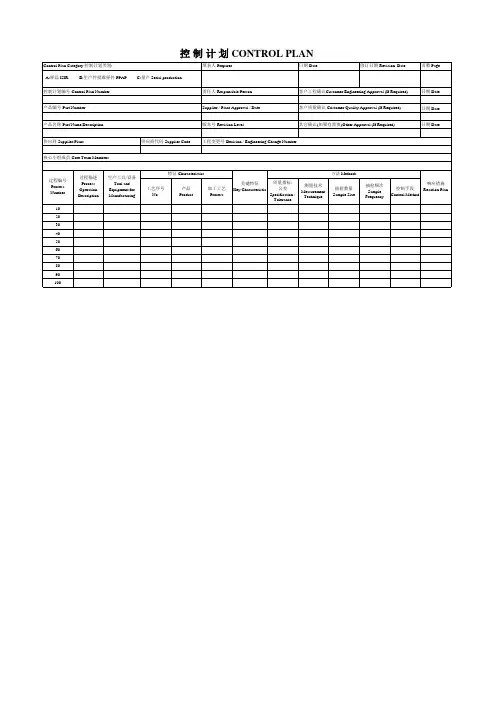

控制计划-中英文

- 格式:xls

- 大小:33.50 KB

- 文档页数:1

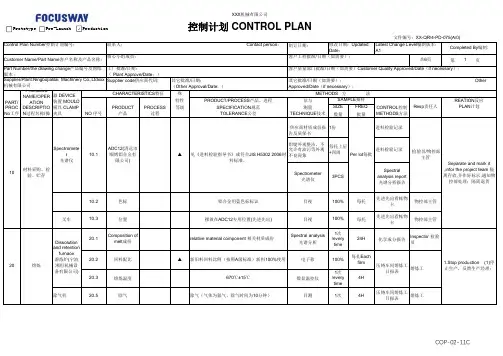

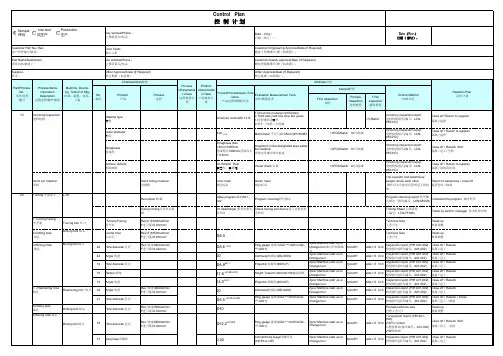

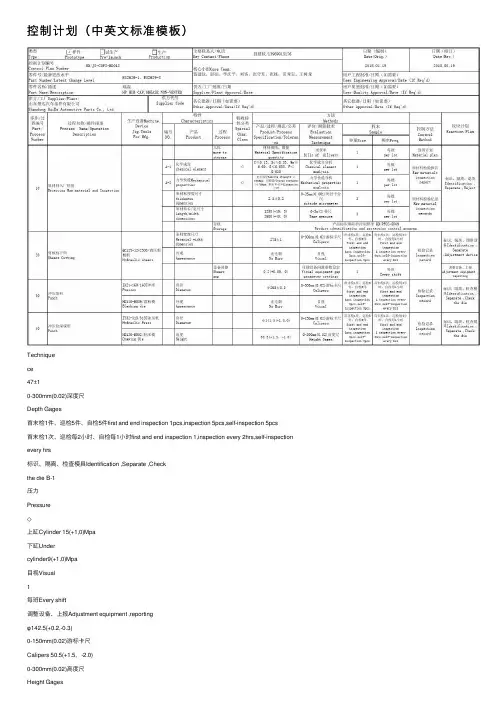

制订日期:共6页第1页SPEC特殊CHAR特性PRODUCT/PROCESS产品、进程EVALUATION/评估与PRODUCT PROCESS CLASS等级SPECIFICATION规范MEASUREMENT测量SIZE FREQ CONTROL控制产品过程TOLERANCE公差TECHNIQUE技术数量批量METHODS方法供应商材质成份报告及质保书1份进料检验记录铝锭外观整洁,不允许有油污等外观不良现象每托上层+四周进料检验记录10.2色标铝合金用蓝色标标识目视100%每托先进先出看帐物卡物控部主管叉车10.3位置摆放在ADC12专用位置(先进先出)目视100%每托先进先出看帐物卡物控部主管20.1Composition ofmelt成份relative material component 相关材质成份Spectral analysis光谱分析1次/everytime24H化学成分报告Inspector 检验员20.2回料配比▲新旧料回料比例(按照A级标准)新料100%使用电子称100%每扎Eachfirm20.3熔炼温度670℃±15℃数显温控仪1次/everytime4H除气机20.5除气除气(气体为氮气、除气时间为10分钟)目测1次4H 压铸车间熔炼工日报表熔炼工Customer Name/Part Name客户名称及产品名称:核心小组成员:客户工程批准/日期(如需要):Part Number/the drawing change产品编号及图纸版本:工厂批准/日期:( Plant Approve/Date:)客户质量部门批准/日期(如需要)Customer Quality Approved/Date(if necessary):控制计划 CONTROL PLAN文件编号:XX-QR/4-PD-075(A/0)Control Plan Number控制计划编号:联系人: Contact person:修改日期:UpdatedDate:Latest Change Level编制版本:A1Completed By编制:Supplier/Plant:Ningbojialilai Machinery Co.,Ltdxxx 机械有限公司Supplier code供应商代码:其它批准/日期:(Other Approval/Date: )其它批准/日期(如需要): OtherApproved/Date(if necessary):PART/ PROC No工序PROCESSNAME/OPERATIONDESCRIPTION过程名称/操MACHINE机器 DEVICE装置 MOULD模具 CLAMP夹具CHARACTERISTICS特征METHODS 方法NO 序号SAMPLE抽样Resp责任人REATION反应PLAN计划10材料采购、检验、贮存Spectrometer光谱仪10.1ADC12(清远市顺博铝合金有限公司)20熔炼Dissolutionand retentionfurnace溶炼炉(宁波湘恒机械设备有限公司)1.Stop production (1)停止生产,反馈生产经理;压铸车间熔炼工日报表熔炼工▲见《进料检验指导书》或符合JIS H5302 2006材料标准。

