喜利得技术手册(化学锚栓-HIT-RE 500注入式锚固胶配合钢筋)

- 格式:pdf

- 大小:1.96 MB

- 文档页数:9

![[中文]植筋技术手册B2.11_含附录](https://uimg.taocdn.com/3a7118114431b90d6c85c769.webp)

上海滠口实业有限公司业务热线:400-601-8808喜利得植筋胶外观独创的软箔包装+注射系统喜利得植筋胶HILTI-RE500无惧恶劣环境表现始终第一喜利得RE-500锚固胶粘剂是结构植筋加固与重型荷载紧固应用的最佳选择。

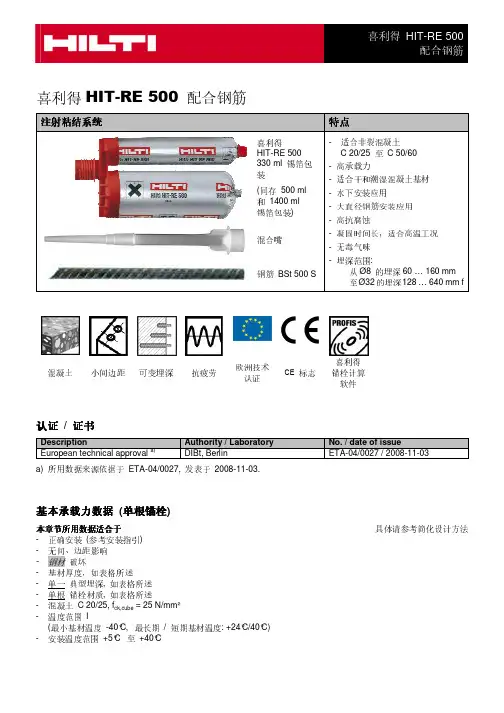

国内外的大量测试报告与认证,结合丰富的重点工程应用案例,证明RE-500的安装不受恶劣环境影响,并且锚固效果如同预埋结构一样安全可靠,堪称是目前后锚固工艺的最高标准(state-of-the-art)基材混凝土/天然硬质石材结构植筋外观独创的软箔包装+注射系统材质双酚A改性树脂(BisphenolAEpoxyResin)固化温度-5-40(℃)剪切强度7.9KN—77.8KN(MPa)包装规格500ml,1400ml用途:混凝土结构植筋加固,特别是重要,悬挑构件,承重动力作用的结构,构件等;重型荷载的固定,如梁柱,机械,设备等;恶劣环境的化学后锚固应用,如潮湿,明水,高低温环境及光滑孔中安装;特别使用于大直径与埋深(如搭接)的植筋与紧固;任何需要大量测试报告的重型荷载应用特性:强劲而稳定的粘结力沿锚固深度均匀分布,锚固效果如同预埋结构;安装不受恶劣环境影响,设计力值于潮湿孔与光滑孔中可完全发挥,水钻钻孔不需凿毛处理,并可在明水环境下安装;宽广的温度适应范围,安装完成后可以承载-50℃到+80℃的环境温度;无膨胀应力锚固,适用于小边距,小间距安装;不含苯乙烯及乙二胺,无异味,符合无毒环保要求,固化后可用于饮用水接触的设备安装;独创的软箔包装,材料损耗少;专用双螺旋混合嘴,保证精确的混合配比,专业配套施工工具,确保规范施工;国家标准混凝土结构加固设计规范GB50367-2006认证合格A级胶及该规范参编单位;长期性能获得中国,瑞士,日本,美国及法国等国家权威认证;耐火设计数据齐全(根据ISO834,至F240/4小时);根部及双面焊接测试合格;先进的植筋及锚栓设计软件(EXBAR/PROFIS)及全球工程技术服务使用/储存环境要求使用时,胶粘剂本身不能低于5℃,开封后的胶粘剂须在4周内用完;运输和储存温度须介于5℃至25℃之间,存放于干燥避光的环境;应严格按照喜利得规定的的施工步骤进行施工固化时间表基材温度初凝时间固化时间-5(℃) 4小时 72小时0(℃) 3小时 50小时5(℃) 2小时 24小时20(℃) 30分钟 12小时30(℃) 20分钟 8小时40(℃) 12分钟 4小时施工步骤 :1)使用喜利得TE-76电钻系统钻孔2)使用刷子及吹气筒清孔,至少三次以上3)用喜利得MD2500专用注射胶枪灌胶,前三枪胶水必须废弃不用4)从孔内底部开始注胶,达孔深的2/3左右5)按顺时针方向缓缓旋入钢筋,确保到达孔底6)检查孔表面有否有胶水溢出以确保孔内充实7)按建议固化时间等待药剂固化,期间不要对钢筋碰撞或敲击8)完成,进行后续施工,负荷加载植筋规范1.0.1 为使混凝十结构的加固,做到技术可靠、安全适用、经济合理、确保质量,制定本规范。

