英文版挖掘机使用说明书

- 格式:docx

- 大小:36.87 KB

- 文档页数:2

OWNER’S MANUALSUPER KODIAKMODEL # KP-2INTRODUCTIONOPERATIONSAFETYSERVICEWARRANTYCONTACTSPECIFICATIONSTROUBLESHOOTING PLEASE READ AND SAVE THESEINSTRUCTIONSINTRODUCTION TO B-AIR KP-2YOUR NEW KODIAK B-AIR #KP-2 BLOWER HAS A 2 HP HIGH EFFICIENCY MOTOR, WHICH HAS STATE OF THE ART CONSTRUCTION AND SCREENS ON OPEN VENTS FOR SAFETY AND LONG LIFE. THE HANDLE IS DESIGNED FOR EASY CARRYING. UNITS ARE ALSO STACKABLE FOR SPACE EFFICIENCY. OPERATION/USEFOR COMMERCIAL APPLICATIONS ONLYNOT INTENDED FOR HOME USETHIS HIGH PRESSURE AIR VOLUME UNIT IS INTENDED TO INFLATE LARGE COMMERCIAL INFLATABLE PLAY STRUCTURES.A)CAREFULLY PLACE THE B-AIR UNIT ON STABLE FLAT DRY SURFACE-KEEPING CHILDREN AWAY.B)ATTACH AN INFLATABLE TUBE AROUND THE EXHAUST OPENINGUSING STRAPS OR ANY OTHER FORM OF TIGHTENER.C)PLUG CORD INTO A GROUNDED GFCI OUTLET ONLY.D)TURN ON SWITCH AND MAKE SURE IT IS OPERATING CORRECTLY.E)ALL BLOWERS IN OPERATION MUST BE SUPERVISED AT ALL TIMES. STORAGESTORE UNIT INDOORS IN A CLEAN DRY ENVIRONMENT TO ENSURE LONG LIFEWARNINGALL BLOWERS IN OPERATION MUST BE SUPERVISED AND ATTENDED AT ALL TIMES.THE USE OF A 3-PRONG TO 2-PRONG ADAPTER IS PROHIBITED.ONLY USE A 2-PRONG TO 2-PRONG ADAPTER.IF THE POWER SUPPLY CORD IS DAMAGED, IT MUST BE REPLACED BY THE MANUFACTURER, ITS SERVICE AGENT OR SIMILARLY QUALIFIED PERSONS IN ORDER TO AVOID A HAZARD.SAFETY1)BLOWER MUST HAVE BACK PRESSURE, MEANING IT MUST BEATTACHED TO AN INFLATABLE OR DUCT TO AVOID ANY DAMAGETO MOTOR.2)KEEP CHILDREN AWAY FROM UNIT AT ALL TIMES WHILE INOPERATION AND/OR PLUGGED IN.3)DO NOT PUT FINGERS OR OTHER OBJECTS IN UNIT WHILE INOPERATION AND/OR PLUGGED IN.4)DO NOT OPERATE IN POOLED WATER TO AVOID ELECTRIC SHOCK.5)UNIT MUST BE KEPT DRY AT ALL TIMES, INCLUDING MOTOR,WIRING AND EXTERIOR. IF UNIT BECOMES WET, THOROUGHLYDRY BEFORE NEXT OPERATION.6)INDOOR USE: USE ONLY WITH A GROUNDED PLUG AND/OREXTENSION CORD TO AVOID RISK OF ELECTRICAL SHOCK ORFIRE. REMEMBER NEVER TO USE A CORD WITH ANY KIND OFDAMAGE OR WEAR.7)MAKE SURE THE POWER SOURCE IS SUFFICIENT TO MEET THEREQUIREMENTS OF THE BLOWER.8)KEEP AIR INTAKES CLEAR AT ALL TIMES TO AVOID CLOGGING ORBLOCKING IN ORDER TO PREVENT OVERHEATING THE UNIT.BLOCKING THE AIR INTAKES COULD RESULT IN A FIRE ORELECTRICAL HAZARDS. AN OPTIONAL “MESH FILTER SYSTEM” TOMINIMIZE LINT BUILD-UP IN INDOOR FACILITIES IS ALSOAVAILABLE.9)DO NOT REMOVE ANY SCREENS OR SAFETY GUARDS FROM THISUNIT TO PREVENT INJURY TO PERSONS, AND TO AVOID OBJECTSFROM COMING IN CONTACT WITH THE BLOWER WHEEL. UNITDAMAGE IN THIS MANNER WILL VOID YOUR WARRANTY.10)DO NOT OPERATE UNIT CLOSE TO ANY DANGEROUS AREAS, SUCHAS EXPLOSIVE GASES, FLAMMABLES, HEATERS ANDUNVENTILATED ENVIRONMENTS, WHICH MAY RESULT INEXPLOSIONS OR ELECTRICAL HAZARDS.11)DO NOT USE ANY FORM OF SPEED CONTROL DEVICE AS DOING SOMAY RISK INJURY OR FIRE.12)ALWAYS PLACE BLOWER ON A SMOOTH AND LEVELED SURFACEFOR SAFE OPERATION.13)DO NOT OPERATE IN STACKED POSITION.14)DO NOT USE UNIT IF DAMAGED.15)BEFORE CLEANING OR SERVICING UNPLUG UNIT.16)ALL BLOWERS IN OPERATION MUST BE SUPERVISED AT ALL TIMES.17)DO NOT EXPOSE TO RAIN, WATER OR SNOW.18)OUTDOOR USE: UNIT MUST BE CONNECTED TO A G.F.C.I (GROUNDFAULT CIRCUIT INTERRUPTER) PROTECTED RECEPTACLE.WARRANTY1 YEAR:B-AIR WILL COVER ALL PARTS (EXCEPT POWER CORD).WHITHIN ONE YEAR OF PURCHASE B-AIR WILL PAY REPAIR COSTS AND ONE WAY UPS GROUND SERVICE SHIPPING TO YOUR LOCATION WHITHIN THE 48 CONTIGUOUS STATES. PROOF OF PURCHASE IS REQUIRED.CUSTOMER IS RESPONSIBLE FOR SHIPMENT OF DAMAGED UNIT TO B-AIR WAREHOUSE FOR REPAIR.CANADA AND NON-CONTIGUOUS STATES MUST PAY FREIGHT BOTH WAYS.5-YEAR:B-AIR WILL COVER HOUSING FROM DATE OF ORIGINAL PURCHASE. PROOF OF PURCHASE IS REQUIRED.SERVICEIN ORDER TO RECEIVE SERVICE OR REPLACEMENT PARTS UNDER WARRANTY, YOU MUST:A) CALL FOR A RMA# (Return Merchandise Authorization Number)B) HAVE PROOF OF PURCHASEC) SHIP TO B-AIR BLOWER•IF IMMEDIATE SERVICE IS REQUIRED, B-AIR WILL SHIP A REFURBISHED BLOWER IMMEDIATELY TO REPLACE THEONE REQUIRING SERVICE PROVIDED A VALID CREDIT CARDIS PROVIDED AND CHARGED. ONCE WE RECEIVE YOURBLOWER, WE WILL CREDIT YOUR CREDIT CARD ACCOUNT.•WE WILL GLADLY REPAIR YOUR BLOWER AND SHIP WITHIN24 HOURS.UPON INSPECTION, WE WILL ADVISE YOU OF THE REPAIRS NEEDED AND THE COST (IF APPLICABLE).B-AIR WILL ISSUE REPAIR OR REPLACEMENT PARTS DEPENDING ON WARRANTY.CORDS1)DO NOT USE EXTENSION CORDS FOR OUTSIDE USE.2)USE 3 PRONG ADAPTORS THAT ARE UL AND CE APPROVED AND NOTLESS THAN 12-3 WITH GROUND FAULT CIRCUIT INTERRUPTER(GFCI).3)DO NOT USE CORDS THAT SHOW ANY KIND OR WEAR OR DAMAGE.4)CORDS ARE NOT COVERED BY WARRANTY.B-AIR BLOWERS LIMITED WARRANTYCOVERS1)B-AIR BLOWERS ARE COVERED AGAINST DEFECTS IN MATERIALAND CRAFTSMANSHIP USED UNDER NORMAL INTENDED USE TOORIGINAL PURCHASER FOR A TERM OF (1) ONE-YEAR FROM THEORIGINAL DATE OF PURCHASE.2)B-AIR BLOWERS HOUSING IS COVERED FOR A TERM OF (5) FIVEFULL YEARS FROM THE DATE OF THE ORIGINAL PURCHASE. DOES NOT COVER1)ANY SIGNS OF MISUSE INCLUDING; BUT NOT LIMITED TO ROUGHHANDLING, ABUSE, TAMPERING, IMPROPER VOLTAGE USE,UNAUTHORIZED MAINTENANCE AND REPAIRS.CONTACTINTERTEX, INC. / B-AIR BLOWERS1851 TYBURN STREETGLENDALE, CA 912041-877-800-2247 (BAIR)FAX: (818) 242-2430EMAIL:**************WEB SITE: SPECIFICATIONSMODEL# KP-2VOLTS 115 V 230 VCYCLE 60 Hz 50 HzMAX AIR VOLUME 1520 CFM 1480 CFMAMPS 14 A 10 AMAX STATIC PRESSURE 10.8 INCH 8.6 INCHWEIGHT NET/SHIP 46/50 LBS 46/50 LBSUNIT SIZE (L x W x H) 19”x 18”x 18.5” 19”x 18”x 18.5”WHEEL SPEED (RPM) 3460 2850MOTOR 2 HP 2 HPATTACHED CORD 25 FT / 12AWG 25 FT / 1.5MM2TROUBLESHOOTINGPROBLEM POSSIBLE CAUSE SOLUTIONMotor Not Running a) Switch is OFF a) Turn Switch ONb) Bad Outlet b) Check Outlet/ Change toAnother Outletc) Faulty Switch/Cord c) Call Factory for newSwitch/Replace Cord Scraping Noise From Blower a) Wheel Out Of Line a) Call Factory forReplacement Advise Weak Air Flow a) Obstructed Vents/Inlets a) Clean Out Vents/Inlets。

