XKFD-DQ027 #2炉#2播煤增压风机电机指导书

- 格式:doc

- 大小:15.50 KB

- 文档页数:6

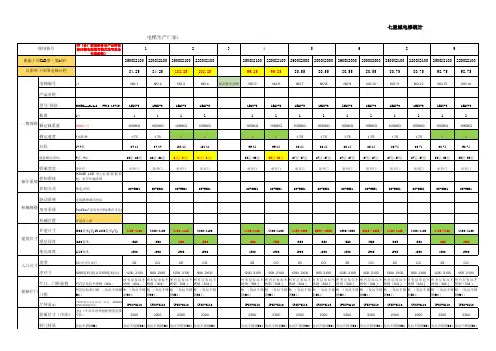

七星城电梯统计电梯生产厂家:

填写说明:因施工图纸还为出,目前仅有总图和地下室开挖图,额定重量请根据楼层高度,最少1000KG考虑,或者按规

根据各自产品特点填写井道建筑尺寸需求,入口尺寸等,本批电梯,高层全部有机房,机房高度,顶层高度注:表示贵方土建与我方要求不符合之处。

1、提升高度大于90m,速度最小为2m/s,并且顶层高度最小为4450。

2、担架梯井道宽度最小为2

表示我司查看贵方土建图后与原表不同之处。

者按规定比1000KG高,请备注说明。

层高度有和要求,请说明。

小为2600,普通客梯井道宽度最小2050,深度最小2090。

220kV 微机五防系统改造的简要介绍发布时间:2022-01-06T01:08:34.084Z 来源:《中国电业》2021年22期作者:顾汛[导读] 随着电子技术在各个行业领域的飞速发展,电力的“五防”也将发生革命性的转变顾汛广东大唐国际潮州发电有限责任公司广东省潮州市 515723摘要:随着电子技术在各个行业领域的飞速发展,电力的“五防”也将发生革命性的转变。

现代电力系统规模不断扩大,从而促使电压的等级也得到了进一步提高。

为了使电力系统的安全稳定运行能够得以充分保障,并将各种操作事故防范于未然,因此不仅要加强运行管理的手段,与此同时还要对电力“五防”工作引起充分的重视。

关键词:五防系统;五防钥匙;五防锁前言:潮州发电公司220kV微机五防系统,之前为珠海长园共创公司生产的FY2004版标准程序,与之配套的电脑钥匙为V20026版电脑钥匙(简称26版钥匙),其型号为FKYD-S1A,就地6kV开关柜设有五防编码锁,型号为FSZL;NCS系统采用南瑞科技NS2000(V8)系统,厂用电6kV监控系统为南京东大金智的DCAP-4000系统。

截止2019年,该套五防系统投产使用已超过10年。

一、项目改造的目的与意义根据南方电网公司下发文件《关于加强防误闭锁装置管理、防止电厂发生恶性电气误操作事件的通知》(调调[2018]31号)的要求,应尽快取消五防电脑钥匙单一固定密码“测试解锁”的功能,因此需要对五防系统进行升级改造。

过去潮州发电公司220kV网控各断路器汇控柜的五防锁,目前仅在柜门处安装,无法完善实现每一个开关、刀闸的五防闭锁功能。

此次改造取消了汇控柜柜门的五防锁,改为所有开关、刀闸操作把手上安装五防闭锁罩。

对1-4号启备变、1号主变、2号主变的户外电磁锁增加了五防锁,并在后台系统增加相应的刀闸、断路器闭锁逻辑条件,确保在该间隔断路器、刀闸均拉开的情况下方能进行操作,降低运行人员误操作的风险。

二、项目原理的简要介绍本次改造后使用的是长园共创公司自主开发设计的PSM70电力安全防误管理系统,本套微机型防止电气误操作系统以微型计算机、通讯适配器、电脑钥匙、闭锁设备和锁具为核心设备,在系统调试时预先输入了使用本系统的变电站或发电厂的接线图及防误规则,并记忆保存了所有需要闭锁的设备状态,系统还可以通过监控系统或FY2000在线防误系统得到现场的设备实际状态。