Hilti HIT-RE500 Injectable Mortar with Grade 500 Rebar2 -34 – 6 7 - 13 14 -15 16 – 17 18 - 22 23 – 36 37 - 45 46 - 68 69 - 70 71 73 - 80 81 - 87Sample Submission and Approval Form Chemical Anchor System Summary & SAFEset Product CatalogueTechnical data & Setting Details Detailed Consumption Table Method Statement for Installation Loading Test Report (BS5080: Part 1)*Fire Performance Assessment Report (WF 327804/B Issue 2)* Fire Performance Test Report (IBMB 3357/0550-5)* Government Letter Country of OriginMaterial Safety Data Sheet Job ReferenceSAMPLE SUBMISSION AND APPROVAL FORMContract Title: ________________________________ Ref. No.: ________________________________________________________ Date: ________________________Ref. No. of________________________PreviousSubmission:Contract No: ________________________________ (1)________________________ File Reference: ________________________________ (2)________________________ DETAILS OF SUBMISSIONTo: Contract Manager’s Representative Attention: ________________________ From: ________________________________The enclosed sample and catalogue* / certificate of origin* / technical data* / test report* / job reference* as described below have been checked for compliance with the Specifications and Drawings, and are submitted for approval.1.General Informationa.Material Description HIT – RE500 Injection Adhesive____________________________________________________________________________________________________________________b.Location: Re-bar fastening____________________________________________________________________________________________________________________c.Specification Ref. Page:__________________________ Item: _________________________________________________ _________________________________________________ _______________________d.Drawing Ref. No.______________________________________________________________________________________________________________________________________________________________________________e.B.Q. Ref.No.:______________________________________________________________________________________________________________________________________________________________________________f.Anticipated date of approval:__________________________________________________________2.Technical InformationThe submitted sample has been checked against the specification and drawings as listed below:-Specification Requirements Submitted Sample(State details against each item)a.BrandNot specified Hiltib.Country of OriginNot specified Germanyc.Manufacturer’s Name & AddressNot specified Hilti Corporation, FL-9494 Principality of Liechtenstein.d.Factory’s Name & Address(es)Not specified Hilti Gmbh Ind. Ges. F. BefestigungstechnikHiltistrasse 6, D-86916 Kaufering, Germany.e.Supplier (with Applicator, if any)Not specified Hilti (Hong Kong) Ltdf. AppearanceNot specified According to the sample submittedg. Color +Not specified Redh. SpecificationNot specified Attachedi. Manufacturer’s CatalogueNot specified Attachedj. Test Report (Original/Certificated True Copy)Not specified Attachedk. Previous Job ReferenceNot specified Attachedl. Supplementary InformationNot specified NILFor and on behalf of the Contractor____________________________(Quality Control Manager)CONTRACT MANAGER’S COMMENTSTo:From: Contract Manager’s Representative: ________________________________On the basis of the sample and information given, the above sample submitted is:(1) * Approved.