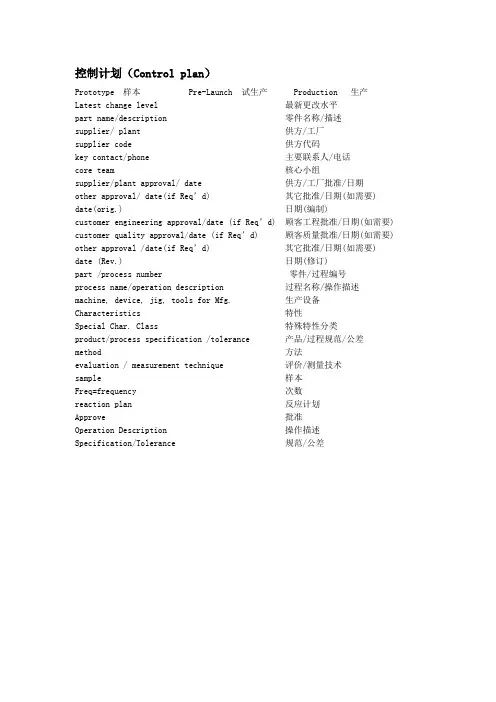

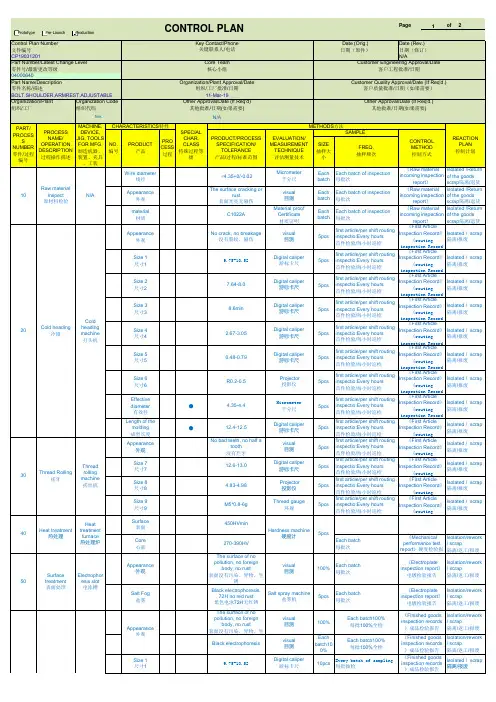

控制计划(Control plan)Prototype 样本 Pre-Launch 试生产 Production 生产Latest change level 最新更改水平part name/description 零件名称/描述supplier/ plant 供方/工厂supplier code 供方代码key contact/phone 主要联系人/电话core team 核心小组supplier/plant approval/ date 供方/工厂批准/日期other approval/ date(if Req’d)其它批准/日期(如需要) date(orig.) 日期(编制)customer engineering approval/date (if Req’d)顾客工程批准/日期(如需要) customer quality approval/date (if Req’d)顾客质量批准/日期(如需要) other approval /date(if Req’d)其它批准/日期(如需要) date (Rev.) 日期(修订)part /process number 零件/过程编号process name/operation description 过程名称/操作描述machine, device, jig, tools for Mfg. 生产设备Characteristics 特性Special Char. Class 特殊特性分类product/process specification /tolerance 产品/过程规范/公差method 方法evaluation / measurement technique 评价/测量技术sample 样本Freq=frequency 次数reaction plan 反应计划Approve 批准Operation Description 操作描述Specification/Tolerance 规范/公差01) Receiving inspection 进货检查02) 过程控制 Process ControlOperation Description操作描述Assemble 装配Blower 风机Heater coil 加热芯体Water Hose 热水胶管Evaporator coil 蒸发芯体water valve 水阀wire harness 线束cover plate 盖板Metal cover 金属盖子Plastic cover 塑胶盖子Sponge 海绵plastic parts 塑料件Washer 垫圈Screw 螺丝Bolt 螺栓nut 螺母front plate 前板rear plate 后板resistance 电阻beacon 警示灯coolant 冷却液self tapping screw 自攻螺丝to tight a bolt 拧紧螺栓to loosen a bolt 拧松螺栓punched hole 冲孔add lubricant oil 加润滑油argon welding 氩焊to move, to carry, to handle搬运be put in storage 入库packing 包装barcode 条形码fuse together 熔合processing, to process加工delivery, to deliver 交货easily damaged parts 易损件standard parts 标准件to lubricate 润滑spring 弹簧Machine, device, jig, tools for Mfg. (机器,装置,夹具,工装)生产设备fixture 夹具(治具)Torque Wrench 扭矩扳手Device 装置ATE:Automatic Test Equipment 自动测试设备Driver 螺丝起子Ammeter, galvanometer 电流表Voltmeters 电压表Solder iron 电烙铁Caliper 游标卡尺Oven 烤箱Rivet machine 拉钉机Rivet gun 拉钉枪Screw driver 起子Electric screw driver 电动起子Hydraulic machine 液压机Pneumatic screw driver 气动起子automatic screwdriver 电动启子barcode scanner 条形码扫描仪fuse machine/heat stake 热熔机calculagraph 计时器air gun 气枪Tap 丝锥pressure gauge 压力表tape measure 卷尺Multimeter 万用表Product/Process Characteristics 产品/过程特性Appearance 外观Performance 功能Orientation 方向Thickness 厚度Width 宽度Performance 功能Position 位置Type 型号Sealing 密封性DIM:Dimension 尺寸Specification 规格Type 型号Wind fliud 风向Vibration 振动Abnormal sound 异音Current 电流On-off Control 通断控制Torque 扭矩Pressure 压力Specification/Tolerance 规范/公差cosmetic inspection 外观检查inner parts inspection 内部检查exposed metal/bare metal 金属裸露cosmetic defect 外观不良lack of painting 烤漆不到位slipped screw head/slippery slipped thread滑丝missing part 漏件wrong part 错件oxidation 氧化defective threading 抽芽不良poor staking 铆合不良blister 气泡angular offset 角度偏差dent 压痕slug mark 压痕scratch 刮伤deformation 变形filings 铁削defective label 不良标签abrasion 磨损Breaking. (be)broken,(be)cracked 断裂nick 缺口speck 瑕疪shine 亮班splay 银纹gas mark 焦痕delaminating 起鳞speckle 斑点mildewed =moldy = mouldy 发霉burr(金属)flash(塑件) 毛边excessive gap 间隙过大grease/oil stains 油污inclusion 杂质shrinking/shrinkage 缩水mixed color 杂色fold of packaging belt 打包带折皱painting make-up 补漆discoloration 羿色water spots 水渍impurity 杂质Inclusion 杂质Mismatch 错位failure, trouble 故障rust 生锈peel 脱漆Contamination 脏污Gap 间隙label error 标签错误Missing label 漏贴rejection criteria 拒收标准Suspected rejects 可疑庇abrasion 损伤、磨损Texture surface 印花纹表面Streak 条纹stains 污点Blotch 斑点discoloration 脱色dirt grime 灰尘blush 毛边薄膜sink 下凹Hickey 漏漆labels and logos 贴纸与商标Configuration labels 组合贴纸corrugated container 瓦摆纸箱Delaminating 脱层splattering 散点Gouge 锉孔puckering 折痕Damage 损伤Scratch 刮伤Loosing 松动Leakage 泄漏fasten 锁紧(螺丝) fit together 组装在一起Evaluation / measurement technique 评价/测量技术Visual (check)目测Touch manually 手感Listen 耳听Sample 样本Each batch 每批Once a day 每天一次Continuous 连续Once every operation 每次开机Each shift 每班Control Method 控制方法FAI first article inspection 首件检查Sample/spot inspection 抽检(点检)100%/full inspection 全检Operator inspection(check) 自检Patrol inspection 巡检Last article inspection 末检SPC control SPC控制Reaction plan 反应计划Review 评审Reword 返工Repair 返修to return delivery to. to send delivery back to return of goods退货scraped 报废Separate 隔离final-inspection 终检(成品监查)。

