铸造缺陷中英对照表

- 格式:xlsx

- 大小:11.29 KB

- 文档页数:2

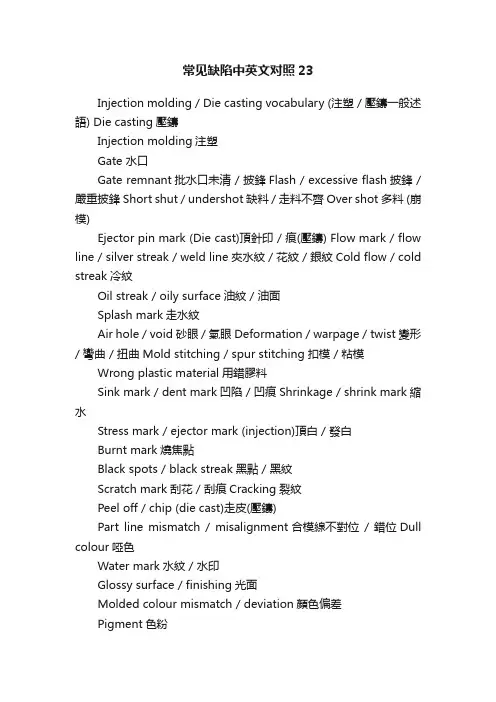

常见缺陷中英文对照23Injection molding / Die casting vocabulary (注塑 / 壓鑄一般述語) Die casting壓鑄Injection molding注塑Gate 水口Gate remnant批水口未清 / 披鋒Flash / excessive flash披鋒 / 嚴重披鋒Short shut / undershot缺料 / 走料不齊Over shot多料 (崩模)Ejector pin mark (Die cast)頂針印 / 痕(壓鑄) Flow mark / flow line / silver streak / weld line夾水紋 / 花紋 / 銀紋Cold flow / cold streak冷紋Oil streak / oily surface油紋 / 油面Splash mark走水紋Air hole / void砂眼 / 氣眼Deformation / warpage / twist變形/ 彎曲 / 扭曲Mold stitching / spur stitching扣模 / 粘模Wrong plastic material用錯膠料Sink mark / dent mark凹陷 / 凹痕Shrinkage / shrink mark縮水Stress mark / ejector mark (injection)頂白 / 發白Burnt mark燒焦點Black spots / black streak黑點 / 黑紋Scratch mark刮花 / 刮痕Cracking裂紋Peel off / chip (die cast)走皮(壓鑄)Part line mismatch / misalignment合模線不對位/ 錯位Dull colour啞色Water mark水紋 / 水印Glossy surface / finishing光面Molded colour mismatch / deviation顏色偏差Pigment色粉Zinc alloy鋅合金Plastic raw material塑膠料Regrind material 水口料 / 翻用料File mark / trim mark銼紋 / 銼損Dirty mark / contamination污糟/ 污漬Material contamination混料Stain mark模漬Blistering起泡Poor surface texture表面粗糙Tread extrusion拉絲Exposed insert露骨Dimension out-specification尺寸不合Mating failure裝配試驗不合格Poor molding-undefined molding defect啤塑差(一般性) Mixing colour混色Incorrect post (die cast)鍋釘尺寸不符Brittleness料脆Casting壓鑄件Gate mark水口位不良Page 1。