K O L L M O R G E N | A K o l l m o r g e n C O M PA N Y欢迎来到科尔摩根官方微信科尔摩根3目录u AKM ™ 同步伺服电机4u AKD ™ 伺服驱动器8u AKM ™ 各种选件12u AKM ™ 防水型和食品级防水型电机13u AKM ™ 系统综述14u AKM ™ 图纸和性能数据AKM1x 16AKM2x 20AKM3x24AKM4x 28AKM5x 34AKM6x 40AKM7x 44AKM8x48u L 10 轴承疲劳寿命和轴负载53u 反馈选件56u 抱闸选件60u 伺服电机连接器选件61u 型号命名67u MOTIONEERING ® Online71科尔摩根A K M 同步伺服电机选型指南克服设计、采购和时间障碍科尔摩根明白:帮助原始设备制造商的工程师克服障碍,可以显著提高其工作成效。

因而,我们主要通过如下三种方式来提供帮助:集成标准和定制产品在很多情况下,理想方案都不是一成不变的。

我们拥有专业应用知识,可以根据全面的产品组合来修改标准产品或开发全定制解决方案,从而为设计奠定良好的基础。

提供运动控制解决方案而不仅仅是部件在各公司减少供应商数量和工程人力的过程中,他们需要一家能够提供多种集成解决方案的全系统供应商。

科尔摩根就采用了全面响应模式,为客户提供全套解决方案,这些方案将编程软件、工程服务以及同类优秀的运动控制部件结合起来。

覆盖全球我们在美洲、欧洲、中东和亚洲拥有众多直销、工程支持单位、生产工厂以及分销商,临近全球各地的原始设备制造商。

这种便利优势可以加速我们的供货过程,根据客户需要随时随地供货。

财务和运营稳定性科尔摩根隶属于Fortive 公司。

Fortive 业务系统是推动Fortive 各部门发展的一个关键力量。

该系统采用“不断改善”(Kaizen )原理。

由高素质人才构成的多学科团队使用世界级的工具对过程进行评估,并制定相关计划以达到卓越的性能。

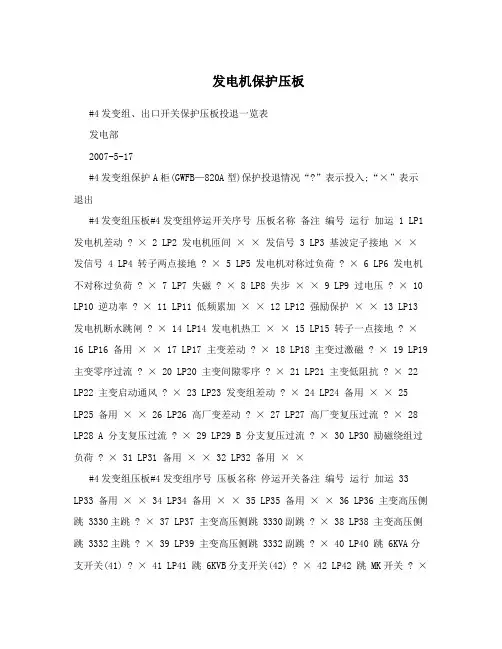

发电机保护压板#4发变组、出口开关保护压板投退一览表发电部2007-5-17#4发变组保护A柜(GWFB—820A型)保护投退情况“?”表示投入;“×”表示退出#4发变组压板#4发变组停运开关序号压板名称备注编号运行加运 1 LP1 发电机差动? × 2 LP2 发电机匝间× × 发信号 3 LP3 基波定子接地× × 发信号 4 LP4 转子两点接地? × 5 LP5 发电机对称过负荷? × 6 LP6 发电机不对称过负荷? × 7 LP7 失磁? × 8 LP8失步× × 9 LP9 过电压? × 10 LP10 逆功率? × 11 LP11 低频累加× × 12 LP12 强励保护× × 13 LP13 发电机断水跳闸? × 14 LP14 发电机热工× × 15 LP15 转子一点接地? × 16 LP16 备用× × 17 LP17 主变差动? × 18 LP18 主变过激磁? × 19 LP19 主变零序过流? × 20 LP20 主变间隙零序? × 21 LP21 主变低阻抗? × 22 LP22 主变启动通风? × 23 LP23 发变组差动? × 24 LP24 备用× × 25LP25 备用× × 26 LP26 高厂变差动? × 27 LP27 高厂变复压过流? × 28 LP28 A 分支复压过流? × 29 LP29 B 分支复压过流? × 30 LP30 励磁绕组过负荷? × 31 LP31 备用× × 32 LP32 备用× ×#4发变组压板#4发变组序号压板名称停运开关备注编号运行加运 33LP33 备用× × 34 LP34 备用× × 35 LP35 备用× × 36 LP36 主变高压侧跳 3330主跳? × 37 LP37 主变高压侧跳 3330副跳? × 38 LP38 主变高压侧跳 3332主跳? × 39 LP39 主变高压侧跳 3332副跳? × 40 LP40 跳 6KVA分支开关(41) ? × 41 LP41 跳 6KVB分支开关(42) ? × 42 LP42 跳 MK开关? ×43 LP43 关调速汽门? × 44 LP44 关主汽门? × 45 LP45 #4 机励磁调节器灭磁? × 46 LP46 备用× × 47 LP47 (失磁)减出力? × 48 LP48 启动 3332失灵? × 49 LP49 启动主变通风? × 50 LP50 备用× × 51 LP51 启动 A分支快切(41M) ? × 52 LP52 启动 B分支快切(42M) ? × 53 LP53 跳(手动励磁柜) 2K开关? × 54 LP54 闭锁 A分支快切? × 55 LP55 闭锁 B分支快切? × 56 LP56 启动 3330失灵? × 57 LP57 备用× × 58 LP58 备用× × 59 LP59备用× × 60 LP60 大轴5 (励磁电压) ? × 正常运行时A、B只投一柜,随转子一、两点接地(正常运行时A、B只投一柜)保护柜投退。