Mini digger SpringerMAX-PROINSTRUCTIONContact:P.H.U. ELGO-PLUSul. Przemysłowa 187-880 Brześć Kujawski POLANDTel.: +48 602 841 094www.elgoplus.ple-mail: *******************1.INTRODUCTIONThis instruction contains basic informations of usage and terms of use mini digger SpringerMAX-PRO. Proper maintenance and the correct way to use the machine condition the safe and reliable operation. The procedures described in this manual are the optimal methods of working with the machine and perform maintenance. In order to reduce the likelihood of an accident and prevention of incidents as a result of which the machine could be damaged or cause to make it dangerous to be thoroughly familiar with the content of warnings and comments given in the instructions for the machinery.Operators should carefully read all of this manual and observe all its recommendations.Failure to follow these recommendations could be the basis for the withdrawal of the manufacturer's warranty for the product.This manual must be readily available and always kept near the mini digger!ELGO-PLUS reserves the right to change specifications, construction, instruction, and extension or modernization of the product without prior notice. ELGO-PLUS Company is not obligated to make such changes to previously manufactured machines.Description of signs used in instruction:2.MACHINE FEATURES2.1.General descriptionThe machine is designed for earthworks carried out in normal daylight conditions. If the machine is to be used for other purposes or have to work in a potentially hazardous environment, then follow the special safety regulations, and the machine itself should be equipped according to the working conditions. For further information, please contact the manufacturer.KJPIC.2.1 General construction2.2.Technical dataPIC.2.MACHINES DIMENSIONS2.4.Removable equipmentPIC. 2.3 NAME PLATE3.SAFETY INSTRUCTIONSThe mini diggers user duties are knowledge of and compliance with applicable laws, therefore, included safety instructions are only recommendations.•The operator must be healthy and be at least 18 years of age.•Mini digger must be maintained in good condition.•Inspection and repairs can be carried out only after the machine is turned off•It is forbidden to make unauthorized modifications to the machine without the manufacturer's consent•It is forbidden to work the machine in explosive atmospheres and confined spaces without adequate ventilation•Mini digger is not intended for public roads, it can only moves beyond them.•It is forbidden to smoking and approaching other sources of ignition while refueling.•The operator should exercise extreme caution when working, all people nearby mini digger should still be within his sight.•Do not fill fuel other than what is recommended for the engine. Detailed recommendations are contained in the engine manual.•Mini digger can be operated at the appropriate level of engine and hydraulic oil.•Mini digger is designed to work in the daytime, in the case of work in conditions of limited visibility, it should be provided appropriate lighting equipment to the work area on Your own.•It is forbidden to use the machine in clothing unsuitable for this or another that can cause danger (eg. long dangling pieces of clothing).•It is forbidden to use the machine if the operator contamination with substances such as oil, grease, etc. that may cause a slip hazard.•The contents of this chapter contains instructions and precautions that must be followed to ensure proper and safe operation and maintenance.These rules do not exempt the operator from the obligation to comply with the law or other applicable rules regarding safety and health.Users dutiesThe user is obliged to pay attention to the specific requirements and hazards during work as well as personal safety. This is necessary to prevent serious injury or damage, and even deaths Responsibility for otherIt should work with the machine so as to avoid the risk of accidents and injuries. You have the right and obligation to prevent this. No one is allowed to enter the working area of the machine during its operation without prior notice to the operator. If someone must enter into the working area of the machine to perform a specific job, that person must exercise extreme caution and without the need not to move from the back of the machine or remain in a dangerous areaIf someone is in the area of machine operation the operator must keep extra care. The operator can operate the machine only when you see this person, or if this person comprehensible signals to the operator, where it is locatedDamagesUser duty is to report any damage or wear that could affect safety. During the inspection, maintenance and repairs, on-site operator allowed to stay only person with the required knowledge of operating the machine and knowledge of controls.Safety information when using and operating the batteryWhile use battery, observe the safety instructions and relevant national regulations. Before carrying out any battery operation (including battery charging and starter battery use), you should familiarize yourself with safe methods for working with batteries with an electrolyte.Description of the marks on the machine4.STEERING ELEMENTSPIC.4.1 STEERING ELEMENTSLeft track steering ( A, Pic.4.1)1N2Right track steering ( B, Rys.4.1)1N2Moving forwardPush forward both steering levers (A and B, Pic.4.1), machine will go forward.Moving backwardPull back both steering levers (A and B, Pic.4.1), machine will go backward.Turning leftPush forward the right steering lever (B, Pic.4.1), the right track starts to move forward, the machine will go forward turning left.Or:Pull back left steering lever (A, Pic.4.1) the left track starts to move backward, the machine will go back turning to the left.Turning rightPush forward the left steering lever (A, Pic.4.1), the left track starts to move forward, the machine will go forward turning right. Or :Pull back right steering lever (B, Pic.4.1) the right track starts to move backwards, the machine will go back turning to the right.Support position steering ( C, Pic.4.1)Arm position steering ( D, Pic.4.1)NN 12341 2Jib position steering ( E, Pic.4.1)Hydraulic hammer starting ( F, PIC.4.1)5. USAGE5.1. Before workingN 2341N 1- Before starting the mini digger familiar with the contents of this manual.- Defects and damages that affect safety must be removed before use.- Do not operate the machine while under the influence of alcohol, drugs or other intoxicants. - Dress in appropriate clothing that allows for safe operation.- To increase the safety of the head is recommended to use a protective helmet.- Adjust the seat.- Do not overload the machine. Overloading adversely affect safety.- Before starting the mini see if there is someone in her immediate vicinity.- Check for leaks.- Check for damaged or loose parts that could cause damage.- Check if there is fuel in the tank.- Check the hydraulic oil tank.- Check engine oil level.- Before driving check that the machine is not near other people.- When it is very cold do not direct the machine to work hard after starting.- Check battery mounting.- Check the battery cables mounting.- Check the fuel tank for leaks or cracks.5.2Starting and shutting down the machineMini digger can be started by pulling a starting rope or by a starter with key located next to the engine.Before starting, unlock the fuel / ignition lever and unlock key.To turn off the machine lock the ignition key.RYS.5.1 ENGINEBAPIC.5.2 KEY STARTER5.2.DrivingWhen driving on flat ground, set back attachments and lift it off the ground to avoid knocked out of the terrain elements.When driving on uneven terrain shoul d move the machine so as not tilted to one side more than 10⁰. Riding uphillIf the tracks are sliding on the slope, push the bucket into the ground and pull the arm backwards to facilitate the uphill drive.Riding downhillIn case of downhill riding, drive the mini digger as slow as possible.5.3.StoppingTo park the machine choose flat terrain1. Set steering levers in neutral position2. Lower the bucket to the ground, keeping the bottom of the bucket parallel to the ground5.4.ParkingPay attention to weather conditions and take necessary steps to ensure that the machine is not frozen to the ground, plunged into it, or suffered other consequences.Long-term parkingFollow the instructions for parking and in addition:-check the machine for leaks and if there is no damage to the working system and tracks.-remove form the track accumulated soil-recure the machine against the corrosion and thoroughly lubricate-fill the fuel tank and oil to the maximum-shut off the fuel supply to the engine, according to the recommendations in the engine manual5.5.Bucket workingMini digger is a multi-purpose machine that can be equipped with a variety of specialized work equipment in order to perform many types of work. Below are described some operations5.5.1.Digging ditchesInstall a appropriate bucket for this kind of work. To work effectively set tracks in accordance with the direction of the ditch.In the case of a broad ditches first dig on both sides of the trench, and then select the material from the central area..5.5.2.Loading worksIn order to increase the effectiveness of the trolley set it in order to obtain a small angle of the mini diggers arm and good visibility for the operator.5.6.TransportWhile transporting the machine, follow the existing rules on weight, width, height, length and anchoring loads.Remove grease, oil, mud, ice, etc., from ramps or platform surface to prevent slipping off the machine.5.7.Loading1. Turn on brakes of transporting vehicle2. Put blocks under the wheels of transporting vehicle3. Secure the ramps- check the strength, width, length and thickness of the plank ramps is sufficiently safe for loading, - pay attention to the angle of ramps was 15 ⁰ or less.4. Check that the left and right ramp are the same height.5. Ride slowly to the ramps.6. Load the machine on a vehicle properly and ensure its secured7. Turn off the engine.8. After loading, put blocks under tracks and attached machine using transport belts5.8.Equipment changing1. Place the machine on a flat, sturdy and level ground.2. Lower the light fixture to touch the ground.3. Stop the engine.4. Remove the bolts securing the mounting equipment to the jib and the jib cylinder.5. Remove the bolts and remove the equipment.6. Set the jib that the mounting holes are concentrically positioned fixture with jib holes / arm and the hydraulic cylinder.7.Lubricate the inner surface8. Put pins9. Tighten the screw bolts.B DCARYS.5.2 BUCKET CHANGING5.9.1 FITTING AND OPERATION OF HYDRAULIC HAMMER5.9.1. The hydraulic hammer Atlas Copco SB52 is mounted in place of the bucket (pic.5.9.1)PIC.5.9.15.9.2. To use the hydraulic breaker, connect the hydraulic hoses and connect with quick couplings (PIC 5.9.2 - A,B).ABPIC 5.9.25.9.3 Operation of the hydraulic hammer1. Before start using the hydraulic hammer machine need to run for around 15 minutes to let the hydraulic oil takes the right temperature.2. Hydraulic hummer need to be lubricated before and during using.3. To start working by hammer the tip must be pressed into the breaking material and then hammers is start running by pushing the lever (F, PIC.4.1) to the left.4. Continuous operation of the hammer cannot be longer than 15 seconds, when the material does not want to break, change the place of impact.ALL DETAILED INFORMATION ARE INCLUDED IN HYDRAULIC HAMMER OWNERS MANUAL6.SERVICE6.1.Service positionBefore working by the machine:1. Set the machine on a flat, sturdy and level ground.2. Working system should rest on the ground.3. Allow machine to coolPIC.6.1 POINTS OF LUBRICATION AND OIL REPLENISHMENT6.2.Hydraulic oil replenishmentTake care of proper hydraulic oil level. The tank is located under the driver's seat and has got 24 liters of hydraulic oil.PIC.6.2 HYDRAULIC OIL REPLENISHMENTA BThe hydraulic oil level is checked with a bayonet placed under the oil fill cap6.3.Hydraulic oil changingIt is recommended that the oil and oil filter were changed once a year, assuming that the machine is working 8 hours a day. In justified cases, the exchange should be carried out frequently. The oil filter is located under the oil tank cap B (Pic.6.2).Recommended hydraulic oil is AGIP ARNICA 46 or other with the same parameters (norm ISO L-HV and DIN 51524 t.3 HVLP).6.4.Hydraulic cylinders and pins lubcricationAll points where parts are in move must be properly lubricated. Below there is exepmplary lubrication point, All these points are equipped with grease nipples.APIC.6.4 POINT OF LUBRICATION6.5.Hydraulic pressure controlPIC.6.5 HYDRAULIC PRESSURE CONTROL6.6.Tracks tension regulationIn case of too low tracks tension it is necessary to adjust it by using the adjustment screws on both sides of the mini digger. To tension rubber tracks, first loosen support screws on sides of bracket (A), than regulate the tension by regulation screws (B).BBRYS.6.6 TRACKS TENSION REGULATION6.7.Brass pins changingIn the case of use of the brass pins, replace them with new ones. Knock out the pins out of the nest and embed new.APIC.6.7 BRASS PINS6.8.Hydraulic oli tank valveThe hydraulic oil tank is equipped with shut-off valve. The valve is used when operating the hydraulic pump and preventing oil spills after disconnecting the hydraulic hose.APIC.6.8 TANK VALVE6.9.Battery changingBattery is mounted next to gasoline engine, under the operators seat.The replacement should begin with the disconnection of the black (-) mass lead. Then disconnect the positive (+) cable in red.Loosen the wing screws and remove the retaining plate. After this, you can remove the used battery. Install the new battery in reverse order, paying particular attention to its secure mounting.PIC.6.9 BATTERYAB BCCD6.10.Machine maintenance tableX(1) Empty the tank, when the oil filter is not heavily soiled, you can use it again Mini digger is filled up with hydraulic oil AGIP (ENI) ARNICA 46.To next fill up it is recommended the same oil or other with the same parameters: ISO L-HV and DIN 51524 t.3 HVLP6.11.Pressure throttlingThe pressure in the hydraulic system can be throttled by a throttle valve (at hydraulic distributor).A21PIC.6.9 THROTTLING VALVE7.SPARE PARTSWhen ordering spare parts, always state the information on the name plate of the machine or enter the symbol of the part.WARRANTY CARD1. Warranty for smooth operation of the device is granted for a period of 24 months from the date of purchase for private users and 12 months for companies. Warranty does not cover consumable parts subject to normal use (replace parts).2. The manufacturer provides free repair, in case of under warranty against manufacturing defects.3. The manufacturer provides to resolve the complaint within 30 days from the date of notification.4. The buyer loses all rights guarantees in the event of unauthorized changes in construction or operation contrary to the instructions.5. Any damage caused by improper transportation or storage device, its improper operation, maintenance and other reasons not caused by the manufacturer - can be removed only at the expense of the user.6. If the above mentioned causes have caused permanent changes in the quality unit granted the guarantee expires.7. Machine repairing made during the warranty period by persons not authorized by the manufacturer will void the warranty.8. Warranty does not cover direct and indirect losses caused by defective machine.9. The warranty card is not valid without the date stamp and signature, as well as amendments and deletions made by unauthorized persons.10. In matters not covered by these warranty conditions apply to the Civil Code.11. The buyer pays the transportation cost for the mini digger to and from the service point or cover the travel cost for a service technician to the service point.Mini digger SpringerMAX-PROPurchase date:…………………………………..Serial number:…………………………….Sellers stamp and signature:……………………………….SERVICEDeclaration of conformity WEFor the purposes of the Machinery Directive 2006/42/EC, Annex II, 1.AProducer:PHU ELGO-PLUSPrzemysłowa 1, 87-880 Brześć Kujawski POLANDA person domiciled or resident in the community authorized to compile the technical file: Owner Andrzej ZielińskiThe undersigned hereby declares that the product::TRADE MARK: MINI DIGGER SpringerMAX-PROFUNCTION: MULTIFUNCTIONAL MINI DIGGERTYPE/MODEL: SpringerMAX-PROcomplies with the following European directives:•machinery directive 2006/42/WE of 17.05.2006 (Dz.U. L 157 z 9.06.2006 page 24) and its amendment 2009/127/WE of 21.10.2009 (Dz.U. L 310 z 25.11.2009 page 29).Andrzej ZielińskiOwner。

