马丁轻型清扫器安装说明

- 格式:docx

- 大小:946.92 KB

- 文档页数:4

除尘器安装说明书三篇篇一:电除尘器安装说明书(中文)1、适用范围1.1本说明书适用于电除尘器本体安装。

技术改造大修亦可参照执行。

1.2同类型电除尘器及某些产品的特殊规定与本说明书不一致时,应按特殊规定执行。

1.3规范性引用文件下列文件中的条款通过本说明书的引用而成为本说明书的条款。

凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本说明书,然而,鼓励根据本说明书达成协议的各方研究是否要使用这些文件的最新版本。

凡是不注日期的引用文件,其最新版本适用于本说明书。

JB/T5910-1997 电除尘器JB/T8536-1997 电除尘器机械安装技术条件JB5908-1991 电除尘器主要件抽样检验及包装运输贮存规范JB/T5906-1997 电除尘器阳极板JB/T5909.1-4 电除尘器用瓷绝缘子2、设备保管与开箱验收2.1设备到达现场后,按下列要求保管:2.1.1堆放场地要合理布局,基础稳固,便于装运、作业,并作好防洪防涝设施;2.1.2产品堆放要符合预装及安装工艺流程要求,避免多次倒运以防变形;2.1.3电除尘器零部件的包装运输、标志贮存应符合JB5908-1991的规定。

2.2设备开箱验收2.2.1设备开箱、清点、验收应有制造厂、用户、施工单位共同参加。

2.2.2验收条件a.供货清册、装箱清单等技术文件资料齐全;b.设备铭牌上的型号、规格、数量与工程设计相符;c.检查产品质量,如因运输、装卸、贮存过程产生变形和尺寸变动,应作校正,对无法修复的要给予报废及更换。

d.设备验收标准依据制造厂家设计图纸、有关技术文件及JB/T5910-1997规定。

3、施工前准备3.1安装条件3.1.1施工单位应熟悉设备的结构、性能及有关图纸和技术文件、编制施工组织设计文件和施工质量卡,施工过程中要严格做好质量检验记录(见《文件包》);3.1.2按交货清单清点零部件;3.1.3电瓷产品耐压试验应符合JB/T59091-4的规定;3.1.4施工现场应有“三通一平”(即水通、电通、道路通、场地平整)条件,并具备防火、防冻、防雨等安全设施;3.1.5钢筋混凝土基础及支柱,应经验收合格并提供耐压试验报告后方可进行设备安装;3.1.6电除尘器的安装应根据安装说明书,安装图纸及相应的技术要求,在吉利达现场技术代表的指导下进行。

水泥仓顶除尘器安装细节水泥生产过程中会产生大量的粉尘,这些粉尘会对人员健康和环境造成严重的危害。

为了保护工人和环境,水泥厂需要安装除尘器。

水泥仓顶除尘器是最常用的一种,本文将介绍水泥仓顶除尘器的安装细节。

1. 选址与安装位置水泥仓顶除尘器应尽可能的靠近水泥仓顶,这样可以最大限度地减小管道长度和阻力。

一般而言,水泥仓顶除尘器应该设置在仓体顶部的略高位置,从而保证除尘器的收尘口与仓体的出料口水平。

除此之外,除尘器在安装时应该考虑到以下因素:•应考虑周边设备的协调,在保证运行效果的同时,占用空间尽可能的少。

•除尘器与设备的连接角度和连接口要达到最佳安装效果,尽量减少管道长度并降低阻力,保证除尘器系统的正常通风和除尘。

•除尘器周围的环境应该保持清洁,由于水泥会随着时间的推移逐渐在除尘器的接口处聚积,定期清洗除尘器及管道是非常必要的。

2. 选择合适的管道保证除尘器的正常运行,合适的管道连接是至关重要的。

应在安装过程中选择具有耐腐蚀、阻力小、易于安装和维护的管道。

同时,应该注意以下因素:•如果可能,应选择更短、直径较大的管道,以降低管道阻力。

•确保所选择的管道与除尘器口和接口的标准相同,以免出现不匹配的情况。

•部署对应数量和大小的过滤网,以减缓过快运行的尘埃粒子,从而防止过滤网被堵塞,影响除尘器的正常运行。

3. 调整开口度合适的开口度对于除尘器的性能来说非常重要。

开口度越大,废气流量越大,但收尘效果却会变差。

为了找到最佳开口度,需要进行如下的试验和调整:•可以通过调整波纹管的质量和长度等参数来提高收尘效果。

•手动调节控制阀,以找到最佳开口度。

4. 插入式除尘器无法超标达标的原因在水泥生产中,插入式除尘器经常被用来收集粉尘,但有时会出现超标的现象。

通过分析,我们可以得出以下的原因:•除尘器的收尘口被堵塞。

•除尘器的管道阻力过大。

•除尘器运行负荷过大。

为了避免这些问题的出现,我们可以通过合理调整除尘器的开口度、清理除尘器的管道和过滤网、防止除尘器过度运行等方式来解决问题。

皮带平行托辊清扫器安装标准全文共四篇示例,供读者参考第一篇示例:一、安装位置的确定1. 安装位置应该在皮带输送机的头部,与驱动滚筒保持一定间距,确保皮带平行托辊清扫器能够有效清理输送带上的杂物。

2. 确保安装位置能够方便维修和更换清扫器的刷片,同时不影响其他设备的正常运行。

3. 在安装位置上留有足够的空间,以确保皮带平行托辊清扫器的安装和维护操作得以顺利进行。

二、安装步骤1. 将清扫器的支架固定在输送带的机架上,确保支架平整并牢固稳固。

2. 安装托辊,确保托辊与输送带平行,并且能够顺畅地旋转,保证清扫器的正常工作效果。

3. 安装刷片,调整刷片的角度和位置,确保刷片与输送带紧密接触,并且能够有效清理杂物。

4. 连接清扫器与供电设备,确保清扫器正常工作,而且能够随时接通和断开电源。

5. 对安装的整体进行检查和试运行,确保皮带平行托辊清扫器的安装质量和性能达到要求。

三、安装注意事项1. 在安装过程中,要遵守相关的操作规程和操作流程,确保安全生产。

2. 定期检查清扫器的工作状态,发现问题及时进行处理,以避免清扫器工作效果的下降。

3. 严格按照制造商提供的安装手册进行操作,避免因为安装不当而导致设备的损坏和事故的发生。

4. 在安装时,要注意防止扭曲、变形和损坏,确保设备的完好性和可靠性。

四、结语在实际的生产现场中,皮带平行托辊清扫器的安装是非常重要的一环,直接影响到设备的使用效果和维护成本。

只有按照标准规范的流程,认真细致地进行安装工作,才能确保设备的正常运行和延长设备的使用寿命。

希望以上的安装标准能够为相关人员提供帮助,确保皮带平行托辊清扫器的有效工作。

第二篇示例:皮带平行托辊清扫器是一种用于清扫传送带上杂物和粉尘的设备,安装正确与否直接影响设备的使用效果和寿命。

下面就来介绍一下皮带平行托辊清扫器的安装标准。

第一步,确定安装位置。

安装皮带平行托辊清扫器时,首先要确定清扫器的安装位置。

通常来说,清扫器应该安装在传送带的头部或尾部,以确保最大限度地清除传送带上的杂物和粉尘。

安徽正威刷业有限公司马丁工程SC16合金二级清扫器用于输送煤泥等含水率较大的带式输送机,安装在卸载滚筒下方回程段位置,解决残留物料在输送机回程段洒落造成的环境污染和残留物料粘黏在托辊上引起的回程皮带跑偏的问题。

