炼铁系统

- 格式:ppt

- 大小:13.02 MB

- 文档页数:70

简述高炉炼铁工艺流程及八大系统高炉炼铁是一种重要的冶炼工艺,通过高炉将铁矿石转化为生铁。

Blast furnace ironmaking is an important smelting process that converts iron ore into pig iron through a blast furnace.高炉炼铁工艺一般包括八大系统,分别是原料系统、燃料系统、风口系统、炉料系统、炉渣系统、渣铁系统、炉底系统和炉体冷却系统。

The blast furnace ironmaking process generally includes eight major systems: raw material system, fuel system, tuyere system, burden system, slag system, hot metal system, hearth system, and furnace cooling system.原料系统包括铁矿石、焦炭和石灰石等原料,这些原料经过预处理后送入高炉顶部。

The raw material system includes iron ore, coke, limestone, and other materials, which are pre-processed and then charged into the top of the blast furnace.燃料系统主要是焦炭和其他燃料的供给和燃烧控制。

The fuel system mainly involves the supply and combustion control of coke and other fuels.风口系统通过送风机将空气送入高炉内,控制高炉内的氧气含量和温度。

The tuyere system uses blowers to inject air into the blast furnace, controlling the oxygen content and temperature inside the furnace.炉料系统指的是铁矿石、焦炭和其他原料在高炉内的分布和堆积状况。

炼铁的设备组成

炼铁是将铁矿石转化为纯铁的过程,其设备组成会因为炼钢方式、炼铁厂的规模、技术水平等因素而有所不同,但通常会包括以下几个主要设备:

1. 高炉:通过煤焦炭的燃烧将铁矿石还原成纯铁的过程中的主要设备。

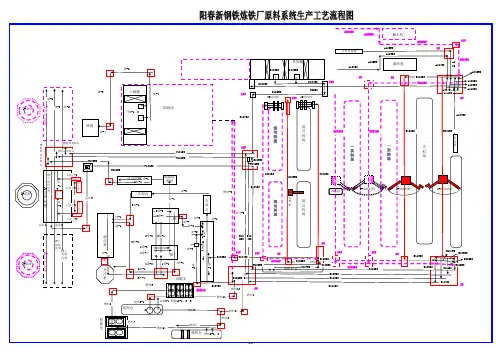

2. 进料系统:将铁矿石、焦炭和石灰石等原料粉碎后送入高炉。

3. 热风炉:用于供给高炉内所需的热风,加速还原反应。

4. 发电机组:为炼铁厂提供所需的电力。

5. 除尘设备:将炼铁过程中产生的烟尘、沙尘、脱硫产物等粉尘等进行过滤、回收或处理。

6. 水处理设备:用于处理炼铁过程中产生的废水,以保护周边环境。

7. 控制系统:用于调控高炉内的温度、氧化还原环境、进料比例和送风压力等参数,以确保高炉正常运行。

除了以上设备,还可能需要一些辅助设备,如原料仓、焦炉、熔炉、氧气站等,以提高炼铁效率、节约能源,降低成本。

简述高炉炼铁工艺流程及八大系统英文回答:The process of ironmaking in a blast furnace involves several steps and is divided into eight major systems.Let's take a look at the process and these systems.1. Raw Materials Handling System: The first step in the ironmaking process is the handling of raw materials. Iron ore, coke, and limestone are the primary raw materials used in a blast furnace. They are carefully measured and mixed before being transported to the furnace.2. Charging System: In this system, the mixed raw materials are charged into the blast furnace. The materials are carefully layered to ensure proper distribution and efficient operation of the furnace.3. Blast System: The blast system supplies hot air, known as the blast, into the furnace. The blast ispreheated before entering the furnace to enhance the combustion of coke and facilitate the reduction of iron ore.4. Combustion System: The combustion system is responsible for burning coke to generate heat. The heat produced is used to melt the iron ore and create a reducing atmosphere in the furnace.5. Reduction System: In this system, the iron ore is reduced to metallic iron. The carbon monoxide produced from the combustion of coke reacts with the iron oxide in the ore, resulting in the formation of molten iron.6. Slag System: The slag system is responsible for the formation and removal of slag. Slag is a byproduct of the ironmaking process and consists of impurities that are separated from the molten iron. It helps protect the lining of the furnace and improves the efficiency of the process.7. Tapping System: Once the iron is melted andseparated from the impurities, it is tapped out of the furnace through the tapping hole. The tapping systemensures a controlled flow of molten iron and slag from the furnace.8. Gas Cleaning System: The gas cleaning system is responsible for removing impurities from the off-gas generated during the ironmaking process. This helps minimize environmental pollution and recover valuable byproducts.中文回答:高炉炼铁工艺流程包括八大系统。