Sample 样件Trial Run试生产Production生产7.Turning OutsideDiameter车外圆Turning tool 车刀4Outside diameter 外径Rev 转速2500rad/min Φ14.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Inspection report (PIR A01-Close off / Rework隔离 / 返工Chamfer 倒角F进刀量=0.03mm/r 1.4±0.015Projector 投影仪(490127)3pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工5Outside diameter 外径Φ12.6±0.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工1Outside diameter 外径Φ16.18 0/-0.04Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工25Angle 角度45.6°±5°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8.Cutting Groove 割槽Cutting tool 切断刀2Outside diameter 外径Rev 转速2500rad/minФ 14+0.05Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework /Sort隔离 / 返工/全检38Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11Width宽度 2.2 +0.2/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8Length 长度11.8±0.2Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工41Angle 角度3°±1°Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工26Radius圆弧R0.1 +0.1(2X)Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9.Cutting off 切断Cutting tool 切断刀17Length 长度Rev 转速2500rad/minF进刀量=0.03mm/r23.4±0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工10.Drilling hole 钻孔Drilling tool 钻头22Inside diameter 外径Rev 转速2500rad/minΦ6+0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工36Concentricity 同轴度Φ0.02Concentricity Gage同轴度仪(19753-A-10P)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工40Roughness 粗糙度F进刀量=0.03mm/r Ra6.3Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工14Length 长度9±0.25Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工33Angle 角度118°±3°Contracer轮廓仪(DD-0009)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工31Chamfer 倒角0.2 +0.2/0.1*45Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11.Drilling hole 钻孔Drilling tool 钻头Hole diameter 孔径Rev 转速2500rad/minF进刀量=0.03mm/rΦ10Process technice size过程工艺尺寸Reset-up重新调整12.Boring Hole镗孔Boring tool 镗刀23Inside diameter 外径Rev 转速3000rad/minF进刀量=0.02mm/rΦ8.8±0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工30Chamfer 倒角0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13highness 高度 2.5+0.2Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工12highness 高度 1.2±0.025Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工35parallel平行度0.02Dial indicator千分表3pcs/ Machine start up orChange tool 3pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工24Inside diameter 外径Φ13 +0.04Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework / Scrap隔离 / 返工 / 报废Turning tool 车刀6Outside diameter 外径Rev 转速2500rad/minΦ14.6+0.1Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工39Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工28Chamfer 倒角0.2±0.05*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9highness 高度 3.8+0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工29Chamfer 倒角0.2±0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工7highness 高度19.6+0.05/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13.Turning Outside Diameter车外圆。

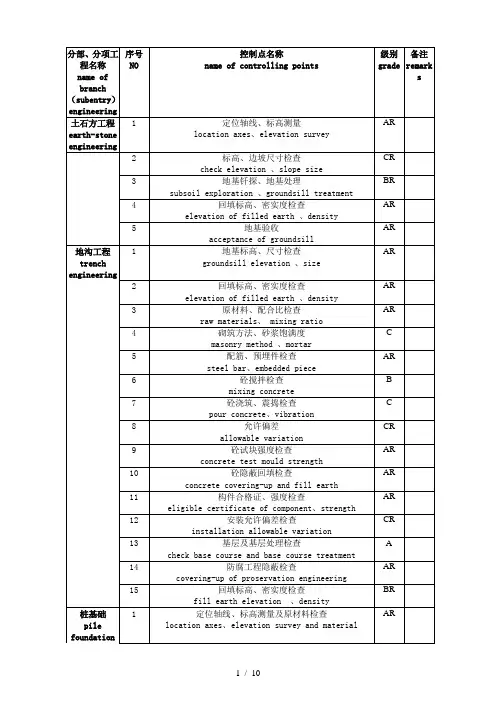

注:(note)1、表中施工质量控制点分为A、B、C三级,其中:construction quality controlling points have three grades (A、B、C grade)A级为最要的施工质量控制点,必须由施工分包方、TCC及业主(监理)三方质量检查人员共同检查确认。

A grade is the most important point。

confirmed by subcontractor 、TCC、owner (supervisor)all together。

B级为重要的施工质量控制点,由施工分包方、TCC双方质量检查人员共同检查确认。

B grade is the more important point 。

confirmed by subcontractor 、TCC、together。

C级为一般施工质量控制点,由施工分包方质控人员检查确认。

C grade is normal point 。

confirmed by subcontractor 。

各级中有检查记录要求的应加R,如AR、BR、CR。

If it has demand of check record ,it should add R after the quality grade (eg AR、BR、CR02. 施工质量控制点明细表应报业主确认后,方可执行。

construction quality controlling points may be carried out after been confirmed by owner。

3. 施工质量控制点明细表中的质量控制点,可根据业主的需要进行适当的增减。

construction quality controlling points may increase or decrease on owner` demand。