下面由清扫器厂家安徽正威刷业为大家介绍下它的相关知识,帮助大家了解它的更多作用。

一、马丁工程SC16合金二级清扫器产品特点1.合金二级清扫器刀片采用分体式结构,单片刀片长度150mm ,由天然橡胶快和碳化钨复合纳米材料组装而成,橡胶底座采用对称设计,适用于双向运行皮带机,清扫受力更均匀,清扫器使用寿命长。

2. 合金二级清扫器刀片刃口采用独特的圆弧设计,对皮带磨损更小。

3. 合金二级清扫器张紧器采用本公司专利设计产品。

一体式铸造组件,坚固耐用。

独特的禁锢螺栓可以在频繁震动的工作环境下一直保持禁锢不松动,提高了产品的可靠性。

4.该清扫器采用合金刀片,不适合皮带连接方式为金属带扣的带式输送机。

安徽正威刷业有限公司二、马丁工程SC16合金二级清扫器安装方法1.按照发货清单,开箱检查,箱内应有主机架(装有刀头) , 左右弹簧张紧器各一只及相应安装紧固螺丝等配置。

如有不符,请与我公司或其区域销售代表联系,调整配齐。

2.请仔细阅读安装操作说明书,了解合金二级清扫器的组成结构。

3.测量皮带机头部滚筒的直径、皮带厚度、皮带宽度。

4.将左右联接角钢焊接在主机横梁上,保证清扫器与皮带机有一定的接触力,并确定皮带机有一定的调整量。

5.安装固定后,调节弹簧系统上的调整螺母压缩弹簧,使刀头与皮带有一定压力,锁紧螺母。

三、马丁工程SC16合金二级清扫器安装案例安徽正威刷业有限公司是一个充满生机和蓬勃发展高速企业。

公司努力致力于实现“组织系统化、管理规范化、工作程序化、效率标准化”的发展目标。

依托学科优势,集成资源、突出特色、自主创新为建设发展思路,打造国内煤炭矿山行业产品研究开发、设计、经营服务为一体的高新技术企业。

公司主营业务包括矿山机械设备及配件,园林机械配件,工程设备配件,毛刷等各行业提供优良、产品和技术服务。

马丁工程一级PDHD弹簧式清扫器,具备方便更换的耐磨刀片,具有快速清除皮带工作面上面的物料、高能弹簧防震设计等优点。

下面由清扫器厂家安徽正威刷业为大家介绍下它的相关知识,帮助大家了解它的更多特点及安装方法。

一、正威刷业ZW-EQC结构功能和特点正威刷业ZW-EQC系列弹簧清扫器采用独特的张紧装置配合高性能弹簧,能够使刀片在皮带不断抖动的情况下,始终能够紧密的贴附在皮上,并保持稳定的张紧力,并减少抖动对刀片基座的疲劳性损伤,提高刀片的使用寿命。

使用简便易维护一調节刀口的张紧度无需拆卸清扫器,仅需调节张紧器上的丝杆即可。

该清扫器清扫果明显,持久耐用,受到用户的一致好评。

安徽正威刷业有限公司二、正威刷业ZW-EQC应用范围煤矿、水泥厂、钢铁厂、发电厂等工厂的物料输送皮带系统等。

三、正威刷业ZW-EQC规格型号四、正威刷业ZW-EQC安装步骤1.按照发货清单,开箱检查,箱内应有主机架(装有刀头) , 左右弹簧张紧器各一只及相应安装紧固螺丝等配置。