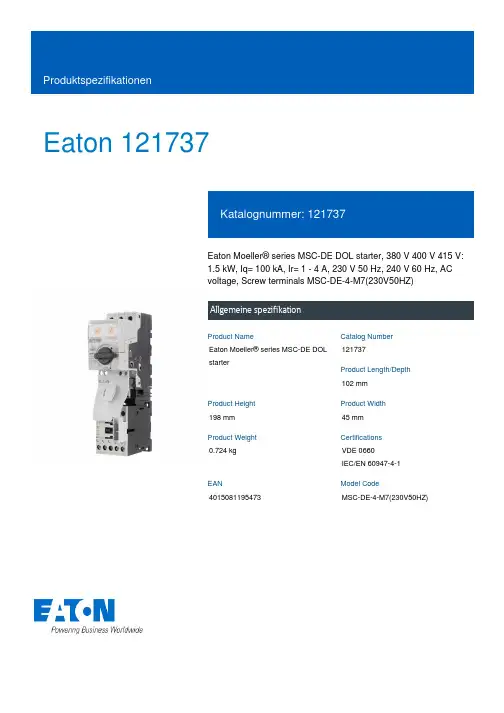

Eaton 121737Eaton Moeller® series MSC-DE DOL starter, 380 V 400 V 415 V: 1.5 kW, Iq= 100 kA, Ir= 1 - 4 A, 230 V 50 Hz, 240 V 60 Hz, AC voltage, Screw terminals MSC-DE-4-M7(230V50HZ)Allgemeine spezifikationEaton Moeller® series MSC-DE DOL starter121737102 mm198 mm 45 mm 0.724 kgVDE 0660 IEC/EN 60947-4-14015081195473MSC-DE-4-M7(230V50HZ)Product NameCatalog Number Product Length/Depth Product Height Product Width Product Weight Certifications EANModel CodeShort-circuit releaseTemperature compensated overload protection AdjustableScrew terminalsNo1700 (Class 10) AC-4 cycle operation, Main conducting paths For all combinations with an SWD activation, you need not adhere to the minimum current flow times and minimum cut-out periods.500 (Class 5) AC-4 cycle operation, Main conducting paths 900 (Class 15) AC-4 cycle operation, Main conducting paths 1000 (Class 20) AC-4 cycle operation, Main conducting paths Note: Going below the minimum current flow time can cause overheating of the load (motor).≤ 500 ms, main conducting paths, AC-4 cycle operationIP20NEMA OtherDirect starterDIN rail11 A4 AFitted with: Functions ClassConnectionConnection to SmartWire-DTCoordination typeCurrent flow times - minCut-out periods - minDegree of protectionModelMounting methodNumber of auxiliary contacts (normally closed contacts) Number of auxiliary contacts (normally open contacts) Overload release current setting - minOverload release current setting - maxOvervoltage categoryIII36000 V AC Also motors with efficiency class IE3Starter with electronic trip unit ACMax. 2000 m-25 °C55 °C3.6 A4 A0.75 kW1.5 kW230 - 415 V AC 186 A1.4 W, Dual-frequency coil in a cold state and 1.0 x Us, at 50 Hz 230 V230 V0 V0 V0 V0 VPollution degree Rated impulse withstand voltage (Uimp)Suitable forTypeVoltage type Altitude Ambient operating temperature - min Ambient operating temperature - max Rated operational current (Ie)Rated operational current (Ie) at AC-3, 380 V, 400 V, 415 V Rated operational power at AC-3, 220/230 V, 50 Hz Rated operational power at AC-3, 380/400 V, 50 Hz Rated operational voltage Short-circuit release (Irm) - max Power consumption, sealing, 50 HzRated control supply voltage (Us) at AC, 50 Hz - min Rated control supply voltage (Us) at AC, 50 Hz - max Rated control supply voltage (Us) at AC, 60 Hz - min Rated control supply voltage (Us) at AC, 60 Hz - max Rated control supply voltage (Us) at DC - min Rated control supply voltage (Us) at DC - max0.9 W0 W0.3 W4 A1.4 WMeets the product standard's requirements.Meets the product standard's requirements.Meets the product standard's requirements.Meets the product standard's requirements.Meets the product standard's requirements.Does not apply, since the entire switchgear needs to be evaluated.Does not apply, since the entire switchgear needs to