水源热泵样本

- 格式:pdf

- 大小:4.94 MB

- 文档页数:36

WPWE冷热水型模块化水源热泵机组R22:10.3kW ~ 59.5kWR410A:11.0kW ~ 62.0kWNovember 2011水环式系统地下水式系统地下环路式系统3.4.系统介绍与集中式空调系统相比,水源热泵系统一大优势在于在部分负荷时只需启动机组本身和循环水,不用频繁启停锅炉和冷却塔系统,这样大大节省了能源消耗;而在过渡季节,空调系统中各机组同时供冷和供暖的情况下,节能效果更加明显。

与水-风型水源热泵机组相比,水-水热泵在工程应用中具有以下的优点,建议业主或设计单位从实际需要出发,对不同的空调区域采用最为合适的机组形式:1.2.水温波动范围小,保证机组运行高效可靠,更可避免风冷机组冬季除霜的问题;各机组之间运行相对独立,个别机组的故障不会影响整个系统和其它机组的正常运行。

单户单表,每个用户可将自身的电表系统和空调系统连接,单独计费。

大楼管理人员、物业部门、业主再也无须为空调费用的结算发愁,真正实现公正与公平。

无需设立专门的锅炉房、冷冻机房和大型的通风管道,因此安装和投资费用大大减少。

两管制系统实现四管制系统功能,可同时满足各区域单独制冷/制热需求。

节约初投资高效节能可靠性高单独计费应用灵活室内侧采用传统的风机盘管形式,便于控制噪音、保证层高;减少机组数量,简化冷却水系统设计,易于达到水力平衡,减少水泵设计负荷,便于进行维护保养。

对于室内末端数量众多的场合,优势尤其明显;在室内侧可以用传统方式加载新风机组,运行性能稳定、可靠;针对住宅等使用场所,可以适当考虑各个房间的同时使用系数,合理减小主机的容量配置,进一步节省能源和初投资。

机组特性水冷式设计,采用高效涡旋式压缩机,能效比高;部分型号为双压缩机机组,可以实现逐级卸载,部分负荷效率更高;热力膨胀阀精确控制制冷剂流量,运行更稳定,应用范围更宽广。

机组针对水环、地下水及地下环路系统等多种应用进行不同调校,保证在不同工况条件下机组的正常运行。

水源热泵控制系统水源热泵作为一种用地下恒温水源代替冷却塔的高效节能空调, 在实际应用中, 为了进一步提高节能效果, 还应尽可能减少主机、冷冻水泵和冷却水泵等主要耗能设备的用能。

传统的空调水系统使用定流量的运行方式, 水源热泵主机本身具有能量调节机构, 根据负载变化输出的能量能够在额定值的25%-100%的范围内调整。

可是, 冷冻水泵和冷却水泵却不随着负载变化做出相应的调节, 流量保持不变, 导致水系统经常在大流量、小温差的工况下运行, 电能浪费很大。

采用定温差变流量的水系统控制, 能够避免这种浪费。

采用这种控制方式, 能够把进回水的温差固定在一个较大的给定值上, 在用户负荷较小时, 经过减少流量来满足用户要求, 这样水泵的能耗能够大大减少。

随着冷机技术的进步, 蒸发器的流量能够在额定流量的60%-100%范围内变化, 这样就为采用交流变频调速器对水源热泵系统中的水泵进行变流量节能控制提供了技术保证。

本文将利用PLC、触摸屏和变频器对水源热泵进行变频节能控制。

2 变频节能控制方案采用变频器配合可编程控制器组成控制单元,其中冷却水泵、冷冻水泵均采用温度自动闭环调节, 即用温度传感器对冷却水、冷冻水的水温进行采样,并转换成电信号(一般为4-20 mA,0-10 V等)后送至PLC,经过PLC将该信号与设定值进行比较再作PID运算后, 决定变频器输出频率,以达到改变冷冻水泵、冷却水泵转速,从而达到节能目的。

