KAMSTRUP热能表选型指南601

- 格式:pdf

- 大小:79.83 KB

- 文档页数:1

热量表技术标准和产品检验方法1.范围本标准规定了热量表的热量计量原理与主要参数、技术要求、试验方法、检验规则和包装与贮存条件。

本标准适用于测量计算流动介质为水,温度为2~160℃,压力不大于2.5MPa的热量表。

2.引用标准下列标准包含的条文,通过在本标准中引用而构成为本标准的条文。

BSEN1434 1997国际法定计量组织的75号国际建议(OLMLR75)GB/T 778.3—1996冷水表第3部分:试验方法和试验设备JB/T 8802—1998热水表行业规范GB/T9329—1999仪器仪表运输、贮存基本环境条件及试验方法3.术语3.1热量表用于测量显示水流过热交换系统所释放或吸收的热量的仪器。

3.2整体热量表由流量传感器、计算仪、配对温度传感器等部件所组成不可分离的热量表。

3.3流量传感器安装在热交换系统中,用于采集水的流量并发出流量信号的部件。

3.4温度传感器安装在热交换系统中,用于采集热交换系统入口和出口水的温度并发出温度信号的部件。

3.5计算仪接收来自流量传感器和温度传感器对的信号,进行热量计算存储和显示系统所交换的热量值的部件。

3.6配对温度传感器在同一个热量表上,分别用来测量热交换系统的入口和出口温度的两支温度传感器。

3.7温差在热交换系统内的热载体水的入口温度和出口温度的差值.3.7.1最小温差温差的下限值,在此温差时,热量表不得超过误差界限。

3.7.2最大温差温差的上限值,在此温差时,热量表不得超过误差界限。

3.8流量单位时间通过热量表的热载体水的体积。

3.8.1最小流量热载体水在系统内的最小流量,在此流量时,热量表不得超过误差界限。

3.8.2额定流量热载体水在系统正常连续运行的最大流量,在此流量时,热量表不得超过误差界限。

3.8.3最大流量热载体水在系统内,有限时间(<1小时/天;<200小时/年)内,正常运行的最大流量,在此流量时,热量表不得超过误差界限。

3.8.4累积流量热交换系统内流过的载体水的体积的总和。

如何选择热量表型号及其安装使用详解以下就热表的设计选型及安装使用中的注意事项作一简单介绍,并就有关配套管理规定提出建议。

1设计中应注意的问题1.1设计选型在设计选型时,应根据供热系统的运行条件及环境状态来确定热表的型式、尺寸、准确度及环境等级等参数。

其中涉及许多的因素,主要应注意考虑以下几点。

1.1.1热表型式热表包括3部分:流量传感器、配对温度传感器和计算器。

常见的热表有机械式、电磁式、超声波式、振荡式等等。

一般来说采用机械式流量计量的热表的价格会比采用非机械式流量计量的热表低;但非机械式热表的精度及长久稳定性要比机械式的好,相应的故障率及运行维护成本也就比机械式的低。

选用时应综合考虑一次投资及维护保养等成本。

1.12介质温度介质温度涉及供回水的最高、最低温度及最大、最小温差。

如果介质温度及供回水温差超出热表的使用范围,有可能导致测量误差超标或造成热表的损坏。

1.1.3系统压力供热采暖系统中一般采用的系统压力有PN10,PN16和PN250热表的设计制造也是按此分级进行的,可根据系统压力选用相应额定压力的热表。

如果管道内的压力波动超过1.5倍额定压力的话,热表的流量测量元件有可能会受到损坏。

1.1.4流量及管径系统流量是热表选型的最重要参数之一。

通常,管径与管内流量是相互对应的。

对于一个设计合理的系统而言,其管道直径与热表的口径可能非常接近或相同。

但二者并不一定等同。

一些设计人员习惯于按系统管径来选用热表,这是错误的。

因为,选用热表的主要参数是系统流量而不是系统管径,应该按照流量大小来确定热表的型号。

鉴于工程设计中通常计算的是最大负荷状态下的流量,而在实际运行中多数情况F的流量都远远小于这个流量,所以,有时按照最大设计流量的80%来确定热表的额定流量往往更符合实际运行要求。

