精益生产管理方式(英文版)

- 格式:ppt

- 大小:1.28 MB

- 文档页数:22

精益生产英文资料介绍General questions about lean operationsWhat is lean?Lean operations involve the elimination of waste, whether it be time, materials, efficiency or processes. It also means figuratively tightening the belt in pursuit of increased productivity gains that will increase a company’s ability to compete more successfully.Why lean?Increased global competition will likely force all but the strong to the sidelines. Belt tightening and a lean mindset will enable the game to continue as companies steady themselves for the challenges and opportunities that await them.The truly lean company of today will be a survivor in the global battle for customers and bottom line profits. The need for lean is obvious and the potential rewards are dazzling. There will be those who will probably resist the necessary changes. Training will start you on the road to overcoming this resistance and ultimately achieving a successful transition.Who participates in lean Operations?Eventually, everyone in the company is a participant in the quest for a lean organization.Is lean applicable only to manufacturing?The concept includes many non-manufacturing areas such as purchasing, clerical, office and technical. Also, these areas often contribute in making lean achievements in manufacturing more successful.What organizations can benefit from lean projects?Every organization offers goods or services. This includes such diverse sectors as merchandising, hospitals, banking, insurance, public utilities, government, military, prisons, churches, schools and, of course, manufacturing.Can lean activities be started in more than one division at a time?Yes, it can be done, but starting in one division is preferable. The experience gained permits corrections and mod ifications to be introduced with less fuss. In this way, any “bugs” can be eliminated before the concept is initiated plant-wide.How should employees approach problems?They should approach problems with a positive attitude—one that says, “We can solve it!” Open discussion and use of various problem-solving tools, in a positive and cooperative manner, will shed new light on any problem.How important is it to establish objectives and milestones?Individuals or groups working on lean projects should be encouraged to establish an objective and develop a plan to achieve it. The plan is further broken into milestones so that progress can be constantly measured against the plan. This information should be charted and posted for all to see and have it serve as a constant reminder.What if a lean project overlaps into other areas of an organization?That will happen, especially in the long run, but in the short run and particularly the early phases, it should be avoided. We are talking about change and many people resist having to do and support new ways of doing things. When it is clear that a project is going to affect more than one area, try to involve those who will be affected in coming up with solutions.Examples of measurements and results in a lean environmentMeasuring improvements in lean operation organizations requires the use of several traditional and many non-traditional measurements. The following is an explanation of some frequently used measurements and examples of how they have been applied:Work in process (WIP)This is a measure of the amount of material which has left raw materials stock but has not yet become finished goods. Examples:•WIP cut from twenty-two days to one dayo Disc drives and tape storage•WIP on floor cut 67%o Electrical circuit breakersInventoryInventory consists of both raw materials and finished goods. Examples:•Finished goods inventory cut 92%o Large—size twist drills•Inventory turns up from 3.5 to 20o Motorcycle assemblyFloor space requirementsFloor space reductions result in lower costs for utilities, building maintenance and capitalinvestment to meet expansion requirements. Examples:•Space reduced to one—third of original requirementso Computer printers•Floor space cut from 51,000 to 9,000 square feeto Computer logic unitwcy506 (2006-8-13 13:08:15)Lead-TimeLead-time is the time which elapses between receipt of an order and the time the product or service is shipped to the customer. Examples:•Reduced lead time from 17 weeks to 1 weeko CAD/CAM equipment•Cut production lead time from 14 days to 2 dayso Defense weapons systemsFlow distanceFlow distance is the distance a part or document travels during the manufacturing process. Examples:•Flow distance cut from 1,100 to 180 feeto Diagnostic drug analyzer•Flow distance cut from 31,000 to 275 feeto Computer productsScrap and reworkScrap and rework reductions can represent huge savings. Examples:•Defects reduced 52%, number of inspectors cut from 75 to 6o Motorcycle assembly•Scrap and salvage cost reduced 54%o Electronic air cleanersProduct or model changeoverThe speed and frequency of product or model changeovers (set-ups) is an indication of the degree to which the organization can respond to changing demands in the market place and its ability to efficiently reduce inventories by building only