2.1冷冻水系统系统采用定温差变流量的方式运行, 在保证最末端设备冷冻水流量供给的情况下, 确定一个冷冻水泵变频器工作的最小工作频率作为水泵运行的下限频率并锁定; 将电动机工频设定为上限频率, 改变变频器频率就能够调节系统的流量。

另一方面, 在系统运行时, 由于低温冷冻水温度取决于蒸发器的运行参数, 一般冷冻水出水温度设定为8-10℃,因此, 只需控制高温冷冻水(回水)的温度,即可控制温差。

为了确保冷冻水的出水回水温差在设定的范围内, 方案采用温度传感器在冷冻水入口测量水温T, 并与PLC、变频器及水泵组成闭环控制系统, 将冷冻水回水温度控制在△T( 一般取5-7℃) 。

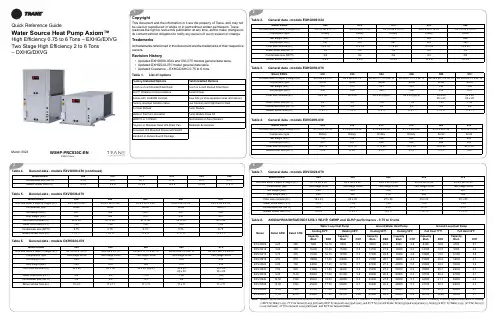

1234©2023 TraneQuick Reference GuideWater Source Heat Pump Axiom™High Efficiency 0.75 to 6 Tons – EXHG/EXVG Two Stage High Efficiency 2 to 6 Tons – DXHG/DXVGCopyrightThis document and the information in it are the property of Trane, and may not be used or reproduced in whole or in part without written permission. Trane reserves the right to revise this publication at any time, and to make changes to its content without obligation to notify any person of such revision or change.TrademarksAll trademarks referenced in this document are the trademarks of their respective owners.Revision History•Updated EXHG009-0024 and 030-070 models general data table.•Updated DXHG024-070 model general data table.•Updated Clearance – EXHG/DXHG 0.75 to 6 tons.Table 1.List of optionsFactory Installed OptionsField Installed Options1-inch or 2-inch Ducted Filter Rack 2-inch or 4-inch Ducted Filter Rack Air-Fi ® Wireless Communications Ducted PanelDeluxe 24V, UC400B Controls Hose Kits (or ship separate hoses and valves)Factory-mounted Isolation Valve Low, Medium and High Electric Heat Hot Gas ReheatPump ModuleMatte or Foil Face Insulation Pump Module Hose Kit MERV 8 or 13 FiltersThermostats or Zone Sensors Polymer or Stainless Steel IAQ Drain Pan Waterside EconomizerRecessed Unit Mounted Disconnect Switch Standard or Deluxe Sound PackageTable 2.General data - models EXHG009-024Model EXHG009012015018024Unit size width x depth x height (in.)25.5 x 46 x 17.7525.5 x 46 x 17.7525.5 x 49 x 18.7525.5 x 55 x 19.7525.5 x 55 x 19.75Compressor type Rotary Rotary Rotary Rotary Scroll Net weight (lbs.)173173173269269Ship weight (lbs.)297297297393393Filter size nominal (in.)16 x 1917 x 1917 x 2018 x 2319 x 23Water in/out size (FPT)1/21/21/23/43/4Condensate size (NPTI)3/43/43/43/43/4Blower wheel Size (in.)9 x 89 x 810 x 810 x 910 x 9Table 3.General data - models EXHG030-070Model EXHG030036042048060070Unit size width x depth x height (in.)28 x 68 x 21.7528 x 68 x 21.7529.38 x 77.75 x 22.1329.38 x 77.75 x 22.1329.38 x 86.75 x 22.1329.38 x 86.75 x 22.13Compressor type Scroll Scroll Scroll Scroll Scroll Scroll Net weight (lbs.)313313381381434434Ship weight (lbs.)458458560560613613Filter size nominal (in.)20 x 3020 x 3020 x 20 (qty-2)20 x 20 (qty-2)30 x 2020 x 2030 x 2020 x 20Water in/out size (FPT)3/43/4 1.00 1.00 1.00 1.00Condensate size (NPTI)3/43/43/43/43/43/4Blower