manual_伺服电机手册2(中文)

- 格式:pdf

- 大小:21.93 MB

- 文档页数:129

交流伺服电机产品手册

很高兴能够与您交流伺服电机产品手册。

伺服电机产品手册是伺服电机厂商提供的关于伺服电机产品的详细信息的文档。

它通常包含以下内容:

1. 产品介绍:介绍伺服电机的基本概念、应用范围和优势。

2. 技术规格:包括电机的额定电压、额定电流、转速、扭矩等技术参数。

3. 产品结构:描述伺服电机的构造和部件,包括转子、定子、电磁绕组等。

4. 功能特点:介绍伺服电机的特殊功能,如高速响应、扭矩控制、位置控制等。

5. 安装说明:指导用户如何正确安装伺服电机,包括电气连接和机械安装。

6. 编码器介绍:描述伺服电机所配备的编码器的工作原理和应用。

7. 保养维护:提供伺服电机的保养维护指导,包括定期检查和清洁。

8. 故障诊断:列举常见故障和解决方法,以帮助用户快速排除问题。

9. 安全注意事项:告知用户使用伺服电机时需注意的安全事项。

以上是一般伺服电机产品手册的一些主要内容,具体手册内容可能会有所不同。

相信通过手册的阅读和理解,您能更好地了解和使用伺服电机产品。

宁波菲仕运动控制技术有限公司宁波菲仕电机技术有限公司永磁交流伺服电机Ultract III(第二版)使用说明书目录一、概述 (3)二、规范说明 (3)三、检查 (3)四、安装 (4)五、编码器配置 (4)六、接线 (6)七、PHASE电机与驱动器接线 (10)Ⅰ、匹配PHASE驱动器接线 (10)(1)、配置正余弦编码器接线 (10)(2)、配置绝对值编码器接线 (11)(3)、配置旋转变压器接线 (12)Ⅱ、匹配LENZE驱动器接线 (13)(1)、配置旋转变压器接线 (13)(2)、配置绝对值编码器接线 (14)(3)、配置数字增量式编码器接线 (15)Ⅲ、匹配KEB驱动器接线 (16)(1)、配置正余弦编码器接线 (16)(2)、配置旋转变压器接线 (17)(3)、配置绝对值编码器接线 (18)Ⅳ、匹配SIEMENS驱动器接线 (19)(1)、配置正余弦编码器接线 (19)(2)、配置旋转变压器接线 (20)Ⅴ、匹配Schneider驱动器接线 (21)(1)、配置旋转变压器接线 (21)(2/3)、配置绝对值编码器接线 (22)Ⅵ、匹配B&R驱动器接线 (24)(1)、配置绝对值编码器接线 (24)Ⅶ、匹配CT驱动器接线 (25)(1)、配置绝对值编码器接线 (25)Ⅷ、匹配Kinwaytech(御能)驱动器接线 (26)(1)、配置旋转变压器接线 (26)Ⅸ、匹配Inovance(汇川)、Modrol(蒙德)驱动器接线 (27)(1)、配置旋转变压器接线 (27)Ⅹ、匹配Vector(威科达)驱动器接线 (28)(1)、配置数字增量式编码器 (28)八、运行与维护 (29)衷心感谢您选用菲仕伺服电机,为使本电机一直维持良好的运行状态,请将本手册随整机附送给最终用户。

虽然在您的选型过程中,可能已经对本产品有所了解并与本公司的技术人员进行了某些沟通,但为充分发挥本电机最佳功能,仍请在使用前,仔细阅读本使用说明书,必要时请与PHASE的有关人员联系,获得必要的帮助,以便正确的使用和维护电机,使之运行可靠,经久耐用。

