FEM9.311 Rules for the Design of Storage and Retrieval Machines Structures S欧洲物料搬运协会.

- 格式:pdf

- 大小:473.00 KB

- 文档页数:6

A blood case caused by a watchToday I want to tell you a story.The hero of the story is li lei.One morning li lei woke up and washed, he put his watch on the edge of the washstand, his wife (do you know who his wife is?).Han Meimei was afraid the watch would get wet, so she took the watch and put it on the table.At this moment, their son came to the table and wanted to take the bread, but knocked his father's watch on the ground and broke it.li lei loved the watch, so he beat his son and scolded his wife. Han Meimei was also angry, and the two started to quarrel. Then li lei didn't eat the breakfast and drove directly to the company. When he arrived at the company, li lei suddenly remembered that he had left his bag at home, so he had to turn around and go home.But no one was at home. Han meimei went to work and the son went to school. Li lei's own key was in the bag, so he couldn't get into the door and had to call han meimei for the key.When han meimei rushed home, she knocked over a fruit stand and the owner did not let her go.She had to pay the money for the owner.When li lei arrived at the company, he was 15 minutes late, so he was scolded by his boss. Li lei was in a terrible mood. Han meimei was also deducted for early retirement.Their son, who played baseball for the day, could have done well, but was out of the mood.What a terrible day!Isn't it?At that time, a mysterious man appeared in front of li lei, said to him: "hello, li lei, I am festinger, this story's author, if I can let time back to this morning, your watch broke at the moment, would you like?"Of course he would!So, let's see what happens next.The watch was broken.Li lei love his watch, but also know that it can't change the fact and to comfort his son: "it doesn't matter, I can take to be repaired watches, but the next time you may not be so careless."After that, the family had a happy breakfast and went to work on their own.As we all expected, the son was happy, the wife was happy, li lei was also happy, then everything would not happen.This is the festinger rule.He stresses that 10 percent of our lives are beyond our control, and 90 percent of what we can control.In this case, the watch is 10 percent off our control.The next series of things is another 90 percent.Although we can't control the previous 10 percent, we can fully determine the remaining 90 percent through our mindsets and actions.In real life, I often hear people complain: how can I be so unlucky? There is always something bad about me every day. Who can help me?Only we can help ourselves.If you know and can use the "festinger rule", all problems will be solved。

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN ISO 8589 February 2010ICS 67.240 English VersionSensory analysis - General guidance for the design of testrooms (ISO 8589:2007)Analyse sensorielle - Directives générales pour laconception de locaux destinés à l'analyse (ISO 8589:2007) Sensorische Analyse - Allgemeiner Leitfaden für die Gestaltung von Prüfräumen (ISO 8589:2007) This European Standard was approved by CEN on 31 January 2010.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATION C O M I T É E U R O P ÉE N D E N O R M A LI S A T I O NEUR OP ÄIS C HES KOM ITEE FÜR NOR M UNGManagement Centre: Avenue Marnix 17, B-1000 Brussels© 2010 CEN All rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN ISO 8589:2010: EForewordThe text of ISO 8589:2007 has been prepared by Technical Committee ISO/TC 34 “Food products” of the International Organization for Standardization (ISO) and has been taken over as EN ISO 8589:2010.This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by August 2010, and conflicting national standards shall be withdrawn at the latest by August 2010.Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights.According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.Endorsement noticeThe text of ISO 8589:2007 has been approved by CEN as a EN ISO 8589:2010 without any modification.BS EN ISO 8589:2010EN ISO 8589:2010 (E)© ISO 2010 iiiContentsPage 1Scope.....................................................................................................................................................1 2Normative references...........................................................................................................................1 3Terms and definitions...........................................................................................................................1 4Principle.................................................................................................................................................1 5Creation of test rooms..........................................................................................................................2 6Testing area...........................................................................................................................................2 6.1General requirements...........................................................................................................................2 6.2Testing booths......................................................................................................................................4 6.3Area for group work..............................................................................................................................5 7Preparation area....................................................................................................................................6 7.1General requirements...........................................................................................................................6 7.2Equipment .............................................................................................................................................6 8Office......................................................................................................................................................7 8.1General requirements...........................................................................................................................7 8.2Size.........................................................................................................................................................7 8.3Fittings...................................................................................................................................................7 9Additional areas....................................................................................................................................7 