CAT Electronic Technician Training ET操作菜单详解威斯特中国服务部目录1.工具栏 (2)2.文件菜单 (4)3.显示菜单 (6)4.诊断菜单 (6)5.信息菜单 (9)6.服务菜单 (13)7.实用功能 (15)8.帮助功能 (16)正文1. 工具栏上图为ET未与ECM连接时的状态。

上图为ET已经与ECM连接时的状态。

注:如果您的ET实际显示的工具栏与上图相比,项目较少,可以自己添加工具栏项目。

菜单栏:英文File View Diagnostics Information Service Utilities Help 中文文件显示诊断信息服务实用帮助工具栏:图标英文名称中文名称解释Status Tool 状态工具显示发动机的运行参数Active Diagnostic Codes 现有的故障代码目前存在的故障的代码Logged Diagnostic Codes 记录的历史故障代码过去发生过的故障代码纪录Active Event Codes 现有的事件代码目前存在的、影响发动机运行的事件的代码Logged Event Codes 记录的历史事件代码过去发生过的、影响发动机运行的事件的代码纪录ECM Summary ECM概要ECM本身的简要信息Configuration Tool 设置工具ECM设置参数更改Flash Memory 刷新内存程序刷新ECM内存中的程序Connect 连接使ET与ECM开始通信Disconnect 断开连接断开ET与ECM之间的通信Display help contents 显示帮助内容显示详细的ET使用说明书Exit the application 退出退出ETEnable Trainer 激活培训模式进入培训模式,模拟的连接界面供练习使用Disable Trainer 退出培训模式退出培训模式Print 打印通过打印机输出Print Preview 打印预览打印效果的预览Print to File 打印到文件将需保存的页面保存成文件,供以后或其他人查看2. 文件菜单(1)Open (文件打开功能)对于在现场ET与ECM连接时输出储存的特殊格式文件,在离开现场后可以通过该功能打开查看。