国内以往设计时采用的系统管内流速较低,管径偏大,所以按流量方式选择的热表的口径往往会比系统管道口径小。

在这种情况下,建议采用变径措施。

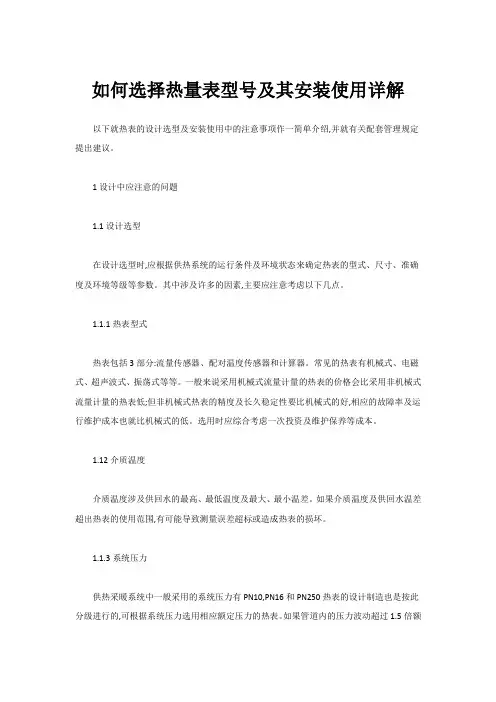

热能表 22PEM-1U.. MID 2014/32/EU EN 14342021-09/B 版2热能表 22PEM-1U..目录页码说明概述法律公告安装说明4 6 7供电11操作控制与指示12接线图说明接线分配模拟输出连接与BACnet, Modbus, MP-Bus连接传感器接线与M-Bus连接13 14 15热能表激活显示图标激活注意事项激活步骤16 17 18显示回路用户回路诊断回路22 24错误代码26密封与安全封条出厂封条系统安全封条妥善粘贴安全封条28 29 30传感器模块更换31传感器模块备件34配件可选配件354Subject to technical modifications热能表 22PEM-1U..说明认证热能表符合EN1434的要求,并根据欧洲测量仪器指令(MID) 2014/32/EU(MI-004)进行了型式认证。

热能表被作为热量表获得认证,并没进行冷量表认证。

因此,在法律要求的交易中使用热能表作为冷量表是不符合法规要求的,但可在任何时间将热能表用作“内部使用”的冷量表。

使用与功能热能表用于记录闭式供暖系统、制冷系统或供暖/制冷系统中的热能。

交货范围 –热能表–两条连续编号(一次性)的安全封条,带有大约40cm的接线 –绝缘外壳 –硅胶套圈–安装指南T1T2逻辑模块传感器模块水质要求只有当水质满足AGFW 建议的FW-510和VDI 2035的条件时,才能保证热能表测量的稳定性。

热能表安装在调试和安装热能表之前,应仔细研究操作手册,以防止安装调试过程中出现错误。

本操作手册适用于以下热能表搏力谋产品型号DNDN (″)G (″)额定流量 qp (m 3/h)22PEM-1UC 151/23/4 1.522PEM-1UD 203/41 2.522PEM-1UE 251 1 1/4 3.522PEM-1UF 32 1 1/4 1 1/2622PEM-1UG 40 1 1/221022PEM-1UH5022 1/215热能表结构热能表由一个传感器模块和一个逻辑模块组成。

DMXC2000MBus转Modbus转换器使用说明书二零一四年三月北京黑蚂蚁节能技术有限公司第一章产品简介1.1产品概述MBUS转MODBUS是指MBUS协议和MODBUS协议的互相转换,使用于任何MODBUS主站读取MBUS设备的数据。

转换器最多支持256块热能表数据的读取,支持所有欧洲标准协议的超声波仪表,如:卡姆鲁普(Kamstrup)、西门子、兰吉尔(Landis+Gyr)、恩乐曼、埃创、非特拉、天罡、伟岸、瑞纳、爱拓利、真兰、荷德鲁美特、丹佛斯等公司生产的热量表、水表通讯。

支持所有国家标准(CJ-T_188)的超声波仪表和水表。

也可以跟据用户的实际需求,定制读取其他MBUS仪表的数据。

模块支持多类型表同时挂接。

提供配套管理软件,可以配置MODBUS地址、波特率、校验位及仪表类型等。

转换器采用DC12V输入电压,MBUS接口用于连接MBUS仪表(具有总线短路保护功能),RS485用于和MODBUS主站连接,RS485采用光电隔离。

如果读取欧洲标准协议的仪表,可以采用一级地址读取仪表数据,仪表地址必须设成1~256,如果采用二级地址采集仪表数据,就需要把仪表的二级地址和逻辑短地址(1~255)进行映射,通过逻辑短地址(1~255)读取仪表数据,仪表的型号可以由用户设定。

