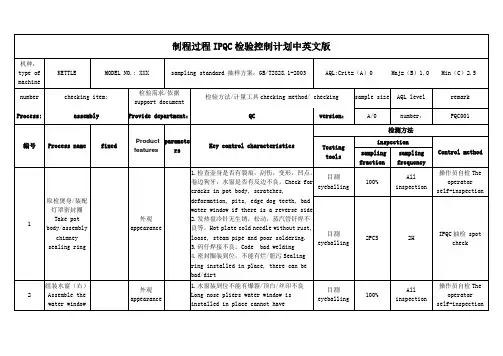

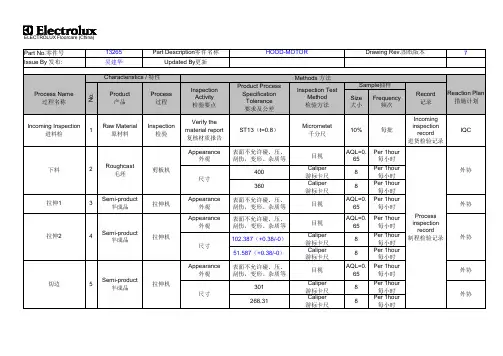

小家电产品制程过程IPQC检验控制计划中英文版

- 格式:docx

- 大小:38.57 KB

- 文档页数:11

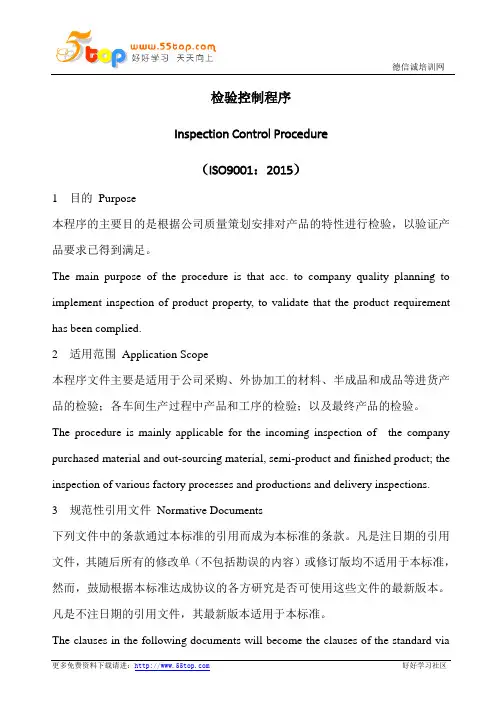

检验控制程序Inspection Control Procedure(ISO9001:2015)1目的Purpose本程序的主要目的是根据公司质量策划安排对产品的特性进行检验,以验证产品要求已得到满足。

The main purpose of the procedure is that acc. to company quality planning to implement inspection of product property, to validate that the product requirement has been complied.2适用范围Application Scope本程序文件主要是适用于公司采购、外协加工的材料、半成品和成品等进货产品的检验;各车间生产过程中产品和工序的检验;以及最终产品的检验。

The procedure is mainly applicable for the incoming inspection of the company purchased material and out-sourcing material, semi-product and finished product; the inspection of various factory processes and productions and delivery inspections.3规范性引用文件Normative Documents下列文件中的条款通过本标准的引用而成为本标准的条款。

凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标准达成协议的各方研究是否可使用这些文件的最新版本。

凡是不注日期的引用文件,其最新版本适用于本标准。

The clauses in the following documents will become the clauses of the standard viathe quote of the standard. All the quoted documents with date, all the future changes form(corrected contents excluded) or the revise editions are not applicable to the standard. While, encourage the parties who has had an agreement acc. to standard to study whether can use the latest version of these documents. All quoted documents which not notes the data, the latest version is applicable to the standardISO9001:2015 质量管理体系要求9.1产品的监视和测量ISO9001:2015 Quality Management System Requirement 9.1 Production Monitoring and Measurement4术语和定义Terms and Definitions本程序采用GB/T19000中确定的的专业术语。