10 Additional information.. (7)Annex A (informative) Examples of test room layouts (8)Bibliography (16)BS EN ISO 8589:2010EN ISO 8589:2010 (E)This page deliberately set blankINTERNATIONAL STANDARD1Sensory analysis — General guidance for the design of test rooms1 ScopeThis International Standard provides general guidance for the design of test rooms intended for the sensory analysis of products.It describes the requirements to set up a test room comprising a testing area, a preparation area, and an office, specifying those that are essential or those that are merely desirable.This International Standard is not specific for any product or test type.NOTE The test space can be similar for food and non-food products that are evaluated using sensory methods. However, the test rooms might need to be adapted for each specialized use. Modifications to the design are often needed for specific products and for specific types of testing. This is particularly true if the test rooms are to be used for the evaluation of non-food products.Although many of the general principles are similar, this International Standard does not address test facilities for the specialized examination of products in inspection or in-plant quality-control applications.2 Normative referencesThe following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.ISO 5492, Sensory analysis — Vocabulary3 Terms and definitionsFor the purposes of this document, the terms and definitions given in ISO 5492 apply.4 PrincipleThe test rooms are designed⎯ to conduct sensory evaluations under known and controlled conditions with a minimum of distractions,and⎯ to reduce the effects that psychological factors and physical conditions can have on human judgement. EN ISO 8589:2010 (E)BS EN ISO 8589:2010© BSI 201025 Creation of test roomsThe creation of test rooms intended for sensory analysis differs, depending on whether a new building or an existing facility is used.A typical test facility comprises the following:⎯ a testing area in which work may be carried out individually in testing booths or in groups;⎯ a preparation area;⎯ an office;⎯ a cloakroom and toilets;⎯ a storage room for supplies;⎯ a storage room for samples;⎯ a waiting room for assessors.The minimum requirements are⎯ a testing area in which work may be carried out individually in testing booths or in groups, and⎯ a preparation area.The test room should be easily accessible to the assessors and should not be located in an area where there is a heavy traffic flow (for example, near a cafeteria), unless arrangements have been made to reduce noise and distraction. Reasonable arrangements should also be made for accessibility to the area by those with physical disabilities.An area for assessors to gather or wait prior to entering the panel room is desirable. The organization of the areas should be easily accessible for cleaning and should allow for good conditions of hygiene.See the examples of test room layouts given in Annex A.6 Testing area6.1 General requirements6.1.1 LocationThe testing area should be located near the preparation area. The areas should be close enough to each other to facilitate sample presentation, but the areas should be separate to reduce interference, such as from odour and noise. (See also 7.1.)The assessors shall not enter or leave the testing area through the preparation area, as this could result in bias in the test results.BS EN ISO 8589:2010EN ISO 8589:2010 (E)© BSI 201036.1.2 Temperature and relative humidityThe temperature in the testing area shall be controlled. Relative humidity should be controllable if it can affect the product during evaluation.Generally, the levels should be comfortable for the assessors, unless the product test requires unusual conditions.6.1.3 NoiseThe noise level shall be kept to a minimum during the tests. Therefore, it is desirable for the room to be sound-resistant, with floors that can minimize noises associated with walking or when moving objects.6.1.4 OdoursThe testing area shall be kept reasonably free from odours. One way to achieve this is by installing an air system with activated carbon filters. If necessary, a slight positive pressure may be created in the testing area to reduce the inflow of air from other areas.The testing area shall be constructed from materials which are easy to clean and can be kept odour free. Furnishings and equipment, such as carpets, chairs, etc., shall not emit odours that can interfere with the evaluation. Depending on the use of the laboratory, the use of fabric surfaces may need to be limited because of odour absorption and difficulties in cleaning.Cleaning agents that are used should not leave odours in the testing area.6.1.5 DecorationThe colour of the walls and furnishings of the testing area shall be neutral so that the colour of samples is not modified. Matt off-white or light neutral grey are recommended colours (dark grey may be appropriate for floors and chairs).6.1.6 LightingThe source, type of lighting and lighting levels are very important in all sensory testing. Attention shall be given to general lighting in all rooms, and to lighting in each panel booth when applicable. The lighting in the testing area shall be uniform, free from strong shadows, and controllable.Although not required, lights may be chosen that attempt to reproduce a specific lighting condition.EXAMPLE Lights with a correlated colour temperature of 6 500 °K provide a good, neutral light similar to “northern daylight” and lights of 5 000 °K to 5 500 °K with a high colour-rendering index may simulate “noon” daylight.Special lighting may be especially important in the case of colour assessment of products or materials. Special lighting devices may also be needed to mask colour or visual differences that are unwanted, non-test variables in the product. Devices that may be used include⎯ a dimmer device,⎯ coloured light sources,⎯ coloured filters,⎯ black light, or⎯ monochromatic light sources such as sodium vapour lamps.In consumer testing, lighting that is typical of lighting found in the place where the product will be used often may be chosen. Thus, the type of lighting needed depends on the type of test that is conducted.BS EN ISO 8589:2010EN ISO 8589:2010 (E)© BSI 201046.1.7 Safety considerationsAny special safety considerations appropriate for the type of laboratory should be considered, such as special ventilation hoods for odour samples, chemical wash stations if working with chemicals, and special fire considerations if working with cooking equipment.Regardless of the type of laboratory, exit signs should be placed appropriately.6.2 Testing booths6.2.1 General requirementsIn many sensory tests, assessors