注:国家标准(CJ-T_188)协议不支持多级地址,只能通过地址映射来实现短地址(1~255)的通信。

1.2产品技术特性1、供电电压:DC12V输入。

2、隔离:电源、MBUS、RS485三端隔离。

3、MODBUS:MODBUS RTU从设备(波特率1200-115200可配置,地址可配置,校验可配置,8位数据,1位停止位)4、MODBUS连接方式:RS4855、负载:最多支持256块仪表,表的型号可设置;6、MBUS波特率:默认2400波特率,8位数据,偶校验,1位停止位,可设置;7、出厂设置:MODBUS波特率:9600,无校验,1位停止位8、工作温度:-20~+70度1.3MODBUS寄存器与超声波热表的数据对应表MODBUS寄存器地址对应数据备注40001-40002累计热量精确到小数点后2位40003-40004累计流量精确到小数点后2位40005-40006热功率精确到小数点后2位40007-40008流速精确到小数点后2位40009进水温度,单位:0.01℃精确到小数点后2位40010回水温度,单位:0.01℃精确到小数点后2位40011-40012累计工作时间,单位:小时40013-40014累计故障时间,单位:小时40015-40018累计热量单位字符串格式类似于"MWh","GJ"40019-40022累计流量单位字符串格式类似于"m^3"40023-40026热功率单位字符串格式类似于“W”,“kW”40027-40030流速单位字符串格式类似于"l/h","m^3/h"1.4MODBUS寄存器与远传水表的数据对应表MODBUS寄存器地址对应数据备注40100-40101当前累计流量精确到小数点后2位40102-40103结算日累计流量精确到小数点后2位,部分水表没有该数据。