what is needed. Examples:•Reduced from one model changeover per month to several per dayo Self-propelled lawn mowers•Reduced time per changeover from 8 hours to 18 minuteso Cough dropsOther measuresProductivity:•Reduced paperwork by 70% (Kanban)o Hydraulic valves•Productivity, including yield, up 35%o Disc packs and discsJobs:•Number of job categories cut 95%o SemiconductorsEquipment:•Storage racks cut 67%o Circuit breakersTrainingWho provides the training?Leader training is commonly provided by the coordinator. The leader trains the members, with help from the coordinator, as necessary. Member training can be done all at once or a little at a time and as needed.What are some of the techniques, expressions and concepts used by members of a lean team?First, team members must be familiar with problem-solving and process control techniques such as: brainstorming, data gathering (sampling), Pareto analysis, cause and effect problem analysis, histograms, control charts, stratification, scatter diagrams, etc.Secondly, there are a number of techniques and expressions that should be familiar to lean practioners. Some examples include:•The 5S•Kaizen activities•Inventory reduction•SMED (Single Minute Exchange of Die)•TPM (Total Preventative Maintenance)•Poka Yoke (Mistake Proofing)•Waste Elimination•The Pull Concept•Just-In-Time•Cycle time reduction•Takt Time•Other items include-Lean production layout-Communication strategies and the “visual factory”What are the 5SThe 5S are initials of Japanese words that stand for several aspects of housekeeping. The comparable words in English are:•Sort-“What is not in use, throw it out”•Set-In-Order-“Rearrange the work area”•Shine-”Cleanliness is next to godliness”•Standardize-“Establish policy guidelines”•Sustain-“Keep 5-S activities from unraveling”Why would we start with cleaning and organizing the workplace? Well, why not? It is not a daunting task. Actually, it is to everyone’s advantage to start with a clean slate, so to speak. Some degree of success is assured. Because the results of cleaning and organizing are so visible, ideas should abound as employees from one department observe what is happening in other departments around the plant.What are Kaizen activities?Kaizen is a Japanese word that means “continuous improvement.” The improvements individually are usually small and incremental, but collectively dramatic. Masaaki Imai, a Japanese consultant, has popularized Kaizen as an important business strategy. He believes the following six major systems should be in place in order to successfully achieve a Kaizen strategy: •Total quality management•Just-in-time•Total productive maintenance•Policy deployment• A suggestion system•Team activitiesWhat is the importance of inventory reduction?Lead time can be dramatically reduced at a number of places in the processing of orders.Work-in-progress (WIP) is a leading cause of long lead time. WIP can include paperwork, raw materials, in-process inventory and even finished products.There must be a unified approach between management and operators on how to achieve inventory reduction.Office paperwork can be, and usually is, just as likely to hit “log jams” as the physical pro ducts are that are out in the shop.What is SMED?SMED stands for “Single Minute Exchange of Die.” If refers to the time it should take to set-up a machine to produce a part. In automotive plants there are numerous instances where it would take three or four hours to do a set-up. However, after the application of lean techniques, the set-up time would be reduced to minutes!What is TPM?TPM stands for “Total Preventative Maintenance.” The goal of TPM is to maximize equipment effectiveness throughout the life of the equipment.The absence of a lean mentality is obvious when machine maintenance is totally the responsibility of the maintenance specialists. The truth is that operators can contribute in keeping the equipment in good condition. TPM should involve everyone at all levels. The Lean team can contribute to developing a maintenance system that they are a part of. The goal should be zero breakdowns.What is Poka-Yoke?Poka-yoke is a Japanese word meaning “mistake proofing.” Poka-yoke devices can dramatically cut defects. A simple example is the three pronged electric plug-in. You can not plug it in wrong! There are poka-yoke devices to detect errors that have been made. Other poka-yoke devices are designed to shut down the machine before it could create a defective part.wcy506 (2006-8-13 13:09:59)wcy506 (2006-8-13 13:11:01)The continuous improvement coordinatorWhat is the role of the continuous improvement coordinator?The coordinator is the individual responsible for successfully coordinating and directing lean activities within an organization.What does the coordinator do?The duties of the coordinator include the following:•See to it that the policies of the steering committee are understood and are followed by everyone involved.•Establish an ongoing education and training program per the dictates of the steering committee. Personally conducts training and/or arranges for competent instructo,。