如有不符,请与我公司或其区域销售代表联系,调整配齐。

2.请仔细阅读安装操作说明书,了解ZW-EQC清扫器的组成结构。

3.测量皮带机头部滚筒的直径、皮带厚度、皮带宽度。

4.将左右联接角钢焊接在主机横梁上,保证清扫器与皮带机有一定的接触力,并确定皮带机有一定的调整量。

5.安装固定后,调节弹簧系统上的调整螺母压缩弹簧,使刀头与皮带有一定压力,锁紧螺母。

五、正威刷业ZW-EQC外形安装简图安徽正威刷业有限公司六、正威刷业ZW-EQC安装案例安徽正威刷业有限公司是一个充满生机和蓬勃发展高速企业。

公司努力致力于实现“组织系统化、管理规范化、工作程序化、效率标准化”的发展目标。

依托学科优势,集成资源、突出特色、自主创新为建设发展思路,打造国内煤炭矿山行业产品研究开发、设计、经营服务为一体的高新技术企业。

公司主营业务包括矿山机械设备及配件,园林机械配件,工程设备配件,毛刷等各行业提供优良、产品和技术服务。

Table of ContentsIntroduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 At A Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8 Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-12 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-14 Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-18 Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19-20 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21IntroductionABOUTThank you for purchasing a TrueClean® product.This manual contains installation, operation, and maintenance instructions for the TrueClean ToteCleaner™ .TrueClean ToteCleaners are designed for minimal routine maintenance, but care and attention should be given to the instructions provided in this manual .Do not remove any labeling on any TrueClean product .Immediately replace any label that is missing .If, at any point, you have questions or concerns regarding your ToteCleaner, please call 800.654.5635 or 417.831.1411.SafetyIMPORTANT SAFETY INFORMATIONRead this manual before installing, operating, and maintaining this equipment .Failure to read the manual can result in personal injury and/or equipment damage .Do not attempt to remove and/or modify any TrueClean products or programming. Doing so can create unsafe conditions for the operator(s) and/or surrounding persons .Any change to TrueClean products or programming will void any and all warranties .Do not place any TrueClean product in an application where general product service ratings are exceeded. Doing so puts the operator(s) and/or surrounding persons at risk of personal injury and/ or result in equipment damage .Do not remove any labeling on any TrueClean product. Immediately replace any label that is missing .DISCLAIMER OF LIABILITYTrueClean does not assume responsibility and expressly disclaims liability for loss, damage, or expenses that arise in any way from the installation, operation, use, or maintenance performed in accordance with this manual .TrueClean assumes no responsibility for any infringement of patents or other rights of third parties that may result from use of the module .No license is granted by implication or otherwise under any patent or patent rights .TrueClean reserves the right to make changes to the product, specifications, or this manual without prior notice .At a Glance TOTECLEANER™1 Jet Spray Assembly Device2 Rotary Spray Assembly Device3 Tank Lid (a) with Down Tube (b)4 Pump5 VFD6 Pump Cart7 ToteTilter™ (sold separately)8Hose Kit (sold separately)78ComponentsVARIABLE FREQUENCY DRIVE (VFD):Become familiar with the control panel functions before operating the ToteCleaner . The following glossary defines objects found on the control panel.•START — turns the pump on once the system is completely installed •STOP — shuts the pump off • SPEED UP/DOWN — increases or decreases the motor Hz setpoint for pump speed .During cleaning, operators will target 30psig for the rotary spray device or full speed(60Hz) for the jet device.Note: The entire VFD user manual can be viewed online here.Stop Speed UpStartSpeed DownFig. 1 - VFDSPRAY ASSEMBLY INSTRUCTIONS:1. Apply anti-seize to threads on spray tube.2. Attach spray tube onto lid by threading it into the center bung. Be careful not to over-tighten,as this could damage the bung .3. Attach the provided cleaning device by screwing it onto the spray tube. Secure with an open-ended or adjustable wrench .a. Tighten, using the flats nearest the threads. Using the flats on the lower body can causedamage to the device .b. For full assembly, please refer to Figures 2 and 3.Fig. 2 - Alfa Laval GJ9 4-Nozzle 0.150Fig. 3 - MultiMidget 360 3/4” NPT1. Confirm that the tote is drained of all flowing product.2. Confirm that the tote to be cleaned is elevated at least seven inches off the floor.3. Confirm that the ToteCleaner cart is on a structurally sound, flat, and level surface.4. Screw spray assembly into large opening on the top of the tote .5. Connect 1.5” elbow to spray assembly with gasket* and clamp*.6. Connect 1.5” supply hose to elbow with gasket* and clamp*.7. Connect supply hose to pump outlet with gasket* and clamp*.8. Attach Camlock by Tri-Clamp® adapter to the tote outlet drain .9. Connect 2” elbow to the adapter with gasket* and clamp*.10. Connect 2” elbow to the return port on the cart with gasket* and clamp*.11. Connect 2” return hose from elbow on the tote outlet to the elbow on the cart.12. Connect water supply to supply port on cart with gasket* and clamp*.13. Connect drain hose to drain port with gasket* and clamp*. Run the hose to a safe place to drain.14. Plug the power cord into appropriate power supply, as labelled on the control panel .15. If appropriate, switch disconnect on remotely mounted electrical panel to ON .Note: *Included with Optional Hose Kit, sold separately.The TrueClean ToteCleaner is designed to allow versatility in the washes that can be performed . If cleaning needs are minimal, a rinse wash may be run by following the Rinse Wash sequence of operation .If the use of chemicals is desired, a caustic or acid wash may be run by following the Caustic/ Acid Wash sequence of operation .If both a caustic and an acid wash are desired, repeat the sequence of operation outlined under Caustic/Acid Wash .The steps for each are identical .If a sanitizer wash is desired, follow the Sanitizer Wash sequence of operation .Below are examples of common wash recipes .• Caustic wash: Initial rinse • Caustic wash • Post rinse• Caustic wash with sanitizer: Initial rinse • Caustic wash • Post rinse • Sanitizer wash• Caustic/acid wash: Initial rinse • Caustic wash • Post rinse • Acid wash • Post rinse• Caustic/acid wash with sanitizer: Initial rinse • Caustic wash • Post rinse • Acid wash • Post rinse • Sanitizer washRINSE WASH1. Close recirculation valve, and open supply and drain valves.• Please refer to Figure 4 for valve configuration.2. Confirm that there is water flowing to the supply valve.3. Press START button to start the pump .4. When wash is complete, push STOP button .5. Next, close the supply valve and allow the tote to completely drain.• If a rinse wash is the only wash to be run, also open the recirculation valve to allow the pump and supply hose to drain with the tote .• Please refer to Figure 5 for valve configuration.Fig. 4Fig. 5CAUSTIC/ACID WASH1. Close drain valve. Open recirculation and supply valves, allowing water to fill the tote.• Please refer to Figure 6 for valve configuration.2. Monitor water level until there are four to six inches of water in the bottom. Close the supplyvalve, taking care to leave the recirculation valve open .• Please refer to Figure 7 for valve configuration.3. Disconnect the elbow at the spray assembly, unscrew the spray assembly, and dose causticsolution into the tote through the lid connection .• CAUTION: Personal protective equipment (PPE) should be used when handling hazardous chemicals to protect the operator and/or bystanders from chemical contact .• Please refer to Figure 8 as an example of proper dosing procedure.4. Screw spray assembly back onto lid connection, and reattach elbow .5. Press START button to start the pump .6. When wash is complete, push STOP button .7. Next, open the drain and recirculation valves .Allow the tote to completely drain .• Please refer to Figure 5 for valve configuration.Fig. 7Fig. 6Fig. 8SANITIZER WASH1. Close drain valve. Open recirculation and supply valves, allowing water to begin filling the tote.• Please refer to Figure 6 for valve configuration.2. Monitor water level until there are four to six inches of water in the tote, then close the supplyvalve, taking care to leave the recirculation valve open .• Please refer to Figure 7 for valve configuration.3. Disconnect the elbow at the spray assembly, unscrew the spray assembly, and dose sanitizersolution into the tote through the lid connection .• CAUTION: Personal protective equipment (PPE) should be used when handling hazardous chemicals to protect the operator and/or bystanders from chemical contact .• Please refer to Figure 8 as an example of proper dosing procedure.4. Screw spray assembly back onto lid connection, and reattach elbow .5. Press START button to start the pump .6. When wash is complete, push STOP button .7. Close the supply valve and open the recirculation valve to allow the tote and hoses tocompletely drain .• Please refer to Figure 5 for valve configuration.8. Upon completion of the final wash power down, close all valves and disconnect all hoses fromthe tote .It is advised that preventative maintenance be performed periodically throughout the lifetime of this system to ensure longevity and maintain efficiency. There are four items that are maintainable on this system: pump, butterfly valves, spray device, and all Tri-Clamp gaskets.Click the links below to view the manuals and maintenance procedures for the pump, butterfly valves, and spray device .• VFD Manual• Alfa Laval MultiMidget Spray Device Manual• Alfa Laval GJ9 Spray Device Manual• Alfa Laval Solid C Pump Manual• Alfa Laval LKB Butterfly Valve Manual• Ace Hose ManualCentrifugal pump maintenance can be found on pages 14-22 of Alfa Laval SolidC Pump Manual . The recommended maintenance schedule can be found below in Figure 9.Fig. 9 - Pump Maintenance ScheduleButterfly valve maintenance can be found on pages 17-25 of Alfa Laval LKB Butterfly Valve Manual. The recommended maintenance schedule can be found below in Figure 10.Fig. 10 - Butterfly Maintenance ScheduleAlfa Laval GJ9 4-Nozzle 0.150 maintenance can be found on pages 18-29 of GJ9 Manual . MultiMidget 360 3/4” NPT maintenance can be found on pages 11 of MultiMidget Manual .The Tri-Clamp gaskets should be replaced once every three to six months. If it is found that the gaskets are failing prior to three months, replace gaskets accordingly .SPRAY ASSEMBLY PARTS LIST: TTC-SA-SDSPRAY ASSEMBLY PARTS LIST: TTC-SA-JDTOTECLEANER PARTS LISTOPTIONAL HOSE KIT PARTS LIST: TTC-HOSEKITParts ListWarrantyA .GENERAL PROVISIONS: Central States Industrial Equipment & Service Inc. (the “Company”) warrants exclusively tothe original purchaser (the “Customer”) that equipment or parts thereof manufactured and sold by the Company will be free from defects in material and workmanship only, under normal use and service, for a period of one (1) year from the original shipment date. The Company shall not be liable for any loss of revenue or profit, loss by reason of plant shutdown, non-operation or increased cost of operation, loss of products or materials, or other special or consequential loss or damages resulting from any such warranted defects .This warranty will not apply to any equipment or parts which has been subjected to accident, alteration, abuse, or misuse .This warranty is in lieu of all other warranties .All other warranties, both express or implied (including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose) warranties are hereby excluded and waived. The Company’s only obligation and liability shall be to fulfill the warranty specifically stated herein. The Company will neither assume nor authorize any other person to assume for it any other obligation or liability in connection with the equipment or parts .In the event of a claim under this warranty, the Company’s sole and exclusive liability for any warranted equipment or parts shall be, at the Company’s option, limited to the following (a) the purchase price of the equipment or parts that are defective, (b) replacement of the defective equipment or parts or (c) repair of the defective equipment or parts .B .RETURN OF PARTS OR EQUIPMENT TO COMPANY PLANT: In the event the Company elects to inspect the allegeddefective equipment or parts for possible repair, Company will notify Customer in writing, and the equipment or parts must be returned with transportation cost prepaid by the Customer .In the event the Company’s inspection confirms defective equipment or parts covered by this warranty, the Company shall have the option to select any of the remedies described in Section A above .No transportation for returned or replaced items will be paid by the Company unless written approval for transportation charges is given by the Company .C .COMPONENTS NOT MANUFACTURED BY THE COMPANY: Components not manufactured by the Company, butfurnished as part of its equipment (for example: valves, controls, gauges, electrical switches or instruments, etc .) will be warranted by the Company only to the extent of the component manufacturer’s warranty .D .REPAIR OF EQUIPMENT INSTALLED IN THE CONTINENTAL UNITED STATES: In the event the Company electsto repair a covered item and it is, in the judgement of the Company, impractical to return the equipment or parts for repairs, the Company may arrange for the repairs to be made by its personnel or, at its option, sublet such repairs to a qualified company. The Customer will be expected to cooperate by making the equipment or parts available and accessible when the work is scheduled and is expected to provide the necessary utilities .If local labor conditions prohibit such work being done by Company personnel under the conditions and at the rates payable by its contracts with its employees, the Company obligation shall be limited to supervision of the work, replacement of defective parts, and labor costs in an amount equal to the amount which would be payable fora reasonable number of hours required to make the repairs at the rates payable under the terms of Companycontracts with its employees .In such event, all labor costs shall be paid by the Customer and the Company will reimburse the Customer to the extent set forth above .E .REPAIR OF EQUIPMENT INSTALLED OUTSIDE THE CONTINENTAL UNITED STATES: In the event the Companyelects to repair a covered item for a Customer located outside the continental United States and it is, in the judgement of the Company, impractical to return the equipment for repairs, the Company shall have the additional options (in addition to the other options described herein) of either sending a service representative to repair (or supervise the repairs) or paying Customer a reasonable amount to allow the Customer to have the repairs made locally; provided, that in such situation, Company shall have no obligation to repair or replace equipment or parts that are repaired on by third party contractors selected by Customer .21TC TOTECLEANER™ IOM—REV 2/21。