4.施工质量控制点明细表中各质量控制点的检查等级,可根据工程新在地建设工程质量监督站或业主的具体要求作适当调整。

控制计划(中英⽂标准模板)Techniquece47±10-300mm(0.02)深度尺Depth Gages⾸末检1件、巡检5件、⾃检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs⾸末检1次、巡检每2⼩时、⾃检每1⼩时first and end inspection 1,inspection every 2hrs,self-inspection every hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压⼒Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa⽬视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ142.5(+0.2,-0.3)0-150mm(0.02)游标卡尺A-3◇47±10-300mm(0.02)深度尺Depth Gages⾸末检1件、巡检5件、⾃检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs⾸末检1次、巡检每2⼩时、⾃检每1⼩时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压⼒Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa⽬视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ214±0.50-300mm(0.02)游标卡尺Calipers6×φ8.7±0.250-150mm(0.02)游标卡尺Calipers A-4◇HDJ-H0001检具Gage⾸末检1件、巡检5件、⾃检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs末检1次、巡检每2⼩时、⾃检每1⼩时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrsφ205±0.750-300mm(0.02)游标卡尺Calipers 深度Depth检验记录Inspection record50整形ShapingJY32-315/315T油压机Hydraulic Press 直径Diameter ⾸末检1件、巡检3件、⾃检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs ⾸末检1次、巡检每4⼩时、⾃检每1⼩时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs 检验记录Inspection recordHD134-H014/整形模Shaping Die⾼度Height检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,CheckHD146-H011/切边冲孔模Trimming and Punching die位置度Location degreeJA21-160/160T冲床Presses深度Depth直径Diameter 检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die40冲压拉深成形Punch冲压切边冲孔Trimming and PunchingJB21-160B-SM/160T冲床直径Diameter⾸末检1件、巡检3件、⾃检3件first and endinspection⾸末检1次、巡检每4⼩时、⾃检每1⼩时first and end inspection60⾸末检1件、巡检3件、⾃检3件first and end inspection 1pcs,inspection3pcs,self-inspection 3pcs⾸末检1次、巡检每4⼩时、⾃检每1⼩时first and end inspection 1,inspection every 4hrs,self-inspection every hrsTechnique ce10(+2,0)0-300mm(0.02)⾼度尺Height Gages85°±0.5°0-360°(2′)万能⾓度尺Universal angle rulerA-5◇⾸末检、巡检0-10mm(0.01)百分表/⾃检 0-1mm塞尺First and endinspection 0-10mm(0.01) Dialindicator/Self-inspection 0-1mmFeeler⾸末检1件、巡检5件(X-R图)、⾃检5件first and endinspection1pcs,inspection 5pcs(X-R末检1次、巡检每2⼩时、⾃检每1⼩时first and end inspection1,inspection every2hrs,self-inspection everyhrsφ4(+2,-1)0-150mm(0.02)游标卡尺Calipers1±0.250-300mm(0.02)⾼度尺Height Gages90⽆油污No dirt⽬测Visual全检Fullinspection每批per lot检验记录Inspectionrecord标识、隔离、退货Identification , Separate ,Reject 喷塑⽓压Spraypressure0.4-0.5MPa喷塑电压Spray voltage50-60KV烘烤温度Bakingtemperature180-200℃烘烤时间Baking time30-40min⽆漏喷No leakage jet⽬测equipment ,reporting100喷塑SprayXNG-36-1B/粉末喷涂⽣产线Powder coatingproduction lines⽬测Visual1产线外观Appearance全检Fullinspectionper lot70冲压翻边成形FlangingJB21-160B-SM/160T冲床Presses件、⾃检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs时、⾃检每1⼩时first and endinspection1,inspection every4hrs,self-inspectionevery hrs80冲压压字Pressure logoJA21-160/160T冲床Presses孔径diameter I.D.⾸末检1件、巡检3件、⾃检3件first and endinspection1pcs,inspection3pcs,self-Separate ,Checkthe die⾓度AngleHD124-H008/翻边模Flanging die平⾯度Flatness⾼度Height标识、隔离、检查模具Identification , Separate ,Checkthe die HD150-H006/压字模Pressure logodie(E32629-3)HD150-H005/压字模Pressure logodie(E32629-1)⾼度Height检验记录Inspectionrecord⾸末检1次、巡检每4⼩时、⾃检每1⼩时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord外观Appearance外协镀锌Outsourcing galvanized检验记录Inspectionrecord每班Every shift检验记录Inspectionrecord台⾯,上⾯压5kg物体)/0.15mm feeler ( cover flat on the marble countertops, pressure 5kg objects above )盐雾试验≥1000⼩时/Salt spray test≥1000hrs盐雾腐蚀试验机/Salt spray corrosiontest machine3每季度Each quarter盐雾试验报告Salt spray testreport110丝印完整Full screen⽬测Visual全检Fullinspection每批per lot检验记录Inspectionrecord标识、隔离、退货Identification ,Separate ,Reject A-3◇47±10-300mm(0.02)深度尺Depth Gages10A-4◇HDJ-H0001检具Gage10A-5◇0.15mm塞尺(端盖平放在⼤理⽯台⾯,上⾯压5kg物体)/0.15mm feeler (cover flat on themarble countertops, pressure 5kg objectsPackaging Specifications点数Counting2箱2 box标识、隔离、返⼯Identification , Separate ,Rework清晰Clear⽬测Visual包装规范Packaging Specifications⽬测Visual物资发货单Material Invoice点数Counting标识、隔离、返⼯Identification , Separate ,Rework 平⾯度Flatness防腐蚀性能Corrosion100喷塑SprayXNG-36-1B/粉末喷涂⽣产线Powder coating production lines全检Fullinspection每批per lot外协丝印Outsourcing Screen外观Appearance检验记录InspectionrecordSampling inspection and packaging 标识、隔离、处理Identification ,Separate ,Dealwith位置度Location degree平⾯度Flatness数量Quantity每批per lot检验记录Inspectionrecord标识Label标识、隔离、返⼯Identification ,Separate ,Rework包装Package数量Quantity130⼊库&出货Warehousing & shipping全检Fullinspection每批per lot物资发货单Material Invoice。