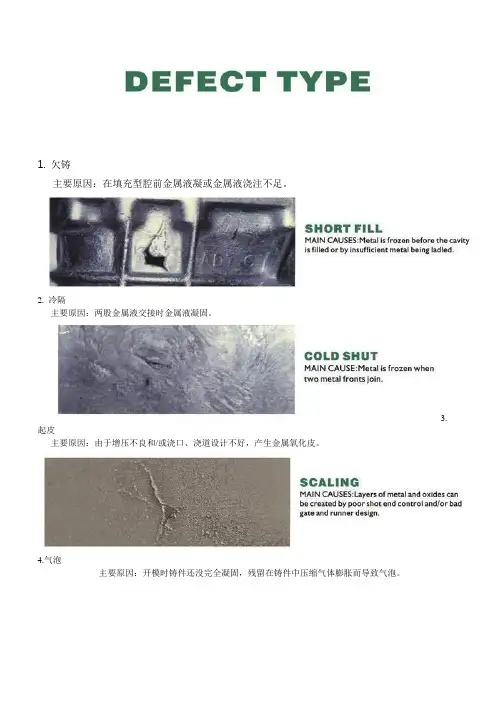

1. 欠铸主要原因:在填充型腔前金属液凝或金属液浇注不足。

2. 冷隔主要原因:两股金属液交接时金属液凝固。

3. 起皮主要原因:由于增压不良和/或浇口、浇道设计不好,产生金属氧化皮。

4.气泡主要原因:开模时铸件还没完全凝固,残留在铸件中压缩气体膨胀而导致气泡。

5. 飞边主要原因:在行腔最后填充时,铸件投影面区域金属液压力太高,一股压力穿过分型线,缩模力不够,模具涨开,金属液逃逸。

6. 铸点主要原因:金属液在压室过分冷却,金属固体微粒被压入型腔,铸点在铸件表面用肉眼可以清楚看见。

7. 压射润滑油油污主要原因:压射润滑油使用过多。

8. 气孔主要原因:铸件中残留来自各种原因的气体,压铸参数不好,排气、溢流系统或浇口、浇道设计不好。

9. 拉伤主要原因:拔模斜度不够或表面凹陷,在顶出时产品表面被破坏,可通过改变铸件顶出时温度来改善。

模具表面粗糙度不好是另一个原因。

10.热裂/裂纹主要原因:凝固过程中,在应力状态下收缩时产生,最后在表面有可见的裂纹(不是热脆)。

11.热脆主要原因:合金成分引起在高温时金属太脆(凝固后),铸件冷却(收缩)过程中,导致铸件表面裂纹出现在高应力区。

注意:该缺陷伴随热裂出现。

12. 凹陷主要原因:凹陷是铸件表面附近的收缩坑导致,出现凝固时铸件表面凹向收缩坑。

凹陷同样由模具热学控制不好的缩孔导致,因为凹陷的形成需要热点。

13. 金属爆破主要原因:铸件在完全凝固前顶出和孔洞的伴随物,铸件中被受限制的气体冲破未凝固铸件表面。

14.热变形主要原因:铸件顶出后,在冷却至室温过程中产生变形。

根本原因有时是铸件几何结构或合金规范,热变形在较低温度下顶出可减缓,不平衡模具温度是产生该类缺陷主要原因。

15.粘模主要原因:化学侵蚀和合金与模具钢粘合,在顶出时铸件被拉破。

可改变合金和/或降低模具或合金液温度来改善。

16. 缩孔主要原因:在凝固过程中金属缩小体积,在凝固前而不能提供更多的金属液。

热点也导致在特定区域产生缩孔。

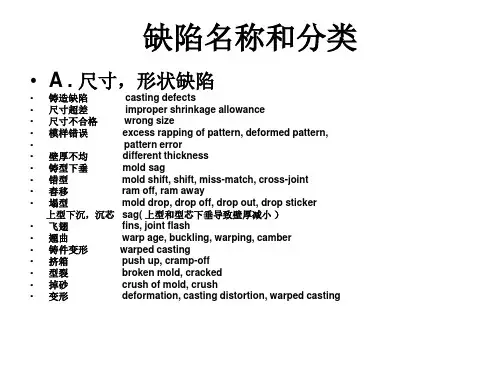

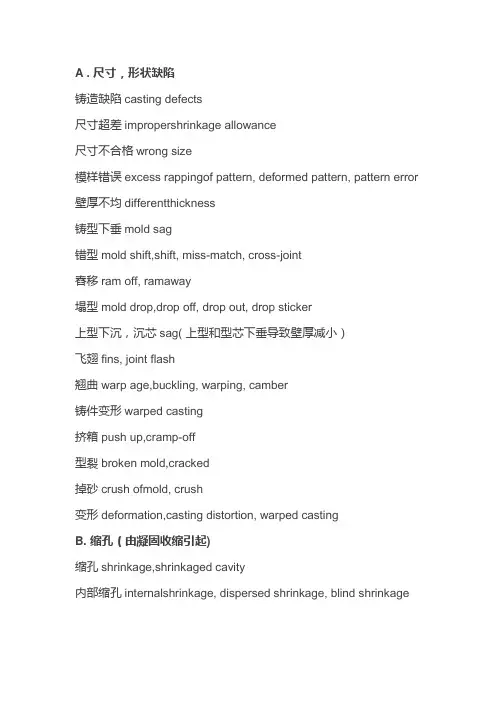

A .尺寸,形状缺陷铸造缺陷casting defects尺寸超差impropershrinkage allowance尺寸不合格wrong size模样错误excess rappingof pattern, deformed pattern, pattern error 壁厚不均differentthickness铸型下垂mold sag错型mold shift,shift, miss-match, cross-joint舂移ram off, ramaway塌型mold drop,drop off, drop out, drop sticker上型下沉,沉芯sag( 上型和型芯下垂导致壁厚减小)飞翅fins, joint flash翘曲warp age,buckling, warping, camber铸件变形warped casting挤箱push up,cramp-off型裂broken mold,cracked掉砂crush ofmold, crush变形deformation,casting distortion, warped castingB.缩孔(由凝固收缩引起)缩孔shrinkage,shrinkaged cavity内部缩孔internalshrinkage, dispersed shrinkage, blind shrinkage敞露缩孔open shrinkage,external shrinkages, sink marks, depression缩松porosity, shrinkage porosity,leakers, micro shrinkage, disperded shrinkage缩陷sink marks,draw, suck-in芯面缩孔core shrinkage内角缩孔cornershrinkage, fillet shrinkage出汗孔extruded bead,exudation线状缩孔fissure likeshrinkageC.