马丁工程SC16合金二级清扫器属用于输送煤泥等含水率较大的带式输送机,安装在卸载滚筒下方回程段位置,解决残留物料在输送机回程段洒落造成的环境污染和残留物料粘黏在托辊上引起的回程皮带跑偏的问题。

下面由清扫器厂家安徽正威刷业为大家介绍下它的相关知识,帮助大家了解它的更多作用。

一、马丁工程SC16合金二级清扫器产品特点1.合金二级清扫器刀片采用分体式结构,单片刀片长度150mm,由天然橡胶快和碳化钨复合纳米材料组装而成,橡胶底座采用对称设计,适用于双向运行皮带机,清扫受力更均匀,清扫器使用寿命长。

2.合金二级清扫器刀片刃口采用独特的圆弧设计,对皮带磨损更小。

3.合金二级清扫器张紧器采用本公司专利设计产品。

一体式铸造组件,坚固耐用。

独特的禁锢螺栓可以在频繁震动的工作环境下一直保持禁锢不松动,提高了产品的可靠性。

安徽正威刷业有限公司4.该而机清扫器采用合金刀片,不适合皮带连接方式为金属带扣的带式输送机。

二、马丁工程SC16合金二级清扫器安装方法1.按照发货清单,开箱检查,箱内应有主机架(装有刀头) , 左右弹簧张紧器各一只及相应安装紧固螺丝等配置。

如有不符,请与我公司或其区域销售代表联系,调整配齐。

2.请仔细阅读安装操作说明书,了解合金二级清扫器的组成结构。

3.测量皮带机头部滚筒的直径、皮带厚度、皮带宽度。

4.将左右联接角钢焊接在主机横梁上,保证清扫器与皮带机有一定的接触力,并确定皮带机有一定的调整量。

5.安装固定后,调节弹簧系统上的调整螺母压缩弹簧,使刀头与皮带有一定压力,锁紧螺母。

三、马丁工程SC16合金二级清扫器安装案例安徽正威刷业有限公司是一个充满生机和蓬勃发展高速企业。

公司努力致力于实现“组织系统化、管理规范化、工作程序化、效率标安徽正威刷业有限公司准化”的发展目标。

依托学科优势,集成资源、突出特色、自主创新为建设发展思路,打造国内煤炭矿山行业产品研究开发、设计、经营服务为一体的高新技术企业。

公司主营业务包括矿山机械设备及配件,园林机械配件,工程设备配件,毛刷等各行业提供优良、产品和技术服务。

安徽正威刷业有限公司马丁二级合金清扫器主要用于输送煤泥等含水率较大的带式输送机,安装在卸载滚筒下方回程段位置,解决残留物料在输送机回程段洒落造成的环境污染和残留物料粘黏在托辊上引起的回程皮带跑偏的问题。