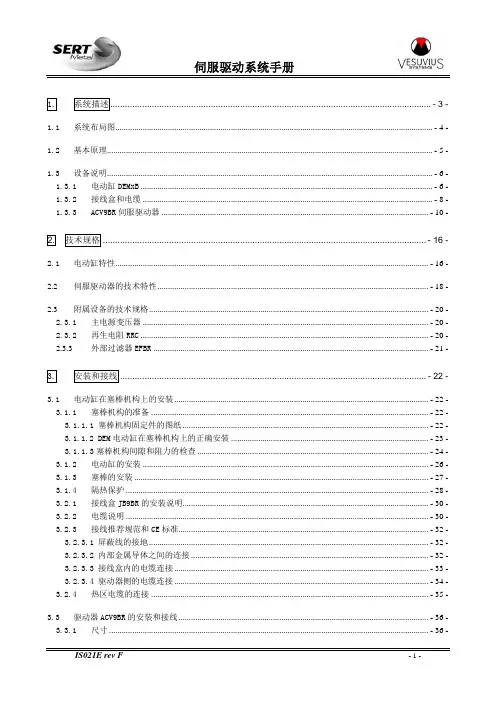

1.系统描述...................................................................................................................................- 3 -1.1系统布局图.......................................................................................................................................................- 4 -1.2基本原理...........................................................................................................................................................- 5 -1.3设备说明...........................................................................................................................................................- 6 -1.3.1电动缸DEMxB...........................................................................................................................................- 6 -1.3.2接线盒和电缆..........................................................................................................................................- 8 -1.3.3ACV9BR伺服驱动器...............................................................................................................................- 10 -2.技术规格....................................................................................................................................- 16 -2.1电动缸特性.....................................................................................................................................................- 16 -2.2伺服驱动器的技术特性.................................................................................................................................- 18 -2.3附属设备的技术规格.....................................................................................................................................- 20 -2.3.1主电源变压器........................................................................................................................................- 20 -2.3.2再生电阻RRC.........................................................................................................................................- 20 -2.3.3外部过滤器EFBR...................................................................................................................................- 21 -3.安装和接线.............................................................................................................................- 22 -3.1电动缸在塞棒机构上的安装.........................................................................................................................- 22 -3.1.1塞棒机构的准备....................................................................................................................................- 22 -3.1.1.1 塞棒机构固定件的图纸.....................................................................................................................- 22 -3.1.1.2 DEM电动缸在塞棒机构上的正确安装..............................................................................................- 23 -3.1.1.3塞棒机构间隙和阻力的检查..............................................................................................................- 24 -3.1.2电动缸的安装........................................................................................................................................- 26 -3.1.3塞棒的安装............................................................................................................................................- 27 -3.1.4隔热保护................................................................................................................................................- 28 -3.2.1接线盒JB9BR的安装说明.....................................................................................................................- 30 -3.2.2电缆说明................................................................................................................................................- 30 -3.2.3接线推荐规范和CE标准.......................................................................................................................- 32 -3.2.3.1 屏蔽线的接地.....................................................................................................................................- 32 -3.2.3.2 内部金属导体之间的连接.................................................................................................................- 32 -3.2.3.3 接线盒内的电缆连接.........................................................................................................................- 33 -3.2.3.4 驱动器侧的电缆连接.........................................................................................................................- 34 -3.2.4热区电缆的连接....................................................................................................................................- 35 -3.3驱动器ACV9BR的安装和接线.......................................................................................................................- 36 -3.3.1尺寸........................................................................................................................................................- 36 -3.3.2安装、定位和冷却................................................................................................................................- 37 -3.3.3电源的连接............................................................................................................................................- 39 -4.操作........................................................................................................................................- 40 -4.1手动模式.........................................................................................................................................................- 40 -4.2远程工作模式.................................................................................................................................................- 41 -4.3自动模式.........................................................................................................................................................- 41 -4.4塞棒关闭和安全装置.....................................................................................................................................- 42 -4.4.1塞棒关闭................................................................................................................................................- 42 -4.4.2断开电机电源(可选项).....................................................................................................................- 42 -4.5运行故障的处理.............................................................................................................................................- 43 -5.维护........................................................................................................................................- 44 -5.1检查周期.........................................................................................................................................................- 44 -5.2电动缸的检查和维护.....................................................................................................................................- 45 -5.3推荐的备件.....................................................................................................................................................- 49 -5.4伺服驱动器的故障代码.................................................................................................................................- 53 -5.5故障的数字输出代码.....................................................................................................................................- 57 -5.6驱动器复位和状态显示.................................................................................................................................- 58 -5.7没有报警显示时的故障排除.........................................................................................................................- 59 -6.辅助设备.................................................................................................................................- 61 -6.1DEM系列电动缸的测试台..............................................................................................................................- 61 -6.2塞棒机构MQS..................................................................................................................................................- 61 -1.系统描述SERT的塞棒执行器系统用于控制塞棒和塞棒机构的位置,以控制流入结晶器的钢水的流量。

SF 说明书目录1.前言 01.1 开箱 01.2 使用上注意事项 01.3 适用伺服马达 01.4 注意事项 (1)1.5 安装 (1)2.面板操作 (3)2.1 辅助功能模式 (4)2.1.1警报追溯模式之操作 (4)2.1.2清除警报追溯资料 (4)2.1.3寸动功能 (5)2.1.4检查软件版本 (5)2.1.5重新开机(Reset) (6)2.1.6输入接点显示 (6)2.1.7输出接点显示 (7)2.1.8参数56~59自动设定步骤一 (8)2.1.9参数56~59自动设定步骤二 (8)2.1.10使用者参数初始设定 (9)2.1.11Fn7、Fn8、Fn9功能锁住与开放 (9)2.2 使用者参数设定模式 (11)2.2.1驱动器使用者参数 (12)2.2.2控制器参数 (20)2.3 监视模式 (25)2.3.116位区段 (25)2.3.232位区段 (26)2.3.3PC通讯专用参数 (27)2.4 警报号码显示 (28)3.RS232联机 (30)3.1 通信协议 (30)3.2 通信功能 (30)3.2.1PCÅDriver (31)3.2.2PCÆDriver (32)4.接线 (34)4.1 CN1控制器接头 (34)4.2 CN2编码器接线 (37)4.3 CN1及CN2 电路 (37)接头 (39)4.4 RS2324.5 标准接线 (40)4.5.1位置控制 (40)4.5.2速度控制 (41)4.5.3扭力控制 (42)4.6 电源、马达接线 (43)4.6.1SF15、SF20、SF50、SF75 (43)4.6.2SF30A (44)5.外形尺寸图 (45)6.驱动器规格 (50)7.使用步骤 (51)7.1 位置模式使用步骤 (51)7.2 速度模式使用步骤 (52)8.当控制器用时特有的功能 (53)8.1 寸动 (55)8.1.1相关输入接点 (55)8.1.2相关参数设定 (55)8.1.3动作流程 (55)8.2 归原点 (56)8.2.1相关输入接点 (56)8.2.2相关参数设定 (56)8.2.3动作流程 (57)8.2.4归原点流程图 (58)8.3 点到点运动 (59)8.3.1相关输入接点 (59)8.3.2相关参数设定 (59)8.3.3动作流程 (61)8.4 通讯定位 (61)1. 前言这次承蒙惠购AC servo SF系列产品,至为感谢。