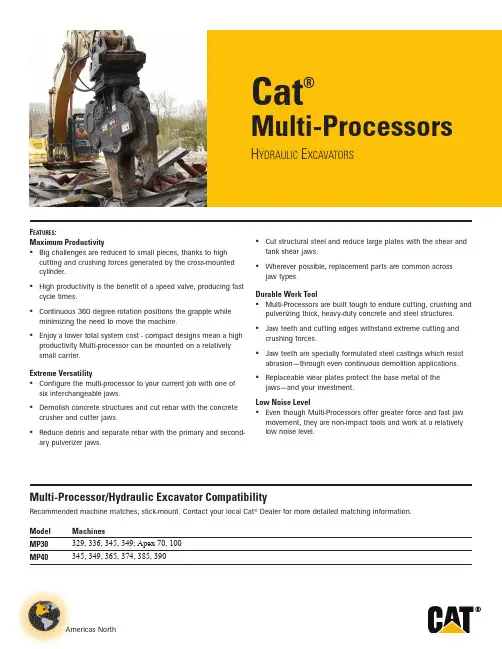

Americas NorthCat®Multi-ProcessorsH ydraulic E xcavatorsF eatures :Maximum ProductivityBig challenges are reduced to small pieces, thanks to high cutting and crushing forces generated by the cross-mounted cylinder. High productivity is the benefit of a speed valve, producing fast cycle times. Continuous 360 degree rotation positions the grapple while minimizing the need to move the machine. Enjoy a lower total system cost - compact designs mean a high productivity Multi-processor can be mounted on a relatively small carrier.Extreme VersatilityConfigure the multi-processor to your current job with one of six interchangeable jaws. Demolish concrete structures and cut rebar with the concrete crusher and cutter jaws. Reduce debris and separate rebar with the primary and second-ary pulverizer jaws.Multi-Processor/Hydraulic Excavator CompatibilityRecommended machine matches, stick-mount. Contact your local Cat ® Dealer for more detailed matching information.Model MachinesMP30329, 336, 345, 349; Apex 70, 100MP40345, 349, 365, 374, 385, 390Cut structural steel and reduce large plates with the shear and tank shear jaws. Wherever possible, replacement parts are common across jaw types.Durable Work ToolMulti-Processors are built tough to endure cutting, crushing and pulverizing thick, heavy-duty concrete and steel structures. Jaw teeth and cutting edges withstand extreme cutting and crushing forces. Jaw teeth are specially formulated steel castings which resist abrasion — through even continuous demolition applications. Replaceable wear plates protect the base metal of the jaws — and your investment.Low Noise LevelEven though Multi-Processors offer greater force and fast jaw movement, they are non-impact tools and work at a relativelylow noise level.Cat Multi-Processors2 Multi-Processors for Hydraulic ExcavatorsMulti-Processor Concrete Cutter (CC) JawConcrete Cutter (CC) jaws demolish heavily reinforced concrete with large diameter, densely pack-aged rebar. In addition, the operator can use the inner "shear" jaw to cut smaller steel structures like pipe and cables.F eatures :Three Replaceable Crusher TeethThe front part of the jaw cracks concrete to expose the rebar.Angled Top Cutting EdgesProfile of the inner jaw compresses steel, forcing it to the rear of the jaw where cutting forces are greatest.Fully Reversible KnivesIt's easy to keep performance at maximum by rotating the knives, each one has four sharp edges.Side CutterThe jaw is kept aligned while cutting and the base metal is protected from wear.Wear PlatesWelded-on plates protect the base metal.Multi-Processor Concrete Cutter (CC) Jaw SpecificationsContact your local Cat Dealer for in-depth specifications including hydraulic requirements, cutting and crushing capacities.MP30MP40Weight (housing, jaw, bracket)kg (lb)3,850 (8,190)6,370 (14,045)Weight (jaw only)kg (lb)1,260 (2,780)2,230 (4,915)A Length mm (in) 2,800 (110.2)3,500 (137.8)B Height mm (in) 1,980 (78.0)2,340 (92.1)Widthmm (in) 1,010 (39.8)1,180 (46.5)Width, Fixed Jaw mm (in) 380 (15.0)460 (18.1)Width, Moving Jaw mm (in) 130 (5.1)160 (6.3)C1Jaw Opening mm (in) 420 (16.5)600 (23.6)C2Jaw Opening mm (in) 540 (21.2)720 (28.3)C3Jaw Openingmm (in) 975 (38.4)1,280 (50.4)D Jaw Depth mm(in)890 (35.0)1,100 (43.3)Cutter Lengthmm (in) 520 (20.5)600 (23.6)Cycle Time (open, close, open)seconds6.57.5Arm Torque*Fully Open kN•m (ft•lb)1,257 (926,978)1,855 (1,368,509)Fully Closed kN•m (ft•lb)759 (559,574)1,081 (796,930)Crushing Force 1At tooth-jaw tip kN (st)1,230 (138)1,470 (165)2At cutter tip kN (st)1,780 (200)2,120 (238)3At primary bladekN(st)4,120(463)4,330(487)* T otal cylinder force × length of lever armCat Multi-ProcessorsMulti-Processors for Hydraulic Excavators 3Multi-Processor Crusher (CR) JawCrusher (CR) jaws reduce moderately reinforced concrete structures and cut rebar.F eatures :Six Replaceable Crusher TeethSix opposed teeth create stress cracks in concrete, shattering it. The teeth are bolt-on for easy replacement.Fully Reversible KnivesIt's easy to keep performance at maximum by rotating the knives, each one has four sharp edges.Wear PlatesWelded-on plates protect the base metal.Multi-Processor Crusher (CR) Jaw SpecificationsContact your local Cat Dealer for in-depth specifications including hydraulic requirements, cutting and crushing capacities.MP30MP40Weight (housing, jaw, bracket) kg (lb) 3,860 (8,510)6,370 (14,045)Weight (jaw only) kg (lb) 1,270 (2,800)2,230 (4,915)A Length mm (in) 2,770 (102.0)3,500 (137.8)B Height mm (in) 1,980 (78.0)2,380 (93.7)Widthmm (in) 1,010 (39.8)1,180 (46.5)Width, Fixed Jaw mm (in) 380 (15.0)460 (18.1)Width, Moving Jaw mm (in) 130 (5.1)160 (6.3)C1Jaw Opening mm (in) 400 (15.7)500 (19.7)C2Jaw Opening mm (in) 770 (30.3)800 (31.5)C3Jaw Openingmm (in) 1,050 (41.3)1,320 (52.0)D Jaw Depth mm(in)920 (36.2)1,100 (43.3)Cutter Lengthmm (in) 260 (10.2)250 (9.8)Cycle Time (open, close, open)seconds6.57.5Crushing Force 1At tooth-jaw tip kN (st)1,230 (138)1,480 (166)2At 2nd tooth kN (st)1,740 (196)2,150 (242)3At primary bladekN(st)3,680(414)4,600(517)321BADC2C1C3Cat Multi-Processors4 Multi-Processors for Hydraulic ExcavatorsMulti-Processor Primary Pulverizer (PP) Jaw:The wide, broad jaw holds ranks of opposed teeth, which shatter concrete, and reduce it.It's easy to keep performance at maximum by rotating the knives, each one has four sharp edges.Welded-on plates protect the base metal.Multi-Processor Primary Pulverizer (PP) Jaw SpecificationsContact your local Cat Dealer for in-depth specifications including hydraulic requirements, cutting and crushing capacities.MP30Weight (housing, jaw, bracket)kg (lb)4,180 (9,215)Weight (jaw only)kg (lb)1,590 (3,505)A Length mm (in)2,800 (110.2)B Height mm (in)1,980 (78.0)Widthmm (in)1,010 (39.8)Width, Fixed Jaw mm (in)610 (24.0)Width, Moving Jaw mm (in)370 (14.6)C1Jaw Opening mm (in)420 (16.5)C2Jaw Opening mm (in)540 (21.3)C3Jaw Openingmm (in)960 (37.8)D Jaw Depth mm(in)940 (37.0)Cutter Lengthmm (in)205 (8.1)Cycle Time (open, close, open)seconds6.5Crushing Force 1At tooth-jaw tip kN (st)1,230 (138)2At 2nd tooth kN (st)1,580 (178)3At primary bladekN(st)3,850(433)Cat Multi-ProcessorsMulti-Processors for Hydraulic Excavators 5Multi-Processor Secondary Pulverizer (PS) JawSecondary Pulverizer (PS) jaws recycle demolished concrete to gravel-sized pieces, fully separating and cleaning rebar. An inner knife sections rebar for easier handling.F eatures :Fixed Lower Jaw with Crusher BarsThe upper jaw compresses concrete against the crusher bars integrated in the lower jaw, grinding it into small pieces.Three Replaceable Crusher TeethT eeth on the upper jaw are offset from the crusher bars in the lower, creating massive stress risers in the concrete.Fully Reversible KnivesIt's easy to keep performance at maximum by rotating the knives, each one has four sharp edges.Multi-Processor Secondary Pulverizer (PS) Jaw SpecificationsContact your local Cat Dealer for in-depth specifications including hydraulic requirements, cutting and crushing capacities.MP30MP40Weight (housing, jaw, bracket)kg (lb)4,080 (8,995)6,730 (14,835)Weight (jaw only)kg (lb)1,490 (3,285)2,590 (5,710)A Length mm (in)2,950 (116.1)3,650 (143.7)B Height mm (in)2,200 (86.6)2,550 (100.4)Widthmm (in)1,010 (39.8)1,180 (46.5)Width, Fixed Jaw mm (in)580 (22.8)700 (27.6)Width, Moving Jaw mm (in)420 (16.5)480 (18.9)C1Jaw Opening mm (in)390 (15.4)500 (19.7)C2Jaw Opening mm (in)750 (29.5)950 (37.4)C3Jaw Openingmm (in)1,100 (43.3)1,400 (55.1)D Jaw Depth mm(in)970 (38.2)1,170 (46.0)Cutter Lengthmm (in)200 (7.9)250 (9.8)Cycle Time (open, close, open)seconds6.57.5Crushing Force 1At tooth-jaw tip kN (st)1,180 (133)1,450 (163)2At 2nd tooth kN (st)1,510 (170)1,870 (210)3At primary bladekN(st)4,500(506)5,040(566)Cat Multi-Processors6 Multi-Processors for Hydraulic ExcavatorsMulti-Processor Shear (S) JawShear (S) jaws are ideal for structural demolition and cutting angle and channel iron, beams, pipe and rebar.F eatures :Angled Top Cutting EdgesProfile of the jaw compresses steel, forcing it to the rear of the jaw where cutting forces are greatest.Fully Reversible KnivesIt's easy to keep performance at maximum by rotating the knives, each one has four sharp edges.Piercing TipShear pierces, then cuts — it can handle beams wider than the depth of the jaw.Side Cutters & Front CuttersSide blades and a front cross blade keep the jaw aligned and reduce the possibility of jamming.Wear PlateThe moving jaw structure is protected by a bolt-on wear plate.Multi-Processor Shear (S) Jaw SpecificationsContact your local Cat Dealer for in-depth specifications including hydraulic requirements, cutting and crushing capacities.MP30MP40Weight (housing, jaw, bracket)kg (lb)3,890 (8,575.0)6,430 (14,175)Weight (jaw only)kg (lb)1,300 (2,865.0)2,290 (5,050)A Length mm (in)2,700 (106.3)3,400 (133.9)B Height mm (in)1,680 (66.1)1,980 (78.0)Widthmm (in)1,010 (39.8)1,180 (46.5)Width, Fixed Jaw mm (in)370 (14.6)460 (18.1)Width, Moving Jaw mm (in)120 (4.7)150 (5.9)C1Jaw Opening mm (in)450 (17.7)590 (23.2)C2Jaw Opening mm (in)470 (18.5)630 (24.8)D Jaw Depthmm(in)710 (28.0)880 (34.6)Cutter Lengthmm (in)600 (23.6)760 (29.9)Cycle Time (open, close, open)seconds6.57.5Arm Torque*Fully Open kN•m (ft•lb)1,348 (994,124)2,000 (1,477,789)Fully Closed kN•m (ft•lb)907 (668,968)1,358 (1,001,792)Cutting Force1At tooth-jaw tip kN (st)1,560 (175)1,890 (212)2At primary blade kN (st)2,790 (313)3,060 (344)3At throatkN(st)7,070(794)8,840(993)* T otal cylinder force × length of lever armCat Multi-ProcessorsMulti-Processors for Hydraulic Excavators 7Multi-Processor Tank Shear (TS) JawT ank Shear (TS) jaws quickly and cleanly cut thick steel plate, leaving flat, easily handled sections. Rail cars, grain bins, oil and fuel tanks can all be rapidly reduced.F eatures :Double Row Cutting EdgesA total of nine knives around the periphery of the upper and lower jaws cut a rectangular slot in the steel, leaving the remaining sections flat and easy to handle.Fully Reversible KnivesIt's easy to keep performance at maximum by rotating the knives, each one has four sharp edges.Piercing TipPunches a hole in the tank to allow access to the cutting jaw.Multi-Processor Tank Shear (TS) Jaw SpecificationsContact your local Cat Dealer for in-depth specifications including hydraulic requirements, cutting and crushing capacities.MP30Weight (housing, jaw, bracket)kg (lb)4,380 (9,655)Weight (jaw only)kg (lb)1,790 (3,945)A Length mm (in)2,800 (110)B Height mm (in)2,100 (82.7)Widthmm (in)1,180 (46.5)Width, Fixed Jaw mm (in)340 (13.4)Width, Moving Jaw mm (in)150 (5.9)C Jaw Openingmm (in)510 (20.1)D Jaw Depth mm(in)580 (22.8)Cutter Lengthmm (in)580 (22.8)Cycle Time (open, close, open)seconds6.5Cutting Force1At tooth-jaw tip kN (st)1,850 (208)2At primary blade kN (st)2,740 (308)3At throatkN(st)5,190(583)Cat Multi-ProcessorsFor more complete information on Cat products, dealer services, and industry solutions, visit us on the web at ©2014 CaterpillarAll Rights ReservedMaterials and specifications are subject to change without notice. Featured machines in photos may include additional equipment. See your Cat dealer for available options.CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow,” and the POWER EDGE trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.GEHQ0166-06 (01-14) Replaces GEHQ0166-05。

