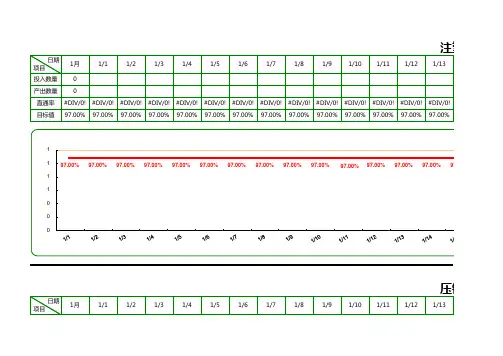

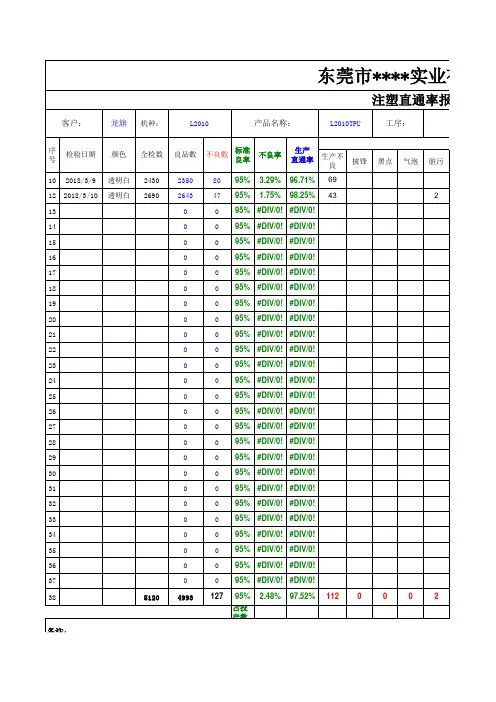

生产线直通率统计表

- 格式:xls

- 大小:38.00 KB

- 文档页数:2

直通率报告模板篇一:中试验证总结报告(模板)深圳金宏威实业有限公司中试验证总结报告(模板)文件编号:版本:项目名称:编制:日期:审核:日期:批准:日期:深圳市金宏威实业发展有限公司文件修订历史目录1.验证情况概述 ................................................ ................................................... ................................. 12. 验证结果 ................................................ .......................................................................................... 1 验证总体情况 ................................................ ................................................... ......................... 1 工艺验证 ................................................ ................................................... ................................. 2 装备验证 ................................................ ................................................... ................................. 5 装备验证发现问题概况 ................................................ ................................................... ....... 5 ICT装备 ................................................ ................................................... ............................... 5 FT装备 ................................................ ................................................... ................................. 6 老化装备 ............................................................................. 6 结构验证 ................................................ ................................................... ................................. 9 产品数据验证 ................................................ ................................................... ....................... 11 技术验证 .......(转载于: 小龙文档网:直通率报告模板)................................................ ................................................... ........................ 13 物料验证 ................................................ ................................................... ............................... 14 其他(如等) .............................................. ................................................... ........................ 15 4. 附件 ................................................ ................................................... ............................................ 16 试产直通率报告-------------------中试验证小组提........... 16 试产问题点清单-------------------中试验证小组提供 ................................................ .. (16)1.验证情况概述请在此处概括描述本批试产验证情况,包括产品版本说明、验证批次、数量、时间、地点、验证组、物料情况等。