(2) * Not approved because __________________________________________________________________________________________________________________________________________________________________________________________________ Remarks: _______________________________________________________________________ ______________________________________________________________________________________________________________________________________________ Approval does not alter the requirements of the ContractContract Manager’s Representative: _________________________________________________________Date:cc. ____________________________________________________________________________________________________________________________________________________________(* Delete if appropriate)(+ For glass or vitreous mosaic tiles, the contractor is required to confirm the colour range(s) of the submitted sample, i.e. a) light and or medium; or b) dark)技術化學安卡錨栓總覽Injectable mortar Hilti HIT-RE 500Applications■Structural connections with post-installed rebar (e.g. extension/connection to walls, slabs, stairs, columns, foundations, etc.)■Substitution of misplaced/missing rebars or couplers■Anchoring structural steel connections (e.g. steel columns, beams, etc.)■Anchoring crash barriers, noise barriers, etc.■Structural renovation of buildings, bridges and other civil struc-tures, retrofitting and re-strengthening of concrete members possible■Suitable for underwater applications in hammer-drilled holes Advantages■High performance and technical superiority as per international approvals■Especially suitable for large-diameter elements and/or deep embedment depths■No expansion forces in concrete allow secure fastenings even close to edges and/or with close spacing■Virtually odourless hence convenient to work with ■Suitable for anchoring in diamond cored holes■Unique foil packaging and compatible Hilti HIT injection system makes handling extremely easyBase materials◾Concrete (uncracked)Always observe/follow the instructions accompanying the product or refer to/techlib.to the documents for details.Dispenser HDE 500-A22Applications■Injection of Hilti HIT adhesive mortar for fastening anchor rods and rebars in concrete and masonry■No need for external power source supply■Serial fastenings and/or injection in deep holesAdvantages■Dose adjustment knob for accurate and controlled dispensing ■Fast, easy foil pack loading■High battery capacity (up to 100x500ml foil packs)Dispenser HDMApplications■Injection of Hilti HIT adhesive mortar for fastening anchor rods and rebars in concrete and masonry Advantages■Fast, easy foil pack loading4Hammer drill bit TE-YDApplications■Drilling holes for anchoring structural steel connections (e.g. steel columns, beams)Advantages■Drilling and hole cleaning in one stepHammer drill bit TE-CDApplications■Drilling holes for structural connections with post-installed rebarsAdvantages■Drilling and hole cleaning in one stepAccessories for blowing out drilled holes Hilti HITApplications■For fast and efficient removal of dust and debris from drilled holes of varying diameters and depths to allow correct installa-tion of anchors and rebarHilti HIT Profi accessories Air nozzleApplications■Clearing dust and debris from drilled holes under various condi-tions including where adhesive anchors are set at great depth Advantages■Fast, effective cleaning of drilled holesAccessories for using brushes to clean holes Hilti HITApplications■For the proper brushing of drilled holes of varying diameters andembedment depths8Profi accessories for mortar injection Hilti HITApplications■For injection of Hilti HIT adhesive mortars in a variety of situa-tions including deep holes, overhead holes and in underwater applicationsAdvantages■Injection pistons and flexible extension hoses help ensure con-sistent injection of the adhesive into the hole without formationof air voidsOverhead cupHIT Profi accessories (Glasses & empty cases)Mixers and extensions Hilti HITUniversal vacuum cleaner VC 40-UMApplications■Removing dust from drilling, slitting, grinding, cutting and dry coring■Removing slurry from wet coring and cleaningAdvantages■Hilti AirBoost filter technology for consistently high suction performance■Very good handling thanks to compact design■Full exploitation of tank capacity due to placement of filter and hose connection in the upper part of the machine■Robust housing to withstand