be evaluated.Meets the product standard's requirements.Does not apply, since the entire switchgear needs to be evaluated.Meets the product standard's requirements.Does not apply, since the entire switchgear needs to be Simple, flexible and safe! Distribution system for motor-starter combinationsETN.MSC-DE-4-M7(230V50HZ).edzIL034038ZUWIN-WIN mit Push-in-TechnikProduktübersicht für den MaschinenbauSortimentskatalog Motoren schalten und schützenDA-CS-msc_de_bg1DA-CD-msc_de_bg1eaton-manual-motor-starters-device-msc-d-dol-starter-wiring-diagram.epseaton-manual-motor-starters-starter-msc-d-dol-starter-dimensions-002.epseaton-manual-motor-starters-mounting-msc-d-dol-starter-3d-drawing.eps eaton-manual-motor-starters-starter-msc-d-dol-starter-3d-drawing.epsEquipment heat dissipation, current-dependent PvidHeat dissipation capacity PdissHeat dissipation per pole, current-dependent PvidRated operational current for specified heat dissipation (In) Static heat dissipation, non-current-dependent Pvs10.2.2 Corrosion resistance10.2.3.1 Verification of thermal stability of enclosures10.2.3.2 Verification of resistance of insulating materials to normal heat10.2.3.3 Resist. of insul. mat. to abnormal heat/fire by internal elect. effects10.2.4 Resistance to ultra-violet (UV) radiation10.2.5 Lifting10.2.6 Mechanical impact10.2.7 Inscriptions10.3 Degree of protection of assemblies10.4 Clearances and creepage distances10.5 Protection against electric shock BroschüreneCAD model Installationsanleitung Installationsvideos KatalogemCAD model Schaltpläne ZeichnungenEaton Konzern plc Eaton-Haus30 Pembroke-Straße Dublin 4, Irland © 2023 Eaton. Alle Rechte vorbehalten.Eaton ist eine eingetragene Marke.Alle anderen Warenzeichen sind Eigentum ihrer jeweiligenBesitzer./socialmediaevaluated.Does not apply, since the entire switchgear needs to be evaluated.Is the panel builder's responsibility.Is the panel builder's responsibility.Is the panel builder's responsibility.Is the panel builder's responsibility.Is the panel builder's responsibility.The panel builder is responsible for the temperature rise calculation. Eaton will provide heat dissipation data for the devices.Is the panel builder's responsibility. The specifications for the switchgear must be observed.Is the panel builder's responsibility. The specifications for the switchgear must be observed.The device meets the requirements, provided the information in the instruction leaflet (IL) is observed.10.6 Incorporation of switching devices and components 10.7 Internal electrical circuits and connections 10.8 Connections for external conductors 10.9.2 Power-frequency electric strength 10.9.3 Impulse withstand voltage 10.9.4 Testing of enclosures made of insulating material 10.10 Temperature rise10.11 Short-circuit rating10.12 Electromagnetic compatibility10.13 Mechanical function。

