弹塑性力学第一章

- 格式:ppt

- 大小:2.22 MB

- 文档页数:31

![[工学]第1章 岩土弹塑性力学](https://uimg.taocdn.com/e84c57aedd88d0d233d46ae4.webp)

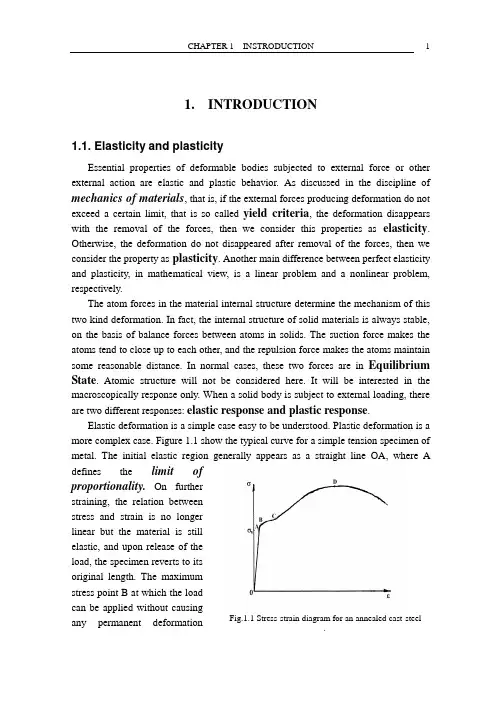

1. INTRODUCTION1.1. Elasticity and plasticityEssential properties of deformable bodies subjected to external force or other external action are elastic and plastic behavior. As discussed in the discipline of mechanics of materials, that is, if the external forces producing deformation do not exceed a certain limit, that is so called yield criteria, the deformation disappears with the removal of the forces, then we consider this properties as elasticity. Otherwise, the deformation do not disappeared after removal of the forces, then we consider the property as plasticity. Another main difference between perfect elasticity and plasticity, in mathematical view, is a linear problem and a nonlinear problem, respectively.The atom forces in the material internal structure determine the mechanism of this two kind deformation. In fact, the internal structure of solid materials is always stable, on the basis of balance forces between atoms in solids. The suction force makes the atoms tend to close up to each other, and the repulsion force makes the atoms maintain some reasonable distance. In normal cases, these two forces are in Equilibrium State. Atomic structure will not be considered here. It will be interested in the macroscopically response only. When a solid body is subject to external loading, there are two different responses: elastic response and plastic response.Elastic deformation is a simple case easy to be understood. Plastic deformation is a more complex case. Figure 1.1 show the typical curve for a simple tension specimen of metal. The initial elastic region generally appears as a straight line OA, where Adefines the limit ofproportionality.On furtherstraining, the relation betweenstress and strain is no longerlinear but the material is stillelastic, and upon release of theload, the specimen reverts to itsoriginal length. The maximumstress point B at which the loadcan be applied without causingany permanent deformation Fig.1.1 Stress-strain diagram for an annealed cast-steelspecimen.(a) (b) (c) (d)Fig. 1.2 Stress-strain diagrams: (a) ductile metal, (b) cast iron and glass, (c) typical concrete or rock,(d) soils, triaxial compression. (Experimental data taken from reference [15].)defines the elastic limit . The point B is also called the yield point , for it marks the initiation of plastic or irreversible deformation. Usually, there is very little difference between the proportional limit, A, and the elastic limit, B. The behavior in the flat region BC is generally referer to as plastic flow . After C the material is exhibited strain hardening or also known as work hardening. Over some point D the material may be exhibit strain softening, as shown in figure 1.1.Now, consider the unloading from some point E beyond the yield point. The behavior is as indicated in figure 1.1. That is, when the stress is reduced, the strain decreases along an almost elastic unloading line OA .So we say that the unloading obey the elastic rule.Fig. 1.2 is the typical graph of stresses versus relative elongation (compression) for four kinds of materials.1.2. Basic hypothesisThe subject of theory of elasticity and plasticity is concerned with the deformation and motion of elastic-plastic bodies or structures under the action of applied load or other disturbances. The general assumptions employed in the study of theory of elasticity and plasticity are the same as those used in the mechanics of continuous medium. Therefore, throughout this book, we have: (a), continuum hypothesis, we shell suppose that the macroscopic behavior of the solid bodies is the same as if they were perfectly continuous in structure; and physical quantities such as the mass and momentum associated with the matter contained within a given small volume will be regarded as being spread uniformly and without any caves, cracks and discontinuous.