伺服电机调试手册伺服电机这玩意儿,在现代工业里那可是相当重要!就好像是机器的“动力心脏”,要是调试不好,这机器运转起来可就容易出岔子。

我记得有一次,我去一家工厂帮忙调试伺服电机。

那是一个炎热的夏天,车间里的温度高得吓人,汗水不停地从额头往下淌。

这台机器是新引进的,厂家的技术人员还没来得及培训,工人们就着急要开工。

我到了现场,看到那一堆错综复杂的线路和陌生的控制面板,心里也有点打鼓。

但是没办法,硬着头皮也得上啊!我先仔细地研究了一下说明书和相关资料,然后开始动手调试。

第一步,当然是要检查电机的连接线路,确保没有松动或者接错的地方。

这就像是给人做体检,先得把外在的情况搞清楚。

我拿着万用表,一根线一根线地测,眼睛紧紧盯着表盘上的数字,生怕错过了任何一个小细节。

接着,就是设置参数了。

这可真是个技术活,要根据机器的具体需求来调整转速、扭矩等等。

我一边对照着机器的规格书,一边在控制面板上小心翼翼地输入着数字,每按一次确认键,心里都祈祷着千万别出错。

在调试的过程中,还遇到了一个小插曲。

电机突然发出了一阵异常的响声,吓得旁边的工人都往后退了几步。

我赶紧停下手中的操作,仔细听着声音的来源。

原来是一个螺丝松了,导致电机运转不平衡。

我迅速找到那个螺丝,用扳手拧紧,这才让电机恢复了正常。

调试完之后,还不能马上就说大功告成了。

得进行试运行,观察一段时间,看看电机在各种工况下的表现是否稳定。

这时候,我的心还是悬着的,就怕在试运行的时候又出什么问题。

好在,经过几个小时的努力,这台伺服电机终于调试好了,机器也顺利地运转起来。

看着工人们脸上露出的笑容,我心里那叫一个满足。

下面咱就正式来说说伺服电机调试的那些事儿。

首先,在调试之前,一定要做好充分的准备工作。

把需要用到的工具都准备齐全,像万用表、螺丝刀、扳手这些,可别等到要用的时候才发现没带,那可就抓瞎了。

然后,要对电机的型号、参数、工作环境等有一个清晰的了解。

接下来就是具体的调试步骤啦。

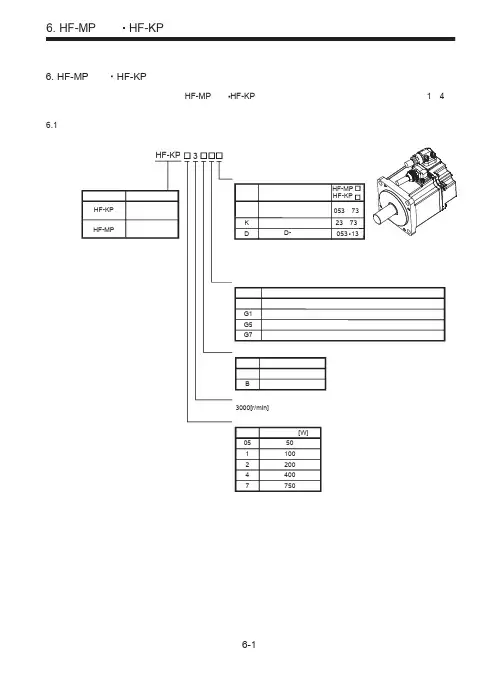

概要1 - 1确认事项1 - 2伺服电机1 - 3 伺服放大器1 - 4 型号说明1-1(1) 警告标识的种类和意义安装、配线施工、维护、检查之前,请熟读和使用该手册及其它附属资料。

请在确认设备知识、安全信息及注意事项后,开始使用。

本手册将安全注意事项的等级划分为“危险”及“注意”。

警 告 标 识 含 义危 险该标识表示若错误操作,则有可能发生危险情况,从而造成死亡或重伤。

注 意该标识表示若错误操作,则有可能发生危险情况,从而造成人身受到中度伤害、轻伤以及仅设备受损。

另外,即使是记载在“注意”中的事项,也有可能因情况不同而导致严重后果。

标有警告标识的正文处均为重要内容,请遵守。

读完该手册后,请将其保管在使用人任何时候都能看到的地方。

(2) 符号根据需要采用符号,以便一看就能理解显示的要点。

符 号 含 义 符 号 含 义一般禁止 指示一般使用者的行为禁止触摸 务必接地禁止拆解 小心触电小心燃烧 小心高温安全注意事项1.使用注意事项危 险1.请绝对不要用手触及伺服放大器的内部。