are required to make independent personal judgements. Assessors often use individual testing booths to limit distractions and to avoid communication during evaluations where individual assessment is necessary.6.2.2 NumberThe number of booths that can be installed depends on the space available and the tests usually carried out in the testing area. This number shall be chosen to allow sufficient space for movement and for the serving of samples from the serving area.6.2.3 Set-upAlthough permanent testing booths are recommended, the use of temporary, portable, testing booths may be necessary.If the testing booths are constructed along a wall dividing the testing area from the preparation area, it is recommended that there be openings to allow samples to be passed from the preparation area to the testing booth. The openings shall be designed for easy passage of samples and covered by sliding doors or hatches which close quietly. A counter on the serving-area side of the wall is convenient. It is recommended that the openings be designed so that assessors cannot see samples being prepared or coded.Electrical outlets, if needed, should be conveniently located to accommodate electrical equipment that may be required for specific testing situations.If a computer system is used by assessors for data input, the necessary computer components shall be configured so as to allow the assessor to concentrate on the sensory task. For example, the screen should be at a comfortable height for viewing and should be configured so that there is minimal glare, and screen savers should generally not be used. The keyboard or other input device should be at a comfortable level and placed so that it is not in the way of the evaluation of samples.Unless the panel is served at specific time intervals, it is recommended that a system be devised for the assessor to signal to the operator when he/she is ready for a sample. This is especially important when a wall separates the preparation area from the testing area. A switch to turn on a light on the preparation side, or a system in which a card is simply slipped under the serving door, may be used.It may be helpful for booths to be numbered or have a sign to permit their identification and the location of the assessors.BS EN ISO 8589:2010EN ISO 8589:2010 (E)© BSI 201056.2.4 Layout and sizeThe working area in each testing booth shall be sufficiently large to accommodate the following easily: ⎯ the samples;⎯ the utensils;⎯ the expectoration cups;⎯ a sink, if necessary;⎯ the rinsing agents;⎯ the answer forms and pens or computer input devices.The working area shall also provide adequate space to enable the completion of the answer forms or to accommodate computerized equipment for the transmission of the responses.It is recommended that the working area be at least 0,9 m wide and 0,6 m deep. If additional equipment is needed in the booth, the size may need to be increased. The working surface of the testing booths shall be of an appropriate height to allow sample evaluation to be carried out in comfort.The lateral dividers between the testing booths should extend beyond the counter surface so as to partially screen the assessors. An extension of at least 0,3 m beyond the counter generally works well. The dividers may extend from floor to ceiling for complete privacy, with a design allowing adequate ventilation and cleaning. Alternatively, the dividers may be suspended from the wall and enclose only the seated assessor.If the assessors are to be seated, comfortable seats of a height compatible with the working surface shall be provided. If the seat cannot be adjusted or moved, a distance of at least 0,35 m between the seat and the working surface is recommended. Seats that move should be able to be moved quietly.Testing booths may be equipped with sinks. In this case, the quality and temperature of the water (if it is used in the evaluation), shall be controlled. Sinks should not be used unless there is provision for sanitation and odour control. Suction-type sinks ensure waste disposal but they are noisy.At least one booth should be designed for a height and width to accommodate an assessor in a wheelchair, if required by local laws.6.2.5 ColourThe interior of a booth for general use shall be painted a matt gray with a luminance factor of about 15 % (for example Munsell reference N4 to N5). However, when mainly light colours and near-white colours are to be compared, the interior of the booth may be painted so as to have a luminance factor of 30 % or higher (for example Munsell reference N6) in order to give a lower brightness contrast with the colour to be examined.6.2.6 LightingSee 6.1.6 for general lighting recommendations.6.3 Area for group work6.3.1 General requirementsAn area for group work is often provided to allow discussion among the assessors and the operator. This area could be used during the initial training sessions and at any time when discussion among the assessors is required.BS EN ISO 8589:2010EN ISO 8589:2010 (E)© BSI 20106The area shall be large enough to contain a table that can accommodate comfortable chairs for all the assessors testing at one time. (See the examples in Annex A.) The table shall be large enough to hold the following:⎯ a tray or place setting to hold ballots and samples for each assessor;⎯ extra materials, such as reference samples, if used, and pens, pencils or cups;⎯ computer workstations, if necessary.A movable centre in the table is helpful for passing samples. The table may also be equipped with removable panels which separate the assessors for individual work. It is recommended that a large writing board or chart be available for recording discussion points.6.3.2 LightingLighting requirements for group work are usually like those described in 6.1.6.7 Preparation area7.1 General requirementsA laboratory (or kitchen) for the preparation of samples shall be located in the immediate vicinity of the testing area. Its location shall be such that assessors do not have to pass through the preparation area to gain access to the testing area, which could cause bias in test results.Efficient workflow arrangements in and between these functional areas are essential.The area shall be well ventilated so that food preparation odours and foreign odours are removed.The materials selected for the floors, walls, ceilings and furnishings shall be easy to maintain and be both odour free and impervious to odours.It is necessary to provide for a certain amount of flexibility in the plumbing and gas and electricity services during the construction of this area, to allow for future changes in the location of equipment.7.2 EquipmentThe type of equipment required in the