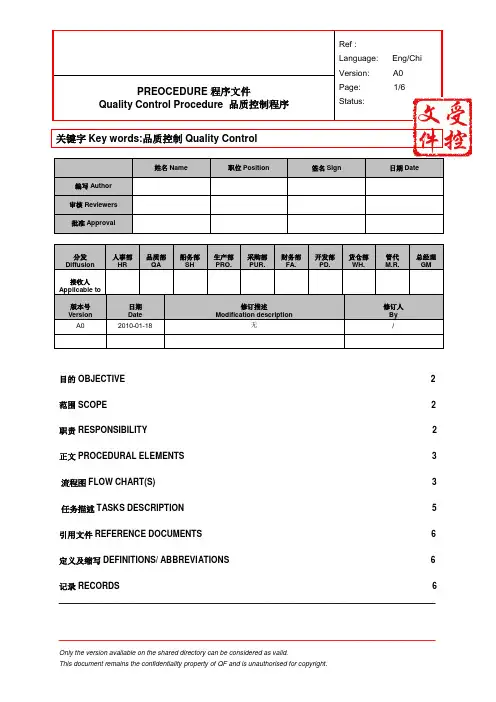

Page: 1/6Status:PREOCEDURE 程序文件Quality Control Procedure 品质控制程序__________________________________________________________姓名Name职位Position签名Sign日期Date编写Author 审核 Reviewers 批准 Approval分发Diffusion 人事部 HR品质部 QA船务部 SH生产部 PRO.采购部 PUR.财务部 FA.开发部 PD.货仓部 WH.管代 M.R. 总经理 GM接收人Applicable to版本号Version 日期 Date 修订描述Modification description修订人 By A0 2010-01-18 无/目的OBJECTIVE 2 范围SCOPE 2 职责RESPONSIBILITY 2 正文PROCEDURAL ELEMENTS 3 流程图FLOW CHART(S) 3 任务描述TASKS DESCRIPTION5引用文件REFERENCE DOCUMENTS 6 定义及缩写DEFINITIONS/ ABBREVIATIONS 6 记录RECORDS 6__________________________________________________________ 关键字Key words:品质控制Quality ControlPage: 2/6Status:PREOCEDURE 程序文件Quality Control Procedure 品质控制程序__________________________________________________________Objective 目的Ensure quality control in process are efficiently and effectively inspected. 确保制程中品质控制有效。

产品质量先期策划与控制计划英语In the ever-evolving landscape of business, the cornerstone of success lies in the meticulous craftsmanship of quality products. Quality Planning and Control, often abbreviated as QPAC, is a strategic approach that ensures the delivery of products that not only meet but exceed customer expectations. It's a proactive measure that involves a systematic process of defining, implementing, and maintaining quality standards from the inception of a product idea to its final delivery.The journey of QPAC begins with a deep dive into customer needs and expectations, which is the heartbeat of any product development. By understanding the market and the end-users, companies can tailor their products to satisfy specific demands and preferences. This understanding is thentranslated into a robust design and development plan, where every detail is scrutinized for its impact on quality.As the product moves from the conceptual stage to the tangible reality, the control plan comes into play. It's a dynamic document that outlines the steps taken to ensure the product is manufactured to the highest standards. It includes everything from the selection of raw materials to the final inspection before the product leaves the factory. Each stepis meticulously monitored and controlled to prevent any deviation from the set quality benchmarks.The beauty of QPAC lies in its ability to anticipate and mitigate potential issues before they escalate. By implementing a robust system of checks and balances, companies can ensure that the final product is of the highest quality. This not only enhances customer satisfaction but also builds a reputation for excellence that is invaluable in today's competitive market.Moreover, QPAC is not a one-time event but a continuous process of improvement. As new technologies emerge and customer needs evolve, the control plan must adapt accordingly. This agility allows companies to stay ahead of the curve and maintain their competitive edge.In conclusion, the art of Quality Planning and Control is a symphony of precision, foresight, and adaptability. It's a testament to the commitment of businesses to deliver excellence and a promise to customers that they will receive nothing but the best. It's a practice that, when embraced, can elevate a product from good to great, and a company from average to exceptional.。