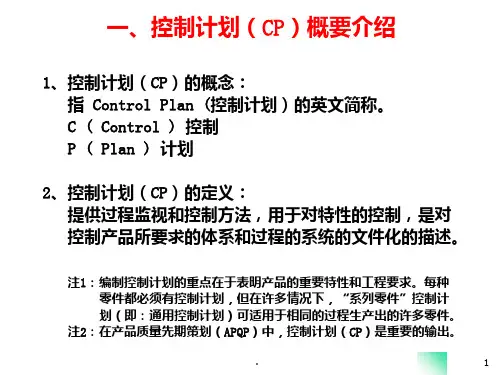

控制计划控制程序(IATF16949-2016)1、目的1. Purpose对控制零件和过程的体系,通过控制特性的过程监视和控制方法来最大限度地减少过程和产品变差;并随着测量系统和控制方法的评价和改进对其进行修订,使控制计划在整个产品寿命周期中得到保持和使用,确保按顾客的要求制造出优质的产品。

It aims to control the part and process systems and reduce process and product variations to the utmost extent through process monitoring and control methods of the control characteristics; the control plan shall be revised along with the evaluation and improvement of the measurement system and the control methods and shall be maintained and used in the whole product life cycle so as to ensure that high qualify product is manufactured according to the requirements of the customer.2、适用范围2. Scope适用于本公司内产品的样件、小批量试产和批量生产所用的控制计划。

如客户有特殊要求,必须按照客户的要求执行。

It applies to the control plans used in the product sample, small-lot trial production and volume production of the company. If the customerhas special requirements, it shall be implemented according to the requirements of the customer.3、定义3. Definition无None4、职责4. ResponsibilitiesAPQP项目小组负责控制计划的策划,质量部负责编制与维护The APQP project team shall be responsible for planning of the control plan and the quality department shall be responsible for preparation and maintenance of it.5、程序5. Procedure5.1 当顾客和公司有需求和要求时,项目小组在不同阶段制订出相应的控制计划(即:样件控制计划、试生产控制计划、生产控制计划),项目组按工艺文件将其发行至相关部门,由其执行。