下面由清扫器厂家安徽正威刷业为大家介绍下它的相关知识,帮助大家了解它的更多作用。

一、马丁二级合金清扫器产品特点1. 马丁二级合金清扫器的张紧器采用本公司专利设计产品。

一体式铸造组件,坚固耐用。

独特的禁锢螺栓可以在频繁震动的工作环境下一直保持禁锢不松动,提高了产品的可靠性。

2.马丁二级合金清扫器的刀片采用分体式结构,单片刀片长度150mm ,由天然橡胶快和碳化钨复合纳米材料组装而成,橡胶底座采用对称设计,适用于双向运行皮带机,清扫受力更均匀,清扫器使用寿命长。

3.马丁二级合金清扫器刀片刃口采用独特的圆弧设计,对皮带磨损更小。

4.该清扫器采用合金刀片,不适合皮带连接方式为金属带扣的带安徽正威刷业有限公司式输送机。

二、马丁二级合金清扫器安装方法1.按照发货清单,开箱检查,箱内应有主机架(装有刀头) , 左右弹簧张紧器各一只及相应安装紧固螺丝等配置。

如有不符,请与我公司或其区域销售代表联系,调整配齐。

2.请仔细阅读安装操作说明书,了解合金二级清扫器的组成结构。

3.测量皮带机头部滚筒的直径、皮带厚度、皮带宽度。

4.将左右联接角钢焊接在主机横梁上,保证清扫器与皮带机有一定的接触力,并确定皮带机有一定的调整量。

5.安装固定后,调节弹簧系统上的调整螺母压缩弹簧,使刀头与皮带有一定压力,锁紧螺母。

三、马丁二级合金清扫器安装案例安徽正威刷业有限公司是一个充满生机和蓬勃发展高速企业。

公司努力致力于实现“组织系统化、管理规范化、工作程序化、效率标准化”的发展目标。

依托学科优势,集成资源、突出特色、自主创新为建设发展思路,打造国内煤炭矿山行业产品研究开发、设计、经营服务为一体的高新技术企业。

安徽正威刷业有限公司公司主营业务包括矿山机械设备及配件,园林机械配件,工程设备配件,毛刷等各行业提供优良、产品和技术服务。

内蒙古创源金属有限公司3×330MW自备电厂电袋复合除尘器安装工程作业指导书批准:审核:编制:年月日年月日年月日福建龙净环保股份有限公司目录一、目的和适用范围 (1)二、编制依据 (1)三、作业人员资格要求及施工需要的工机具 (1)四、作业程序及方法 (2)五、质量保证措施 (23)六、安全文明施工 (23)七、附录 (25)一、目的和适用范围本工程为内蒙古创源金属有限公司3×330MW机组电袋除尘器安装工程。

3台机组除尘器由福建龙净环保股份有限公司设计制造。

编制目的是为了除尘器顺利安装就位并且符合安装工艺要求,使工程安全优质地达到标准要求。

1、保证施工质量、施工进度、施工安全。

2、以设计图纸及相关规范为依据,切合实际地进行施工程序,施工技术上的指导。

3、作为施工技术交底的依据。

4、作为生产计划、调度、进度控制的依据。

二、编制依据1、厂家图纸和厂家安装说明书2、《火电施工质量检验及评定标准》(锅炉篇)1996年版。

3、《电力建设施工及验收技术规范》。

4、《火电施工质量检验及评定标准》焊接篇5、《电力建设施工及验收技术规范》火力发电厂焊接篇6、《电力建设安全工作规程》DL5009-1-92三、作业人员资格要求及施工需要的工机具1、作业人员资格要求1.1参加作业人员均能熟悉图纸。

1.2参加作业人员具有相关的工作经验。

1.3作业人员能熟练使用工机具。

1.4特殊工种必须持证上岗。

1.5参加作业人员接受过安全教育并考试合格。

1.6参加作业人员在作业前必须经过技术、质量、安全交底会签。

2、施工需要的工机、量具四、作业程序及方法1、除尘器安装作业程序安装施工流程:钢支架→钢支架圈梁→灰斗→墙板→楼梯平台→管撑、承压件→阴阳极→进口喇叭安装→花板安装→气包平台→净气室→旁路烟道→提升阀→压缩空气系统及清灰系统→桥架安装及电缆敷设→滤袋及袋笼安装→预涂灰及荧光粉检漏→调试。