HoshizakiNumber: 71363“A Superior Degree of Reliability”Models URC-5F URC-9F URC-14F URC-22F URC-23F Condenser Units Hoshizaki America, Inc.PARTS LISTCONTENTSAuxiliary Codes (3)Note About Ordering Parts (4)A. Condenser Unit (5)B. Accessories (9)Auxiliary CodesURC-5FR-5 April 2006S-5 January 2007 T-5 January 2008 U-5 January 2009 V-5 January 2010 A-5 January 2011 B-5 January 2012 B-0 October 2012 C-0 January 2013 D-0 January 2014 D-1 August 2014 E-0 January 2015 URC-9FR-5 July 2006S-5 May 2007T-5 January 2008 U-5 January 2009 V-5 January 2010 A-5 January 2011 B-5 January 2012 B-0 October 2012 C-0 January 2013 D-0 January 2014 D-1 April 2014E-0 January 2015URC-14FQ-5 October 2005 R-5 February 2006 S-5 January 2007 T-5 January 2008 T-6 May 2008T-7 November 2008 U-5 January 2009 V-5 January 2010 A-5 January 2011B-5 January 2012 B-0 October 2012 C-0 January 2013 D-0 January 2014 D-1 April 2014E-0 January 2015 URC-22FU-5 March 2009V-5 January 2010 A-5 January 2011B-5 January 2012 B-0 October 2012 C-0 January 2013 C-1 August 2013D-0 January 2014 E-0 January 2015 URC-23FT-5 May 2008U-5 November 2009 V-5 January 2010 A-5 January 2011B-5 January 2012 B-0 October 2012 C-0 January 2013 C-1 October 2013 D-0 January 2014 D-1 October 2014 E-0 January 2015Auxiliary Code BreakdownAuxiliary Codes "-5"The auxiliary code is the first two characters in the serial number. The first character indicates the year. Y ears progress or regress in alphabetical order. The series runs from "A" through "V" and the letters "I" and "O" are skipped. The second character indicates significant part changes within a year. Base is "5" and this number advances for each change.Auxiliary Codes "-0"The auxiliary code is the first two characters in the serial number. The first character indi-cates the year. Y ears progress or regress in alphabetical order. The series runs from "A" through "V" and the letters "I" and "O" are skipped. The second character indicates signifi-cant part changes within a year. Base is "0" and this number advances for each change. Note About Ordering PartsMost assemblies cannot be ordered as complete units; parts in the assemblies generally must be ordered separately.A. Condenser UnitURC-5F, URC-9F1/2R-5 to E-012345678910URC-5F and URC-9FA. Condenser UnitURC-14F, URC-22F, URC-23F2/2Q-5 to E-01234567 89URC-14F. URC-22F and URC-23F10Title: A. Condenser Unit Model: URC-_FIndexNo.Description Material or ModelNumber Part NumberRequired NumberQ-5toC-0C-1(H)C-1(K)D-0D-1(D)D-1(H)E-01Condenser URC-5F216519-021111111URC-9F1A1231-011111111URC-14F104777-021111111URC-22F104918-021111111URC-23F1A1048-011111-1A3506-01111 2Shroud URC-5F216522-0111111-2A7228-0111URC-9F2A3869-011111-2A7152-01111URC-14F324150G021111-3A7881-01111URC-22F325010G01111111-3A8629-011URC-23F325010G0211-2A7185-0111111 3Fan Motor URC-5FURC-9F4A3201-011111111URC-14FURC-22FURC-23F22222224Fan Blade URC-5FURC-9F4A1493-011111111URC-14FURC-22FURC-23F22222225Capacitor10.0MFD,250VAC URC-5FURC-9F443192-011111111URC-14FURC-22FURC-23F22222226Louver Panel URC-5F216521-011111111URC-9F2A7139-011111111URC-14F213968-011111-2A7139-01111URC-22F325014G021-2A7110-01111111URC-23F325014G021-2A7110-0111111 7Right Side Panel URC-5F2A1884-011111111URC-9FURC-14F2A1914-011111111URC-22FURC-23F2A1926-011111111Title: A. Condenser Unit Model: URC-_FIndexNo.Description Material or ModelNumber Part NumberRequired NumberQ-5toC-0C-1(H)C-1(K)D-0D-1(D)D-1(H)E-08Left Side Panel URC-5F2A1885-011111111URC-9F2A1914-011111-2A7153-01111URC-14F2A1915-011111111URC-22FURC-23F2A1925-011111111 9T op Panel URC-5F2A0897-011111111UCR-9F2A3889-011111-2A7142-01111URC-14F2A0900-011111-2A7142-01111URC-22F326137G021-3A7841-0111111-3A7977-011URC-23F3A3489G0111-3A7977-011111110Headmaster (Condensing Pressure Regulator - C.P.R.)URC-5FURC-9FURC-14FURC-22F4A0229-011111111B. AccessoriesURC-_F 1/2Q-5 to C-011a1b2B. AccessoriesURC-_F 2/2C-1 to E-0121a1a1b1b3Title: B. Accessories Model: URC-_FIndexNo.Description Material orModel Number Part NumberRequired NumberQ-5toC-0C-1(H)C-1(K)D-0D-1(D)D-1(H)E-01Leg URC-5F3A1704G0122222-3A7823-0144URC-9F URC-14F 3A1704G012222-3A7823-01444URC-22F3A1704G012-3A7823-01444444URC-23F3A1704G0122-3A7823-0144444 1a Hex Head Bolt W/Washer 8×20. SS7B023082010101010101010 1b Hex Nut M8, SS7N11-080010101010101010 2T2 Screw 4×8, SS7P32-04084444444 3Plate URC-5F3A3872-0122URC-9F222URC-14F222URC-22F222222URC-23F2222211。