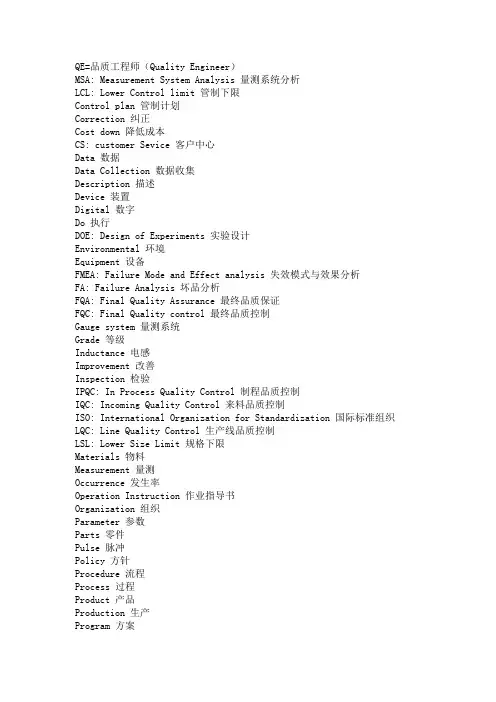

QE=品质工程师(Quality Engineer)MSA: Measurement System Analysis 量测系统分析LCL: Lower Control limit 管制下限Control plan 管制计划Correction 纠正Cost down 降低成本CS: customer Sevice 客户中心Data 数据Data Collection 数据收集Description 描述Device 装置Digital 数字Do 执行DOE: Design of Experiments 实验设计Environmental 环境Equipment 设备FMEA: Failure Mode and Effect analysis 失效模式与效果分析FA: Failure Analysis 坏品分析FQA: Final Quality Assurance 最终品质保证FQC: Final Quality control 最终品质控制Gauge system 量测系统Grade 等级Inductance 电感Improvement 改善Inspection 检验IPQC: In Process Quality Control 制程品质控制IQC: Incoming Quality Control 来料品质控制ISO: International Organization for Standardization 国际标准组织LQC: Line Quality Control 生产线品质控制LSL: Lower Size Limit 规格下限Materials 物料Measurement 量测Occurrence 发生率Operation Instruction 作业指导书Organization 组织Parameter 参数Parts 零件Pulse 脉冲Policy 方针Procedure 流程Process 过程Product 产品Production 生产Program 方案Projects 项目QA: Quality Assurance 品质保证QC: Quality Control 品质控制QE: Quality Engineering 品质工程QFD: Quality Function Design 品质机能展开Quality 质量Quality manual 品质手册Quality policy 品质政策Range 全距Record 记录Reflow 回流Reject 拒收Repair 返修Repeatability 再现性Reproducibility 再生性Requirement 要求Residual 误差Response 响应Responsibilities 职责Review 评审Rework 返工Rolled yield 直通率sample 抽样,样本Scrap 报废SOP: Standard Operation Procedure 标准作业书SPC: Statistical Process Control 统计制程管制Specification 规格SQA: Source(Supplier) Quality Assurance 供应商品质保证Taguchi-method 田口方法TQC: Total Quality Control 全面品质控制TQM: Total Quality Management 全面品质管理Traceability 追溯UCL: Upper Control Limit 管制上限USL: Upper Size Limit 规格上限Validation 确认Variable 计量值Verification 验证Version 版本QCC Quality Control Circle 品质圈/QC小组PDCA Plan Do Check Action 计划执行检查总结Consumer electronics 消费性电子产品Communication 通讯类产品Core value (核心价值)Love 爱心Confidence 信心Decision 决心Corporate culture (公司文化)Integration 融合Responsibility 责任Progress 进步QC quality control 品质管理人员FQC final quality control 终点品质管制人员IPQC in process quality control 制程中的品质管制人员OQC output quality control 最终出货品质管制人员IQC incoming quality control 进料品质管制人员TQC total quality control 全面质量管理POC passage quality control 段检人员QA quality assurance 质量保证人员OQA output quality assurance 出货质量保证人员QE quality engineering 品质工程人员FAI first article inspection 新品首件检查FAA first article assurance 首件确认CP capability index 能力指数SSQA standardized supplier quality audit 合格供应商品质评估FMEA failure model effectiveness analysis 失效模式分析AQL Acceptable Quality Level 运作类允收品质水准S/S Sample size 抽样检验样本大小ACC Accept 允收REE Reject 拒收CR Critical 极严重的MAJ Major 主要的MIN Minor 轻微的Q/R/S Quality/Reliability/Service 品质/可靠度/服务P/N Part Number 料号L/N Lot Number 批号AOD Accept On Deviation 特采UAI Use As It 特采FPIR First Piece Inspection Report 首件检查报告PPM Percent Per Million 百万分之一SPC Statistical Process Control 统计制程管制SQC Statistical Quality Control 统计品质管制GRR Gauge Reproducibility & Repeatability 量具之再制性及重测性判断量可靠与否DIM Dimension 尺寸DIA Diameter 直径QIT Quality Improvement Team 品质改善小组ZD Zero Defect 零缺点QI Quality Improvement 品质改善QP Quality Policy 目标方针TQM Total Quality Management 全面品质管理RMA Return Material Audit 退料认可7QCTools 7 Quality Control Tools 品管七大手法通用之件类ECN Engineering Change Notice 工程变更通知(供应商)ECO Engineering Change Order 工程改动要求(客户)PCN Process Change Notice 工序改动通知PMP Product Management Plan 生产管制计划SIP Standard Inspection Procedure 制程检验标准程序SOP Standard Operation Procedure 制造作业规范IS Inspection Specification 成品检验规范BOM Bill Of Material 物料清单PS Package Specification 包装规范SPEC Specification 规格DWG Drawing 图面系统文件类ES Engineering Standard 工程标准IWS International Workman Standard 工艺标准ISO International Standardization Organization 国际标准化组织GS General Specification 一般规格部类PMC Production & Material Control 生产和物料控制PCC Product control center 生产管制中心PPC Production Plan Control 生产计划控制MC Material Control 物料控制DCC Document Control Center 资料控制中心QE Quality Engineering 品质工程(部)QA Quality Assurance 品质保证处QC Quality Control 品质管制(课)PD Product Department 生产部LAB Laboratory 实验室IE Industrial Engineering 工业工程R&D Research & Design 设计开发部。