2、施工前应具备的条件2.1施工所用工器具都已准备齐全,大型吊装机械已安装完备,并具备使用条件。

Operator manual操作手册ChinaPLDC04180-00Wet & Dry Vacuum CleanerV-WD-27V-WD-62V-WD-72ENCNTo view, print or download theparts manual, visit:Model Part No.:1244332 V-WD-27, CN (220-240 V)1244337 V-WD-62, CN (220-240 V)1244342 V-WD-72, CN (220-240 V)ENINTRODUCTIONThis manual is furnished with each new model.It provides necessary operation and maintenance instructionsRead all instructions before using this machine.This machine will provide excellent service. However, the best results will be obtained at minimum costs if:• The machine is operated with reasonable care.• The machine is maintained regularly - per the maintenanceinstructions provided.• The machine is maintained with manufacturer supplied orequivalent parts.T o view, print or download manuals online visit /manualsUNPACKING MACHINECarefully check machine for signs of damage. Report damages at once to carrier. Check machine contents to ensure all parts and accessories are included. Contact distributor or T ennant for missing items.INTENDED USEThis wet & dry vacuum cleaner is intended for commercial use, for example in hotels, schools, hospitals, shops, offices and rental businesses. The machine is suitable for picking up dry non-flammable dust and debris and liquids in an indoor environment. It is not suitable for picking up hazardous liquids or materials. Donot use this machine other than described in this manual.Do not dispose of electrical equipment into household waste! ccording to the European Directive 2012/19/EU on waste, electrical and electronic equipment (WEEE) and its incorporation into national law, electrical equipment that is no longer suitable for use must be separately collected and sentfor recovery in an environmental-friendly manner.Always remember to recycle.TENNANT CLEANING SYSTEM & EQUIPMENT (Shanghai) CO. LTDBuilding 1, No. 3777, Cao Ying Road Shanghai 201712People’s Republic of China Specifications and parts are subject to change without notice.Original Instructions. Copyright ©2019 T ennant Company.All rights reserved.INSTRUCTIONS THAT MUST BE STRICTL Y FOLLOWED - SAFE USERead carefully the manual before use, in order towork safely.Warning: Before operating, the appliance must be correctly assembled as described in manual. Check that all the equippedfiltering elements are in place and efficient.-This appliance must be kept out of the reach ofchildren, of people with reduced physical, sensory or mental abilities or lacking of experience and knowledge.-CAUTION: Children must be kept under control, do not allow children to use the appliance as a toy.-WARNING: Users must be properly trained to use the machine.-CAUTION: Components used in packaging (ex: plastic bags) can be dangerous; keep away from children, animals and people not aware of their actions.-T o correctly dispose of the packaging follow your local disposal ordinance.-Make sure the voltage of power source is the same as indicated on the rating plate of the vacuum cleaner. Verify that the outlet is compatible with the plug. Power cord must always be unrolled before using the appliance. Do not use the power cord coiled.-Do not handle/use plug or appliance with wet hands. -Do not pick up anything that can damage the filtering elements (such as glass, metal etc.).-Do not use the power cord to move or lift the machine. -Never immerse the machine in water and never use a pressure washer to clean the machine.-Do not use this appliance beyond 2000 m (6560 ft) above sea level.-WARNING: This machine is not suitable for picking up dangerous dust.-CAUTION: Don’t pick up flammable, incandescent, explosive or toxic dust/blends. Maximumtemperature allowed is 40°C (104°F).Warning: Any application not described in this manual is potentially dangerous,therefore it must be avoided.Warning: Do not leave a working machine unsupervised. Always unplug the machine if the appliance is not working. Keep awayfrom children and from people not aware of their actions.-WARNING: This appliance must be used on a levelsurface to prevent from rolling. Do not operate, move or store appliance on a sloping plane.-WARNING: This appliance must be stored indoor and in a dry area.-WARNING: Keep hands, feet, ears, loose clothing, hair and all parts of the body (human or animals) away from openings.-WARNING: Use only original spare parts. Using other accessories might compromise the operator’s safety.-Warning: This machine is not suitable for picking up dust in environments where electro-static discharges or spark can cause damages to electronic components and persons.-Only an authorized service centre can replace power cord of the appliance.V-WD-27V-WD-62V-WD-72Voltage 220-240 V 220-240 V 220-240 V Frequency 50-60 Hz 50-60 Hz 50-60 Hz Motor Power 1100 W 2200 W 3300 W Max Airflow 200 m 3/h400 m 3/h600 m 3/h Max Water lift 2.380 mmH 2O 2.380 mmH 2O 2.380 mmH 2O T ank Capacity 27 L 62 L 72 L Power cord length 8,5 m 8,5 m 8,5 m Weight7,8 kg 18,5 Kg 23,4 Kg Sound Pressure Level Lp(A) [dBA]71,275,479,0Hand-arm vibration < 2,5 m/s²< 2,5 m/s²< 2,5 m/s²Construction class II II II ProtectionIPX4IPX4IPX4TECHNICAL SPECIFICATIONSEN Warning: Do not tamper or modify theappliance. Failure to comply with theseinstructions could result in severepersonal injury or death. Tampering will void thewarranty.The manufacturer refuses all responsibilityfor damages or injuries due to improperuse of the machine or in case of failure tofailure to comply with the instructions given inthis manual.Always disconnect power cord frompower source after operating and beforeservicing. After every use and beforesending the appliance to a service center, it mustbe thoroughly cleaned and tank rinsed out toavoid hazard.-Do routine maintenance. Inspect gaskets seals,plastic parts, filters, switches and replace thosewhich have begun to leak or are damaged.-Using a machine with a damaged power cord couldresult in an electrocution. Check the cord lookingfor cuts, cracks or aging signs and replace it, if it’snecessary.-Do not use an extension cord with this machine.-Only an authorized service center can do reparationor maintenance of the appliance. Use only originalspare parts.-T o keep the appliance fully functional it is necessaryto clean main polyester filter by shaking it after everyuse and replacing filter bag if it’s full.-Clean every part of the appliance after each use:empty the tank, shake the filters, replace filteringbag if it’s full and clean the machine with a dampcloth before storing the vacuum cleaner.-WARNING: In case of foam or liquid leak turn off theappliance immediately.-WARNING: In case overturning, lift the appliance inthe upright position before switching the motors off.-Don’t pick up water from sink or tub. Do not useappliance as a pump to clean out clogged drains,sinks, or other plumbing fixtures. The appliance isintended for vacuuming air and water mixtures.-Do not use or pick up aggressive soaps, they coulddamage the appliance.WARNING: The float valve will stop thevacuuming when the tank is full of liquidsor if machine overturns; ensure float valveis installed and operating properly before use.-WARNING: Do not use outdoors or in a coldenvironment.-During a power quality disturbance of the facilitieselectrical grid, this appliance may cause temporarydrops in voltage.DRY PICK UP (PAGE 6)1. Insert main polyester filter into the tank (Fig. 1).2. Mount the motor head on top of tank and lock itwith latches (Fig. 3).3. Push vacuum hose into hose inlet (Fig. 4).4. Attach wand and desired tool to hose ends (Fig.5).5. If your vacuum is equipped with vacuum bag,slide vacuum bag over the deflector (Fig. 7).6. Plug power cord into a properly grounded outletand turn appliance on (Fig. 6).WET PICK UP (PAGE 6)1. Remove main polyester filter from the tank (Fig.2).2. Mount the motor head on top of tank and lock itwith latches (Fig. 3).3. Push vacuum hose into hose inlet (Fig. 4).4. Attach wand and hoses to hose end (Fig. 5).5. Attach squegee floor tool to the other end.6. Plug power cord into a properly grounded outletand turn appliance on (Fig. 6).COMPONENTS DESCRIPTION (PAGE 6)A - Motor headB - On/Off SwitchC - LatchesD - InletE - T ankF - Castor wheelsG - Main polyester filter. Use only for dry pick up(not for wet pick up).H - Float valveI - Vacuum hoseJ - Power cordK - Wand Clip (only V-WD-62)L - Two-piece wandM - Hose nozzleN - Crevice toolO - Round brushP - T ool adaptor (only V-WD-62 and 72)Q - Squeegee floor toolR - Brush floor toolS - Upholstery tool (only V-WD-27)T - Trolley (only V-WD-62 and 72)CN简介每款新型号机器都配有本手册。

安徽正威刷业有限公司马丁清扫器是输送机必不可少的配件,马丁工程一级弹簧式清扫器、马丁工程一级重型清扫器、马丁轻型清扫器、马丁合金二级清扫器等都属于马丁清扫器。

下面由清扫器厂家安徽正威刷业为大家介绍下它的相关知识,帮助大家了解它的更多特点。

一、马丁合金二级清扫器产品特点1. 马丁合金二级清扫器的张紧器采用专利设计产品。

一体式铸造组件,坚固耐用。

独特的禁锢螺栓可以在频繁震动的工作环境下一直保持禁锢不松动,提高了产品的可靠性。

2.马丁合金二级清扫器的刀片采用分体式结构,单片刀片长度150mm ,由天然橡胶快和碳化钨复合纳米材料组装而成,橡胶底座采用对称设计,适用于双向运行皮带机,清扫受力更均匀,清扫器使用寿命长。