艾默生CT变频器代理商咨询电话:0755-******** QQ:2407299229EV1000、EV2000高性能通用型艾默生变频器G为恒转矩负载,P为风机水泵负载(EV1000:0.4-5.5KW EV2000:5.5-280KW)EV1000-2S0004G 单相220VAC 0.4KW EV1000-2S0007G 单相220VAC0.75KW EV1000-2S0015G 单相220VAC 1.5KW EV1000-2S0022G 单相220VAC 2.2KW EV1000-4T0007G 三相380VAC0.75KW EV1000-4T0015G 三相380VAC1.5KW EV1000-4T0022G 三相380VAC2.2KW EV1000-4T0037G 三相380VAC3.7KW EV1000-4T0055G 三相380VAC5.5KW EV1000-4T0037P 三相380VAC3.7KW EV1000-4T0055P 三相380VAC 5.5KWEV2000-4T0055G/0075P 5.5KW/7.5KW EV2000-4T0075G/0110P7.5KW/11KW EV2000-4T0110G/0150P 11KW/15KW EV2000-4T0150G/1085P 15KW/18.5KW EV2000-4T0185G1/0220P118.5KW/22KW EV2000-4T0220G1/0300P1 22KW/30KW EV2000-4T0300G1/0370P1 30KW/37KW EV2000-4T0370G/0450P37KW/45KW EV2000-4T0450G1/0550P1 45KW/55KW EV2000-4T0550G 55KW EV2000-4T0750G 75KW EV2000-4T0900G 90KW EV2000-4T1100G 110KW EV2000-4T1320G 132KW EV2000-4T1600G 160KW EV2000-4T2000G 200KW EV2000-4T2200G 220KW EV2000-4T0750P 75KW EV2000-4T0900P 90KW EV2000-4T1100P 110KW EV2000-4T1320P 132KW EV2000-4T1600P 160KW EV2000-4T2000P 200KW EV2000-4T2200P 220KW EV2000-4T2800P 280KWEV3000系列矢量艾默生变频器(2.2KW-220KW)EV3000艾默生变频器是高品质、多功能、低噪音的矢量控制通用变频器。

