Dry Etch工艺及设备介绍 PPT

- 格式:ppt

- 大小:1.64 MB

- 文档页数:23

微/纳制造工艺技术Micro & Nano Fabrication TechnologyLecture 8 Dry Etching主讲:乔大勇OutlineOverview of dry etchingFundamentals of plasmaReactive Ion Etching (RIE)Deep RIEWhy dry etchingSmallLargeUse of chemicalsAcceptable High Batch production High Low Tool price Acceptable ,controllable High ,Uncontrollable Selectivity Acceptable ,controllable High ,controllable Etch rate ControllableIsotropic or anisotropic Side wall profile Very small >3 micronEtching tolerance Dry etching Wet etching Etching type Overview of dry etchingWetCl 2AlCHF 3Silicon OxideCF 4Silicon Nitride SF 6Silicon, PolysiliconDryH 3PO4AlHF Silicon OxideH 3PO 4Silicon Nirtide KOH, TMAH,EDPSiliconChemical used Etching target ModeComparison of Dry and Wet etchingWhy dry etchingOverview of dry etchingOverview of dry etchingPlasma is generated by RF and DC excitation of source gases in a vacuum system. Take SF6as an example, plasma composed of equal numbers of positive (SF5+) and negative charges (F-and e) and a different number of unionized molecules and radicals (F).Positive ions are accelerated and strike substrate with high kinetic energy, leading to material removal (Highly anisotropic and low selectivity). Neutral radicals interact with substrate surface to form volatile products (Isotropic and high selectivity)Fundamentals of plasma90%states of matter in Universe is plasma. Lightning and polar light are natural plasma. All stars are combination of matters in plasma state.IceWaterSteamPlasma (Ionized gas)Cold Warm Hot HotterMolecules fixed in lattices Molecules free to move Molecules free to move, large space Ions and electrons move, large spaceFundamentals of plasmaMan made PlasmaFundamentals of plasmaFundamentals of plasmaMan made PlasmagasAre-Ar+Ar+Ar+ArSheath-V+Fundamentals of plasmaMan made PlasmaExcitation(激发)跃迁eA A e +→+*For CF 4,4.0eV energy is needed for excitation. Symbol * stands for excited atoms, which will go back to general state in 1/billion second~several seconds by relaxation procedure.Fundamentals of plasmaMan made Plasma)(*Photos h A A ν+→Relaxation (驰豫)Light emitted during relaxation. Different gas plasma emitted different color. For Argon plasma, the color is pink.Fundamentals of plasmaMan made PlasmaDissociation (分裂)For CF4,12.5eV is neede for dissociation 。

【面板制程刻蚀篇】史上最全Dry Etch 分类、工艺Dry Etch工序的目的广义而言,所谓的刻蚀技术,是将显影后所产生的光阻图案真实地转印到光阻下的材质上,形成由光刻技术定义的图形。

它包含了将材质整面均匀移除及图案选择性部分去除,可分为湿式刻蚀(wet etching)和干式刻蚀(dry etching)两种技术。

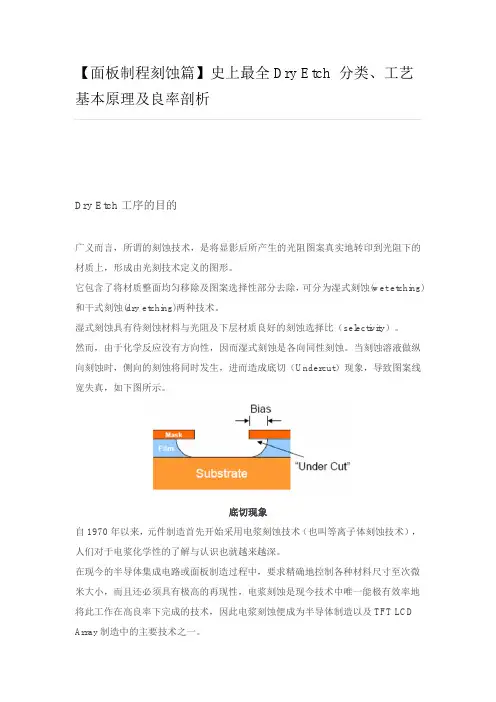

湿式刻蚀具有待刻蚀材料与光阻及下层材质良好的刻蚀选择比(selectivity)。

然而,由于化学反应没有方向性,因而湿式刻蚀是各向同性刻蚀。

当刻蚀溶液做纵向刻蚀时,侧向的刻蚀将同时发生,进而造成底切(Undercut)现象,导致图案线宽失真,如下图所示。

底切现象自1970年以来,元件制造首先开始采用电浆刻蚀技术(也叫等离子体刻蚀技术),人们对于电浆化学性的了解与认识也就越来越深。

在现今的半导体集成电路或面板制造过程中,要求精确地控制各种材料尺寸至次微米大小,而且还必须具有极高的再现性,电浆刻蚀是现今技术中唯一能极有效率地将此工作在高良率下完成的技术,因此电浆刻蚀便成为半导体制造以及TFT LCD Array制造中的主要技术之一。

