大金单螺杆水冷式冷水机CUW系列

- 格式:pdf

- 大小:13.08 MB

- 文档页数:29

淄博供电公司检修中心综合楼大金CUW水冷空调工程报价文件淄博金达制冷工程有限公司电话:日期:2009年7月6日一、空调方案选型及报价1、工程概况:本项目为山东电力集团公司淄博供电公司检修综合楼中央空调系统,总建筑面积约3400㎡,设计机组为水冷冷水机组加换热器形式,机组夏季制冷、冬季采用集中供热热源。

2、选型依据GBJ19-87《采暖通风与空气调节设计规范》DBJ14-BT1-95《山东建筑设计技术标准》JGJ26-86《民用建筑节能设计标准》TJ301-74《建筑安装工程质量检验评定标准》GB50243-2002《安装工程验收规范》3、计算参数室外:夏季日平均温度31.3℃,平均风速2.8m/s;冬季日平均温度-10℃,平均风速3.2m/s,相对湿度54%。

室内:夏季室内温度24±2℃,相对温度55-65%。

冬季室内温度18±2℃,相对温度55-65%。

风流速小于0.3 m/s;。

主机设备技术参数:制冷工况:进水12℃,出水7℃;室外35℃。

制热工况:进水40℃,出水45℃;室外7℃。

4、选型负荷及数量对于此建筑物,我们推荐使用一台日本大金水冷螺杆式冷水机组CUW100,制冷量340KW,机房在地下一层。

冬季采用板式换热器换热,进入室内空调末端制热。

水泵冬夏季共用。

冷却塔在室外屋顶合适的位置。

选型报价表二、大金CUW单螺杆水冷机组技术特点多机头,便于调节单螺杆压缩机,振动噪音小干式蒸发器,油路少,寿命长高节能——COP达到国家GB标准二级以上。

干式蒸发器——结构简单、性能稳定。

低噪音——静音化设计业界第一。

新型高效压缩机——目前世界上效率最高的单螺杆压缩机。

高信赖的使用寿命——机组维修周期在40000小时以上。

多级容量调节——调节范围:0%~40%~70%~100%。

操作方便、可视性强——大尺寸液晶触摸式面板。

压缩机机械特性1.全系列采用目前压缩机领域最先进的半封闭式单螺杆压缩机,其高效性、可靠性、稳定性及可维护性等诸方面在同类产品中均首屈一指。

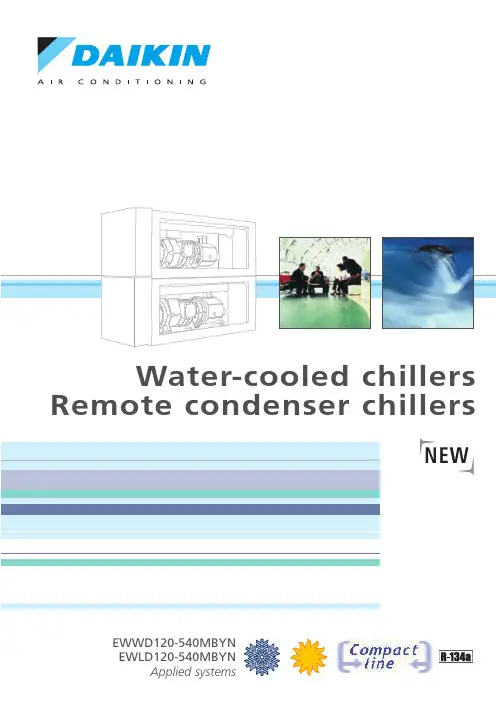

EWWD120-540MBYN EWLD120-540MBYNApplied systemsWater-cooled chillers Remote condenser chillersNEWw w w .d a i k i n e u r o p e .c o mFlexible applicationDaikin’s unique position as a manufacturer of air conditioning equipment,compressors and refrigerants has led to its close involvement in environmental issues.For several years Daikin has had the intention to become a leader in theprovision of environmental friendly products. This challenge demands the eco design and development of a wide range of products and an energy management system;which involves energy conservation and reduction of waste.•flow switch standard supplied with the unit•water filter with diameter perforations of 1mm supplied as standard accessory •Standard fitted with victaulic joints on evaporator:-Victualic joints absorb vibrations, reduce operating sound and thermal deflection and simplify chiller piping and installation-They can accommodate 8°angles and guarantee stress free, leak tight water piping connection.Easy installationLeaving water condenser°CLeaving Water Evaporator (°C)Pull-down areaContinuous operation areaWaterGlycol60504030201044-10410162030•9 models available with cooling capacities ranging from 123 to 546kW and heating capacities from 147 to 655kW•ideal for use in severe weather conditions and over a wide operation range.•2 independent circuits from 360kW onwards•remote condenser version available (EWLD120-540MBY)•compact, simple and robust construction•extended operation range from 50°C to 60°CA range to rely on.The new large Daikin chillers are fitted with a G-type single screw compressor with stepless capacity control. The G-type stepless single screw compressor enables capacity requirements to be closely matched by modulating the sliding valve position according to the chilled water control condition. Main advantages of continuous modulation are better part load efficiency and more stable chilled water temperatures with closer control tolerance. Capacity control is infinitely variable between 30% and 100% on single circuit units and between 15% and 100% on dual circuit units.Single screw compressorElectronic control•advanced pco 2control•detailed information on and accurate control of all functional parameters by easy menu scrolling: schedule timer, floating set point, free cooling, double evaporator pump, manual pump on,date and time information, daily pump on.•chilled water and brine temperatures down to -10°C on standardunit. (Parameter in the service menu of the DDC controller must be set by the installer)•changeable digital input/output such as remote on/off, remote cooling/heating, dual setpoint and limit capacity.