否则有可能触电。

2.伺服放大器及伺服电机的地线端子务请接地。

否则有可能导致触电。

3.请在切断电源5分钟后进行配线和检查。

否则有可能导致触电。

4.请不要损伤电缆线、或对电缆线施加不必要的应力、压载重物、夹挤。

否则有可能导致故障、破损和触电。

5.运行过程中,请不要触摸伺服电机的旋转部分。

否则有可能受伤。

注 意1.请按指定的组合方式使用伺服电机和伺服放大器。

否则有可能发生火灾和故障。

2.请绝对不要在易于被溅到水的地方、腐蚀性气体的环境、易燃气体的环境及可燃物旁使用。

否则有可能发生火灾和故障。

3.伺服放大器、伺服电机及外围设备的温度较高,务请注意保持距离。

否则易烫伤。

4.在通电过程中及切断电源后一段时间内,伺服放大器的散热器、再生电阻器、伺服电机等有可能处于高温状态,故请不要触摸。

否则有可能烫伤。

5.最终产品内的伺服电机在运行过程中,若其表面温度超过70℃时,则请在最终产品上贴上小心高温的标签。

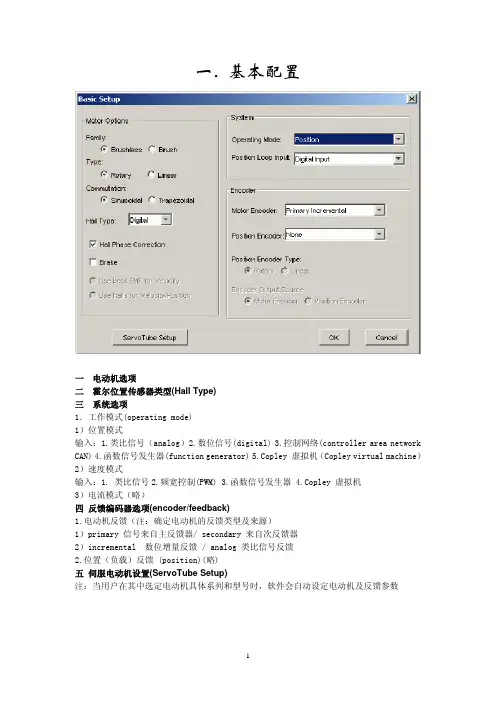

一. 基本配置一电动机选项二霍尔位置传感器类型(Hall Type)三系统选项1.工作模式(operating mode)1)位置模式输入:1.类比信号(analog)2.数位信号(digital) 3.控制网络(controller area network CAN) 4.函数信号发生器(function generator) 5.Copley 虚拟机(Copley virtual machine)2)速度模式输入:1. 类比信号2.频宽控制(PWM) 3.函数信号发生器 4.Copley 虚拟机3)电流模式(略)四反馈编码器选项(encoder/feedback)1.电动机反馈(注:确定电动机的反馈类型及来源)1)primary 信号来自主反馈器/ secondary 来自次反馈器2)incremental 数位增量反馈 / analog 类比信号反馈2.位置(负载)反馈 (position)(略)五伺服电动机设置(ServoTube Setup)注:当用户在其中选定电动机具体系列和型号时,软件会自动设定电动机及反馈参数二.具体配置一电动机及反馈配置(Motor/Feedback)1. 用户可直接载入现成的配置文件2. 转动电动机参数转动惯量(Motor Inertial),磁极数(Number of poles),最大转矩(Peak Torque),连续转矩(Continuous Torque), 速度限制(Velocity Limit),单位制(unit),转矩常数(Torque Constant),反电动势常数 (Back EMF Constant),电阻,电感3. 线形电动机参数:质量,最大推力,连续推力...4. 反馈参数依照技术说明书填写编码器参数编码器精度(encoder resolution)注:如果同时存在两个反馈器,必须确保电动机匝数和位置匝数之比等于电动机编码器匝数和位置编码器匝数之比 ???????????5. 制动参数制动流程:制动指令(enable input)—〉电动机减速/计时开始,当速度降至事先设定的“制动激活速度”(Stop Activation Velocity)或时长超过“制动延迟时间”(the Brake/Stop Delay Time)—〉制动开始/发出制动信号/计时开始,当时长超过制动反应时间,所有输出端终止输出(设此延迟目的是为了在电动机电源切断前使其速度降至0)注:在电流模式中,当伺服收到制动指令便立即停止输出(电流),同时发出制动信号。