—Hazlux ® LE2 LED SeriesThe LE2 LED Series is a slim, shock and vibration resistant fixture made of copper-free aluminum. This durable product has exposed hardware made from stainless steel and is suitable for marine and wet locations.thermal shock and impact resistant polycarbonate lensCorrosion resistantcopper-freealuminum housingExposed stainlesssteel fastenersL I N E A R L I G H T I N G©2023 ABB. All rights reserved. Rev: 12/2022Operating temperature: -40°F to 122°F (-40°C +50°C) optimal 77°F (25°C)Exposed hardware made of stainless steel Slim and compact design Housing made of copper-free aluminum Anti-corrosion housing (tested for 1000hrs)Shock and impact resistant polycarbonate lens Lens tested to IK08Efficacy: up to 137 Lm/WLumen output: from 5,480 lumens to 10,960 lumens Meanwell LED’s UL 8750 LED safety CRI Ra>70Correlated Color Temperature (CCT): 5000K (standard), 3000K and 4000K (optional)Operating voltage: universal 120-277 VAC, 347-480 VAC (50/60Hz)Power factor 0.95Driver efficiency 90% THD <20%Surge protection standard at 4KV(Contact your sales representative if high protection is required.)Pendant mountOptional yoke/pipe bracket for wall/ceiling or pole mountChain mount (“Chain” supplied by others)UL844UL 1598A marine UL 1598 wet locations UL 8750 LED safetyCUL approved to CSA 22.2 No. 137,CSA 22.2 No. 250.0-08, CSA 22.2 No. 250.13FCC IP66IK08DLCNot all product variations listed on this page are DLC qualified. Visit /search to confirm qualification.5G (shock and vibration resistant) 1000hrs salt spray 5 year limited warranty—Hazlux ® LE2 LED SeriesKey features and informationA R L I G H T I N GBUG rating: B3-U0-G1C0/180,115.0C30/210,115.0C60/240,114.0C90/270,107.0C0/180,60.8C30/210,60.8C60/240,61.3C90/270,61.0—®Chain supplied by others.Pipe clamp and yoke/pipe bracket required for stanchion installation.Sold separately.UB02 - Y oke/pipe bracket(SUS 304) stainless steel SC02 - S tainless steelsafety cable kitPC01 - P ipe clamp (1 pair)Pipe clamp (M8*48mm) for pole Ø 1-7/8" (48mm)PC02 - P ipe clamp (1 pair)Pipe clamp (M8*60mm) for pole Ø 2-3/8" (60mm)—Pendant mount (included standard)—Yoke/pipe bracket (optional accessory)Ceiling and wall—Accessories—Chain mount (compatible)—Stanchion mount (optional accessory)M O U NTI N G A N D O P TI O N A L ACCE S S O R I E S (sold separately)—Hazlux® LE2 LED SeriesN U M B E R I N G S YS TE M—Lighting fixture—Ordering information —Accessories (sold separately)1Dimensions are approximate and subject to change. LE2-87.6kg/16.7lbs47.2 x 5.0 x 7.6 inSC02 - S tainless steelsafety cable kit1.8"1.2"Ø.25"Ø.12"L= 39.4"HookLE2-4LE2-8SeriesLE2Wattage/lumens8Voltage1Color tempK3OpticsWLensCMountingPColorGMarketU 13579 2468Hazlux® linear light LED2 Wattage/lumens440W (5,480 lm)880W (10,960 lm)3 Voltage1120-277V4347-480V4 Color temp K33000K1K44000K1K55000K (standard)5 Optics W110°6 Lens C Clear polycarbonateF Frosted polycarbonate17 Mounting P NPT 3/4 pendant mountU NPT 3/4 pendant mount + yoke bracket8 Color G Gray9 Market U U.S. marketBlank Canadian market1Longer lead time, contact your sales representative for more detailsPC01Pipe clamp (1 pair)Pipe clamp (M8*48mm) for pole Ø 1-7/8" (48mm)PC02Pipe clamp (1 pair)Pipe clamp (M8*60mm) for pole Ø 2-3/8" (60mm)SC02Stainless steel safety cable kitUB02Yoke/pipe bracket (SUS 304) stainless steelLINEARLIGHTINGNote: For Canadian market, please add "-CA" to the part no. (ex: PC01-CA).。

XKFD-DQ027 #2炉#2播煤增压风机电机指

导书

Q/B XKFD-DQ027 000100

3、RK01-xxxx 年 02 月20 日发布xx 年 02 月20 日实施江苏徐矿发电有限公司发布#2 炉#2 播煤增压风机电机检修作业指导书江苏徐矿发电有限公司 A 级检修作业指导书

第2 页/共12 页

1、1 作业指导书编审表作业指导书编审表批准人审核人江苏徐矿发电有限公司编写人审核人检修承包方编写人江苏徐矿发电有限公司 A 级检修作业指导书

第3 页/共12 页

1、2 作业指导书清单作业指导书清单序号类别名称页数检修计划4/10主要检修项目4/10工作许可4/10修后目标4/10质检点分布4/10一检修工作任务单验收人员4/10设备基本参数5/10设备修前状况5/10人员准备6/10工具准备6/10工作许可准备7/10材料、备件准备8/10施工现场准备8/10二

修前准备卡检修危险点辨析及预控措施9/10三

检修工序及质量控制卡检修工序步骤及内容、质量验收

10/10江苏徐矿发电有限公司 A 级检修作业指导书

第4 页/共12 页

1、3 检修工作任务单江苏徐矿发电有限公司 A 级检修作业指导书

第5 页/共12 页一检修工作任务单设备名称 #2 炉#2 播煤增压风机电机设备编号设备检修类别 #2 机组 A 级检修检修计划计划工作时间xx 年月日至月日计划工日主要检修项目1 电机解体,定子铁芯、定子绕组清扫、检查2 绑线、槽楔检查3 引出线和接线盒清扫、检查4 定转子间隙及磁中心位置检查、调整5 端盖及附件检查6 冷却器清扫、检修7 冷却器清扫、检修8 外风扇等其他部件检查及处理9 就位找正后电动机地脚螺栓紧固情况复查10 电动机外壳接地线测量及检查11 电动机试运12 抽转子也属承包方工作范围√ 电气第一种工作票□ 电气第二种工作票□ 电气继保工作票□ 热机工作票□ 热控工作票