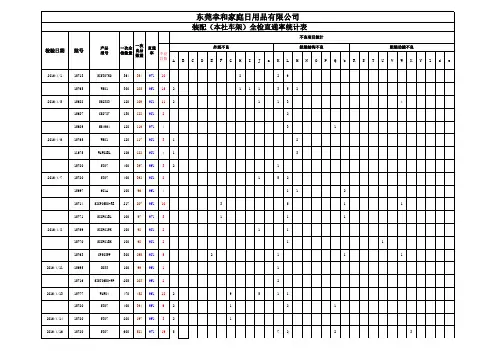

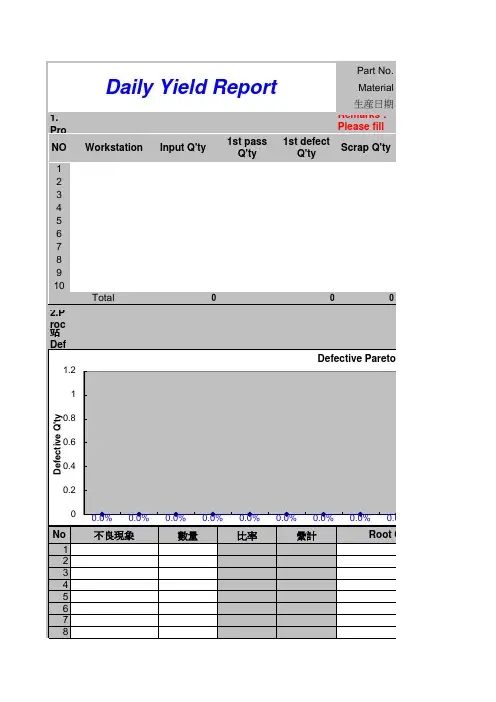

Part No.Material 生産日期1. Process Yield Control Remarks : Please fill white box onNO Input Q'ty1st pass Q'ty1st defect Q'tyScrap Q'ty123456789102.Process Defective Description In Detail 站Defective DetailsNo 數量比率纍計12345678Total不良現象Workstation Root CaDaily Yield Report0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 1.2 D e f e c t i v e Q 't y Defective Pareto C910111213141500站Defective DetailsNo 數量比率纍計12345678910111213141500站Defective DetailsTotalTotal不良現象Root Ca0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 1.2 D e f e c t i v e Q 't y Defective Pareto Ch1.2Defective Pareto ChNo 數量比率纍計1234567891067891000站Defective DetailsNo 數量比率纍計Total不良現象不良現象Root CaRoot Ca0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 D e f e c t i v e Q 't y 0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 1.2 D e f e c t i v e Q 't y Defective Pareto Ch2345678910111213141500站Defective DetailsNo 數量比率纍計12345678910111213Total不良現象Root Ca0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 1.2 D e f e c t i v e Q 't y Defective Pareto Ch1500站Defective DetailsNo 數量比率纍計12345678910111213141500站Defective DetailsTotalTotal不良現象Root Ca0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 1.2 D e f e c t i v e Q 't y Defective Pareto Ch0.60.8 1 1.2 v e Q 't y Defective Pareto ChNo 數量比率纍計12345678910111213141500站Defective DetailsNo 數量比率纍計12345Total不良現象不良現象Root CaRoot Ca0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 D e f e c t i v0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 1.2 D e f e c t i v e Q 't y Defective Pareto Ch678910111213141500站Defective DetailsNo 數量比率纍計12345678910111213141500站Defective DetailsTotalTotal不良現象Root Ca0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 1.2 D e f e c t i v e Q 't y Defective Pareto ChNo 數量比率纍計12345678910111213141500Total 不良現象Root Ca0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.0%0.2 0.4 0.6 0.8 1 1.2 D e f e c t i v e Q 't y Defective Pareto ChWork Order:Material Lot No.: Please fill white box only.Total 良品數1st Pass Yield(直通率)Final Yield100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%100.00%0100.00%100.00%Due day Ownerot Cause Corrective Action 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0%0.0%25.0%50.0%75.0%100.0%D e f e c t i v e R a t eeto ChartDue day Ownerot Cause Corrective Action 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0%0.0%25.0%50.0%75.0%100.0%D e f e c t i v e R a t eeto Chart100.0%eto ChartDue day Owner Due day Owner ot Cause Corrective Action ot Cause Corrective Action 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 25.0%50.0%75.0%D e f e c t i v e R a t e 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 25.0%50.0%75.0% 100.0%D e f e c t i v e R a t e eto ChartDue day Owner12.28ot Cause Corrective Action 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 25.0%50.0%75.0%100.0%D e f e c t i v e R a t e eto ChartDue day Owner ot Cause Corrective Action 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 25.0%50.0%75.0%100.0%D e f e c t i v e R a t e eto Chart50.0% 75.0% 100.0%v e R a t e eto ChartDue day Owner Due day Owner ot Cause Corrective Action ot Cause Corrective Action 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 25.0%50.0%D e f e c t i v 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 25.0%50.0%75.0% 100.0%D e f e c t i v e R a t e eto Chart0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 25.0% 50.0% 75.0% 100.0%DefectiveRateeto ChartDue day Owner ot Cause Corrective Action0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 0.0% 25.0% 50.0% 75.0% 100.0%DefectiveRateeto ChartDue day Owner ot Cause Corrective Action。

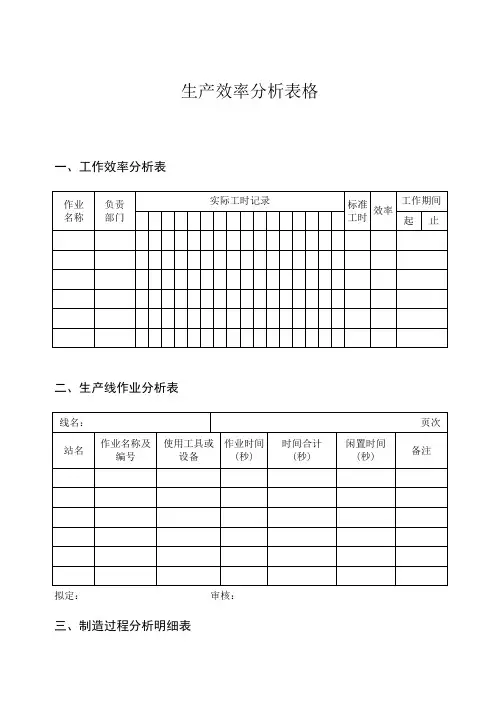

生产效率分析表格一、工作效率分析表

二、生产线作业分析表

拟定:审核:

三、制造过程分析明细表

拟定:审核:四、产量分析表

五、各制造过程产量分析表

348

六、月份各部门生产效率分析表

审核:填表:

349

七、月份各产品产出率报告表

核对:

八、月份完工产品效率汇总表

350

九、生产效率不佳原因分析表

月份:

十、零件自制外购对比分析表

日期:

初拟:修订:批示:审核:分析人:

351

十一、经济生产量分析表

十二、工厂设备投资经济效益分析

续表352

审核:分析表:

十三、机器生产效率统计表

机别:月份:

353

十四、设备利用率分析

期间:月日至月日资料来源:□资料分析

□抽查

审核:分析员:十五、生产进度异常原因分析

354

续表

十六、生产故障分析表

部门:年月编号:

355。

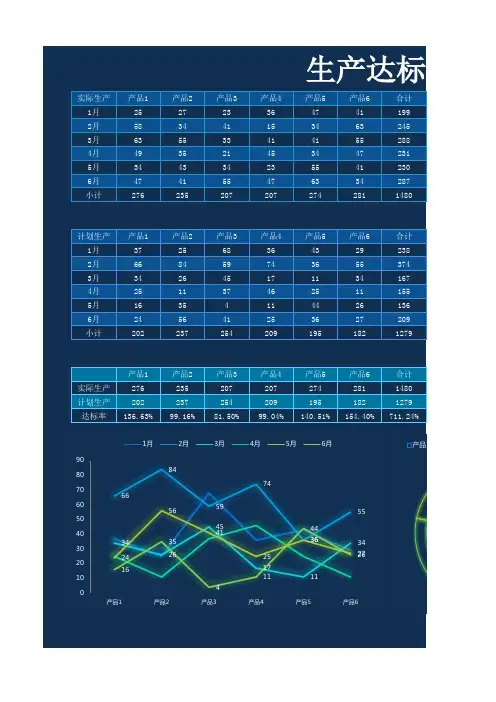

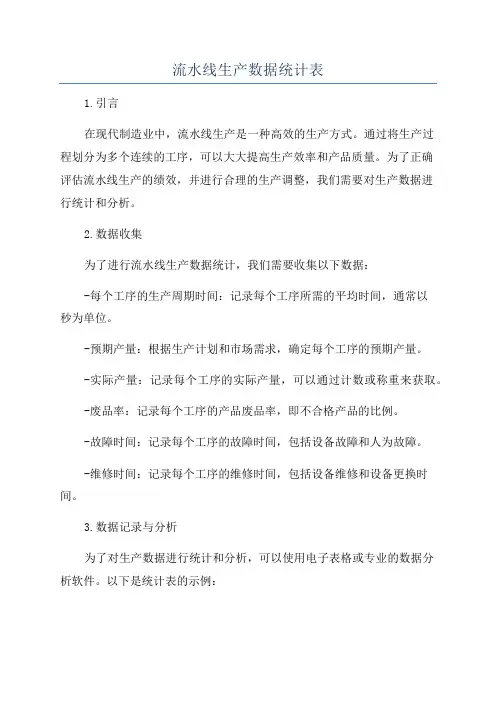

流水线生产数据统计表1.引言在现代制造业中,流水线生产是一种高效的生产方式。

通过将生产过程划分为多个连续的工序,可以大大提高生产效率和产品质量。

为了正确评估流水线生产的绩效,并进行合理的生产调整,我们需要对生产数据进行统计和分析。

2.数据收集为了进行流水线生产数据统计,我们需要收集以下数据:-每个工序的生产周期时间:记录每个工序所需的平均时间,通常以秒为单位。

-预期产量:根据生产计划和市场需求,确定每个工序的预期产量。

-实际产量:记录每个工序的实际产量,可以通过计数或称重来获取。

-废品率:记录每个工序的产品废品率,即不合格产品的比例。

-故障时间:记录每个工序的故障时间,包括设备故障和人为故障。

-维修时间:记录每个工序的维修时间,包括设备维修和设备更换时间。

3.数据记录与分析为了对生产数据进行统计和分析,可以使用电子表格或专业的数据分析软件。

以下是统计表的示例:-------------------------------------------------------------------------------时间段,工序1,工序2,工序3,....,工序n,总计-------------------------------------------------------------------------------生产周期时间,30秒,45秒,40秒,....,35秒,-预期产量,1000个,800个,1200个,....,1500个,4500个实际产量,980个,780个,1150个,....,1490个,4400个废品率,2%,3%,5%,....,1%,3%故障时间,2小时,1.5小时,1小时,....,2.5小时,7小时维修时间,1小时,0.5小时,0.5小时,....,1.5小时,3.5小时从上表中可以看出,工序1的生产周期时间为30秒,预期产量为1000个,实际产量为980个,废品率为2%。