wheel Size (in.)11 x 1111 x 1111 x 1111 x 1111 x 1111 x 11Table 4.General data - models EXVG009-030Model EXVG009012015018024030Unit size width x depth x height (in.)21.5 x 21.5 x 3421.5 x 21.5 x 3421.5 x 23 x 3621.5 x 26 x 3821.5 x 26 x 3824 x 32.5 x 42Compressor type Rotary Rotary Rotary Rotary Scroll Scroll Net weight (lbs.)152152188222236280Ship weight (lbs.)207207246282296343Filter size nominal (in.)16 X 1916 X 1917 X 2018 X 2318 X 2320 X 30Water in/out size (FPT)0.500.500.750.750.751.00Condensate size (NPTI)0.750.750.750.750.750.75Blower wheel Size (in.)9 x 89 x 810 x 810 x 910 x 911 x 11Table 5.General data - models EXVG036-070Model EXVG036042048060070Unit size width x depth x height (in.)24 x 32.5 x 4225.4 x 32.5 x 4925.4 x 32.5 x 4925.4 x 32.5 x 5525.4 x 32.5 x 55Compressor type Scroll Scroll Scroll Scroll Scroll Net weight (lbs.)281329345367432Ship weight (lbs.)344394410436501Filter size nominal (in.)20 X 3027 X 3027 X 3030 X 3330 X 33Water in/out size (FPT) 1.00 1.00 1.00 1.00 1.00Condensate size (NPTI)0.750.750.750.750.75Blower wheel Size (in.)11 x 1111 x 1111 x 1111 x 1111 x 11Table 6.General data - models DXHG024-070Model DXHG024036048060070Unit size width x depth x height (in.)25.5 x 55 x 19.7528 x 68 x 21.7529.38 x 77.75 x 22.1329.38 x 86.75 x 22.1329.38 x 86.75 x 22.13Compressor type Two-Stage ScrollTwo-Stage ScrollTwo-Stage ScrollTwo-Stage ScrollTwo-Stage ScrollNet weight (lbs.)269313381434434Ship weight (lbs.)393458560613613Filter size nominal (in.)18 x 2320 x 3020 x 20 (qty-2)30 x 2020 x 2030 x 2020 x 20Water in/out size (FPT)3/43/4 1.00 1.00 1.00Condensate size (NPTI)3/43/43/43/43/4Blower wheel Size (in.)10 x 911 x 1111 x 1111 x 1111 x 11Table 4.General data - models EXVG009-030 (continued)Model EXVG 009012015018024030Table 7.General data - models DXVG024-070Model DXVG024036048060070Unit size width x depth x height (in.)21.5 x 26 x 3824 x 32.5 x 4225.4 x 32.5 x 4925.4 x 32.5 x 5525.4 x 32.5 x 55Compressor type Two-Stage ScrollTwo-Stage ScrollTwo-Stage ScrollTwo-Stage ScrollTwo-Stage ScrollNet weight (lbs.)236279354371437Ship weight (lbs.)296342419440506Filter size nominal (in.)18 x 2323 x 3027 x 3030 x 3330 x 33Water in/out size (FPT)0.75 1.00 1.00 1.00 1.00Condensate size (NPTI)0.750.750.750.750.75Blower wheel Size (in.)10 x 911 x 1111 x 1111 x 1111 x 11Table 8.ANSI/AHRI/ASHRAE/ISO13256-1 WLHP , GWHP and GLHP performance - 0.75 to 6 tonsModelRated GPMRated CFMWater Loop Heat PumpGround Water Heat Pump Ground Loop Heat PumpCooling 86°F Heating 68°F Cooling 59°F Heating 50°F Full Cool 77°F Full Heat 32°F Capacity BtuhEER Capacity Btuh COP Capacity Btuh EER Capacity Btuh COP Capacity Btuh EER Capacity Btuh COP EXV/H009 