Volvo Trucks.Driving ProgressInformación de servicioInformación de producto sobre camiones Volvo,para personal de servicios de emergenciaFL FEPrólogoLas descripciones y los procedimientos de servicio se basan en diseños y en estudios demétodos realizados hasta septiembre2012.Los productos son desarrollados continuamente.Para los vehículos y componentes fabricados luego de la fecha mencionada,pueden por lo tanto corresponder especificaciones y métodos de reparación distintos.Cuando se considere que ello pesa significativamente para el manual presente,se publicaráuna versión actualizada del mismo que incluya los cambios.En la próxima edición del manual estas modificaciones quedan actualizadas.En las instrucciones en donde hay incluido el número de operación en el rubro,tan solo se trata de una referencia al tarifario VST(Volvo Standard Times).Las instrucciones sin número de operación en el rubro son solamente una información general y no hacen referencia a VST.En esta información de servicio se utilizan los siguientes niveles en observación y advertencia. Nota:Indica un método,práctica o condición que debe ser seguido para que la función del vehículo o componente sea realizada en la forma apropiada.Precaución:Indica un procedimiento que no es seguro y que puede acarrear daños al producto.Advertencia:Indica un procedimiento que no es seguro y que puede acarrear heridas al personal o graves daños al producto.Peligro:Indica un procedimiento que no es seguro y que puede causar heridas graves al personal e incluso la muerte.Volvo Truck CorporationGöteborg,SwedenNúmero de pedido:89073870©2012Volvo Truck Corporation,Göteborg,SwedenInformación de productos-FE,FL Información de producto sobre servicios de emergencia de Volvo TrucksContenido•“Introducción”,página2•“Cabina”,página3•“Sistema eléctrico”,página4•“Habitáculo del conductor”,página7•“Ajuste del volante”,página7•“Sistema SCR”,página9IntroducciónT1008650 La finalidad de este documento es proporcionar informaciónsobre productos de tipo técnico,que pueda usarse para es-tablecer rutinas y métodos para actuaciones de salvamentoen accidentes de tráfico donde se haya visto involucrado uncamión Volvo.El presente documento se destina a los Equipos de salva-mento locales,responsables de actuaciones de salvamentoen el lugar del accidente.El documento contiene la siguienteinformación:•Cabina del conductor•Sistema eléctrico•Puesto de conducción y ajustes del volante•SRS/sistema de airbag•Sistema SCRCabinaLas cabinas antiguas están fabricadas en chapa de acero de materiales blandos unidos por soldadura.Por su lado,los modelos de cabina más modernos están fabricados en acero de alta resistencia.A continuación presentamos un dibujo esquemático de la es-tructura de cabina,donde las zonas de chapa de alta resis-tencia se han marcado de color gris claro y gris oscuro.Refuerzo decabinaC8063199Sistema eléctrico Recomendaciones generales:Hay dos tipos de interruptores para cortar la corriente eléc-trica del vehículo.Son el interruptor principal y el disyun-tor de ADR.Interruptor principal•El interruptor de suministro principal sólo funciona cuan-do el motor estádesconectado.NO corta la alimentación del tacógrafo,el sistema de cierre centralizado,la alarma Despuésde usarDisyuntor de ADR•En vehículos que transportan mercancías peligrosas de-be haber siempre un disyuntor de ADR.Cuando se usa este disyuntor se corta todo el sumi-nistro eléctrico independientemente de si el motor¡Advertencia!para desconectar Nota!Solamente la desconexión desde la batería o con el disyuntor de ADR corta TODO el suministro eléctrico.•Cuando se ha desconectado la alimentación de batería, se guarda energía en la unidad de mando de SRS duran-te unos segundos,tiempo suficiente para activar el air-bag o el tensor de cinturón de seguridad.Para asegurar que el sistema estádesenergizado,esperar unos3se-gundos después de desconectar la alimentación de labatería.•Antes de desconectar la corriente:¡Considerar la po-sible necesidad de abrir puertas o mover el asiento del conductor!(Ver:“Habitáculo del conductor”,página 7Si el asiento del conductor es ajustable eléctricamente,no seráposible ajustarlo después de cortar la electricidad porque el asiento no tiene mandos mecánicos.•La apariencia y la función varían entre diferentes inte-rruptores principales.Algunos modelos de camión care-cen de interruptor principal.¿Cómo se desconecta la corriente?•Desconectar el interruptor principal.No se desconec-tan todos los circuitos del camión;algunas partes especí-ficas del vehículo permanecen energizadas.No todas lascabinas tienen interruptor principal.•Interrumpir el circuito de batería soltando/cortando elcable de los bornes de batería.Ésta es la forma más se-gura de interrumpir la tensión.Se interrumpe toda la ten-sión,incluso del tacógrafo.Tener en cuenta que el vehículo sigue estando energiza-do si sólo se quita la llave de contacto.Con respecto aSRS,permanece energía almacenada en la unidad de man-do de SRS durante unos segundos después de cortarse elsuministro.Esta energía es suficiente para activar el airbag yel tensor de cinturón de seguridad durante hasta tres segun-dos después de cortar el suministro.La cifra indica la posición normal de la batería.1Caja de baterías de montaje lateral.Se puede montar en el lado izquierdo o derecho.2Caja de baterías de montaje posterior.T3072656Diferentes formas de cortar el suministro eléctrico:D.Interruptor principal telemandado.No existe en todos los vehículos.Pulsando el botón izquierdo dos veces dentro de cinco segundos,se desconecta el interruptor principal.Algunos circuitos permanecenenergizados.T301-7347C.Disyuntor de ADR.Sólo existe en vehículos que trans-portan mercancías peligrosas.Desconecta TODA lacorriente.C8063014B.Interruptor principal/interruptor de batería.Se encuentra en todos los vehículos.Algunos circuitos siguen excitados.A.Batería.Cuando se interrumpe el circuito de batería,empezar con el borne nega-tivo.Si es necesario cortar,hacerlo lo más cerca posible de la batería para reducir el riesgo de conexiones junto a los cables principales.Nota!¡Atención!No todos los componentes de la figura arri-ba están en todos los vehículos.Sistema de cierre centralizadoEl sistema de cierre centralizado se inmoviliza interrumpien-do el circuito de batería.En vehículos para transporte de mercancías peligrosas,el cierre centralizado también se in-moviliza desde el interruptor principal.Las puertas bloqueadas se pueden abrir desde el interior usando la empuñadura de apertura.Habitáculo del conductorDiseño del asientoExisten varios modelos de asiento para los diferentes mode-los de camión.El ajuste de posición de asiento vuelto atrás y adelante es en algunos casos mecánicos,pero los modelos más avanza-dos tienen ajuste eléctrico.Los modelos con ajuste mecánico se ajustan con una empu-ñadura situada debajo de la parte frontal del cojín de asiento,y los que tienen ajuste eléctrico se ajustan con un botón si-tuado en el lado izquierdo del asiento.Nota:los asientos con ajuste eléctrico no tienen sistema de ajuste mecánico.Para más información,ver:“Sistema eléctrico”,página 4Ajuste de asiento en sentidolongitudinalT8010409T8010449Ajuste con horquilla.Ajuste eléctrico.Ajuste del volanteHay un botón de operación neumática o una palanca mecá-nica en la columna de dirección.Cuando es necesario cortar o aserrar en el volante,la mane-ra más fácil es hacerlo en las zonas marcadas en blanco de acuerdo a la figura de abajo.El resto de las secciones están reforzadas.Perfil de refuerzo del volante y ajuste delvolanteT0013497T6009538Ajuste del volante.Cortar el volante.Sistema SCRRecomendaciones generales:•Cuando se para el motor,la solución de urea es bombea-da de vuelta al depósito de urea y se vacía la solución de urea del sistema SCR.Este proceso tarda unos dos minu-tos.Si se usa el interruptor de ADR para cortar la corrien-te antes de terminarse este proceso,el sistema puedeseguir estando presurizado y contener de solución deSi se usacuando•La urea es muy corrosiva y puede dañar conectores.Si la urea entra en contacto con conectores desenchufados, hay que cambiarlos de inmediato.No sirve de nada lim-piar porque la solución de urea se dispersa rápidamente en el cable,causando oxidación del metal.El derrameevaporaciónLas zonasen vehículosSistema SCREl sistema de urea es la parte del sistema de postratamientode los gases de escape que tienen algunos motores nuevospara cumplir con los requisitos de emisiones de Euro 4.Se inyecta una solución de urea en los gases de escape an-tes de que atraviesen el catalizador,para reducir las emisio-nes de óxidos de nitrógeno en los gases de escape.Los componentes principales del sistema SCR son:de-pósito de urea,unidad de bomba,unidad dosificadora y silenciador con catalizador incorporado.Sinopsis del sistema SCR y sus componentesprincipales:T20229851.Depósito de urea2.Unidad de bomba3.Unidad dosificadora4.SilenciadorSolución de ureaLa solución de urea,formada por agua destilada y un 32,5%de urea,es un líquido incoloro que puede tener un suaveolor a amoniaco.La solución de urea puede ser agresiva contra determinadosmateriales y se debe manipular con cuidado.La solución no es inflamable.A temperaturas altas la solución de urea se descompone enamoniaco y dióxido de carbono,y a temperaturas inferioresa –11°C la solución se puede congelar.La solución de urea es corrosiva a los metales,especialmen-te el cobre y el aluminio.Manipulación de la solución de urea:En caso de contacto con la piel:enjuague bien con agua tibia y quítese las prendas contaminadas.En caso de contacto con los ojos:enjuague bien con agua durante varios minutos y acuda a unmédico en caso necesario.En caso de inhalación:respire aire fresco y acuda a un médico en caso necesario. En caso de ingestión:beba agua89073870Spanish1.05Edición01 Volvo Truck Corporation。