An outline of:Lean Thinking Banish Waste and Create Wealth in YourCorporationBy James P。

Womack and Daniel T。

JonesNew York, NY:Free Press,Simon &Schuster,Inc., 1996, Second Edition,2003 Preface to the 2003 Edition. Forecasts are always wrong. That is why lean thinkersstrive to reduce order—to—delivery time. During the 2002 meltdown,this 1996 book went back on the Business Week bestseller list。

We have added what we have learned since 1996 in this edition. Lean Thinking is more relevant today。

Lean ideas are the single most powerful tool available for creating value and eliminating waste in any organization。

Part I: Lean PrinciplesTaiichi Ohno (1912 – 1990), a Toyota executive,identified seven types of waste found in any process:• Transportation. Unnecessary transport of parts under production.• Inventory. Stacks of parts waiting to be completed or finished products waiting to be shipped.• Motion。

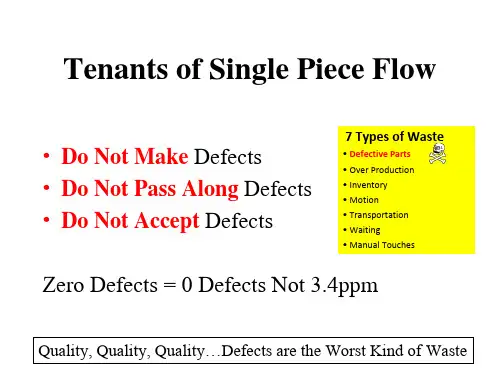

Lean Production Tools Courseware (English Version) IntroductionThe Lean Production Tools Courseware provides an in-depth understanding of various tools used in lean manufacturing. Lean production aims to eliminate waste and improve efficiency in manufacturing processes. This courseware will guide learners through the basics of lean production and provide detailed insights into the key tools employed in this methodology.1. Overview of Lean ProductionLean production, also known as lean manufacturing, is a systematic approach to optimize the production process by eliminating non-value-added activities or waste. It focuses on improving quality, reducing lead time, and increasing productivity. Lean production is widely used in various industries to enhance operational efficiency and customer satisfaction.2. Seven WastesThe concept of waste is fundamental in lean production. The courseware covers the seven wastes commonly found in manufacturing processes:2.1 OverproductionOverproduction occurs when more products are produced than required, resulting in excessive inventory, longer lead times, and higher costs.2.2 InventoryInventory refers to the excess stock of raw materials, work-in-progress, or finished goods. This excess inventory ties up capital and occupies valuable space.2.3 WaitingWaiting waste is the time wasted when components, machines, or workers are idle due to delays in the production process.2.4 MotionMotion waste refers to unnecessary movement or transportation of materials, tools, or equipment. It can lead to physical strain and inefficiency.2.5 TransportationTransportation waste involves the unnecessary movement of materials or products between different processes or locations, resulting in delays and increased costs.2.6 DefectsDefects waste includes any products or components that do not meet quality standards and require rework or disposal. Defects waste adds extra cost and reduces customer satisfaction.2.7 OverprocessingOverprocessing waste occurs when more work or processing is done than necessary, resulting in increased time and costs without providing additional value to the customer.3. Lean Production Tools3.1 Value Stream Mapping (VSM)Value Stream Mapping is a graphical tool used to analyze and improve the flow of materials and information in a manufacturing process. It helps identify and eliminate non-value-added activities, streamline processes, and reduce lead time.3.2 5S MethodologyThe 5S Methodology consists of five principles: Sort, Set in Order, Shine, Standardize, and Sustain. It aims to create a clean, organized, and efficient work environment. The 5S methodology enhances productivity, safety, and employee morale.3.3 Kanban SystemKanban is a visual system that helps manage inventory and control the flow of materials in production. It uses signals to indicate when items should be produced or replenished, reducing inventory levels and preventing overproduction.3.4 Just-in-Time (JIT)Just-in-Time is a production strategy that aims to minimize inventory levels by producing and delivering products at the exact time they are needed. JIT helps reduce lead time, improve efficiency, and lower costs.3.5 Poka-YokePoka-Yoke is a technique used to prevent or detect errors in the production process. It involves implementing mechanisms or devices that prevent mistakes or provide immediate feedback, reducing defects and improving quality.3.6 KaizenKaizen, meaning continuous improvement in Japanese, is a philosophy that focuses on small, incremental changes to improve processes and eliminate waste. It encourages employee involvement and promotes a culture of continuous improvement.ConclusionThe Lean Production Tools Courseware provides a comprehensive overview of the key tools used in lean manufacturing. By understanding and implementing these tools, organizations can achieve higher efficiency, improve quality, and reduce waste in their production processes. By continuously striving for improvement, organizations can gain a competitive advantage in today’s dynamic market.。