Discover the advantages:Belimo Energy Valve™ & Thermal Energy MeterEnergy Valve and Thermal Energy Meter2P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o nsThe new Energy Valve and Thermal Energy Meter provide energy control and efficient energy billing. Accurate measurement and monitoring of energy consumption in a heating and cooling system with direct IoT-based cost accounting using a single device. Theyare designed to EN1434/MID standards, ensuring high accuracy and reliability, allowing for transparent tenant billing. Belimo is stepping into a new era of integrated thermal energy management.Transparent tenant billing3 Energy Valve and Thermal Energy MeterThe Belimo Energy Valve is an IoT cloud-connected pressureindependent valve that monitors coil performance and energyconsumption while maintaining Delta T. With a patented glycolmonitoring and compensation feature that provides accurate,repeatability flow measurement and ensures glycol content meetsdesign requirements.“The installation of EnergyValves in Citizens Plaza, RachelJackson, and the AndrewJackson building was a majorsuccess. The results exceededmy expectations. We now havesavings that we can see.”Chad Lovell, Operationsand Safety SpecialistJones Lang LaSalle Energy savingsyou can seeCloud OptimizationMonitors and enhances energy usage delivering optimalsystem performance. System analytics are alsoprovided to show historical performance.Delta T ManagementThe Belimo Delta T Manager algorithm reduces pumpingand chiller/boiler operating costs by increasing plantefficiency and maintaining design Delta T.Energy MonitoringAn integrated energy meter provides accurate coil andenergy consumption data for tenant billing. The data is usedto verify system performance after commissioning and actsas a baseline. This feature helps achieve LEED pointsthrough Energy and Atmosphere within credits 1 and 5.Energy Valve and Thermal Energy Meter4P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n sKey features at a glanceCertified metering, MID approvalThe requirements meet EN 1434 and type approval according to theEU MID 2014/32/EU (MI-004).IoT-based billingOwner-authorized third parties are able to securely access data consumptionand provide billing services.Digitally supported workflowsThe Belimo Assistant App guides youthrough the setup process.Easy integrationUsing BACnet IP or MSTP , Modbus TCPor RTU, the Energy Valve can easily communicate directly to the BMS.Power over Ethernet (PoE)The device can connect with one standard Ethernet cable that providespower and allows data transmission.Modular designThe unit consists of two temperaturesensors and a BTU meter withmetering and logic functionality.5Energy Valve and Thermal Energy Meter P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n s aPower ControlAllows the power output to be set to a specific value providing a linear response, making the coil and valve characteristic irrelevant allowing the Energy Valve to be both pressure and temperature independent.Energy monitoringThe thermal energy data is accurately measured, logged, and identifies areas for optimization when detected.Glycol measurement and compensationEquip with a patented glycol algorithm that compensates to ensure accurate readings.Delta T ManagerLogic built-in monitor coil performance and optimize the available energy of the coil by maintaining the Delta T.Dynamic Coil PerformanceAccurately provides transparency inpower degradation and other operational issues in real-time.Easy interaction through NFCQuick data access, field adjustable,commissioning and troubleshooting with theBelimo Assistant App and a smartphone.Energy Valve and Thermal Energy Meter6P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n sThermal Energy MeterBelimo’s new Thermal Energy Meters are designed according to EN1434/MID standards and provide remote IoT-based billing. The energy meters have a patented glycol monitoring and compensation feature that provides accurate, repeatability flow measurement and ensures glycol content meets design requirements. The thermal energy meters incorporate ultrasonic transit time technology with no moving parts eliminating wear over time. Each unit is individually wet calibrated to ensure accuracy and repeatability over the life of the product. The meters offer accurate and reliable measurement of energy consumed, providing customers with the information required to analyze their consumption and control costs.FEATURES –I oT -based BillingThermal energy meters offer Ethernet connectivity to support remote IoT metering and billing.–G lycol Measurement and CompensationEnergy meters are equipped with a patented glycol compensationalgorithm that automatically selects the correct glycol concentration to provide precise flow and energy measurement, ensuring reliable measurement and eliminating manual input and inaccuracy.– S eamless IntegrationWith BACnet/IP or MSTP , Modbus TCP or RTU (always on board), the thermal energy meter can communicate directly to the BMS.– O ptional PoEThe thermal energy meter can connect with one standard Ethernet cableproviding power and data transmission simplifying installation.– B uilt-in Data LoggerBuilt-in data logger captures the energy, flow, and operational data for further system optimization and efficiency.– D igitally AccessEasily set or adjust parameters using NFC and the Belimo Assistant Appor a web server.7Energy Valve and Thermal Energy Meter P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n s aBelimo Energy Valve™The Energy Valve has a patented Power Control and Belimo Delta T Manager™ logic built in to monitor coil performance and optimize the available energy of the coil by maintaining Delta T. In addition to the standard analog signal and feedback wiring, it communicates its data to the Building Management System (BMS) via BACnet MS/TP or BACnet IP as well as Modbus RTU and Modbus TCP/IP . The built-in web server enables clear visualization of the valves’ operation in real time. Performance data is stored for 13 months on board the valve. Cloud data provides lifetime data access.FEATURES –D elta T Optimization & Flow Setpoints Cloud analytics provide recommended Delta T and flow setpoints which can be updated remotely or automatically to save time and improve efficiency.–P erformance ReportingKey performance indicators aregraphically illustrated showing current and historical performance data of flow rates, energy usage, Delta T, and other points of interest.–O ptional PoEThe device can be powered, and the data transferred directly via an Ethernet cable (PoE)–O nline Tech SupportBelimo’s industry leading technical support team available to assist you remotely.–S oftware UpdatesLatest software and security updates automatically provided for maximumproductivity and reliability.Energy Valve and Thermal Energy Meter8P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n sDigitally supportedWebviewSafe and easy interaction through NFC with the Belimo Assistant App and your smart phone provides quick data access, field adjustable, commissioning, and troubleshooting. Configure and ensure proper performance. Local override function for commissioning and maintenance during operation (when powered) is possible with a few clicks. More transparency, easily read and forward parameters for more efficient operation.Webview is an onboard graphical user interface that provides the ability to easily configure and change parameters on the Thermal Energy Meter and Energy Valve. The operation overview provides flows, temperatures, energy, glycol concentration, Delta T, operational errors, and other system information, along with historical trend data. Below is an example of the overview page of Webview for the Energy Valve.Cloud ConnectionConnecting to the Belimo cloud offers a variety of benefits. By maintaining the Energy Valve in the cloud, authorized users can interact with the data directly or change parameters. Device owners can approve third-party vendors to integrate API via the cloud, enabling additional features such as billing oranalytical services; the possibilities are endless.9Energy Valve and Thermal Energy Meter P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n s aPlatform for on-siteEnergy Valve optimizationThe Belimo Clear Edge is an analytical device that leverages the data from all installed Energy Valves in a BACnet Building Automation System (BAS). It automatically analyzes the Belimo Energy Valve data to optimize, manage, and monitor key performance indicators of water coil performance and hydronic energy consumption. The Clear Edge offers trending capability with automated Delta T setpoint adjustment to increase system performance and energy savings strategies. An internet connection is not needed.The Belimo Clear Edge technology is accessible as a plug-in for SkySpark from Stackhub ().FEATURES – A ggregated Start ScreenA simplified view of Key Performance Indicators (KPI’s) including BACnet object name, instance number, supply and return temperatures, Delta T, delta setpoint, flow, current energy usage, and 30 days of energy consumption.– E nergy DashboardInput cost and kWh data, pump efficiency, and other building specific variables provide aggregated cost and energysavings due to reduced pumping. Reporting is available by the day, month, quarter, and year.– A utomatic and Continuous Delta T OptimizationSoftware analytics providing the optimal Delta T and flow setpoints, which are automatically written to the Delta T Manager to save time and improve efficiency.– C oil Power and Delta T CurvesScatter plots that automatically generate load profiles and flow saturation points of coil characteristics and Delta T performance.– S etpoint ConfigurationChange parameters on installed Energy Valves individually or collectively.– A utomatic DiscoveryEnergy Valves on a BACnet network are viewable with a single click. Point mappings automatically provide fastand easy analysis and optimization.Energy Valve and Thermal Energy Meter10P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n sMost capable valvein the HVAC industryFeaturesTypical PI Valve*Energy Valve*Typical pressure independent valves based on globe valve technology.11Energy Valve and Thermal Energy Meter P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n s aAwards and accoladesAwards2019 –C ontrol Trends: HVAC Control Valve Solution of the Year2018–EnergieGenie Award2017–AHR Expo: Innovation Award Finalist2016– ACME: Innovation Award – P oznan International Trade Fair:Gold Medal – C ontrol Trends: Energy SavingsSolution Product of the Year 2015– E nergy Show: Best Energy EfficientProduct of the Year – AREX: Award of Excellence – CSA: Innovation in Commissioning – D eutscher Rechenzentrumspreis:German Data Centre Prize 2014– C ontrol Trends: Energy SavingProduct of the Year – AHR EXPO: Innovation Award – Shanghai Energy Conference: Golden Key Award – Poznan International Trade Fair: Gold Medal 2013– B uilding Efficiency Congress Fair:Building Efficiency Award – Interclima Show: Silver Trophy Award – B CIA: Technical Innovation of the YearProducts – Trade Fair: Building Efficiency – I nnovation Competition:Intelligent Energy Management 2012– C ontrol Trends: Best CommercialProduct of the Year – H VR Awards: Air Conditioning Productof the YearNew Energy Valve Technology at Charles Hayden Library Reaps the Rewards of Higher Delta T!“One thing that impressed us was having such intelligence right on the valve actuator,” said PeterCooper, Manager of Sustainable Engineering and Utility Planning at MIT, Hayden Library. “You can characterize a coil’s performance with just a couple of pieces of data and with that information you can observe the degradation of coils and refocus your maintenanceefforts accordingly.”Belimo Energy Valve™ Cures Medical University’s Low Delta T!“The University started seeing a 10-degree Delta T,” said Scott Czubkowski, PE, Director of Engineering at Kerney Associates. “It went from a 7-degree to a 10-degree Delta T within a day.” But that was not all. Kerney and Associates found that within one hour, the system went from using600 gallons of water to 100 gallons per minute.Red Wing School District will Achieve Payback in Under Two Years.“Savings are always difficult to quantify for new buildings; however, at River Bluff, we are pumping approximately 50% less water than that of a similar sized building in our district,” Kevin Johnson, Director of Building and Grounds and Technology Director, Red Wing School District said. “This equates to substantial pump cost savings over the long-term and represents an improvement overtraditional valves, which often deliver far more GPM than needed to maintain temperature setpoints.”Belimo Energy Valve Retrofit at Tennessee State Office Building Reduces District Energy Chilled Water Usage by 49%“As a result of the retrofit project, we were able to reduce chilled water pumping by 49%, which equated to about $23,000 in annual savings”, said Chad Lovell. “The total cost of the project, including installation, was $53,474. A simple financial calculation produced a payback in about 2.4 years. The installation of Energy Valves inCitizens Plaza, Rachel Jackson, and the Andrew Jackson building was a major success. The results exceeded myexpectations. We now have savings that we can see.”P F _35 – 04/2023 – S u b j e c t t o t e c h n i c a l m o d i fi c a t i o n s12All inclusiveAt Belimo, we continually invest in new technologies that increase customer value by improving occupant comfort, energy efficiency,simplified installation, and maintenance-free operation. Our sales team is available to consult and provide insight and advice on how to achieve the best solution to help increase your system performance.Belimo will continue to focus on providing you with exceptional product availability, fast delivery times, and world-class customer service and technical support. We remain dedicated to continuously improve our standards and are committed to providing you the highest value possible.Whatever your HVAC application, our global network of support experts are on hand and ready to assist.5-year guaranteeComplete product range Short delivery timeOn site around the globeTested qualityComprehensive supportBelimo AmericasUSA, Latin America, and the Caribbean: Canada: www.belimo.ca, Brazil: .brBelimo Worldwide: Energy Valve and Thermal Energy Meter。