产品手册Product manual三一掘进机SANY ROAD HEADER企业简介半煤岩全岩智能化快速掘进钻装机辅助设备售后服务0305091519252731 QUALITY CHANGES THE WORLD企业简介BRIEFINTRODUCTION 三一重型装备有限公司创立于2004年,是一家专业从事矿山机械、煤炭掘、采、运成套设备研发、制造及销售的大型装备制造企业,是全球装备制造头部企业三一集团旗下的核心事业部。

2009年11月25日三一重装的母公司三一国际在香港联交所主板成功上市,成为国内首家在香港上市的煤机制造企业。

主导产品覆盖综掘、采煤机、液压支架、刮板机、宽体车、矿车和破碎设备等产品门类50余种型号。

产业布局经过17年的创新发展,三一重装作为一家全球化公司,目前产品远销俄罗斯、印度、印度尼西亚、巴西、阿根廷、乌克兰、波兰、南非等20余个国家和地区。

在国内设立13个分公司,销售服务覆盖全国1000余家矿山企业。

创新研发三一重装研究院下设采掘研究院、智能化研究院、宽体车项目部、纯水支架项目部和破碎装备项目部,现已被认定为国家级企业技术中心、国家级高新技术企业,拥有国家级博士后科研工作站、行业第一家院士工作站、省级工程中心及省级工程实验室,连续四年被评为煤机行业“双十佳”企业,通过了CNAS(国内)与ANAB(国际)双重信息安全认证。

企业愿景秉持“创建一流企业,造就一流人才,做出一流贡献”的企业愿景,肩负“品质改变世界”的企业使命,秉承“自强不息,产业报国”的企业精神,三一重装致力于为全球矿产资源生产企业的绿色、安全、高效开采提供成套设备,成为其最值得信赖的长期合作伙伴,为中华民族贡献一个世界级品牌。

半煤岩关重件安全系数3倍以上,并厂内反复耐久性试验验证,使用寿命长,运输系统采用高强耐磨板,耐磨寿命提高3-5倍优质钨钴类合金,具备高强度及耐磨性,截齿损耗低内喷雾独家专利技术,内喷雾性能可靠,具备使用性和维修性。