preparation area depends on the range of products which will be processed there.The principal elements are the following:⎯ a working surface;⎯ a sink and other equipment needed for washing supplies;⎯ equipment, including electrical equipment, necessary for the conservation, preparation, control, andpresentation of samples (e.g. containers, dishes, appliances, etc.), that is in good working order and calibrated as necessary for testing;⎯ equipment for cleaning;⎯ a waste container;⎯ storage facilities.BS EN ISO 8589:2010EN ISO 8589:2010 (E)© BSI 2010Additional equipment may also be necessary.Containers for sample preparation and storage, and utensils and cutlery used in sample preparation, shall be manufactured from materials that will not impart any odour or taste to the product and that prevent adulteration or contamination of samples.8 Office8.1 General requirementsThe office is a working area where paperwork involved with sensory analysis testing is carried out. It is essential that the office be separate from, but near, the testing area.8.2 SizeAdequate space is required for planning tests, devising answer forms, sorting and decoding answer forms, statistical analysis of data, writing reports, and, if necessary, for meeting with clients to discuss tests and results.8.3 FittingsDepending on the specific tasks that will be done in the office, it may contain the following equipment: desk or work table, filing cabinet, bookshelf, chairs, telephone, calculator and computer to carry out statistical analysis of data.Photocopying services and file storage should be available, but are not necessary in this office.9 Additional areasIt is useful to provide a cloakroom and toilets near the testing area, but not in a place that would impact evaluations.Facilities for storing equipment needed to maintain the cleanliness and hygiene of the facility are important.10 Additional informationIt is essential that all building codes in the local area be reviewed before the construction or modification of any testing facility. Building codes should be followed.Annex A(informative)Examples of test room layoutsKey1 Meeting room2 Office3 Area for group work4 Testing booths5 Distribution area6 Preparation area7 Store roomFigure A.1 — First example of a floor plan for a test roomKey1 Office2 Testing booths3 Distribution area4 Preparation area5 Meeting room and area for group workFigure A.2 — Second example of a floor plan for a test roomKey1 Office2 Testing booths3 Distribution area4 Preparation area5 Meeting room and area for group workFigure A.3 — Third example of a floor plan for a test roomKey1 Testing booths2 Preparation area3 Meeting room and area for group workFigure A.4 — Fourth example of a floor plan for a test roomFigure A.5 — Table equipped with removable dividersKey1 Removable dividersFigure A.6 — Example of a floor plan for a testing area for working in testing booths or in groupsKey1 Serving counter2 Individual testing booths3 Divider between booths4 Hatch5 Wall with openings for passing samplesFigure A.7 — Plan for testing booths and serving counter separated by a wallKey1 Serving counter2 Hatch3 SinkFigure A.8 — Herring-bone layout of testing boothsFigure A.9 — Various types of sliding doors and hatchesKey1 Lateral layout of testing booths2 Distribution area3 Desk of panel chairmanFigure A.10 — Testing area with a facility for supervision by the panel chairmanNOTEA testing booth could include the following equipment:⎯ 1 sliding keyboard support⎯ 1 cut-up on the bottom of the booth with the computer-screen shelf support ⎯ 1 tray-unit central support on castors ⎯ 1 mirror⎯ 2 fluorescent lamps with a switch ⎯ 1 rod support towel ⎯ 1 white basin⎯ 1 tap for infrared waterFigure A.11 — Some examples of a testing boothBibliography[1] ISO 6658, Sensory analysis — Methodology — General guidanceICS 67.240Price based on 16 pages © ISO 2010BS EN ISO 8589:2010EN ISO 8589:2010 (E)This page has been intentionally left blankBSI Group Headquarters 389 Chiswick High Road, London, W4 4AL, UK Tel +44 (0)20 8996 9001 Fax +44 (0)20 8996 7001 / standards BSI - British Standards InstitutionBSI is the independent national body responsible for preparing British Standards. It presents the UK view on standards in Europe and at the international level. It is incorporated by Royal Charter.RevisionsBritish Standards are updated by amendment or revision. Users of British Standards should make sure that they possess the latest amendments or editions.It is the constant aim of BSI to improve the quality of our products and services. We would be grateful if anyone finding an inaccuracy or ambiguity while using this British Standard would inform the Secretary of the technical committee responsible, the identity of which can be found on the inside front cover. Tel:+44 (0)20 8996 9000. Fax: +44 (0)20 8996 7400.BSI offers members an individual updating service called PLUS which ensures that subscribers automatically receive the latest editions of standards. Buying standardsOrders for all BSI, international and foreign standards publications should be addressed to Customer Services. Tel: +44 (0)20 8996 9001. Fax: +44 (0)20 8996 7001 Email: orders@ You may also buy directly using a debit/credit card from the BSI Shop on the Website /shopIn response to orders for international standards, it is BSI policy to supply the BSI implementation of those that have been published as British Standards, unless otherwise requested.Information on standardsBSI provides a wide range of information on national, European and international standards through its Library and its Technical Help to Exporters Service. Various BSI electronic information services are also available which give details on all its products and services. Contact Information Centre. Tel: +44 (0)20 8996 7111 Fax: +44 (0)20 8996 7048 Email: info@ Subscribing members of BSI are kept up to date with standards developments and receive substantial discounts on the purchase price of standards. For details of these and other benefits contact Membership Administration. Tel: +44 (0)20 8996 7002 Fax: +44 (0)20 8996 7001 Email: membership@ Information regarding online access to British Standards via British Standards Online can be found at /BSOLFurther information about BSI is available on the BSI website at http:// CopyrightCopyright subsists in all BSI publications. BSI also holds the copyright, in the UK, of the publications of the international standardization bodies. Except as permitted under the Copyright, Designs and Patents Act 1988 no extract may be reproduced, stored in a retrieval system or transmitted in any form or by any means – electronic, photocopying, recording or otherwise – without prior written permission from BSI.This does not preclude the free use, in the course of implementing the standard, of necessary details such as symbols, and size, type or grade designations. If these details are to be used for any other purpose than implementation then the prior written permission of BSI must be obtained.Details and advice can be obtained from the Copyright and Licensing Manager. Tel: +44 (0)20 8996 7070 Email: copyright@BS EN ISO8589:2010。