IntroductionBefore using the motorOnly qualified personnel of electrical and mechanical engineering should work with the product.Use the product correctly after thoroughly reading the section "Safety precautions."In addition, be sure to observe the contents described in warning, caution, and note in this manual. The product described in this document has been designed and manufacturedto be incorporated in general industrial equipment. Do not use for any other purpose. Oriental Motor Co., Ltd. is not responsible for any damage caused through failure to observe this warning.Safety precautionsThe precautions described below are intended to ensure the safe and correct use of the product, and to prevent the customer and others from exposure to the risk of injury.[Description of graphic symbols] :Indicates "prohibited" actions that must not be performed. :Indicates "compulsory" actions that must be performed.PreparationChecking the productVerify that the items listed below are included. Report any missing or damaged items to thebranch or sales office from which you purchased the product.☐ Motor ................................................1 unitThe combination type comes with the motor and its dedicated gearhead pre-assembled.☐ Capacitor .........................................1 piece (for only single-phase motors)☐ Capacitor cap .................................1 piece (for only single-phase motors)☐ Parallel key ......................................1 piece (only for combination type)For BH6G2-☐, BH8G-☐ and BH6G2-☐RA, the parallel key is fixed to the gearheadoutput shaft.☐ Mounting screw ............................1 set (only for combination type parallel shaft)Hexagonal socket head screw, hexagonal nuts, washer, spring washer: 4 pieces each☐ OPERATING MANUAL ..................1 copy (this document)HM-9139-13Thank you for purchasing an Oriental Motor product.This Operating Manual describes product handling procedures and safety precautions.•Please read it thoroughly to ensure safe operation.•Always keep the manual where it is readily available.Checking the model nameThis operation manual covers the following products. Make sure that the product is the one you ordered and is listed below by checking the model number listed on the nameplate. Verify that the voltage and output listed on the nameplate are appropriate for your application and that the correct value capacitor has been provided.Enter the number representing the gear ratio of the gearhead in the box ☐ within themodel name.BHI62AT-A BHI62C-A BHI62CT-A BHI62E-A BHI62ET-A BHI62F-A BHI62FT-A BHI62S-A BHI62ST-A BHI62U-A BHI62UT2-AInstallationLocation for installationInstall the motor and capacitor in a location that meets the following conditions.Using the motor and capacitor in a location that does not satisfy these conditions could damage them. •Indoors•Ambient temperature: –10 °C to +40 °C [+14 °F to +104 °F] (non-freezing) (–10 °C to +50 °C [+14 °F to +122 °F] for 100/200 VAC) (non-freezing) •Ambient humidity: 85% or less (non-condensing)•Not exposed to explosive, flammable, or corrosive gases •Not exposed to direct sunlight •Not exposed to dust•Not exposed to water or oil•A place where heat can escape easily•Not exposed to continuous vibration or excessive impact •1,000 meters or less above sea levelto cause a secondary damage. Grease leakage may lead to problems in the customer's equipment or products.z Combination type: parallel shaft gearheadSecure the motor with mounting screw set (supplied) through the four mounting holes provided. (Mounting plate thickness is 10 mm (0.39 in.) when using the supplied mounting screws.)zCombination type: right-angle shaft gearheadSecure the motor with screws (notsupplied) through the four mounting holes provided. Do not leave a gap between themotor and mounting plate.in damage to the gearhead internal bearings.•The diameter of the boss of the shaft is Ø58h8, use it as a guide for proper alignment.Removing and assembling the gearheadSee the following steps to replace the gearhead or to change the outlet position of the lead wires and the position of the terminal box.Removing the gearhead from the motorRemove the hexagonal socket head screws (2 places or 4 places) assembling the motor and gearhead and detach the motor from the gearhead.Hexagonal socket head screwAssembling the gearhead to the motor1. Keep the pilot sections of the motor andgearhead in parallel, and assemble the gearhead with the motor while slowly rotating it clockwise/counterclockwise. At this time, note so that the pinion of the motor output shaft does not hit the side panel or gears of the gearhead strongly.2. Check that there is no gap between themotor and gearhead, and tighten them with hexagonal socket head screws (2 pieces or4 pieces).Assemble the gearhead to the motor in a condition where the motor output shaft is in an upward direction.shorter service life.•Do not allow dust to attach to the pilot sections of the motor and gearhead. Also, assemble the motor and gearhead carefully by not pinching theO-ring at the motor pilot section. If the O-ring is crushed or severed, grease may leak from the gearhead.zRround shaft typeSecure the motor with hexagonal socket head screws (not supplied) through the four mounting holes provided. Do not leave a gap between the motor and mounting plate.z Motor with cooling fanWhen installing a motor with cooling fan onto a device, leave 10 mm (0.39 in.) or more behind the fan cover or open a ventilation hole so that the cooling inlet on the back of the motor cover is not blocked.Mounting the capacitor (only for single-phase motors)Before mounting the provided capacitor, check that the capacitor’s capacitance matches that stated on the motor’s nameplate.Mount the capacitor securely by using M4 screws (not provided).Ø4.3 mm(Ø0.169 in.)closer, the life of the capacitor will be shortened.reduced by adding a frictional load.z Combination type: parallel shaft gearhead,Combination type: right-angle shaft (solid shaft) gearheadThe gearhead shaft is provided with a key slot for connecting the transmission parts. Whenconnecting the transmission parts, ensure that theshaft and parts have a clearance fit, and always fix the parallel key to the output shaft with a screw toprevent the parts from rattling or spinning.When using the output shaft end tapped hole of a gearheadUse a tapped hole [M6, Effective depth 12 mm (0.47 in.)] provided at the end of the output shaft of BH6G2-☐ and BH6G2-☐RA as an auxiliary means for preventing the transfer mechanism from disengaging.z Combination type: right-angle shaft (hollow shaft) gearheadMounting method of the load varies depending on the load shaft conditions. See the following figures.The hollow output shaft inside dimension is processed to a tolerance of H8, and incorporates a key slot for load shaft attachment. A load shaft tolerance of h7 isrecommended. Also, apply anti-seizing agent such as molybdenum disulfide grease on the surface of the load shaft and the bore of the hollow output shaft.After attaching the load, attach the safety cover.[Unit: mm (in.)]••Stepped load shaft••Non-stepped load shaftConnectionInsulate all the wire connections such as the connecting part between the motor lead wires and the power supply.Be sure to ground the product using the Protective Earth Terminal on the motor.stress.z•terminal box.On the BHI62ST-A , refer to the following specifications.Applicable crimp terminal: Insulated round crimp terminal Terminal screw size: M4Tightening torque: 1.0 to 1.3 N·m (8.8 to 11.5 lb-in)Applicable lead wire: AWG18 (0.75 mm 2) or thickers s[Unit: mm (in.)] •For wiring, be sure to use cable (not provided) that meets the following specifications.Applicable cable diameter: Ø6 to Ø12 mm (Ø0.236 to Ø0.472 in.) Applicable lead wire: AWG24 to 12 (0.2 to 3.5 mm 2) Length of strip is 8 mm (0.31 in.) •When sealing the terminal box cover, ensure that no scraps or particles get caught between the contact surfaces.•The terminal cover mounting screws are specifically designed for mounting the terminal cover. They are provided with a rubber seal and flat washer that keep the terminal box dust-resistant and splashproof.In order to maintain a tight seal around the terminal box, use only the provided screws. Also, this terminal box is constructed to hold a gasket. If this gasket comes out of the box, please reseal it correctly on the box.Also refer to the tightening torque table (below) to determine the appropriate tightening torque to use when fastening the terminal cover and cable gland.Terminal cover 0.3 to 0.4 N·m (42 to 56 oz-in)Cable gand 2.5 to 3.8 N·m (350 to 530 oz-in)Cable clamp 0.2 to 0.3 N·m (28 to 42 oz-in)Terminal block0.5 to 0.8 N·m (71 to 113 oz-in)Changing the cable outlet positionThe cable outlet can be oriented and fixed in three different directions by changing the mounting direction of the terminal box. Follow the procedure below:1. Loosen the terminal cover mounting screws (M4×3 pieces) and remove the terminal coverand sheet gasket from the terminal box.2. Loosen the terminal box mounting screws (M4×4 pieces) and remove the terminal box from the terminal block base.3. Turn the cable outlet on the terminal box clockwise or counterclockwise by 90° at atime from the factory-set position.4. Install the terminal box onto the terminal block base.5. Install the sheet gasket and terminal cover onto the terminal box.