the harshest jobsite conditions ■New tank concept for easy and virtually dust-free dust removal ■Maximum total load of dust: up to 40 kgo n g K o n g 8228 8118 M a c a u 008008228 8118 (M o n - F r i 8:30 a m - 6:00 p m / S a t 8:30 a m - 1:00 p m ) | F a s t O r d e r i n g , P r o m p t & F r e e D e l i v e r y C u s t o m e r H o t l i n e : H o n g K o n g 8228 8118 M a c a u 008008228 8118 (M o n - F r i 8:30 a m - 6:00 p m / S a t 8:30 a m - 1:00 p m ) | F a s t O r d e r i n g , P r o m p t & F r e e D e l i v e r y 2H I T -R E 500I n j e c t i o n A d h e s i v eB e s tC h e m i c a l A n c h o rf o r r e b a r f a s t e n i ng u n d e r d i f f e r e n t c o n d i t i o n sH i g h P e r f o r m a n c e & S a f e t y V s o t h e r i n j e c t i o n a d h e s i v e40% h i g h e r t e n s i l e l o a d i n n o r m a l h o l e .30% h i g h e r t e n s i l e l o a d i n w e t a n d w a t e r -f i l l e d h o l e .S u i t a b l e f o r b o t h d r i l l e d o r d i a m o n d c o r e d h o l e .✓✓✓S a v e M a t e r i a l & L a b o u r C o s t V s h a r d c a r t r i d g e i n j e c t i o n a d h e s i v e70% l e s s w a s t a g e c o m p a r e d t o h a r d c a r t r i d g e .R e d u c e d i s p o s a l c o s t .S h o r t d i s p e n s i n g t i m e .✓✓✓y A p p r o v e d b a r f a s t e n i n gy i n j e c t i o n a d h e s i v e l i s t e d i n “F i r e p r o t e c t i o n s f o r s t r u c t u r a l u s e o f C e n t r a l D a t a B a n k ”.i r e r e s i s t a n c e W a r r i n g t o n t e s t r e p o r t .d s i m p le l o a d i n g s e l e c t i o n t a b l e .n i e n t & F l e x i b l e V s o t h e r o n a d h e s i v eg e c a n b e u s e d f r o m 5˚C t o 40˚C .o r k i n g t i m e (20m i n s ) a t 30˚C .d i s pe n s i n gf o r c e r e q u i r e d , c o m p a r e d t o h a r d e .W E A K E R b o n d s t r e n g t h70% M O R E w a s t a g e c o m p a r e d t o f o i l p a c kL I M I T E D t e m p e r a t u r e r a n g e (20˚C t o 32˚C ) f o r c a r t r i d g e d i s p e n s i n gI N S U F F I C I E N T w o r k i n g t i m e (8.5m i n s ) a t 30˚CH I G H E R d i s p e n s i n g f o r c eL A C K o f r e f e r e n c e / a p p r o v alO t h e r I n j e c t i o n A d h e s i v eHIT RE 500 foil pack, mixerCartridge Holder, HIT-CB 500Basic Setting Detail, Loading Data & Testing LoadRemarks:1.It is based on non-cracked concrete with strength 30N/mm 2;2.Yield strength of rebar f yk is 500N/mm 2;3.There is no factor of safety introduced in the ultimate mean pull out load. Please applyappropriate factor of safety in your design ;4.Onsite pullout test can be carried out to verify the workmanship of the installation but shouldnot be verification of the ultimate loading. The testing load shall be subjected to the designer’s decision but should not exceed the 0.87 x yield load to avoid permanent damage to the rebar.5.All the spacing and edge distance requirement for reinforced concrete design should be reference toBS8110;6.If there is a fire resistance concern, the loading should be referred to the fire tableTechnical InformationSetting DetailsConsumption Table for Quick ReferenceRemark:1)Please refer to ‘Detail ed consumption table’ for more information2)The filled volume was calculated by the following equation and is for reference only.Filled volume = [(D/2)2- (R/2)2] x 3.14 x Iwhere D = hole diameter, I = hole depth, R = rebar diameter2)The filled volume showed in the table did not include any wastage during the installation.3) 1 trigger pull of dispenser HDM is approx. 6 ml of RE 500.To dispense 1 cartridge of 500ml RE 500 needs approx. 80 triggers.Mechanical PropertiesTechnical Information*Please note that above consumption table is based on good workmanship andfor reference only*Please note that above consumption table is based on good workmanship andfor reference onlyMethod statement of RE500 installationMethod statement of RE500 installationMethod statement of RE500 installation。