2.25285790016.109900 5.6880025.08200 4.8830018.86100 3.7EXV/H012 3.003801160016.4015200 5.81370027.912300 5.01230019.59300 4.0EXV/H015 3.754751510016.1018700 5.31700025.815300 4.61580019.012100 3.8EXV/H018 4.505701880017.6023600 5.72110028.718800 4.91960020.614600 4.1EXV/H024 6.007602460017.4032100 5.72740027.225900 5.02560020.319500 3.9EXV/H0307.509503140017.8038400 5.83500027.231000 5.03280020.723600 4.1EXV/H0369.0011403550017.6043100 5.83940026.535000 5.03710020.427200 4.1EXV/H04210.5013303840018.0048000 6.44330027.538500 5.54050021.129400 4.3EXV/H04812.0015204540017.7055600 6.15040026.444800 5.34710020.334600 4.3EXV/H06015.0019005570017.5069000 5.96080025.755900 5.15770020.142900 4.1EXV/H07017.5022156380017.30821005.406890024.9669004.86610019.80520004.1Note: Rated in accordance ANSI/AHRI/ASHRAE/ISO13256-1. Certified conditions are 80.6°F DB/66.2°F WB EAT in cooling and 68°F DB/59°F WB EAT in heating. Entering liquid temperature in coolingis 86°F for Water Loop, 77°F for Ground Loop (full load), 68°F for Ground Loop (part load), and 59°F for Ground Water. Entering liquid temperature in heating is 68°F for Water Loop, 32°F for Ground Loop (full load), 41°F for Ground Loop (part load), and 50°F for Ground Water.March 2023WSHP-PRC030C-EN©2023 TraneTrane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice. We are committed to using environmentally conscious print practices.Trane - by Trane Technologies (NYSE: TT), a global climate innovator - creates comfortable, energy efficient indoor environments for commercial and residential applications. For more information, please visit or .1456167Table 9.ANSI/AHRI/ASHRAE/ISO13256-1 WLHP , GWHP and GLHP performance - 2 to 6 tonsModelLoadRated GPM Rated CFMWater Loop Heat PumpGround Water Heat Pump Ground Loop Heat Pump Cooling 86°F Heating 68°F Cooling 59°F Heating 50°F Full Cool 77°F Full Heat 32°F CapacityBtuhEER Capacity Btuh COP Capacity Btuh EER Capacity Btuh COP Capacity Btuh EER Capacity Btuh COP DXV/H024Full 6.0760*******.832100 5.52750024.425700 4.92590019.219400 3.9DXV/H024Part 6.06081850017.724100 5.92050028.318900 4.92000024.516300 4.3DXV/H036Full 9.011403300017.340900 5.93710025.132900 5.13450019.725500 4.1DXV/H036Part 9.0912*******.330500 6.32760029.324300 5.22660025.221100 4.5DXV/H048Full 12.015204520017.955200 6.15040026.444400 5.34660020.634500 4.3DXV/H048Part 12.012163280018.740000 6.63690031.231900 5.33570026.728000 4.7DXV/H060Full 15.019005210017.663900 6.05660024.851700 5.25390019.939800 4.2DXV/H060Part 15.015203830018.747300 6.64200029.937800 5.44100025.832400 4.6DXV/H070Full 17.522156440017.382700 5.46910023.867400 4.86680019.652900 4.0DXV/H070Part17.517724710018.9597006.05110029.7480005.05000025.6420004.4Note: Performance data EXVG 0.5 Ton or 0.75 Ton Rated in accordance with ANSI/AHRI/ASHRAE/ISO13256-1. Certified conditions are 80.6°F DB/66.2°F WB EAT in cooling and 68°F DB/59°F WB EATin heating. Entering liquid temperature in cooling is 86°F for Water Loop, 77°F for Ground Loop (full load), 68°F for Ground Loop (part load), and 59°F for Ground Water. Entering liquid temperature in heating is 68°F for Water Loop, 32°F for Ground Loop (full load), 41°F for Ground Loop (part load), and 50°F for Ground Water.Table 10.Electrical data - 0.75 to 6 tons, EX*009-070Model No.Unit Volts Blower Motor HPMinimum Circuit AmpacityMaximum Overcurrent ProtectiveDeviceEXH/EXV009208-230/60/11/3 6/615/15EXH/EXV009265/60/11/3 515EXH/EXV012208-230/60/11/3 8/815/15EXH/EXV012265/60/11/3 715EXH/EXV015208-230/60/11/3 10/1015/15EXH/EXV015265/60/11/3 715EXH/EXV018208-230/60/11/2 12/1220/20EXH/EXV018265/60/11/2 1015EXH/EXV024208-230/60/11/2 19/1930/30EXH/EXV024265/60/11/2 1320EXH/EXV024208-230/60/31/2 11/1115/15EXH/EXV024460/60/31/2 615EXH/EXV030208-230/60/1 3/4 20/2030/30EXH/EXV030265/60/1 3/4 1625EXH/EXV030208-230/60/3 3/4 13/1320/20EXH/EXV030460/60/3 3/4 715EXH/EXV036208-230/60/1 3/4 23/2335/35EXH/EXV036265/60/1 3/4 1725EXH/EXV036208-230/60/3 3/4 15/1520/20EXH/EXV036460/60/3 1 715EXH/EXV042208-230/60/1 3/4 25/2540/40EXH/EXV042208-230/60/3 3/417/1725/25EXH/EXV042460/60/3 1 915EXH/EXV048208-230/60/1125/2540/40EXH/EXV048208-230/60/3120/2030/30EXH/EXV048460/60/31915EXH/EXV060208-230/60/1131/3150/50EXH/EXV060208-230/60/3122/2235/35EXH/EXV060460/60/311015EXH/EXV070208-230/60/1139/3960/60EXH/EXV070208-230/60/3126/2640/40Table 10.Electrical data - 0.75 to 6 tons, EX*009-070 (continued)Model No.Unit Volts Blower Motor HPMinimum Circuit AmpacityMaximum Overcurrent ProtectiveDeviceEXH/EXV070460/60/311320Table 11.Electrical data - 2 to 6 tons, DX*024-070Model No.Unit Volts Blower Motor HPMinimum Circuit AmpacityMaximum Overcurrent Protective DeviceDXH/DXV024208-230/60/11/217/1725/25DXH/DXV024265/60/11/21320DXH/DXV024208-230/60/31/210/1015/15DXH/DXV024460/60/31/2615DXH/DXV036208-230/60/13/419/1930/30DXH/DXV036265/60/13/41520DXH/DXV036208-230/60/33/413/1320/20DXH/DXV036460/60/31715DXH/DXV048208-230/60/1125/2540/40DXH/DXV048208-230/60/3121/2130/30DXH/DXV048460/60/311015DXH/DXV060208-230/60/1131/3150/50DXH/DXV060208-230/60/3122/2235/35DXH/DXV060460/60/311015DXH/DXV070208-230/60/1139/3960/60DXH/DXV070208-230/60/3126/2640/40DXH/DXV070460/60/311215Table 10.Electrical data - 0.75 to 6 tons, EX*009-070 (continued)Model No.Unit Volts Blower Motor HPMinimum Circuit AmpacityMaximum Overcurrent ProtectiveDeviceWSHP-PRC030C-EN 01 Mar 2023Supersedes WSHP-PRC030B-EN (Oct 2021)。