其它工作许可条件:□ 动火工作票□ 脚手架□ 拆除保温□ 封堵打开√ 围栏设置□ 安全网□ 其它工作许可工作票编号:修后目标接线盒内压线螺丝紧固本体无锈斑,漆膜光滑无尘土;接线盒绝缘子、引线无发热绝缘老化现象;冷却器通风管无污物、破损现象,通风良好;定、转子间隙误差在质量要求范围(测3 点与平均值的误差≤10%)。

轴承(瓦)油脂(油质)符合要求且所加油量合适;交流、支流耐压符合试验要求,直流

2、5UN 耐压1 分钟;交流

1、5UN 耐压1 分钟;绝缘电阻≥1M Ω/KV 和吸收比≥

1、5(20°);试转时振动≤60μm;温度(轴承)

≤85 °;(轴瓦)≤65 °;三相电流平衡,不摆动。

W 点工序及质检点内容 H 点工序及质检点内容W-1 螺丝紧固检查 H-1 引线、定子绕组、铁芯检查无异常W-2 电缆线绝缘皮无磨损 H-2 电气预防性试验、数据收集、记录W-3 加油量合适H-3 电机试转数据记录W-4 间隙测量、冷却器内无杂物、风叶无裂纹 H-4 文明生产验收情况W-5 附件检查 H-5

W-6 冷却器检查 H-6 质检点分布W-7 外观整洁接地线良好、现场干净 H-7 验收人员江苏徐矿发电有限公司 A 级检

修作业指导书

第6 页/共12 页

1、4 修前准备卡二

修前准备卡设备基本参数#2 机组#2 播煤增压风机型号 YKK500-

2、额定功率900KW、额定电压6KV、额定电98 A 、额定转速2983 rpm绝缘等级 F、接线方式 Y、重量7100 kg、生产厂家上海电机厂设备修前状况检修前交底(设备运行状况、历次主要检修经验和教训、检修前主要缺陷、)振动大。

设备定期试验,需要收集和分析试验数据。

江苏徐矿发电有限公司 A 级检修作业指导书

第7 页/共12 页二

修前准备卡(续)人员准备序号工作组人员姓名工种检查结果备注1 2 3 4 5 6 7 8 9 工具准备序号工器具名称工具编号检查结果备注1常用工具:

1、一字螺丝刀

2、字螺丝刀

3、尖嘴钳

4、斜口钳

5、毛刷

6、大锤

7、手锤

8、手电筒

9、紫铜棒10、锉刀1

1、活扳手 2 起重工具:钢丝绳、叉车3检验仪器:交直流耐压发生器、电摇表、万用表 4 试验器具:直流电桥5液压拆卸工具1 套、油盘1个、吊链1T、2T 各一个江苏徐矿发电有限公司 A 级检修作业指导书

第8 页/共12 页工作许可准备1 电气第一种工作票√ 备注2 电气第二种工作票 3 电气继电保护工作票 4 热机工作票 5 热控工作票 6 动火工作票7 其它工作许可条件江苏徐矿发电有限公司 A 级检修作业指导书

第9 页/共12 页二

修前准备卡(续)材料准备序号名称规格与型号

数量生产厂家备注1 棉布2酒精、丙酮等清洗剂3 破布4 塑料带

1、砂布

2、备件准备序号名称编码(图号)数量生产厂家备注1234567施工现场准备序号现场准备项目检查结果1 地面铺胶皮或塑料布

1、设置围栏, 2 3 4 江苏徐矿发电有限公司 A 级检修作业指导书

第10 页/共12 页二

修前准备卡(续)检修危险点辨析及预控措施序号作业内容危险因素可能导致的后果预控措施依据1 办理工作票措施未执行人身、设备伤害办理工作票,确认安全措施执行完善,组织人员宣读,签字方可开工。

《安规》第78 条2临时电源的使用触电人身触电、跌伤

1、湿手不准从事接引电源工作。

2、电源线及灯具和电动工具绝缘应良好,电线无破损现象,同时使用漏电保护器。

3、电源线要架空。

4、保证良好的照明效果。

《安规》第4

3、44 条3现场环境是否良好现场是否交叉作业人身、设备伤害加强监护《安规》4 冷却器损坏损坏人身、设备伤害防

止碰撞冷却器检修规程5 落物伤人人身伤害加强监护做好防止高空落物措施,工作中戴安全帽和手套《安规》6 设备检修损坏设备伤害防止碰撞损伤线圈检修规程。