•A gasket is installed between the terminal box and terminal block base. Don’t forget to assemble the gasket. When assembling the parts, also be careful not to let any foreign object enter between the terminal box and terminal block base. •Refer to the aforementioned table for the screw tightening torque.z Layout of terminalsSingle-phase type4 terminals Terminal blockCable clamp Z2U2U1Three -phase type[ Combination type ]• 200 VAC/220 VAC/230 VAC motors•[ Round shaft type ]Connecting Protective Earth Terminal (cable type)Insulated round crimp terminal Terminal screw size: M4Tightening torque: 1.0 to 1.3 N·m (8.8 to 11.5 lb-in)Applicable lead wire: AWG18 (0.75 mm 2) or thicker[Unit: mm (in.)]9s sz Three-phase 380 VAC/400 VAC/415 VAC motorsConnect the motor to a terminal box by following the procedure below:1. Loosen the terminal cover mounting screws (M4×3 pieces) and remove the terminal coverand sheet gasket from the terminal box.2. Pass the cable through the cable gland and connect the lead wires to the terminal block.Connect the lead wire for grounding to the Protective Earth Terminal.3.Install the sheet gasket and terminal cover on the terminal box.The terminal box can be removed. Loosen the terminal box mounting screws (M4×4 pieces)and take out the terminal box.•terminal box.•Use a cable (not supplied) of the following specifications:Applicable cable diameter: Ø6 to Ø12 mm (Ø0.236 to 0.472 in.) Applicable lead wire: AWG20 (0.5 mm 2) or thicker•When connecting the cable on the terminal block, use the following crimp terminal.Insulated round crimp terminals s[Unit: mm (in.)]•Don’t forget to assemble the sheet gasket between terminal box and terminal cover. When assembling the parts, also be careful not to let any foreign object enter between the terminal cover and terminal box.•Refer to the table below to determine the appropriate tightening torque to use when fastening the terminal cover and cable gland.Terminal cover 0.3 to 1.0 N·m (42 to 142 oz-in)Terminal box1.0 to 1.5 N·m (142 to 210 oz-in)Cable gland (Tightening nut)2.0 to 2.5 N·m (280 to 350 oz-in)Cable gland (Nipple) 2.0 to3.75 N·m (280 to 530 oz-in)Terminal block1.0 to 1.2 N·m (142 to 170 oz-in)Protective Earth Terminal1.0 to 1.5 N·m (142 to 210 oz-in)Connection diagramThe direction of rotation is as viewed from the side of the motor’s output shaft.“CW” indicates clockwise and “CCW” counterclockwise. The gearhead’s output shaft may, depending on the gear ratio, turn in the opposite direction of the motor shaft.Check the rotation direction before connecting.z Single-phase motor*1•A , C , E , F appear at the position in the model number indicated by the box (☐).Enter T (terminal box) in the box ( ) within the model name.*2•Colors shown in the connection diagram indicate the colors of lead wires and Z2, U2,and U1 indicate terminal codes inside the terminal box.••Capacitor connection (only for single-phase motors)When crimp terminals are used, use the FASTON terminals 187 Series (TE Connectivity).Use the supplied capacitor cap to insulate the capacitorterminal connection.The capacitor has fourterminals that are internally connected as shown in thefigure.<Capacitor internal wiring diagram>187 Series z Three -phase motor*1•S , U appear at the position in the model number indicated by the box (☐).Enter T or T2 (terminal box) in the box ( ) within the model name.*2•Colors shown in the connection diagram indicate the colors of lead wires and U, V, andW indicate terminal codes inside the terminal box.••For protection of contact (switch)If the switch is used for starting/stopping the motor or switching the rotation direction, R 0=5 to 200 ΩC 0=0.1 to 0.2 µF 250 VAC EPCR1201-2OperationThe motor rotates when the power supply is turned on.For protection against electric shock, do not turn on the power supply until the wiring is complete.can be measured by fastening a thermometer to the motor’s surface, or with thermo-tape.•Bring single-phase motors to a complete stop before switching thedirection of rotation. If you try to switch the direction of rotation before the motor has stopped, it may not change or may require time.•Use the provided capacitor for single-phase motors and always keep the capacitor connected after the motor is started. •The three-phase 380/400/415 VAC motors cannot be combined with an inverter. If combined with an inverter, these motors may be damaged due to deteriorated insulation of the motor coil.Time ratingThis motor can be operated continuously (continuous rating).•Unauthorized reproduction or copying of all or part of this manual is prohibited. •Oriental Motor shall not be liable whatsoever for any problems relating to industrial property rights arising from use of any information, circuit, equipment or device provided or referenced in this manual.•Characteristics, specifications and dimensions are subject to change without notice. •While we make every effort to offer accurate information in the manual, we welcome your input. Should you find unclear descriptions, errors or omissions, please contact the nearest office.•is a registered trademark or trademark of Oriental Motor Co., Ltd., in Japan and other countries.© Copyright ORIENTAL MOTOR CO., LTD. 2011Published in March 2020Technical Support Tel:(800)468-39828:30 A.M. to 5:00 P .M., P .S.T. (M-F)7:30 A.M. to 5:00 P .M., C.S.T. (M-F) Schiessstraße 44, 40549 Düsseldorf, Germany Technical Support Tel:00 800/22 55 66 22www.orientalmotor.de Tel:01256-347090 Tel:01 47 86 97 50www.orientalmotor.fr Tel:02-93906346www.orientalmotor.itTel:+55-11-3266-6018.br• Please contact your nearest Oriental Motor o ce for further information.4-8-1Higashiueno,Taito-ku,Tokyo 110-8536 JapanTel:03-6744-0361www.orientalmotor.co.jpTel:0800-060708 SingaporeTel:1800-8420280.sg Tel:1800-806161.my KoreaTel:080-777-2042www.inaom.co.kr Tel:1800-888-881www.orientalmotor.co.th Tel:400-820-6516 Tel:+91-80-41125586www.orientalmotor.co.in Hong Kong BranchTel:+852-2427-9800This motor is equipped with a feature listed below to prevent the motor from burning out as a result of abnormal heating which may be caused by misapplication.Thermal protection (“THERMALLY PROTECTED” is stamped on the motor nameplate)When the motor reaches a predetermined temperature, the internal thermal protector is activated and the motor is stopped.With the automatic resume feature, the motor automatically begins operating again as soon as the motor temperature falls.Always turn the power off before performing inspections.Thermal protector activation range:Power is turned off at 150 °C±5 °C (302 °F±9 °F) [130 °C±5 °C (266 °F±9 °F)]*Power is turned back on at 96 °C±15 °C (205 °F±27 °F) [83 °C±15 °C (181 °F±27 °F)]* *[ ] indicates the value for the three-phase 380/400/415 VAC motors.When the motor is not functioning normally, perform an inspection covering the points listed in the table bellow.If the inspection shows that everything is normal but the motor and control unit still are not functioning correctly, contact the nearest ORIENTAL MOTOR office.Specifications/ General specificationsCheck on the Oriental Motor Website for the product specifications.Regulations and standardsUL Standards, CSA Standards, CCC SystemThis product is recognized by UL under the UL and CSA Standards, and also certified by CQC under the China Compulsory Certification (CCC) system.The motor model name represents the model that conforms to the standards.The three-phase 380/400/415 VAC motors have obtained only the certification under the CCC system.• z Standards for accessoriesCapacitor: UL File No.E83671 (CYWT2)Capacitor cap: UL File No.E56078 (YDTU2)CE MarkingThis product is affixed the CE Marking under the Low Voltage Directive.z Low Voltage Directive Applicable standardsEN 60034-1, EN 60034-5, EN 60664-1, EN 60950-1Installation conditions (For EN standard)•Overvoltage category:Ⅱ •Pollution degree: 2•Protection against electric shock: Class ⅠequipmentWhen the machinery to which the motor is mounted requires overvoltage category Ⅲand pollution degree 3 specifications, install the motor in a cabinet that comply with IP54 and connect to power supply via an isolation transformer.The motor with a terminal box requires overvoltage category Ⅲ* and pollution degree 3 specifications (except for the motor installation surface of the round shaft type). *If EN 60950-1 is required, Overvoltage category is Ⅱ.z Motor temperature rise testsTemperature rise tests required by the above standards are performed in a state that has been attached a gearhead or a heat radiation plate.The size and material for the heat radiation plates are as follows.Electrical appliance and material safety lawBHI62ST-A bears amark.RoHS DirectiveThe products do not contain the substances exceeding the restriction values of RoHS Directive (2011/65/EU).。