•self diagnostic and can be set up in several languages.•Lead lag function is standard•standard equipped with night setback and peak load limitation.•optional digital controller can be installed up to 600 m from the unit.•remote DDC (EKRUPC) can be installed up to 1,000m from the unit•thanks to the standard DICN, simultaneous operation of up to 4 chillers is allowed.This function enables a Daikin 2MW chiller plant to be operated via a single controller.NEWSHELL & TUBE CONDENSER•special header distribution system and design of water system results in high efficiency and reduced heat transfer surface•compact dimensions and lower weight result in a smaller refrigerant volume.BPHE EVAPORATOR•brazed plate heat exchanger made of stainless steel plate, brazed gas tight with copper•optimised distribution benefits of R-134a•the use of this plate heat exchanger results in a compact units: single and double circuits have the same small footprint (2,672mm x 898mm)Heat exchangerNote: 1. For refrigerant charge of EWLD-MBY , please consult the databookNOTE: 1. For refrigerant charge of EWLD-MBY , please consult the databookNominal capacitycooling (EWWD)kW cooling (EWLD)kW heating (EWWD)kW Nominal inputcooling (EWWD)kW cooling (EWLD)kW heating (EWWD)kWEER EWWD/EWLD COP Capacity steps %Refrigerant circuittype charge (1)kg control oil type oil chargel Compressor type No. of circuits/compressors Dimensionsmm Machine weight (EWWD/EWLD)kg Sound power level standard /low noise option dB(A)Casing Piping connectionsevaporator water in/outlet evaporator water drain condenser water in/outlet condenser water drain relief device outletOperation range leaving water condenser °C EWWD/EWLD condensing temperature °C leaving water evaporator°C Power supplyYN EWWD-MBYN/EWLD-MBYN120/120180/170240/240280/26012318324927311617023526514721629032728.745.261.669.232.049.866.577.934.554.072.883.44.29/3.63 4.05/3.41 4.04/3.53 3.95/3.404.2643.983.9230 ~ 100R-134a18353738thermostatic expansion valveelectronic expansion valveFVC68D7.5101014Semi-hermetic single screw compressor1/11,014 x 2,672 x 898993 / 8841,263 / 1,1001,515 / 1,3321,613 / 1,41887/8193/8794/8893/87Polyester painted galvanised steel plate / Ivory white - Munsell 5Y7.5/13"OD3" victaulicfield installation2" 1/2 victaulic 3" victaulicM61 x 1"2 x 1"20°C ~ 50°C / 25°C ~ 55°C20°C ~ 50°C / 25°C ~ 55°C20°C ~ 60°C / 25°C ~ 62°C 20°C ~ 60°C / 25°C ~ 62°C25°C ~ 55°C -10°C ~ 20°C 3~/50Hz/400VEWWD-MBYN/EWLD-MBYNNominal capacitycooling (EWWD)kW cooling (EWLD)kW heating (EWWD)kW Nominal inputcooling (EWWD)kW cooling (EWLD)kW heating (EWWD)kWEER (EWWD/EWLD)COPCapacity steps %Refrigerant circuit typecharge (1)kgcontrol oil typeoil chargelCompressor type No. of circuits/compressors Dimensionsmm Machine weight (EWWD/EWLD)kg Sound power level standart/Low Noise option dB(A)Casingmaterial / colour Piping connectionsevaporator water in/outlet evaporator water drain condenser water inlet/outlet condenser water drain relief device outletOperation range leaving water condenser °C EWWD/EWLD condensing temperature °C leaving water evaporator°C Power supplyYN360/340440/400500/480520/500540/5403664324985225463404054705005304305055806176558910712713113898.4116133144156106.91271461561674.11/3.46 4.04/3.49 3.92/3.53 3.98/3.47 3.96/3.404.023.98 3.97 3.963.9230 ~ 10015 ~ 100R-134a70727475762 x thermostatic expansion valve1x