精益生产方式简介摘要:精益生产是一种起源于丰田和汽车制造的流水线制造方法论。

也被称为“丰田生产系统”。

精益生产的目标被描述为“在适当的时间(或第仪式间,the first time)使适当的东西到达适当的地点,同时使浪费最小化和适应变化”。

创立了精益生产原则的大野耐一发现他的方法论不但可以减小浪费,还能够增进产品流动和提高质量。

本文对精益生产进行了具体的分析,得出它的优越性,并把它与传统的生产方式进行比较,通过分析可以知道精益生产是解救困难企业的法宝。

关键词:丰田汽车,精益生产,优越性,特点,企业一、丰田公司的精益生产方式精益生产(Lean Production,简称LP)是美国麻省理工学院数位国际汽车计划组织(IMVP)的专家对日本“丰田JIT(Justin Time)生产方式”的赞誉之称,精,即少而精,不投入多余的生产要素,只是在适当的时间生产必要数量的市场急需产品(或下道工序急需的产品);益,即所有经营活动都要有益有效,具有经济性。

精益生产是当前工业界最佳的一种生产组织体系和方式。

精益生产是战后日本汽车工业遭到的“资源稀缺”和“多品种、少批量”的市场制约的产物,它是从丰田相佐诘开始,经丰田喜一郎及大野耐一等人的共同努力直到60年代才逐步完善而形成的。

精益生产既是一种以最大限度地减少企业生产所占用的资源和降低企业管理和运营成本为主要目标的生产方式,同时它又是一种理念,一种文化。

实施精益生产就是决心追求完美的历程,也是追求卓越的过程,它是支撑个人与企业生命的一种精神力量,也是在永无止境的学习过程中获得自我满足的一种境界。

其目标是精益求精,尽善尽美,永无止境的追求七个零的终极目标。

精益生产的实质是管理过程,包括人事组织管理的优化,大力精简中间管理层,进行组织扁平化改革,减少非直接生产人员;推进行生产均衡化同步化,实现零库存与柔性生产;推行全生产过程(包括整个供应链)的质量保证体系,实现零不良;减少和降低任何环节上的浪费,实现零浪费;最终实现拉动式准时化生产方式。

浅谈JITJIT(just in time),宏观意义上讲就是及时制,在管理上也叫做“精益生产管理”。

JIT 准时化生产方式(Just In Time, JIT)是日本在20世纪五六十年代研究和开始实施的生产管理方式,是一种有效地利用各种资源、降低成本的准则,其含义是:在需要的时间和地点生产必要数量和完美质量的产品和零部件,以杜绝超量生产,消除无效劳动和浪费,达到用最少的投入实现量大的。