RE500工法植入钢筋工艺1.化学植筋采用RE500粘着植筋胶,植筋胶的性能指标应符合<<混凝土结构加固设计规范>>GB-50367-2006 中 A级胶标准要求,禁止使用现场混合配置和含乙二胺的粘结剂,植筋胶需采用原装进口的产品,并有本系统大型同类项目使用的业绩。

2.必须通过长期性能测试,能满足50年长期使用要求,以国内外权威测试机构(CMA,ETA,ASTM等)提供的报告为准.3.植筋胶应具有抗腐蚀(对钢筋不产生腐蚀)、耐火、抗震动、抗疲劳(疲劳测试不小于2x106次)、抗冲击、抗老化性能,并通过权威机构的认证和测试,满足高温焊接和孔中湿度环境施工的要求。

4.植筋施工前应对植筋胶进行现场抗拔破坏试验,数量不少6根,但施工前应将试验数据报请设计方复核批准。

5.植筋工程质量应进行抗拔承载力的现场检查。

同规格,同型号,基本相同部位的锚栓组成一个检验批,抽取数量按每批锚栓总数的1‰计算,且不少于3根。

非破坏拉拔试验必须大于钢筋屈服强度的90%。

6.参考标准:<<混凝土结构后锚固技术规程>>--JGJ145-2004 J407-2005,<<混凝土结构加固设计规范>> GB-50367-20067.施工步骤a)准备:检查被植筋混凝土表面是否完好,钢筋探测核对标记植筋部位。

b)钻孔:在根据钢筋直径按照技术参数表中资料要求,根据直径对应深度打孔,检查孔径及孔深满足A-1表要求。

c)清孔:利用压缩空气清孔,用毛刷刷三遍,吹三遍,确保孔壁无尘。

d)注胶:首先将植筋胶直接放入胶枪中,将搅拌头旋到胶的头部,扣动胶枪直到胶流出为止,前两次打的胶不用。

注胶时,将搅拌头插入孔的底部开始注胶,逐渐向外移动,直至注满孔体积的2/3即可。

注射下一个孔时,按下胶枪后面的舌头,因为自动加压,避免胶继续流出,造成浪费。

更换新的胶时,按下胶枪后面的舌头,拉出拉杆,将胶取出。

152以下数据为单支II 级钢筋在指定基材中的设计抗拉力值,未考虑边距、间距、不同基材强度、载重方向、基材温度及其它因素的影响。

完整的设计技术细节,请参阅植筋技术手册(FTM B2.11)及EXBAR 植筋设计软件,或请联系喜利得技术工程师。

以上手册及软件请洽喜利得技术服务部免费索取。

HIT-RE 500 锚固胶粘剂拉力设计值 R d (kN ): 混凝土强度标准值 f ck,cube = 30 N/mm 2,II 级带肋钢筋强度标准值 f yk = 335 N/mm 2HIT-HY 150 MAX 锚固胶粘剂拉力设计值 R d (kN ): 混凝土强度标准值 f ck,cube = 30 N/mm 2,II 级带肋钢筋强度标准值 f yk = 335 N/mm2HIT-HY 150 锚固胶粘剂拉力设计值 R d (kN ): 混凝土强度标准值 f ck,cube = 30 N/mm 2,II 级带肋钢筋强度标准值 f yk = 335 N/mm 2153以下数据为单支II 级钢筋在指定基材中的设计抗拉力值,未考虑边距、间距、不同基材强度、载重方向、基材温度及其它因素的影响。

完整的设计技术细节,请参阅植筋技术手册(FTM B2.11)及EXBAR 植筋设计软件,或请联系喜利得技术工程师。

以上手册及软件请洽喜利得技术服务部免费索取。

HIT-RE 500 锚固胶粘剂拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 30 N/mm 2,埋深同HVA HIT-HY 150 锚固胶粘剂拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2,埋深同HVA HVA 定型化学锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2HDA 重型自切底锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2M8-M24螺杆,钢材等级5.8;M27-M39螺杆,钢材等级8.8uk M8-M24螺杆,钢材等级A4-70;M27-M39螺杆,钢材等级A4时,f uk 变化范围为700N/mm 至 500N/mm154HDA重型自切底锚栓拉 / 剪力设计值 R d(kN): 混凝土强度 f ck,cube = 25 N/mm2 HSL-3重型锚栓拉 / 剪力设计值 R d(kN): 混凝土强度 f ck,cube = 25 N/mm22HSC安全锚栓拉 / 剪力设计值 R d(kN): 混凝土强度 f ck,cube = 25 N/mm2155HSC 安全锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2HST 螺栓式锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2HSA 螺栓式锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2156HSA 螺栓式锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2HUS-H 切底自攻锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2HLC 套筒式锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 20 N/mm 2HKD 敲击式锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度 f ck,cube = 25 N/mm 2HKV 敲击式锚栓拉 / 剪力推荐值 L rec (kN ): 混凝土强度 f ck,cube = 25 N/mm 2157HUD 万用锚栓拉 / 剪力设计值 R d (kN ): HPS-1 敲击式锚栓拉 / 剪力设计值 R d (kN ):1)1)158HRD-U 框架锚栓拉 / 剪力设计值 R d (kN ):HLD 隔间墙锚栓拉力设计值 R d (kN )空心砖锚栓拉 / 剪力设计值 R d (kN ):DBZ 楔入式锚栓拉 / 剪力设计值 R d (kN ): 混凝土强度f cc ≥15 N/mm 2。