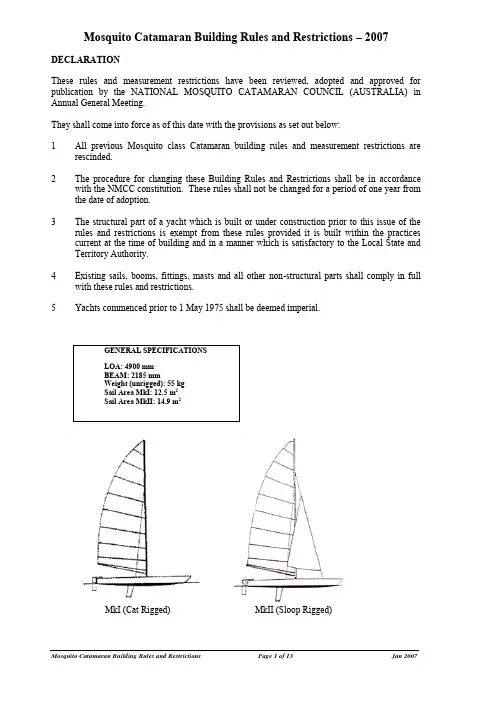

Mosquito Catamaran Building Rules and Restrictions – 2007DECLARATIONThese rules and measurement restrictions have been reviewed, adopted and approved for publication by the NATIONAL MOSQUITO CATAMARAN COUNCIL (AUSTRALIA) in Annual General Meeting.They shall come into force as of this date with the provisions as set out below:1 All previous Mosquito class Catamaran building rules and measurement restrictions arerescinded.2 The procedure for changing these Building Rules and Restrictions shall be in accordancewith the NMCC constitution. These rules shall not be changed for a period of one year from the date of adoption.3 The structural part of a yacht which is built or under construction prior to this issue of therules and restrictions is exempt from these rules provided it is built within the practices current at the time of building and in a manner which is satisfactory to the Local State and Territory Authority.4 Existing sails, booms, fittings, masts and all other non-structural parts shall comply in fullwith these rules and restrictions.5 Yachts commenced prior to 1 May 1975 shall be deemed imperial.MkI (Cat Rigged) MkII (Sloop Rigged) GENERAL SPECIFICATIONS LOA: 4900 mm BEAM: 2185 mmWeight (unrigged): 55 kg Sail Area MkI: 12.5 m 2 Sail Area MkII: 14.9 m 2TABLE OF CONTENTS1 General2 Registration3 Measurement - General4 Recognition Marks5 Measurement - Hulls6 Beams7 Trampoline8 Centreboards9 Rudders10 Weight11 Mast12 Boom13 Standing rigging14 Sails15 'Black bands'16 Mainsheet traveller17 Hiking aids18 Prohibited fittings19 De-restrictions20 Safety Requirements21 Spinnaker1 GENERAL1.1 The National Mosquito Catamaran Council (Australia) does not accept legal responsibility inrespect of these rules or any claim arising there from.1.2 A Mosquito Catamaran is a restricted class which can be sailed in two modes; Mark I (catrigged, one person) or Mark II (sloop rigged, two persons). To sail competitively in class racing a boat shall comply with class rules. These rules take precedence over measurement forms and plans.1.3 The object of these restrictions is to provide uniform specifications and restrictions for theabove class and are to be read in conjunction with the plans.1.4 Where there is no State or Territory Authority, its function as stated in these rules shall becarried out by the National Mosquito Catamaran Council (Australia), or its delegated representatives.2 REGISTRATION2.1 No boat shall be allowed to race in the Class unless it has a valid Class MeasurementCertificate.Application for measurement and registration shall be the responsibility of the owner, who shall apply to the appropriate authority, submitting at the same time the proposed name of the boat and sail number. No two boats in the Class registered in the same State shall have the same name.2.2 The owner shall arrange the attendance of an approved Measurer who shall complete themeasurement form and, if satisfied, shall certify thereon that the boat complies with the Class rules and the current AYF safety prescriptions.2.3 The measurement form, when complete, shall be returned by the owner to his StateAuthority, together with any measurement fee required. On receipt of these a measurement certificate shall be issued to the owner. The State Authority shall then enter the boat on its official Class Register. Each time a boat is submitted for measurement a fee shall be charged.2.4 Change of ownership invalidates the certificate but re-registration may be effected byreturning the old certificate to the State Authority, together with an application in writing containing the name and address of the new owner and the appropriate re-registration fee if any. Re-measurement is not necessary.The State Authority shall issue a new certificate to the owner, and amend its Class Register accordingly.2.5 The boat is defined as a pair of hulls. The registered sail number applies to that pair of hulls.A hull may be replaced because of serious damage but is subject to measurement. A newpair of hulls, for any reason, constitutes a new boat and as such requires a new sail number.3 MEASUREMENT - GENERAL3.1 This is a restricted class. Measurement tolerances are intended to allow for genuine errorsonly and shall not be deliberately used to alter the design. The measurer may report on the measurement form anything which he considers departs from the intended nature and design of the boat, or to be against the general interest of the Class.3.2 Only an official measurer appointed by the National or State Authority shall measure a boatand sign the declaration on the measurement form that it complies with the Class Rules.3.3 A measurer shall not measure a boat owned or built by himself.3.4 It shall be the responsibility of the owner to see that the boat is correctly measured and toensure that it thereafter complies with the current Class Rules.3.5 All certified boats shall be liable to re-measurement at the discretion of the NationalAuthority, State or Territory Authority, or Race Committee, but only by an official measurer.Any boat re-measured at a Class Meeting and found not to comply with the Class Rules may be disqualified by protest.3.6 A certificate may be invalidated by structural alteration, replacement of components or repairof the boat and the boat shall be re-measured in respect of the affected parts by an official measurer.3.7 New sails shall be measured, and registered on the Class Measurement Certificate by anofficial measurer.3.8 Completed hulls must comply with these restrictions in all respects but, at the builder'sdiscretion, may differ from the internal specifications outlined in the plans.3.9 Builders shall be classified as either amateur or professional. To retain amateur status,builders shall be restricted to the construction of one pair of hulls per annum. Professional builders shall be required to gain registration with their State or Territory Authority before marketing their hulls. To be eligible for registration a builder shall have produced at least one prototype boat in sloop rigged configuration and shall have had it complete without structural damage at least four races in conditions of more than 20 knots and 1.5 metre seas.3.10 Professional builders shall not be involved with