气体缺陷(由气体引起的孔)气孔blowholes,gas hole, blow针孔pinholes裂纹状缺陷,线状缺陷fissure defectsD.裂纹裂纹crack缩裂shrinkage crack季裂seasoncracking, season crack应力热裂hot cracking,hot tearing, hot tear淬火裂纹quench crack,quenching crack应力冷裂cold cracking,breakage, cold tearing, cold tear 龟裂crack激冷层裂纹,白裂chill crackE.夹杂物夹渣slaginclusion, slag blowholes砂眼sandinclusion, raised sand, sand hole其他夹杂物the other inclusion胀砂push up,cramp-off, sand hole掉砂crush, crushof mold硬点hard spot浮渣dross ( 浇注后在铸型内形成的缺陷,尤其是石墨、氧化物和硫化物的线状缺陷的总称,另外,浇注过程中被卷进去的缺陷成为夹渣和砂眼,两者的区别是形成原因不同)石墨浮渣graphite dross,carbon dross氧化皮夹渣oxide dross, oxideinclusion, skins, seams硫化物熔渣sulfide dross沉淀物sludge夹渣物sand inclusion,oxide inclusion, skins, seams黑点,黑渣black spots,lustrous carbon涂料夹渣blacking,refractory coating inclusions光亮碳膜lustrous carbonfilms, kish tracksF.外观缺陷浇不足misrun, shortrun, cold lap, cold shut冷隔cold shut,cold laps轻度冷隔seam两重皮plate皱皮surface fold,gas run, elephant skin, seams, scare, flow marks 漏箱run-out,runout, break-out, bleeder漏芯mold drop,stiker未浇满short pours,short run, poured short气孔blowholes, blow飞翅fins,joint flash胀砂,气疱swell, blister芯撑未融合chaplet shut,insert cold shut, unfused chaplet热粘砂burn in热痕flow marks内渗豆,冷豆,冷隔internal sweating, coldshot, shot iron外渗物sweating磷化物渗豆phosphide sweat铅渗豆lead sweat锡渗豆tin sweat掉砂rat, sticker (型砂的一部分附着在模样上而形成的表面缺陷)G.型芯缺陷砂芯断裂crushed core,broken core砂芯压碎broken core芯面缩孔core blow砂芯缩孔core blow砂芯下垂sag core,deformed core砂芯弯曲deformed core漂芯shiftedcore, core raise, raised core, mold element cutout 偏芯core shiftH.表面缺陷沾砂burn on,sand burning, burn in , penetration粘型(金属型)fusion两重皮laminations ,plat机械粘砂penetration ,metal penetration夹渣结疤scabs ,expansion scabs , corner scab表面粗糙rough casting ,rough surface鼠尾buckle , rattail涂料结疤blacking scab ,wash scabs烘干不足sever surface ,wash scabs熟痕surfacedefect casting by combination of gas and shrinkage ( 在靠近厚断面处形成下陷的蛇状伤痕)涂料剥落wash