EngineEngine Model*Cat ®C3.3B Net Power (ISO 9249)48.5 kW65 hp*Engine meets U.S. EPA Tier 4 Final/EU Stage IIIB emission standards.WeightsOperating Weight with Cab 8400 kg 18,519 lb Operating Specifications Maximum Dig Depth4150 mm13'7"308E2 CRMini Hydraulic Excavator2Highperformance in a compact radius and swing boom design for greaterversatility and controllability.ContentsCompact Radius ..................................................4Operator Station ..................................................5COMPASS Control Panel ...................................6Performance and Controllability ......................8Variable Angle Boom ..........................................9Undercarriage ...................................................10Work Tools ..........................................................11Engine and Serviceability ................................12Specifi cations ....................................................14Standard Equipment .........................................17Optional Equipment...........................................18Notes . (19)The Cat 308E2 CR Mini Hydraulic Excavator delivers high performance with the versatility of a swing boomfront linkage in a durable Compact Radius design to help you work in the tightest applications. With the COMPASS display panel, Tier 4 Final/Stage IIIB engine and High Defi nition Hydraulic (HDH) system, the308E2 CR is more productive, versatile and cost effective.3Compact RadiusWork in the tightest spaces.Compact RadiusThe compact radius design gives greater machine versatility and the capability to work within confi ned areas. The radius of the upper body stays within 280 mm (11 in) of the undercarriage providing fl exibility for different work site applications with a reduced risk of damage and less stress for the operator.This allows the operator to concentrate on the work being done without having to worry about damaging the back of the machineor other job site obstacles.45Comfortable Working EnvironmentSpacious and comfortable operator station with excellent visibility and legroom keeps the operator comfortable and helps reduce fatigue. All hydraulic functions are fully pilot operated, lowering owning and operating costs and resulting in less downtime. The operator station also features:• Heated, air suspension seat • COMPASS display panel • Ergonomic joysticks• Dynamic operator sound pressure 70 dB(A) ISO 6396• Average exterior sound pressure 99 dB(A) ISO 6395 – dynamic testOperator StationSuperior comfort to keep you productive throughout the work day.The COMPASS control panel on the Cat E2 Series mini hydraulicexcavators was specifi cally designed by Caterpillar for compactexcavators. It adds several new features to the machines increasingthe amount of customer value. All of the following features arestandard on all E2 Series models.C omplete – All of the control panel features are standard on allE2 Series modelsO peration – Simple operation of the pattern changer, hydraulic quickcoupler and fuel gauge visibility all at the push of a buttonM aintenance – Maintenance intervals, diagnostics and work hoursP erformance – Maintain optimum performance levels with adjustablework tool fl ow featuresA ndS ecurity – Anti theft device with individual user and masterpasswordsS ystem – Ergonomically designed control panelPasscode Protected Security SystemA standard anti-theft device comes on every E2 Series compactexcavator. A fi ve digit alphanumeric password is required to start themachine when the anti-theft feature is enabled. There is a masterpassword and up to fi ve user passwords can be created by theowner if desired.Keep your machine safe on a busy job site by locking it when youare not around.Adjustable Auxiliary Work Tool Flow ControlThe E2 Series machines feature simple adjustability of the fl ow goingdown the boom and stick to the work tool. Both the standard mainline and optional secondary auxiliary hydraulics can be adjustedon a scale of 1–15 through a few buttons on the control panel.Adjust the fl ow to your different tools with a simple push of a button. COMPASS Control PanelComplete, Operational, Maintenance, Performance and Security System.6Rearview CameraIncrease operator productivity and effi ciency with enhanced visibility with the rear view camera.Work more confi dently with greater visibility.Continuous FlowOnce this feature is enabled through a button on the monitor, the E2 Series machines can run in continuous fl ow mode. With the auxiliary hydraulics on the right hand joystick, just hold the roller switch at the desired fl ow rate and direction for 2.5 seconds and the machine will maintain that fl ow rate until it is turned off.Maintain hydraulic fl ow to your tools at any fl ow and in any direction with the simple push of a button.Pattern ChangerChange the operating pattern between excavator and backhoe with a simple press of a button from the comfort of the cab. (Optional in Europe)Exclusive push button pattern changer is safe and easy.Maintenance and Performance InformationEasily keep track of various maintenance and performance parameters of your machine.Reset the maintenance intervals and ensure the machine is receiving proper care maximizing the life of the machine.Site Reference SystemOutput from pitch and roll sensors aid in grading and level trenching for improved effi ciency and job site fi nishing.Finish the job faster with site information.UNLOCK the new features and experience the value of the exclusive COMPASS control panel on the Cat E2 Series compact excavators7High digging forces that provide power through even the most compacted ground, coupled with direct, smooth control through responsive hydraulics, ensure that the Cat 308E2 CR delivers the high productivity that customers demand.ControllabilityThe Cat 308E2 CR front linkage has been perfectly balanced with the hydraulics to deliver the high level of control required for fi ne grading and landscaping applications.• Automatic two speed function improves job site maneuverability by balancing high speed travel requirements and control.• Joystick mounted auxiliary control enhances machine controllability. The intuitive controls give fi ne modulation.• Auxiliary lines including quick connectors are fi tted as standard, meaning the Cat 308E2 CR comes ready to work.• Optional boom and stick lowering check valve includes integral overload warning device.High Definition Hydraulic System• Delivers fuel savings, effi ciency, controllability and precision.• Industry leading variable displacement, load sensing, fl ow sharing system.Lift CapacityTo meet the diverse needs of today’s customer, the 308E2 CR has high level lift capacity and outstanding stability – all in a compact radius design to provide on site versatility to get the job done.CounterweightAn optional rear counterweight can be added to provideadditional lift capacity and stability.Performance and ControllabilityPowerful digging combined with smooth responsive control.8Variable Angle BoomIncreased fl exibility and versatility.Durable Front LinkageUptime and service intervals are increased with durable and reliable booms, sticks and linkage pins. Each boom and stick is builtto provide superior strength to withstand any tough application. The variable angle boom option offers fl exibility and versatilityin the working envelope.With full extension, the working range offers a maximum dig depth extending to 3980 mm (157 in). The maximum reach extends760 mm (30 in) beyond the standard boom and stick confi guration to 7780 mm (306 in). The working height reaches 1360 mm (54 in) beyond the standard boom and stick confi guration to 8000 mm (315 in). When retracted, the Cat 308E2 Variable Angle BoomMini Excavator can work closer to the blade and tracks, providing increased lifting capacity while working productively inconfi ned areas.910Depending on the customers application, the Cat 308E2 CR has three different track options to choose from, allowing the correct machine confi guration to suit the job.Rubber BeltProvides the lowest ground disturbance of all track options with excellent traction in conditions that are soft underfoot. The standard track offering is 450 mm (17.7 in) width.Steel TrackGood for demolition and heavy duty applications. A triple grouser track is available in two width options: 450 mm (17.7 in) and 600 mm (23.6 in).Steel Track with Rubber PadsThe 450 mm (17.7 in) wide shoe has four holes to attach the rubber pads to the steel track shoes. This option prevents damage to paved road surfaces and minimizes noise and vibration during travel while providing maximum stability.UndercarriageExcellent stability.Blade WidthsThe dozer blade is an important and useful tool for the Hydraulic Mini Excavator used for backfi lling trenches,levelling, landscaping and site clean up. There are two blade width options available to accommodate the differences in track widths.The blade comes standard with a replaceable weld-on dozer cutting edge constructed of hardened steel for longer life.Tie Down PointsLarge oval tie down points are located in two positions on the undercarriage for easy and safe machine tie down fortransportation.11Wide Range of Work ToolsA wide range of Cat Work Tools have been designed specifi cally to get the best out of your machine and deliver excellent value through high productivity and long life.Available work tools include:• Buckets (heavy duty and heavy duty capacity)• Tilting and Swing Ditch Cleaning Buckets • Hydraulic Hammers • Augers• Vibratory Compactors • Shears • Rippers• Dual Lock Mechanical Coupler • Dual Lock Hydraulic Coupler • Tilting CouplerTo maximize performance and productivity, Cat mechanical and hydraulic quick couplers are compatible with all standard work tools, enabling the operator to simply release one work tool and pick up another.One-way fl ow (hammer) and two-way fl ow (auger) auxiliary lines with quick connectors are fi tted as standard. This allows the machine to adapt to a wide variety of applications without re-confi guring the auxiliary lines. Versatility is further enhanced with the option of a second auxiliary supply(for a rotating grapple).Work ToolsMatched to meet your application needs.Customer SupportYour Cat dealer is ready to assist you with your purchase decision and everything after.• Financing packages are fl exible to meet your needs • Unmatched parts availability keeps you working• Make comparisons of machines, with estimates of component life, preventative maintenance and cost of production• For more information on Cat products, dealer services and industry solutions, visit 12Engine and ServiceabilitySuperior power with easy access and minimal maintenance requirements keep you working.EngineThe Cat C3.3B electronic engine delivers quiet operation with superior power and fuel effi ciency while meeting Tier 4 Final/Stage IIIB emission standards.Easy ServiceConvenient service features make maintenance easy, reducing your downtime:• Lifting side hood allows access to air fi lter, main implement valve,1-way/2-way auxiliary fl ow selector, accumulator, fuel fi lter and hydraulic tank. This eliminates the need to lift the cab when maintaining and servicing the machine.• Swing open door provides access to major components and service points including engine oil check and fi ll, vertically mounted engine oil fi lter, starter motor and alternator.• S·O·S SM oil sampling valve allows easy sampling of the hydraulic fl uid for preventative maintenance.• The 308E2 CR is Product Link™ ready and the Cat Product Link system simplifi es equipment fl eet tracking. Using satellite or cellular technology, the system automatically reports information such as location, machine hours, active and logged service codes and security alarms.Power on DemandAutomatic system ensures optimal fuel effi ciency through appropriate engine rating to meet all operational requirements as needed.Auto Engine ShutdownEngaging this feature allows the operator to save fuel by powering down the machine after a designated inactive period. The operator can adjust the range from 1-15 minutes to meet their needs. The system will only shut down after the set time, provided the hydraulic lever is up. Electronics will remain powered after shutdown.13308E2 CR Mini Hydraulic Excavator Specifications1415308E2 CR Mini Hydraulic Excavator SpecificationsDimensionsLift Capacities at Ground Level*Lift Point Radius 4000 mm (13'1")6050 mm (19'10")Front Side Front Side Blade Down kg 365017101880920lb 8,0463,7704,1442,028Blade Upkg 18401530970820lb4,0563,3732,1381,808* The above loads are consistent with hydraulic excavator lift capacity rating standard ISO 10567:2007 and they do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. The excavator bucket weight is not included on this chart. Lifting capacities are for standard stick.Standard StickLong Stick mm ft/in mm ft/in 1Dig Depth 415013'7"469015'5" 2Vertical Wall29809'9"355011'8" 3Maximum Reach at Ground Level 682022'9"735024'1" 4Maximum Reach702023'0"754024'9" 5Maximum Dig Height664021'9"699022'11" 6Maximum Dump Clearance 467015'4"501016'5" 7Linkage In Minimum Radius 28009'2"328010'9" 8Tail SwingStandard Counterweight 14504'9"14504'9" 9Maximum Blade Height4201'5" 4201'5"10Maximum Blade Depth3201'1" 3201'1"11Boom Height in Shipping Position22807'6"22307'4"12O/A Shipping Height 25508'4"25508'4"13Swing Bearing Height 7352'5" 7352'5"14O/A Undercarriage Length 29039'6"29039'6"15O/A Shipping Length 638020'11"634020'10"16Boom Swing Right 10103'4"10103'4"17Boom Swing Left 6352'1" 6352'1"18Track Belt/Shoe Width 4501'6" 4501'6"19O/A Track Width23207'7"23207'7"1119308E2 CR Mini Hydraulic Excavator Specifications Dimensions with Variable Angle BoomStandard Stick with Angle Boom ExtendedStandard Stick with Angle Boom Retractedmm in mm in1Dig Depth398015737101462Vertical Wall382015036001423Maximum Reach at Ground Level763230063652514Maximum Reach778030665502585Maximum Dig Height800031552002056Maximum Dump Clearance608023933601327Linkage In Minimum Radius292511532351278Tail SwingStandard Counterweight1450 571450 57With Extra Counterweight1565621565629Maximum Blade Height 420 17 420 1710Maximum Blade Depth 320 13 320 1311Boom Height in Shipping Position22809022008712O/A Shipping Height2550100255010013Swing Bearing Height 735 29 735 2914O/A Undercarriage Length2903114290311415O/A Shipping Length7010276579522816Boom Swing Right10104010104017Boom Swing Left 635 25 635 2518Track Belt/Shoe Width 450 18 450 1819O/A Track Width232091232091Lift Capacities at Ground Level with Variable Angle BoomVariable Angle Boom Minimum*Variable Angle Boom Maximum*Lift Point Radius5000 mm (16'5")5500 mm (18'1")5000 mm (16'5")6800 mm (22'4")Front Side Front Side Front Side Front Side Blade Down kg2354107090290224799451451575lb5,1912,3591,9891,9895,4662,0843,1991,268 Blade Up kg129410709029021164945714575lb2,8532,3591,9891,9892,5672,0841,5741,268 * The above loads are in compliance with hydraulic excavator lift capacity rating standard ISO 10567:2007 and they do not exceed 87% of hydraulic lifting capacity or 75% of tipping capacity. The excavator bucket weight is not included on this chart. Lifting capacities are for standard stick.16308E2 CR Standard EquipmentENGINE• Cat C3.3B diesel engine (meets Tier 4 Final/ Stage IIIB emission standards)• Automatic engine idle• Automatic engine shut-off• Automatic two speed travel• Diesel Particulate Filter(North America only)• Diesel Oxidation Catalyst(North America only)• Fuel and water separator• Power on demandHYDRAULIC SYSTEM• 1-way and 2-way (combined function)• Accumulator• Automatic swing parking brake• Auxiliary hydraulic lines• Adjustable auxiliary relief• Auxiliary line quick disconnects• Cat interlock system: hydraulic lockout • Continuous auxiliary fl ow• Ecology drain• Hydraulic oil cooler• High defi nition hydraulics• Load sensing/fl ow sharing OPERATOR ENVIRONMENT• 100% pilot control ergonomic joysticks• Adjustable armrests• Air conditioning/heat• COMPASS: complete, operation,maintenance, performance andsecurity system–Multiple languages• Cup holder• High back suspension seat, heated• Hydraulic neutral lockout bar• Interior light• Literature holder• Pattern changer (optional in Europe)• Radio (optional in Europe)• Site reference system: leveling• Tool storage area• Travel control pedals with hand levers• Washable fl oor mat• Windshield wiperUNDERCARRIAGE• Dozer blade with fl oat function• Track, rubber belt, 450 mm (18 in) width• Tie down eyes on track frame• Towing eye on base frameFRONT LINKAGE• 180 degree bucket rotation• Certifi ed lifting eye on bucket linkage(optional in Europe)• Front shovel capable• Thumb ready stickELECTRICAL• 12 volt electrical system• 60 ampere alternator• 650 CCA maintenance free battery• Fuse box• Ignition key start/stop switch• Slow blow fuse• Warning hornLIGHTS AND MIRRORS• Cab and boom light with time delaycapability• Mirror, rear view, cab leftSAFETY AND SECURITY• Anti-theft system (COMPASS)• Caterpillar Corporate “One Key” System• Door locks• Lockable fuel cap• Rearview camera• Retractable seat belt• Roll Over Protective Structure (ROPS)(ISO 12117-2)• Tip Over Protective Structure (TOPS)(ISO 12117)• Top guard – ISO 10262 (Level II)• Travel alarm (optional in Europe)Standard EquipmentStandard equipment may vary. Consult your Cat dealer for details.17308E2 CR Optional EquipmentENGINE• Engine block heater HYDRAULIC SYSTEM• Quick coupler lines• Boom lowering check valve*• Stick lowering check valve*• Secondary auxiliary hydraulic lines* *Standard on V AB confi guration.UNDERCARRIAGE• Blade, weld on• Track, triple grouser (steel), 450 mm (18 in)• Track, triple grouser (steel) with rubber pad,450 mm (18 in)• Track, triple grouser (steel), 600 mm (24 in)FRONT LINKAGE• Quick coupler: manual or hydraulic• Thumb• Buckets• Full range of performance matchedwork tools–Auger, hammer, shear, ripperLIGHTS AND MIRRORS• Mirror, cab rearSAFETY AND SECURITY• Battery disconnect• Front wire mesh guard• Front steel plate guard• Rain guardTECHNOLOGY• Product LinkOTHER ATTACHMENTS• Counterweight, extra, 1121 kg (2,493 lb)*Optional EquipmentOptional equipment may vary. Consult your Cat dealer for details.18Notes19AEHQ7916 (08-2016) For more complete information on Cat products, dealer services, and industry solutions, visit us on the webat © 2016 CaterpillarAll rights reservedMaterials and specifi cations are subject to change without notice. Featured machines in photos may includeadditional equipment. See your Cat dealer for available options.CAT, CATERPILLAR, , their respective logos, “Caterpillar Yellow” and the “Power Edge”trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and maynot be used without permission.。