voting on the registration of other builders inthis rule.4 RECOGNITION MARKS4.1 The yacht's registered number shall be permanently marked, legible and easily visible to therear face of the rear beam port side.4.2 The sail numbers and class emblem shall be placed on both sides of the mainsail, inaccordance with current ISAF rules and Yachting Australia prescriptions.4.3 The numbers and emblems shall sharply contrast in colour with the sail. Letters and numberson the sail shall be of the following minimum sizes:∙height 300 mm ± 15 mm∙width 200 mm ± 15 mm (except Figure 1 and Letter I)∙thickness 45 mm ± 5 mm.5 MEASUREMENT - HULLS5.1 Each hull shall be symmetrical.5.2 The bow shall be the datum point for all longitudinal measurements.DimensionsMeasured to:5.2.1 Centre line of forward chainplates 900 mm minimum; 930 mm maximum;5.2.2 Forward edge of main beam 2250 mm minimum; 2300 mm maximum;5.2.3 Centre line of side stay chainplates 2780 mm minimum; 2860 mm maximum;5.2.4 Forward edge of centreplate case 2860 mm minimum;5.2.5 Aft edge of centreplate case 3353 mm maximum;5.2.6 Forward edge of rear beam 4380 mm minimum; 4440 mm maximum.5.3 Overall length 4900 mm maximum. The length of the hull shall be measured in a straightline along the tops of the main and rear beams, measuring between two perpendiculars to this line which just touch the tip of the bow and the aftermost point of the transom respectively.5.4 Overall width (i.e. maximum beam) 2185 mm. The beam is considered inclusive of anyfittings and fixtures on the hulls.5.5 The deck widths and hull girths, including deck and hull curves respectively shall bemeasured between the inner and outer sheer lines at the following points on both hulls: `The sheer line is the intersection of the deck and the side of the hull and does not include "anti-slip systems" placed on the gunwales to achieve hull width dimensions.'5.5.1 Forward edge of main beam∙deck width 345 mm ± 5 mm∙hull girth 1065 mm ± 25 mm5.5.2 Aft edge of rear beam∙deck width 355 mm ± 5 mm∙hull girth 800 mm ± 25 mm.5.6 The bow profile shall be as per plan ± 20% on measurement from bow datum line labelled onPlan Sheet 1.5.7 The transom profile shall be as per plan ± 5 mm. This does not include the hull sides andrear deck thickness as indicated by the dotted line on the transom profile.5.8 The hull cross-sectional profile shall fit within the measuring templates and shall touch thekeel line. The templates shall be located at right angles to the deck line at the following positions:∙Beneath the forward edge of the front chain plate.∙Beneath the forward edge of the main beam.∙Beneath the after edge of the rear beam.5.9 The longitudinal profile of the deck shall fall within the tolerance determined by measuringtemplates placed on the deck immediately forward of the front beam and aft of the rear beam.Sighting from behind the transom, the tip of the bow shall be not less than 100 mm below the line of sight between the centre lines of the template.5.10 Materials used in hull and deck construction are optional.5.11 The leading and trailing edges of the centreboard slots shall be parallel and within 10o of theperpendicular from a straight line along the tops of the main and rear beams.5.12 The method of construction of timber Mosquito hulls is optional. The hull sides shall have afair curve from top to bottom. When viewed from bow to stern, the sheer line of the deck shall not be concave between the deck measurement points, except for fittings and beam recesses.5.13 The deck curvature shall be within 5 mm of the deck template as drawn on the plan but thegunwale may be radiused to a maximum of 3 mm.6 BEAMS6.1 The hulls shall be joined by a main beam and rear beam which shall each be in onecontinuous piece. There shall be no beam or strut attached to the hulls other than the main beam and rear beam.The main beam and rear beam shall each be of straight aluminium alloy of constant section along its length. Holes may be drilled in the beams for fastenings only. Holes remaining after the removal of redundant fittings are permitted.6.2 The main and rear beam shall be; a rectangular hollow section 50 mm plus or minus 1 mm by39 mm plus or minus 1 mm by minimum 3 mm wall. Beam edges may be rounded to amaximum of 2 mm radius.6.3 There shall be no fairings fitted to the beams.6.4 The main beam shall be fitted with a strut and tie as per drawing. The leading edge of the tiemay be rounded, but not sharpened, to not more than 5 mm from the leading edge. The strut shall be of circular cross-section of diameter not less than 21 mm and minimum length 152 mm. The tie shall be of stainless steel and shall have the following minimum dimensions:∙width 35 mm∙thickness 3 mm(as per plan drawing).6.5 The central beam shall be 50 mm diameter x 1.5 mm wall thickness, or 50 mm square x 1.5mm wall thickness (with rounded corners).6.6 All beam fastenings shall be marine grade stainless, monel or aluminium. Lightening holesare not permitted in any part of the beams.6.7 The main and rear beams shall be inserted into their beam boxes with the …x‟ axis of thebeam-section mounted perpendicular to the hull sheer line. When measured at the beam datum point, beam penetration into the hull must be equal at the inner and outer sheer lines and not exceed 6mm below the sheer line. (This does not include the striker strap.) See Rule5.5 for the definition of the sheer line. The …x‟ axis is the longer dimension of the rectangularbeam section7 TRAMPOLINE7.1 The trampoline shall not extend beyond the front and rear beams or past the centreline of thedecks.7.2 The method of attachment is optional.7.3 Net trampoline materials are prohibited.8 CENTREBOARDS8.1 Two centreboards shall be fitted, one per hull.8.2 The centreboards shall have no moving parts except that uphaul/downhaul cords and latchesare allowed.8.3 Lightening holes are allowed in that part of the centreboard enclosed by the centrecase whenthe centreboard is in the fully down position.8.4 The maximum length shall be 1220 mm. The maximum width shall be 305 mm. Thethickness of the centreboards shall be 22 mm ± 2 mm. Width and thickness measurements are to be taken on that part of the board enclosed in the centreplate case when the board is fully inserted.9 RUDDERS9.1 The rudder boxes are to be held captive to the transoms to prevent loss due to capsize.9.2 With the rudders in the fore-and-aft position the centre planes of each hull and its ruddershall coincide.10 WEIGHT10.1 The total weight of the assembled hulls shall not be less than 55 kg when in dry condition tothe measurer's satisfaction. The assembled hulls may include the following items:∙The hulls including anti-skid material∙Main beam, rear beam, centre