户用热量表的选型建议随着现代家庭对于舒适生活需求的不断提高,人们对于室内温度的控制越来越精细。

因此,一款好的户用热量表对于家庭来说非常重要。

但是,众多的品牌和型号会让消费者在选购时感到困惑。

本文将为大家介绍一些选购户用热量表的建议,帮助大家更好地选购。

一、了解户用热量表的种类户用热量表的种类可以按照测量原理分为多种类型,其中比较常见的有机械式和电子式两种。

机械式热量表是利用热力学原理,通过传导热量来测量流体的热量值;而电子式热量表则是通过传感器来检测流体的热量值,并通过电路计算得出热量值。

二、选择可靠的品牌在购买户用热量表时,我们首先需要选择知名品牌的产品。

一般来说,知名品牌的产品在生产工艺和材料方面都会更为精细,能够提供更为精准的测量数据,并且质量更加可靠。

如果是一些小厂商的产品,它们的工艺和质量往往无法得到保障,使用起来可能会出现问题。

三、了解使用环境在选择户用热量表时,我们需要根据具体使用环境来选择适合的产品。

一般来说,如果是在室内使用,选择电子式热量表会更为合适;如果是在户外使用,选择机械式热量表会更稳定。

同时,我们还需考虑安装方式、使用条件和维修保养等因素,以确保这款产品能够长期稳定运行。

四、保证测量准确性在选择产品时,我们还需注意该热量表的测量准确性。

一般来说,一个好的户用热量表的准确度应该在±2%以内。

如果误差太大,可能导致家庭内的温度不稳定,从而影响家庭居住的舒适性。

此外,我们还需要注意热量表的测量范围、分辨率和测量时间等因素。

五、选择合适的功能在购买户用热量表时,我们还需选择适合自己需求的功能。

一般来说,一款好的户用热量表应该具备以下功能:•数据存储功能:能够记录并保存测量结果,便于日后查看;•自动校准功能:能够自动校准,确保测量的数据准确无误;•低功耗设计:应该采用低功耗设计,以延长产品的使用寿命;•显示屏幕:应该具备经验丰富的显示屏幕,可在冷暖环境下正常使用。