3.马丁合金二级清扫器刀片刃口采用独特的圆弧设计,对皮带磨损更小。

二、马丁一级重型清扫器产品特点1.清扫刀片由特种聚氨酯制作,具有阻燃抗静电、高耐磨性、高弹安徽正威刷业有限公司性、耐酸性强、摩擦系数低、不会对输送带造成伤害,使用寿命长。

2.超重型清扫器刀片相对于重型清扫器在高度和厚度上均有较大的增加。

3.根据刀片磨损程度可调节刀片补偿。

4.刀片材质为聚醚型材质,比普通聚氨酯的材质耐磨程度要高出50%,分子量为900万以上。

5.缓冲系统分为一次缓冲和二次缓冲,提高了机架的缓冲效果,从而延长了清扫器的使用寿命。

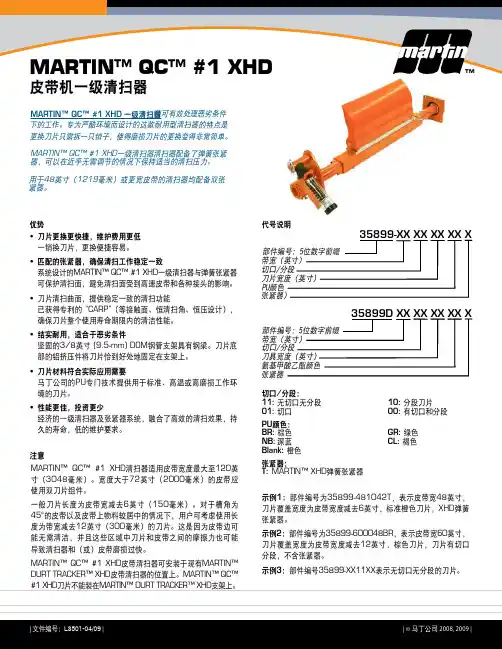

三、马丁轻型清扫器产品特点本产品适用于无机械接头的输送带。

弹性刮板清扫器可保证刀片始终接触输送带表面,当遇到大块阻力及输送带接头等突出物时,具有偏移避让井迅速复位。

1.清扫刀片具有高弹性,能达到清扫力和阻力值平衡,不损伤皮带;2.外部应用弹簧张紧器,可随时保持清扫压力稳定,保证了清扫效果;3.刀片设计独特,在不损伤皮带的前提下,使用寿命更长;4.安装、维修方便,检查率低;5.品种齐全,适合各种皮带带宽。

四、马丁工程一级弹簧式清扫器特点马丁弹簧清扫器采用独特的张紧装置配合高性能弹簧,能够使刀安徽正威刷业有限公司片在皮带不断抖动的情况下,始终能够紧密的贴附在皮上,并保持稳定的张紧力,并减少抖动对刀片基座的疲劳性损伤,提高刀片的使用寿命。

目录一、 前言------------------------------------------------2二、 工作原理------------------------------------------2三、 除尘器部件----------------------------------------3四、 安全须知------------------------------------------6五、 操作说明-----------------------------------------6六、 维护说明----------------------------------------9七、 故障检查-------------------------------------------12 附录一、除尘器技术性能参数表---------------------------14 附录二、除尘器结构图-------------------------------15一、 前言本手册介绍了除尘器的原理及构造、操作和维护方法,以便用户能了解、使用该除尘器。

本手册仅提供给用户有关管理和操作人员在使用维护中参照并制定适合的用户操作维护计划。

本手册为技术资料,仅限于相关人员参阅,未经本公司同意,不得外泄给第三方。

二、 工作原理1.概述除尘器由立柱、灰斗、进风装置、中箱体、上箱体、滤袋组件、喷吹系统、离线装置、旁通装置等组成。

整套除尘器还包括平台扶梯、防雨棚、防雨罩和现场控制系统等。

其工作原理如下:含尘气体从袋式除尘器入口进入各单元,大颗粒粉尘经分离后直接落入灰斗、其余粉尘随气流进入中箱体过滤区,过滤后的洁净气体透过滤袋经上箱体、排风管排出。

随着过滤工况的进行,当滤袋表面积尘达到一定量时,除尘器的阻力会升高,由清灰控制装置(差压或定时、手动控制)按设定程序打开电磁脉冲阀喷吹,抖落滤袋上的粉尘。

落入灰斗中的粉尘借助卸灰系统送出。

安徽正威刷业有限公司马丁轻型清扫器主要作用是将输送带承载面内由于重量等原因粘着在输送带上的残留物料清扫干净,以保证输送带的正常使用。

下面由清扫器厂家安徽正威刷业为大家介绍下它的相关知识,帮助大家了解它的特点及安装方法。

一、马丁轻型清扫器产品说明及特点本产品适用于无机械接头的输送带。

弹性刮板清扫器可保证刀片始终接触输送带表面,当遇到大块阻力及输送带接头等突出物时,具有偏移避让井迅速复位。

1.清扫刀片具有高弹性,能达到清扫力和阻力值平衡,不损伤皮带;2.外部应用弹簧张紧器,可随时保持清扫压力稳定,保证了清扫效果;3.刀片设计独特,在不损伤皮带的前提下,使用寿命更长;4.安装、维修方便,检查率低;5.品种齐全,适合各种皮带带宽。

二、安装前的重要提示1.安装之前,必须熟知工作中所用相关设备的安全操作规程以及施工现场的安全生产规范。

安徽正威刷业有限公司2.切断输送机的启动电源,挂上”有人操作,禁止合闸”的警示牌。

3.如果设备在井下或密闭的区域内,动用割枪或电焊之前,必须对煤气和灰尘含量进行检测。

确认煤气和灰尘含量在安全值范围内方可操作,否则可能发生事故。

4.使用割枪或电焊对皮带输送机架开孔前,应使用阻燃罩将输送机皮带罩住,否则将有可能损坏皮带。

5.安装工作完毕,在启动输送机皮带之前,应将安装区域内和输送机皮带上的工具、铁器、焊渣等收拾干净。

否则将有可能造成严重的人身伤害,或者导致输送机皮带的损坏。

6.在输送机运行状态下,如果要调整清扫器的张紧力,操作时千万要小心谨慎,防止手中的工具、身体或衣服被卷入输送带,导致严重的人身伤亡。

对于维护的操作,请在停机状态下进行,切记!三、马丁轻型清扫器外形及安装简图四、马丁轻型清扫器安装步骤1.按照发货清单,开箱检查,箱内应有主机架(装有刀片) , 左右弹簧张紧器各一只及相应安装紧固螺丝等配置。

