于未按照设计参数操作。

国内外知名热流道品牌大全1.北美洲知名热流道品牌(英文名-中文名-国家)MOLD-MASTERS(马斯特)加拿大品牌:全球市场占有率最高D-M-E INCOE(英柯欧)美国品牌:北美标准的先行者HUSKY(赫斯基)加拿大品牌、CACO美国品牌、INCOE 美国品牌FASTHEA T美国品牌、HASCO德国品牌2.欧洲知名热流道品牌SYNVENTIVE (圣万提)荷兰品牌EWIKON 德国品牌、GUNTHER MASTIP(坤特)德国品牌:专攻瓶胚模热流道SPEAR 德国品牌、PLASTHING 英国品牌、UNITEMP 瑞典品牌THERMOPLY意大利品牌3.亚洲知名热流道品牌FISA(菲莎)日本品牌:世界第一家弹簧自锁针阀热流道企业SEIKI 日本品牌、HOTSYS南韩品牌YUDO 柳道万和:亚洲市场占有率前列HOTSYS 信好、SINO中国(YUDO子公司)MOULD-TIP麦士德中国、ANOLE阿诺立、NISSEN-TIP宁塑、MOZOI默作(弹簧自锁针阀)4.澳洲知名热流道品牌MASTIP 新西兰品牌主要提提DME(北美的标准)是全球最大的模具标准配件供应商之一,拥有五十年的丰富经验,历史悠久。

HUSKY FISA(第一家弹簧自锁针阀)最大特点,依靠弹簧和注射压力的平衡控制针阀开关,装配调试和维护简单,模具精度不高,日本国内客户基本自己有维护能力,广泛应用在家电、汽车饰件、精密多腔模具中。

GUNTHER MASTIP (专攻瓶胚模热流道)MOLD-MASTER(世界上占有率最高)其中MOLD-MASTER堪称热流道中的劳斯莱斯—-加热部分在喷嘴上。

他们中的很大成本在调试和维护上,客户基本不能自己维护。

国产热流道品牌:麦士德、KLN克朗宁、ANOLE阿诺立、MOZOI默作热流道系统,江浙沪沿海地区以及广东地区的热流道品牌很多。

先锐是YUDO在中国的子公司。

作为国内的企业已经慢慢的走向国际市场。

Welcome toThe Bergquist Company世界上最大的导热界面材料供应商•行业内的一些著名商标…Sil-Pad ®Gap-Pad ®Thermal Clad®Liqui-Bond ®Bond-Ply®Hi-Flow®公司简介为什么选择贝格斯Sil-PadGap FillersHi-FlowTapeThermal CladThermal Properties Touch Screens ECG ProductsThermal Products Switch Group Electronic Components Group导热产品部•绝缘导热片•填缝材料•相变材料•导热双面胶带•导热膏•绝缘金属基板Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG Products导热界面材料界面之间的空气需通过导热界面材料消除•宏观:表面变形,凸起,平整性•微观:表面粗糙度导热界面材料的流变性及润湿性流变性:材料的流动性或变形性润湿性:材料接触表面的能力Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG ProductsSil-PadGap FillersHi-FlowTapeThermal CladThermal Properties Touch Screens ECG ProductsThermal Products Switch Group Electronic Components Group 导热界面材料性能•最大的导热系数•最大的润湿性•最薄的界面厚度导热界面材料种类贝格斯导热界面材料•导热膏•TIC•凝胶•TIG & GEL•相变材料•Hi-Flow (HF)•液态添缝材料•Gap Fillers (GF)•片状添缝材料–厚材料(≥ 10 mils) •Gap Pad (GP)–薄材料(≤ 10 mils) •Sil-Pad (SP)•液态导热胶•Liqui-Bond (LB)•导热胶带•Bond-Ply (BP)Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG Products客户关心的性能•热阻•厚度•柔软度•出油率Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG Products客户关心的性能•热阻导热系数厚度材质压力Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG ProductsGap-Pad 性能比较导热系数比较Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG Products缝隙填充材料-Gap Pad厚度对热阻的影响缝隙填充材料-Gap Pad客户关心的性能•柔软度Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG ProductsGap-Pad性能比较硬度比较Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG Products缝隙填充材料-Gap Pad客户关心的性能•厚度--一般压缩20-40%Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG ProductsBergquist 优势•最全的产品线–不同的热性能–不同的硬度–不同的厚度–不同的表面粘性–增强及非增强–低硅油析出–片状,卷材及膏状Thermal Products Switch Group Electronic Components GroupSil-Pad Gap Fillers Hi-Flow Tape Thermal Clad Thermal Properties Touch Screens ECG Products特点•用于填充不规则表面和不平行表面,具有弹性,变形性和柔软性的特点。

Ultra系列热流道操作手册原始说明的翻译Ultra系列热流道版本: 1.5版 — 2015年2月文档编号: 5079288本产品手册介绍了注塑机的安全操作和/或维护信息。

赫斯基保留对产品进行更改的权利,以便持续改进产品功能和/或性能。

这些更改可能导致客户需要对设备采取不同的和/或额外的安全措施。

当发生此类更改时,赫斯基将向客户发布通告。

本文件包含赫斯基注塑系统有限公司的专有信息。

除非经合同明确授权,否则未经赫斯基注塑系统有限公司的事先书面许可,不得进一步发布本文件的全部或部分内容或者将其用于商业用途。

尽管如此,赫斯基注塑系统有限公司授权客户可以复制本文件的内容,但仅供内部有限使用。

本材料中引用的Husky®产品或服务的名称或徽标是赫斯基注塑系统有限公司的商标,经授权可由其特定的附属公司使用。

所有第三方商标均为相应第三方的财产,并且受相关版权法、商标法或其它知识产权法律或条约的保护。

所有这些第三方均明确保留所有相关的知识产权。

©赫斯基注塑系统有限公司2010–2015年版权所有。

保留所有权利。

ii 1.5版 — 2015年2月操作手册 1.5版 — 2015年2月一般信息电话支持号码北美免费电话1-800-465-HUSKY (4875)欧洲欧盟(大多数国家)008000 800 4300直线电话和非欧盟成员+ (352) 52115-4300亚洲免费电话800-820-1667或+800-4875-9477直线电话+86-21-3849-4520拉丁美洲巴西+55-11-4589-7200墨西哥+52-5550891160选项5对于不太紧急的问题,您也可以向赫斯基发送电子邮件:techsupport@husky.ca。

赫斯基地区服务和销售办事处如需了解离您最近的赫斯基服务和销售办事处地址,请访问www.husky.co。

产品升级赫斯基提供多种升级选项来提高您的产量、缩短周期并为您的赫斯基设备添加更多的功能。