erosion气疱blister ,surface or subsurface blow hole表面粗糙rough surface ,seems , scars起皮stripping剥落结疤pull down ,spalling scab伤痕crow’s feet麻面pittingsurface , orange peel , alligator skin热裂痕surface folds, gas runs泡疤表面surface folds ,gas runs象皮状皱皮surface fold , gasrun , elephant skin皱皮surface fold, gas run , seams , scare , flow marks 波纹wave冲砂wash冲蚀erosionI.组织缺陷(铸铁)球化不良poor nodularity, degenerated graphite蠕墨化不良degeneratedgraphite异常石墨abnormalgraphite开花状石墨exploded graphite过冷石墨under cooledgraphite , D-type graphite石墨细小颗粒chunky graphite石墨粗大kish graphite ,kish整列石墨aligned graphite石墨漂浮floated graphite石墨魏氏组织Widmannstattengraphite麻口mottled cast iron , mottle灰点mottle反麻口inverse mottle ( 与麻口相反,在薄断面处和尖角处形成的麻口)白口chill反白口reverse chill , inverse chill冷豆extruded bead , exudation ,internal sweating退火不足miss annealing , incomplete annealing粗大枝晶组织coarsened dendritic反偏析inverse segregation比重偏析gravity segregation溶质偏析solute segregation宏观偏析macroscopic segregation微观偏析microscopic segregationJ.断口缺陷表面铁素体ferrite rim表面珠光体pearlite rim白缘,脱碳pearlitic rim , picture frame , pearlitelayer不均匀断口heterogeneous fractured surface破碎激冷层scattered chill structure , cold flakes晶粒粗大rough grain尖钉状断口spiky fractured surface冰糖状断口rock candy fracture surfaceK.力学性能缺陷硬点hard spot ( 对铸件,硬点是硬区、白口或冷豆等力学性能缺陷的总称;对铝合金,硬点是铸件内各种高硬度相,如初晶Si相、金属间化合物、氧化物,偏析等总称)硬度不良poor hardness , too high or lowhardnessL.使用性能缺陷腐蚀性不良poor corrosion resistance切削性不良poor machinability麻点torn surface锌晶间腐蚀zinc intergranular corrosion电导率不良poor electrical conductivityM.其他缺陷残留飞翅residual fin残留黑皮residualblack skin浇道冒口断口缺肉broken casting at gate , riser or vent端部缺肉inside cut切口缺肉(压铸件)inside cut翘曲( 喷丸引起)camber, excessive cleaning铸件弯曲( 铸件变形)warped casting , casting distortion , deformed mold , mold creep打磨缺肉crow’s feet铸造管理缺陷裂纹crack压痕impression残留物型砂残留sand inclusions喷丸粒残留residual shot锌蒸汽向炉壁渗透zinc infiltration into refractory。