JIT系统以准时生产为出发点,首先揭示出生产过量的浪费,进而暴露出其他方面的浪费(如设备布局不当、人员过多)然后对设备、人员等资源进行调整。

如此不断循环,使成本不断降低,计划和控制水平高。

80年代,随着日本企业在国际市场竞争中的胜利,准时化生产方式被作为日本企业成功的秘诀。

JIT成功案例分析:1.丰田的生产和管理系统长期以来一直是丰田公司的核心竞争力和高效率的源泉,同时也成为国际上企业经营管理效仿的榜样,例如,作为丰田生产管理一大特点的看板管理已被世界各地的企业所采用。

如今,世界很多大型企业都在学习丰田管理模式的基础上,建立了各自的管理系统,以试图实现标杆超越,像通用电气公司、福特公司、克莱斯勒公司等世界著名企业都加入了这一行列。

但是,令人惊异的是,尽管丰田管理模式已为全球所认同和接受,真正成功的企业却并不多,如今位于日本的丰田公司每天都要接受数以万计的企业高级管理者参观,这些参观者将他们看到的管理方式带到本国后,并没有得到意想的效果,为此,很多人认为丰田管理模式的成功根源于其独特的文化因素。

但事实并非如此,例如同是日本公司的尼桑和本田却并没有达到丰田的标准,而丰田本身却将其独特的管理模式带到了全世界,这其中的代表就是位于美国肯塔基州的丰田乔治城汽车生产厂,该厂自1988年7月开始在1300英亩的厂址上进行批量生产,年生产能力为200000辆Camry轿车,相当于以往美国从日本进口同类型轿车的总量。

2. 中国嘉陵股份有限公司所生产的“嘉陵”摩托车是全国第一品牌,现有8种排量(35-150ml)100多个车型,累计产销量逾1000多万辆,占全国摩托车总量的1/5以上,现已形成年产200万辆的生产能力。

Drive and implement Lean manufacturing across the operations in order to eliminate waste, minimize inventory and maximize flow• Develop procedures in partnering with suppliers in order to achieve Lean manufacturing• Reducing system response time and ensure the production system was capable of immediately changing and adapting to market demands.• Required to collect and analyze data for determining an improvement strategy.• Facilitate and teach Lean manufacturing tools and techniques. Coach existing and new teams with Lean projects.• Ability to strategically prioritize and manage process improvement opportunities in alignment with business goals and objectives.• Working hand in hand with internal six-sigma expert in developing and drive Lean Sigma.• Acts as change agent to instill Lean Sigma culture throughout organization• Must have the ability to lead, work with teams, and understand team dynamics.OEE(Overall Equipment Effectiveness)--- 全局设备效率OEE = (Running time / Loading time) x (Actual Output / Theoretical output) x (Good Output / Actual out put)世界级企业的全局设备效率OEE为85%或更好。

精益生产英文词汇

以下是关于精益生产(Lean Production)的一些英文词汇:

1.Lean Production: 精益生产

2.Kaizen: 改善,不断改进

3.Just-In-Time (JIT): 准时生产,即时生产

4.Continuous Improvement: 持续改进

5.Waste Elimination: 消除浪费

6.Value Stream Mapping (VSM): 价值流程图

7.5S Methodology: 5S方法(整理、整顿、清扫、清洁、素养)

8.Kanban: 看板

9.Andon: 安灯

10.Poka-Yoke: 防错

11.Single-Minute Exchange of Die (SMED): 单分模换模

12.Total Productive Maintenance (TPM): 全员生产维护

13.Batch Production: 分批生产

14.Cellular Manufacturing: 单元化生产

15.Pull System: 拉动系统

16.Flow Production: 流水生产

17.Visual Management: 视觉管理

18.Standard Work: 标准作业

19.Gemba: 现场(实地)

20.Muda: 浪费

21.Mura: 不稳定

22.Muri: 过度负荷

这些术语涵盖了精益生产的核心概念和工具。

请注意,根据上下文,可能会有不同的翻译和表达方式。