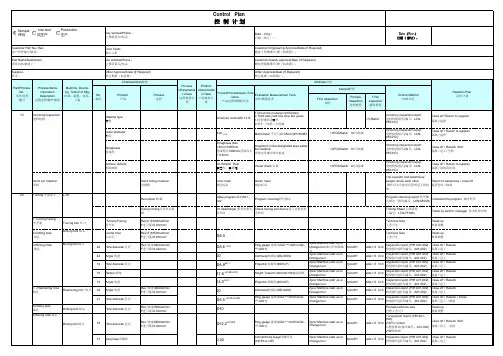

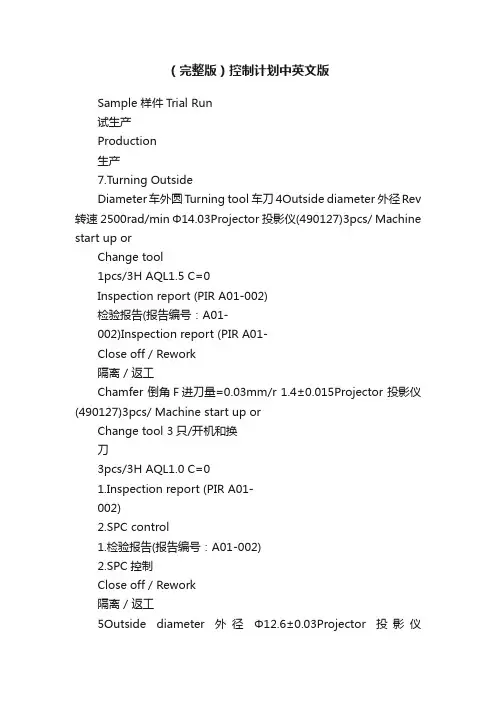

Sample 样件Trial Run试生产Production生产7.Turning OutsideDiameter车外圆Turning tool 车刀4Outside diameter 外径Rev 转速2500rad/min Φ14.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Inspection report (PIR A01-Close off / Rework隔离 / 返工Chamfer 倒角F进刀量=0.03mm/r 1.4±0.015Projector 投影仪(490127)3pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工5Outside diameter 外径Φ12.6±0.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工1Outside diameter 外径Φ16.18 0/-0.04Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工25Angle 角度45.6°±5°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8.Cutting Groove 割槽Cutting tool 切断刀2Outside diameter 外径Rev 转速2500rad/minФ 14+0.05Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework /Sort隔离 / 返工/全检38Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11Width宽度 2.2 +0.2/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8Length 长度11.8±0.2Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工41Angle 角度3°±1°Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工26Radius圆弧R0.1 +0.1(2X)Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9.Cutting off 切断Cutting tool 切断刀17Length 长度Rev 转速2500rad/minF进刀量=0.03mm/r23.4±0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工10.Drilling hole 钻孔Drilling tool 钻头22Inside diameter 外径Rev 转速2500rad/minΦ6+0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工36Concentricity 同轴度Φ0.02Concentricity Gage同轴度仪(19753-A-10P)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工40Roughness 粗糙度F进刀量=0.03mm/r Ra6.3Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工14Length 长度9±0.25Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工33Angle 角度118°±3°Contracer轮廓仪(DD-0009)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工31Chamfer 倒角0.2 +0.2/0.1*45Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11.Drilling hole 钻孔Drilling tool 钻头Hole diameter 孔径Rev 转速2500rad/minF进刀量=0.03mm/rΦ10Process technice size过程工艺尺寸Reset-up重新调整12.Boring Hole镗孔Boring tool 镗刀23Inside diameter 外径Rev 转速3000rad/minF进刀量=0.02mm/rΦ8.8±0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工30Chamfer 倒角0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13highness 高度 2.5+0.2Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工12highness 高度 1.2±0.025Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工35parallel平行度0.02Dial indicator千分表3pcs/ Machine start up orChange tool 3pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工24Inside diameter 外径Φ13 +0.04Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework / Scrap隔离 / 返工 / 报废Turning tool 车刀6Outside diameter 外径Rev 转速2500rad/minΦ14.6+0.1Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工39Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工28Chamfer 倒角0.2±0.05*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9highness 高度 3.8+0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工29Chamfer 倒角0.2±0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工7highness 高度19.6+0.05/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13.Turning Outside Diameter车外圆。