![铸造缺陷名称分类(中英文)[1]1](https://uimg.taocdn.com/ed885e4514791711cc7917eb.webp)

A 。

尺寸,形状缺陷铸造缺陷casting defects尺寸超差impropershrinkage allowance尺寸不合格wrong size模样错误excess rappingof pattern,deformed pattern, pattern error 壁厚不均differentthickness铸型下垂mold sag错型mold shift,shift,miss—match,cross—joint舂移ram off,ramaway塌型mold drop,drop off, drop out,drop sticker上型下沉,沉芯sag(上型和型芯下垂导致壁厚减小)飞翅fins,joint flash翘曲warp age,buckling, warping,camber铸件变形warped casting挤箱push up,cramp-off型裂broken mold,cracked掉砂crush ofmold,crush变形deformation,casting distortion, warped castingB.缩孔(由凝固收缩引起)缩孔shrinkage,shrinkaged cavity内部缩孔internalshrinkage,dispersed shrinkage,blind shrinkage敞露缩孔open shrinkage,external shrinkages,sink marks, depression缩松porosity, shrinkage porosity,leakers, micro shrinkage, disperded shrinkage缩陷sink marks,draw,suck-in芯面缩孔core shrinkage内角缩孔cornershrinkage,fillet shrinkage出汗孔extruded bead,exudation线状缩孔fissure likeshrinkageC.气体缺陷(由气体引起的孔)气孔blowholes,gas hole, blow针孔pinholes裂纹状缺陷,线状缺陷fissure defectsD.裂纹裂纹crack缩裂shrinkage crack季裂seasoncracking, season crack应力热裂hot cracking,hot tearing,hot tear淬火裂纹quench crack,quenching crack应力冷裂cold cracking,breakage, cold tearing, cold tear龟裂crack激冷层裂纹,白裂chill crackE.夹杂物夹渣slaginclusion, slag blowholes砂眼sandinclusion, raised sand, sand hole其他夹杂物the other inclusion胀砂push up,cramp-off,sand hole掉砂crush, crushof mold硬点hard spot浮渣dross ( 浇注后在铸型内形成的缺陷,尤其是石墨、氧化物和硫化物的线状缺陷的总称,另外,浇注过程中被卷进去的缺陷成为夹渣和砂眼,两者的区别是形成原因不同)石墨浮渣graphite dross,carbon dross氧化皮夹渣oxide dross,oxideinclusion,skins,seams硫化物熔渣sulfide dross沉淀物sludge夹渣物sand inclusion,oxide inclusion, skins,seams黑点,黑渣black spots,lustrous carbon涂料夹渣blacking,refractory coating inclusions光亮碳膜lustrous carbonfilms, kish tracksF。