(b), Uniform hypothesis and isotropic hypothesis, that is, the materials of elastic-plastic body is homogeneous and uniformly distributed over its volume so that the smallest element cut from the body possesses the same specific physical properties as the body. The elastic properties are the same in all directions. (c), small deformation hypothesis, in this book, we discuss small deformation only.1.3. Historical remarksBefore the engineering design of structures, one must not only know the internal force field acting on the structural material and but also know the material response. It means that we need give an analysis of the stresses, deformation and displacement of structural elements. Therefore we have to know the constitutive relation of materials. Seeking some methods to solve these problems, many researchers have continually studied for over 2000 years.The pioneering works of theory of elasticity and plasticity are given by Augustin Cauchy (1789-1857), Marie-Henri Navier (1785-1836), Leonard Euler (1707-1783), Simon Denis Poisson (1781-1840), Barre de Saint-venant (1797-1886), Nikolai Ivanobich Mushihailishibili (1691-1976),Ludwig Prandtl (1875-1858), Thomas Young (1773-1829), Richard von Mises (1883-1953), and many others.The general principles employed in the study of theory of elasticity and plasticity are the same as those used in studying the mechanics of continuous medium. Their basic formulations can be attributed primarily to the work of Euler and Cauchy. Euler first brought forward the general principles of linear and angular momentum balance for continuous media upon which rest all continuum mechanics, including theory elasticity and plasticity. Cauchy first given the concept of the stress and strain at a point and also found the general differential equations of motion or equilibrium of a continuum in term of the stress. Cauchy’s work on elasticity provided a detailedkinematical theory of strain and deformation. The extension of the mathematical theory to more general solids was first made by Navier in 1821 using special assumption concerning the molecular forces of elastic solids. Technical application began earliest in 1855, when Saint-Venant solved the problem of the twisting of prismatic bars and worked out detailed numerical results. Saint-Venant also took up the problem of plastic flow and developed two-dimensional governing equations which were subsequently generalized to three dimensions by M.Levy in 1871. In 1864 H. Tresca reported experiments to the French Academy, which suggested that the plastic yielding of a metal occured when the maximum shear stress reached to a critical value. After Tresca in 1913 R.V on Mises published his yield condition theory based on theory of distortional energy.In the last century (1901-2000) the theory of elasticity and plasticity have rapidly developed in theory and engineering practical. Many great contributors should be mentioned. Such as B.G.Galerkin, G.R.Kirchhoff, S.P.Timoshenko, grange, A.Nadai, A.A.Il’yushin, W.W.Sokolovsky, W.Prager, R.Hill, Kh.A.Rakhmatulin, G.I.Taylor, P.Perzyna, and many others.In this period, especially in last 50 years, theory of elasticity and plasticity rapidly developed in China too. Qian Xueshen, Qian Weichang, Hu Haichang ,Wang Ren, Huang Kezhi, Xu Benye,Wu Jike, Huang zhuping, Gao yuchen, Wang ziqiang, and many others developed the theory of elasticity and plasticity, specially in the engineering applications. In this period published many valuable books about elasticity and plasticity on theoretical and engineering application.。