thermost. exp. val v e+1x el e ctr. exp. val v eelectronic expansion valveFVC68D102 x 10 2 x 1010 + 14 2 x 14Semi-hermetic single screw compressor2/22,000 x 2,672 x 8982,526 / 2,2002,778 / 2,4323,030 / 2,6643,128 / 2,7503,326 / 2,83696/9096/9096/9096/9096/90Polyester painted galvanised steel plate / Ivory white - Munsell 5Y7.5/13" victaulic field installation 3" victaulic M62 x 1"3 x 1"4 x 1"20°C ~ 50°C / 25°C ~ 55°C20°C ~ 50°C / 25°C ~ 55°C20°C ~ 60°C / 25°C ~ 62°C20°C ~ 60°C25°C ~ 62°C25°C ~ 55°C -10°C ~ 20°C 3~/50Hz/400VOption Number Option description Completely combinable optionsop03dual pressure relief valve on the condenser (EWWD) op12suction stop valveop52main isolator switchop57a-meter, V-meterOPLN low noise operationAvailable kitsEKCLWS Leaving water controlsensor for DICN EKAC200A BMS cardEKBMSMBA BMS gateway modbus / j-bus protocol EKBMSBNA BMS gateway bacnet protocol EKRUPC Remote user interfaceTo install EKBMSMBA, EKBMSBNA --> EKAC200A needs to be installed on the unit(S) Option required for Swedish national law SNFS 1992 : 16120180/170240280/260360/340440/400500/480520540o (S)o (S)o (S)o (S)o (S)o (S)o (S)o (S)o (S)factory mounted o o o o o o o o o factory mounted o o o o o o o o o factory mounted o o o o o o o o o factory mounted o o o o o o o o o factory mountedo o o o o o o o o kito o o o o o o o o kito o o o o o o o o kito o o o o o o o o kito o o o o o o o o kito availableunit sizeAvailability1. Nominal cooling capacities are based on: evaporator: 12°C/7°C - condenser: 30°C/35°C (EWWD); condensing temperature: 45°C (EWLD) - liquid temperature: 40°C (EWLD)2. Nominal heating capacities are based on: evaporator: 12°C/7°C - condenser: 40°C/45°C3. The sound power level is an absolute value indicating the "power" which a sound source generates. Measuring conditionsE P L E 05-51 / 685 / 05/06 / L a M o v i d a P r i n t e d o n n o n -c h l o r i n a t e d p a p e r / P r i n t e d i n B e l g i umZandvoordestraat 300B-8400 Oostende, Belgium “The present leaflet is drawn up by way of information only and does not constitute an offer binding upon Daikin Europe N.V ..Daikin Europe N.V . has compiled the content of this leaflet to the best of its knowledge. No express or implied warranty is given for the completeness, accuracy, reliability or fitness for particular purpose of its content and the products and services presented therein. Specifications are subject to change without prior notice. Daikin Europe N.V . explicitly rejects any liability for any direct or indirect damage, in the broadest sense, arising from or related to the use and/or interpretation of this leaflet.All content is copyrighted by Daikin Europe N.V ..”Daikin Europe N.V. is approved by LRQA for its Quality Management System in accordance with the ISO9001 standard.ISO9001 pertains to quality assurance regarding design, development, manufacturing as well as to services related to the product.ISO14001 assures an effective environmental management system in order to help protect human health and the environment from the potential impact of our activities, products and services and to assist in maintaining and improving the quality of the environment.Daikin units comply with the European regulations that guarantee the safety of the product.Daikin Europe NV participates in the Eurovent Certification Programme for Air Conditioners (AC),Liquid Chilling Packages (LCP) and Fan Coil Units (FC); the certified data of certified models are listed in the Eurovent Directory.。