beam∙Mast step and main beam strut and tie∙Trampoline and attachments for fitting to beam and hulls∙Chainplates and rudder gudgeons∙Mainsheet traveller track or hawse, car and associated control devices (excluding rope) ∙Jib track, hawse and barber-hauler systems∙Centre-board control fittings∙All shock cords and fittings used for attachment of trapeze systems to the platform∙Hatch-cover mounting bases∙Toe straps, foot straps and bracing lines∙All fixed mounting plates and brackets∙All fasteners (e.g. bolts, rivets, screws) for securing the above∙CorrectorsAny items not listed above shall be excluded.No other fittings or equipment shall be included in the minimum weight. Any permanently attached fittings in addition to the above shall be described (with weight stated) on the measurement certificate and duly endorsed by the State Measurer. Allowance for this endorsed weight shall be made at any State or National weighing.10.2 The correctors shall be made of a solid material and when fitted shall be fixed in a visiblelocation. They shall have no purpose other than to increase the weight of the boat to the minimum figure specified in clause 10.1.10.3 If correctors are altered or removed, the boat shall be re-weighed by an official measurer anda new certificate obtained.11 MAST11.1 The mast shall be made of an extruded aluminium alloy.11.2 The maximum height of the top of the mast including all permanent fittings shall not begreater than 7360 mm above the top of the main beam.11.3 The forestay attachment point shall be 5280 mm ± 100 mm from the top of the main beam. Ifmore than one potential forestay attachment point is provided then all such points shall fall within the measurement tolerance.11.4 Section size:∙width 59 mm min; 63 mm max.∙depth 86 mm min; 91 mm max.11.5 Tapered mast permitted, but when used tapering shall only be above the 5180 mm mark. 11.6 Mast rotation control must be fitted.12 BOOM12.1 The boom may be of any material, but shall be inherently straight and of constant sectionthroughout its length.12.2 Excluding fittings the boom shall pass through an 80 mm diameter circle.12.3 Maximum length shall be 2800 mm measured along the length of boom from the back of themast track to the end of the boom or outhaul fittings.13 STANDING RIGGING13.1 The standing rigging shall consist of the shrouds, the forestay(s), the forestay strop and thediamond stays.13.2 There shall be one shroud to each hull, the attachment point being on the outer top-sides. 13.3 The mast shall carry one pair of diamond stays only, which shall be rigged below the hounds.13.4 On Mark II yachts there shall be one forestay only which shall be attached to a strop betweenthe hulls, but twin forestays may be fitted on Mark I yachts.13.5 The bridle height shall be a minimum of 380 mm above the deck line. The measurement willbe a vertical measurement to the centre of the bridle ring from a straight edge laid across the decks at the bridle attachment points.13.6 Struts, stays or devices which limit the natural fore and aft movement of the forestay andforestay strop are prohibited (jib luff tension device excluded).13.7 There shall be no other standing rigging.13.8 All standing rigging shall be circular in section, minimum diameter 3 mm, and shall have nofairings.13.9 Adjusting the standing rigging whilst racing is prohibited, except that diamond stays may beadjusted.14 SAILS14.1 The rig shall consist of mainsail and foresail for Mark II or mainsail only for Mark I exceptwhen a spinnaker is being used as per item 21. The current ISAF Equipment Rules of Sailing shall apply where no conflict with these rules arises.14.2 Removable battens shall be removed from the sails for measurement. Sails shall be measuredon a flat surface. Just sufficient tension shall be applied to remove waves and wrinkles at the lines of measurement. The leech shall have no hollows having the effect of increasing the sail area.14.3 Foresail14.3.1 A maximum of three foresail battens is allowed, in the leech only. Each batten shall be nomore than 300 mm in length and 50 mm in width.14.3.2 The jib shall either use hanks, a stitched double luff, zipper luff, nylon foil or otherapproved devices to attach it to the forestay. If a foil is used then this must be treated as part of the sail for measuring purposes.14.3.3 The length of the luff shall not be more than 4120 mm.The length of the leech shall be not more than 3810 mm.The length of the foot shall not be more than 1680 mm.The maximum foot round shall be 100 mm.14.3.4 At the half leech point the nearest point of the luff shall be not more than 790 mm.The half leech point shall be found by folding the head to the clew and smoothing the sail out flat.14.3.5 The head of the sail shall not exceed 50mm.14.3.6 The leech in no area shall be convex and must be a fair curve.Foresail Measurement Diagram14.4 Mainsail14.4.1 The sail shall be loose footed and shall be attached to the boom or fittings at or near thetack and clew only.14.4.2 There shall be a maximum of eight battens from the leech to the luff. There shall be noother battens and no batten may extend more than 100 mm beyond the leech of the sail. 14.4.3 A headboard is optional and when used shall not exceed 120 mm in height or width.14.4.4 The sail shall be hoisted within the integral luff groove of the mast extrusion, and shallnot be fitted with a sleeve, double luff or other fairing device. The head of the mainsail shall not extend beyond the top of the mast.14.4.5 All cross measurements are taken to include the bolt rope. All cross measurements aretaken to the nearest point on the luff with the exception of dimension `A'.Dimension `A' is found by swinging an arc with a radius of 845 mm from the head of the sail to intersect the leech and the luff. The straight line intersecting these two shall be not greater than 750 mm.Mainsail Measurement Diagram15 `BLACK BANDS'15.1 A system of `black bands' 25 mm wide of a colour contrasting with that of the mast and boomshall be used on the spars to mark the limits of extension of the mail sail's length along its luff and foot.15.2 Two bands shall be painted in any position on the mast with their inner edges 6900 mm apart,except when the mainsail is set to the mast head in which case only one band shall be used, with its upper edge positioned 6900 mm below the top of the mast.15.3 One band only shall be painted on the boom with its inner edge 2550 mm (measured alongthe length of boom) from the aft edge of the mast track or its extension.15.4 When the mainsail is set on its spar the luff and foot shall be wholly contained within theinner edges of the bands.16 MAINSHEET TRAVELLERThe mainsheet traveller track shall be straight along the rear beam. The type of traveller is optional.17 HIKING AIDSFoot loops, blocks, toe straps, anti-slip surface treatment, trapeze gear and bracing lines are permitted. No other aids are allowed.18 PROHIBITED FITTINGS18.1 Hydrofoils, outriggers, ballast, suction bailers, keel bands except in the way of centreboardslot, rubbing stakes, spray deflectors, chines, and any projection from the skin other than normal fittings.18.2 Any device not called for in the plans and restrictions and not de-restricted in Item 19.18.3 Weight belts of any description.19 DE-RESTRICTIONSOnly items in the following list may deviate from the plan in the manner described.