六、结论在选购户用热量表时,我们需要选择可靠的品牌,了解使用环境,保证测量准确性,选择合适的功能。

热量表型式评价大纲引言本大纲等效采用欧洲标准EN1434.4-2007 型式试验热量表和国际建议OIMLR75.1-2002 通用要求热量表。

1 范围本大纲适用于以水为介质的口径不大于200mm的热量表的型式评价。

2 引用文献本大纲引用下列文献JJF 1015-2002 计量器具型式评价和型式批准通用规范JJF 1016-2009 计量器具型式评价大纲编写导则GB/T 778.3-2007 封闭满管道中水流量的测量饮用冷水水表和热水水表第3部分:试验方法和试验设备GB/T 2423.1-2008 电工电子产品环境试验第2部分:试验方法试验A:低温GB/T 2423.2-2008 电工电子产品环境试验第2部分:试验方法试验B:高温GB/T 2423.4-2008 电工电子产品环境试验第2部分:试验方法试验Db:交变湿热GB/T 17626.2-2006 电磁兼容试验和测量技术静电放电抗扰度试验GB/T 17626.3-2006 电磁兼容试验和测量技术射频电磁场辐射抗扰度试验GB/T 17626.4-2008 电磁兼容试验和测量技术电快速瞬变脉冲群抗扰度试验GB/T 17626.5-2008 电磁兼容试验和测量技术浪涌(冲击)抗扰度试验GB/T 17626.11-2008 电磁兼容试验和测量技术电压暂降、短时中断和电压变化的抗扰度试验JJG 162-2009 冷水水表JJG 225 热量表OIML R75.1-2002 《Heat meters Part 1: General requirements》(热量表第1部分:通用要求)EN 1434.1-2007 《Heat meters Part 1: General requirements》(热量表第1部分:通用要求)EN 1434.4-2007 《Heat meters Part 4: Pattern approval tests》(热量表第4部分:型式试验)EN 13757-2004 Communication systems for and remote reading of meters(仪表通讯系统和远程读数)IEC 60751:2008Industrail platinum resistance thermometer and platinium temperaturesensors (工业铂电阻温度计和铂电阻传感器)上述文件中的条款通过本大纲的引用而成为本大纲的条款。

MEPS认证译文SECTION 2 CALCULATIONS FOR THE ENERGY LABLE定义(a)rated power(input)额定功率(输入)(b)Rated capacity(output)额定冷量(输出)(c)Energy efficiency ratio for Cooling (EER) 制冷能效比EER(d)Coefficient of Performance (COP) for heating 制热能效比COP(e)Annual Energy Efficiency Ratio (AEER) for cooling 制冷全年能效比AEER(f)Annual Coefficient of Performance (ACOP) for heating 制热能效比COP ACOP(g)Star Rating Index (SRI)(h)Star Rating(i)Some of the requirements for energy label validity(j)The performance criteria for energy label validity(k)Test report format(l)Printing requirements for air conditioner appliance energy labels(m)Minimum requirements for air conditioner appliance energy labels.(n)Power quality (power factor)第二节能效标签的计算2.1 该节的范围该部分列出了计算容量输出,输入功率,SRI 值,以及星级评定的公式和过程,这些都会在能效标签上体现。