水源热泵的热回收应用实例图1水源热泵热回收系统原理图这种热回收方式适用于冷量大、排气温度较低的离心式冷水机组;冷凝热的回收率高,热水的供应量较大;改造的过程中只涉及冷却水系统,对冷水机组影响较小。

3设计细节3.1温度设置为尽量通过板式换热器回收冷却水热量,冷端出水温度应尽量设高,暂定为比37℃仅低1℃的36℃。

通过热泵加热循环水,蓄热水箱内水温达到52℃。

为了使生活热水箱内温度分布均匀,减少热水混合时的热量损失,水箱进出水管伸入水箱内,均匀分布于水箱内,水管贴近水箱,水箱内水管的喷淋开口均匀布置。

水管喷淋孔的布置示意如下:图2蓄热水箱内水管布置图3.2流量确定前面已经介绍,每天锅炉的用水量为7吨左右,锅炉出汽压力0.74Mpa,温度166℃,查表可知蒸汽相变热为1997kJ/kg。

80%的蒸汽,即5.6吨自来水产生的蒸汽,提供生活热水用热。

锅炉进水温度按照18℃计算,其焓值为75kJ/kg,由此可得每天生活热水耗热量为5.6×1000×(1997-75)=1.076×107kJ。

使用热回收方案,为提供相同的热量,把18℃的自来水加热到52℃(218kJ/kg),所需的总水量为1.076×107/(218-75)=75.2t为保证及时供给所需热水,加水时间不宜过长,现设定为4小时,算出板式换热器冷端流量为18.8t/h,相应热端流量为68t/h。

水源热泵冷热端流量均设为18.8t/h。

冷却水被分成三路,通过F3,F4,F5控制,根据不同的运行工况,F4,F5开启或关闭,而流入冷却塔的原冷却水流量则通过F3做相应调节。

3.3自控系统系统不同的运行工况可以通过阀门进行调节,具体设定为:4热泵加热循环水:热水温度未达52℃时,打开阀门F1,F4,水泵2,关闭F2,F5,水泵1,开启热泵(F3调)5生活热水箱补水:热水箱需要补水时,打开阀门F2,F4,F5,水泵1,关闭F1,水泵2,开启热泵(F3调)6水温水位均未满足要求时先进行补水(同b)3.4保温因为要利用冷却水的热量,通过板式换热器和热泵的两路37℃冷却水管均需保温。

IS O 1 4 0 0 1 是由 IS O (国际标准化组织制定,适用于环境管理的管理体系标准。

以国家环境管理体系认证机构认可委员会认定的认证机构,针对环境管理体系的各项要求和相关实施内容的审核,本公司获得 ISO14001认证。

00212Q15806R3L (证书号 IS O 9 0 0 1 是由 IS O (国际标准化组织制定的品质保证工厂认定制定。

针对工厂制造商品的设计和生产等方面进行品质保证的认证。

本公司获得 IS O 9 0 0 1 认证。

O H SAS18001职业健康安全管理体系认证01113060279 (证书号 O H S AS 1 8 0 0 1 是由英国标准协会 (B S I、挪威船级社 (D N V 等 1 3 个组织联合推出的国际性标准。

该认证为企业提供结构化的运行机制,帮助企业改善安全生产管理,推动职业健康安全机制和持续的改进措施。

本公司获得 O H S AS 1 8 0 0 1 认证。

2012 12 PCVCN1111B 12/12/005 SHJS AK大金孜孜以求,一直以更好地满足用户需求为核心,不断突破创新,研发适应时代需求的先进空调系统。

前进的每一步都努力为用户带来更舒适、节能、环保的空调享受。

2011年10月,大金推出水源热泵VRV系统热回收型。

通过追加BS 装置和三管制系统实现冷媒侧热回收功能,系统节能性进一步提高的同时,更能在同一冷媒系统中实现同时制冷/制热功能,满足不同用户的舒适性需求。

充分利用可再生能源,缔造绿色节能空间结合多项可再生能源,将“低碳绿色生活”的愿景化为现实行动高效灵活的空调系统有效保障土壤热平衡宽广的水温运转范围,即使在恶劣环境下也能保障系统稳定运转结合多种绿色环保技术,关爱地球环境系统(热回收型全新上市。

通过冷媒侧热回收功能,实现同一系统同时制冷/制热,进一步深入发掘系统的节能性。

系统灵活,便捷对应追加/改造需求主机室内安装,机身小巧,可加快改造进程,解决室外机摆放难题自由对应加班及负荷不足的需求,系统灵活控制,科学实现分户计费可逐层改造,不影响其他租户,减小资金压力可保留部分原有设备,降低改造成本全变频空调系统全新上市,节能性大幅度提高。