∙Position of ports in deck.∙Fittings - type and manufacture of all fittings.∙Mast rotation control.∙Rudders, tillers and associated mechanisms.∙Whisker pole.∙Wind indicators.∙Number of trapezes.∙Boom vang - circular track shall have a pitch circle diameter not greater than 0.7 m.∙Leech lines.∙Shape of centreboards - within the limits of section 8.∙Jib and mainsheet arrangement and fittings.∙Jib and main luff tensioning devices.20 SAFETY REQUIREMENTSBoats shall comply with current safety regulations of the Australian Yachting Federation.21 SPINNAKEREither the NMCC or a state authority may choose to run an event in which the use of a spinnaker is permitted, in which case this rule shall apply. This rule also applies to Mosquito class boats sailing with a spinnaker at any other events.21.1 The spinnaker pole shall be attached to the centre of the main beam, and shall be fixed in afore and aft position.21.2 No part of the spinnaker pole or its fittings may extend more than 3030 mm from the front ofthe main beam.21.3 The head of the spinnaker shall not be hoisted more than 6380 mm from the top of the mainbeam.21.4 The maximum luff length shall be 6950 mm.21.5 The maximum foot length shall be 3500 mm.CHANGE HISTORYTHIS SECTION DOES NOT FORM PART OF THE BUILDING RULES AND RESTRICTIONS Versions1 July 1997 Peter Hallsworth National Technical Officer1 April 2000 Roger Wilson National Secretary10 January 2001 Ross Bennett National Technical Officer3 January 2007 Tim Shepperd National Technical Officer Accepted at Annual General Meeting, 11th January 2000:14.3 ForesailReplace:14.3.3 The foresail must lie totally within a triangle drawn to themaximum measurements adjacent, but excluding the footround.Luff 4120 mmLeech 3810 mmFoot 1680 mmFoot round 100 mmBy:14.3.3 The length of the luff shall not be more than 4120mm. Thelength of the leech shall not be more than 3810mm. Thelength of the foot shall not be more than 1680mm. Themaximum foot round shall be 100mm.14.3.4 At the half leech point the nearest point on the luff shall notbe more than 790mm. The half leech point shall be foundby folding the head to the clew and smoothing the sail outflat.14.3.5 The head of the sail shall not exceed 50mm.14.3.6 The leech in no area shall be convex and must be a faircurve.APPENDIX 1 _PROCEDURE FOR ALTERATION TO PLANS, BUILDING RULES ANDRESTRICTIONSReplace the following clauses:Any such motion of alteration shall then be circulated to other State Associations at least three months prior to the National Annual General Meeting to allow time for adequate discussion of the proposed alteration. The method of voting on motions received from interstate shall be at the discretion of each association but a postal vote or special general meeting (to involve all members) is recommended.Voting at the National Annual General Meeting shall be by State Delegate who shall be accorded one vote for every 20 (or part thereof) currently financial members of his/her State Association.A two-thirds majority of the votes shall be required for the proposal to be accepted, where upon it shall apply from 1st July after the Annual General Meeting.By:Any such motion of alteration shall then be circulated to other State Associations at least three months prior a National General Meeting to allow time for adequate discussion of the proposed alteration. The method of voting on motions received from interstate shall be at the discretion of each association but a postal vote or special general meeting (to involve all members) is recommended.Voting at the National General Meeting shall be by State Delegate who shall be accorded one vote for every20 (or part thereof) currently financial members of his/her State Association.A two-thirds majority of the votes shall be required for the proposal to be accepted, where upon it shall apply from a date specified in the proposal or, if no date is specified, from 3 months after the date of the National General Meeting.MEASUREMENT _ HULLSCurrent Restriction:5.12 The method of construction of timber Mosquito hulls is optional. The hull sides shall have a fair curve from top to bottom.Proposal:5.12Add the following wording:“When viewed from bow to stern, the sheer line of the deck shall not be concave between the deck measurement points.AGM: Add “except for fittings and beam recesses”Explanation: (none)BEAMSCurrent Restriction:NOT APPLICABLEProposal:Add new 6.7 as follows:6.7 The main and rear beams shall be inserted into their beam boxes with the …x‟ axis of the beam-section mounted perpendicular to the hull sheer line. When measured at the beam datum point, beam penetration into the hull must be equal at the inner and outer sheer lines and not exceed 6mm below the sheer line. (This does not include the striker strap.) See Rule 5.5 for the definition of the sheer line.AGM: Add clarification on meaning of …x‟ axis.Explanation: The main and rear beams are a rectangular hollow section. The larger dimension of the section is frequently referred to as its …x‟-axis. The intention of this new rule is to ensure the x-dimension is as close to vertical as possible in future boats as in the original plans. This will prevent laying the beams “flat”. It will also prevent tilting the beams.It will prevent inserting the beams deep into the hulls with their top level with the deck. It will also prevent inserting the beams into the hulls in such a way that the hulls are canted off the vertical alignment.MAINSAILCurrent Restriction:14.4.3 The headboard shall not exceed 120 mm in height or width.Proposal:Alter the wording of 14.4.3 as follows:14.4.3 A headboard is optional and when used shall not exceed 120 mm in height or width.Explanation: During the 1999-2000 nationals much debate occurred if the Mosquito mainsail required a headboard. Current Rule 14.4.3 states maximum sizes for one but does not state one has to exist. The intention of this proposed rule change is to restrict the head size and then allow the sailmaker and customer to decide on the construction of the head using the latest materials and methods.。