该部分适用所有在AS/NZS3823.1.1 范围里的单相无风管的电器,以及三相电器,有风管的电器,以及供应商选择注册能效标签的多分体电器。

BULLETIN TH-1Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281 • Fax: 203-385-0408email:*****************•All specifications are subject to change without notice. All sales subject to standard terms and conditions. © Ashcroft Inc. 2012 09/12 BULLETIN TH-1Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA Tel: 203-378-8281 • Fax: 203-385-0408email:*****************•All specifications are subject to change without notice. All sales subject to standard terms and conditions. © Ashcroft Inc. 2012 09/12 Eight Steps to Thermowell SelectionHow to Order TYPICAL CODE – 75W0750HT260CNote 1 – Examplesa. 3⁄4˝ NPT – 304 – .260˝ Bore – U – 71⁄2˝ – T apered 75W0750HT260Cb. Same as “a.” except Lagging (Standard Length)75W0750LHT260Cc. Same as “b.” except Special Lagging = 31⁄2˝75W0750LHT260CL0350d. Same as “a.” except Tip Diameter (E) = .500˝75W0750LHT260CXDQE500e. 11⁄2˝ – 300# Raised Face Flange – 316 – U = 101⁄2˝.385˝ Bore – Straight – with Stainless Steel Cap & Chain,Standard Lagging Extension 15W1050LSF385S2R300Note 2 –For Special (Non-Standard) Lagging – enter L _ _ _where _ _ _=Lagging Length in Inches x 100Example – 31⁄2˝ x 100 = L0350Note 3 –For Special Diameters – Enter XDQ and write Identity and Value of Special Diameter below Code, such as “E = .500˝”Note 4 –Other “X” variations will be assigned for special designs Note 5 –If “U” dimension is < 3˝ standard lag = 2˝If “U” dimension is > 3˝ standard lag = 3˝ᕡᕢᕣᕤᕥᕦᕧA thermowell is highly recommended for use with temperature indicating and control instrumentation to isolate the temperature sensor from the media being measured. A thermowell performs an invaluable triple-duty service;• Protects delicate instrument sens-ing elements against corrosive effects and resulting physicaldamage caused by media flow.• Permits instrument interchange or calibration check without disturb-ing or closing down the process.• Helps to contain costly or danger-ous process fluids when properly installed as an integral part of the vessel or piping.Visit for more information. Or call us direct at 800-328-8258 and let one of our experts help you specify the right thermowell for your application.Eight Steps to Thermowell SelectionPROCESS CONNECTION SIZEis the size of the portion of the thermowell that connects with the vessel or pipe. This can be in the form of a thread size, flange size, pipe size, tri-clamp, etc.INSERTION LENGTHis commonly called the “U” dimension, this is that portion of the shank from the process connection (underside of the threads) to the tip of the shank which is inserted into the process area. For the most accurate reading it is recommended that the entire sensitive portion of the bulb be immersed in the media.LAGGING EXTENSION & INSTALLATION WRENCH FLATSis shown as “T” on engineering drawings when applicable. This is used when the vessel or pipe into which the thermowell is inserted is insulated. This is the extra length between the process connection and the instrument connection of a thermo-well, which is determined by the insulation thickness. The standard lagging extension is 3˝ (except for thermowells with a 2½˝ “U” the T will be 2˝). Non standard extensions can be supplied although, we suggest 3˝ increments to provide the proper insertion to match standard instrument stem lengths.SHANK CONFIGURATIONis the shape of that portion of a thermowell that is inserted into the process. The tapered shank is recommended as opposed to a stepped or straight shank due to the superior strength and vibration resistance.PROCESS CONNECTION TYPEis the portion of the thermowell which provides the connection with the vessel or pipe. These connections can be integral male threads, prepared surfaces for welding or brazing, flanges for mechanical pressure seals, etc.BOREis the inside cylindrical diameter of a thermowell which is sized to accommodate the stem or bulb of thermal instruments. This dimension can be critical as the toler-ance should provide easy installation of the instrument, but a snug fit to minimize thermal la g. Standard bore diameter is .260˝ or .385˝.MATERIALselection is commonly based on corrosion resistance and strength. Selection should be compatible with process media, temperature and velocity as well as the material of the vessel or pipe to which it will be installed.INSTRUMENT INSERTION LENGTHis commonly called the “S” dimension, is actually a thermometer specification and not a thermowell specification. This is often given in thermowell catalogs for convenience.It is the length from the top of the mounting threads of a thermometer to the end of its stem.INTRODUCTIONAshcroft ®thermowells are available for light duty applications, high pressures, high temperatures, or high velocity applications; as well as meeting many general service industry needs. Selected on the basis of pressure, temperature, flow, vibration and corrosion parameters, basic thermowell types include: threaded, socket weld, weld in,flanged, sanitary and van stone. The threaded type is generally the least costly and most versatile. Also available are custom thermowells for unique applications. Proper thermowell selection is critical to most applications. T o configure an Ashcroft ®thermowell part number follow the eight steps.ᕡᕢᕣᕤᕥᕦᕧᕨTypical “S” dimensions for threaded wellsWITHOUT STANDARD LAG LAG“U”“S”“T”“S”21⁄242641⁄263971⁄29312101⁄212315131⁄215318161⁄218——191⁄2—324221⁄224——SPECIAL LAG EXAMPLES:21⁄245941⁄26915Raised Face Ring JointFlat Face THREADED WELLSTapered shankshave a smaller diameter tip than the base of the well providing greater stiffness and quicker response time than a straight well.The tapered shank is recommended due to its superior strength and vibration resistance.Stepped shankshave a significantly reduced tip diameter improving heat transfer to the sensing ele-ment. It makes the sensor more responsive to the changes in the process temperature.Straight shanksare the original design shank style for a protection tube or thermowell. This style would be the considered in a low pressure,low velocity application.FLANGED WELLSFlat face flangesare typically used when the mating flange is made from a casting. Flat face flanges should not be mated with a raised face flange.Raised face flangesare most commonly found in process plant applications. The raised face has a texture to grip the gasket that is placed between the two flanges.Ring Joint flangesare used in high pressure and/or high temperature applications. This flange has a groove that accepts a metal ring gasket which once the bolts are tightened provides a metal to metal seal.Sizing a THREADED Ashcroft thermowell with an Ashcroft bimetallic thermometer.Example without a lagging extension:Requirement is for 4 ½ inch immersion into the process media. This would be the “U” dimension.Add the U dimension to the 1.75 inch dimension for the wrench flats and process connection. This will equal the OAL (overall length). The stem length of the thermometer will be a ¼ inch shorter than the thermowell OAL.“U” 4.50 + “Threads & wrench flats” 1.75 = OAL 6.25. Stem length for bimetal thermometer = 6 inches Example with a lagging extension:Requirement is for 4 ½ inch immersion into the process media and 6” lagging extension.Add the U dimension to the lag plus the 1.75 inch wrench flats and process connection. 4.50 (U) + 6.00 (T) + 1.75 = 12.25 (OAL)Bimetal thermometer stem length would equal 12 inchesSizing a FLANGED Ashcroft thermowell with an Ashcroft bimetallic thermometer.Example requirement is for a 7 inch immersion into the process media.This would be the “U” dimension.Add the U dimension to the 2.25 inch flange/installation dimension.This will equal the OAL (overall length).Stem length = OAL - .25“U” 7 + “Flange/installation dim.” 2.25 = OAL 9.25. Stem length for bimetal thermometer = 9 inches Note:Flange size, flange rating and flange face type are mandatory for proper design and installation.Standard flange sizes are 1˝, 11⁄2˝ and 2˝ with standard ratings of 150#, 300#, 600# and special ratings of 900#, 1500# and 2500#.Face types consist of raised, flat and ring joint.Without these 3 pieces of information you cannot properly select a flanged thermowell.。