伺服拖动系统使用手册(V1.0)哈尔滨晟普科技有限公司前言感谢您购买晟普科技SP系列抽油机伺服拖动系统。

本使用说明书介绍了如何正确使用SP系列抽油机伺服拖动系统。

在使用(安装、运行、维护、检查等)前,请务必认真阅读本使用说明书。

另外,请在理解产品的安全注意事项后再使用该产品。

与安全有关的标记说明本手册根据与安全有关的内容,使用了下列标记。

有安全标记的说明,表示重要内容,请务必遵守。

表示如果操作错误,将会导致危险情况的发生,造成死亡或重伤。

表示如果操作错误,将会导致危险情况的发生,可能会造成中等程度的受伤或轻伤,或设备损坏。

另外,即使是标识中所述事项,有时也可能会造成严重的后果。

表示不属于“危险”和“注意”,但非常重要,需要用户遵守的事项。

安全注意事项⏹到货时确认◆请勿安装受损或缺少零件的伺服驱动器和电机否则会有受伤的危险。

⏹保管与搬运◆搬运伺服驱动器时轻拿轻放;运输时,确保伺服驱动器包装完好,防止振坏。

◆请勿保管在下述环境中,否则会导致触电、机器损坏或引发火灾:•阳光直射的场所•环境温度超过保管、设置温度条件的场所•相对湿度超过保管、设置湿度条件的场所•有水、油及药品滴落的场所•振动或冲击可传递到主体的场所◆请勿盘坐在本产品上或者在其上面放置重物.否则可能会导致设备故障或人员受伤◆请勿握住电缆线或电机轴进行搬运。

否则会导致设备故障或人员受伤⏹安装◆安装时请轻拿轻放。

◆只有具备资格的电气工程师才允许安装和维护伺服单元。

◆请勿将该产品安装在会溅到水的场所或易发生腐蚀的环境中。

否则可能会导致触电或引发火灾。

◆请勿将该产品安装在易燃性气体及可燃物的附近。

否则可能会导致触电或引发火灾。

◆安装过程中请勿使异物进入产品内部。

否则可能会导致故障或引发火灾。

◆请确保伺服单元与其他机器之间具有规定的间隔。

否则会导致故障或引发火灾。

◆请勿施加过大冲击。

否则可能会导致故障。

◆伺服驱动器外壳必须安全接地。

⏹配线◆请勿在伺服单元的输出端子U、V、W上连接三相AC380V电源。

伺服电机说明书伺服电机是一种高精度、高可靠性的电机,具有精准的位置控制、速度控制和力控制能力,广泛应用于机器人、工业自动化、航空航天、医疗等领域,是现代工业自动化的重要组成部分。