螺杆式冷水机组的发展历史及趋势螺杆式制冷压缩机是一种容积型回转式压缩机,由于其高效、耐久、结构紧凑和对负载进行平稳调节的特点,兼有了活塞式压缩机和离心式压缩机二者的优点,从而逐渐在活塞式和离心式之间找到自己的位置,并在一定冷量范围内有加速取代活塞式和离心式制冷压缩机的趋势,在食品冷冻、冷藏、制冰、民用及商用空调、工业制冷等领域广泛得到应用。

螺杆式制冷压缩机从压缩机理上可分为:双螺杆(twin screw)和单螺杆(single screw)。

螺杆式制冷压缩机从型式上可分为:开启式、半封闭式、全封闭式三种。

历史及背景同离心式制冷机组相比,螺杆式压缩机组的发展较晚。

■1934年瑞典皇家工学院教授Lysholm(里斯曼)发明第一台双螺杆式气体压缩机。

■从60年代开始,喷油双螺杆机组应用于制冷机组。

瑞典SRM公司(双螺杆)首先发明双边不对称型线螺杆,使螺杆机效率大大提高。

■1960年法国人Zimmern(辛麦恩)(单螺杆)发明单螺杆的新结构。

1962年试制出第一台样机。

■70年代初,荷兰GRASSO(格拉索)制成第一台单螺杆制冷压缩机。

■1972年,日本开始生产单螺杆空气压缩机。

■1982年,开始生产单螺杆制冷压缩机。

螺杆机在中国的发展情况:■1975年,由上海第一冷冻机厂完成我国第一台氨喷油双螺杆制冷压缩机制造。

■1976年,大连冷冻机厂成功设计制造我国第一台单机双级螺杆式制冷压缩机。

■1986年,武汉冷冻机厂开发了XBY齿型的新型单边不对称圆弧齿型。

进一步提高了国产螺杆制冷压缩机水平。

■90年开始,国外著名厂商进入我国,在螺杆机方面进行多家合资生产。

其中有:中美合资:上海一冷-开利 23XL系列空调用螺杆冷水机组中日合资:烟台荏原螺杆模块式冷(热)水机组中美合资:烟台顿汉布什空调用全封闭螺杆冷水机组中美合资:武汉麦克维尔 WHS系列R22,R134a单螺杆冷水机组中美合资:江阴特灵 RTHB系列螺杆冷水机组中美合资:无锡约克 YS、YCWS系列螺杆冷水机组中日合资:1998年大冷-前川单机双级双螺杆压缩机组中日合资:1998年大金-三石 CUW系列单螺杆冷水机组中国台湾地区的复盛在上海设厂生产双螺杆制冷压缩机。

麦克维尔风冷冷水(热泵机组凝聚意大利 40余年的风冷热泵设计、制造和应用技术精华,积累 10多年中国模块机市场实际应用经验,更大程度的满足了用户对产品高效性、安全性、智能性、舒适性上的要求。

麦克维尔 MAC-D Plus 系列模块式风冷冷水(热泵机组是在原 MAC-D 系列的成功基础上,精雕细琢,全力打造的新一代模块式风冷冷水(热泵机组。

它继承了麦克维尔原 MAC-D 系列的众多优势,并以更出色的能效比(比原系列产品提高 2%~4%,更宽广的使用范围,更方便可靠的系统管理,而傲居模块式风冷热泵技术发展的尖端。

MAC-D Plus系列模块机组用途广泛,特别适用别墅、宾馆、医院、写字楼、娱乐场所、餐厅、超市等空调场合,以节省空调系统的运行费用。

另外,该系列机组还适用于工业冷却中的各种应用场合。

精确电子节流技术机组采用 500级 PMV 电子膨胀阀节流精确控制,使制冷系统形成动态匹配,充分提升系统内每一部件的最佳效能,水温控制的精度更高。

电子膨胀阀特有的大范围节流调节能力,使得机组可以在任何部分负荷时稳定运行,自动适应多变的使用环境温度,调节过程中彻底解决制冷系统的振荡问题。

运行可靠模块化结构,机组分级启动,减小机组启动电流对电网的冲击;机组经严格的长时间测试,无论是在高达 48℃的炎热天气制冷,还是 -10℃的严寒气候制热,均可正常运行;机组本身均自带高低压保护、制冷防冻保护、冬季防冻保护、压缩机过载保护和水压差开关等,最大程度的确保了机组安全;出现任何故障报警时,控制器进行实时自动闪光报警。

静音低噪整机采用箱体隔震设计,多重降噪处理,加上名牌全封闭涡旋压缩机和特殊风叶双转速低噪声风机的采用,制冷模式下更具有夜间静音功能,机组噪声、振动均占据业界领先水平;依托国家级精密噪声室及噪声频谱分析,对风机,电机等部件进行了严格的比对、选择和改进,对结构和管路进行了专业的降噪设计。

机组噪声明显改善。

创新的智能静音模式,根据机组运行状态及室外环境温度自动智能调节风机转速 (高档 /低档,使机组始终处于最佳运行状态,轻松实现全年高效节能、静音低噪运行。