供热计量经验谈一、关于贝娜塔公司丹麦贝娜塔公司是最早加入丹麦供热协会的成员之一,也是丹麦供热协会中国分会的十个成员之一。

公司创立于1939年,总部设在丹麦首都哥本哈根,在从事热能控制、分配仪器仪表的生产与开发的同时为热量及水量消耗的独立收费提供完整的配套服务,在热能领域已有90余年的丰富经验。

我们可向客户提供:专业的计量方案设计先进的配套计量产品完整的计费账单服务在贝娜塔公司众多产品中,RMK 87毛细管型®蒸发式热分配表和FUTURA电子式热分配表是公司的拳头产品,也是同类产品中的佼佼者。

RMK 87毛细管型®蒸发式热分配表是唯一适用于低温系统(T min=52.5℃)的蒸发式热分配表,独特的毛细管型蒸发管灵敏度极高,对于精确地测量热能消耗起到决定性作用。

管内液体无毒无味不溢流,对人体无害。

与传统的热分配表不同,RMK 87毛细管型®蒸发式热分配表既可垂直安装也可水平安装,提高了热分配表对不同散热器安装的适应性。

Futura电子式热分配表同时适用于高温系统和低温系统,两个传感器同时测量,准确记录用户的实际用热量。

可更换的锂电池,最大程度上延长了热分配表的使用寿命。

同时Futura电子式热分配表可以安装无线传输模块,真正实现远程读表。

功能强大,操作灵活的WinBill计费软件则是贝娜塔公司的另一杰作。

Winbill计费软件在能源计量以及账单服务领域表现出众,并且全部汉化,专为中国市场设计。

贝娜塔公司在向客户提供最优质产品的同时,还具备一整套完善的服务体系。

一条龙式的服务也是公司的优势之一。

专业的工程师会定期上门服务,负责装表、读表、抄表、录入数据,每年更换一次玻璃管;在每一个采暖季后,全中文的热费账单送至客户手中。

专业的技术人员则与当地设计院的专家、业内人士密切合作,针对新旧住宅不同的采暖系统制定不同的切实可行的热计量实施方案,力求做到先期投资少、维护费用低、计算科学合理。

Kamstrup热能表通信模块设计与开发

薛昊

【期刊名称】《科技广场》

【年(卷),期】2007(000)005

【摘要】本文主要介绍RS-485、RS-232接口.系统建立上位机与多片单片机通讯的主从式网络,并且定义报文内容,规定帧内容.

【总页数】3页(P200-202)

【作者】薛昊

【作者单位】天津工业大学,天津,300160

【正文语种】中文

【中图分类】TP273

【相关文献】

1.无线式智能热能表的设计 [J], 周旭;郭栋;王浩;刘吉行;刘炳初

2.电动汽车直流费控表中CAN通信模块的设计与实现 [J], 段延喜;朱青;刘宏立

3.基于EPON智能电能表光通信模块的设计与实现 [J], 廖晓群;薛秀娥

4.基于银泉大功率无线通信模块的电能表设计 [J], 王若鲁;万年旺;熊剑;陈飞

5.智能热能表及温控一体化系统设计 [J], 张庆鑫;陈志军;闫学勤

因版权原因,仅展示原文概要,查看原文内容请购买。