A .尺寸,形状缺陷铸造缺陷casting defects尺寸超差impropershrinkage allowance尺寸不合格wrong size模样错误excess rappingof pattern, deformed pattern, pattern error 壁厚不均differentthickness铸型下垂mold sag错型mold shift,shift, miss-match, cross-joint舂移ram off, ramaway塌型mold drop,drop off, drop out, drop sticker上型下沉,沉芯sag( 上型和型芯下垂导致壁厚减小)飞翅fins, joint flash翘曲warp age,buckling, warping, camber铸件变形warped casting挤箱push up,cramp-off型裂broken mold,cracked掉砂crush ofmold, crush变形deformation,casting distortion, warped castingB.缩孔(由凝固收缩引起)缩孔shrinkage,shrinkaged cavity内部缩孔internalshrinkage, dispersed shrinkage, blind shrinkage敞露缩孔open shrinkage,external shrinkages, sink marks, depression缩松porosity, shrinkage porosity,leakers, micro shrinkage, disperded shrinkage缩陷sink marks,draw, suck-in芯面缩孔core shrinkage内角缩孔cornershrinkage, fillet shrinkage出汗孔extruded bead,exudation线状缩孔fissure likeshrinkageC.气体缺陷(由气体引起的孔)气孔blowholes,gas hole, blow针孔pinholes裂纹状缺陷,线状缺陷fissure defectsD.裂纹裂纹crack缩裂shrinkage crack季裂seasoncracking, season crack应力热裂hot cracking,hot tearing, hot tear淬火裂纹quench crack,quenching crack应力冷裂cold cracking,breakage, cold tearing, cold tear 龟裂crack激冷层裂纹,白裂chill crackE.夹杂物夹渣slaginclusion, slag blowholes砂眼sandinclusion, raised sand, sand hole其他夹杂物the other inclusion胀砂push up,cramp-off, sand hole掉砂crush, crushof mold硬点hard spot浮渣dross ( 浇注后在铸型内形成的缺陷,尤其是石墨、氧化物和硫化物的线状缺陷的总称,另外,浇注过程中被卷进去的缺陷成为夹渣和砂眼,两者的区别是形成原因不同)石墨浮渣graphite dross,carbon dross氧化皮夹渣oxide dross, oxideinclusion, skins, seams硫化物熔渣sulfide dross沉淀物sludge夹渣物sand inclusion,oxide inclusion, skins, seams黑点,黑渣black spots,lustrous carbon涂料夹渣blacking,refractory coating inclusions光亮碳膜lustrous carbonfilms, kish tracksF.外观缺陷浇不足misrun, shortrun, cold lap, cold shut冷隔cold shut,cold laps轻度冷隔seam两重皮plate皱皮surface fold,gas run, elephant skin, seams, scare, flow marks 漏箱run-out,runout, break-out, bleeder漏芯mold drop,stiker未浇满short pours,short run, poured short气孔blowholes, blow飞翅fins,joint flash胀砂,气疱swell, blister芯撑未融合chaplet shut,insert cold shut, unfused chaplet热粘砂burn in热痕flow marks内渗豆,冷豆,冷隔internal sweating, coldshot, shot iron外渗物sweating磷化物渗豆phosphide sweat铅渗豆lead sweat锡渗豆tin sweat掉砂rat, sticker (型砂的一部分附着在模样上而形成的表面缺陷)G.型芯缺陷砂芯断裂crushed core,broken core砂芯压碎broken core芯面缩孔core blow砂芯缩孔core blow砂芯下垂sag core,deformed core砂芯弯曲deformed core漂芯shiftedcore, core raise, raised core, mold element cutout 偏芯core shiftH.表面缺陷沾砂burn on,sand burning, burn in , penetration粘型(金属型)fusion两重皮laminations ,plat机械粘砂penetration ,metal penetration夹渣结疤scabs ,expansion scabs , corner scab表面粗糙rough casting ,rough surface鼠尾buckle , rattail涂料结疤blacking scab ,wash scabs烘干不足sever surface ,wash scabs熟痕surfacedefect casting by combination of gas and shrinkage ( 在靠近厚断面处形成下陷的蛇状伤痕)涂料剥落wash erosion气疱blister ,surface or subsurface blow hole表面粗糙rough surface ,seems , scars起皮stripping剥落结疤pull down ,spalling scab伤痕crow’s feet麻面pittingsurface , orange peel , alligator skin热裂痕surface folds, gas runs泡疤表面surface folds ,gas runs象皮状皱皮surface fold , gasrun , elephant skin皱皮surface fold, gas run , seams , scare , flow marks 波纹wave冲砂wash冲蚀erosionI.组织缺陷(铸铁)球化不良poor nodularity, degenerated graphite蠕墨化不良degeneratedgraphite异常石墨abnormalgraphite开花状石墨exploded graphite过冷石墨under cooledgraphite , D-type graphite石墨细小颗粒chunky graphite石墨粗大kish graphite ,kish整列石墨aligned graphite石墨漂浮floated graphite石墨魏氏组织Widmannstattengraphite麻口mottled cast iron , mottle灰点mottle反麻口inverse mottle ( 与麻口相反,在薄断面处和尖角处形成的麻口)白口chill反白口reverse chill , inverse chill冷豆extruded bead , exudation ,internal sweating退火不足miss annealing , incomplete annealing粗大枝晶组织coarsened dendritic反偏析inverse segregation比重偏析gravity segregation溶质偏析solute segregation宏观偏析macroscopic segregation微观偏析microscopic segregationJ.断口缺陷表面铁素体ferrite rim表面珠光体pearlite rim白缘,脱碳pearlitic rim , picture frame , pearlitelayer不均匀断口heterogeneous fractured surface破碎激冷层scattered chill structure , cold flakes晶粒粗大rough grain尖钉状断口spiky fractured surface冰糖状断口rock candy fracture surfaceK.力学性能缺陷硬点hard spot ( 对铸件,硬点是硬区、白口或冷豆等力学性能缺陷的总称;对铝合金,硬点是铸件内各种高硬度相,如初晶Si相、金属间化合物、氧化物,偏析等总称)硬度不良poor hardness , too high or lowhardnessL.使用性能缺陷腐蚀性不良poor corrosion resistance切削性不良poor machinability麻点torn surface锌晶间腐蚀zinc intergranular corrosion电导率不良poor electrical conductivityM.其他缺陷残留飞翅residual fin残留黑皮residualblack skin浇道冒口断口缺肉broken casting at gate , riser or vent端部缺肉inside cut切口缺肉(压铸件)inside cut翘曲( 喷丸引起)camber, excessive cleaning铸件弯曲( 铸件变形)warped casting , casting distortion , deformed mold , mold creep打磨缺肉crow’s feet铸造管理缺陷裂纹crack压痕impression残留物型砂残留sand inclusions喷丸粒残留residual shot锌蒸汽向炉壁渗透zinc infiltration into refractory。