干式刻蚀通常指利用辉光放电(glow discharge)方式,产生包含离子、电子等带电粒子以及具有高度化学活性的中性原子、分子及自由基的电浆,来进行图案转印(pattern transfer)的刻蚀技术。

干法刻蚀是亚微米尺寸下刻蚀器件的最主要方法,广泛应用于半导体或面板前段制程。

Dry Etch 的分类及工艺的基本原理蚀刻技术中的术语1.各向同性与各向异性蚀刻( Isotropic and Anisotropic Etching)不同的蚀刻机制将对蚀刻后的轮廓(Profile)产生直接的影响。

如下图所示,纯粹的化学蚀刻通常没有方向选择性,上下左右刻蚀速度相同,蚀刻后将形成圆弧的轮廓,并在遮罩(Mask)下形成底切(Undercut),这种刻蚀被称为各向同性蚀刻。

刻蚀(ETCH)工艺的基础知识刻蚀(ETCH)工艺的基础知识何谓蚀刻(Etch)?答:将形成在晶圆表面上的薄膜全部,或特定处所去除至必要厚度的制程。

蚀刻种类:答:(1) 干蚀刻(2) 湿蚀刻蚀刻对象依薄膜种类可分为:答:poly,oxide, metal半导体中一般金属导线材质为何?答:鵭线(W)/铝线(Al)/铜线(Cu)何谓dielectric 蚀刻(介电质蚀刻)?答:Oxide etch and nitride etch半导体中一般介电质材质为何?答:氧化硅/氮化硅何谓湿式蚀刻答:利用液相的酸液或溶剂;将不要的薄膜去除何谓电浆Plasma?答:电浆是物质的第四状态.带有正,负电荷及中性粒子之总和;其中包含电子,正离子, 负离子,中性分子,活性基及发散光子等,产生电浆的方法可使用高温或高电压.何谓干式蚀刻?答:利用plasma将不要的薄膜去除何谓Under-etching(蚀刻不足)?答:系指被蚀刻材料,在被蚀刻途中停止造成应被去除的薄膜仍有残留何谓Over-etching(过蚀刻)答:蚀刻过多造成底层被破坏何谓Etch rate(蚀刻速率)答:单位时间内可去除的蚀刻材料厚度或深度何谓Seasoning(陈化处理)答:是在蚀刻室的清净或更换零件后,为要稳定制程条件,使用仿真(dummy)晶圆进行数次的蚀刻循环。

Asher的主要用途:答:光阻去除Wet bench dryer 功用为何?答:将晶圆表面的水份去除列举目前Wet bench dry方法:答:(1) Spin Dryer (2) Marangoni dry (3) IPA Vapor Dry何谓Spin Dryer答:利用离心力将晶圆表面的水份去除何谓Maragoni Dryer答:利用表面张力将晶圆表面的水份去除何谓IPA Vapor Dryer答:利用IPA(异丙醇)和水共溶原理将晶圆表面的水份去除测Particle时,使用何种测量仪器?答:TencorSurfscan测蚀刻速率时,使用何者量测仪器?答:膜厚计,测量膜厚差值何谓AEI答:After Etching Inspection 蚀刻后的检查AEI目检Wafer须检查哪些项目:答:(1) 正面颜色是否异常及刮伤(2) 有无缺角及Particle (3)刻号是否正确金属蚀刻机台转非金属蚀刻机台时应如何处理?答:清机防止金属污染问题金属蚀刻机台asher的功用为何?答:去光阻及防止腐蚀金属蚀刻后为何不可使用一般硫酸槽进行清洗?答:因为金属线会溶于硫酸中"Hot Plate"机台是什幺用途?答:烘烤Hot Plate 烘烤温度为何?答:90~120 度C何种气体为Poly ETCH主要使用气体?答:Cl2, HBr, HCl用于Al 金属蚀刻的主要气体为答:Cl2, BCl3用于W金属蚀刻的主要气体为答:SF6何种气体为oxide vai/contact ETCH主要使用气体?答:C4F8, C5F8, C4F6硫酸槽的化学成份为:答:H2SO4/H2O2AMP槽的化学成份为:答:NH4OH/H2O2/H2OUV curing 是什幺用途?答:利用UV光对光阻进行预处理以加强光阻的强度"UV curing"用于何种层次?答:金属层何谓EMO?答:机台紧急开关EMO作用为何?答:当机台有危险发生之顾虑或已不可控制,可紧急按下湿式蚀刻门上贴有那些警示标示?答:(1) 警告.内部有严重危险.严禁打开此门(2) 机械手臂危险. 严禁打开此门(3) 化学药剂危险. 严禁打开此门遇化学溶液泄漏时应如何处置?答:严禁以手去测试漏出之液体. 应以酸碱试纸测试. 并寻找泄漏管路.遇IPA 槽着火时应如何处置??答:立即关闭IPA 输送管路并以机台之灭火器灭火及通知紧急应变小组BOE槽之主成份为何?答:HF(氢氟酸)与NH4F(氟化铵).BOE为那三个英文字缩写?答:Buffered Oxide Etcher 。