(完整版)控制计划中英文版Sample 样件Trial Run试生产Production生产7.Turning OutsideDiameter车外圆Turning tool 车刀4Outside diameter 外径Rev 转速2500rad/min Φ14.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Inspection report (PIR A01-Close off / Rework隔离 / 返工Chamfer 倒角F进刀量=0.03mm/r 1.4±0.015Projector 投影仪(490127)3pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工5Outside diameter 外径Φ12.6±0.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工1Outside diameter 外径Φ16.18 0/-0.04Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工25Angle 角度45.6°±5°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8.Cutting Groove 割槽Cutting tool 切断刀2Outside diameter 外径Rev 转速2500rad/minФ 14+0.05Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework /Sort隔离 / 返工/全检38Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11Width宽度 2.2 +0.2/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8Length 长度11.8±0.2Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工41Angle 角度3°±1°Projector 投影仪(490127)3pcs/ Machine start up or1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工26Radius圆弧R0.1 +0.1(2X)Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9.Cutting off 切断Cutting tool 切断刀17Length 长度Rev 转速2500rad/minF进刀量=0.03mm/r23.4±0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工10.Drilling hole 钻孔Drilling tool 钻头22Inside diameter 外径Rev 转速2500rad/minΦ6+0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up or1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工36Concentricity 同轴度Φ0.02Concentricity Gage同轴度仪(19753-A-10P)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工40Roughness 粗糙度F进刀量=0.03mm/r Ra6.3Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工14Length 长度9±0.25Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工33Angle 角度118°±3°Contracer轮廓仪(DD-0009)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工31Chamfer 倒角0.2 +0.2/0.1*45Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11.Drilling hole 钻孔Drilling tool 钻头Hole diameter 孔径Rev 转速2500rad/minF进刀量=0.03mm/rΦ10Process technice size过程工艺尺寸Reset-up重新调整12.Boring Hole镗孔Boring tool 镗刀23Inside diameter 外径Rev 转速3000rad/minF进刀量=0.02mm/rΦ8.8±0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工30Chamfer 倒角0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13highness 高度 2.5+0.2Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工12highness 高度1.2±0.025Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工35parallel平行度0.02Dial indicator千分表3pcs/ Machine start up orChange tool 3pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工24Inside diameter 外径Φ13 +0.04Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework / Scrap隔离 / 返工 / 报废Turning tool 车刀6Outside diameter 外径Rev 转速2500rad/minΦ14.6+0.1Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工39Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工28Chamfer 倒角0.2±0.05*45°Projector 投影仪(490127)3pcs/Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9highness 高度3.8+0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工29Chamfer 倒角0.2±0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工7highness 高度19.6+0.05/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13.Turning Outside Diameter车外圆。