注塑件缺陷中英文对照表中文英文----------------------------起泡Blister起霜Blooming破孔Blow hole泛白Blushing侧壁皱纹Body wrinkle冒口带肉Breaking-in膜泡、气泡Bubble糊斑Burn mark毛边(金属)Burr(for metal)翘曲Camber气泡Cell表面中部波皱Center buckle细裂痕Check龟裂Checking修整表面缺陷Chipping铸件凹痕Clamp-off塌陷Collapse色斑Color mottle腐蚀Corrosion外观不良Cosmetic defect裂痕Crack碎裂、龟裂Crazing变形Deformation切边碎片Edge裂边Edge crack退色Fading填充料斑Filler speak裂纹Fissure凸缘起皱Flange wrinkle毛边Flash刮伤Flaw流痕Flow mark,flow line字体模糊Foggy毛边Galling光滑Glazing光泽Gloss污斑Grease pits油污、脏污Grease,oil stains磨痕Grinding defect发裂Haircrack雾度Haze水锈Incrustation杂质Inclusion压痕Indentation内部气孔Internal porosity发霉Mildewed,moldy,mouldy偏模Mismatch杂色Mixed color斑点Mottle缩颈Necking割痕Nick橘皮状表面缺陷Orange peel溢流Overflow剥离Peeling,peel-off坑Pit点状腐蚀Pitting corrosion模板印痕Plate mark麻点Pock痘斑Pock mark树脂流纹Resin streak树脂脱落Resin wear凹陷Riding松垂Sagging皂化Saponification疤痕Scar废料Scrap废料阻塞Scrap jam刮伤、划痕、划伤Scratch深冲表面划伤Scuffing裂痕Seam模口挤痕Shock line充填不足Short shot凹孔Shrinkage pool缩水Shrinking,shrinkage凹痕、凹陷Sink mark,shrink Line,sink mark表皮折迭Skin inclusion螺丝滑头、滑手Slipped screw head,slippery screw thread 斑点Speckle矫直Straightening条状痕、条纹Streak表面裂痕Surface check橘皮状表皮皱折Surface roughening波动Surging冒汗Sweat out扭曲Torsion翘曲Warpage波痕Waviness熔塌Webbing焊痕、熔接线Weld mark,weld line 白化Whitening皱纹Wrinkle欢迎您的下载,资料仅供参考!致力为企业和个人提供合同协议,策划案计划书,学习资料等等打造全网一站式需求。