如有不符,请与我公安徽正威刷业有限公司司或其区域销售代表联系,调整配齐。

2.请仔细阅读安装操作说明书,了解马丁轻型清扫器的组成结构。

矿车清扫器操作规程一、安全操作规则1. 操作人员必须熟悉矿车清扫器的结构、特点、工作原理等,并接受相应的培训和指导。

2. 操作人员必须穿戴好安全防护装备,包括头盔、防护眼镜、耳塞、防护手套、防护鞋等。

3. 在操作前,必须检查矿车清扫器的各个部位是否正常,如有异常,应及时报修或更换。

4. 操作前必须认真阅读并遵守矿车清扫器的操作说明书,以确保正确操作。

二、操作流程1. 在操作前,应查阅矿车清扫器的操作步骤,并按照步骤进行操作。

2. 操作人员应将矿车清扫器停在平稳的地面上,并确保矿车清扫器的底部离地面一定距离。

3. 根据需要,选择合适的清扫头,将其安装到矿车清扫器上,并确保安装牢固。

4. 操作人员应坐在操作座椅上,并系好安全带,用脚控制矿车清扫器的行进速度和方向。

5. 在操作过程中,应保持专注,注意观察周围环境,遇到障碍物时及时停车处理。

6. 清扫操作应始终保持直线,不得随意改变方向或加速减速,以免造成意外伤害。

7. 在清扫过程中,应注意回收清扫垃圾的容量,及时清理并处理垃圾,防止溢出或堵塞。

三、安全事故处理1. 如果发生意外事故,操作人员应立即停止操作,并迅速报告相关负责人。

2. 在处理事故时,应优先保护人员生命安全,同时采取必要的应急措施。

3. 如有人员受伤,应及时提供急救,并通知医疗人员进行处理。

4. 事故发生后,应立即进行事故分析和调查,找出事故原因,并提出相关改进意见,以防止类似事故再次发生。

四、保养和维护1. 每天使用结束后,应对矿车清扫器进行必要的清洁工作,清理残留的垃圾和灰尘,并进行日常的维护工作。

2. 定期对矿车清扫器进行检查,包括各个部位的松动、磨损情况等,及时进行维修和更换。

3. 定期对矿车清扫头进行检查和清理,保持其清洁状态,以确保正常工作。

4. 在保养和维护过程中,应按照矿车清扫器的说明书进行操作,使用合适的工具和设备。

五、注意事项1. 操作矿车清扫器时,应注意环境安全,避免与其他设备和人员发生碰撞。

安徽正威刷业有限公司

马丁轻型清扫器主要作用是将输送带承载面内由于重量等原因粘着在输送带上的残留物料清扫干净,以保证输送带的正常使用。

下面由清扫器厂家安徽正威刷业为大家介绍下它的相关知识,帮助大家了解它的特点及安装方法。

一、马丁轻型清扫器产品说明及特点

本产品适用于无机械接头的输送带。

弹性刮板清扫器可保证刀片始终接触输送带表面,当遇到大块阻力及输送带接头等突出物时,具有偏移避让井迅速复位。

1.清扫刀片具有高弹性,能达到清扫力和阻力值平衡,不损伤皮带;

2.外部应用弹簧张紧器,可随时保持清扫压力稳定,保证了清扫效果;

3.刀片设计独特,在不损伤皮带的前提下,使用寿命更长;

4.安装、维修方便,检查率低;

5.品种齐全,适合各种皮带带宽。

二、安装前的重要提示

1.安装之前,

必须熟知工作中所用相关设备的安全操作规程以及

施工现场的安全生产规范。

2.切断输送机的启动电源,挂上”有人操作,禁止合闸”的警示牌。

3.如果设备在井下或密闭的区域内,动用割枪或电焊之前,必须对煤气和灰尘含量进行检测。

确认煤气和灰尘含量在安全值范围内方可操作,否则可能发生事故。

4.使用割枪或电焊对皮带输送机架开孔前,应使用阻燃罩将输送机皮带罩住,否则将有可能损坏皮带。

5.安装工作完毕,在启动输送机皮带之前,应将安装区域内和输送机皮带上的工具、铁器、焊渣等收拾干净。

否则将有可能造成严重的人身伤害,或者导致输送机皮带的损坏。

6.在输送机运行状态下,如果要调整清扫器的张紧力,操作时千万要小心谨慎,防止手中的工具、身体或衣服被卷入输送带,导致严重的人身伤亡。

对于维护的操作,请在停机状态下进行,切记! 三、马丁轻型清扫器外形及安装简图

四、马丁轻型清扫器安装步骤

安徽正威刷业有限公司

1.按照发货清单,开箱检查,箱内应有主机架(装有刀片) , 左右弹簧张紧器各一只及相应安装紧固螺丝等配置。

如有不符,请与我公司或其区域销售代表联系,调整配齐。

2.请仔细阅读安装操作说明书,了解马丁轻型清扫器的组成结构。

3.测量皮带机头部滚筒的直径、皮带厚度、皮带宽度。

4.在头部漏斗外侧壁左右各开一个φ65圆孔(以头部滚筒轴心线为坐标原点划线,用气割开孔) ,同时在安装机架上开孔,

5.安装固定,使组装好的清扫器轴心线与滚筒抽心线平行,刀头紧贴带面,然后调整使刀尖线的中心对准滚筒轴心线的中心,将横梁底部的锁紧螺钉拧紧并用螺母锁定.

6.通过调节螺母调整弹簧长度,给刀头施加预紧力,然后用锁紧螺母锁紧。

五、马丁轻型清扫器维护

三个月调整一次张紧力。

为防止影响清扫效果,在日常使用过程中,不要让刀片之间夹杂绳索、铁丝等异物。

安徽正威刷业有限公司是一个充满生机和蓬勃发展高速企业。

公司努力致力于实现“组织系统化、管理规范化、工作程序化、效率标准化”的发展目标。

依托学科优势,集成资源、突出特色、自主创新为建设发展思路,打造国内煤炭矿山行业产品研究开发、设计、经营服务为一体的高新技术企业。

公司主营业务包括矿山机械设备及配件,园林机械配件,工程设

安徽正威刷业有限公司

备配件,毛刷等各行业提供优良、产品和技术服务。

正威公司历经数载的风雨磨炼,在各界朋友的支持下,成就了皮带输送机辅助设备及毛刷等制造行业的一颗闪耀的明星。

公司秉承“以人为本、用户至上”的经营理念,抓质量、讲信誉、重服务、本着对国家、社会、用户负责任的态度,携手各社会团体和合作伙伴,积极协作、奋斗进取,以矫健的步伐迈向新未来。

更多详情请点击咨询官网安徽正威刷业。

安徽正威刷业有限公司。