OPERATIONAL QUALIFICATION STERILE PROCESS VALIDATIONCLEANING VALIDATION (1/25)1. DOCUMENT HISTORYAdoption by PIC/S Committee 10 - 11 December 1998Entry into force of version PR 1/99-1 01 March 1999Entry into force of version PI 006-1 01 September 20012. INTRODUCTIONThe basic principles and application of qualification and validation are describedin Annex 15 to the PIC/S and EU Guide to GMP. This document comprises individual Recommendations on four topics relating to Equipment Qualification and Process Validation in pharmaceutical manufacture, as follows:Ø Validation Master PlanØ Installation and Operational QualificationØ Non-Sterile Process ValidationØ Cleaning ValidationThe four Recommendations comprising this document define general principles pertaining to each of the topics.2. 导言PIC/S和EU GMP指导原则的附录15中对确认(Qualification)和验证(Validation)的基本原则及应用进行了阐述。

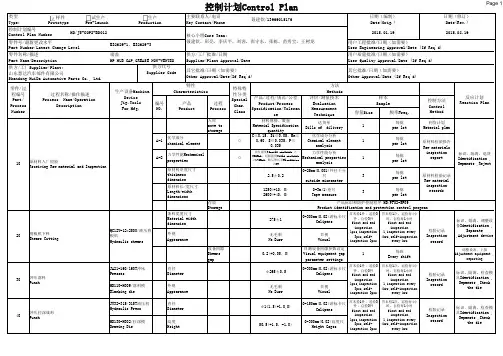

容量Size 频率Freq.入库move to storage材料规格、数量Material Specificationquantity送货单Bills of dilivery1每批per lot到货计划Material planA-1◇C≤0.15、Si≤0.05、Mn≤0.60、S≤0.035、P≤0.035化学成分分析Chemical elementanalysis1每批per lotA-2◇抗拉强度Tensile strength ≥305Mpa、屈服强度Yield strength≥175Mpa、断后伸长率Elongation≥29力学性能分析Mechanical propertiesanalysis1每批per lot2.5±0.20-25mm(0.001)外径千分尺outside micrometer3每批per lot1250(+10,0)2600(+40,0)0-3m(1)卷尺Tape measure3每批per lot存放Storage275±10-300mm(0.02)游标卡尺Calipers无毛刺No Burr目视Visual设备间隙Shears gap0.2(+0.05,0)目测设备间隙参数设定Visual equipment gapparameter settings1每班Every shift调整设备、上报Adjustment equipment ,reporting φ265±0.50-300mm(0.02)游标卡尺Calipers无毛刺No Burr目视Visualφ141.5(+1.0,0)0-150mm(0.02)游标卡尺Calipers50.5(+1.5,-1.0)0-300mm(0.02)高度尺Height Gages高度Height 首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord标识、隔离、检查模具Identification ,Separate ,Checkthe die供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)标识、隔离、调整设备Identification ,Separate,Adjustment device 生产设备Machine.DeviceJig.ToolsFor Mfg.特性Characteristics零件名称/描述Part Name/Description 端盖HP HUB CAP,GREASE NON-VENTEDJY32-315/315T油压机Hydraulic Press直径Diameter40冲压拉深成形Punch供方/工厂批准/日期Supplier/Plant Approval/Date过程名称/操作描述Process Name/OperationDescriptionHD130-H002/拉深模Drawing Die条料宽度尺寸Material widthdimension其它批准/日期(如需要)Other Approval/Date (If Req'd)检验记录Inspectionrecord用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change LevelE32629-1、E32629-3零件/过程编号Part/ Process Number评价/测量技术EvaluationMeasurementTechnique样本Sample控制方法ControlMethod特殊特性分类SpecialChar.Class方法Methods标识、隔离、退货Identification ,Separate ,Reject产品标识和防护控制程序 HD/PF02-SP09Product identification and protection control program反应计划Reaction Plan 编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance10原材料入厂检验Receiving Raw material and Inspection力学性能Mechanicalproperties原材料检验报告Raw materialsinspectionreport原材料长/宽尺寸Length/widthdimensions原材料检验记录Raw materialinspectionrecords化学成分chemical element原材料厚度尺寸thicknessdimension20剪板机下料Shears CuttingQC12Y-12*2500/液压剪板机Hydraulic shears外观Appearance首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs30冲压落料Punch首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord标识、隔离、检查模具Identification ,Separate ,Checkthe die外观AppearanceJA21-160/160T冲床PressesHD110-H009/落料模Blanking die直径Diameter容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance47±10-300mm(0.02)深度尺Depth Gages首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs首末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压力Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa目视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ142.5(+0.2,-0.3)0-150mm(0.02)游标卡尺Calipers 50.5(+1.5,-2.0)0-300mm(0.02)高度尺Height GagesA-3◇47±10-300mm(0.02)深度尺Depth