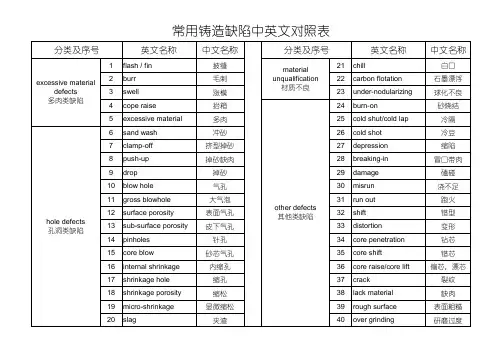

·Metallic projections金属多肉缺陷·Cavities空洞类缺陷·Discontinuities断、裂缺陷·Defects表面缺陷(瑕疵)·Incomplete casting铸件不完整·Incorrect dimension尺寸不符合·Inclusions or structural anomalies夹杂或结构异常Table 1 International classification of common casting defects 表1 一般铸造缺陷的国际分类No. Description描述Commonname一般名称Sketch图Metallic ProjectionsA100: Metallic projections in the form of fins or flash 飞边尾翅、披缝形式的多肉A110: Metallic projections in the form of fins (or flash) without change in principal casting dimensions飞边尾翅(披缝)形式的多肉,不改变铸件基本尺寸A111 Thin fins (or flash) at theparting line or at core prints在分型线或芯头上的飞边(飞翅)Joint flash or fins 飞边(飞翅)A112 Projections in the form ofveins on the castingSurface铸件表面的毛刺Veining or finning 毛刺A113 Network of projections onthe surface of die castingsHeat-checked dieA 114(a) Thin projection parallel to acasting surface, in re-entrantangles平行于铸件表面,在凹角处小块多肉Fillet scab 圆角夹砂A115 Thin metallic projectionlocated at a re-entrantangle and dividing the anglein two parts在凹角处小块多肉将圆角分成两部分Fillet vein 圆角毛刺A120 Metallic projections in the form of fins with changes in principal casting dimensions 飞边多肉改变了铸件的基本尺寸A 123(a) Formation of fins in planesrelated to direction of moldassembly (precision castingwith waste pattern);principal castingdimensions change合型不精确在平面上形成飞翅,改变铸件基本尺寸Cracked or broken mold铸型裂纹或塌箱A200 Massive projections 大块多肉A210 Swells胀箱A 212(a) Excess metal in the vicinityof the gate orbeneath the sprue在内浇口附近或直浇道下方有大块金属Erosion, cut, or wash冲砂A 213(a) Metal projections in theform of elongated areas inthe direction of moldassembly在合型延长方向上的多肉Crush 掉砂A220:Projections with rough surfaces表面粗糙A 221(a) Projections with roughsurfaces on the copesurface of the casting铸件上箱面粗糙Mold drop or sticker 铸型掉砂A 222(a) Projections with roughsurfaces on the dragsurface of the casting(massive projections)铸件下箱面粗糙(成块的) Raised core or mold element cutoff砂芯上浮,掉砂A 223(a) Projections with roughsurfaces on the dragsurface of the casting (indispersed areas)铸件下箱面粗糙(分散的) Raised sand 型砂上浮A 224(a) Projections with roughsurfaces on other parts of thecasting铸件的其它位置表面粗糙Mold drop 铸型掉砂A 225(a) Projections with roughsurfaces over extensiveareas of the casting铸件上大面积表面粗糙Corner scab 直角夹砂A 226(a) Projections with roughsurfaces in an areaformed by a core由砂芯形成的表面处粗糙Broken or crushed Core断芯CavitiesB 100: Cavities with generally rounded, smooth walls perceptible to the naked eye(blowholes, pinholes)裸眼看孔洞壁感觉是圆的、光滑的B 110: Class B 100 cavities internal to the casting, not extending to the surface, discernibleonly by special methods, machining, or fracture of the castingB100类型孔洞是在铸件壁内,未延伸至铸件表面,只能由特殊方法、设备或破碎铸件才能辨别B111(a)Internal, rounded cavities,usually smooth-walled, ofvaried size, isolated or groupedirregularly in all areas of thecasting在铸件壁内,圆的孔洞,通常洞壁光滑,有不同的大小,有单个的也有多个的,可以在铸件的各个部位Blowholes,pinholes气孔,针孔B112(a)As above, but limited to thevicinity of metallic pieces placedin the mold (chills, inserts,chaplets, etc.)和上面一样,但只限于在金属薄片放入铸型的邻近区域(过冷物、冷铁嵌入物、芯撑等)Blowholes,adjacentto inserts, chills,chaplets, etc.气孔,邻近过冷物、嵌入物、芯撑等B113(a)Like B 111, but accompaniedby slag inclusions(G 122)象B111类型,但是伴有渣Slag blowholes渣气孔B120 Class B 100 cavities located at or near the casting surface, largely exposed or at least connected with the exteriorB 100 类型,位于或接近铸件表面,大部分暴露或与外部相连。