容量Size 频率Freq.入库move to storage材料规格、数量Material Specificationquantity送货单Bills of dilivery1每批per lot到货计划Material planA-1◇C≤0.15、Si≤0.05、Mn≤0.60、S≤0.035、P≤0.035化学成分分析Chemical elementanalysis1每批per lotA-2◇抗拉强度Tensile strength ≥305Mpa、屈服强度Yield strength≥175Mpa、断后伸长率Elongation≥29力学性能分析Mechanical propertiesanalysis1每批per lot2.5±0.20-25mm(0.001)外径千分尺outside micrometer3每批per lot1250(+10,0)2600(+40,0)0-3m(1)卷尺Tape measure3每批per lot存放Storage275±10-300mm(0.02)游标卡尺Calipers无毛刺No Burr目视Visual设备间隙Shears gap0.2(+0.05,0)目测设备间隙参数设定Visual equipment gapparameter settings1每班Every shift调整设备、上报Adjustment equipment ,reporting φ265±0.50-300mm(0.02)游标卡尺Calipers无毛刺No Burr目视Visualφ141.5(+1.0,0)0-150mm(0.02)游标卡尺Calipers50.5(+1.5,-1.0)0-300mm(0.02)高度尺Height Gages高度Height 首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord标识、隔离、检查模具Identification ,Separate ,Checkthe die供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)标识、隔离、调整设备Identification ,Separate,Adjustment device 生产设备Machine.DeviceJig.ToolsFor Mfg.特性Characteristics零件名称/描述Part Name/Description 端盖HP HUB CAP,GREASE NON-VENTEDJY32-315/315T油压机Hydraulic Press直径Diameter40冲压拉深成形Punch供方/工厂批准/日期Supplier/Plant Approval/Date过程名称/操作描述Process Name/OperationDescriptionHD130-H002/拉深模Drawing Die条料宽度尺寸Material widthdimension其它批准/日期(如需要)Other Approval/Date (If Req'd)检验记录Inspectionrecord用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change LevelE32629-1、E32629-3零件/过程编号Part/ Process Number评价/测量技术EvaluationMeasurementTechnique样本Sample控制方法ControlMethod特殊特性分类SpecialChar.Class方法Methods标识、隔离、退货Identification ,Separate ,Reject产品标识和防护控制程序 HD/PF02-SP09Product identification and protection control program反应计划Reaction Plan 编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance10原材料入厂检验Receiving Raw material and Inspection力学性能Mechanicalproperties原材料检验报告Raw materialsinspectionreport原材料长/宽尺寸Length/widthdimensions原材料检验记录Raw materialinspectionrecords化学成分chemical element原材料厚度尺寸thicknessdimension20剪板机下料Shears CuttingQC12Y-12*2500/液压剪板机Hydraulic shears外观Appearance首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs30冲压落料Punch首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord标识、隔离、检查模具Identification ,Separate ,Checkthe die外观AppearanceJA21-160/160T冲床PressesHD110-H009/落料模Blanking die直径Diameter容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance47±10-300mm(0.02)深度尺Depth Gages首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs首末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压力Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa目视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ142.5(+0.2,-0.3)0-150mm(0.02)游标卡尺Calipers 50.5(+1.5,-2.0)0-300mm(0.02)高度尺Height GagesA-3◇47±10-300mm(0.02)深度尺Depth Gages首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs首末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压力Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa目视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ214±0.50-300mm(0.02)游标卡尺Calipers6×φ8.7±0.250-150mm(0.02)游标卡尺Calipers A-4◇HDJ-H0001检具Gage首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrsφ205±0.750-300mm(0.02)游标卡尺Calipers 深度Depth检验记录Inspection record50整形ShapingJY32-315/315T油压机Hydraulic Press 直径Diameter 首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs 首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs 检验记录Inspection recordHD134-H014/整形模Shaping Die高度Height检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die孔径diameter I.D.HD146-H011/切边冲孔模Trimming and Punching die位置度Location degreeJA21-160/160T冲床Presses深度Depth直径Diameter 检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die40冲压拉深成形Punch冲压切边冲孔Trimming and PunchingJB21-160B-SM/160T冲床直径Diameter首末检1件、巡检3件、自检3件first and endinspection首末检1次、巡检每4小时、自检每1小时first and end inspection60首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance10(+2,0)0-300mm(0.02)高度尺Height Gages85°±0.5°0-360°(2′)万能角度尺Universal angle rulerA-5◇首末检、巡检0-10mm(0.01)百分表/自检 0-1mm塞尺First and endinspection 0-10mm(0.01) Dialindicator/Self-inspection 0-1mmFeeler首末检1件、巡检5件(X-R图)、自检5件first and end inspection 1pcs,inspectio n 5pcs(X-R chart),self-inspection 5pcs末检1次、巡检每2小时、自检每1小时first and endinspection1,inspection every2hrs,self-inspection everyhrsφ4(+2,-1)0-150mm(0.02)游标卡尺Calipers 1±0.250-300mm(0.02)高度尺Height Gages90无油污No dirt 目测Visual全检Full inspection每批per lot检验记录Inspection record 标识、隔离、退货Identification ,Separate ,Reject喷塑气压Spray pressure0.4-0.5MPa喷塑电压Spray voltage 50-60KV烘烤温度Bakingtemperature 180-200℃烘烤时间Baking time30-40min 无漏喷No leakage jet目测Visual调整设备、上报Adjustment equipment ,reporting100喷塑SprayXNG-36-1B/粉末喷涂生产线Powder coating production lines目测Visual1产线外观Appearance全检Full inspectionper lot70冲压翻边成形FlangingJB21-160B-SM/160T冲床Presses件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs80冲压压字Pressure logoJA21-160/160T冲床Presses孔径diameter I.D.首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs标识、隔离、检查模具Identification ,Separate ,Checkthe die角度AngleHD124-H008/翻边模Flanging die平面度Flatness高度Height 标识、隔离、检查模具Identification ,Separate ,Checkthe dieHD150-H006/压字模Pressure logo die(E32629-3)HD150-H005/压字模Pressure logo die(E32629-1)高度Height检验记录Inspection record首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs检验记录Inspection record外观Appearance外协镀锌Outsourcing galvanized检验记录Inspection record每班Every shift检验记录Inspection record容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/ToleranceA-5◇0.15mm塞尺(端盖平放在大理石台面,上面压5kg物体)/0.15mm feeler ( cover flat on the marble countertops, pressure5kg objects above )盐雾试验≥1000小时/Salt spray test≥1000hrs盐雾腐蚀试验机/Salt spray corrosiontest machine3每季度Each quarter 盐雾试验报告Salt spray testreport 110丝印完整Full screen目测Visual全检Full inspection每批per lot检验记录Inspection record标识、隔离、退货Identification ,Separate ,RejectA-3◇47±10-300mm(0.02)深度尺Depth Gages10A-4◇HDJ-H0001检具Gage 10A-5◇0.15mm塞尺(端盖平放在大理石台面,上面压5kg 物体)/0.15mm feeler (cover flat on the marble countertops,pressure 5kg objectsabove )10包装规范Packaging Specifications点数Counting 2箱2 box标识、隔离、返工Identification ,Separate ,Rework清晰Clear 目测Visual 包装规范Packaging Specifications 目测Visual 物资发货单Material Invoice点数Counting标识、隔离、返工Identification ,Separate ,Rework平面度Flatness防腐蚀性能Corrosion100喷塑SprayXNG-36-1B/粉末喷涂生产线Powder coating production lines全检Full inspection每批per lot外协丝印Outsourcing Screen外观Appearance 检验记录Inspection record深度Depth120抽检并包装Sampling inspection and packaging标识、隔离、处理Identification ,Separate ,Dealwith位置度Location degree平面度Flatness数量Quantity 每批per lot检验记录Inspection record标识Label标识、隔离、返工Identification ,Separate ,Rework包装Package 数量Quantity130入库&出货Warehousing & shipping全检Full inspection每批per lot 物资发货单Material Invoice。