Gages首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs首末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压力Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa目视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ214±0.50-300mm(0.02)游标卡尺Calipers6×φ8.7±0.250-150mm(0.02)游标卡尺Calipers A-4◇HDJ-H0001检具Gage首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrsφ205±0.750-300mm(0.02)游标卡尺Calipers 深度Depth检验记录Inspection record50整形ShapingJY32-315/315T油压机Hydraulic Press 直径Diameter 首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs 首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs 检验记录Inspection recordHD134-H014/整形模Shaping Die高度Height检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die孔径diameter I.D.HD146-H011/切边冲孔模Trimming and Punching die位置度Location degreeJA21-160/160T冲床Presses深度Depth直径Diameter 检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die40冲压拉深成形Punch冲压切边冲孔Trimming and PunchingJB21-160B-SM/160T冲床直径Diameter首末检1件、巡检3件、自检3件first and endinspection首末检1次、巡检每4小时、自检每1小时first and end inspection60首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance10(+2,0)0-300mm(0.02)高度尺Height Gages85°±0.5°0-360°(2′)万能角度尺Universal angle rulerA-5◇首末检、巡检0-10mm(0.01)百分表/自检 0-1mm塞尺First and endinspection 0-10mm(0.01) Dialindicator/Self-inspection 0-1mmFeeler首末检1件、巡检5件(X-R图)、自检5件first and end inspection 1pcs,inspectio n 5pcs(X-R chart),self-inspection 5pcs末检1次、巡检每2小时、自检每1小时first and endinspection1,inspection every2hrs,self-inspection everyhrsφ4(+2,-1)0-150mm(0.02)游标卡尺Calipers 1±0.250-300mm(0.02)高度尺Height Gages90无油污No dirt 目测Visual全检Full inspection每批per lot检验记录Inspection record 标识、隔离、退货Identification ,Separate ,Reject喷塑气压Spray pressure0.4-0.5MPa喷塑电压Spray voltage 50-60KV烘烤温度Bakingtemperature 180-200℃烘烤时间Baking time30-40min 无漏喷No leakage jet目测Visual调整设备、上报Adjustment equipment ,reporting100喷塑SprayXNG-36-1B/粉末喷涂生产线Powder coating production lines目测Visual1产线外观Appearance全检Full inspectionper lot70冲压翻边成形FlangingJB21-160B-SM/160T冲床Presses件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs80冲压压字Pressure logoJA21-160/160T冲床Presses孔径diameter I.D.首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs标识、隔离、检查模具Identification ,Separate ,Checkthe die角度AngleHD124-H008/翻边模Flanging die平面度Flatness高度Height 标识、隔离、检查模具Identification ,Separate ,Checkthe dieHD150-H006/压字模Pressure logo die(E32629-3)HD150-H005/压字模Pressure logo die(E32629-1)高度Height检验记录Inspection record首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs检验记录Inspection record外观Appearance外协镀锌Outsourcing galvanized检验记录Inspection record每班Every shift检验记录Inspection record容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/ToleranceA-5◇0.15mm塞尺(端盖平放在大理石台面,上面压5kg物体)/0.15mm feeler ( cover flat on the marble countertops, pressure5kg objects above )盐雾试验≥1000小时/Salt spray test≥1000hrs盐雾腐蚀试验机/Salt spray corrosiontest machine3每季度Each quarter 盐雾试验报告Salt spray testreport 110丝印完整Full screen目测Visual全检Full inspection每批per lot检验记录Inspection record标识、隔离、退货Identification ,Separate ,RejectA-3◇47±10-300mm(0.02)深度尺Depth Gages10A-4◇HDJ-H0001检具Gage 10A-5◇0.15mm塞尺(端盖平放在大理石台面,上面压5kg 物体)/0.15mm feeler (cover flat on the marble countertops,pressure 5kg objectsabove )10包装规范Packaging Specifications点数Counting 2箱2 box标识、隔离、返工Identification ,Separate ,Rework清晰Clear 目测Visual 包装规范Packaging Specifications 目测Visual 物资发货单Material Invoice点数Counting标识、隔离、返工Identification ,Separate ,Rework平面度Flatness防腐蚀性能Corrosion100喷塑SprayXNG-36-1B/粉末喷涂生产线Powder coating production lines全检Full inspection每批per lot外协丝印Outsourcing Screen外观Appearance 检验记录Inspection record深度Depth120抽检并包装Sampling inspection and packaging标识、隔离、处理Identification ,Separate ,Dealwith位置度Location degree平面度Flatness数量Quantity 每批per lot检验记录Inspection record标识Label标识、隔离、返工Identification ,Separate ,Rework包装Package 数量Quantity130入库&出货Warehousing & shipping全检Full inspection每批per lot 物资发货单Material Invoice。