《弹塑性力学》课程第一篇 基础理论部分第一章 应力状态理论1.1 基本概念1. 应力的概念应力:微分面上内力的分布集度。

从数学上看,应力sPF s ∆∆=→∆0lim ν由于微分面上的应力是一个矢量,因此,它可以分解成微分面法线方向的正应力νσ和微分面上的剪应力ντ。

注意弹塑性力学中正应力和剪应力的正负号规定。

2. 一点的应力状态(1)一点的应力状态概念凡提到应力,必须同时指明它是对物体内哪一点并过该点的哪一个微分面。

物体内同一点各微分面上的应力情况,称为该点的应力状态。

(2)应力张量物体内任一点不同微分面上的应力情况一般是不同的,这就产生了一个如何描绘一点的应力状态的问题。

应力张量概念的提出,就是为了解决这个问题。

在直角坐标系里,一点的应力张量可表示为⎪⎪⎪⎪⎭⎫⎝⎛=z zy zx yz yyx xz xy x ij στττστττσσ若已知一点的应力张量,则过该点任意微分面ν上的应力矢量p就可以由以下公式求出:n m l p xz xy x x ττσν++= (1-1’a ) n m l p yz y yx y τστν++=(1-1’b )n m l p z zy zx z σττν++=(1-1’c )由式(1-1),还可进一步求出该微分面上的总应力p 、正应力νσ和剪应力v τ: 222z y x p p p p ++=(1-2a )nl mn lm n m l zx yz xy z y x τττσσσσν222222+++++=(1-2b )22ννστ-=p(1-2c )(3)主平面、主方向与主应力由一点的应力状态概念可知,通过物体内任一点都可能存在这样的微分面:在该微分面上,只有正应力,而剪应力为零。

这样的微分面即称为主平面,该面的法线方向即称为主方向,相应的正应力称为主应力。

主应力、主方向的求解在数学上归结为求解以下的特征问题:}{}]{[i n i ij n n σσ=(1-3)式中,][ij σ为该点应力张量分量构成的矩阵,n σ为主应力,}{i n 为主方向矢量。

第一章绪论1.1弹塑性力学的任务固体力学是研究固体材料及其构成的物体结构在外部干扰(载荷、温度交化等)下的力学响应的科学,按其研究对象区分为不同的学科分支。

弹性力学和塑性力学是固体力学的两个重要分支。

弹性力学是研究固体材料及由其构成的物体结构在弹性变形阶段的力学行为,包括在外部干扰下弹性物体的内力(应力)、变形(应变)和位移的分布,以及与之相关的原理、理论和方法;塑性力学则研究它们在塑性变形阶段的力学响应。

大多数材料都同时具有弹性和塑性性质,当外载较小时,材料呈现为弹性的或基本上是弹性的;当载荷渐增时,材料将进入塑性变形阶段,即材料的行为呈现为塑性的。

所谓弹性和塑性,只是材料力学性质的流变学分类法中两个典型性质或理想模型;同一种材料在不同条件下可以主要表现为弹性的或塑性的。

因此,所谓弹性材料或弹性物体是指在—定条件下主要呈现弹性性态的材料或物体。

塑性材料或塑性物体的含义与此相类。

如上所述。

大多数材料往往都同时具有弹性和塑性性质,特别是在塑性变形阶段,变形中既有可恢复的弹性变形,又有不可恢复的塑性变形,因此有时又称为弹塑性材料。

本书主要介绍分析弹塑性材料和结构在外部干扰下力学响应的基本原理、理论和方法。

以及相应的“破坏”准则或失效难则。

以弹性分析为基础的结构设计是假定材料为理想弹性,相应于这种设计观点就以分析结果的实际适用范作为设计的失效准则,即认为应力(严柞地说是应力的某一函数值)到达一定限值(弹性界限),将进入塑性变形阶段时、材料将破坏。

结构中如果有一处或—部分材料“破坏”,则认为结构失效(丧失设计所规定的效用)。

由于一般的结构都处于非均匀受力状态,当高应力点或高应力区的材料到达弹性界限时,类他的大部分材料仍处于弹性界限之内;而实际材料在应力超过弹性界限以后并不实际发生破坏,仍具有一定的继续承受应力(载荷)的能力,只不过刚度相对地降低。

因此弹性设计方法不能充分发挥材料的潜力,导致材料的某种浪费。