控制计划管理实施规范程序-中英文版1.0 Purpose目的This procedure instruction describes the application of the control plan本程序文件描述的控制计划的应用。

The Control plan has the following purpose:控制计划有以下的目的:Description of the system to check the parts and processes 检验产品和过程的系统描述Support for the manufacture of quality products corresponding to the customer requirements.支持符合客户要求的产品质量的生产Written summary of the system used for the process and product control为用于过程和产品控制编制系统摘要2.0 Scope范围This procedure applies to all departments and all the automotive related products.本程序适用于所有的职能部门及所有汽车产品。

3.0 Definitions定义3.1 CP-Control Plan 控制计划4.0 Responsibility权责4.1 APQP小组负责试生产控制计划及初始量产控制计划的制定4.2 质量部负责主导协调量产后的量产控制计划的修订。

5.0 Procedure程序5.1 The control plan is compulsory for the pre series and series stage and also has to include the processsteps from incoming to out coming控制计划在预批量和批量阶段是必须的,而且要包括从进货到出货的全部阶段。

(完整版)控制计划中英文版Sample 样件Trial Run试生产Production生产7.Turning OutsideDiameter车外圆Turning tool 车刀4Outside diameter 外径Rev 转速2500rad/min Φ14.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Inspection report (PIR A01-Close off / Rework隔离 / 返工Chamfer 倒角F进刀量=0.03mm/r 1.4±0.015Projector 投影仪(490127)3pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工5Outside diameter 外径Φ12.6±0.03Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工1Outside diameter 外径Φ16.18 0/-0.04Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 3只/开机和换刀3pcs/3H AQL1.0 C=01.Inspection report (PIR A01-002)2.SPC control1.检验报告(报告编号:A01-002)2.SPC控制Close off / Rework隔离 / 返工25Angle 角度45.6°±5°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8.Cutting Groove 割槽Cutting tool 切断刀2Outside diameter 外径Rev 转速2500rad/minФ 14+0.05Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework /Sort隔离 / 返工/全检38Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11Width宽度 2.2 +0.2/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工8Length 长度11.8±0.2Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工41Angle 角度3°±1°Projector 投影仪(490127)3pcs/ Machine start up or1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工26Radius圆弧R0.1 +0.1(2X)Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9.Cutting off 切断Cutting tool 切断刀17Length 长度Rev 转速2500rad/minF进刀量=0.03mm/r23.4±0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工10.Drilling hole 钻孔Drilling tool 钻头22Inside diameter 外径Rev 转速2500rad/minΦ6+0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up or1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工36Concentricity 同轴度Φ0.02Concentricity Gage同轴度仪(19753-A-10P)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工40Roughness 粗糙度F进刀量=0.03mm/r Ra6.3Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工14Length 长度9±0.25Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工33Angle 角度118°±3°Contracer轮廓仪(DD-0009)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工31Chamfer 倒角0.2 +0.2/0.1*45Projector 投影仪(490127)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工11.Drilling hole 钻孔Drilling tool 钻头Hole diameter 孔径Rev 转速2500rad/minF进刀量=0.03mm/rΦ10Process technice size过程工艺尺寸Reset-up重新调整12.Boring Hole镗孔Boring tool 镗刀23Inside diameter 外径Rev 转速3000rad/minF进刀量=0.02mm/rΦ8.8±0.1Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工30Chamfer 倒角0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13highness 高度 2.5+0.2Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工12highness 高度1.2±0.025Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工35parallel平行度0.02Dial indicator千分表3pcs/ Machine start up orChange tool 3pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工24Inside diameter 外径Φ13 +0.04Ping gauge 塞规(UGZ-***-0001/UGZ-***-0001)3pcs/ Machine start up orChange tool3pcs/3H AQL1.0 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework / Scrap隔离 / 返工 / 报废Turning tool 车刀6Outside diameter 外径Rev 转速2500rad/minΦ14.6+0.1Micrometer 千分尺(0~25mm)451384833pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工39Roughness 粗糙度F进刀量=0.03mm/r Ra1.6Roughness Tester 粗糙度仪DTS03A3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工28Chamfer 倒角0.2±0.05*45°Projector 投影仪(490127)3pcs/Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工9highness 高度3.8+0.1Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工29Chamfer 倒角0.2±0.1*45°Projector 投影仪(490127)3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工7highness 高度19.6+0.05/0Height Tester0~30mm(01194)高度规3pcs/ Machine start up orChange tool 1pcs/3H AQL1.5 C=0Inspection report (PIR A01-002)检验报告(报告编号:A01-002)Close off / Rework隔离 / 返工13.Turning Outside Diameter车外圆。