本说明书旨在介绍伺服电机的基本原理、特点、安装和维护等方面,帮助用户更好地了解和应用伺服电机。

一、原理伺服电机采用反馈控制系统,通过测量输出轴位置、速度或力矩的反馈信号与控制器发出的控制信号相比较,控制输出轴的运动,使之达到所需的位置、速度或力矩。

伺服电机的控制系统包括控制器、编码器、电机驱动器等部分,其中编码器是实现位置、速度反馈的关键部件。

控制器可以根据要求输出各种控制信号,如脉冲信号、模拟信号、数字信号等,通过驱动器将信号转化为适合电机的电源信号,从而实现电机的运动控制。

二、特点1、高精度:伺服电机具有高精度的位置、速度和力控制能力,其控制精度可以达到0.001mm、0.01rpm或0.1N·m等级。

2、高可靠性:伺服电机采用闭环反馈控制,具有抗负载扰动、抗干扰、稳定性强、可靠性高等特点。

3、高动态响应:伺服电机具有快速响应、高加速度、高速度等特点,可以满足高速、高精度的运动控制需求。

4、多控制方式:伺服电机可以采用位置控制、速度控制、力矩控制等多种控制方式,可以满足不同的应用需求。

5、广泛应用:伺服电机广泛应用于机器人、工业自动化、航空航天、医疗等领域,是现代工业自动化的重要组成部分。

三、安装1、安装位置:伺服电机的安装位置应避免受到震动、热源、电磁干扰等影响,应尽量放置在平稳、通风、温度适宜的环境中。

2、接线方式:伺服电机的接线应按照驱动器的接线图连接,注意接线的正确性和接触的可靠性,以免影响电机的性能和寿命。

3、机械安装:伺服电机的机械安装应符合电机的机械参数要求,如轴向间隙、同轴度、端面平行度、轴向跳动等要求,以免影响电机的位置控制精度和运动稳定性。

四、维护1、保养注意事项:伺服电机应定期进行保养,包括清洁电机和驱动器的内部和外部,检查接线的可靠性和紧固度,防止灰尘、潮气等对电机的影响。

1、电动机内装有光电编码器,安装时严禁敲打电动机,用户不得自行拆装光电编码器,否则会破坏编码器与电动机绕组的相对位置(零点),致使电动机无法运行。

2、在正常气候条件下,用500V兆欧表测量电动机对机壳的绝缘电阻,其值不应小于20兆欧。

3、请按本使用说明书所述的电动机与驱动单元的接线方式正确连接,确保保护接地牢固可靠。

4、电动机从零速至最高速空载运行,应无异常噪声和震动,方可投入负载运行。

5、电动机在运行中,切勿接触运转中的电动机轴以及电动机外壳。

6、具有相应资格的人员,才能调整、维护电动机。

7、不得拖拽电线(缆)、电动机轴搬运电动机。

8、用户对本产品的任何改动本公司将不承担任何责任,产品的保修单将因此作废。

产品特点我公司制造的HM系列正弦波型交流永磁同步伺服电动机,采用高性能的稀土永磁材料,具有高转矩惯量比、低速特性好、过载能力强等特点,电机采用380V高压驱动器驱动,构成高性价比的伺服驱动系统,能广泛满足数控机床及相关产业机械的需求。

伺服电机型号规格说明HM - 13 - 06.0 - 020 - A - 1 - 1●选型指南电机型号电机简单参数适配驱动器功率模块型号启动倍数额定转矩额定转速额定电流HM-11-02.0-030-A-□-□2Nm 3000rpm 1.8A 15A 3.00HM-11-04.0-020-A-□-□4Nm 2000rpm 2.5A 15A 3.00HM-11-04.0-025-A-□-□4Nm 2500rpm 3.3A 25A 3.00HM-11-04.0-030-A-□-□4Nm 3000rpm 3.6A 25A 3.00HM-11-06.0-020-A-□-□6Nm 2000rpm 3.5A 25A 3.00HM-11-06.0-025-A-□-□6Nm 2500rpm 5.0A 40A 3.00HM-11-06.0-030-A-□-□6Nm 3000rpm 5.5A 40A 3.00HM-11-08.0-015-A-□-□8Nm 1500rpm 3.6A 25A 3.00HM-11-08.0-020-A-□-□8Nm 2000rpm 5.0A 40A 3.00HM-11-08.0-025-A-□-□8Nm 2500rpm 6.5A 40A 3.00HM-11-08.0-030-A-□-□8Nm 3000rpm 7.2A 40A 2.95HM-11-10.0-015-A-□-□10Nm 1500rpm 4.5A 25A 2.94HM-11-10.0-020-A-□-□10Nm 2000rpm 6.5A 40A 3.00HM-11-10.0-025-A-□-□10Nm 2500rpm 8.3A 40A 2.55HM-13-04.0-020-A-□-□4Nm 2000rpm 2.6A 15A 3.00HM-13-04.0-025-A-□-□4Nm 2500rpm 3.3A 25A 3.00HM-13-04.0-030-A-□-□4Nm 3000rpm 3.6A 25A 3.00HM-13-05.0-020-A-□-□5Nm 2000rpm 3.3A 25A 3.00HM-13-05.0-025-A-□-□5Nm 2500rpm 4.2A 25A 3.00HM-13-05.0-030-A-□-□5Nm 3000rpm 4.5A 25A 2.94HM-13-06.0-020-A-□-□6Nm 2000rpm 3.9A 25A 3.00HM-13-06.0-025-A-□-□6Nm 2500rpm 5.0A 40A 3.00HM-13-06.0-030-A-□-□6Nm 3000rpm 5.4A 40A 3.00HM-13-07.5-020-A-□-□7.5Nm 2000rpm 4.2A 25A 3.00HM-13-07.5-030-A-□-□7.5Nm 3000rpm 6.8A 40A 3.00HM-13-10.0-015-A-□-□10Nm 1500rpm 4.5A 25A 2.94HM-13-10.0-020-A-□-□10Nm 2000rpm 6.5A 40A 3.00HM-13-10.0-025-A-□-□10Nm 2500rpm 8.3A 40A 2.55HM-13-15.0-015-A-□-□15Nm 1500rpm 6.8A 40A 3.00HM-13-20.0-010-A-□-□20Nm 1000rpm 7.0A 40A 3.00HM-18-22.0-010-A-□-□22Nm 1000rpm 7.7A 40A 2.75备注:选型步骤:1、用户首先根据负载情况及机械加工要求,选择合适转矩及转速级别的伺服电机。