(全篇)制造流程与品质管理计划英文版Manufacturing Process and Quality Management PlanIn today's competitive market, it is crucial for companies to have a well-defined manufacturing process and quality management plan in place. This document outlines the steps involved in the manufacturing process and how quality will be managed to ensure the final product meets the highest standards.Manufacturing Process1. Design Phase:- Determine product specifications and requirements- Develop detailed design and engineering plans2. Procurement Phase:- Source raw materials and components from approved suppliers- Negotiate contracts and secure necessary resources3. Production Phase:- Assemble components according to design plans- Test prototypes for quality assurance4. Quality Control Phase:- Implement quality control measures at each stage of production - Conduct inspections and tests to identify defects5. Packaging and Shipping Phase:- Package finished products securely- Arrange for shipping to distribution centers or customersQuality Management Plan1. Quality Standards:- Adhere to industry-specific quality standards and regulations- Establish internal quality control measures to meet or exceed standards2. Quality Assurance:- Implement quality assurance processes to prevent defects- Conduct regular audits to ensure compliance with quality standards3. Training and Development:- Provide training to employees on quality control procedures- Encourage continuous improvement through feedback and training programs4. Supplier Management:- Evaluate suppliers based on quality of products and services- Establish partnerships with reliable suppliers to ensure consistent quality5. Customer Feedback:- Collect feedback from customers to identify areas for improvement- Use customer feedback to make necessary adjustments to the manufacturing process6. Continuous Improvement:- Implement a system for monitoring and measuring quality metrics - Identify opportunities for improvement and make necessary changesBy following this manufacturing process and quality management plan, we aim to produce high-quality products that meet customer expectations and maintain a competitive edge in the market.。

生产过程管理程序Production Management Procedure(IATF16949-2016)1.目的 Objective规范生产运作程序,提高生产效率,使产品安全、合法以及质量随时随地得到有效控制,保证产品准时出货。

To regulate the production operation procedure and improve production efficiency to ensure the products safety, legality and quality can be controlled efficiently and to ensure the products can be delivered on time.2.适用范围 Applicable Scope适用于本公司生产部来料投入至成品入库全过程。

Be applied to the production process from preparing the materials to warehousing the finished products.3. 职责Responsibilities3.1. 计划部负责制定《生产计划》,下发《生产任务单》给生产部。

PMC is responsible for making the <production plan> and distributing <production task notice> to production department.3.2. 生产部每日实行自检、互检制度,负责制程生产的实施与控制。

Production department shall implement self-inspection and mutual inspection everyday and implement and control the production process.3.3.品质部负责产品合法性的确认、质量和安全等整个生产过程品质的监控与跟踪。

质量保证计划Quality Control Plan(项目编号:TRSC/1701152)Project No:TRSC/17011522017年7月17日07-17-2017质量保证计划Quality Control Plan1.概述General Description1.1目的Purpose为满足张家港特锐机械制造有限公司采购项目,项目编号:TRSC/1701152的要求,制定如下专项质量保证计划。

To meet the requirement of Tedrail (Project No.: TRSC/1701152), make the followingquality control plan:2. 质量目标Quality Objectives根据该项目合同及附件中有关技术要求,满足下述质量目标:满足首检确认后双方达成一致的《产品技术规范》及《产品部件尺寸验收质量表单》等质量要求According to the relevant technical requirements of the project contract, meet thefollowing quality objectives:Meet the FAI confirmed that the two sides agreed to reach a consensus on the "productdelivery and acceptance specification" and "product parts size and acceptance qualityform" and other quality requirements3. 技术准备Technical Preparation为保证满足本项目零件的制造、检查和验收的技术要求,供应商应建立和贯彻有效的质量控制程序,用以保证产品的设计质量。