Jackco Transnational Inc.©2017Azusa , CA 888-452-252610 TON HYDRAULICFLOOR JACKUSER'S MANUALMODEL 66510*This hydraulic jack conforms to all "ANSI / ASME" safety standards.To see more jackco products please visit our website at FOR YOUR SAFETY•Read these safety instructions carefully and keep this manual in an easy to find place as you may need to use it again.•Non-compliance with these rules may result in injury or damage to the jack or the vehicle.•Do not modify the jack in any way.•Never exceed the rated capacity of the jack.•This jack is a lifting device only and should never be used to move the vehicle.•The jack should be supported on a solid and level ground. Never use the jack in a surface where it may sink into the ground.•Ensure that there are no persons inside the vehicle to be lifted. Switch off the engine and apply the brake.•Position the jack under the manufacturer’s recommended lifting point for the vehicle. Off-centered loads can slip and accidents may result.•During raising and lowering of the load, precautions should be taken to avoid movement of the vehicle. Traffic may cause the raised vehicle to rock during roadside use of the jack.•Never work under a raised vehicle without supporting it with mechanical/jack stands.•Never position any part of your body near the movable parts of the jack.•Ensure that there are no persons or obstructions underneath the vehicle prior to lowering.•Do not adjust the overload bypass valve under any circumstance.Use wheel chocks appropriately.2SPECIFICATIONOPERATING INSTRUCTIONImportant: Sometimes during shipment and handling, air gets into the hydraulic system, causing poor lifting performance. Before initial operation, purge any air from the system by fully opening release (Turn handle knob (#3-8) counter-clockwise). Then, while holding the saddle down, pump pedal (#3-2) rapidly several times.To Lift a Vehicle:1. T urn handle knob (#3-8) clockwise until resistance is felt to close release valve.Do not over-tighten.2. P lace jack directly under object to be lifted. Make sure saddle takes up weightfirmly and centrally. Check positioning under slight load to confirm jack or load will not slip.3. R aise jack by pumping handle until desired height is reached. After lifting, secureload by appropriate means. Do not use jack as the only means of support.To Lower a vehicle:1. S lowly turn handle knob (#3-8) counter-clockwise. Speed of descent is controlledby amount release valve is turned.3• Checking hydraulic oil level1. O pen release valve (Turn handle knob (#3-8) counter -clockwise and push ram to its lowest position.2. R emove filler plug.3. F ill the clean hydraulic jack oil .Do not use hydraulic brake fluid .4. R einstall filler plug .• Only original replacement parts should be used. Extremely Important: never use brake fluid.• When the jack is not in use, make sure the lifting arm is fully retracted to avoid corrosion.• Keep the jack in a clean, dry place and out of children’s reach.• Replace the hydraulic fluid in the reservoir at least once a year. To check the hydraulic fluid level, lower the lifting arm completely.• The hydraulic fluid level should be just below the filler plug. Replenish if necessary, and reinstall the rubber filler plug. Excessive hydraulic oil may render the jack inoperative.• Inspect the jack before each use. Take corrective action or remove the jack from service if any of the following problems are found:a. Cracked or damaged frameb. Leaking hydraulic fluidc. Scored, damaged piston rodd. Loose hardwaree. Modified equipment• Keep warning labels and instructional decals clean and readable. You may use a mild soap solution to wash external surfaces of the jack.MAINTENANCEImportant: Both the maintenance and repair of the jack may only be performed by qualified persons, who have sufficient knowledge of the hydraulic system used in thesejacksRegularly lubricate the moving parts in the wheels, arms, handle and pump roller pin.4TROUBLESHOOTINGCaution: To prevent personal injury, all inspection, maintenance, and repairprocedures must be performed when the jack is free of load.PARTS LISTLIMITED ONE YEAR WARRANTYJackco Transnational Inc. warrants all Jackco equipment and tools to the original purchaser against any manufacturing defect in material or workmanship for a period of one (1) year from the original date of purchase. If the defective equipment or tool is determined to be covered under this warranty, it shall be repaired or replaced at manufacturer's discretion without charge, provided that the equipment or tool must be returned with proof of purchase to the dealer and freight prepaid, if returned to the manufacturer. This warranty shall not apply to damage due to accident, negligent use, and lack of maintenance, abuse or applications other than the specific function the equipment or tool is designed for.No other warranties, expressed or implied, including those of merchantability or fitness for particular purpose shall be applicable to Jackco except as specifically stated herein. In no event shall Jackco be liable to any party for any special, direct, indirect, consequential, punitive damage of any nature caused by the sale or use of the equipment or tool.Note: This warranty gives the original purchaser specific legal rights which may very from state to state.Jackco Transnational Inc. © 2017Azusa, CA888-452-2526 。